Professional Documents

Culture Documents

Gas - Adding or Extending Piping: Permit Requirements

Gas - Adding or Extending Piping: Permit Requirements

Uploaded by

Andrian WicaksonoCopyright:

Available Formats

You might also like

- Design of Water Based Fire Protection SystemsDocument43 pagesDesign of Water Based Fire Protection SystemsKumararaja Konikki94% (33)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- ASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 5 Optimized Control SequencesDocument20 pagesASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 5 Optimized Control Sequencesmdalt9180No ratings yet

- Manual SylberDocument72 pagesManual Sylberniladam2002No ratings yet

- SOP For Duct Leak TestingDocument8 pagesSOP For Duct Leak TestingSubodh Murkewar50% (2)

- Sleeperwall 1Document6 pagesSleeperwall 1John SmithNo ratings yet

- BS EN ISO 527-4-Plastics PDFDocument20 pagesBS EN ISO 527-4-Plastics PDFShezad Ali100% (1)

- GE-1 Weights Building MaterialsDocument2 pagesGE-1 Weights Building Materialsreset00No ratings yet

- ReticulationDocument118 pagesReticulationIzzul Hazim100% (1)

- Chapter 4 - Gas Piping Installations PDFDocument14 pagesChapter 4 - Gas Piping Installations PDFGeorge_Wabag_2014No ratings yet

- Residential Gas Pipe InstallationDocument1 pageResidential Gas Pipe InstallationFrancisco GonzalezNo ratings yet

- Plumbing Installations: A Homeowner Guide To The City of Winnipeg Plumbing Requirements For A Single-Family DwellingDocument20 pagesPlumbing Installations: A Homeowner Guide To The City of Winnipeg Plumbing Requirements For A Single-Family DwellingLai Huynh VanNo ratings yet

- Sprinkler 001Document66 pagesSprinkler 001Kevin Tsui100% (1)

- Dunkirk PSB Boiler Installation ManualDocument28 pagesDunkirk PSB Boiler Installation ManualaprichNo ratings yet

- Gas Reticulation Project Group 8Document13 pagesGas Reticulation Project Group 8Mohd Hafiz50% (2)

- Module 10 Q&ADocument7 pagesModule 10 Q&ACorin FramptonNo ratings yet

- Wayne Combustion Hsg200 Owners ManualDocument23 pagesWayne Combustion Hsg200 Owners Manualwotm28No ratings yet

- Bosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualDocument36 pagesBosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualMerlin1950No ratings yet

- Gas Load Calculations: City of Vacaville Community Development Building DivisionDocument2 pagesGas Load Calculations: City of Vacaville Community Development Building DivisionHammad MalikNo ratings yet

- Saunier Duval Thema C23 Installation ManualDocument20 pagesSaunier Duval Thema C23 Installation ManualZmarandoiu SorinaNo ratings yet

- Instructions For Installation and Servicing: Vaillant Combined AppliancesDocument62 pagesInstructions For Installation and Servicing: Vaillant Combined AppliancesCristina TibulcaNo ratings yet

- Burnham Corp Nstallation Operating and Service Instructions Gas Boilers Series 2 Model B For Burnham Series 2 BoilerDocument52 pagesBurnham Corp Nstallation Operating and Service Instructions Gas Boilers Series 2 Model B For Burnham Series 2 BoilerjjamerNo ratings yet

- Quote 1311 r2 Poly Gulf Unit 3Document5 pagesQuote 1311 r2 Poly Gulf Unit 3Evin VargheseNo ratings yet

- IBRDocument33 pagesIBRBrijraj Pandey100% (5)

- Baxi Solo 2 40rs Gcno.41-077-77Document42 pagesBaxi Solo 2 40rs Gcno.41-077-77sjallandNo ratings yet

- Ductwork&PressureLosses GreenhackDocument5 pagesDuctwork&PressureLosses GreenhackAdarshNo ratings yet

