Professional Documents

Culture Documents

Klinger Gasket Catalogue

Klinger Gasket Catalogue

Uploaded by

Art JamesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Klinger Gasket Catalogue

Klinger Gasket Catalogue

Uploaded by

Art JamesCopyright:

Available Formats

1.

The saf e way t o t he ri ght gasket

2. Gasket mat eri al s

3. Gasket s

4. PTFE Product s

5. Vari ous

C

o

n

t

e

n

t

KLINGER GmbH, Phone +49 (0) 6126 950- 0, Fax +49 (0) 6126 950340/ 950341

http:/ / www.kl i nger- gmbh.de, e- mai l : mai l @kl i nger- gmbh.de

1

Techni cal f ax servi ce

I mport ant appl i cat i on paramet ers

Mount i ng i nst ruct i ons

Shel f l i f e of KLI NGER gasket s

KLI NGERexpert

T

h

e

s

a

f

e

w

a

y

Operating fluid

Medi um

Pressure [ bar]

Temperature [C]

Temperature vari ati ons duri ng

servi ce

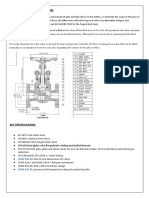

Flange with bolts

Fl ange:

Materi al

Di mensi on acc. to

DIN/ ANSI

DN

PN

Drawi ng i ncl uded

Bol ts:

Type

Number

Si ze

Materi al / grade

Comments

Company

Contact

Street Ci ty or town

Phone Fax e- mai l

For i mproved rel i abi l i ty and

securi ty the techni cal mai l servi ce i s

an addi ti on to the KLINGER- expert

cal cul ati on program. In most cases,

the answers to the fol l owi ng three

groups of questi ons are suffi ci ent to

ensure the ri ght gasket i s sel ected.

Pl ease compl ete the questi onnai re i n

ful l . Our repl y wi l l often be on your

desk i n 24 hours.

Complete, print, fax. . . .

Germany +49 (0) 6126- 950 -340

In other countri es, pl ease refer to the

l ocal Kl i nger adress.

Technical fax service

Gasket

Di mensi on acc. to

DIN ANSI

or i ndi cate the compressed

di mensi ons

D

a

[ mm] D

i

[ mm]

Gasket thi ckness [ mm]

free choi ce

condi ti oned by desi gn, si nce

D

i

D

a

Installation instructions/

shelf life

Due to the hi gh demands on the

safety of gasketed j oi nts and the

current requi rements wi th respect to

utmost ti ghtness, choi ce and fi tti ng

of the ri ght gasket wi th the proper

experti se i s a must.

Accordi ngl y a number of requi re-

ments have to be met by the gasket

materi al s and the compl ete fl ange

j oi nt to obtai n a rel i abl e seal i ng

connecti on.

Adjustment to the unevenness of

the sealing surface

Thi s depends on the compressi bi l i ty

of the gasket and the surface con-

di ti on of the seal i ng surface and sur-

face l oad.

Resistance to the fluid to be

sealed

When sel ecti ng the gasket, care

shoul d be taken to ensure that the

seal i ng materi al i s resi stant to the

fl ui d under servi ce condi ti ons.

In general , properl y l oaded gas-

kets show better resi stance than

underl oaded gaskets.

Strength of the sealing

connection

The mechani cal behavi our of the gas-

ket i s determi ned by the compl ete

j oi nt system.

Increasi ngl y hi gh requi rements

on the ti ghtness of fl ange j oi nt (e.g.

ti ghtness cl ass L0.01) requi re the

appl i cati on of hi gh surface l oads on

the gasket as the i nternal pressure i s

i ncreased.

Under such operati ng condi ti ons,

the sel ected fl ange j oi nt must be

assessed for i ts sui tabi l i ty to these

l oads i n order that mechani cal

overl oad i s avoi ded.

A ti ght gasket j oi nt requi res a

defi ned surface l oad.

The servi ce l i fe of the gasket

al so depends on the fact the gasket

stress must al ways be hi gher than the

mi ni mum surface l oad requi red to

prevent l eaks.

The gasket characteri sti cs

requi red for Kl i nger gaskets are deter-

mi ned through speci al l eak tests i n an

extensi ve seri es of measurements and

form the basi s for the KLINGER-

expert

gasket sel ecti on program and

the speci fi cati ons i n the product data

sheets.

Required gasket thickness

No general rul e exi sts to determi ne

the requi red gasket thi ckness. In most

cases, 2 mm thi ckness wi l l do.

Thi nner gaskets al l ow hi gher surface

l oads.

Low-temperature range

applications

Kl i nger gaskets are al so sui tabl e for

very l ow temperatures. A prerequi si te

for a ti ght connecti on i s that the

requi red surface l oad i s mai ntai ned

over the compl ete temperature range.

Fl ui d resi stance i s guaranteed to

- 196C. In the l ow- temperature range,

the materi al must not be exposed to

addi ti onal l oads.

Quality control

Everybody i n the Kl i nger organi sati on

has been charged wi th defi ned qual i ty

functi ons wi thi n a total qual i ty con-

cept to achi eve the obj ecti ves of the

Kl i nger qual i ty pol i cy. These obj ec-

ti ves and fundamental functi ons as

wel l as the responsi bl e departments

are defi ned i n the qual i ty manual and

i ncl ude the fol l owi ng

subj ects:

Innovati ve qual i ty pl anni ng,

i ni ti al sampl es, prototypes

Suppl i er qual i ty control

Process i nspecti on, rel ease

procedures, process control

Inspecti on, measuri ng and test

equi pment, documentati on,

qual i ty system control s

Al l KLINGERsi l - gaskets are free

of asbestos.

General l y asbestos- free fi bre gas-

kets have greater embri ttl ement and

l ower fl exi bi l i ty at temperature than

asbestos- based gasket materi al s. As a

rul e, more care i s requi red when

choosi ng or assembl i ng an asbestos-

free gasket.

For opti mum performance of the

gasket, al ways heed the fol l owi ng

mounti ng i nstructi ons:

1. Choosing the gasket

The most sui tabl e gasket materi al can

be sel ected usi ng KLINGER

Informati on materi al parti cul arl y the

resi stance tabl e and pT di agrams

see al so KLINGERexpert

The safe

way to the ri ght gasket.

2. Gasket thickness

The gasket shoul d be as thi n as

techni cal l y practi cal . In the case of

graphi te gaskets, a mi ni mum thi ck-

ness/ wi dth rati o of 1/ 5 i s requi red.

3. Flanges must be parallel,

clean, and dry; the gasket must

be installed centrally.

Pl ease note the proper i nner and outer

di ameters; make sure the gasket never

proj ects i nto the fl ui d stream i n an

uncompressed state!

4. The gaskets shall be mounted

in a dry state. Do not use sepa-

rating agents, sealing aids or the

like!

As standard, KLINGER gasket mate-

ri al s have an anti - sti ck fi ni sh. In very

di ffi cul t i nstal l ati on condi ti ons,

separati ng agents such as dry sprays

on mol ybdenum sul phi de or tefl on

bases, e.g. KLINGERfl on spray, may

be used. Make sure that the sol vents

and propel l ants are compl etel y

evaporated.

Do not use oi l or grease- contai n-

i ng products, as they may affect the

safety of the fl ange connecti on. As a

rul e, graphi te gaskets must be used

wi th no addi ti ves at al l , i .e. dry;

however, they are avai l abl e wi th an

anti - sti ck fi ni sh (AS).

5. On mounting, tighten the bolts

evenly and crosswise (see sketch)

in two to three passes.

The bol ts shoul d be l ubri cated. We

recommend the use of a bol t l ubri cant

al l owi ng fri cti on coeffi ci ents from

approx. 0.10 to 0.14 to be set.

