Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

54 views84 Full

84 Full

Uploaded by

cutefrenzyThermal cycling tests were conducted on carbon steels to study the effects on microstructure and corrosion rate. Samples underwent heat treatment then thermal cycling up to 500°C and -10°C in oil over 1-50 cycles. Microstructural analysis found grain size increased with more cycles. Corrosion tests found the rate increased with cycling, especially for low cycles, and was higher for steels with more carbon. Thermal cycling introduced residual stresses leading to increased corrosion.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You might also like

- The Wealthy Barber - Everyone's Commonsense Guide To Becoming Financially IndependentDocument219 pagesThe Wealthy Barber - Everyone's Commonsense Guide To Becoming Financially IndependentcutefrenzyNo ratings yet

- 09 Samss 091Document19 pages09 Samss 091Sohail Tisekar100% (1)

- Report No. 1 - PROPELLER CONSTRUCTIONDocument10 pagesReport No. 1 - PROPELLER CONSTRUCTIONRev Xavier CruzNo ratings yet

- SR TestDocument10 pagesSR TestkuladeepkatragaddaNo ratings yet

- Cold-Formed Steel Design Manual PDFDocument296 pagesCold-Formed Steel Design Manual PDFGoran Nikolajevic100% (1)

- Nuts & Bolts CEB SpecDocument12 pagesNuts & Bolts CEB SpecHemantha BalasuriyaNo ratings yet

- 3.cryogenic Heat TreatmentDocument5 pages3.cryogenic Heat TreatmentNitin ShelkeNo ratings yet

- High-Temperature Oxidation and Pickling Behaviour of HSLA SteelsDocument16 pagesHigh-Temperature Oxidation and Pickling Behaviour of HSLA SteelsMuhammad Ali AbroNo ratings yet

- Metallurgical Studies of Quench-and-Self-Tempered-Produced RebarDocument12 pagesMetallurgical Studies of Quench-and-Self-Tempered-Produced RebarJerry WangNo ratings yet

- Austentite Steel Thermal StabilizationDocument17 pagesAustentite Steel Thermal StabilizationArangamar KumaranNo ratings yet

- Kulliyyah of Engineering: Heat TreatmentDocument15 pagesKulliyyah of Engineering: Heat TreatmentWafa ZullfakherNo ratings yet

- Vikil D. Malwe, Major Components of Power Plants Are Subjected To HighDocument28 pagesVikil D. Malwe, Major Components of Power Plants Are Subjected To HighsaleemNo ratings yet

- metals-09-00916Document8 pagesmetals-09-00916Abdul RafiNo ratings yet

- Effect of Heat Treatment On Microstructures and Mechanical Prop of Spring SteelDocument7 pagesEffect of Heat Treatment On Microstructures and Mechanical Prop of Spring SteelMahmood KhanNo ratings yet

- A Study of Microstructure and Phase Transformations of Medium Carbon Dual Phase SteelsDocument9 pagesA Study of Microstructure and Phase Transformations of Medium Carbon Dual Phase Steelsahmed ezwaiNo ratings yet

- The Effect of Water-Vapor Content and Gas Flow RateDocument22 pagesThe Effect of Water-Vapor Content and Gas Flow RateFrancois BornmanNo ratings yet

- Bake Hardening ST 14 SteelDocument8 pagesBake Hardening ST 14 SteelDavid JendraNo ratings yet

- Journal of Alloys and Compounds: S. Osman Yilmaz, Tanju TekerDocument7 pagesJournal of Alloys and Compounds: S. Osman Yilmaz, Tanju TekerElif ArancıNo ratings yet

- 1-S2.0-Flash Butt Welding Application On 16MnCr5 Chain Steel and Investigations of Mechanical Properties-MainDocument9 pages1-S2.0-Flash Butt Welding Application On 16MnCr5 Chain Steel and Investigations of Mechanical Properties-MainHARIMETLYNo ratings yet

- Iron Ore Characterisation During High Temperature Thermal ProcessingDocument14 pagesIron Ore Characterisation During High Temperature Thermal ProcessingKrol PrietoNo ratings yet

- Content: Lecture 20: Process Control BOF SteelmakingDocument4 pagesContent: Lecture 20: Process Control BOF Steelmakingarjun prajapatiNo ratings yet

- Retained Austenite and PittingDocument6 pagesRetained Austenite and PittingSuhaib AshrafNo ratings yet

- Solidification Behavior, Microstructure, Mechanical PropertiesDocument12 pagesSolidification Behavior, Microstructure, Mechanical PropertiesCarlos LaoNo ratings yet

- InTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsDocument19 pagesInTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsSiap SiapNo ratings yet

- In-Situ Observation and Formation Mechanism of Iron Surface Oxidation in The Initial Stages at 1,150 °CDocument8 pagesIn-Situ Observation and Formation Mechanism of Iron Surface Oxidation in The Initial Stages at 1,150 °CJJNo ratings yet

- Effect of Solution Annealing Heat Treatm PDFDocument3 pagesEffect of Solution Annealing Heat Treatm PDFaltieri1No ratings yet

- The Erosion-Corrosion of Alloys Under Oxidizing-Sulphidizing Conditions at High TemperatureDocument8 pagesThe Erosion-Corrosion of Alloys Under Oxidizing-Sulphidizing Conditions at High Temperaturemoney43No ratings yet

- Characterization of The Carbides in The Steel X20CrMoV12.1 Used in Thermal Power PlantsDocument5 pagesCharacterization of The Carbides in The Steel X20CrMoV12.1 Used in Thermal Power PlantsHilarioPerezNo ratings yet

- Investigating Corrosion Effects and Heat Transfer Enhancement in Smaller Size Radiators Using CNT-nanofluidsDocument8 pagesInvestigating Corrosion Effects and Heat Transfer Enhancement in Smaller Size Radiators Using CNT-nanofluidsvuongcoi102No ratings yet

- Jurnal Kelompok 1Document10 pagesJurnal Kelompok 1Agy RandhikoNo ratings yet

- 2005, D. CLOVER, CorrosionDocument11 pages2005, D. CLOVER, Corrosionahmed ezwaiNo ratings yet

- Fireside Corrosion of Alloys For Combustion Power PlantsDocument11 pagesFireside Corrosion of Alloys For Combustion Power Plantsdealer82No ratings yet