- SECTION 02660 Pipeline Testing: Hcss 02660-1 June 2008Document8 pagesSECTION 02660 Pipeline Testing: Hcss 02660-1 June 2008moyassine7139No ratings yet

- Design of Water Supply For PlumbingDocument23 pagesDesign of Water Supply For PlumbingssgjmlimNo ratings yet

- Installers Manual ING 2010Document161 pagesInstallers Manual ING 2010Aminu IbrahimNo ratings yet

- Nordyne Line SizeDocument4 pagesNordyne Line SizeRay RavelNo ratings yet

- Aerco Boiler Design GuideDocument58 pagesAerco Boiler Design Guidemnt6176No ratings yet

- Water Cooled Fcu Piping DetailsDocument14 pagesWater Cooled Fcu Piping Detailsfernandoreyes893No ratings yet

- 330130Document7 pages330130Cool SharyNo ratings yet

- Gaspipe SizingDocument15 pagesGaspipe SizingmaxxhaloNo ratings yet

- p405 01Document8 pagesp405 01Utku KepcenNo ratings yet

- Gas ResInstallationSizingDocument3 pagesGas ResInstallationSizingLamHotNo ratings yet

- Fire Pump Installation GuideDocument3 pagesFire Pump Installation GuideJeff D. AgustinNo ratings yet

- Manual NXR4Document20 pagesManual NXR4libertysyndrome2010No ratings yet

- Wayne Hsg24 ManualDocument22 pagesWayne Hsg24 ManualGabrielle D'AnnvnzioNo ratings yet

- City Gas' Guidelines For The Installation of Gas Water HeaterDocument9 pagesCity Gas' Guidelines For The Installation of Gas Water HeaterDavid WeeNo ratings yet

- Pipe Sizing Steam Supply and Condensate Return Lines: DefinitionsDocument6 pagesPipe Sizing Steam Supply and Condensate Return Lines: Definitionsferdie14No ratings yet

- Kitchen HoodDocument10 pagesKitchen HoodkumarNo ratings yet

- Pentair Training Program: First Week Office LecturesDocument37 pagesPentair Training Program: First Week Office LecturesCobra_007No ratings yet

- Guidelines For Sizing: FeaturesDocument8 pagesGuidelines For Sizing: FeaturesApih Ibrahim100% (1)

- Amana Amvc95Document12 pagesAmana Amvc95Veljko MilasinovicNo ratings yet

- Attic HVAC UnitsDocument5 pagesAttic HVAC Unitsjonnee_nguyenNo ratings yet

- Appendices: Recommended Rules For Sizing The Water Supply SystemDocument21 pagesAppendices: Recommended Rules For Sizing The Water Supply Systemrex tanongNo ratings yet

- Watson McDaniel EngineeringDataDocument61 pagesWatson McDaniel EngineeringDataViswanathan DamodaranNo ratings yet

- Water Base ProtectionDocument42 pagesWater Base ProtectionandreasbudiNo ratings yet

- Optima 701 ManualDocument32 pagesOptima 701 ManualJonathan James ConwayNo ratings yet

- Worcester Greenstar Junior Instruction GuideDocument65 pagesWorcester Greenstar Junior Instruction GuidePeter ThomasNo ratings yet

- Duct & Vent EngineeringDocument70 pagesDuct & Vent Engineeringtop20202080% (5)

- Installers Manual ING 2010Document161 pagesInstallers Manual ING 2010aco1970No ratings yet

- Johnson & Starley Janus Water Heater Owner's GuideDocument8 pagesJohnson & Starley Janus Water Heater Owner's GuideMark WeatherillNo ratings yet

- STP PDFDocument7 pagesSTP PDFJames FernNo ratings yet

- Conveyor Ovens - Continuous ProcessDocument2 pagesConveyor Ovens - Continuous ProcessAmalina SolahuddinNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- MRI Philips Internal MeetingDocument2 pagesMRI Philips Internal Meetingm_johairieNo ratings yet

