Professional Documents

Culture Documents

5A, 28V Input, Step Down Swift™ DC/DC Converter With Eco-Mode™

5A, 28V Input, Step Down Swift™ DC/DC Converter With Eco-Mode™

Uploaded by

thunderer2014Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5A, 28V Input, Step Down Swift™ DC/DC Converter With Eco-Mode™

5A, 28V Input, Step Down Swift™ DC/DC Converter With Eco-Mode™

Uploaded by

thunderer2014Copyright:

Available Formats

0

10

20

30

40

50

60

70

80

90

100

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

E

f

f

i

c

i

e

n

c

y

-

%

Output Current - A C007

V

IN

= 12 V

V

IN

= 24 V

PH

VIN

GND

BOOT

VSENSE

COMP

SS

C

SS

D1

VIN EN

C

I

C

BOOT

L

O

C

O

Ren1

R

O2

C

1

C

2

R

3

Ren2

R

O1

TPS54531

V

OUT

T P S 5 4 5 3 1

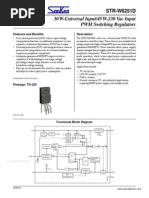

www.ti.com SLVSBI5 MAY 2013

5 A , 2 8 V I N P U T , S T E P D O W N S W I F T D C / D C C O N V E R T E R W I T H E C O - mod e

C he ck for S ample s: T P S 5 4 5 3 1

1 F E A T U R E S D E S C R I P T I O N

The TPS54531 is a 28-V, 5-A non-synchronous buck

2 3 .5 V to 2 8 V I nput V oltage R ange

converter that integrates a low R

DS(on)

high side

A d justable O utput V oltage D own to 0.8 V

MOSFET. To increase efficiency at light loads, a

I nte grate d 8 0 m H igh S id e MO S F E T S upports

pulse skipping Eco-mode feature is automatically

up to 5 A C ontinuous O utput C urre nt activated. Furthermore, the 1 A shutdown supply

current allows the device to be used in battery

H igh E fficie ncy at Light Load s with a P ulse

powered applications. Current mode control with

S kipping E co- mod e

internal slope compensation simplifies the external

F ixe d 5 70kH z S witching F re que ncy

compensation calculations and reduces component

T ypical 1 A S hutd own Quie sce nt C urre nt count while allowing the use of ceramic output

capacitors. A resistor divider programs the hysteresis

A d justable S low S tart Limits I nrush C urre nts

of the input under-voltage lockout. An overvoltage

P rogrammable U V LO T hre shold

transient protection circuit limits voltage overshoots

O ve rvoltage T ransie nt P rote ction during startup and transient conditions. A cycle by

cycle current limit scheme, frequency fold back and

C ycle - by- C ycle C urre nt Limit, F re que ncy F old

thermal shutdown protect the device and the load in

Back and T he rmal S hutd own P rote ction

the event of an overload condition. The TPS54531 is

A vailable in E asy- to- U se T he rmally E nhance d

available in 8-pin SOIC PowerPAD

TM

package that

S O I C 8 P owe rP A D

T M

P ackage

have been internally optimized to improve thermal

performance.

A P P LI C A T I O N S

C onsume r A pplications such as S e t- T op

Boxe s, C P E E quipme nt, LC D D isplays,

P e riphe rals, and Batte ry C harge rs

I nd ustrial and C ar A ud io P owe r S upplie s

5 V , 1 2 V and 2 4 V D istribute d P owe r S yste ms

S I MP LI F I E D S C H E MA T I C E F F I C I E N C Y

T P S 5 4 5 3 1

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2Eco-mode, PowerPAD are trademarks of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Copyright 2013, Texas Instruments Incorporated

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

T P S 5 4 5 3 1

SLVSBI5 MAY 2013 www.ti.com

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

D E S C R I P T I O N C O N T I N U E D

For additional design needs, see:

T P S 5 4 2 3 1 T P S 5 4 2 3 2 T P S 5 4 2 3 3 T P S 5 4 5 3 1 T P S 5 4 3 3 2

I

O

(Max) 2A 2A 2A 5A 3.5A

Input Voltage Range 3.5V - 28V 3.5V - 28V 3.5V - 28V 3.5V - 28V 3.5V - 28V

Switching Freq. (Typ) 570kHz 1000kHz 285kHz 570kHz 1000kHz

Switch Current Limit (Min) 2.3A 2.3A 2.3A 5.5A 4.2A

Pin/Package 8SOIC 8SOIC 8SOIC 8SO PowerPAD 8SO PowerPAD

O R D E R I N G I N F O R MA T I O N

(1 )

T

J

P A C KA GE S W I T C H I N G F R E QU E N C Y P A R T N U MBE R

(2 )

40C to 150C 8 pin SOIC PowerPAD 570 kHz TPS54531DDA

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

web site at www.ti.com.

(2) The DDA package is also available taped and reeled. Add an R suffix to the device type (i.e., TPS54531DDAR). See applications

section of data sheet for layout information.

A BS O LU T E MA XI MU M R A T I N GS

(1 )

over operating free-air temperature range (unless otherwise noted)

V A LU E U N I T

VIN 0.3 to 30

EN 0.3 to 6

BOOT 38

Input Voltage V

VSENSE 0.3 to 3

COMP 0.3 to 3

SS 0.3 to 3

BOOT-PH 8

Output Voltage PH 0.6 to 30 V

PH (10 ns transient from ground to negative peak) 5

EN 100 A

BOOT 100 mA

Source Current

VSENSE 10 A

PH Current Limit A

VIN Current Limit A

Sink Current COMP 100

A

SS 200

Electrostatic Human body model (HBM) 2 kV

Discharge

Charged device model (CDM) 1 kV

Operating Junction Temperature 40 to 150 C

Storage Temperature 65 to 150 C

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

2 Submit Documentation Feedback Copyright 2013, Texas Instruments Incorporated

Product Folder Links: TPS54531

T P S 5 4 5 3 1

www.ti.com SLVSBI5 MAY 2013

P A C KA GE D I S S I P A T I O N R A T I N GS

(1 ) (2 ) (3 )

T H E R MA L I MP E D A N C E P S E U D O T H E R MA L I MP E D A N C E

P A C KA GE

JU N C T I O N T O A MBI E N T JU N C T I O N T O T O P

SOIC8 PowerPAD 50C/W 5C/W

(1) Maximum power dissipation may be limited by overcurrent protection

(2) Power rating at a specific ambient temperature T

A

should be determined with a junction temperature of 150C. This is the point where

distortion starts to substantially increase. Thermal management of the PCB should strive to keep the junction temperature at or below

150C for best performance and long-term reliability. See power dissipation estimate in application section of this data sheet for more

information.

(3) Test board conditions:

(a) 2 inches x 1.5 inches, 2 layers, thickness: 0.062 inch

(b) 2-ounce copper traces located on the top and bottom of the PCB

(c) 6 thermal vias located under the device package

R E C O MME N D E D O P E R A T I N G C O N D I T I O N S

over operating free-air temperature range (unless otherwise noted)

MI N T YP MA X U N I T

Operating Input Voltage on (VIN pin) 3.5 28 V

Operating junction temperature, T

J

40 150 C

E LE C T R I C A L C H A R A C T E R I S T I C S

T

J

= 40C to 150C, VIN = 3.5V to 28V (unless otherwise noted)

D E S C R I P T I O N T E S T C O N D I T I O N S MI N T YP MA X U N I T

S U P P LY V O LT A GE (V I N P I N )

Internal undervoltage lockout threshold Rising and Falling 3.5 V

Shutdown supply current EN = 0V, VIN = 12V, 40C to 85C 1 4 A

Operating non switching supply current VSENSE = 0.85 V 110 190 A

E N A BLE A N D U V LO (E N P I N )

