Professional Documents

Culture Documents

Pemanfaatan Pati Karagenn Sebagai Edibel Film

Pemanfaatan Pati Karagenn Sebagai Edibel Film

Uploaded by

Ooy Theboys'saOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pemanfaatan Pati Karagenn Sebagai Edibel Film

Pemanfaatan Pati Karagenn Sebagai Edibel Film

Uploaded by

Ooy Theboys'saCopyright:

Available Formats

All Rights Reserved

*Corresponding author.

Email: manal.sorour@yahoo.com

International Food Research Journal 21(1): 189-193 (2014)

Journal homepage: http://www.ifrj.upm.edu.my

Abdou, E. S. and

*

Sorour, M. A.

Food Engineering and Packaging Department, Food Technology Research Institute,

Agriculture Research Center, Giza, Egypt

Preparation and characterization of starch/carrageenan edible flms

Abstract

The mechanical and water vapor permeability of starch/carrageenan cast flms were investigated,

the rheological properties of starch/carrageenan blends were also studied. The blends were

prepared by different concentrations of starch and carrageenan. Three concentration of starch

(0.75%, 1% and 1.25%) and two concentrations of carrageenan (0.5% and 0.75%) were used

with adding 0.5% glycerol as plasticizer the results show that all samples behaves as non-

Newtonian pseudoplastic fuid and obeys the power law relationship. The mechanical and

water vapor permeability of the cast flms increase with increasing carrageenan content.

Introduction

Recently, considerable research has been

conducted to develop and apply bio based polymers

made from a variety of agricultural commodities

and/or of food waste products (Vasconez et al.,

2009). This increased interest was intensifed due to

concerns about limited natural resources of the fossil

fuel reserve and the environmental impact caused by

the use of non-biodegradable plastic-based packaging

materials (Catarina et al., 2009). Such biopolymers

include starches, cellulose derivatives, chitosan/

chitin, gums, proteins (animal or plant-based) and

lipids (Cutter, 2006 and Elsabee and Abdou, 2013).

These materials offer the possibility of obtaining thin

flms and coatings to cover fresh or processed foods to

extend their shelf life. Edible flms and coatings offer

extra advantages such as edibility, biocompatibility,

esthetic appearance, barrier to gasses properties, non-

toxicity, non-polluting and its low cost (Han, 2000).

In addition, bio-flms and coatings, by themselves are

acting as carriers of foods additives (i.e.: antioxidants,

antimicrobials), and have been particularly considered

in food preservation due to their ability to extend the

shelf life (Sallam, 2007).

Starch is a natural polymer that can readily

be cast into flms. It consists of (1-4) linked -D-

glucopyranosyl units, two kinds of chain are present

in natural starch: amylopectin and amylose. The

linear polymer, amylose, makes up about 20 wt% of

the granule, and the branched polymer, amylopectin,

the remainder. Amylose is crystalline and can have

an average molecular weight as high as 500,000,

while amylopectin is highly branched and have very

high molecular-weight (Chandra and Rustgi, 1998).

Despite their ease of preparation, starch flms have

poor physical properties. These can be improved by

blending with either synthetic polymers to produce

biodegradable materials (Lawton and Fanta, 1994)

or other natural polymers in edible packaging

(Arvanitoyannis et al., 1996; Psomiadou et al.,

1996; Arvanitoyannis et al., 1998a; Arvanitoyannis,

1998b).

Red seaweeds produce different types of sulfated

polysaccharides, as carrageenans (Noseda and

Cerezo, 1995; Chiovitti et al., 2004; Viana et al.,

2004; Falshaw et al., 2005). The carrageenans are a

family of sulfated, linear polysaccharides that occur

in the cell wall and intercellular matrix of numerous

species of red seaweeds (Rhodophyta) (Therkelsen,

1993; Knutsen et al., 1994). Their primary structures

are based on an alternating disaccharide repeating

sequence of -D-galactose linked at position 3, and

-Dgalactoselinked at position 4. Carrageenans

have extensive industrial applications as thickeners,

stabilizers and gelling agents in food and related

products (such as cosmetics, toiletries and

toothpaste).

