Professional Documents

Culture Documents

Rising Disc

Rising Disc

Uploaded by

wenigmaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rising Disc

Rising Disc

Uploaded by

wenigmaCopyright:

Available Formats

Last Updated: May 18, 2009

VR Series

RISING DISC

PROCESS VALVES

VESSEL & REACTOR VALVES

The Strahman family of products include:

S A M P L I N G V A L V E S

Strahman has a full line of sampling valves that produce live samples without exception.

Our sampling valves unique design prevent failure caused by sediment or clogging.

D R A I N V A L V E S

Strahman Drain Valves are designed to prevent clogging. They are ideal for use in liquid and gas

service or with slurries, polymers, and high viscosity fluids that tend to solidify at room temperature.

W A S H D O W N E Q U I P M E N T

Strahman offers a full line of mixing units, hose stations, hoses, nozzles and wash down accessories.

Our wash down line is designed for industrial use and is used in a wide variety of industries including

food, beverage, pharmaceutical, chemical and other applications.

L I N E B L I N DS

Strahman Line Blinds provide zero leakage down stream and total isolation on process pipelines,

vessels, and maritime applications. No pipeline movement is required when blind position is

changed.

Please contact your local Strahman representative for further details

or

visit our website: www.strahmanvalves.com

VALVES, INC.

Corporate Headquarters:

Strahman Valves, Inc. 2801 Baglyos Circle, Bethlehem, PA 18020

Tel: 484. 893.5080 Fax: 484.893.5099

Strahman France:

Savoie Hexapole, F-73420, Mery, France

Tel: + 33 4 79 35 78 00 Fax: + 33 4 79 35 78 20

Strahman MG Gmbh

Eisenbahnstrasse 104a

D-77833 Ottersweier, Germany

Tel: + 49 7223 22057 Fax: +49 7223 20165

ISO 9001 CERTIFIED

E s t a b l I s h e d 1 9 2 1

Rising Disc Valves

CRUST BREAKING BOTTOM OUTLET VALVES

Code: VR4M-VR6M

Purge connections

can be added to

flush the valve and

clean downstream

Optional full jacketing

Jacket Connections

(oil or steam) customized

to actual valve position

An extended stuffing box

eliminates dead space and

improves stem/disc

alignment

Live loaded packing

arrangement is standard

Mechanical position indicator

Standard branch angle:

45 & 60

90, and other specific

angles available upon

request

M Seal for high Pressure &

Temperature. Dual Seal,

Soft Seal, M Ring and M

Control are available

JACKET CONNECTIONS

Flanges

ANSI,DIN,JIS

Butt Weld Socket Weld

Fig. 042D

Extended body design provides

a flush design and a dead space

free connection to the vessel

TECHNICAL & GENERAL INFORMATION

Design Code & Construction

Design standard compliant with ASME B16.34

International standards include ANSI, DIN, JIS, API etc.

Wide range of material selections including carbon steel / stainless steel / Titanium / Hastelloy / Duplex /

Monel / Tantalum / Zirconium

Fabricated, cast, forged and bar stock designs

Combinations of fabricated, sand and investment casings, and bar stock available

Surface Finish

For polymer applications, Strahman recommends a surface facing of 300 (Ra 0.4) for all parts are in

contact with the medium

Quality assurance & testing

ISO 9001 compliant

PED / ATEX / CE marking

TUV / HPO / TA Luft

Standard testing procedures

SEALING SYSTEMS

Dual Seal- The Dual Seal is a unique

double sealing system that works like a

piston operating within a cylindrical

seat. Unlike other designs, the secondary

resilient seal ring is mounted on the pis-

ton and will expand after metal to metal

contact of the primary seat ring. The

design provides a true metal to metal

seal in case of resilient seat failure.

Temperature

Min: -50

o

C / -60

o

F

Max: 200

o

C / 450

o

F

Pressure

Max: 250 bar / 3550 psig

& full vacuum

M Seal- This sealing system offers a

wide range of material combinations

selected to create a differential hard-

ness between body and plunger seat.

The maintenance friendly design of the

M Seal system provides long & reliable

valve performance and is suitable for

almost all process conditions.

Temperature

Min: -200

o

C / -330

o

F

Max: 815

o

C / 1500

o

F

Pressure

Max: 630 bar / 9000 psig

Greater hardness on

body seat assures

that wear occurs on

piston first

- Easy maintenance is key

Solid Disc/Stem design

provides the geometrical

arrangement that ensures

long-term sealing perform-

ance

M Ring Seal- The M Ring Seal is

also based on a differential hardness

between the body and the piston sur-

face. The replaceable metallic seal

ring made of aluminum, nickel or tita-

nium provides excellent sealing per-

formance especially in applications that

combine full vacuum and temperatures

above 200

o

C.

Temperature

Min: -200

o

C / -330

o

F

Max: 450

o

C / 840

o

F

Pressure

Max: 250 bar / 3550 psig

& full vacuum

Locking nut is secured

by a tack weld

Resilient metal

ring seals between the

body seat and disc and

provides high perform-

ance sealing for vacuum

and high temperature

applications

Valve Body

Valve Body

Locking nut is secured

by a tack weld

Valve Body

A secondary seal ring is

made of resilient material

like PTFE, PTFE glass filled

The primary metal to metal

seal ring compresses the

secondary resilient seal

ring

Threaded

connections

NPT & BSP

Rising Disc Valves

CRUST BREAKING BOTTOM OUTLET VALVES

Code: VR4M-VR6M

Purge connections

can be added to

flush the valve and

clean downstream

Optional full jacketing

Jacket Connections

(oil or steam) customized

to actual valve position

An extended stuffing box

eliminates dead space and

improves stem/disc

alignment

Live loaded packing

arrangement is standard

Mechanical position indicator

Standard branch angle:

45 & 60

90, and other specific

angles available upon

request

M Seal for high Pressure &

Temperature. Dual Seal,

Soft Seal, M Ring and M

Control are available

JACKET CONNECTIONS

Flanges

ANSI,DIN,JIS

Butt Weld Socket Weld

Fig. 042D

Extended body design provides

a flush design and a dead space

free connection to the vessel

TECHNICAL & GENERAL INFORMATION

Design Code & Construction

Design standard compliant with ASME B16.34

International standards include ANSI, DIN, JIS, API etc.