Enable threshold Rising and Falling 1.25 1.35 V

Input current Enable threshold 50 mV -1 A

Input current Enable threshold + 50 mV -4 A

V O LT A GE R E F E R E N C E

Voltage reference 0.772 0.8 0.828 V

H I GH - S I D E MO S F E T

BOOT-PH = 3 V, VIN = 3.5 V 115 200 m

On resistance

BOOT-PH = 6 V, VIN = 12 V 80 150

E R R O R A MP LI F I E R

Error amplifier transconductance (gm) 2 A < I

(COMP)

< 2 A, V

(COMP)

= 1 V 92 mhos

Error amplifier DC gain

(1)

VSENSE = 0.8 V 800 V/V

Error amplifier unity gain bandwidth

(1)

5 pF capacitance from COMP to GND pins 2.7 MHz

Error amplifier source/sink current V

(COMP)

= 1 V, 100 mV overdrive 7 A

Switch current to COMP transconductance

(1)

VIN = 12 V 20 A/V

S W I T C H I N G F R E QU E N C Y

Switching Frequency VIN = 12V, 25C 456 570 684 kHz

Minimum controllable on time VIN = 12V, 25C 105 130 ns

Maximum controllable duty ratio

(1)

BOOT-PH = 6 V 90% 93%

P U LS E S KI P P I N G E C O - MO D E

Pulse skipping Eco-mode switch current threshold 160 mA

C U R R E N T LI MI T

Current limit threshold VIN = 12 V 6.3 10.5 A

(1) Specified by design

Copyright 2013, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Links: TPS54531

1

2

3

4

5

6

7

8 BOOT

VIN

EN

SS

PH

GND

COMP

VSENSE

PowerPAD

(Pin 9)

TM

T P S 5 4 5 3 1

SLVSBI5 MAY 2013 www.ti.com

E LE C T R I C A L C H A R A C T E R I S T I C S (continue d )

T

J

= 40C to 150C, VIN = 3.5V to 28V (unless otherwise noted)

D E S C R I P T I O N T E S T C O N D I T I O N S MI N T YP MA X U N I T

T H E R MA L S H U T D O W N

Thermal Shutdown 165 C

S LO W S T A R T (S S P I N )

Charge current V

(SS)

= 0.4 V 2 A

D E V I C E I N F O R MA T I O N

P I N A S S I GN ME N T S

D D A P A C KA GE

(T O P V I E W )

P I N F U N C T I O N S

P I N D E S C R I P T I O N

N A ME N O .

BOOT 1 A 0.1 F bootstrap capacitor is required between BOOT and PH. If the voltage on this capacitor falls

below the minimum requirement, the high-side MOSFET is forced to switch off until the capacitor is

refreshed.

VIN 2 Input supply voltage, 3.5 V to 28 V.

EN 3 Enable pin. Pull below 1.25V to disable. Float to enable. Programming the input undervoltage lockout with

two resistors is recommended.

SS 4 Slow start pin. An external capacitor connected to this pin sets the output rise time.

VSENSE 5 Inverting node of the gm error amplifier.

COMP 6 Error amplifier output, and input to the PWM comparator. Connect frequency compensation components

to this pin.

GND 7 Ground.

PH 8 The source of the internal high-side power MOSFET.

PowerPAD 9 GND pin must be connected to the exposed pad for proper operation. This pin is only available in the

DDA package.

4 Submit Documentation Feedback Copyright 2013, Texas Instruments Incorporated

Product Folder Links: TPS54531

Error

Amplifier

R Q

S

Boot

Charge

Boot

UVLO

Current

Sense

Oscillator

Frequency

Shift

Gate

Drive

Logic

Slope

Compensation

PWM

Latch

PWM

Comparator

ECO-MODE

Minimum Clamp

Maximum

Clamp

Voltage

Reference

Discharge

Logic

VSENSE

COMP

PH

BOOT

VIN

GND

Thermal

Shutdown

EN

Enable

Comparator

Shutdown

Logic

Shutdown

Enable

Threshold

S

1.25 V

0.8 V

80 mW

165C

2.1V

SS

Shutdown

VSENSE

1 A m 3 A m

gm = 92 A/V

DC gain = 800 V/V

BW = 2.7 MHz

m

2 kW

2 A m

TPS54531

T P S 5 4 5 3 1

www.ti.com SLVSBI5 MAY 2013

F U N C T I O N A L BLO C K D I A GR A M

Copyright 2013, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Links: TPS54531

I

-

S

S

C

h

a

r

g

e

C

u

r

r

e

n

t

-

A

S

S

T - Junction Temperature - C

J

2

2.1

50 25 0 25 50 75 100 125

1.9

150

V = 12 V

IN

5

6

7

8

9

10

11

12

3 8 13 18 23 28

C

u

r

r

e

n

t

L

i

m

i

t

T

h

r

e

s

h

o

l

d

(

A

)

Input Voltage (V)

T = 40C

T = 25C

T = 150C

C014

T

J

T

J

T

J

T

m

i

n

o

n

-

M

i

n

i

m

u

m

C

o

n

t

r

o

l

l

a

b

l

e

O

n

T

i

m

e

-

n

s

T - Junction Temperature - C

J

110

120

130

140

50 25 0 25 50 75 100 125

100

150

V = 12 V

IN

D

m

i

n

-

M

i

n

i

m

u

m

C

o

n

t

r

o

l

l

a

b

l

e

D

u

t

y

R

a

t

i

o

-

%

T - Junction Temperature - C

J

5.0

5.5

6.0

7.0

7.5

50 25 0 25 50 75 100 125

6.5

V = 12 V

IN

150

V

-

V

o

l

t

a

g

e

R

e

f

e

r

e

n

c

e

-

V

r

e

f

T - Junction Temperature - C

J

0.788

0.800

0.812

0.824

50 25 0 25 50 75 100 125

0.776

150

V = 12 V

IN

0.782

0.794

0.806

0.818

R

d

s

o

n

-

O

n

R

e

s

i

s

t

a

n

c

e

-

m

T - Junction Temperature - C

J

80

90

100

110

120

50 25 0 25 50 75 100 125

70

60

150

V = 12 V

IN

F

-

O

s

c

i

l

l

a

t

o

r

F

r

e

q

u

e

n

c

y

-

k

H

z

S

W

T - Junction Temperature - C

J

560

570

580

590

50 25 0 25 50 75 100 125

550

150

V = 12 V

IN

I

-

S

h

u

t

d

o

w

n

C

u

r

r

e

n

t

-

A

S

D

V - Input Voltage - V

IN

0

1

2

3

4

3 8 13 18 23 28

EN = 0V

T = 150C

J

T = 40C

J

T = 25C

J

T P S 5 4 5 3 1

SLVSBI5 MAY 2013 www.ti.com

C H A R A C T E R I ZA T I O N C U R V E S

O N R E S I S T A N C E S H U T D O W N QU I E S C E N T C U R R E N T S W I T C H I N G F R E QU E N C Y

vs vs vs

JU N C T I O N T E MP E R A T U R E I N P U T V O LT A GE JU N C T I O N T E MP E R A T U R E

F igure 1 . F igure 2 . F igure 3 .

MI N I MU M C O N T R O LLA BLE D U T Y

V O LT A GE R E F E R E N C E MI N I MU M C O N T R O LLA BLE O N T I ME R A T I O

vs vs vs

JU N C T I O N T E MP E R A T U R E JU N C T I O N T E MP E R A T U R E JU N C T I O N T E MP E R A T U R E

F igure 4 . F igure 5 . F igure 6.

S S C H A R GE C U R R E N T C U R R E N T LI MI T T H R E S H O LD

vs vs

JU N C T I O N T E MP E R A T U R E I N P U T V O LT A GE

F igure 7. F igure 8 .

6 Submit Documentation Feedback Copyright 2013, Texas Instruments Incorporated

Product Folder Links: TPS54531

T P S 5 4 5 3 1

www.ti.com SLVSBI5 MAY 2013

O V E R V I E W

The TPS54531 is a 28-V, 5-A, step-down (buck) converter with an integrated high-side n-channel MOSFET. To

improve performance during line and load transients, the device implements a constant frequency, current mode

control which reduces output capacitance and simplifies external frequency compensation design. The

TPS54531 has a pre-set switching frequency of 570kHz.