To obtai n suffi ci ent bol t el asti ci ty

(note

VO

,

BO

), the bol ts are

normal l y ti ghtened unti l the max.

ti ghteni ng force or the max. possi bl e

torque i s reached.

Thi s shoul d produce a permanent

seal provi ded that the max. permi s-

si bl e gasket stress i s not exceeded.

The use of torque meters or other

sophi sti cated torque methods i s not

prerequi si te, but wi l l l ead to better

resul ts and hi gher safety.

We al so recommend reti ght-

eni ng the gaskets to the max. pos-

si bl e torque at ambi ent temperature

pri or to starti ng the pl ant for the fi rst

ti me.

6. In most cases, no retight-

ening is required as long as the

following hints are observed.

Any reti ghteni ng of fi bre gaskets

shoul d onl y be performed when they

are col d and before or duri ng the fi rst

startup phase of the pi pel i ne or pl ant

(thi s may be the case when rather

thi ck gaskets are used). Reti ghteni ng

at hi gher operati ng temperatures and

l onger operati ng ti mes may l ead to a

fai l ure of the gasket connecti on and

shoul d be avoi ded. A gasket sel ected

and fi tted accordi ng to these i nstruc-

ti ons wi l l have a l ong servi ce l i fe.

7. Re-use

For safety reasons, re- use of gaskets

i s not general l y advi sabl e.

Hi gher- l oaded, but not over-

l oaded, gaskets have a l onger l i fe than

underl oaded ones.

Speci al gasket materi al s for

water/ steam appl i cati ons whi ch di s-

pl ay no embri ttl ement at temperature

(e.g. KLINGERgraphi te l ami nate,

KLINGERtop chem, etc.) must be used

i f i t cannot be guaranteed that the

fi tted gasket wi l l onl y be subj ected to

stati c stresses, or i f stress fl uctuati ons

can be assumed i n di sconti nuous

operati on.

In the case of gaskets used i n

di sconti nuous water/ steam ci rcui ts,

we recommend a mi n. surface l oad i n

servi ce of approx. 30 MPa.

In such appl i cati ons, the gasket

shoul d be as thi n as techni cal l y pos-

si bl e and practi cal .

Tightness

Ti ghtness depends on the surface

l oad appl i ed at fi tti ng and i n operati -

on.

A gasket whi ch i s sel ected and

fi tted accordi ng to these i nstructi ons

wi l l have a l ong servi ce l i fe. For safety

reasons, re- use of gaskets i s not

advi sabl e.

Max. permissible surface load

The max. permi ssi bl e surface l oad of

a gasket materi al i s a functi on of

pressure, temperature and gasket

thi ckness and must not be surpassed.

The gasketed j oi nt remai ns ti ght

as l ong as the surface l oad present i n

servi ce i s hi gher than the requi red

mi n. surface l oad and the max.

permi ssi bl e surface l oad

BO

of the

gasket i s not surpassed.

Important

application parameters/

quality control

I

I

I

I

Shelf life of KLINGERsil material

Li ke al l el astomers or el astomer-

contai ni ng materi al s the KLINGERsi l

materi al i s subj ect to natural agei ng

dependi ng on el astomer type,

vul cani sati on method and storage

condi ti ons.

For KLINGERsi l sheets and gas-

kets, the percentage of el astomer bond-

i ng agent i s approx. 12%. The rel a-

ti vel y l ow percentage of consti tuents

subj ect to agei ng means that the

i nfl uence on the compl ete product i s

l ower than wi th a pure el astomer.

Neverthel ess, unfavourabl e

storage condi ti ons such as i ncreased

temperature, extremel y l ow ai r humi d-

i ty and extreme exposure to l i ght may

l ead to earl y deteri orati on i n materi al

qual i ty.

Ideal storage condi ti ons are:

l ess than 25C ambi ent temperature,

50 - 60% rel ati ve ai r humi di ty and a

darkened storage room.

These condi ti ons wi l l al l ow a

mi n. shel f l i fe of 5 years. To date, we

are not i n a posi ti on ei ther to speci fy

an absol ute l i mi t or i ndi cate preci sel y

the reducti on i n storage l i fe i f one of

these three factors i s not adhered to.

Storage temperature i s the most

i mportant vari abl e.

Storage temperatures of 30C over

l ong peri ods of ti me may cause a

deteri orati on i n the characteri sti cs

after 2 years.

As no exact statements can be

made on these devi ati ons, we recom-

mend that the storage rooms be con-

di ti oned as descri bed above where

l onger storage i s requi red.

Ready- to- mount gaskets shoul d

be stored hori zontal l y, otherwi se

parti cul arl y wi th l arger di mensi ons

and hangi ng storage stresses and

permanent deformati ons occur whi ch

wi l l at l east compl i cate the mounti ng

process.

3

.

0

0

2

/

8

.

2

0

0

0

Mounting instructions

for KLINGER-gaskets

KLINGER GmbH

P.O. Box 1370, D- 65503 Idstei n

Ri ch.- Kl i nger- Strae, D- 65510 Idstei n

Tel +49 (0) 61 26 950- 0

Fax +49 (0) 61 26 950 340/ 341

e- mai l : mai l @kl i nger- gmbh.de

http:/ / www.kl i nger- gmbh.de

Subj ect to techni cal al terati ons.

Status: August 2000

Cert i f i ed accordi ng t o

DI N EN I SO 9001.

3. Flanges should be parallel,

metallically clean and dry, the

gasket has to be mounted

centrically.

Pl ease pay attenti on to the correct

i nner- and outer di ameter, never the

gaskets shoul d tower i nto the

throughhol e!

4. The mounting of the gasket

should be performed without any

grease- or oil-containing

separating media.

KLINGERsi l gasketmateri al i s

equi pped wi th an anti adhesi on l ayer

on pri nci pl e. If there i s an extreme

demand on anti adhesi on effect we

propose the use of dry- sprays on the

basi s of mol ybdenum di sul phi de or of

Tefl on, e.g. KLINGERfl on Spray. The

fuel gas and the sol vent shoul d be

evaporated compl etel y.

On no account oil or grease

containing products may be used,

as they have an negative

influence on the safety of the

complete flange connection.

Graphi te- gaskets have to be

mounted wi thout grease, oi l and other

anti adhesi on materi al i n any way!

5. During installation the bolts

have to be tightened in several

steps, equal and crosswise.

The screws shoul d be greased i f

possi bl e. Ti ghteni ng normal l y shoul d

performed unti l the max. bol tpower i s

reached (to get suffi ci ent el ongati on

and spri ng- l i ke behavi our of the bol t).

Thereby a safe and durabl e seal i ng

wi l l be achi eved i n the rul e, provi ded

that bol t qual i ty and gasket materi al

have been sel ected correct (materi al

and thi ckness).

6. "Re-tighten" is usually not

necessary if a. m. references will

be followed.

If re- ti ghteni ng i s necessary,

thi s shoul d be done under l ow

temperature before or duri ng the start-

up of the pi pi ng or the pl ant.

Re- ti ghteni ng under hi gher servi ce

temperatures can cause the fai l of the

seal i ng connecti on and therefore thi s

shoul d avoi ded i n the rul e.

A gasket sel ected and mounted i n the

correct way and under consi derati on

of the a.m. references wi l l be durabl e

and l ong ti me stabl e.

7. "Multi-use" of a gasket.

To use a gasket more than one ti me

can not be recommended.

If there is an demand on advice

please contact a KLINGER

company or an representative

Generally KLINGER-gaskets are

asbestos free. The KLINGERsil

qualities use according to the

types different fibres as an

substitute to the asbestos. Based

on this different composition the

asbestos-free gaskets show a

different behaviour on

temperature load. Therefore in

general more care is necessary

during the selection of the gasket

type and during installation.