Wide range of material selections including carbon steel / stainless steel / Titanium / Hastelloy / Duplex /

Monel / Tantalum / Zirconium

Fabricated, cast, forged and bar stock designs

Combinations of fabricated, sand and investment casings, and bar stock available

Surface Finish

For polymer applications, Strahman recommends a surface facing of 300 (Ra 0.4) for all parts are in

contact with the medium

Quality assurance & testing

ISO 9001 compliant

PED / ATEX / CE marking

TUV / HPO / TA Luft

Standard testing procedures

SEALING SYSTEMS

Dual Seal- The Dual Seal is a unique

double sealing system that works like a

piston operating within a cylindrical

seat. Unlike other designs, the secondary

resilient seal ring is mounted on the pis-

ton and will expand after metal to metal

contact of the primary seat ring. The

design provides a true metal to metal

seal in case of resilient seat failure.

Temperature

Min: -50

o

C / -60

o

F

Max: 200

o

C / 450

o

F

Pressure

Max: 250 bar / 3550 psig

& full vacuum

M Seal- This sealing system offers a

wide range of material combinations

selected to create a differential hard-

ness between body and plunger seat.

The maintenance friendly design of the

M Seal system provides long & reliable

valve performance and is suitable for

almost all process conditions.

Temperature

Min: -200

o

C / -330

o

F

Max: 815

o

C / 1500

o

F

Pressure

Max: 630 bar / 9000 psig

Greater hardness on

body seat assures

that wear occurs on

piston first

- Easy maintenance is key

Solid Disc/Stem design

provides the geometrical

arrangement that ensures

long-term sealing perform-

ance

M Ring Seal- The M Ring Seal is

also based on a differential hardness

between the body and the piston sur-

face. The replaceable metallic seal

ring made of aluminum, nickel or tita-

nium provides excellent sealing per-

formance especially in applications that

combine full vacuum and temperatures

above 200

o

C.

Temperature

Min: -200

o

C / -330

o

F

Max: 450

o

C / 840

o

F

Pressure

Max: 250 bar / 3550 psig

& full vacuum

Locking nut is secured

by a tack weld

Resilient metal

ring seals between the

body seat and disc and

provides high perform-

ance sealing for vacuum

and high temperature

applications

Valve Body

Valve Body

Locking nut is secured

by a tack weld

Valve Body

A secondary seal ring is

made of resilient material

like PTFE, PTFE glass filled

The primary metal to metal

seal ring compresses the

secondary resilient seal

ring

Threaded

connections

NPT & BSP

VACUUM HOOD

All packing arrangements

use a lantern ring that:

Provides better stem

piston guiding

Avoids dead space in

body cavities

Typical Packing Materials:

PTFE

PTFE / Aramide Braid

Carbon / Graphite Braid

Graphite Braid

PTFE / Aramide Braid + Graphite

Lamellar + Expanded Graphite

Pure Graphite

Live loaded packing

arrangement

minimizes maintenance

Optional 1/4 inch NPTF can be

used for leak detection or inert

gas injection to avoid leakage to

atmosphere by creating an over

pressure

Bottom ring material

is selected with a

differential hardness

from the piston to

prevent piston

damage

For valves on full vacuum service Strahman offers a

special vacuum package that maintains tightness to

atmosphere. Valves with this package are usually

equipped with an M Ring Seal design as process

sealing. The system uses a replaceable aluminium or

nickel seal ring and provides high vacuum performance.

This special vacuum package provides zero leakage

between atmosphere and process.

Viton or Graphite

column gasket

Mechanical

position indicator

Spring

loaded

secondary

packing

made of

PTFE or

Graphite

Metal seated test

valve allows checking

of packing perform-

ance. Can also be

used for gas injection

Vacuum hood

gasket made of

Aramide

compound or

Graphite

Live loaded packing

arrangement is standard

STANDARD PAD GASKET RANGE

PTFE

Aramide / Nitrile

Carbon / Aramide

Laminated Graphite

Laminated Graphite / 316

Spiral Wound 316L / PTFE

Spiral Wound 316L / Graphite

Spiral Wound 321 / Graphite

Spiral Wound Inconel / Graphite

Spiral Wound Titanium / Graphite

Welded Lips

Metallic O Ring Helicoflex Gasket Aluminium/316

Metallic O Ring Helicoflex Gasket Nickel/Nimonic 90

316L RTJ

Nitrile O Ring

EPDM O Ring

Silicone O Ring

Fluorocarbon (Viton) O Ring

Silicone FEP Jacketed O Ring

Perfluoroelastomer (Kalrez) O Ring

PACKING DEFINITION

Valve Coding System

P Piston

D Disc

R Rising Disc

A Accessories

4 45

o

Branch Angle

6 60

o

Branch Angle

9 90

o

Branch Angle

S Straight

$ Special

B Extended Body

P Extended Plunger c

D Dismountable Seat

$ Special

V R 4 M B J

V Vessel Reactor Valves

S Soft Seated

M M Seal

C M Control

D Dual Seal

R M Ring Seal

J Jacketed

- Non-Jacketed

Strahman has two Rising Disc styles available:

Figure 040 for large valves and low pressure applications. Uses a fabricated pipe or cast body

design

Figure 042 for small valves and high pressure applications. Uses a bar stock body design

BODY ARRANGEMENTS

Strahman Rising Disc design is a bottom outlet valve. When opening, the disc rises into the vessel or

reactor to break through any crust or solidified material to facilitate draining.