Several isomers of carrageenan are known as

-, -, and -carrageenan (-kappa, - lambda and -

iota), and they differ in the number and position of the

ester sulfate groups on the repeating galactose units

(Zablackis and Santos, 1986). -carrageenan has only

one negative charge per disaccharide with a tendency

of forming a strong and rigid gel. -carrageenan

has two and -carrageenan bears on the average 2.7

charges per disaccharide unit. The gelling power of

-carrageenan inhances its good flm forming ability

Keywords

Rheological properties

Starch

Carrageenan

Mechanical properties

Water vapor permeability

Article history

Received: 25 June 2013

Received in revised form:

1 September 2013

Accepted: 5 September 2013

190 Abdou, E. S. and Sorour, M. A./IFRJ 21(1): 189-193

(Park et al., 2001; Briones et al., 2004; Choi et al.,

2005).

Blending of starch with -carrageenan results

in the formation of edible coating with good flm

forming and mechanical properties, starch must be

gelatinized frst before blending with carrageenan.

Rheology concerns with the fow and deformation of

substances and, in particular, to their behavior in the

transient area between solids and fuids. Moreover,

rheology attempts to defne a relationship between

the stress acting on a given material and the resulting

deformation and/or fow that takes place (Gipsy and

Gustavo, 2005)

Knowledge of the rheological properties of food

products is important for design and process evaluation,

process control, and consumer acceptability of a

product. In addition, the characterization of time-

dependent rheological properties of food systems is

important to establish relationships between structure

and fow, and to correlate physical parameters with

sensory evaluation (Figoni and Shoemaker, 1983).

When a material is sheared at a constant shear rate, the

viscosity of a thixotropic material will decrease over a

period of time, implying a progressive breakdown of

structure. Rheopectic materials manifest the opposite

sort of behavior. The food products containing

polymers exhibit thixotropic behavior, such as for

concentrated yogurt, milled sesame, milled black

cumin paste and mayonnaise (Basim, 2003).

Time dependent fow behavior can be investigated

as a function of time throughout tests where both the

degree of shear load and the measuring temperature are

preset as constant values. Foods such as suspensions,

emulsions and foams are time dependent fuids and

show thixotropy and rheopexy behavior. Thixotropic

behavior means the reduction in structural strength

during the shear load phase and the more or less

rapid, but complete structural regeneration during

the subsequent rest phase (Mezger, 2002). As starch

and carrageenan blends can be used as edible flm

and coating we have investigated the preparation and

characterization of starch/carrageenan blends and the

obtained edible flms.

Material and Methods

Raw materials

Starch was obtained from (NENTEHCH LTD,

BRIXWORTH. NORTHANTS.U.K.). Carrageenan

was obtained from Mefad company (Giza, Egypt).

Gelatinization of starch solution in microwave

Starch was gelatinized frst in microwave before

blending with carrageenan. Starch samples with

predetermined starch concentrations, was prepared

by using starch and distilled water, the samples

were stirred gently just before heating them in the

microwave oven in order to ensure that the starch was

fully suspended in the water. Starch samples (150

ml) were heated at full power in the microwave oven

WP800 for approximately 3 minutes.

Blend formation

Starch was blended with Carrageenan by different

ratios of starch and carrageenan using glycerol as

plasticizer. Starch was gelatinized in 150 ml distilled

water and carrageenan dissolved in 50 ml distilled

water so the total volume of the blend was 200 ml.

The different formulas of the blends were as follows:

Sample 1 (0.75% starch + 0.75% carrageenan),

sample 2 (0.75% starch + 0.5% carrageenan), sample

3 (1% starch + 0.75% carrageenan), sample 4 (1%

starch + 0.5% carrageenan), sample 5 (1.25% starch

+ 0.75% carrageenan) and sample 6 (1.25% starch +

0.5% carrageenan.

Rheological properties

The rheological properties of the prepared blends

were studied to investigate the fow behavior of

blends which is an important factor for food coating

materials. Rheological parameters (shear stress, shear

rate, viscosity) of starch/carrageenan blends were

measured at different temperatures using Brookfeld

Engineering labs DV-III Rheometer. The blend was

placed in a small sample adapter and a constant

temperature water bath was used to maintain the

desired temperature. The viscometer was operated

between 10 and 50 rpm and shear stress, shear

rate, viscosity data were obtained directly from the

instrument, the SC4-21 spindle was selected for the

measurement. Rheological measurements were made

at different concentrations of starch and carrageenan

and different time of shearing.