- Phase Transformation in AISI 410 Stainless Steel PDFDocument10 pagesPhase Transformation in AISI 410 Stainless Steel PDFirajfarjiNo ratings yet

- Effect of Alloying Elements On Thermal Diffusivity of Gray Cast Iron Used in Automotive Brake DisksDocument5 pagesEffect of Alloying Elements On Thermal Diffusivity of Gray Cast Iron Used in Automotive Brake DisksUlises RochaNo ratings yet

- Reference 2Document11 pagesReference 2Khaled AlhawariNo ratings yet

- CFD Modeling of Spontaneous Heating in A Large-Scale Coal ChamberDocument8 pagesCFD Modeling of Spontaneous Heating in A Large-Scale Coal ChamberdenichezNo ratings yet

- Optmzn of HT - AMSDocument4 pagesOptmzn of HT - AMSsushmaxNo ratings yet

- The Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelDocument8 pagesThe Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelGopala Rao ThellaputtaNo ratings yet

- Effect of Heat Treatment On Microstructure and Mechanical PropertiesDocument9 pagesEffect of Heat Treatment On Microstructure and Mechanical PropertiesEliseo Hernández DuránNo ratings yet

- Auomotivr Fuel TanksDocument9 pagesAuomotivr Fuel Tankscolumba_mcNo ratings yet

- Effect of Heat Treatment On Tribological Characteristics of CuAl10Ni5Fe4 Nickel Aluminum BronzeDocument7 pagesEffect of Heat Treatment On Tribological Characteristics of CuAl10Ni5Fe4 Nickel Aluminum BronzeFathia AlkelaeNo ratings yet

- Ojay 1ST Publication PDFDocument16 pagesOjay 1ST Publication PDFvenkatrangan2003No ratings yet

- Alloy Solutions To Metal Dusting Problems in The Petrochemical Industry PDFDocument8 pagesAlloy Solutions To Metal Dusting Problems in The Petrochemical Industry PDFZeeshan SajidNo ratings yet

- 21-20MnCr5 Carburising SteelDocument4 pages21-20MnCr5 Carburising SteelKwstas PetsazNo ratings yet

- Obiukwu Osita, Udeani Henry, Ubani ProgressDocument12 pagesObiukwu Osita, Udeani Henry, Ubani ProgressPrashant KumarNo ratings yet

- Effect of Volume Fraction of Undissolved Cementite On The High Cycle Fatigue Properties of High Carbon SteelsDocument5 pagesEffect of Volume Fraction of Undissolved Cementite On The High Cycle Fatigue Properties of High Carbon SteelsEngels OchoaNo ratings yet

- Structural SteelsDocument5 pagesStructural SteelsijazNo ratings yet

- Decarburization Kinetics During Annealingil.44.618Document5 pagesDecarburization Kinetics During Annealingil.44.618Suvro ChakrabortyNo ratings yet

- Control of Slopping in Basic Oxygen Steel MakingDocument72 pagesControl of Slopping in Basic Oxygen Steel MakingNarasimha Murthy InampudiNo ratings yet

- Brazing Allloy Cusil ABADocument12 pagesBrazing Allloy Cusil ABADheeraj SharmaNo ratings yet

- Continuous and Cyclic Oxidation of T91 Ferritic Steel Under SteamDocument20 pagesContinuous and Cyclic Oxidation of T91 Ferritic Steel Under Steamrampw14581No ratings yet

- Sliding Wear Performance of Reinforced A413 Alloy at Elevated Temperatures PDFDocument8 pagesSliding Wear Performance of Reinforced A413 Alloy at Elevated Temperatures PDFirajfarjiNo ratings yet

- Effect of Heat Treatment On Microstructure and Hardness of Steel 67sicr5Document7 pagesEffect of Heat Treatment On Microstructure and Hardness of Steel 67sicr5ZarikhNo ratings yet

- Carburization of Austenitic and Ferritic Stainless Steels in Liquid SodiumDocument24 pagesCarburization of Austenitic and Ferritic Stainless Steels in Liquid Sodium鄭勝元No ratings yet

- Effect of Hardness and Wear Resistance On en 353 Steel by Heat TreatmentDocument4 pagesEffect of Hardness and Wear Resistance On en 353 Steel by Heat TreatmentIJMERNo ratings yet

- Ferdian 14060Document7 pagesFerdian 14060Marko JukićNo ratings yet

- Effect of Heat Treatment On Tribological Characteristics of CuAl10Ni5Fe4 NABDocument7 pagesEffect of Heat Treatment On Tribological Characteristics of CuAl10Ni5Fe4 NABFathia AlkelaeNo ratings yet

- 9705 Non Prop Final ReportDocument59 pages9705 Non Prop Final Reportchpinto1No ratings yet

- High Temperature CorrosionDocument16 pagesHigh Temperature CorrosionBubai111100% (1)

- Rheology and Metal Forming of Fire-Refined CopperDocument6 pagesRheology and Metal Forming of Fire-Refined CoppervitordeleteNo ratings yet

- The Effect of Soldering Process Variables On Themicrostructure and Mechanical Properties of Eutecticsn-Ag/Cu Solder JointsDocument7 pagesThe Effect of Soldering Process Variables On Themicrostructure and Mechanical Properties of Eutecticsn-Ag/Cu Solder Jointsاوس محمد رؤوف لؤيNo ratings yet

- Viet Duc Lee 2015Document31 pagesViet Duc Lee 2015Majed NesrineNo ratings yet

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelRating: 5 out of 5 stars5/5 (4)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- RDC Product CatalogDocument4 pagesRDC Product CatalogcutefrenzyNo ratings yet

- Catalyst Chage OperationDocument59 pagesCatalyst Chage OperationcutefrenzyNo ratings yet

- Genralized Corrosion Cost AnalysisDocument34 pagesGenralized Corrosion Cost AnalysiscutefrenzyNo ratings yet

- Tempil-Iron Carbon DiagramDocument1 pageTempil-Iron Carbon DiagramcutefrenzyNo ratings yet

- Effect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon SteelDocument5 pagesEffect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon Steelmalika_00No ratings yet