Strahman valves are available in a choice of options including material of construction, sealing

systems, actuators and customized or standard connections to piping. Other specific features are full

jacketing, valve tangentially positioned to process pipe or additive injection.

Typical applications: Draining of low viscosity products.

Fig. 040 Fig. 042

LINE & BRANCH CONNECTIONS

Flanges

ANSI, DIN, JIS

Heated

Flanges

Butt

Weld

Fast Bolting Union

Graylock Securamax

ACTUATION OPTIONS

Hand Wheel Bevel Gear Electric Actuator Air Motor

Double or single

acting Air Cylinder

Double or single acting Air

Cylinder with Safety Hand Wheel

Hydraulic

Cylinder

Double or single acting Air

Cylinder with side mounted

Safety Hand Wheel

Studded

Ends

Socket

Weld

Threaded

connections

NPT & BSP

D

H

D

H

H

D

R

H

D

Vessel Pad

Vessel Nozzle Pipe Assembly Pad Custom Vessel Pad

To connect valves to existing vessels or reactors, there are two possibilities: a nozzle or a pad

connection. In both cases, the customer must specify the following vessel connection details:

D (inside diameter), H (height), DN (nominal size), PN (pressure rating) and connection

standard (ISO, ANSI, DIN, etc.). To eliminate retention areas radius R can be specified for

optional contouring. For new projects Strahman can supply valves with easy-to-fit standardized pads

that are ready to be installed.

VESSEL CONNECTIONS

Primary seal metal to metal

ring compresses the resil-

ient secondary seal ring

Locking nut secured

by tack weld

Secondary seal ring made of

resilient material PTFE /

PTFE glass lined

Valve Body

DUAL SEAL DISC & DISMOUNTABLE SEAT

As an option the body seat can be

dismountable. This is an attractive

option when the process is corro-

sive during the reaction. Parts

directly in contact with the process

(seat and trim) are made of

sophisticated alloys while valve

body and piping are fabricated from

regular materials

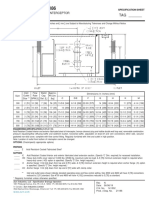

RANGE DEFINITION

VR

Manufactur-

ing Range

3/8- DIN10

1/2- DIN15

3/4- DIN20

1- DIN25

1 1/4- DIN32

1 1/2- DIN40

2- DIN50

2 1/2- DIN65

3- DIN80

4- DIN100

5- DIN125

6- DIN150

8- DIN200

10- DIN250

12- DIN300

14- DIN350

16- DIN400

18- DIN450

20- DIN500

24- DIN600

P

N

1

0

P

N

1

6

P

N

2

0

1

5

0

l

b

s

.

P

N

2

5

P

N

4

0

P

N

5

0

3

0

0

l

b

s

.

P

N

6

4

4

0

0

l

b

s

.

P

N

1

0

0

6

0

0

l

b

s

.

P

N

1

5

0

/

1

6

0

-

9

0

0

l

b

s

.

P

N

2

5

0

-

1

5

0

0

l

b

s

P

N

3

2

0

P

N

4

2

0

2

5

0

0

l

b

s

P

N

6

3

0

4

5

0

0

l

b

s

Fig. 042

Fig. 040

LINE & BRANCH CONNECTIONS

Flanges

ANSI, DIN, JIS

Heated

Flanges

Butt

Weld

Fast Bolting Union

Graylock Securamax

ACTUATION OPTIONS

Hand Wheel Bevel Gear Electric Actuator Air Motor

Double or single

acting Air Cylinder

Double or single acting Air

Cylinder with Safety Hand Wheel

Hydraulic

Cylinder

Double or single acting Air

Cylinder with side mounted

Safety Hand Wheel

Studded

Ends

Socket

Weld

Threaded

connections

NPT & BSP

D

H

D

H

H

D

R

H

D

Vessel Pad

Vessel Nozzle Pipe Assembly Pad Custom Vessel Pad

To connect valves to existing vessels or reactors, there are two possibilities: a nozzle or a pad

connection. In both cases, the customer must specify the following vessel connection details:

D (inside diameter), H (height), DN (nominal size), PN (pressure rating) and connection

standard (ISO, ANSI, DIN, etc.). To eliminate retention areas radius R can be specified for

optional contouring. For new projects Strahman can supply valves with easy-to-fit standardized pads

that are ready to be installed.

VESSEL CONNECTIONS

Primary seal metal to metal

ring compresses the resil-

ient secondary seal ring

Locking nut secured

by tack weld

Secondary seal ring made of

resilient material PTFE /

PTFE glass lined

Valve Body

DUAL SEAL DISC & DISMOUNTABLE SEAT

As an option the body seat can be

dismountable. This is an attractive

option when the process is corro-

sive during the reaction. Parts

directly in contact with the process

(seat and trim) are made of

sophisticated alloys while valve

body and piping are fabricated from

regular materials

RANGE DEFINITION

VR

Manufactur-

ing Range

3/8- DIN10

1/2- DIN15

3/4- DIN20

1- DIN25

1 1/4- DIN32

1 1/2- DIN40

2- DIN50

2 1/2- DIN65

3- DIN80

4- DIN100

5- DIN125

6- DIN150

8- DIN200

10- DIN250

12- DIN300

14- DIN350

16- DIN400

18- DIN450

20- DIN500

24- DIN600

P

N

1

0

P

N

1

6

P

N

2

0

1

5

0

l

b

s

.