The TPS54531 needs a minimum input voltage of 3.5V to operate normally. The EN pin has an internal pull-up

current source that can be used to adjust the input voltage under-voltage lockout (UVLO) with two external

resistors. In addition, the pull-up current provides a default condition when the EN pin is floating for the device to

operate. The operating current is 110 A typically when not switching and under no load. When the device is

disabled, the supply current is 1A typically.

The integrated 80 m high-side MOSFET allows for high efficiency power supply designs with continuous output

currents up to 5A.

The TPS54531 reduces the external component count by integrating the boot recharge diode. The bias voltage

for the integrated high-side MOSFET is supplied by an external capacitor on the BOOT to PH pin. The boot

capacitor voltage is monitored by an UVLO circuit and will turn the high-side MOSFET off when the voltage falls

below a preset threshold of 2.1V typically. The output voltage can be stepped down to as low as the reference

voltage.

By adding an external capacitor, the slow start time of the TPS54531 can be adjustable which enables flexible

output filter selection.

To improve the efficiency at light load conditions, the TPS54531 enters a special pulse skipping Eco-mode

TM

when the peak inductor current drops below 160mA typically.

The frequency foldback reduces the switching frequency during startup and over current conditions to help

control the inductor current. The thermal shut down gives the additional protection under fault conditions.

D E T A I LE D D E S C R I P T I O N

F I XE D F R E QU E N C Y P W M C O N T R O L

The TPS54531 uses a fixed frequency, peak current mode control. The internal switching frequency of the

TPS54531 is fixed at 570kHz.

E C O - MO D E

T M

The TPS54531 is designed to operate in pulse skipping Eco-mode

TM

at light load currents to boost light load

efficiency. When the peak inductor current is lower than 160 mA typically, the COMP pin voltage falls to 0.5 V

typically and the device enters Eco-mode

TM

. When the device is in Eco-mode

TM

, the COMP pin voltage is

clamped at 0.5V internally which prevents the high side integrated MOSFET from switching. The peak inductor

current must rise above 160mA for the COMP pin voltage to rise above 0.5V and exit Eco-mode

TM

. Since the

integrated current comparator catches the peak inductor current only, the average load current entering Eco-

mode

TM

varies with the applications and external output filters.

V O LT A GE R E F E R E N C E (V

re f

)

The voltage reference system produces a 2% initial accuracy voltage reference (3.5% over temperature) by

scaling the output of a temperature stable bandgap circuit. The typical voltage reference is designed at 0.8V.

BO O T S T R A P V O LT A GE (BO O T )

The TPS54531 has an integrated boot regulator and requires a 0.1 F ceramic capacitor between the BOOT and

PH pin to provide the gate drive voltage for the high-side MOSFET. A ceramic capacitor with an X7R or X5R

grade dielectric is recommended because of the stable characteristics over temperature and voltage. To improve

drop out, the TPS54531 is designed to operate at 100% duty cycle as long as the BOOT to PH pin voltage is

greater than 2.1 V typically.

Copyright 2013, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Links: TPS54531

( )

( ) ( )

( )

SS ref

SS

SS

C nF V V

T ms =

I A

m

EN

START EN

V

Ren2 =

V - V

+ 1 A

Ren1

m

START STOP

V - V

Ren1 =

3 A m

EN

1.25 V

VIN

+

Ren1

Ren2

TPS54531

1 A m 3 A m

T P S 5 4 5 3 1

SLVSBI5 MAY 2013 www.ti.com

E N A BLE A N D A D JU S T A BLE I N P U T U N D E R - V O LT A GE LO C KO U T (V I N U V LO )

The EN pin has an internal pull-up current source that provides the default condition of the TPS54531 operating

when the EN pin floats.

The TPS54531 is disabled when the VIN pin voltage falls below internal VIN UVLO threshold. It is recommended

to use an external VIN UVLO to add at least 500 mV Hysteresis unless VIN is greater than (V

OUT

+ 2 V). To

adjust the VIN UVLO with Hysteresis, use the external circuitry connected to the EN pin as shown in Figure 9.

Once the EN pin voltage exceeds 1.25 V, an additional 3 A of hysteresis is added. Use Equation 1 and

Equation 2 to calculate the resistor values needed for the desired VIN UVLO threshold voltages. The V

START

is

the input start threshold voltage, the V

STOP

is the input stop threshold voltage and the V

EN

is the enable threshold

voltage of 1.25 V. The V

STOP

should always be greater than 3.5 V.

F igure 9. A d justable I nput U nd e rvoltage Lockout

(1)

(2)

The external start and stop voltages are approximate. Actual start and stop voltages may vary.

P R O GR A MMA BLE S LO W S T A R T U S I N G S S P I N

It is highly recommended to program the slow start time externally because no slow start time is implemented

internally. The TPS54531 effectively uses the lower voltage of the internal voltage reference or the SS pin

voltage as the power supplys reference voltage fed into the error amplifier and will regulate the output

accordingly. A capacitor (C

SS

) on the SS pin to ground implements a slow start time. The TPS54531 has an

internal pull-up current source of 2A that charges the external slow start capacitor. The equation for the slow

start time (10% to 90%) is shown in Equation 3 . The V

ref

is 0.8 V and the I

SS

current is 2 A.

(3)

The slow start time should be set between 1ms to 10 ms to ensure good start-up behavior. The slow start

capacitor should be no more than 27nF.

If during normal operation, the input voltage drops below the VIN UVLO threshold, or the EN pin is pulled below

1.25 V, or a thermal shutdown event occurs, the TPS54531 stops switching.

E R R O R A MP LI F I E R

The TPS54531 has a transconductance amplifier for the error amplifier. The error amplifier compares the

VSENSE voltage to the internal effective voltage reference presented at the input of the error amplifier. The

transconductance of the error amplifier is 92 A/V during normal operation. Frequency compensation

components are connected between the COMP pin and ground.

8 Submit Documentation Feedback Copyright 2013, Texas Instruments Incorporated

Product Folder Links: TPS54531

T P S 5 4 5 3 1

www.ti.com SLVSBI5 MAY 2013

S LO P E C O MP E N S A T I O N

In order to prevent the sub-harmonic oscillations when operating the device at duty cycles greater than 50%, the

TPS54531 adds a built-in slope compensation which is a compensating ramp to the switch current signal.

C U R R E N T MO D E C O MP E N S A T I O N D E S I GN

The device is able to work with various types of output capacitors with appropriate compensation designs. For

designs using ceramic output capacitors, proper derating of ceramic output capacitance is recommended when

doing the stability analysis. This is because the actual ceramic capacitance drops considerably from the nominal

value when the applied voltage increases. Please refer to the Step by Step Design Procedure in the Application

Information section for the detailed guidelines.

O V E R C U R R E N T P R O T E C T I O N A N D F R E QU E N C Y S H I F T

The TPS54531 implements current mode control that uses the COMP pin voltage to turn off the high-side

MOSFET on a cycle by cycle basis. Every cycle the switch current and the COMP pin voltage are compared;

when the peak inductor current intersects the COMP pin voltage, the high-side switch is turned off. During

overcurrent conditions that pull the output voltage low, the error amplifier responds by driving the COMP pin high,

causing the switch current to increase. The COMP pin has a maximum clamp internally, which limit the output

current.

The TPS54531 provides robust protection during short circuits. There is potential for overcurrent runaway in the

output inductor during a short circuit at the output. The TPS54531 solves this issue by increasing the off time

during short circuit conditions by lowering the switching frequency. The switching frequency is divided by 8, 4, 2,

and 1 as the voltage ramps from 0 V to 0.8 V on VSENSE pin. The relationship between the switching frequency

and the VSENSE pin voltage is shown in Table 1.