- Hfss 2way Thermal DimensionsDocument34 pagesHfss 2way Thermal DimensionscutefrenzyNo ratings yet

- Mek4450 Ife Day1 Lesson2Document32 pagesMek4450 Ife Day1 Lesson2cutefrenzyNo ratings yet

- Oil & Gas Downstream - EN-weldingDocument22 pagesOil & Gas Downstream - EN-weldingcutefrenzyNo ratings yet

- Mine Development: Surface WaterDocument10 pagesMine Development: Surface WatercutefrenzyNo ratings yet

- ReadmeDocument1 pageReadmecutefrenzyNo ratings yet

- Corrdata Step GuideDocument8 pagesCorrdata Step GuidecutefrenzyNo ratings yet

- Nozzle ProDocument185 pagesNozzle Progoodspeed_ph83% (6)

- Figure 12.7: Equivalent Annual Costs As A Function of Miles DrivenDocument3 pagesFigure 12.7: Equivalent Annual Costs As A Function of Miles DrivencutefrenzyNo ratings yet

- 64610Document11 pages64610cutefrenzyNo ratings yet

- Financial Management For Decision MakersDocument2 pagesFinancial Management For Decision MakerscutefrenzyNo ratings yet

- Rate VarianceDocument11 pagesRate VariancecutefrenzyNo ratings yet

- Multi-Pass Micro-Scratching and Tribological Behaviors of An Austenitic Steel in MediaDocument7 pagesMulti-Pass Micro-Scratching and Tribological Behaviors of An Austenitic Steel in MediaA.Alamgir ShaikhNo ratings yet

- Turnover Rates in Heterogeneous CatalysisDocument6 pagesTurnover Rates in Heterogeneous CatalysisWahab ChodharyNo ratings yet

- AIN Plastics Shapes For Machining BrochureDocument4 pagesAIN Plastics Shapes For Machining BrochurelarjcaNo ratings yet

- Rroys Catalogo de MaterialesDocument2 pagesRroys Catalogo de MaterialesHumberto AnguloNo ratings yet

- Redman Fisher GRP Brochure 2013Document12 pagesRedman Fisher GRP Brochure 2013lukebrown92No ratings yet

- Program Studi Magister Jurusan Teknik Material Dan Metalurgi Fti-ItsDocument4 pagesProgram Studi Magister Jurusan Teknik Material Dan Metalurgi Fti-ItsFahriadi PakayaNo ratings yet

- Lab - Iodine Clock - TeacherDocument3 pagesLab - Iodine Clock - Teachertom65656565No ratings yet

- Cationization of CottonDocument16 pagesCationization of CottonjitundcNo ratings yet

- Mechanical Properties and Drop-Weight Impact PerfoDocument11 pagesMechanical Properties and Drop-Weight Impact PerfoPasan SubasingheNo ratings yet

- Metal Fabricator WelderDocument2 pagesMetal Fabricator WelderPravin VisputeNo ratings yet

- Conveyor Belt Related Equations2010Document7 pagesConveyor Belt Related Equations2010Amit BhaduriNo ratings yet

- Hollow Core Tech DataDocument1 pageHollow Core Tech Datacr231181100% (1)

- Chapter 3 PDFDocument13 pagesChapter 3 PDFAbera Mamo100% (4)

- High-Mn Steel Weldment Mechanical Properties at 4.2 KDocument9 pagesHigh-Mn Steel Weldment Mechanical Properties at 4.2 K3834saldNo ratings yet

- MSS SP-95Document17 pagesMSS SP-95Liek FoNo ratings yet

- Gujarat Technological University Mechanical (Machine Design)Document3 pagesGujarat Technological University Mechanical (Machine Design)DharmeshPatelNo ratings yet

- Selection of MaterialsDocument36 pagesSelection of MaterialsMustafa BhattiNo ratings yet

- Imp MaterialsDocument37 pagesImp MaterialsPradeep SamuelNo ratings yet

- Som Unit 1Document158 pagesSom Unit 1Anonymous SEDun6PWNo ratings yet

- Solucionario TreybalDocument2 pagesSolucionario TreybalAnonymous OGuyqCpcy0% (5)

- Field 1 Question and ProblemsDocument4 pagesField 1 Question and ProblemsHazel Cordano100% (1)

- Malaysian FYPDocument138 pagesMalaysian FYPJustin NgNo ratings yet

- CMCE 2351 Fluid Mechanics Laboratory - Sample Density LabDocument4 pagesCMCE 2351 Fluid Mechanics Laboratory - Sample Density LabnotevaleNo ratings yet

- ME3001 Problem Set - 1 3-8-2013Document2 pagesME3001 Problem Set - 1 3-8-2013Athul JohnNo ratings yet

- P I M G S R: Technical Paper by M.C. Alfaro, S. Hayashi, N. Miura and K. WatanabeDocument20 pagesP I M G S R: Technical Paper by M.C. Alfaro, S. Hayashi, N. Miura and K. WatanabepleyvazeNo ratings yet

- Shell StructuresDocument17 pagesShell Structuresdeepanshusoni100% (1)

84 Full

84 Full

Uploaded by

cutefrenzy0 ratings0% found this document useful (0 votes)

54 views8 pagesThermal cycling tests were conducted on carbon steels to study the effects on microstructure and corrosion rate. Samples underwent heat treatment then thermal cycling up to 500°C and -10°C in oil over 1-50 cycles. Microstructural analysis found grain size increased with more cycles. Corrosion tests found the rate increased with cycling, especially for low cycles, and was higher for steels with more carbon. Thermal cycling introduced residual stresses leading to increased corrosion.