On pri nci pl e fol l owi ng mounti ng

i nstructi ons for KLINGER- gasket

materi al have to be taken i n account

1. Selection of the gasket

The sui tabl e type of gasket materi al

can be sel ected accordi ng the

KLINGER i nformati on

fi rst of al l the chemi cal resi stance

and the pT di agram (refer al so to

KLINGER- expert

the rel i abl e route to

successful seal i ng).

2. Gasket thickness as thin as

possible and technically

ingenious!

In general KLINGERsi l gaskets have to

be sel ected thi nner i n si ze than

asbestos contai ni ng gaskets. As an

rul e of thumb 2/ 3 to 3/ 4 of the

thi ckness of asbestos contai ni ng

materi al can be used.

For exampl e: 2 mm i nstead of 3 mm,

resp. 1.5 mm i nstead of 2 mm.

Graphi te- gaskets shal l show

thi ckness- to- wi dths- rati o not l ower

than 1/ 5.

3

.

0

0

2

/

8

.

2

0

0

0

Neverthel ess unfavourabl e storage

condi ti ons can l ead to a premature

reducti on of the materi al s qual i ty.

Above al l there i s to menti on el evated

temperature, too l ow humi di ty as wel l

as strong i l l umi nati on.

As an ideal storage condition we

propose:

I Temperature < 25 C

I rel ati ve humi di ty 50 - 60 %

I darkened storage room

Under these condi ti ons a peri od

of storage of approx. 5 years i s

possi bl e. Actual l y there i s no chance

to defi ne the changi ng of the storage

ti me due to changes of one of the

above i nfl uence factors.

The mai n factor undoubtedl y i s

the storage temperature. As

temperatures hi gher than 30 C

appears over a l onger peri od, a

reducti on of the materi al properti es

can occur al ready after 2 years.

As i n thi s conj uncti on detai l ed

speci fi cati ons are not possi bl e, we

propose the condi ti oni ng of the

storage rooms as menti oned above.

Ready made gaskets shoul d be

stored fl at as, parti cul arl y for bi gger

gasket si zes, tensi ons and di storti ons

can occur and compl i cates the

i nstal l ati on.

Shelf Live of KLINGERgraphit

laminate

Usual l y storage temperature, i l l umi -

nati on etc. have no i nfl uence on the

storabi l i ty peri od of KLINGERgraphi t

l ami nate.

Neverthel ess fol l owi ng condi ti ons

shoul d be real i sed to ensure

appropri ate storage:

I 20 C to + 50 C storage

temperature

I cl ean and dry ai r

(no di rt parti cl es, no aggressi ve

gases or vapours)

I sheets and ready made gaskets

have to be protected agai nst

damagi ng

I sheets and ready made gaskets

have to be stored fl at

Under these condi ti ons storage

ti mes of over 10 years are to expect.

Shelf Live of KLINGERsil gasket

material

KLINGERsi l gasket materi al i s as al l

el astomeres and el astomere

contai ni ng materi al subj ect to a

natural agei ng process. Thi s process

i s dependi ng on the ki nd of el astomer,

i ts vul cani sati on system and the

storage condi ti ons.

For al l KLINGERsi l - sheets and

- gaskets the share of the el astomere

as bi nder i s between 10 to 30 %

accordi ng to DIN 28091- 2. The

rel ati vel y smal l share of parts whi ch

are subj ect to the agei ng process

shows, that thi s i nfl uence on to the

whol e product i s smal l er as on a

product of pure el astomer.

Shelf Live of

KLINGER gasket

material

KLINGER GmbH

P.O. Box 1370, D- 65503 Idstei n

Ri ch.- Kl i nger- Strae, D- 65510 Idstei n

Tel +49 (0) 61 26 950- 0

Fax +49 (0) 61 26 950 340/ 341

e- mai l : mai l @kl i nger- gmbh.de

http:/ / www.kl i nger- gmbh.de

Subj ect to techni cal al terati ons.

Status: August 2000

Cert i f i ed accordi ng t o

DI N EN I SO 9001.

7. On-sit advice:

Wi th parti cul arl y di ffi cul t probl ems we

shal l be gl ad to advi ce you on- si te.

We can suppl y products adapted from

our exi sti ng range or custom-

formul ated products.

6. Ideally you should run your

own tests:

We wi l l suppl y the materi al s you

need to carry out tests under your

own operati ng condi ti ons.

We have devi sed a tri ed and

tested method, to gui de you step by

step to the ri ght gasket for your

needs.

poi nts the way to the ri ght gasket

for the j ob

1. Applications overview:

The gasket characteri sti cs compared

wi th the cri teri a to be met i n typi cal

appl i cati on.

2. Product documentation:

A separate data sheet i s suppl i ed for

each gasket i n our range.

The pT di agrams are an i nval uabl e ai d

to sel ecti ng the gasket most sui tabl e

for a pati cul ar appl i cati on.

3. Data on chemical resistance:

Thi s secti on i ndi cates the resi stance

of the i ndi vi dual Kl i nger gaskets to

over 200 chemi cal s i n common use.

4. Technical information by Fax:

Let us have the detai l s of your

parti cul ar gasket requi rements and

you wi l l recei ve a prompt repl y, i n

some cases wi thi n 24 hours.

5. Sealing calculations

on your PC:

For the experi enced

speci al i st we have

devel oped a power-

ful program whi ch

wi l l answer al l your

questi ons on gasket

constructi on, desi gn and

mai ntenance. We

suppl y the soft- ware

wi th on- l i ne hel p.

KLINGER GmbH

P.O. Box 1370, D- 65503 Idstei n

Ri ch.- Kl i nger- Strae, D- 65510 Idstei n

Tel +49 (0) 6126 950- 0

Fax +49 (0) 6126 950 - 340/ 341

e- mai l : mai l @kl i nger- gmbh.de

http:/ / www.kl i nger- gmbh.de

Subj ect to techni cal al terati ons.

Status: September 2000

Certified according to

DIN EN ISO 9001

2

G

a

s

k

e

t

m

a

t

e

r

i

a

l

s

The f i rst st ep i n gasket sel ect i on

KLI NGERt op- chem

KLI NGERt op- graph- 2000

KLI NGERsof t - chem

Opt i mum f l ange securi t y

KLI NGERsi l Chemi cal resi st ance t abl e

KLI NGERsi l C- 4106

KLI NGERsi l C- 4300

KLI NGERsi l C- 4304

KLI NGERsi l C- 4400

KLI NGERsi l C- 4408

KLI NGERsi l C- 4409

KLI NGERsi l C- 4430

KLI NGERsi l C- 4433

KLI NGERsi l C- 4500

KLI NGERsi l C- 4509

KLI NGERsi l C- 6307

KLI NGERsi l C- 8200

KLI NGERst at i t e

KLI NGERgraphi t e

KLI NGERmi l am PSS

Thi s brochure offers you a

general survey of our gasket materi al s.

It i s the fi rst of seven

steps whi ch are

desi gned to

l ead you to-

wards correct gasket

sel ecti on.

The first

step in gasket

selection

u

p

t

o

5

0

0

C

u

p

t

o

1

5

0

C

u

p

t

o

2

5

0

C

u

p

t

o

4

0

0

C

u

p

t

o

1

5

0

C

u

p

t

o

2

5

0

C

u

p

t

o

3

0

0

C

u

p

t

o

5

0

0

C o

v

e

r

6

0

0

C

F

o

o

d

i

n

d

u

s

t

r

i

e

G

a

s

s

u

p

p

l

y

O

x

y

g

e

n

C

a

u

s

t

i

c

s

A

c

i

d

s

S

p

e

c

i

a

l

a

p

p

l

i

c

a

t

i

o

n

s

W

a

t

e

r

a

n

d

s

t

e

a

m

C

h

e

m

i

c

a

l

s

g

a

s

e

o

u

s

a

n

d

l

i

q

u

i

d

rel ati vel y sui ted

very wel l sui ted

wel l sui ted

This survey should not be

used as the sole means for

gasket selection.