T able 1 . S witching F re que ncy C ond itions

S W I T C H I N G F R E QU E N C Y V S E N S E P I N V O LT A GE

570 kHz VSENSE 0.6 V

570 kHz / 2 0.6 V > VSENSE 0.4 V

570 kHz / 4 0.4 V > VSENSE 0.2 V

570 kHz / 8 0.2 V > VSENSE

O V E R V O LT A GE T R A N S I E N T P R O T E C T I O N

The TPS54531 incorporates an overvoltage transient protection (OVTP) circuit to minimize output voltage

overshoot when recovering from output fault conditions or strong unload transients. The OVTP circuit includes an

overvoltage comparator to compare the VSENSE pin voltage and internal thresholds. When the VSENSE pin

voltage goes above 109% V

ref

, the high-side MOSFET will be forced off. When the VSENSE pin voltage falls

below 107% V

ref

, the high-side MOSFET will be enabled again.

T H E R MA L S H U T D O W N

The device implements an internal thermal shutdown to protect itself if the junction temperature exceeds 165C.

The thermal shutdown forces the device to stop switching when the junction temperature exceeds the thermal

trip threshold. Once the die temperature decreases below 165C, the device reinitiates the power up sequence.

Copyright 2013, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Links: TPS54531

4.7 uH L1

BOOT

1

VIN

2

EN

3

SS

4

VSNS

5

COMP

6

GND

7

PH

8

PWR PAD 9

U1

TPS54531

4.7F

C1

4.7F

C2

0.01F

C3

0.1F

C4

47F

C8

47F

C9 C10

open

0.55V

D1

CDBC540-G

10.2K

R5

51.1

R4

1.96k

R6 130k

R1

665k

R2

2200pF

C6

22pF

C7

C11

open

37.4k

R3

0.01F

C5

VIN 8-28VOLTS

VOUT

VIN

VOUT 5V, 5A

T P S 5 4 5 3 1

SLVSBI5 MAY 2013 www.ti.com

A P P LI C A T I O N I N F O R MA T I O N

F igure 1 0. T ypical A pplication S che matic

S T E P BY S T E P D E S I GN P R O C E D U R E

The following design procedure can be used to select component values for the TPS54531. Alternately, the

WEBENCH software may be used to generate a complete design. The WEBENCH software uses an iterative

design procedure and accesses a comprehensive database of components when generating a design. This

section presents a simplified discussion of the design process.

To begin the design process a few parameters must be decided upon. The designer needs to know the following:

Input voltage range

Output voltage

Input ripple voltage

Output ripple voltage

Output current rating

Operating frequency

For this design example, use the following as the input parameters

T able 2 . D e sign P arame te rs

D E S I GN P A R A ME T E R E XA MP LE V A LU E

Input voltage range 8 V to 28V

Output voltage 5 V

Transient response, 2.5 A load step Vout = +/- 5 %

Input ripple voltage 400 mV

Output ripple voltage 30 mV

Output current rating 5 A

Operating Frequency 570 kHz

S W I T C H I N G F R E QU E N C Y

The switching frequency for the TPS54531 is fixed at 570 kHz.

10 Submit Documentation Feedback Copyright 2013, Texas Instruments Incorporated

Product Folder Links: TPS54531

2

OUT(MAX)

CIN

I

I =

( )

OUT(MAX)

IN OUT(MAX) MAX

BULK SW

I 0.25

V = + I ESR

C f

OUT REF

R5

V = V +1

R6

REF

OUT REF

R5 V

R6 =

V V

-

T P S 5 4 5 3 1

www.ti.com SLVSBI5 MAY 2013

O U T P U T V O LT A GE S E T P O I N T

The output voltage of the TPS54531 is externally adjustable using a resistor divider network. In the application

circuit of Figure 10, this divider network is comprised of R5 and R6. The relationship of the output voltage to the

resistor divider is given by Equation 4 and Equation 5:

(4)

(5)

Choose R5 to be approximately 10.0 k. Slightly increasing or decreasing R5 can result in closer output voltage

matching when using standard value resistors. In this design, R5 = 10.2 k and R6 = 1.96 k, resulting in a 4.96

V output voltage. The 51.1 ohm resistor R4 is provided as a convenient place to break the control loop for

stability testing.

U nd e r V oltage Lockout S e t P oint

The Under Voltage Lock Out (UVLO) can be adjusted using the external voltage divider network of R1 and R2.

R1 is connected between VIN and the EN pin of the TPS54531 and R2 is connected between EN and GND .

The UVLO has two thresholds, one for power up when the input voltage is rising and one for power down or

brown outs when the input voltage is falling. For the example design, the minimum input voltage is 8 V, so the

start voltage threshold is set to 7 V with 2 V hysteresis. Equation 1 and Equation 2 can be used to calculate the

values for the upper and lower resistor values of R1 and R2.

I N P U T C A P A C I T O R S

The TPS54531 requires an input decoupling capacitor and depending on the application, a bulk input capacitor.

The typical recommended value for the decoupling capacitor is 10 F. A high-quality ceramic type X5R or X7R is

recommended. The voltage rating should be greater than the maximum input voltage. A smaller value may be

used as long as all other requirements are met; however 10 F has been shown to work well in a wide variety of

circuits. Additionally, some bulk capacitance may be needed, especially if the TPS54531 circuit is not located

within about 2 inches from the input voltage source. The value for this capacitor is not critical but should be rated

to handle the maximum input voltage including ripple voltage, and should filter the output so that input ripple

voltage is acceptable. For this design two 4.7 F capacitors are used for the input decoupling capacitor. They are

X7R dielectric rated for 50 V. The equivalent series resistance (ESR) is approximately 2m, and the current

rating is 3 A. Additionally, a small 0.01 F capacitor is included for high frequency filtering.

This input ripple voltage can be approximated by Equation 6

(6)

Where I

OUT(MAX)

is the maximum load current, f

SW

is the switching frequency, C

BULK

is the bulk capacitor value

and ESR

MAX

is the maximum series resistance of the bulk capacitor.

The maximum RMS ripple current also needs to be checked. For worst case conditions, this can be

approximated by Equation 7

(7)

In this case, the input ripple voltage would be 243 mV and the RMS ripple current would be 2.5 A. It is also

important to note that the actual input voltage ripple will be greatly affected by parasitics associated with the

layout and the output impedance of the voltage source. The actual input voltage ripple for this circuit is shown in

Design Parameters and is larger than the calculated value. This measured value is still below the specified input

limit of 300 mV. The maximum voltage across the input capacitors would be VIN max plus VIN/2. The chosen

bulk and bypass capacitors are each rated for 50 V and the ripple current capacity is greater than 3 A, both

providing ample margin. It is very important that the maximum ratings for voltage and current are not exceeded

under any circumstance.

Copyright 2013, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Links: TPS54531

2

f

D

>

D

Iout

Co

sw Vout

( ) OUT IN(MAX) OUT

L(PK) OUT(MAX)

IN(MAX) OUT SW

V V V

I = I +

1.6 V L F

-

( )

2

OUT IN(MAX) OUT

2

L(RMS) OUT(MAX)

IN(MAX) OUT SW

V V V

1

I = I +

12 V L F 0.8

-

( )

OUT IN(MAX) OUT

MIN

IN(MAX) IND OUT SW

V V V

L =

V K I F

-

T P S 5 4 5 3 1

SLVSBI5 MAY 2013 www.ti.com

O U T P U T F I LT E R C O MP O N E N T S

Two components need to be selected for the output filter, L

OUT

and C

OUT

. Since the TPS54531 is an externally

compensated device, a wide range of filter component types and values can be supported.

I nd uctor S e le ction

To calculate the minimum value of the output inductor, use Equation 8

(8)

K

IND

is a coefficient that represents the amount of inductor ripple current relative to the maximum output current.

In general, this value is at the discretion of the designer; however, the following guidelines may be used. For

designs using low ESR output capacitors such as ceramics, a value as high as K

IND

= 0.3 may be used. When

using higher ESR output capacitors, K

IND

= 0.2 yields better results.