Original Description:

84

Original Title

84_full

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThermal cycling tests were conducted on carbon steels to study the effects on microstructure and corrosion rate. Samples underwent heat treatment then thermal cycling up to 500°C and -10°C in oil over 1-50 cycles. Microstructural analysis found grain size increased with more cycles. Corrosion tests found the rate increased with cycling, especially for low cycles, and was higher for steels with more carbon. Thermal cycling introduced residual stresses leading to increased corrosion.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

54 views8 pages84 Full

84 Full

Uploaded by

cutefrenzyThermal cycling tests were conducted on carbon steels to study the effects on microstructure and corrosion rate. Samples underwent heat treatment then thermal cycling up to 500°C and -10°C in oil over 1-50 cycles. Microstructural analysis found grain size increased with more cycles. Corrosion tests found the rate increased with cycling, especially for low cycles, and was higher for steels with more carbon. Thermal cycling introduced residual stresses leading to increased corrosion.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 8

The Microstructures and Corrosion of Carbon Steel

after Subjected to Heat Treatment then Thermal

Cycling, Oil Cooled

Authors: Abdlmanam. S. A. Elmaryami, Prof. Dr. Haji Badrul Bin Omar, Prof. Dr. Khalid

Bin Hasnan and Prof. Dr. Mohamed Elshayeb

Address: University Tun Hussein Onn Malaysia, Mechanical Engineering Departmen

864 !arit "a#a, $atu !ahat, %&h&r, Malasia,

ABSTRACT

Thermal cycling tests were carried out on carbon steel u to !"# C$" A single run was

erformed at uer temerature of %&&

o

C and lower temerature of '&

o

C cooled in oil" (or

se)eral numbers of cycles u to '& cycles for an accurate determination of heating and cooling

times"

The effet of thermal ylin! on the following roerties were e)aluated, microstructures,

and corrosion rate"

"rom the obtained results, it was found that* for all tyes of carbon steels, grain si+e

increased with increasing the number of thermal cycling"

"rom the obtained test results, it was found that* the tye of corrosion is uniform attac,-

thermal cycling caused a considerable increase in corrosion rate esecially at low cycles"

The orrosion rate increases with increasing the carbon content for the thermal cycling of

.annealed samles/, while decreases for the thermal cycling of .temered samles/"

Keywords: Heat Treatment, Thermal Cycling, Microstructure, Corrosion, Steel, Hardening,

Temering and Annealing

1. Introduction

0lain carbon steels are emerging as bac,bone structural materials in high temerature

alications such as turbine engine, missiles, etc"

Carbon steels ha)e many ad)antages, high strength, and ductile materials and )ery easy to

alloyed with other elements"""""""" 1tc" On the other hand its disad)antages are the high ability

to corrosion" So, a lot of researches ha)e been studied corrosion mechanisms through which a

better understanding is obtained of the causes of corrosion and the a)ailable means for

re)enting or minimi+ing resulting damage" There are many factors which ha)e a great

influence on corrosion rate, 1n)ironments, metallurgical factors, effect of stress" 1g" Halyna

#humalo, et al 2R"!3 studied the resistance of new austenitic ferritic steels to stress corrosion

4hile #.P.At$ins and %.D. Santlebury 2R"#3" et al studied the acti)ity coefficient of sodium

chloride in a simulated ore solution en)ironment" S.H.&han!, S.B. 'yon, et al 2R"'3

in)estigated the retention of assi)ity on iron after se)eral months5 atmosheric e6osure"

Shin(ihi )oma*a$i et al 2R"73 using si6 different steels" Slow strain rate tensile test and

thermal disrution sectroscoic analysis were alied to secimens subjected to wet8dry

cyclic corrosion tests in a 9aC: solution" Hide$i )atayama, et al 2R"%3 was conducted the

corrosion simulation in a chamber to carbon steels in atmosheric en)ironment by controlling

the en)ironmental factors such as temerature, relati)e humidity and temerature of carbon

steels" A$ira Tahara and Tadashi Shinohara, et al 2R";3" They found that there are two ,inds

of corrosion atterns were distinguished, uniform corrosion and local corrosion and the

addition of 'u, (i and 'r changed the form of the corroded surface from the uniform

corrosion to the combined attern .uniform corrosion < local corrosion/ 4hile M.+amashita,

et al", 2R"=3, studied the initial rust formation rocess on carbon steel under 9a#SO7 and

9aC: solution films with )et>dry cycles using synchrotron radiation ?8rays" ,obert E.

Melhers, et al", 2R"@3 reorted that, the corrosion loss )s" time beha)iour is initially highly

non8linear and then almost linear until corrosion roduct formation begins to control the rate

of corrosion" On the other hand a mathematical modelling was carried out by Hiroshi )ihira,

1t al", 2R"A3 to corrosion rediction for weathering steels"

2. The Iron-Carbon Equilibrium Diaram :

A study of the constitution and structure of all steels and irons must first start with the Bron8

Carbon 1Cuilibrium Diagram, the Bron8 Carbon Constitutional Diagram should e6tend from

* percent Bron to * percent cementite .;";=C$/, the different lain carbon steels were

used, shown in (igure"#"!"

!. E"#E$I%E&T'( )*$K+:

-.. Materials:

Bn this wor, three different hyo8eutectoid and one hyer8eutectoid carbon steels ha)e been

used their comosition are gi)en in Table '"!"

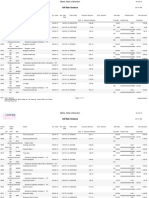

Table"'"!" The different lain carbon steels were used and mar,ed"

Secimen 9o" C$

&', &'', and &''' . to study the annealed / ', '', and ''' .to study the temered martensite/ &"!%

&7, & 77, and &777 .to study the annealed/ 7, 77, and 777 .to study the temered martensite/ &"'

&;, &;;, and &;;; .to study the annealed/ ;, ;;, and ;;; .to study the temered martensite/ &"=

&%, &%%, and &%%% .to study the annealed/ %, %%, and %%% .to study the temered martensite/ !"#

-./ Heat(Treatment and thermal yled e01eriments:

Heat treatment and thermal cycled e6eriments were conducted for two reasons:

' 8 To study the effect of thermal cycling 2!&, #&, and '& times3 on the microstructures"

, 8 To study the effect of thermal cycling 2!&, #&, and '& times3 on the corrosion" The heat8

treatment and thermal cycling were carried out in the furnace* 2Carbolite 8 Bam ford, Sheffield3"

(urnace 9o"!&>@#>!!'&, tye ET('<0D Enland, S'&#AE" (or this furnace the heating and

cooling rate were recorded as shown in (ig"'"! and (ig"'"# resecti)ely*

(ig"'"!" The furnace heating rate" (ig"'"#" The furnace cooling rate

-./... The first sta!e: heat(treatment:

-././. The seond sta!e: thermal ylin!:

The annealed and the temered samles were each di)ided in to three grous, and each grou

were subjected to a different numbers of thermal cycling .!&, #&, and '& cycles/" All samles

were subjected to the same heating cycle, in which the samles were heated below A! to

%&&

o

C and held in the furnace for !% min" Three samles of each heating cycle were cooled in

oil" The total time of a single cycle was 7& min, as shown in (igs"'"%"

2ote: 3O1tial miroso1e, tests4:

The a)ailable otical microscoes .R1BCH1RT META+A", Type ,eiss

24est Fermany3/ Bn the Material Science :aboratory of Faryounis Eni)ersity

4ere used to characteri+e the microstructures of all the test secimens"

-./.- The third sta!e: orrosion testin!:

Thousand of corrosion tests are made e)ery year "The )alue and reliability of the data

Obtained deend on details in)ol)ed" Enfortunately, many tests are not conducted or reorted

roerly, and the information obtained is misleading" Corrosion rate has been measured by

using the weight loss method for thus a 2.Bulgur/ cal)arias .Garese/ D1C"MB9"#78!8#&&' 9&

(ig"'"'" Annealing cycle diagram for the samles were used"

(ig"'"7" Heat treatment diagram for Cuenched and temered

samles were used"

(ig"'"%" T"T" Diagram shows the 2!&, #& and '& cycled cooled in oil3"

#&%#A%3 were used" The difference between the weight samle after and before subjected it to

thermal cycling then remo)al the corroded layer by a ieces of wood .more soft than steel/"

This loss of weight .H4/ is considered as weights of corroded materials were*

(osses o- corrosion . / 0) 1 )

2

3 122

4here 0): losses of weight .mgr/ due to thermal cycling"

)

2

* original weight .gram/"

4. $E+5(T '&D DI+C5++I*&:

5... The effet of heat treatment and thermal ylin! on the mirostrutures:

The microstructural changes caused by heat8treatment were in)estigated to understand the

beha)iour made of the carbon steel" .(igs"'"'" and '"7/ shows that the grain si+e which roduced

as a result of temering is less than the grains si+e roduced by annealing"

4hile the (ig".'"%/ show the samles of microstructures after thermal cycling" This figure clears

that the grain si+e become bigger than heat treated grain si+e" This may be due to the effect of

thermal cycling" Thermal cycling caused residual dimensional changes of the grain si+e

deending on the cycling schedule" The grows in grain si+e increases with increasing the

number of thermal cycling" The ability of annealed steel grain si+e to grow under thermal

cycling is more comared with temered steel"

4.2. The e--ect o- thermal cyclin on corrosion rate:

5./... Annealed steel:

The samles which early annealed then subjected to a number of thermal cycling !&, #&, and '&

cycles then e6osure to corrosion attac, for #7&hr" 4e used oil as a cooling media, (ig"7"!

shows the effect of thermal cycling on corrosion rate" The increasing of thermal cycling leads to

increase the corrosion rate for carbon steel with increase in carbon content" This increase can be

di)ided in two stages*

Bn the first stage the corrosion rate increases gradually with increasing thermal cycling u to !&

cycles" Abo)e that .more than !& cycles/ the corrosion rate becomes constant rate without any

change until '& cycles" This beha)iour can be attributed to the increase in the amount of residual

stresses, this amount of residual stress increases with increasing cycles u to .!& cycles/ and

there is no increasing in residual stresses after that" This figure shows that the carbon contents

ha)e a great influence in corrosion rate" By increasing carbon contents the corrosion rate

increases" The lead to introduce residual stresses which ha)e strong influence on corrosion rate"

Based on the abo)e results, it can be safely concluded that thermal cycling introduced residual

stresses which leads to increase in corrosion rate" Stages by increasing the number of cycles

corrosion rate increases through two deending on amount of thermal cycling"

Bn addition hyereutectoid steels ha)e higher corrosion rate comared with hyoeutectoid steels

at the same number of thermal cycling as shown in (ig"7"!"

5././. Tem1ered steel:

(ig"7"#" shows the results of this test" This figure shows nearly the same ste but oosite

beha)iour" 4here in case of annealing, the high carbon content steels mean that high

corrosion rate" 4hile in case of temering rocess the high carbon content steels show

the least amount of corrosion rate" This means that by increasing the carbon content,

corrosion rate decreases"

Also, another differ is the notice reduction in corrosion rate for all tye of carbon steels"

Another differs, the second stage becomes unlimited and the corrosion rate nearly

gradually increases with increasing thermal cycling"

C*&C(5+I*&

The results of this in6esti!ation sho7 that:

1" (or all tyes of carbon steels, grain si+e increased with increasing the number of

thermal cycling"

2" Thermal cycling causes uniform corrosion attac, for lain carbon steel"

!" Carbon as element alloy has a great influence on corrosion rate, in case of thermal

cycling .the annealed samles/, the corrosion rate increased with increasing the carbon content,

while in case of thermal cycling .the temered samles/, the corrosion rate increased with

decreasing the carbon content"

4" Corrosion rate of the first stage gradually increases with the number of thermal cycling u to !%

cycles, then it ta,e steady state u to '& cycles"

,eommendation: -&r -uture papers* we will change the cooling media and thermal cycling

$e-erences:

!" Halyna Chumalo, Stress Corrosion Crac,ing Resistance of 9ew Austenitic (erritic Steels,

Iournal Corrosion Science 1ngineering, Golume ! 0aer A, !AA@.

#" C"0" At,ins and I"D"Scantlebury, the Acti)ity Coefficient of Sodium Chloride in a Simulated

0ore Solution 1n)ironment, Iournal Corrosion Science 1ngineering, Golume ! 0aer #, !AA%.

'" S"H"Jhang, S"B":yon, Retention of 0assi)ity on Bron after Se)eral Months" Atmosheric

16osure, Iournal Corrosion Science 1ngineering, Golume! 0aer!, !AA%.

7" Shin8ichi Koma+a,i, Ka+uya Kobayashi, ToshiheiMisawa, and Tatsuo (u,u+umi,

1n)ironment embrittlement of automobile sring steels caused by wet8dry cyclic corrosion in

sodium chloride solution , Corrosion Science, Golume 7=, 0ages #7%&8#7;&, #&&%.