P

N

2

5

P

N

4

0

P

N

5

0

3

0

0

l

b

s

.

P

N

6

4

4

0

0

l

b

s

.

P

N

1

0

0

6

0

0

l

b

s

.

P

N

1

5

0

/

1

6

0

-

9

0

0

l

b

s

.

P

N

2

5

0

-

1

5

0

0

l

b

s

P

N

3

2

0

P

N

4

2

0

2

5

0

0

l

b

s

P

N

6

3

0

4

5

0

0

l

b

s

Fig. 042

Fig. 040

LINE & BRANCH CONNECTIONS

Flanges

ANSI, DIN, JIS

Heated

Flanges

Butt

Weld

Fast Bolting Union

Graylock Securamax

ACTUATION OPTIONS

Hand Wheel Bevel Gear Electric Actuator Air Motor

Double or single

acting Air Cylinder

Double or single acting Air

Cylinder with Safety Hand Wheel

Hydraulic

Cylinder

Double or single acting Air

Cylinder with side mounted

Safety Hand Wheel

Studded

Ends

Socket

Weld

Threaded

connections

NPT & BSP

D

H

D

H

H

D

R

H

D

Vessel Pad

Vessel Nozzle Pipe Assembly Pad Custom Vessel Pad

To connect valves to existing vessels or reactors, there are two possibilities: a nozzle or a pad

connection. In both cases, the customer must specify the following vessel connection details:

D (inside diameter), H (height), DN (nominal size), PN (pressure rating) and connection

standard (ISO, ANSI, DIN, etc.). To eliminate retention areas radius R can be specified for

optional contouring. For new projects Strahman can supply valves with easy-to-fit standardized pads

that are ready to be installed.

VESSEL CONNECTIONS

Primary seal metal to metal

ring compresses the resil-

ient secondary seal ring

Locking nut secured

by tack weld

Secondary seal ring made of

resilient material PTFE /

PTFE glass lined

Valve Body

DUAL SEAL DISC & DISMOUNTABLE SEAT

As an option the body seat can be

dismountable. This is an attractive

option when the process is corro-

sive during the reaction. Parts

directly in contact with the process

(seat and trim) are made of

sophisticated alloys while valve

body and piping are fabricated from

regular materials

RANGE DEFINITION

VR

Manufactur-

ing Range

3/8- DIN10

1/2- DIN15

3/4- DIN20

1- DIN25

1 1/4- DIN32

1 1/2- DIN40

2- DIN50

2 1/2- DIN65

3- DIN80

4- DIN100

5- DIN125

6- DIN150

8- DIN200

10- DIN250

12- DIN300

14- DIN350

16- DIN400

18- DIN450

20- DIN500

24- DIN600

P

N

1

0

P

N

1

6

P

N

2

0

1

5

0

l

b

s

.

P

N

2

5

P

N

4

0

P

N

5

0

3

0

0

l

b

s

.

P

N

6

4

4

0

0

l

b

s

.

P

N

1

0

0

6

0

0

l

b

s

.

P

N

1

5

0

/

1

6

0

-

9

0

0

l

b

s

.

P

N

2

5

0

-

1

5

0

0

l

b

s

P

N

3

2

0

P

N

4

2

0

2

5

0

0

l

b

s

P

N

6

3

0

4

5

0

0

l

b

s

Fig. 042

Fig. 040

VACUUM HOOD

All packing arrangements

use a lantern ring that:

Provides better stem

piston guiding

Avoids dead space in

body cavities

Typical Packing Materials:

PTFE

PTFE / Aramide Braid

Carbon / Graphite Braid

Graphite Braid

PTFE / Aramide Braid + Graphite

Lamellar + Expanded Graphite

Pure Graphite

Live loaded packing

arrangement

minimizes maintenance

Optional 1/4 inch NPTF can be

used for leak detection or inert

gas injection to avoid leakage to

atmosphere by creating an over

pressure

Bottom ring material

is selected with a

differential hardness

from the piston to

prevent piston

damage

For valves on full vacuum service Strahman offers a

special vacuum package that maintains tightness to

atmosphere. Valves with this package are usually

equipped with an M Ring Seal design as process

sealing. The system uses a replaceable aluminium or

nickel seal ring and provides high vacuum performance.

This special vacuum package provides zero leakage

between atmosphere and process.

Viton or Graphite

column gasket

Mechanical

position indicator

Spring

loaded

secondary

packing

made of

PTFE or

Graphite

Metal seated test

valve allows checking

of packing perform-

ance. Can also be

used for gas injection

Vacuum hood

gasket made of

Aramide

compound or

Graphite

Live loaded packing

arrangement is standard

STANDARD PAD GASKET RANGE

PTFE

Aramide / Nitrile

Carbon / Aramide

Laminated Graphite

Laminated Graphite / 316

Spiral Wound 316L / PTFE

Spiral Wound 316L / Graphite

Spiral Wound 321 / Graphite

Spiral Wound Inconel / Graphite

Spiral Wound Titanium / Graphite

Welded Lips

Metallic O Ring Helicoflex Gasket Aluminium/316

Metallic O Ring Helicoflex Gasket Nickel/Nimonic 90

316L RTJ

Nitrile O Ring

EPDM O Ring

Silicone O Ring

Fluorocarbon (Viton) O Ring

Silicone FEP Jacketed O Ring

Perfluoroelastomer (Kalrez) O Ring

PACKING DEFINITION

Valve Coding System

P Piston

D Disc

R Rising Disc

A Accessories

4 45

o

Branch Angle

6 60

o

Branch Angle

9 90

o

Branch Angle

S Straight

$ Special

B Extended Body

P Extended Plunger c

D Dismountable Seat

$ Special

V R 4 M B J

V Vessel Reactor Valves

S Soft Seated

M M Seal

C M Control

D Dual Seal

R M Ring Seal

J Jacketed

- Non-Jacketed

Strahman has two Rising Disc styles available:

Figure 040 for large valves and low pressure applications. Uses a fabricated pipe or cast body

design

Figure 042 for small valves and high pressure applications. Uses a bar stock body design

BODY ARRANGEMENTS

Strahman Rising Disc design is a bottom outlet valve. When opening, the disc rises into the vessel or

reactor to break through any crust or solidified material to facilitate draining.