For this design example, use K

IND

= 0.3 and the minimum inductor value is calculated to be 4.8 H. For this

design, a close standard value was chosen: 4.7 H.

For the output filter inductor, it is important that the RMS current and saturation current ratings not be exceeded.

The RMS inductor current can be found from Equation 9

(9)

and the peak inductor current can be determined with Equation 10

(10)

For this design, the RMS inductor current is 5.03 A and the peak inductor current is 5.96 A. The chosen inductor

is a Wurth 4.7 H. It has a saturation current rating of 19.0 A and an RMS current rating of 7.0 A, meeting these

requirements. Smaller or larger inductor values can be used depending on the amount of ripple current the

designer wishes to allow so long as the other design requirements are met. Larger value inductors will have

lower ac current and result in lower output voltage ripple, while smaller inductor values will increase ac current

and output voltage ripple. In general, inductor values for use with the TPS54531 are in the range of 1 H to

47H.

C apacitor S e le ction

There are three primary considerations for selecting the value of the output capacitor. The output capacitor

determines the modulator pole, the output voltage ripple, and how the regulator responds to a large change in

load current. The output capacitance needs to be selected based on the more stringent of these three criteria

The desired response to a large change in the load current is the first criteria. The output capacitor needs to

supply the load with current when the regulator can not. This situation would occur if there are desired hold-up

times for the regulator where the output capacitor must hold the output voltage above a certain level for a

specified amount of time after the input power is removed. The regulator is also temporarily not able to supply

sufficient output current if there is a large, fast increase in the current needs of the load such as a transition from

no load to full load. The regulator usually needs two or more clock cycles for the control loop to see the change

in load current and output voltage and adjust the duty cycle to react to the change. The output capacitor must be

sized to supply the extra current to the load until the control loop responds to the load change. The output

capacitance must be large enough to supply the difference in current for 2 clock cycles while only allowing a

tolerable amount of drop in the output voltage. Equation 11 shows the minimum output capacitance necessary to

accomplish this.

(11)

12 Submit Documentation Feedback Copyright 2013, Texas Instruments Incorporated

Product Folder Links: TPS54531

p

Iout max

p mod =

2 Vout Cout

( )

12

OUT IN(MAX) OUT

COUT(RMS)

IN(MAX) OUT SW C

V V V

1

I =

V L F N

-

<

Voripple

Resr

Iripple

1 1

8 f

>

Co

Voripple

sw

Iripple

T P S 5 4 5 3 1

www.ti.com SLVSBI5 MAY 2013

Where Iout is the change in output current, Fsw is the regulators switching frequency and Vout is the

allowable change in the output voltage. For this example, the transient load response is specified as a 5%

change in Vout for a load step of 2.5 A. For this example, Iout = 2.5 A and Vout = 0.05 x 5.0 = 0.250 V. Using

these numbers gives a minimum capacitance of 35 F. This value does not take the ESR of the output capacitor

into account in the output voltage change. For ceramic capacitors, the ESR is usually small enough to ignore in

this calculation.

Equation 12 calculates the minimum output capacitance needed to meet the output voltage ripple specification.

Where fsw is the switching frequency, Voripple is the maximum allowable output voltage ripple, and Iripple is the

inductor ripple current. In this case, the maximum output voltage ripple is 30 mV. Under this requirement

Equation 12, yields 14 F.

(12)

Equation 13 calculates the maximum ESR an output capacitor can have to meet the output voltage ripple

specification. Equation 13 indicates the ESR should be less than 15.6 m. In this case, the ceramic caps ESR is

much smaller than 15.6 m.

(13)

Additional capacitance de-ratings for aging, temperature and DC bias should be factored in which increases this

minimum value. For this example, two 47 F 10V X5R ceramic capacitor with 3 m of ESR are used. Capacitors

generally have limits to the amount of ripple current they can handle without failing or producing excess heat. An

output capacitor that can support the inductor ripple current must be specified. Some capacitor data sheets

specify the RMS (Root Mean Square) value of the maximum ripple current. Equation 14 can be used to calculate

the RMS ripple current the output capacitor needs to support. For this application, Equation 14 yields 554 mA.

(14)

C O MP E N S A T I O N C O MP O N E N T S

There are several possible methods to design closed loop compensation for dc/dc converters. For the ideal

current mode control, the design equations can be easily simplified. The power stage gain is constant at low

frequencies, and rolls off at -20 dB/decade above the modulator pole frequency. The power stage phase is 0

degrees at low frequencies and starts to fall one decade below the modulator pole frequency reaching a

minimum of -90 degrees one decade above the modulator pole frequency. The modulator pole is a simple pole

shown in Equation 15

(15)

For the TPS54531 most circuits will have relatively high amounts of slope compensation. As more slope

compensation is applied, the power stage characteristics will deviate from the ideal approximations. The phase

loss of the power stage will now approach -180 degrees, making compensation more difficult. The power stage

transfer function can be solved but it is a tedious hand calculation that does not lend itself to simple

approximations. It is best to use Pspice to accurately model the power stage gain and phase so that a reliable

compensation circuit can be designed. Alternately, a direct measurement of the power stage characteristics can

be used. That is the technique used in this design procedure. For this design, L1 = 4.7 H. C8 and C9 are set to

47F each, and the ESR is 3 m. Now the power stage characteristics are shown in Figure 11.

Copyright 2013, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Links: TPS54531

CO

1

C7 =

2 R3 10 F p

CO

1

C6 =

F

2 R3

10

p

PWRSTG

G

20

REF

EA OUT

V 10

R3 =

gm V

-

-180

-120

-60

0

60

120

180

-60

-40

-20

0

20

40

60

10 100 1000 10000 100000 1000000

P

h

a

s

e

-

D

e

g

r

e

e

s

G

a

i

n

-

d

B

Frequency - Hz C011

Gain

Phase

Power Stage

Gain = 5.1 dB

@ 20 kHz

T P S 5 4 5 3 1

SLVSBI5 MAY 2013 www.ti.com

F igure 1 1 . P owe r S tage Gain and P hase C haracte ristics

For this design, the intended crossover frequency is 20 kHz. From the power stage gain and phase plots, the

gain at 20 kHz is 5.1 dB and the phase is about -100 degrees. For 60 degrees of phase margin, additional phase

boost from a feed forward capacitor in parallel with the upper resistor of the voltage set point divider is not

needed. R3 sets the gain of the compensated error amplifier to be equal and opposite the power stage gain at

crossover. The required value of R3 can be calculated from Equation 16.

(16)

To maximize phase gain, the compensator zero is placed one decade below the crossover frequency of 20 kHz.

The required value for C6 is given by Equation 17.

(17)

To maximize phase gain the high frequency pole is placed one decade above the crossover frequency of 20 kHz.

The pole can also be useful to offset the ESR of aluminum electrolytic output capacitors. The value for C7 can be

calculated from Equation 18.

(18)

For this design the calculated values for the compensation components are R3 = 37.4 k ,C6 = 2200 pF and C7

= 22 pF.

BO O T S T R A P C A P A C I T O R

Every TPS54531 design requires a bootstrap capacitor, C4. The bootstrap capacitor must be 0.1 F. The

bootstrap capacitor is located between the PH pins and BOOT pin. The bootstrap capacitor should be a high-

quality ceramic type with X7R or X5R grade dielectric for temperature stability.

C A T C H D I O D E

The TPS54531 is designed to operate using an external catch diode between PH and GND. The selected diode

must meet the absolute maximum ratings for the application: Reverse voltage must be higher than the maximum

voltage at the PH pin, which is VINMAX + 0.5 V. Peak current must be greater than IOUTMAX plus on half the

peak to peak inductor current. Forward voltage drop should be small for higher efficiencies. It is important to note

that the catch diode conduction time is typically longer than the high-side FET on time, so attention paid to diode

parameters can make a marked improvement in overall efficiency. Additionally, check that the device chosen is

capable of dissipating the power losses. For this design, a CDBC540-G is chosen, with a reverse voltage of 40

V, forward current of 5 A, and a forward voltage drop of 0.55 V.