%" Hide,i Katayama, Ka+uhi,o 9ada, Hiroyu,i Masuda, Ma,oto 9agasawa, Masayu,i

Btaga,i, and Kunihiro 4atanabe, Corrosion simulation of carbon steels in atmosheric

en)ironment, Corrosion Science, Golume 7=, 0ages #%AA8#;&;, #&&%.

;" A,ira Tahara and Tadashi Shinohara, Bnfluence of the alloy element on corrosion

morhology of the low alloy steels e6osed to the atmosheric en)ironment, Corrosion

Science, Golume 7=, 0ages #%@A8#%A@, #&&%.

=" M"Lamashita, H"Konishi, T"Ko+a,ura, I"Mi+u,i, and H"Echida, Bn situ obser)ation of

initial rust formation rocess on carbon steel under 9a#SO7 and 9a C: solution films

with wet>dry cycles using synchrotron radiation, ?8rays Corrosion Science, Golume 7=, 0ages

#7A#8#7A@, #&&%.

@" Robert 1" Melchers, and Robert Ieffrey, 1arly corrosion of mild steel in sea water,

Corrosion Science, Golume 7=, 0ages !;=@8!;A', #&&%.

A" Hiroshi Kihira, Ta,ehide Senuma, Mutsuto Tana,a, Kiyoshi 9ishio,a, Lasumori (ujii, and

Luta,a Sa,ata, Acorrosion rediction method for weathering steels, Corrosion Science,

Golume 7=, 0ages #'==8#'A&, #&&%.

!&" Fuy :ac,, 1lements of 0hysical Metallurgy, Third 1dition, coyrightM!A@7 by Addison8

4estley 0ublishing Comany, Bnc.

You might also like

- The Wealthy Barber - Everyone's Commonsense Guide To Becoming Financially IndependentDocument219 pagesThe Wealthy Barber - Everyone's Commonsense Guide To Becoming Financially IndependentcutefrenzyNo ratings yet

- 09 Samss 091Document19 pages09 Samss 091Sohail Tisekar100% (1)

- Report No. 1 - PROPELLER CONSTRUCTIONDocument10 pagesReport No. 1 - PROPELLER CONSTRUCTIONRev Xavier CruzNo ratings yet

- SR TestDocument10 pagesSR TestkuladeepkatragaddaNo ratings yet

- Cold-Formed Steel Design Manual PDFDocument296 pagesCold-Formed Steel Design Manual PDFGoran Nikolajevic100% (1)

- Nuts & Bolts CEB SpecDocument12 pagesNuts & Bolts CEB SpecHemantha BalasuriyaNo ratings yet

- 3.cryogenic Heat TreatmentDocument5 pages3.cryogenic Heat TreatmentNitin ShelkeNo ratings yet

- High-Temperature Oxidation and Pickling Behaviour of HSLA SteelsDocument16 pagesHigh-Temperature Oxidation and Pickling Behaviour of HSLA SteelsMuhammad Ali AbroNo ratings yet

- Metallurgical Studies of Quench-and-Self-Tempered-Produced RebarDocument12 pagesMetallurgical Studies of Quench-and-Self-Tempered-Produced RebarJerry WangNo ratings yet

- Austentite Steel Thermal StabilizationDocument17 pagesAustentite Steel Thermal StabilizationArangamar KumaranNo ratings yet

- Kulliyyah of Engineering: Heat TreatmentDocument15 pagesKulliyyah of Engineering: Heat TreatmentWafa ZullfakherNo ratings yet

- Vikil D. Malwe, Major Components of Power Plants Are Subjected To HighDocument28 pagesVikil D. Malwe, Major Components of Power Plants Are Subjected To HighsaleemNo ratings yet

- metals-09-00916Document8 pagesmetals-09-00916Abdul RafiNo ratings yet

- Effect of Heat Treatment On Microstructures and Mechanical Prop of Spring SteelDocument7 pagesEffect of Heat Treatment On Microstructures and Mechanical Prop of Spring SteelMahmood KhanNo ratings yet

- A Study of Microstructure and Phase Transformations of Medium Carbon Dual Phase SteelsDocument9 pagesA Study of Microstructure and Phase Transformations of Medium Carbon Dual Phase Steelsahmed ezwaiNo ratings yet

- The Effect of Water-Vapor Content and Gas Flow RateDocument22 pagesThe Effect of Water-Vapor Content and Gas Flow RateFrancois BornmanNo ratings yet

- Bake Hardening ST 14 SteelDocument8 pagesBake Hardening ST 14 SteelDavid JendraNo ratings yet

- Journal of Alloys and Compounds: S. Osman Yilmaz, Tanju TekerDocument7 pagesJournal of Alloys and Compounds: S. Osman Yilmaz, Tanju TekerElif ArancıNo ratings yet

- 1-S2.0-Flash Butt Welding Application On 16MnCr5 Chain Steel and Investigations of Mechanical Properties-MainDocument9 pages1-S2.0-Flash Butt Welding Application On 16MnCr5 Chain Steel and Investigations of Mechanical Properties-MainHARIMETLYNo ratings yet

- Iron Ore Characterisation During High Temperature Thermal ProcessingDocument14 pagesIron Ore Characterisation During High Temperature Thermal ProcessingKrol PrietoNo ratings yet

- Content: Lecture 20: Process Control BOF SteelmakingDocument4 pagesContent: Lecture 20: Process Control BOF Steelmakingarjun prajapatiNo ratings yet

- Retained Austenite and PittingDocument6 pagesRetained Austenite and PittingSuhaib AshrafNo ratings yet

- Solidification Behavior, Microstructure, Mechanical PropertiesDocument12 pagesSolidification Behavior, Microstructure, Mechanical PropertiesCarlos LaoNo ratings yet

- InTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsDocument19 pagesInTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsSiap SiapNo ratings yet

- In-Situ Observation and Formation Mechanism of Iron Surface Oxidation in The Initial Stages at 1,150 °CDocument8 pagesIn-Situ Observation and Formation Mechanism of Iron Surface Oxidation in The Initial Stages at 1,150 °CJJNo ratings yet

- Effect of Solution Annealing Heat Treatm PDFDocument3 pagesEffect of Solution Annealing Heat Treatm PDFaltieri1No ratings yet