Film formation of starch/carrageenan

Different concentrations of starch and carrageenan

were blended using glycerol as plasticizer, The

mixtures were cast onto fat, leveled, non-stick Tefon

plates (20 cm x 15 cm)then the plates were held at

50oC for 10 hr. undisturbed and then cooled to the

ambient temperature before peeling the flms off

from the plates.

Water vapor permeability of starch/carrageenan

flms

Water vapor permeability of the flms was

Abdou, E. S. and Sorour, M. A./IFRJ 21(1): 189-193 191

measured using ASTM-E 96/1980 (38C/90%).

Mechanical properties

Tensile strength and elongation of starch/

carrageenan flms were measured using an Instron

Testing Machine model 1195 England using Load

Range 2500 N, Sample Length 25 mm. The reported

values are the average of four measurements.

Results and Discussion

Rheological properties of starch/carrageenan blends

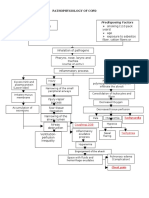

The fow curves (shear rate versus shear stress)

of Starch/carrageenan blends with 0.5% glycerol

were plotted. Figure 1 shows that all samples behave

as non-Newtonian pseudoplastic fuid. Constitutive

equations are also important for providing the

material parameters required by process control, the

shear stress-shear rate and properties of Carrageenan/

gelatinized starch blends obey the following power

law relationship:

(1)

Where, is the shear stress, Pa, k is the consistency

index, is the shear rate, 1/sec, and n is the fow

behavior index.

Thixotropic effect of starch/carrageenan blends

Time dependency of the starch/carrageenan

blends was evaluated by determining the change in

apparent viscosity under different shear rates. All

samples were found to have thixotropic behavior since

viscosity increased as concentration of carrageenan

increased as shown in Figure 2.

Figure 3 shows the relation between time of

shearing and viscosity for Starch/carrageenan blends.

Because the material is shear thinning and time

dependent, the viscosity for decreases continuously

with time, which means that on shearing of the material

causes the aggregated particles to be disrupted and

so they offer less resistance to fow and the viscosity

decreases with time until a constant value. Shear

stress decay data were obtained at different time and

at different concentrations of starch and carrageenan

the variation of shear stress with time of shearing was

ftted to Weltmann model (Weltmann, 1943).

(2)

Where, is the shear stress, Pa and t is the time, s, A,

B are constants.

Figure 4 shows that the shear stress was well

ftted with time according to Weltmann model at

different shear rates for sample 1. The same trend

was observed for all samples studied.

Mechanical properties

Mechanical properties (tensile strength and

elongation) of the starch/carrageenan based flms are

presented in Figures 5 and 6. The behavior of tensile

strength and elongation at break varying according to

the carrageenan content. The tensile strength results

(Figure 5) show that tensile strength signifcantly

increases with the increase of carrageenan content

in the blend, for all flms prepared. Elongation is

a measure of the flms capacity for stretching.

Elongation results (Figure 6) show that elongation at

break increase with increasing carrageenan content

in the blend for all flms prepared. These results of

elongation can be explained because carrageenan is

more hygroscopic than starch; hence water uptake

could explain the plasticization behavior (increased

elongation at break) which accompanies the increase

Figure 1. Effect of shear rate on shear stress for Starch/

carrageenan blends

Figure 2. Effect of carrageenan concentration on apparent

viscosity of the blends

Figure 3. The relation between time of shearing and

viscosity for Starch/carrageenan blends

192 Abdou, E. S. and Sorour, M. A./IFRJ 21(1): 189-193

in carrageenan content. Similar results were observed

by other authors (Larotonda, 2007).

Water vapor permeability

Starch flms due to the hydrophilicity properties

of the starch polymers; provide a minimal barrier

to moisture. Films of polysaccharides have overall

suitable mechanical and optical properties but are

highly sensitive to moisture and exhibit poor water

vapor barriers (Guilbert et al., 1996). Water vapor

permeability in carrageenan based flms has a high

value among other polysaccharide based flms as

reported in literature. Water vapor permeability

values of starch/carrageenan flms water vapor

permeability signifcantly increases with increasing

carrageenan percent. The results show that water

vapor permeability increase from 4.4 to 4.6, 3.6 to

3.7 and 3.6 to 3.8 for samples 1, 2, 3, 4, 5 and 6

respectively.