14 Submit Documentation Feedback Copyright 2013, Texas Instruments Incorporated

Product Folder Links: TPS54531

( ) ( )

( )

Omin IN max O min DS(on) min D O min L D

V = 0.089 V I R + V I R V - - -

( ) ( )

( )

Omax IN min O max DS(on) max D O max L D

V = 0.91 V I R + V I R V - - -

T P S 5 4 5 3 1

www.ti.com SLVSBI5 MAY 2013

S LO W S T A R T C A P A C I T O R

The slow start capacitor determines the minimum amount of time it takes for the output voltage to reach its

nominal programmed value during power up. This is useful if a load requires a controlled voltage slew rate.

This is also used if the output capacitance is very large and would require large amounts of current to quickly

charge the capacitor to the output voltage level. The large currents necessary to charge the capacitor may

make the TPS54531 reach the current limit or excessive current draw from the input power supply may

cause the input voltage rail to sag. Limiting the output voltage slew rate solves both of these problems. The

soft start capacitor value can be calculated using Equation 3. For the example circuit, the soft start time is

not too critical since the output capacitor value is 2 x 47 F which does not require much current to charge to

5 V. The example circuit has the soft start time set to an arbitrary value of 4 ms which requires a 10 nF

capacitor. In TPS54531, Iss is 2 A and Vref is 0.8V.

O U T P U T V O LT A GE LI MI T A T I O N S

Due to the internal design of the TPS54531, there are both upper and lower output voltage limits for any given

input voltage. The upper limit of the output voltage set point is constrained by the maximum duty cycle of 91%

and is given by Equation 19:

(19)

Where:

V

IN min

= Minimum input voltage

I

O max

= Maximum load current

V

D

= Catch diode forward voltage

R

L

= Output inductor series resistance

The equation assumes maximum on resistance for the internal high-side FET.

The lower limit is constrained by the minimum controllable on time which may be as high as 130 ns. The

approximate minimum output voltage for a given input voltage and minimum load current is given by Equation 20:

(20)

Where:

V

IN max

= Maximum input voltage

I

O min

= Minimum load current

V

D

= Catch diode forward voltage

R

L

= Output inductor series resistance

This equation assumes nominal on-resistance for the high-side FET and accounts for worst case variation of

operating frequency set point. Any design operating near the operational limits of the device should be carefully

checked to assure proper functionality.

P O W E R D I S S I P A T I O N E S T I MA T E

The following formulas show how to estimate the device power dissipation under continuous conduction mode

operations. They should not be used if the device is working in the discontinuous conduction mode (DCM) or

pulse skipping Eco-mode

TM

.

The device power dissipation includes:

1) Conduction loss: Pcon = Iout

2

x R

DS(on)

x V

OUT

/V

IN

2) Switching loss: Psw = 0.5 x 10

-9

x V

IN

2

x I

OUT

x Fsw

3) Gate charge loss: Pgc = 22.8 x 10

-9

x Fsw

4) Quiescent current loss: Pq = 0.11 x 10

-3

x V

IN

Where:

I

OUT

is the output current (A).

Copyright 2013, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Links: TPS54531

T P S 5 4 5 3 1

SLVSBI5 MAY 2013 www.ti.com

R

DS(on)

is the on-resistance of the high-side MOSFET ().

VOUT is the output voltage (V).

VIN is the input voltage (V).

Fsw is the switching frequency (Hz).

So

Ptot = Pcon + Psw + Pgc + Pq

For given T

A

, T

J

= T

A

+ Rth x Ptot.

For given T

JMAX

= 150C, T

AMAX

= T

JMAX

Rth x Ptot.

Where:

Ptot is the total device power dissipation (W).

T

A

is the ambient temperature (C).

T

J

is the junction temperature (C) .

Rth is the thermal resistance of the package (C/W).

T

JMAX

is maximum junction temperature (C).

T

AMAX

is maximum ambient temperature (C).

P C B LA YO U T

The VIN pin should be bypassed to ground with a low ESR ceramic bypass capacitor. Care should be taken to

minimize the loop area formed by the bypass capacitor connections, the VIN pin, and the anode of the catch

diode. The typical recommended bypass capacitance is 10-F ceramic with a X5R or X7R dielectric and the

optimum placement is closest to the VIN pins and the source of the anode of the catch diode. See Figure 12 for

a PCB layout example. The GND pin should be tied to the PCB ground plane at the pin of the IC. The PH pin

should be routed to the cathode of the catch diode and to the output inductor. Since the PH connection is the

switching node, the catch diode and output inductor should be located very close to the PH pins, and the area of

the PCB conductor minimized to prevent excessive capacitive coupling. For operation at full rated load, the

exposed thermal pad should be soldered directly to the top side ground area under the IC. Use thermal vias to

connect the top side ground area to an internal or bottom layer ground plane. The total copper area must provide

adequate heat dissipation. Additional vias adjacent to the device can b used to improve heat transfer to the

infernal or bottom layer ground plane . The additional external components can be placed approximately as

shown. It may be possible to obtain acceptable performance with alternate layout schemes, however this layout

has been shown to produce good results and is intended as a guideline.

16 Submit Documentation Feedback Copyright 2013, Texas Instruments Incorporated

Product Folder Links: TPS54531

BOOT

VSENSE

PH

VIN GND

EN

Vout

PH

Vin

TOPSIDE

GROUND

AREA

OUTPUT

INDUCTOR

OUTPUT

FILTER

CAPACITOR

BOOT

CAPACITOR

INPUT

BYPASS

CAPACITOR

CATCH

DIODE

Signal VIA

Route BOOT CAPACITOR

trace on other layer to provide

wide path for topside ground

RESISTOR

DIVIDER

Feedback Trace

COMP

SS

COMPENSATION

NETWORK

Thermal VIA

SLOW START

CAPACITOR

UVLO

RESISTOR

DIVIDER

EXPOSED

THERMAL PAD

T P S 5 4 5 3 1

www.ti.com SLVSBI5 MAY 2013

F igure 1 2 . T P S 5 4 5 3 1 D D A Board Layout

E LE C T R O MA GN E T I C I N T E R F E R E N C E (E MI ) C O N S I D E R A T I O N S

As EMI becomes a rising concern in more and more applications, the internal design of the TPS54531 takes

measures to reduce the EMI. The high-side MOSFET gate drive is designed to reduce the PH pin voltage

ringing. The internal IC rails are isolated to decrease the noise sensitivity. A package bond wire scheme is used

to lower the parasitics effects.

To achieve the best EMI performance, external component selection and board layout are equally important.

Follow the Step by Step Design Procedure above to prevent potential EMI issues.

A P P LI C A T I O N C U R V E S

spacer

Copyright 2013, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Links: TPS54531

V = 200 mV/div (ac coupled)

OUT

I = 1 A/div

OUT

Time = 200 s/div

1.25 A to 3.75 A load step,

slew rate = 500 mA / sec

-180

-120

-60

0

60

120

180

-60

-40

-20

0

20

40

60

10 100 1000 10000 100000 1000000

P

h

a

s

e

-

D

e

g

r

e

e

s

G

a

i

n

-

d

B

Frequency - Hz C011

Gain

Phase

-0.20

-0.15

-0.10

-0.05

0.00

0.05

0.10

0.15

0.20

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

L

o

a

d

R

e

g

u

l

a

t

i

o

n

-

%

Output Current - A C009

V

IN

= 24 V

V

IN

= 12 V

-0.1

-0.08

-0.06

-0.04

-0.02

0

0.02

0.04

0.06

0.08

0.1

8 10 12 14 16 18 20 22 24 26 28

L

i

n

e

R

e

g

u

l

a

t

i

o

n

-

%

Input Voltage - V C010

I

OUT

= 2.5 A

0

10

20

30

40

50

60

70

80

90

100

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

E

f

f

i

c

i

e

n

c

y

-

%

Output Current - A C007

V

IN

= 12 V

V

IN

= 24 V

0

10

20

30

40

50

60

70

80

90

100

0.001 0.01 0.1 1 10

E

f

f

i

c

i

e

n

c

y

-

%

Output Current - A C008

V

IN

= 12 V

V

IN

= 24 V

T P S 5 4 5 3 1

SLVSBI5 MAY 2013 www.ti.com

F igure 1 3 . T P S 5 4 5 3 1 D E fficie ncy F igure 1 4 . T P S 5 4 5 3 1 D Low C urre nt E fficie ncy