- The Erosion-Corrosion of Alloys Under Oxidizing-Sulphidizing Conditions at High TemperatureDocument8 pagesThe Erosion-Corrosion of Alloys Under Oxidizing-Sulphidizing Conditions at High Temperaturemoney43No ratings yet

- Characterization of The Carbides in The Steel X20CrMoV12.1 Used in Thermal Power PlantsDocument5 pagesCharacterization of The Carbides in The Steel X20CrMoV12.1 Used in Thermal Power PlantsHilarioPerezNo ratings yet

- Investigating Corrosion Effects and Heat Transfer Enhancement in Smaller Size Radiators Using CNT-nanofluidsDocument8 pagesInvestigating Corrosion Effects and Heat Transfer Enhancement in Smaller Size Radiators Using CNT-nanofluidsvuongcoi102No ratings yet

- Jurnal Kelompok 1Document10 pagesJurnal Kelompok 1Agy RandhikoNo ratings yet

- 2005, D. CLOVER, CorrosionDocument11 pages2005, D. CLOVER, Corrosionahmed ezwaiNo ratings yet

- Fireside Corrosion of Alloys For Combustion Power PlantsDocument11 pagesFireside Corrosion of Alloys For Combustion Power Plantsdealer82No ratings yet

- Phase Transformation in AISI 410 Stainless Steel PDFDocument10 pagesPhase Transformation in AISI 410 Stainless Steel PDFirajfarjiNo ratings yet

- Effect of Alloying Elements On Thermal Diffusivity of Gray Cast Iron Used in Automotive Brake DisksDocument5 pagesEffect of Alloying Elements On Thermal Diffusivity of Gray Cast Iron Used in Automotive Brake DisksUlises RochaNo ratings yet

- Reference 2Document11 pagesReference 2Khaled AlhawariNo ratings yet

- CFD Modeling of Spontaneous Heating in A Large-Scale Coal ChamberDocument8 pagesCFD Modeling of Spontaneous Heating in A Large-Scale Coal ChamberdenichezNo ratings yet

- Optmzn of HT - AMSDocument4 pagesOptmzn of HT - AMSsushmaxNo ratings yet

- The Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelDocument8 pagesThe Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelGopala Rao ThellaputtaNo ratings yet

- Effect of Heat Treatment On Microstructure and Mechanical PropertiesDocument9 pagesEffect of Heat Treatment On Microstructure and Mechanical PropertiesEliseo Hernández DuránNo ratings yet

- Auomotivr Fuel TanksDocument9 pagesAuomotivr Fuel Tankscolumba_mcNo ratings yet

- Effect of Heat Treatment On Tribological Characteristics of CuAl10Ni5Fe4 Nickel Aluminum BronzeDocument7 pagesEffect of Heat Treatment On Tribological Characteristics of CuAl10Ni5Fe4 Nickel Aluminum BronzeFathia AlkelaeNo ratings yet

- Ojay 1ST Publication PDFDocument16 pagesOjay 1ST Publication PDFvenkatrangan2003No ratings yet

- Alloy Solutions To Metal Dusting Problems in The Petrochemical Industry PDFDocument8 pagesAlloy Solutions To Metal Dusting Problems in The Petrochemical Industry PDFZeeshan SajidNo ratings yet

- 21-20MnCr5 Carburising SteelDocument4 pages21-20MnCr5 Carburising SteelKwstas PetsazNo ratings yet

- Obiukwu Osita, Udeani Henry, Ubani ProgressDocument12 pagesObiukwu Osita, Udeani Henry, Ubani ProgressPrashant KumarNo ratings yet

- Effect of Volume Fraction of Undissolved Cementite On The High Cycle Fatigue Properties of High Carbon SteelsDocument5 pagesEffect of Volume Fraction of Undissolved Cementite On The High Cycle Fatigue Properties of High Carbon SteelsEngels OchoaNo ratings yet

- Structural SteelsDocument5 pagesStructural SteelsijazNo ratings yet

- Decarburization Kinetics During Annealingil.44.618Document5 pagesDecarburization Kinetics During Annealingil.44.618Suvro ChakrabortyNo ratings yet

- Control of Slopping in Basic Oxygen Steel MakingDocument72 pagesControl of Slopping in Basic Oxygen Steel MakingNarasimha Murthy InampudiNo ratings yet

- Brazing Allloy Cusil ABADocument12 pagesBrazing Allloy Cusil ABADheeraj SharmaNo ratings yet

- Continuous and Cyclic Oxidation of T91 Ferritic Steel Under SteamDocument20 pagesContinuous and Cyclic Oxidation of T91 Ferritic Steel Under Steamrampw14581No ratings yet

- Sliding Wear Performance of Reinforced A413 Alloy at Elevated Temperatures PDFDocument8 pagesSliding Wear Performance of Reinforced A413 Alloy at Elevated Temperatures PDFirajfarjiNo ratings yet

- Effect of Heat Treatment On Microstructure and Hardness of Steel 67sicr5Document7 pagesEffect of Heat Treatment On Microstructure and Hardness of Steel 67sicr5ZarikhNo ratings yet

- Carburization of Austenitic and Ferritic Stainless Steels in Liquid SodiumDocument24 pagesCarburization of Austenitic and Ferritic Stainless Steels in Liquid Sodium鄭勝元No ratings yet

- Effect of Hardness and Wear Resistance On en 353 Steel by Heat TreatmentDocument4 pagesEffect of Hardness and Wear Resistance On en 353 Steel by Heat TreatmentIJMERNo ratings yet

- Ferdian 14060Document7 pagesFerdian 14060Marko JukićNo ratings yet

- Effect of Heat Treatment On Tribological Characteristics of CuAl10Ni5Fe4 NABDocument7 pagesEffect of Heat Treatment On Tribological Characteristics of CuAl10Ni5Fe4 NABFathia AlkelaeNo ratings yet

- 9705 Non Prop Final ReportDocument59 pages9705 Non Prop Final Reportchpinto1No ratings yet

- High Temperature CorrosionDocument16 pagesHigh Temperature CorrosionBubai111100% (1)

- Rheology and Metal Forming of Fire-Refined CopperDocument6 pagesRheology and Metal Forming of Fire-Refined CoppervitordeleteNo ratings yet