To assi st you i n gasket

sel ecti on, we have devi sed a

tri ed and tested method desi -

gned to gui de you step by step

to the ri ght gasket for your

needs.

K

L

I

N

G

E

R

t

o

p

l

i

n

e

K

L

I

N

G

E

R

t

o

p

-

c

h

e

m

-

2

0

0

6

K

L

I

N

G

E

R

t

o

p

-

c

h

e

m

-

2

0

0

0

K

L

I

N

G

E

R

t

o

p

-

c

h

e

m

-

2

0

0

3

K

L

I

N

G

E

R

t

o

p

-

c

h

e

m

-

2

0

0

5

K

L

I

N

G

E

R

t

o

p

-

g

r

a

p

h

-

2

0

0

0

K

T

W

r

e

c

o

m

m

e

n

d

a

t

i

o

n

/

D

V

G

W

p

e

r

m

i

t

/

B

A

M

t

e

s

t

e

d

K

T

W

r

e

c

o

m

m

e

n

d

a

t

i

o

n

/

D

V

G

W

p

e

r

m

i

t

/

B

A

M

t

e

s

t

e

d

/

F

i

r

e

S

a

f

e

/

T

A

-

L

u

f

t

-

c

e

r

-

t

i

f

i

c

a

t

i

o

n

/

G

e

r

m

a

n

i

s

c

h

e

r

L

l

o

y

d

K

T

W

r

e

c

o

m

m

e

n

d

a

t

i

o

n

/

D

V

G

W

p

e

r

m

i

t

/

T

A

-

L

u

f

t

-

c

e

r

t

i

f

i

c

a

t

i

o

n

/

G

e

r

m

a

n

i

s

c

h

e

r

L

l

o

y

d

K

T

W

r

e

c

o

m

m

e

n

d

a

t

i

o

n

/

D

V

G

W

p

e

r

m

i

t

K

T

W

r

e

c

o

m

m

e

n

d

a

t

i

o

n

/

D

V

G

W

p

e

r

m

i

t

/

B

A

M

t

e

s

t

e

d

This survey should not be

used as the sole means for

gasket selection.

To assi st you i n gasket

sel ecti on, we have devi sed a

tri ed and tested method desi -

gned to gui de you step by step

to the ri ght gasket for your

needs.

K

L

I

N

G

E

R

s

i

l

C

C

4

1

0

6

C

4

3

0

0

C

4

4

0

0

C

4

2

4

3

C

4

3

0

4

C

4

4

3

0

C

4

5

0

0

C

4

4

3

3

C

4

4

0

9

C

4

5

0

9

C

6

3

0

7

C

8

2

0

0

H

i

g

h

c

o

m

p

r

e

s

s

i

b

i

l

i

t

y

,

f

o

r

l

o

w

s

t

r

e

s

s

e

s

K

T

W

r

e

c

o

m

m

e

n

d

a

t

i

o

n

/

D

V

G

W

p

e

r

m

i

t

/

B

A

M

t

e

s

t

e

d

/

H

T

B

t

e

s

t

e

d

/

G

e

r

m

a

n

i

s

c

h

e

r

L

l

o

y

d

K

T

W

r

e

c

o

m

m

e

n

d

a

t

i

o

n

/

D

V

G

W

p

e

r

m

i

t

/

G

e

r

m

a

n

i

s

c

h

e

r

L

l

o

y

d

V

G

W

p

e

r

m

i

t

K

T

W

r

e

c

o

m

m

e

n

d

a

t

i

o

n

/

D

V

G

W

p

e

r

m

i

t

i

n

p

r

e

p

a

r

a

t

i

o

n

F

i

r

e

S

a

f

e

/

T

A

-

L

u

f

t

-

c

e

r

t

i

f

i

c

a

t

i

o

n

K

T

W

r

e

c

o

m

m

e

n

d

a

t

i

o

n

/

D

V

G

W

p

e

r

m

i

t

/

F

i

r

e

S

a

f

e

/

B

A

M

t

e

s

t

e

d

/

G

e

r

m

.

L

l

o

y

d

K

T

W

r

e

c

o

m

m

e

n

d

a

t

i

o

n

/

D

V

G

W

p

e

r

m

i

t

/

H

T

B

t

e

s

t

e

d

/

B

A

M

t

e

s

t

e

d

/

F

i

r

e

S

a

f

e

/

r

e

i

n

f

o

r

c

e

d

w

i

t

h

c

a

r

b

o

n

f

i

b

r

e

E

x

p

a

n

d

e

d

m

e

t

a

l

r

e

i

n

f

o

r

c

e

d

f

o

r

h

i

g

-

h

e

r

t

h

e

r

m

a

l

a

n

d

m

e

c

h

a

n

i

c

a

l

d

e

m

a

n

d

s

E

x

p

a

n

d

e

d

m

e

t

a

l

r

e

i

n

f

o

r

c

e

d

f

o

r

h

i

g

-

h

e

s

t

t

h

e

r

m

a

l

a

n

d

m

e

c

h

a

n

i

c

a

l

d

e

m

a

n

d

s

/

c

a

r

b

o

n

f

i

b

r

e

r

e

i

n

f

o

r

c

e

d

C

o

n

t

r

o

l

l

e

d

s

w

e

l

l

i

n

o

i

l

s

S

p

e

c

i

f

i

c

a

l

l

y

d

e

s

i

g

n

e

d

f

o

r

u

s

e

w

i

t

h

s

t

r

o

n

g

a

c

i

d

s

u

p

t

o

5

0

0

C

u

p

t

o

1

5

0

C

u

p

t

o

2

5

0

C

u

p

t

o

4

0

0

C

u

p

t

o

1

5

0

C

u

p

t

o

2

5

0

C

u

p

t

o

3

0

0

C

u

p

t

o

5

0

0

C o

v

e

r

6

0

0

C

F

o

o

d

i

n

d

u

s

t

r

i

e

G

a

s

s

u

p

p

l

y

O

x

y

g

e

n

C

a

u

s

t

i

c

s

A

c

i

d

s

S

p

e

c

i

a

l

a

p

p

l

i

c

a

t

i

o

n

s

W

a

t

e

r

a

n

d

s

t

e

a

m

C

h

e

m

i

c

a

l

s

g

a

s

e

o

u

s

a

n

d

l

i

q

u

i

d

rel ati vel y sui ted

very wel l sui ted

wel l sui ted

This survey should not be

used as the sole means for

gasket selection.

To assi st you i n gasket

sel ecti on, we have devi sed a

tri ed and tested method desi -

gned to gui de you step by step

to the ri ght gasket for your

needs.