spacer

spacer

F igure 1 5 . T P S 5 4 5 3 1 D Load R e gulation F igure 1 6. T P S 5 4 5 3 1 D Line R e gulation

spacer

spacer

F igure 1 7. T P S 5 4 5 3 1 T ransie nt R e sponse F igure 1 8 . T P S 5 4 5 3 1 Loop R e sponse

spacer

spacer

18 Submit Documentation Feedback Copyright 2013, Texas Instruments Incorporated

Product Folder Links: TPS54531

V = 2 V/div

OUT

Time = 2 ms/div

EN = 2 V/div

V = 10 V/div

IN

SS = 2 V/div

V = 2 V/div

OUT

Time = 5 ms/div

EN = 2 V/div

V = 10 V/div

IN

SS = 2 V/div

V = 200 mV/div (ac coupled)

IN

Time = 1 s/div

PH = 5 V/div

V = 2 V/div

OUT

Time = 2 ms/div

EN = 2 V/div

V = 10 V/div

IN

SS = 2 V/div

V = 20 mV/div (ac coupled)

OUT

Time = 1 s/div

PH = 5 V/div

V = 20 mV/div (ac coupled)

OUT

Time = 500 s/div

PH = 5 V/div

T P S 5 4 5 3 1

www.ti.com SLVSBI5 MAY 2013

F igure 1 9. T P S 5 4 5 3 1 F ull Load O utput R ipple F igure 2 0. T P S 5 4 5 3 1 E co- mod e O utput R ipple

spacer

spacer

F igure 2 1 . T P S 5 4 5 3 1 F ull Load I nput R ipple F igure 2 2 . T P S 5 4 5 3 1 S tart U p R e lative to V I N

spacer

spacer

F igure 2 3 . T P S 5 4 5 3 1 S tart- up R e lative to E nable F igure 2 4 . T P S 5 4 5 3 1 S hut D own R e lative to V I N

spacer

Copyright 2013, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Links: TPS54531

V = 2 V/div

OUT

Time = 5 ms/div

EN = 2 V/div

V = 10 V/div

IN

SS = 2 V/div

T P S 5 4 5 3 1

SLVSBI5 MAY 2013 www.ti.com

F igure 2 5 . T P S 5 4 5 3 1 S hut D own R e lative to E N

20 Submit Documentation Feedback Copyright 2013, Texas Instruments Incorporated

Product Folder Links: TPS54531

PACKAGE OPTION ADDENDUM

www.ti.com 4-Jun-2013

Addendum-Page 1

PACKAGING INFORMATION

Orderable Device Status

(1)

Package Type Package

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish MSL Peak Temp

(3)

Op Temp (C) Device Marking

(4/5)

Samples

TPS54531DDA ACTIVE SO PowerPAD DDA 8 75 Green (RoHS

& no Sb/Br)

CU NIPDAUAG Level-2-260C-1 YEAR -40 to 85 54531

TPS54531DDAR ACTIVE SO PowerPAD DDA 8 2500 Green (RoHS

& no Sb/Br)

CU NIPDAUAG Level-2-260C-1 YEAR -40 to 85 54531

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)

B0

(mm)

K0

(mm)

P1

(mm)

W

(mm)

Pin1

Quadrant

TPS54531DDAR SO

Power

PAD

DDA 8 2500 330.0 12.8 6.4 5.2 2.1 8.0 12.0 Q1

PACKAGE MATERIALS INFORMATION

www.ti.com 4-Jun-2013

Pack Materials-Page 1

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TPS54531DDAR SO PowerPAD DDA 8 2500 364.0 364.0 27.0

PACKAGE MATERIALS INFORMATION

www.ti.com 4-Jun-2013

Pack Materials-Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as components) are sold subject to TIs terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TIs terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TIs goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or enhanced plastic are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright 2013, Texas Instruments Incorporated

You might also like

- Thomas N. Tozer, Malcolm Rowland - Essentials of Pharmacokinetics and Pharma PDFDocument401 pagesThomas N. Tozer, Malcolm Rowland - Essentials of Pharmacokinetics and Pharma PDFSamNo ratings yet

- The Case of The Missing TimeDocument14 pagesThe Case of The Missing TimeSharingan MangekyouNo ratings yet

- Tps 54628Document22 pagesTps 54628fet_50No ratings yet

- Bias Power Supply For TV and Monitor TFT LCD Panels: FeaturesDocument30 pagesBias Power Supply For TV and Monitor TFT LCD Panels: Featureseduinggv1829No ratings yet

- Bias Power Supply For TV and Monitor TFT LCD Panels: FeaturesDocument35 pagesBias Power Supply For TV and Monitor TFT LCD Panels: Featureseduinggv1829No ratings yet

- DatasheetDocument58 pagesDatasheetselocaNo ratings yet

- Synchronous Buck Nexfet™ Power Block: Features DescriptionDocument20 pagesSynchronous Buck Nexfet™ Power Block: Features DescriptionWalter Apaza Ticona0% (1)

- Complete DDR2, DDR3, DDR3L, and LPDDR3 Memory Power Solution Synchronous Buck Controller, 2-A LDO, With Buffered ReferenceDocument30 pagesComplete DDR2, DDR3, DDR3L, and LPDDR3 Memory Power Solution Synchronous Buck Controller, 2-A LDO, With Buffered Referencesalahudeen03No ratings yet

- Low-Noise Fast-Transient-Response 1.5-A Low-Dropout Voltage RegulatorsDocument28 pagesLow-Noise Fast-Transient-Response 1.5-A Low-Dropout Voltage RegulatorssinnlosNo ratings yet

- IC-ON-LINE - CN dm0465r 44841Document20 pagesIC-ON-LINE - CN dm0465r 44841ubhagavanNo ratings yet

- Tps 51125Document37 pagesTps 51125Naresh Kumar100% (1)

- TPA3116D2Document34 pagesTPA3116D2Matias_UTNNo ratings yet

- Tps 5430Document28 pagesTps 5430Lullaby summerNo ratings yet

- Tle6220gp DatasheetDocument18 pagesTle6220gp Datasheetmaelo99999No ratings yet

- LM 78 L 05Document21 pagesLM 78 L 05peyuco3333No ratings yet

- lm331 PDFDocument21 pageslm331 PDFOsvaldo Dominguez GonzalezNo ratings yet

- Features Description: Ltc3633 Dual Channel 3A, 15V Monolithic Synchronous Step-Down RegulatorDocument28 pagesFeatures Description: Ltc3633 Dual Channel 3A, 15V Monolithic Synchronous Step-Down RegulatorMichael LeeNo ratings yet

- DAC0800/DAC0802 8-Bit Digital-to-Analog Converters: Features DescriptionDocument21 pagesDAC0800/DAC0802 8-Bit Digital-to-Analog Converters: Features DescriptionRaul CruzNo ratings yet

- LM117/LM317A/LM317-N 3-Terminal Adjustable Regulator: FeaturesDocument38 pagesLM117/LM317A/LM317-N 3-Terminal Adjustable Regulator: FeaturesAdibMaulanaNo ratings yet

- ULN2803A Darlington Transistor Arrays: Features DescriptionDocument14 pagesULN2803A Darlington Transistor Arrays: Features DescriptionJohn Joshua MontañezNo ratings yet

- Datasheet LM3429Document34 pagesDatasheet LM3429Bagus KrisviandikNo ratings yet

- LM2852 Synchronous BuckDocument14 pagesLM2852 Synchronous BuckAndrew CavanaughNo ratings yet