- The Effect of Soldering Process Variables On Themicrostructure and Mechanical Properties of Eutecticsn-Ag/Cu Solder JointsDocument7 pagesThe Effect of Soldering Process Variables On Themicrostructure and Mechanical Properties of Eutecticsn-Ag/Cu Solder Jointsاوس محمد رؤوف لؤيNo ratings yet

- Viet Duc Lee 2015Document31 pagesViet Duc Lee 2015Majed NesrineNo ratings yet

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelRating: 5 out of 5 stars5/5 (4)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- RDC Product CatalogDocument4 pagesRDC Product CatalogcutefrenzyNo ratings yet

- Catalyst Chage OperationDocument59 pagesCatalyst Chage OperationcutefrenzyNo ratings yet

- Genralized Corrosion Cost AnalysisDocument34 pagesGenralized Corrosion Cost AnalysiscutefrenzyNo ratings yet

- Tempil-Iron Carbon DiagramDocument1 pageTempil-Iron Carbon DiagramcutefrenzyNo ratings yet

- Effect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon SteelDocument5 pagesEffect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon Steelmalika_00No ratings yet

- Hfss 2way Thermal DimensionsDocument34 pagesHfss 2way Thermal DimensionscutefrenzyNo ratings yet

- Mek4450 Ife Day1 Lesson2Document32 pagesMek4450 Ife Day1 Lesson2cutefrenzyNo ratings yet

- Oil & Gas Downstream - EN-weldingDocument22 pagesOil & Gas Downstream - EN-weldingcutefrenzyNo ratings yet

- Mine Development: Surface WaterDocument10 pagesMine Development: Surface WatercutefrenzyNo ratings yet

- ReadmeDocument1 pageReadmecutefrenzyNo ratings yet

- Corrdata Step GuideDocument8 pagesCorrdata Step GuidecutefrenzyNo ratings yet

- Nozzle ProDocument185 pagesNozzle Progoodspeed_ph83% (6)

- Figure 12.7: Equivalent Annual Costs As A Function of Miles DrivenDocument3 pagesFigure 12.7: Equivalent Annual Costs As A Function of Miles DrivencutefrenzyNo ratings yet

- 64610Document11 pages64610cutefrenzyNo ratings yet

- Financial Management For Decision MakersDocument2 pagesFinancial Management For Decision MakerscutefrenzyNo ratings yet

- Rate VarianceDocument11 pagesRate VariancecutefrenzyNo ratings yet

- Multi-Pass Micro-Scratching and Tribological Behaviors of An Austenitic Steel in MediaDocument7 pagesMulti-Pass Micro-Scratching and Tribological Behaviors of An Austenitic Steel in MediaA.Alamgir ShaikhNo ratings yet

- Turnover Rates in Heterogeneous CatalysisDocument6 pagesTurnover Rates in Heterogeneous CatalysisWahab ChodharyNo ratings yet

- AIN Plastics Shapes For Machining BrochureDocument4 pagesAIN Plastics Shapes For Machining BrochurelarjcaNo ratings yet

- Rroys Catalogo de MaterialesDocument2 pagesRroys Catalogo de MaterialesHumberto AnguloNo ratings yet

- Redman Fisher GRP Brochure 2013Document12 pagesRedman Fisher GRP Brochure 2013lukebrown92No ratings yet

- Program Studi Magister Jurusan Teknik Material Dan Metalurgi Fti-ItsDocument4 pagesProgram Studi Magister Jurusan Teknik Material Dan Metalurgi Fti-ItsFahriadi PakayaNo ratings yet

- Lab - Iodine Clock - TeacherDocument3 pagesLab - Iodine Clock - Teachertom65656565No ratings yet

- Cationization of CottonDocument16 pagesCationization of CottonjitundcNo ratings yet

- Mechanical Properties and Drop-Weight Impact PerfoDocument11 pagesMechanical Properties and Drop-Weight Impact PerfoPasan SubasingheNo ratings yet

- Metal Fabricator WelderDocument2 pagesMetal Fabricator WelderPravin VisputeNo ratings yet

- Conveyor Belt Related Equations2010Document7 pagesConveyor Belt Related Equations2010Amit BhaduriNo ratings yet

- Hollow Core Tech DataDocument1 pageHollow Core Tech Datacr231181100% (1)

- Chapter 3 PDFDocument13 pagesChapter 3 PDFAbera Mamo100% (4)

- High-Mn Steel Weldment Mechanical Properties at 4.2 KDocument9 pagesHigh-Mn Steel Weldment Mechanical Properties at 4.2 K3834saldNo ratings yet

- MSS SP-95Document17 pagesMSS SP-95Liek FoNo ratings yet

- Gujarat Technological University Mechanical (Machine Design)Document3 pagesGujarat Technological University Mechanical (Machine Design)DharmeshPatelNo ratings yet

- Selection of MaterialsDocument36 pagesSelection of MaterialsMustafa BhattiNo ratings yet

- Imp MaterialsDocument37 pagesImp MaterialsPradeep SamuelNo ratings yet

- Som Unit 1Document158 pagesSom Unit 1Anonymous SEDun6PWNo ratings yet

- Solucionario TreybalDocument2 pagesSolucionario TreybalAnonymous OGuyqCpcy0% (5)

- Field 1 Question and ProblemsDocument4 pagesField 1 Question and ProblemsHazel Cordano100% (1)

- Malaysian FYPDocument138 pagesMalaysian FYPJustin NgNo ratings yet

- CMCE 2351 Fluid Mechanics Laboratory - Sample Density LabDocument4 pagesCMCE 2351 Fluid Mechanics Laboratory - Sample Density LabnotevaleNo ratings yet

- ME3001 Problem Set - 1 3-8-2013Document2 pagesME3001 Problem Set - 1 3-8-2013Athul JohnNo ratings yet

- P I M G S R: Technical Paper by M.C. Alfaro, S. Hayashi, N. Miura and K. WatanabeDocument20 pagesP I M G S R: Technical Paper by M.C. Alfaro, S. Hayashi, N. Miura and K. WatanabepleyvazeNo ratings yet

- Shell StructuresDocument17 pagesShell Structuresdeepanshusoni100% (1)