K

L

I

N

G

E

R

S

p

i

r

a

l

w

o

u

n

d

K

L

I

N

G

E

R

f

l

o

n

K

L

I

N

G

E

R

g

r

a

p

h

i

t

S

e

a

l

i

n

g

t

a

p

e

L

a

m

i

n

a

t

-

H

L

a

m

i

n

a

t

-

S

L

S

L

a

m

i

n

a

t

-

P

S

M

L

a

m

i

n

a

t

P

D

M

K

L

I

N

G

E

R

m

a

x

i

f

l

e

x

R

e

a

d

y

-

m

a

d

e

g

a

s

k

e

t

s

S

e

a

l

i

n

g

t

a

p

e

t

y

p

e

N

S

e

a

l

i

n

g

t

a

p

e

t

y

p

e

S

S

e

a

l

e

x

U

n

i

v

e

r

s

a

l

m

a

t

e

r

i

a

l

f

o

r

g

a

s

k

e

t

s

a

n

d

g

l

a

n

d

s

D

V

G

W

p

e

r

m

i

t

/

W

R

C

-

a

p

p

r

o

v

a

l

/

2

p

e

g

g

e

d

s

t

a

i

n

l

e

s

s

s

t

e

e

l

s

h

e

e

t

i

n

s

-

e

r

t

s

a

n

d

o

p

t

i

m

i

z

e

d

s

c

r

a

t

c

h

r

e

s

i

s

t

a

n

c

e

d

u

e

t

o

h

i

g

h

e

r

d

e

n

s

i

t

y

P

u

r

e

g

r

a

p

h

i

t

e

,

h

o

m

o

g

e

n

e

o

u

s

D

V

G

W

p

e

r

m

i

t

/

B

A

M

t

e

s

t

e

d

/

W

R

C

-

a

p

p

r

o

v

a

l

D

V

G

W

p

e

r

m

i

t

/

B

A

M

t

e

s

t

e

d

/

W

R

C

-

a

p

p

r

o

v

a

l

/

p

e

g

g

e

d

s

t

a

i

n

l

e

s

s

s

t

e

e

l

s

h

e

e

t

w

i

t

h

p

u

r

e

g

r

a

p

h

i

t

e

s

u

r

f

a

c

e

D

V

G

W

p

e

r

m

i

t

S

e

a

l

i

n

g

t

a

p

e

w

i

t

h

l

o

w

g

r

e

a

s

e

c

o

n

t

e

n

t

s

D

V

G

W

p

e

r

m

i

t

/

B

A

M

t

e

s

t

e

d

/

T

V

-

c

e

r

t

i

f

i

c

a

t

i

o

n

n

u

m

b

e

r

S

p

i

r

a

l

w

o

u

n

d

g

a

s

k

e

t

u

p

t

o

5

0

0

C

u

p

t

o

1

5

0

C

u

p

t

o

2

5

0

C

u

p

t

o

4

0

0

C

u

p

t

o

1

5

0

C

u

p

t

o

2

5

0

C

u

p

t

o

3

0

0

C

u

p

t

o

5

0

0

C o

v

e

r

6

0

0

C

F

o

o

d

i

n

d

u

s

t

r

i

e

G

a

s

s

u

p

p

l

y

O

x

y

g

e

n

C

a

u

s

t

i

c

s

A

c

i

d

s

S

p

e

c

i

a

l

a

p

p

l

i

c

a

t

i

o

n

s

W

a

t

e

r

a

n

d

s

t

e

a

m

C

h

e

m

i

c

a

l

s

g

a

s

e

o

u

s

a

n

d

l

i

q

u

i

d

rel ati vel y sui ted

very wel l sui ted

wel l sui ted

This survey should not be

used as the sole means for

gasket selection.

To assi st you i n gasket

sel ecti on, we have devi sed a

tri ed and tested method desi -

gned to gui de you step by step

to the ri ght gasket for your

needs.

K

L

I

N

G

E

R

s

o

f

t

S

t

a

t

i

t

e

M

i

l

a

m

K

L

I

N

G

E

R

s

p

e

c

i

a

l

KLINGERspecial offers the end

user novel opportunities for

sealing applications.

On many occasi ons, we come

across appl i cati ons i n whi ch the

gasket i s requi red to ful fi l a mul ti tude

of functi ons beyond those of purel y

seal i ng.

In such cases, the gasket must

partl y compensate for l i mi tati ons i n

the j oi nt constructi on whi ch, for

whatever reason, can not be met, by

the constructi on onl y.

It i s i mportant that from an earl y

stage the desi gner i s i n di scussi ons

wi th the Kl i nger Techni cal department.

Onl y then can he profi t ful l y

from the opportuni ti es avai l abl e wi th

KLINGERspeci al .

Gasket s wi t h si l k- screen-

pri nt

For smal l and mi ddl e producti on

quanti ti es, gaskets wi th si l k- screen-

pri nted seal i ng zones are often the

exact fi tti ng probl em sol ver.

KLI NGERmet al

The hi gh- tech- gasket made of speci al

coated metal foi l wi th speci fi cal l y

desi gned corrugati ons. For mi ddl e to

hi gh producti on quanti ti es.

Subj ect to techni cal al terati ons.

Status: September 2000

Certified according to

DIN EN ISO 9001

F

o

r

s

i

m

p

l

e

s

e

a

l

i

n

g

a

p

p

l

i

c

a

t

i

o

n

s

S

t

a

i

n

l

e

s

s

s

t

e

e

l

t

a

n

g

r

e

i

n

f

o

r

c

e

d

w

i

t

h

m

i

c

a

s

u

r

f

a

c

e

,

f

o

r

v

e

r

y

h

i

g

h

t

e

m

p

e

r

a

t

u

r

e

a

p

p

l

i

c

a

t

i

n

s

u

p

t

o

5

0

0

C

u

p

t

o

1

5

0

C

u

p

t

o

2

5

0

C

u

p

t

o

4

0

0

C

u

p

t

o

1

5

0

C

u

p

t

o

2

5

0

C

u

p

t

o

3

0

0

C

u

p

t

o

5

0

0

C o

v

e

r

6

0

0

C

F

o

o

d

i

n

d

u

s

t

r

i

e

G

a

s

s

u

p

p

l

y

O

x

y

g

e

n

C

a

u

s

t

i

c

s

A

c

i

d

s

S

p

e

c

i

a

l

a

p

p

l

i

c

a

t

i

o

n

s

W

a

t

e

r

a

n

d

s

t

e

a

m

C

h

e

m

i

c

a

l

s

g

a

s

e

o

u

s

a

n

d

l

i

q

u

i

d

rel ati vel y sui ted

very wel l sui ted

wel l sui ted

KLINGERtop- chem offer the

advantages of PTFE gaskets

wi thout the di sadvantages

commonl y associ ated

wi th these types of

materi al s. As a resul t you

wi l l save mai ntenance ti me

and i mprove pl ant safety.

The TopFour!

KLI NGERtop-chem

Four top qual i ty PTFE-based

materi al s for every appl i cati on

T H E L EA D ER I N GA S K ET T EC H N OL OGY F OR M ORE T H A N 1 0 0 Y EA RS

KLINGERtop-chem:

A complete sealing package

for safe performance

100%

90%

80%

70%

-1.6%

K

L

I

N

G

E

R

t

o

p

-

c

h

e

m

-

2

0

0

0

c

o

m

p

e

t

i

t

o

r

A

c

o

m

p

e

t

i

t

o

r

B

c

o

m

p

e

t

i

t

o

r

C

c

o

m

p

e

t

i

t

o

r

D

-23. 5% -25. 2% -27. 4% -16.1%

2

0

0

0

2

0

0

3

2

0

0

5

2

0

0

6

Mechanical resistance

to high temperature

Adaptability

Tightness

Strong alkalis

Strong acids

KLINGERtop-chem

KLINGERtop- chem offer the ad-

vantages of PTFE gaskets wi thout the

di sadvantages commonl y associ ated

wi th PTFE materi al s. Thi s al l ows you

to use these materi al s i n appl i cati ons

where tradi ti onal l y they are unsui t-

abl e, savi ng you mai ntenance ti me

and i mprovi ng pl ant safety.