Strahman valves are available in a choice of options including material of construction, sealing

systems, actuators and customized or standard connections to piping. Other specific features are full

jacketing, valve tangentially positioned to process pipe or additive injection.

Typical applications: Draining of low viscosity products.

Fig. 040 Fig. 042

VACUUM HOOD

All packing arrangements

use a lantern ring that:

Provides better stem

piston guiding

Avoids dead space in

body cavities

Typical Packing Materials:

PTFE

PTFE / Aramide Braid

Carbon / Graphite Braid

Graphite Braid

PTFE / Aramide Braid + Graphite

Lamellar + Expanded Graphite

Pure Graphite

Live loaded packing

arrangement

minimizes maintenance

Optional 1/4 inch NPTF can be

used for leak detection or inert

gas injection to avoid leakage to

atmosphere by creating an over

pressure

Bottom ring material

is selected with a

differential hardness

from the piston to

prevent piston

damage

For valves on full vacuum service Strahman offers a

special vacuum package that maintains tightness to

atmosphere. Valves with this package are usually

equipped with an M Ring Seal design as process

sealing. The system uses a replaceable aluminium or

nickel seal ring and provides high vacuum performance.

This special vacuum package provides zero leakage

between atmosphere and process.

Viton or Graphite

column gasket

Mechanical

position indicator

Spring

loaded

secondary

packing

made of

PTFE or

Graphite

Metal seated test

valve allows checking

of packing perform-

ance. Can also be

used for gas injection

Vacuum hood

gasket made of

Aramide

compound or

Graphite

Live loaded packing

arrangement is standard

STANDARD PAD GASKET RANGE

PTFE

Aramide / Nitrile

Carbon / Aramide

Laminated Graphite

Laminated Graphite / 316

Spiral Wound 316L / PTFE

Spiral Wound 316L / Graphite

Spiral Wound 321 / Graphite

Spiral Wound Inconel / Graphite

Spiral Wound Titanium / Graphite

Welded Lips

Metallic O Ring Helicoflex Gasket Aluminium/316

Metallic O Ring Helicoflex Gasket Nickel/Nimonic 90

316L RTJ

Nitrile O Ring

EPDM O Ring

Silicone O Ring

Fluorocarbon (Viton) O Ring

Silicone FEP Jacketed O Ring

Perfluoroelastomer (Kalrez) O Ring

PACKING DEFINITION

Valve Coding System

P Piston

D Disc

R Rising Disc

A Accessories

4 45

o

Branch Angle

6 60

o

Branch Angle

9 90

o

Branch Angle

S Straight

$ Special

B Extended Body

P Extended Plunger c

D Dismountable Seat

$ Special

V R 4 M B J

V Vessel Reactor Valves

S Soft Seated

M M Seal

C M Control

D Dual Seal

R M Ring Seal

J Jacketed

- Non-Jacketed

Strahman has two Rising Disc styles available:

Figure 040 for large valves and low pressure applications. Uses a fabricated pipe or cast body

design

Figure 042 for small valves and high pressure applications. Uses a bar stock body design

BODY ARRANGEMENTS

Strahman Rising Disc design is a bottom outlet valve. When opening, the disc rises into the vessel or

reactor to break through any crust or solidified material to facilitate draining.

Strahman valves are available in a choice of options including material of construction, sealing

systems, actuators and customized or standard connections to piping. Other specific features are full

jacketing, valve tangentially positioned to process pipe or additive injection.

Typical applications: Draining of low viscosity products.

Fig. 040 Fig. 042

Rising Disc Valves

CRUST BREAKING BOTTOM OUTLET VALVES

Code: VR4M-VR6M

Purge connections

can be added to

flush the valve and

clean downstream

Optional full jacketing

Jacket Connections

(oil or steam) customized

to actual valve position

An extended stuffing box

eliminates dead space and

improves stem/disc

alignment

Live loaded packing

arrangement is standard

Mechanical position indicator

Standard branch angle:

45 & 60

90, and other specific

angles available upon

request

M Seal for high Pressure &

Temperature. Dual Seal,

Soft Seal, M Ring and M

Control are available

JACKET CONNECTIONS

Flanges

ANSI,DIN,JIS

Butt Weld Socket Weld

Fig. 042D

Extended body design provides

a flush design and a dead space

free connection to the vessel

TECHNICAL & GENERAL INFORMATION

Design Code & Construction

Design standard compliant with ASME B16.34

International standards include ANSI, DIN, JIS, API etc.

Wide range of material selections including carbon steel / stainless steel / Titanium / Hastelloy / Duplex /

Monel / Tantalum / Zirconium

Fabricated, cast, forged and bar stock designs

Combinations of fabricated, sand and investment casings, and bar stock available

Surface Finish

For polymer applications, Strahman recommends a surface facing of 300 (Ra 0.4) for all parts are in

contact with the medium

Quality assurance & testing

ISO 9001 compliant

PED / ATEX / CE marking

TUV / HPO / TA Luft

Standard testing procedures

SEALING SYSTEMS

Dual Seal- The Dual Seal is a unique

double sealing system that works like a

piston operating within a cylindrical

seat. Unlike other designs, the secondary

resilient seal ring is mounted on the pis-

ton and will expand after metal to metal

contact of the primary seat ring. The

design provides a true metal to metal

seal in case of resilient seat failure.