Conclusion

From the rheological behavior of the flm forming

starch/carrageenan blends all samples behaves

as non-Newtonian pseudoplastic behavior. Time

dependency of the starch/carrageenan blends was

evaluated all samples were found to have thixotropic

behavior since viscosity of starch/carrageenan blends

increased as concentration of carrageenan increase.

The relation between time of shearing and viscosity

for Starch/carrageenan blends shows that the viscosity

for all samples decreases continuously with time

until a constant value. Mechanical properties (tensile

strength and elongation) of the starch/carrageenan

based flms are evaluated. The behavior of tensile

strength and elongation at break varying according to

the carrageenan content tensile strength signifcantly

increases with the increase of carrageenan content in

the blend, for all flms prepared. Also elongation at

break increase with increasing carrageenan content

in the blend for all flms prepared. The water vapor

permeability values of starch/carrageenan flms show

that water vapor permeability signifcantly increases

with increasing carrageenan percent.

References

Arvanitoyannis, I., Biliaderis, C. G., Ogawa, H. and

Kawasaki, N. 1998a. Biodegradable flms made from

low-density polyethylene (LDPE), rice starch and

potato starch for food packaging applications: Part 1.

Carbohydrate Polymers 36:89-104.

Arvanitoyannis, I., Nakayama A. and Aiba, S. 1998b. Edible

flms made from hydroxypropyl starch and gelatin

and plasticized by polyols and water. Carbohydrate

Polymers 36:105-l 19.

Arvanitoyannis, I., Psomiadou, E. and Nakayama, A. 1996.

Edible flms made from sodium caseinate, starches,

sugars or glycerol Part 1, Carbohydrate Polymers

31:179-192.

Basim Abu-Jdayil. 1983. Modelling the time-dependent

rheological behavior of semisolid food stuffs, Journal

of Food Engineering 57:97102

Briones, A. V., Ambal, W. O., Estrella, R. R., Pangilinan,

R., De Vera, C. J. and Pacis, R. L. 2004. Tensile and

tear strength of carrageenan flm from Philippine

Eucheuma species. Marine Biotechnology 6:148

151.

Catarina, O., Ferreira, C.A., Delgadillo, N.I., Lopes-da-

Silva, J.A. 2009. Food Research institute 42:807

813.

Chandra, R. and Rustgi, R. 1998. Biodegradable Polymers.

Progress Polymer Science 23:12731335.

Chiovitti, A., Bacic, A., Craik, D. J., Kraft, G. T. and Liao,

M. 2004. A nearly idealized 6-O-methylated iota-

Figure 4. Relationship between shear stress and ln (t) at

different shear rate for sample 1

Figure 5. Tensile strength of starch/carrageenan flms

Figure 6. Elongation % of starch/carrageenan flms

Abdou, E. S. and Sorour, M. A./IFRJ 21(1): 189-193 193

carrageenan from the Australian red alga Claviclonium

ovatum (Acrotylaceae, Gigartinales) (Acrotylaceae,

Gigartinales). Carbohydrate Research 339:1459

1466.

Choi, J. H., Choi, W. Y., Cha, D. S., Chinnan, M. J., Park,

H. J. and Lee, D. S. 2005. Diffusivity of potassium

sorbate in kappa-carrageenan based antimicrobial

flm. Food Science and Technology-Lebensmittel-

Wissenschaft and Technologi, 38:417423.

Cutter, C.N. 2006. Opportunities for bio-based packaging

technologies to improve the quality and safety of fresh

and further processed muscle foods, Meat Science

74:131142.

Elsabee, M. Z. and Abdou, E. S. 2013. Chitosan Based

Edible Films and Coatings: A Review Materials

Science and Engineering. 33:18191841

Falshaw, R., Furneaux, R. H. and Stevenson, D. E.

2005. Structural analysis of carrageenans from

the red seaweed Callophyllis hombroniana Mont.

Ktz (Kallymeniaceae, Rhodophyta). Carbohydrate

Research 340:11491158.

Figoni, P. I. and Shoemaker, C. F. 1983. Characterization of

time dependent fow properties of mayonnaise under

steady shear, Journal of Texture Studies 14: 431442.

Guilbert, S., Gontard, N. and Gorris, L. G. M. 1996.