As an exampl e, a compari son

of the l oad beari ng performance of

KLINGERtop- chem- 2000 wi th that

of ri val products i s shown i n the

di agram bel ow. Wi th KLINGERtop-

chem- 2000, the hi gh rel axati on typi -

cal of standard PTFE gaskets i s not

obser ved. The resul ts demonstrate

that at a l oad of 50 MPa and tempe-

rature of 200C, the rel axati on of

thi s materi al i s onl y 1.6%, ensuri ng

that bol t forces are mai ntai ned even

under severe condi ti ons.

KLINGERtop-chem-2006

KLINGERtop- chem- 2006 has

good chemi cal resi stance i n strongl y

al kal i ne condi ti ons and good

mechani cal properti es at medi um

and l ow temperatures and l oads.

KLINGERtop- chem- 2006 i s

opti mi sed for causti c condi ti ons

and al so sui tabl e for a wi de range

of appl i cati ons i n the chemi cal

i ndustr y. Because i t i s free from

pi gments, thi s materi al i s especi al l y

sui ted to food and pharmaceuti cal

appl i cati ons.

KLINGERtop-chem-2005

KLINGERtop- chem- 2005 has

excel l ent chemi cal resi stance i n

strongl y aci di c appl i cati ons and i s

sui tabl e for a wi de range of appl i ca-

ti ons i n the chemi cal i ndustri e.

It has good mechani cal properti es at

medi um and l ow temperatures and

l oads.

As regards medi a, the range

of appl i cati ons approaches that of

KLINGERtop- chem- 2000.

The materi al i s an economi cal

al ternati ve where requi rements l ess

stri ngent.

KLINGERtop-chem-2003

As regards medi a, the range of

appl i cati ons i s comparabl e to that

of KLINGERtop- chem- 2000.

However, KLINGERtop- chem 2003

has greater compressi bi l i ty and i s

i deal for mai ntai ni ng a ti ght seal

even at l ow surface l oads and

temperatures.

KLINGERtop- chem- 2003

has excel l ent chemi cal resi stance

i n strongl y aci di c and al kal i ne

appl i cati ons and excel l ent

mechani cal properti es at medi um

and l ow temperatures and l oads.

Speci al menti on shoul d be gi ven to

i ts hi gh gas ti ghtness at even l ow

surface l oads (TA- Luft certi fi cati on).

The two new grades KLINGER

top- chem- 2005 and - 2006 offer a

more economi cal sol uti on for

standard appl i cati ons. They di ffer i n

respect to thei r chemi cal resi stance:

KLINGERtop- chem- 2005 i s parti cu-

l arl y sui ted for general chemi cal and

strongl y aci di c appl i cati ons.

KLINGERtop- chem- 2006 i s the

better choi ce for causti c medi as.

By way of an i ntroducti on to the

properti es of the KLINGERtop- chem

range, the matri x on the fol l owi ng

page presents the attri butes of the

i ndi vi dual grades. The tabl e i l l ustra-

tes that for al l PTFE appl i cati ons a

sui tabl e materi al can be sel ected

from the KLINGERtop- chem range.

The detai l ed performance data

on the fol l owi ng pages wi l l hel p you

to choose the correct materi al for

your appl i cati on, ensuri ng the safe

performance of the gasket. The

fol l owi ng short descri pti on of the

four grades provi des a general over-

vi ew of properti es and i s the fi rst

step towards maki ng thi s choi ce.

KLINGERtop-chem-2000

The uni versal heavy- duty gasket for

an extremel y wi de range of appl i ca-

ti ons i n the chemi cal and petroche-

mi cal i ndustri es as wel l as i n the

shi p bui l di ng i ndustry for chemi cal

tanker appl i cati ons. Due to i ts uni -

que l oad beari ng properti es i t i s abl e

to wi thstand hi gh temperatures and

pressures and i t i s the onl y PTFE

gasket wi th a Fi re Safe Certi fi cate.

It i s al so the fi rst choi ce i n the food

sector and i n the pharmaceuti cal

i ndustry, for steam appl i cati ons and

i n oxygen pi pes, and where speci al

requi rements are made acc. to TA Luft

(German Cl ean ai r regul ati on).

KLINGERtop- chem- 2000 has

excel l ent chemi cal resi stance i n

strongl y aci di c and al kal i ne appl i ca-

ti ons and offers excepti onal perfor-

mance i n appl i cati ons wi th hi gh

mechani cal requi rements at hi gh

temperatures.

KLINGERtop-chem:

A complete sealing package

for safe performance

100%

90%

80%

70%

-1.6%

K

L

I

N

G

E

R

t

o

p

-

c

h

e

m

-

2

0

0

0

c

o

m

p

e

t

i

t

o

r

A

c

o

m

p

e

t

i

t

o

r

B

c

o

m

p

e

t

i

t

o

r

C

c

o

m

p

e

t

i

t

o

r

D

-23. 5% -25. 2% -27. 4% -16.1%

2

0

0

0

2

0

0

3

2

0

0

5

2

0

0

6

Mechanical resistance

to high temperature

Adaptability

Tightness

Strong alkalis

Strong acids

KLINGERtop-chem

KLINGERtop- chem offer the ad-

vantages of PTFE gaskets wi thout the

di sadvantages commonl y associ ated

wi th PTFE materi al s. Thi s al l ows you

to use these materi al s i n appl i cati ons

where tradi ti onal l y they are unsui t-

abl e, savi ng you mai ntenance ti me

and i mprovi ng pl ant safety.

As an exampl e, a compari son

of the l oad beari ng performance of

KLINGERtop- chem- 2000 wi th that

of ri val products i s shown i n the

di agram bel ow. Wi th KLINGERtop-

chem- 2000, the hi gh rel axati on typi -

cal of standard PTFE gaskets i s not

obser ved. The resul ts demonstrate

that at a l oad of 50 MPa and tempe-

rature of 200C, the rel axati on of

thi s materi al i s onl y 1.6%, ensuri ng

that bol t forces are mai ntai ned even

under severe condi ti ons.

KLINGERtop-chem-2006

KLINGERtop- chem- 2006 has

good chemi cal resi stance i n strongl y

al kal i ne condi ti ons and good

mechani cal properti es at medi um

and l ow temperatures and l oads.

KLINGERtop- chem- 2006 i s

opti mi sed for causti c condi ti ons

and al so sui tabl e for a wi de range

of appl i cati ons i n the chemi cal

i ndustr y. Because i t i s free from

pi gments, thi s materi al i s especi al l y

sui ted to food and pharmaceuti cal

appl i cati ons.

KLINGERtop-chem-2005

KLINGERtop- chem- 2005 has

excel l ent chemi cal resi stance i n

strongl y aci di c appl i cati ons and i s

sui tabl e for a wi de range of appl i ca-

ti ons i n the chemi cal i ndustri e.

It has good mechani cal properti es at

medi um and l ow temperatures and

l oads.

As regards medi a, the range

of appl i cati ons approaches that of

KLINGERtop- chem- 2000.

The materi al i s an economi cal

al ternati ve where requi rements l ess

stri ngent.

KLINGERtop-chem-2003

As regards medi a, the range of

appl i cati ons i s comparabl e to that

of KLINGERtop- chem- 2000.

However, KLINGERtop- chem 2003

has greater compressi bi l i ty and i s

i deal for mai ntai ni ng a ti ght seal

even at l ow surface l oads and

temperatures.

KLINGERtop- chem- 2003

has excel l ent chemi cal resi stance

i n strongl y aci di c and al kal i ne

appl i cati ons and excel l ent

mechani cal properti es at medi um

and l ow temperatures and l oads.

Speci al menti on shoul d be gi ven to

i ts hi gh gas ti ghtness at even l ow

surface l oads (TA- Luft certi fi cati on).