Temperature

Min: -50

o

C / -60

o

F

Max: 200

o

C / 450

o

F

Pressure

Max: 250 bar / 3550 psig

& full vacuum

M Seal- This sealing system offers a

wide range of material combinations

selected to create a differential hard-

ness between body and plunger seat.

The maintenance friendly design of the

M Seal system provides long & reliable

valve performance and is suitable for

almost all process conditions.

Temperature

Min: -200

o

C / -330

o

F

Max: 815

o

C / 1500

o

F

Pressure

Max: 630 bar / 9000 psig

Greater hardness on

body seat assures

that wear occurs on

piston first

- Easy maintenance is key

Solid Disc/Stem design

provides the geometrical

arrangement that ensures

long-term sealing perform-

ance

M Ring Seal- The M Ring Seal is

also based on a differential hardness

between the body and the piston sur-

face. The replaceable metallic seal

ring made of aluminum, nickel or tita-

nium provides excellent sealing per-

formance especially in applications that

combine full vacuum and temperatures

above 200

o

C.

Temperature

Min: -200

o

C / -330

o

F

Max: 450

o

C / 840

o

F

Pressure

Max: 250 bar / 3550 psig

& full vacuum

Locking nut is secured

by a tack weld

Resilient metal

ring seals between the

body seat and disc and

provides high perform-

ance sealing for vacuum

and high temperature

applications

Valve Body

Valve Body

Locking nut is secured

by a tack weld

Valve Body

A secondary seal ring is

made of resilient material

like PTFE, PTFE glass filled

The primary metal to metal

seal ring compresses the

secondary resilient seal

ring

Threaded

connections

NPT & BSP

P Series

PIPE VALVE ASSEMBLIES

PROCESS VALVES

The Strahman family of products include:

S A M P L I N G V A L V E S

Strahman has a full line of sampling valves that produce live samples without exception.

Our sampling valves unique design prevent failure caused by sediment or clogging.

D R A I N V A L V E S

Strahman Drain Valves are designed to prevent clogging. They are ideal for use in liquid and gas

service or with slurries, polymers, and high viscosity fluids that tend to solidify at room temperature.

W A S H D O W N E Q U I P M E N T

Strahman offers a full line of mixing units, hose stations, hoses, nozzles and wash down accessories.

Our wash down line is designed for industrial use and is used in a wide variety of industries including

food, beverage, pharmaceutical, chemical and other applications.

L I N E B L I N D S

Strahman Line Blinds provide zero leakage down stream and total isolation on process pipelines,

vessels, and maritime applications. No pipeline movement is required when blind position is

changed.

Please contact your local Strahman representative for further details

or

visit our website : www.strahmanvalves.com

VALVES, INC.

Corporate Headquarters:

Strahman Valves, Inc. 2801 Baglyos Circle, Bethlehem, PA 18020

Tel: 484. 893.5080 Fax: 484.893.5099

Strahman France:

Savoie Hexapole, F-73420, Mery, France

Tel: + 33 4 79 35 78 00 Fax: + 33 4 79 35 78 20

Strahman MG Gmbh

Eisenbahnstrasse 104a

D-77833 Ottersweier, Germany

Tel: + 49 7223 22057 Fax: +49 7223 20165

ISO 9001 Certified

E s t a b l I s h e d 1 9 2 1

Last Updated: May 18, 2009

Strahman German Offce

Kirchstrasse 16, D-77855, Achern, Germany

Tel: +49 7841 6846530 Fax: +49 7841 6846531

Last Updated: July, 2012

You might also like

- Grove G9 Wafer Gate ValveDocument9 pagesGrove G9 Wafer Gate Valvetxlucky80No ratings yet

- Drew Marine - Sealing Products CatalogDocument19 pagesDrew Marine - Sealing Products CatalogGauravNo ratings yet

- B&R Drg. For CR Tank PDFDocument195 pagesB&R Drg. For CR Tank PDFaabhas100% (2)

- Shand - Jurs Conservation Vent 94020-3CDocument8 pagesShand - Jurs Conservation Vent 94020-3CRuban PaulNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Introduction of Iso Tank ContainersDocument10 pagesIntroduction of Iso Tank ContainerswenigmaNo ratings yet

- Stud Bolt LengthDocument1 pageStud Bolt LengthRyan Goh Chuang HongNo ratings yet

- Piping Quiz & Ans (Fluor Daniel) PDFDocument13 pagesPiping Quiz & Ans (Fluor Daniel) PDFaslam.amb100% (1)

- Disc ValvesDocument8 pagesDisc ValvesMahesh KumarNo ratings yet

- Wedge and Slab Gate ValvesDocument8 pagesWedge and Slab Gate Valvesgad30100% (1)

- 15 Metal Seated Butterfly ValvesDocument8 pages15 Metal Seated Butterfly ValvesrajfmcNo ratings yet

- SBF LongdDocument10 pagesSBF LongdcatalineulaNo ratings yet

- Mechanical Seals in AgitatorsDocument6 pagesMechanical Seals in AgitatorsLy Ca TieuNo ratings yet

- Perar Trunnion Ball ValvesDocument54 pagesPerar Trunnion Ball ValvesUday GokhaleNo ratings yet

- WKM Pow R Seal Gate Valves BrochureDocument28 pagesWKM Pow R Seal Gate Valves BrochureKhai Huynh100% (1)