Prolongation of the shelf life of perishable food

products using biodegradable flms and coatings,

Lebens mittel-Wissenschaft und-Technologie 29:10-

17.

Gustavo, V. and Barbosa, C. 2005. Rheology for the food

industry Gipsy Tabilo-Munizaga. Journal of Food

Engineering 67:147156.

Han, J.H. 2000. Antimicrobial food packaging. Food

Technology 54:5665.

Knutsen, S. H. Mylabodski, D. E., Larsen, B. and Usov,

A. I. 1994. A modifed system of nomenclature for red

algal galactans. Botanica Marina 37:163169.

Larotonda, F. D. S. 2007. Biodegradable flms and coatings

obtained from carrageenan from Mastocarpus stellatus

and starch from Quercussuber. Faculty of Engineering

of the University of Porto. Ph.D thesis.

Lawton, J. W. and Fanta, G. F. 1994. Glycerol-plasticized

flms prepared from starch-poly (vinyl alcohol)

mixtures: effect of (polyethylene-co-acrylic acid).

Carbohydrate Polymers 23:275-280.

Maria, J. F., Pau, T. and Amparo, C. 2008. Effect of

alginate and -carrageenan on tensile properties and

water vapor permeability of sodium caseinatelipid

based flms. Carbohydrate Polymers 74:419426.

Mezger, T. G. 2002. In Ulrich Zorll (Ed.). The rheology

handbook: for users of rotational and oscillatory

rheometers. Germany: Hannover.

Noseda, M. D. and Cerezo, A. S. 1995. Alkali-

modifcation of carrageenans. II. The cyclization

of model compounds containing non-sulfated b-D-

galactoseunits. Carbohydrate Polymers 26:13.

Park, S. Y., Lee, B. I., Jung, S. T. and Park, H. J. 2001.

Biopolymer composite flms based on kappa-

carrageenan and chitosan. Materials Research Bulletin

36:511519.

Psomiadou, E. Arvanitoyannis, I. and Yamamoto, N.

1996. Edible flms made from natural resources;

microcrystalline cellulose (MCC), methylcellulose

(MC) and corn starch and polyols-Part 2. Carbohydrate

Polymers 31:193-204.

Sallam, K.I. 2007. Antimicrobial and antioxidant effects of

sodium acetate, sodium lactate, and sodium citrate in

refrigerated sliced salmon. Food Control 18:566575.

Sun, Y. P., Burtrand, I. L., Soon, T. J. and Hyun, J. P. 2001.

Biopolymer composite flms based on k-carrageenan

and chitosan. Materials Research Bulletin 36: 511-

519.

Therkelsen, G. H. 1993. Carrageenan. In R. L. Whistler

and J. N. BeMiller (Eds.), Industrial gums (3rd ed., pp.

145180). San Diego, CA: Academic Press.

Vsconez, M.B., Flores, S.K., Campos, C.A., Alvarado, J.

and Gerschenson, L.N. 2009. Antimicrobial activity

and physical properties of chitosan-tapioca starch

based edible flms and coatings. Food Research

International 42:762769.

Viana, A. G., Noseda, M. D., Duarte, M. E. R. and Cerezo,

A. S. 2004. Alkali modifcation of carrageenans. Part

V. The iotanu hybrid carrageenan from Eucheuma

denticulatum and its cyclization to iota-carrageenan.

Carbohydrate Polymers 58:455460.

Weltmann, R.N. 1943. Breakdown of thixotropic structure

as function of time. Journal of Applied Physics 14:343-

350.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Management of Post Facial Paralysis Synkinesis 1St Edition Babak Azizzadeh MD Facs Full ChapterDocument67 pagesManagement of Post Facial Paralysis Synkinesis 1St Edition Babak Azizzadeh MD Facs Full Chaptercatherine.green419100% (6)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bad Ragaz Ring Method Gamper Lambeck Chapter 4 Comp Aq TH (2010)Document29 pagesBad Ragaz Ring Method Gamper Lambeck Chapter 4 Comp Aq TH (2010)Talia Gil Villafuerte100% (2)

- CARIOLOGYDocument77 pagesCARIOLOGYteklay100% (3)

- Pewarisan Sifat Warna Dan Tipe Biji Jagungmanado KuningDocument8 pagesPewarisan Sifat Warna Dan Tipe Biji Jagungmanado KuningZallNo ratings yet