The two new grades KLINGER

top- chem- 2005 and - 2006 offer a

more economi cal sol uti on for

standard appl i cati ons. They di ffer i n

respect to thei r chemi cal resi stance:

KLINGERtop- chem- 2005 i s parti cu-

l arl y sui ted for general chemi cal and

strongl y aci di c appl i cati ons.

KLINGERtop- chem- 2006 i s the

better choi ce for causti c medi as.

By way of an i ntroducti on to the

properti es of the KLINGERtop- chem

range, the matri x on the fol l owi ng

page presents the attri butes of the

i ndi vi dual grades. The tabl e i l l ustra-

tes that for al l PTFE appl i cati ons a

sui tabl e materi al can be sel ected

from the KLINGERtop- chem range.

The detai l ed performance data

on the fol l owi ng pages wi l l hel p you

to choose the correct materi al for

your appl i cati on, ensuri ng the safe

performance of the gasket. The

fol l owi ng short descri pti on of the

four grades provi des a general over-

vi ew of properti es and i s the fi rst

step towards maki ng thi s choi ce.

KLINGERtop-chem-2000

The uni versal heavy- duty gasket for

an extremel y wi de range of appl i ca-

ti ons i n the chemi cal and petroche-

mi cal i ndustri es as wel l as i n the

shi p bui l di ng i ndustry for chemi cal

tanker appl i cati ons. Due to i ts uni -

que l oad beari ng properti es i t i s abl e

to wi thstand hi gh temperatures and

pressures and i t i s the onl y PTFE

gasket wi th a Fi re Safe Certi fi cate.

It i s al so the fi rst choi ce i n the food

sector and i n the pharmaceuti cal

i ndustry, for steam appl i cati ons and

i n oxygen pi pes, and where speci al

requi rements are made acc. to TA Luft

(German Cl ean ai r regul ati on).

KLINGERtop- chem- 2000 has

excel l ent chemi cal resi stance i n

strongl y aci di c and al kal i ne appl i ca-

ti ons and offers excepti onal perfor-

mance i n appl i cati ons wi th hi gh

mechani cal requi rements at hi gh

temperatures.

KLINGERtop-chem 2000 2003 2005 2006

Ref. thi ckness of measured val ues, mm 1.5 2 1.5 1.5

Densi ty, g/ cm

3

2.5 1.7 2 2.9

Compressi bi l i ty ASTM F 36 A, % 2 18 7 4

Recovery ASTM F 36 A, % 55 40 35 40

St ress rel axat i on

DIN 52913, 16h, 50MPa, 300 C 35

DIN 52913, 16h, 30MPa, 150 C 30 13 25 18

Kl i nger col d/ hot compressi on

23C/ 50MPa, % 2 10 10

250C/ 50MPa, % 5 30 40

23C/ 25MPa, % 9

250C/ 25MPa, % 38

Ti ght ness

DIN 3535/ 6, ml / mi n 0.5 0.1 0.2 0.1

DIN 28090- 2, mg/ s m 0.05 0.01 0.02 0.01

Thi ckness/ wei ght i ncrease

H

2

SO

4

, 100%: 18h/ 23C,% 0.5/ 1 / 1 2/ 2

HNO

3

,100%: 18h/ 23C, % 1/ 2 / 5 2/ 7 2/ 7

NaOH, 33%, 72h/ 110C, % 5/ 5 / 2 12/ 24

Permi t s/ cert i f i cat i ons

BAM certi fi cati on yes u. preparati on u. preparati on yes

KTW proposal yes yes yes yes

DIN- DVGW permi t yes yes yes yes

Fi re Safe yes

FDA conformi ty yes yes yes yes

TA- Luft certi fi cati on yes yes

Germani scher Ll oyd yes yes u. preparati on u. preparati on

Uni ted States Coast Guard yes

Regi stro Ital i ano Naval e yes

Det Norske Veri tas AS yes

St andard si zes (other si zes on request)

Sheet si zes mm 1,400 / 1,400 1,300 / 1,300 1,400 / 1,400 1,300 / 1,400

Thi ckness mm 1.5 / 2.0 / 3.0 1.5 / 2.0 / 3.0 1.5 / 2.0 / 3.0 1.5 / 2.0 / 3.0

Tol erances thi ckness 10 %, l ength 50 mm, wi dth 50 mm

Typi cal val ues

Subj ect to techni cal al terati ons.

Status: September 2000

The heavy-duty gaskets

KLINGERtop-chem

The heavy-duty gaskets

KLINGERtop-chem

Stability according to Klinger

The l oad beari ng capaci ty of a gasket

can be assessed at ambi ent and

hi gh temperature usi ng the hot com-

pressi on test devel oped by Kl i nger.

In contrast to the test method

accordi ng to DIN 52913 and

BS 7531, the gasket stress i s kept

constant throughout the enti re test.

The gasket i s thus exposed to si gni -

fi cantl y severer condi ti ons.

The thi ckness decrease as a

resul t of a constant l oad i s measured

at a temperature of 23C and al so

after heati ng up to 250C.

The val ue of the thi ckness

decrease at 250C rel ates to the

thi ckness after compressi on at 23C.

The many and varied demands

made on gaskets

The successful operati on of a gasket

depends upon a mul ti pl i ci ty of factors.

Many who use stati c gaskets bel i eve

that the val ues quoted for maxi mum

admi ssi bl e temperature and maxi -

mum operati ng pressure are i nherent

properti es or characteri sti cs of gas-

kets and gasket materi al s.

Unfortunatel y, thi s i s not the

case.

The maxi mum temperatures and

pressures at whi ch gaskets may be

used are i nfl uenced by a l arge

number of factors.

So why does Klinger provide

pT diagrams?

For the reasons gi ven the pT di agram

i s not i nfal l i bl e: i t serves as a rough

gui de for the end user who often has

onl y the operati ng temperatures ad

pressures to go on.

Addi ti onal stresses such as

greatl y fl uctuati ng l oad may si gni fi -

cantl y affect whether a gasket i s

sui tabl e for the appl i cati on.

Resi stance to medi a must be

taken i nto account i n every case.

* Gaskets accordi ng to DIN 2690 are onl y standardi sed up to PN 40

flange

bolt

process

control

tempera-

ture

pressure

medium

50 50 100 150 200 0 C

p

i

b

a

r

20

30

40

50

60

70

80

90

200

100 150 200 250

100

!

"

DIN 2690/ DIN EN 1514-1

form IBC up to PN 40*

50 50 100 150 200 0 C

p

i

b

a

r

20

30

40

50

60

70

80

90

200

100 150 200 250

100

!

"

DIN 2690/ DIN EN 1514-1

form IBC up to PN 40*

50 50 100 150 200 0 C

p

i

b

a

r

20

30

40

50

60

70

80

90

200

100 150 200 250

100

!

"

DIN 2690/ DIN EN 1514-1

form IBC up to PN 40*

50 50 100 150 200 0 C

p

i

b

a

r

20

30

40

50

60

70

80

90

200

100 150 200 250

100

!

"

DIN 2690/ DIN EN 1514-1

form IBC up to PN 40*

KLINGERtop-chem-2000

KLINGERtop-chem-2005

KLINGERtop-chem-2003

KLINGERtop-chem-2006

If your operati ng temperatures

and pressures fal l wi thi n thi s fi el d, i t

i s not usual l y necessary to conduct

a techni cal exami nati on.

If your operati ng temperatures

and pressures are wi thi n thi s fi el d we

recommend a techni cal exami nati on.

If your operati ng temperatures

and pressures are wi thi n thi s bl ank

fi el d, a techni cal exami nati on shoul d

be carri ed out.

1

2

3

Therefore a defi ni te statement

of these val ues for gaskets materi al

i s not possi bl e.