- 2011 07 Mar00080 en Katalog Typs WebDocument28 pages2011 07 Mar00080 en Katalog Typs WebzayerirezaNo ratings yet

- Tyco Vanessa DatasheetDocument16 pagesTyco Vanessa DatasheetJack ChavanNo ratings yet

- ASME Class 150 and 300Document12 pagesASME Class 150 and 300pca97No ratings yet

- Worcester 819 829Document8 pagesWorcester 819 829Văn Đình NhậtNo ratings yet

- Catalogo de Presion ReotempDocument48 pagesCatalogo de Presion Reotempdiuska13No ratings yet

- Head and Well RefDocument5 pagesHead and Well Refmehdi227No ratings yet

- Gasket RefDocument21 pagesGasket Refjun_bucayuNo ratings yet

- TC0859 PDFDocument40 pagesTC0859 PDFBoris ZaslichkoNo ratings yet

- Broady 3500 BrochureDocument12 pagesBroady 3500 Brochureahmedm2020No ratings yet

- Astava CatalogDocument26 pagesAstava CatalogPritesh PatelNo ratings yet

- Spirax Sarco BTM-7Document3 pagesSpirax Sarco BTM-7Bambang Agung LaxmonoNo ratings yet

- WOM Magnum Gate Valve BrochureDocument8 pagesWOM Magnum Gate Valve BrochuresjongejongeNo ratings yet

- Breather Valve - Pressure-Vaccuem Relief ValveDocument2 pagesBreather Valve - Pressure-Vaccuem Relief Valvevphor85No ratings yet

- A1-Cam Groove CouplingsDocument40 pagesA1-Cam Groove CouplingsedwinramonNo ratings yet

- Clarkson KGFDocument8 pagesClarkson KGFJorge Castro CucurellaNo ratings yet

- KE Masterflex RubberDocument4 pagesKE Masterflex RubberBenjamin StricklandNo ratings yet

- Dichta CatalogueDocument62 pagesDichta CataloguemaxatadesignNo ratings yet

- Cryo DiverterDocument56 pagesCryo DiverterANILNo ratings yet

- Aluminum Crust BreakerDocument8 pagesAluminum Crust BreakersenamotoNo ratings yet

- Diapham Valve PDFDocument8 pagesDiapham Valve PDFthouche007No ratings yet

- Garlock Catalogo GasketDocument46 pagesGarlock Catalogo GasketServilab LudicasNo ratings yet

- Ke Masterhose: Metallic and Rubber Flexible HosesDocument40 pagesKe Masterhose: Metallic and Rubber Flexible HosesfcspekNo ratings yet

- Garlock GasketsDocument46 pagesGarlock GasketskfchksdhbvkjhshfNo ratings yet

- AGS Gaskets TrainingDocument31 pagesAGS Gaskets TrainingMee WinNo ratings yet

- Rubber BellowDocument20 pagesRubber BellowPrateek100% (1)

- KN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentDocument14 pagesKN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentravishankarNo ratings yet

- Series 7400Document22 pagesSeries 7400zekha87No ratings yet

- 3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsDocument4 pages3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsrodrurenNo ratings yet

- Tyco Catalogue NetDocument34 pagesTyco Catalogue NetAhmad Nasser0% (1)

- TD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Document2 pagesTD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Rupesh DesaiNo ratings yet

- Garlock Expansion Joints Catalog ManualDocument29 pagesGarlock Expansion Joints Catalog ManualCRISTIAN GUZMÁNNo ratings yet

- 5.1 Pvrv-Fa - VD - Ts - Ka - 7 - GBDocument4 pages5.1 Pvrv-Fa - VD - Ts - Ka - 7 - GBSivareddy InduriNo ratings yet

- O Ring BrochureDocument36 pagesO Ring BrochureJesus N RodriguezNo ratings yet

- Econ Gate ValvesDocument20 pagesEcon Gate ValvesEngr.Mmosaad100% (1)

- PSI Casing End SealsDocument10 pagesPSI Casing End Sealsanup_sahani100% (1)

- WKM HP Butterfly BrochureDocument28 pagesWKM HP Butterfly BrochureAarthi PadmanabhanNo ratings yet

- Knife Gate Valve - For Reference OnlyDocument16 pagesKnife Gate Valve - For Reference Onlysj_scribdNo ratings yet

- GasketDocument45 pagesGasketSathish RajanNo ratings yet

- Velan Ball Valve 1 PDFDocument9 pagesVelan Ball Valve 1 PDFMilena Lemus FonsecaNo ratings yet

- FMC - Knife Edge Gate ValveDocument5 pagesFMC - Knife Edge Gate ValvesheshidharrajubNo ratings yet

- Enquiry Data in MailDocument20 pagesEnquiry Data in MailNITINNo ratings yet

- Ham-Let Astava Line of ManifoldsDocument24 pagesHam-Let Astava Line of ManifoldsjcestupinanNo ratings yet

- Split SleeveDocument3 pagesSplit Sleeveast654No ratings yet

- Baum GMBH Assembly instructions-DIN April 2012 PDFDocument2 pagesBaum GMBH Assembly instructions-DIN April 2012 PDFRensvanLoon1No ratings yet

- SAPP Series PumpsDocument2 pagesSAPP Series Pumpssahildhingra100% (1)

- Distortion in Welding 1111111Document40 pagesDistortion in Welding 1111111wenigma100% (1)

- ISO 1127 and ASTM Pipe TolerancesDocument1 pageISO 1127 and ASTM Pipe ToleranceswenigmaNo ratings yet

- 316L Korozif Kimyasallar Için MalzemelerDocument5 pages316L Korozif Kimyasallar Için MalzemelerwenigmaNo ratings yet