- LMC 567Document14 pagesLMC 567saandoNo ratings yet

- TLC 5925Document27 pagesTLC 5925zektorNo ratings yet

- A5800 and A5801: Discontinued ProductDocument13 pagesA5800 and A5801: Discontinued Productitamar_123No ratings yet

- Datasheet PDFDocument15 pagesDatasheet PDFperro sNo ratings yet

- PTN 78020 WDocument27 pagesPTN 78020 WabrrielNo ratings yet

- 3842 Ic DatasheetDocument13 pages3842 Ic DatasheetEngr Khalid IqbalNo ratings yet

- 1.5A Low Dropout Regulator With Enable: Global Mixed-Mode Technology IncDocument9 pages1.5A Low Dropout Regulator With Enable: Global Mixed-Mode Technology IncImamNo ratings yet

- 1-Tle6240gp V3 1 1Document24 pages1-Tle6240gp V3 1 1Alexandre Da Silva PintoNo ratings yet

- MF10-N Universal Monolithic Dual Switched Capacitor Filter: Features DescriptionDocument35 pagesMF10-N Universal Monolithic Dual Switched Capacitor Filter: Features DescriptionAlbeiro Yr TrancerNo ratings yet

- Tps 2051 BDocument29 pagesTps 2051 Bdragon-red0816No ratings yet

- Data SheetDocument35 pagesData SheetvvvssssvvvNo ratings yet

- PWM Off-Line Switching Regulator Ics: Str-A6000H SeriesDocument13 pagesPWM Off-Line Switching Regulator Ics: Str-A6000H SeriesAnonymous Lfgk6vygNo ratings yet

- STRW6252Document15 pagesSTRW6252miltoncgNo ratings yet

- IC-ON-LINE - CN dm0365r 44840Document20 pagesIC-ON-LINE - CN dm0365r 44840MoscandoNo ratings yet

- Features General Description: 1A Low Dropout Positive Adjustable or Fixed-Mode RegulatorDocument9 pagesFeatures General Description: 1A Low Dropout Positive Adjustable or Fixed-Mode RegulatoriammiaNo ratings yet

- Uc284xa Uc384xaDocument16 pagesUc284xa Uc384xayusufwpNo ratings yet

- DRV 8432Document34 pagesDRV 8432Van Thanh TranNo ratings yet

- Apl 5336Document20 pagesApl 5336FlavianoSilvaNo ratings yet

- FSQ110 Green Mode Fairchild Power Switch (FPS™) : Features DescriptionDocument12 pagesFSQ110 Green Mode Fairchild Power Switch (FPS™) : Features DescriptionJohan BeckersNo ratings yet

- XTR 117Document16 pagesXTR 117Compañero DanielqjNo ratings yet

- Fan 7316Document21 pagesFan 7316sontuyet82No ratings yet

- Datasheet Amp DVD Philips Dumbo PDFDocument17 pagesDatasheet Amp DVD Philips Dumbo PDFfreekenzoNo ratings yet

- Datasheet 53315Document30 pagesDatasheet 53315Bladimir AngamarcaNo ratings yet

- La 42102Document8 pagesLa 42102buyadiNo ratings yet

- Apl 1084Document12 pagesApl 1084EstebanRuizDiazNo ratings yet

- PS223Document11 pagesPS223seyyedali2006No ratings yet

- Off-Line Quasi-Resonant Switching Regulators: STR-X6729Document9 pagesOff-Line Quasi-Resonant Switching Regulators: STR-X6729perro sNo ratings yet

- Obsolete Product(s) - Obsolete Product(s)Document10 pagesObsolete Product(s) - Obsolete Product(s)patopickNo ratings yet

- Tps 92512Document30 pagesTps 92512ppanagosNo ratings yet

- LM 2576 HVDocument37 pagesLM 2576 HVNick CatNo ratings yet

- 300/600ma, Ultra-Fast Transient Response LDO Regulator: General Description FeaturesDocument15 pages300/600ma, Ultra-Fast Transient Response LDO Regulator: General Description FeaturesDouglas RodriguesNo ratings yet

- 1 Tle4216Document15 pages1 Tle4216Villalba XavichoNo ratings yet

- drv8805 PDFDocument19 pagesdrv8805 PDFAdithya ChandrasekaranNo ratings yet

- Data Sheet Ic fr9886Document14 pagesData Sheet Ic fr9886Setya Budi S100% (1)

- 5V-0.5A Very Low Drop Regulator With Reset: DescriptionDocument6 pages5V-0.5A Very Low Drop Regulator With Reset: DescriptionDan EsentherNo ratings yet

- 5101 Motor DriverDocument11 pages5101 Motor DriverMoise CristinaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Idioms For IELTS SpeakingDocument21 pagesIdioms For IELTS SpeakingРоза АсановаNo ratings yet

- Barang 3Document12 pagesBarang 3Sujoko SkinzNo ratings yet

- Sailor100gx TM 98 145912 B PDFDocument276 pagesSailor100gx TM 98 145912 B PDFCarlos CoelhoNo ratings yet

- Forum Arduino CC T GRBL Lcdkeypad Shield 331250 6Document10 pagesForum Arduino CC T GRBL Lcdkeypad Shield 331250 6David duranNo ratings yet

- Islamic WorldviewDocument74 pagesIslamic Worldviewvera290690100% (1)

- May 2008 New Method Measuring Porous Microbial Barriers PartIDocument4 pagesMay 2008 New Method Measuring Porous Microbial Barriers PartIfabrizioalbertiniNo ratings yet

- Datasheet Painel Solar 360W KuMax CS3U PDocument2 pagesDatasheet Painel Solar 360W KuMax CS3U PDenis SilvaNo ratings yet

- CRV Led Spec SheetDocument3 pagesCRV Led Spec SheetGabrielGrecoNo ratings yet

- MSI K9A2 CF Series ManualDocument89 pagesMSI K9A2 CF Series ManualDosije218No ratings yet

- HomeAwayJamalMahjoub WSTEXTDocument11 pagesHomeAwayJamalMahjoub WSTEXTVanDesignsNo ratings yet

- Solar Design LeedDocument10 pagesSolar Design Leedapi-465215783No ratings yet

- 90203-1085DEB Arc Welding Operation Manual (D Series)Document178 pages90203-1085DEB Arc Welding Operation Manual (D Series)Ihcene BoudaliNo ratings yet

- Coalmine Monitoring SystemDocument65 pagesCoalmine Monitoring SystemTechnos_IncNo ratings yet

- 02 000378Document477 pages02 000378JimNo ratings yet

- Icse Class X Physics Practise Sheet 1 ForceDocument3 pagesIcse Class X Physics Practise Sheet 1 ForceMehnaaz Brar100% (2)

- ATR LM ClassDocument30 pagesATR LM ClassKezia Sormin100% (1)

- Journal Ranking - AnthropologyDocument3 pagesJournal Ranking - AnthropologyDavide CarnevaleNo ratings yet

- Tone Worksheet 01Document3 pagesTone Worksheet 01Jason Wall0% (1)

- TLE IA CAG10 w6 7Document4 pagesTLE IA CAG10 w6 7ALLYSSA MAE PELONIANo ratings yet

- Linear Measurement: WelcomeDocument25 pagesLinear Measurement: WelcomeSuman JyotiNo ratings yet

- 03-Speaking Sample Test 3 - DentistryDocument1 page03-Speaking Sample Test 3 - DentistryMorris OETNo ratings yet

- What Is Price Skimming?: First MoverDocument9 pagesWhat Is Price Skimming?: First MoverDiya MukherjeeNo ratings yet

- BTCDocument30 pagesBTCshajib_sustNo ratings yet

- Design and Prototype of Inline Seeder 2022 AAITDocument88 pagesDesign and Prototype of Inline Seeder 2022 AAITHailemariam Weldegebral0% (1)

- BEVAE-181 Sample PPR 2Document4 pagesBEVAE-181 Sample PPR 2saketsharmaytNo ratings yet