KLINGERtop-chem 2000 2003 2005 2006

Ref. thi ckness of measured val ues, mm 1.5 2 1.5 1.5

Densi ty, g/ cm

3

2.5 1.7 2 2.9

Compressi bi l i ty ASTM F 36 A, % 2 18 7 4

Recovery ASTM F 36 A, % 55 40 35 40

St ress rel axat i on

DIN 52913, 16h, 50MPa, 300 C 35

DIN 52913, 16h, 30MPa, 150 C 30 13 25 18

Kl i nger col d/ hot compressi on

23C/ 50MPa, % 2 10 10

250C/ 50MPa, % 5 30 40

23C/ 25MPa, % 9

250C/ 25MPa, % 38

Ti ght ness

DIN 3535/ 6, ml / mi n 0.5 0.1 0.2 0.1

DIN 28090- 2, mg/ s m 0.05 0.01 0.02 0.01

Thi ckness/ wei ght i ncrease

H

2

SO

4

, 100%: 18h/ 23C,% 0.5/ 1 / 1 2/ 2

HNO

3

,100%: 18h/ 23C, % 1/ 2 / 5 2/ 7 2/ 7

NaOH, 33%, 72h/ 110C, % 5/ 5 / 2 12/ 24

Permi t s/ cert i f i cat i ons

BAM certi fi cati on yes u. preparati on u. preparati on yes

KTW proposal yes yes yes yes

DIN- DVGW permi t yes yes yes yes

Fi re Safe yes

FDA conformi ty yes yes yes yes

TA- Luft certi fi cati on yes yes

Germani scher Ll oyd yes yes u. preparati on u. preparati on

Uni ted States Coast Guard yes

Regi stro Ital i ano Naval e yes

Det Norske Veri tas AS yes

St andard si zes (other si zes on request)

Sheet si zes mm 1,400 / 1,400 1,300 / 1,300 1,400 / 1,400 1,300 / 1,400

Thi ckness mm 1.5 / 2.0 / 3.0 1.5 / 2.0 / 3.0 1.5 / 2.0 / 3.0 1.5 / 2.0 / 3.0

Tol erances thi ckness 10 %, l ength 50 mm, wi dth 50 mm

Typi cal val ues

Subj ect to techni cal al terati ons.

Status: September 2000

The heavy-duty gaskets

KLINGERtop-chem

The heavy-duty gaskets

KLINGERtop-chem

Stability according to Klinger

The l oad beari ng capaci ty of a gasket

can be assessed at ambi ent and

hi gh temperature usi ng the hot com-

pressi on test devel oped by Kl i nger.

In contrast to the test method

accordi ng to DIN 52913 and

BS 7531, the gasket stress i s kept

constant throughout the enti re test.

The gasket i s thus exposed to si gni -

fi cantl y severer condi ti ons.

The thi ckness decrease as a

resul t of a constant l oad i s measured

at a temperature of 23C and al so

after heati ng up to 250C.

The val ue of the thi ckness

decrease at 250C rel ates to the

thi ckness after compressi on at 23C.

The many and varied demands

made on gaskets

The successful operati on of a gasket

depends upon a mul ti pl i ci ty of factors.

Many who use stati c gaskets bel i eve

that the val ues quoted for maxi mum

admi ssi bl e temperature and maxi -

mum operati ng pressure are i nherent

properti es or characteri sti cs of gas-

kets and gasket materi al s.

Unfortunatel y, thi s i s not the

case.

The maxi mum temperatures and

pressures at whi ch gaskets may be

used are i nfl uenced by a l arge

number of factors.

So why does Klinger provide

pT diagrams?

For the reasons gi ven the pT di agram

i s not i nfal l i bl e: i t serves as a rough

gui de for the end user who often has

onl y the operati ng temperatures ad

pressures to go on.

Addi ti onal stresses such as

greatl y fl uctuati ng l oad may si gni fi -

cantl y affect whether a gasket i s

sui tabl e for the appl i cati on.

Resi stance to medi a must be

taken i nto account i n every case.

* Gaskets accordi ng to DIN 2690 are onl y standardi sed up to PN 40

flange

bolt

process

control

tempera-

ture

pressure

medium

50 50 100 150 200 0 C

p

i

b

a

r

20

30

40

50

60

70

80

90

200

100 150 200 250

100

!

"

DIN 2690/ DIN EN 1514-1

form IBC up to PN 40*

50 50 100 150 200 0 C

p

i

b

a

r

20

30

40

50

60

70

80

90

200

100 150 200 250

100

!

"

DIN 2690/ DIN EN 1514-1

form IBC up to PN 40*

50 50 100 150 200 0 C

p

i

b

a

r

20

30

40

50

60

70

80

90

200

100 150 200 250

100

!

"

DIN 2690/ DIN EN 1514-1

form IBC up to PN 40*

50 50 100 150 200 0 C

p

i

b

a

r

20

30

40

50

60

70

80

90

200

100 150 200 250

100

!

"

DIN 2690/ DIN EN 1514-1

form IBC up to PN 40*

KLINGERtop-chem-2000

KLINGERtop-chem-2005

KLINGERtop-chem-2003

KLINGERtop-chem-2006

If your operati ng temperatures

and pressures fal l wi thi n thi s fi el d, i t

i s not usual l y necessary to conduct

a techni cal exami nati on.

If your operati ng temperatures

and pressures are wi thi n thi s fi el d we

recommend a techni cal exami nati on.

If your operati ng temperatures

and pressures are wi thi n thi s bl ank

fi el d, a techni cal exami nati on shoul d

be carri ed out.

1

2

3

Therefore a defi ni te statement

of these val ues for gaskets materi al

i s not possi bl e.

Chemical resistances

of the 4 gasket materials

Acet al dehyde

Acetami de

Aceti c aci d

Aceti c aci d ester

Acetone

Acetyl ene

Adi pi c aci d

Ai r

Al um

Al umi ni um acetate

Al umi ni um chl orate

Al umi ni um chl ori de

Ammoni a

Ammoni um carbonate

Ammoni um chl ori de

Ammoni um di phosphate

Ammoni um hydroxi de

Amyl acetate

Ani l i ne

Anon cycl ohexanone

Arcton 12

Arcton 22

Asphal t

Avi ati on fuel

Bari um chl ori de

Benzene

Benzoi c aci d

Bl ast furnace gas

Bl eachi ng sol uti on

Boi l er feed water

Borax

Bori c aci d

Bri ne

Butane

Butanol

Butanone

Butyl acetate

Butyl ami ne

Butyl e al cohol

Butyri c aci d

Caesi um mel t

Cal ci um chl ori de

Cal ci um hydroxi de

Cal ci um hypochl ori te

Cal ci um sul phate

Carbol i c aci d

Carbon di oxi de

Carbon di sul phi de

Carbon tetrachl ori de

Castor oi l

Chl ori ne water

Chl ori ne, dr y

Chl ori ne, moi st

Gresi stant

(Sui tabl e for the appropri ate use as a

compressed gasket between fl ange surfaces)

Isui tabl e wi th suffi ci ent surface stress

Ldo not use wi thout contacti ng manufactur er

Temperatures are max. val ues

Medi um 2000 2003 2005 2006

KLINGERt op- chem

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

I100C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

L

G260C

I260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

Medi um 2000 2003 2005 2006

KLINGERt op- chem

G260C

G260C

G260C

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

L

L

L

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

I100C

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

L

L

L

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

I100C

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

L

L

L

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

L

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

L

L

L

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

I 60 %

L

G260C

G260C

G260C

G260C

Medi um 2000 2003 2005 2006

KLINGERt op- chem

G260C

G260C

G260C

G260C

G260C

G260C

L

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C

G260C