- Shell RollinggDocument26 pagesShell RollinggwenigmaNo ratings yet

- Quality and Production Certificates: Kalite Ve Üretim SertifikalariDocument1 pageQuality and Production Certificates: Kalite Ve Üretim SertifikalariwenigmaNo ratings yet

- Fertilizer Industry Tcm11-16156 Rotary DryerDocument4 pagesFertilizer Industry Tcm11-16156 Rotary DryerwenigmaNo ratings yet

- Dimensions and Weight of Pipes According Norm ANSI B 36.19 and 36.10Document2 pagesDimensions and Weight of Pipes According Norm ANSI B 36.19 and 36.10wenigmaNo ratings yet

- Endüstriyel Normlar ISO 1127 Amerikan Inch 11850 Karşılığı MM SMS (ISO 2037) DIN 11850 MM Alfa Laval DIN11850 Alman Alfa LavalDocument1 pageEndüstriyel Normlar ISO 1127 Amerikan Inch 11850 Karşılığı MM SMS (ISO 2037) DIN 11850 MM Alfa Laval DIN11850 Alman Alfa LavalwenigmaNo ratings yet

- Thermokopullar HakkındaDocument1 pageThermokopullar HakkındawenigmaNo ratings yet

- Code PresentationDocument60 pagesCode PresentationwenigmaNo ratings yet

- Saçların Eski Ve Yeni AdıDocument8 pagesSaçların Eski Ve Yeni AdıwenigmaNo ratings yet

- Pressure Vessels and EquipmentDocument16 pagesPressure Vessels and EquipmentwenigmaNo ratings yet

- Stud Welding Capacitive Discharge WeldingDocument30 pagesStud Welding Capacitive Discharge WeldingwenigmaNo ratings yet

- Tig Torç Kataloğu PDFDocument40 pagesTig Torç Kataloğu PDFwenigmaNo ratings yet

- Datasheet 25104l enDocument3 pagesDatasheet 25104l enwenigmaNo ratings yet

- Part 1 - General: PumpsDocument3 pagesPart 1 - General: PumpsSergio Cataño GaleanoNo ratings yet

- Saes L 610Document5 pagesSaes L 610Sikandar shahNo ratings yet

- Manual Técnico CLARKSON KGA & KGA IOM En-2717016 PDFDocument37 pagesManual Técnico CLARKSON KGA & KGA IOM En-2717016 PDFAlexander Cordova RosalesNo ratings yet

- B2a ElDocument5 pagesB2a ElBALAKRISHNANNo ratings yet

- Type 437Document22 pagesType 437Bouzaida MaherNo ratings yet

- HDI 2000B & 2000P Series Pressure Gauges: Revised 12/05/2003Document20 pagesHDI 2000B & 2000P Series Pressure Gauges: Revised 12/05/2003cmrig74No ratings yet

- Dismantling Joints With 3 Flanges, PN 64Document2 pagesDismantling Joints With 3 Flanges, PN 64Mohd AmirNo ratings yet

- Triple Eccentric Metal Seated Valves: MV SeriesDocument12 pagesTriple Eccentric Metal Seated Valves: MV SeriesAlexandra HarperNo ratings yet

- Notes On Pv-EliteDocument25 pagesNotes On Pv-Elitefahadfiaz100% (1)

- 02 A. Basics of Pipe RoutingDocument7 pages02 A. Basics of Pipe Routingradu.iacobNo ratings yet

- Z1186-Oil Int. SpecsDocument1 pageZ1186-Oil Int. SpecsRawan Alwan ZarifNo ratings yet

- Premium Stainless Steel Liquid Filled Gauge: Description & FeaturesDocument6 pagesPremium Stainless Steel Liquid Filled Gauge: Description & FeaturesKarla FordNo ratings yet

- 3L Filters CompleteDocument56 pages3L Filters Completekmodihm100% (1)

- Client: Contract: Job / Project TitleDocument10 pagesClient: Contract: Job / Project TitleAbdur RehmanNo ratings yet

- Model fm1Document30 pagesModel fm1LeandroNo ratings yet

- 2000.003.04 904b Drilling Machine - Aug2020Document4 pages2000.003.04 904b Drilling Machine - Aug2020MORELLI silvioNo ratings yet

- Appendix 2-1.ep11422 - h-16 PDFDocument15 pagesAppendix 2-1.ep11422 - h-16 PDFbsnegi111No ratings yet

- ASME B16 5 Flange Facing FinishDocument4 pagesASME B16 5 Flange Facing FinishMilton RamirezNo ratings yet

- Irb 6700 PDFDocument170 pagesIrb 6700 PDFArvydas GaurilkaNo ratings yet

- Installation of Closed-Circuit Ammonia Refrigeration SystemsDocument28 pagesInstallation of Closed-Circuit Ammonia Refrigeration SystemsWalisson HenriqueNo ratings yet

- BV3D BV3DZDocument4 pagesBV3D BV3DZYOGESH GOPALNo ratings yet

- 6-44-0013 2013 Standard Specification For Inspection, Flushing and Testing of Piping SystemsDocument9 pages6-44-0013 2013 Standard Specification For Inspection, Flushing and Testing of Piping SystemsdgkmurtiNo ratings yet

- Jacketed Ball Valves LeafletDocument2 pagesJacketed Ball Valves LeafletSherif EltoukhiNo ratings yet

- A Manual Valve 4 02Document11 pagesA Manual Valve 4 02Robbi FerdianNo ratings yet

- Fast Fill Systems: Technical CatalogDocument70 pagesFast Fill Systems: Technical Catalogchristian vergaray gonzalesNo ratings yet

- General Valve CatalogueDocument13 pagesGeneral Valve CatalogueLe NghiNo ratings yet