- Nanotechnology Optical Tweezers ReportDocument13 pagesNanotechnology Optical Tweezers ReportDaria RomanNo ratings yet

- Group Assignment Entrepreneurship Program of Diploma in Administrative Management Business Plan: ProposalDocument8 pagesGroup Assignment Entrepreneurship Program of Diploma in Administrative Management Business Plan: ProposalMuhammad ShafiqNo ratings yet

- Case Report Session Preterm Rupture of Membrane (PROM) - Ketuban Pecah DiniDocument15 pagesCase Report Session Preterm Rupture of Membrane (PROM) - Ketuban Pecah DiniAnto SaragihNo ratings yet

- نباتاتDocument2 pagesنباتاتhaneen refaeeNo ratings yet

- The History of GarlicDocument1 pageThe History of GarlicZehranur QuliyevaNo ratings yet

- Caplan Deron 201808 PHD CannabisDocument158 pagesCaplan Deron 201808 PHD CannabisMihai SimionNo ratings yet

- Anatomy of Male Genital System in StallionDocument15 pagesAnatomy of Male Genital System in StallionbaitongrstNo ratings yet

- Streptococcus Pneumonae: Pathophysiology of CopdDocument1 pageStreptococcus Pneumonae: Pathophysiology of CopdDimpal ChoudharyNo ratings yet

- Natural Regeneration: Don Minore Robert J. LaackeDocument26 pagesNatural Regeneration: Don Minore Robert J. LaackeAngela Marie AlducenteNo ratings yet

- Blood DonationDocument24 pagesBlood DonationKris NNo ratings yet

- Enzyme Application in The Textile IndustryDocument14 pagesEnzyme Application in The Textile IndustryFie100% (1)

- Experiment 12 (Synthesis of Acetylsalicylic Acid)Document8 pagesExperiment 12 (Synthesis of Acetylsalicylic Acid)Cheng Bauzon100% (1)

- Human Development and LearningDocument36 pagesHuman Development and LearningBahasa KuNo ratings yet

- E12 Practice Test 14 Đáp ÁnDocument7 pagesE12 Practice Test 14 Đáp Ánluuhangan18052000No ratings yet

- 07-Detection of E. Coli O157H7 and Other Verocytotoxin-Producing E. ColiDocument15 pages07-Detection of E. Coli O157H7 and Other Verocytotoxin-Producing E. ColiNguyễn Hữu ToànNo ratings yet

- Histogenesis of Salivary Gland NeoplasmsDocument18 pagesHistogenesis of Salivary Gland Neoplasmsporkodi sudhaNo ratings yet

- Cor 007 Module 17Document12 pagesCor 007 Module 17Camille ManlongatNo ratings yet

- Ra 9279Document5 pagesRa 9279lchieSNo ratings yet

- The Evolution of Synthetic Thought: Takshashila EssayDocument42 pagesThe Evolution of Synthetic Thought: Takshashila EssayLINDYLL PONO100% (1)

- VPH 83.43 Rev.1Document60 pagesVPH 83.43 Rev.1jubatus.libroNo ratings yet

- Choosing The Raw Materials For FPJ: Agricultural Training Institute Managing Editor and Layout Artist EditorsDocument2 pagesChoosing The Raw Materials For FPJ: Agricultural Training Institute Managing Editor and Layout Artist EditorsRONALD PACOLNo ratings yet

- Full Time Member, State Planning Commission, Government of Tamil NaduDocument5 pagesFull Time Member, State Planning Commission, Government of Tamil NadughurukumarNo ratings yet

- Epigenetic Age Clock Test Sample ReportDocument78 pagesEpigenetic Age Clock Test Sample ReportHIMMAT SINGHNo ratings yet

- Potassium Bisulphate As A Food PreservativeDocument11 pagesPotassium Bisulphate As A Food PreservativeAdam Lang67% (6)

- Types of Leukocytes and The PlateletsDocument25 pagesTypes of Leukocytes and The PlateletscarcuevajailamarieNo ratings yet

- Parameterization of The AquaCrop Model For Cowpea and Assessing The Impact of Sowing Dates Normally Used On YieldDocument14 pagesParameterization of The AquaCrop Model For Cowpea and Assessing The Impact of Sowing Dates Normally Used On YieldVandeilson Belfort MouraNo ratings yet