- Construction and Building Materials: Tayfun Çiçek, Yasin ÇinçinDocument7 pagesConstruction and Building Materials: Tayfun Çiçek, Yasin ÇinçinInzimam Ul haqNo ratings yet

- ch21 PDFDocument13 pagesch21 PDFRodrigo S QuirinoNo ratings yet

- Fabrication of Water Cooler Cum Air ConditionerDocument3 pagesFabrication of Water Cooler Cum Air Conditionerpramo_dassNo ratings yet

- Carbon Alloy SteelsDocument4 pagesCarbon Alloy SteelsBeyzanur TepecikNo ratings yet

- Concrete Technology (Lab Manual)Document23 pagesConcrete Technology (Lab Manual)VipulShukla100% (3)

- Abandonment of Sewer MainsDocument5 pagesAbandonment of Sewer MainsbarouniamineNo ratings yet

- ISEO IDEA Kw12816 (Base - AntiGerm - DoP - Certifire - CE0497)Document16 pagesISEO IDEA Kw12816 (Base - AntiGerm - DoP - Certifire - CE0497)31863192No ratings yet

- Grade 6 Science Notes Term II Magnets LessonDocument4 pagesGrade 6 Science Notes Term II Magnets LessonShaik Md Shoaib Anas 5A (Shoaib Anas)No ratings yet

- 99 269 Testing of Plastics and Rubber e enDocument56 pages99 269 Testing of Plastics and Rubber e enFerryNo ratings yet

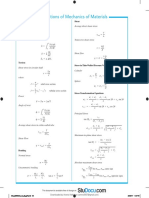

- Mechanics of Materials Equation SheetDocument3 pagesMechanics of Materials Equation SheetAramis Kelkelyan100% (1)

- Company Profile - EskayDocument4 pagesCompany Profile - EskayNarasimha PrasadNo ratings yet

- Ashish Industrial Training ReportDocument31 pagesAshish Industrial Training Reportprosperity facilitationNo ratings yet

- Dr. Shanza Rehan: Eng. Omar Farooq, Dr. FidaDocument23 pagesDr. Shanza Rehan: Eng. Omar Farooq, Dr. FidaMaheenNo ratings yet

- Aisi 4130Document2 pagesAisi 4130Ravi Chaitanya VelamarthyNo ratings yet

- #97753 Bonding Non Metallic Materials Using Indium and High Indium AlloysDocument1 page#97753 Bonding Non Metallic Materials Using Indium and High Indium AlloysEnrico PiccininiNo ratings yet

- Engineering Properties of Reactive Clay Earthworks in SE QueenslandDocument16 pagesEngineering Properties of Reactive Clay Earthworks in SE QueenslandKamesh KumarNo ratings yet

- Bonded Coatings For All Metal Surfaces.: Your Global SpecialistDocument16 pagesBonded Coatings For All Metal Surfaces.: Your Global Specialistghatiyas26No ratings yet

- Mechanical Properties of Solids: (Prepared by Ayyappan C, HSST Physics, GHSS Udma, Kasaragod, Mob: 9961985448)Document4 pagesMechanical Properties of Solids: (Prepared by Ayyappan C, HSST Physics, GHSS Udma, Kasaragod, Mob: 9961985448)sangeetha pNo ratings yet

- Chapter 1: Soft Condensed MatterDocument24 pagesChapter 1: Soft Condensed MatterbyonymousNo ratings yet

- Transport For NSW (TFNSW) Qa Specification 3051 Granular Pavement Base and Subbase MaterialsDocument45 pagesTransport For NSW (TFNSW) Qa Specification 3051 Granular Pavement Base and Subbase MaterialsroshanNo ratings yet

- Phase Transformation in SteelDocument5 pagesPhase Transformation in SteelBobby Yusuf HakaNo ratings yet

- Specific Requirements & Scope of Work For RCC PilingDocument38 pagesSpecific Requirements & Scope of Work For RCC PilingTauqueerAhmadNo ratings yet

- Training Manual Price ListDocument4 pagesTraining Manual Price ListvinviaNo ratings yet

- Reinforced Strip FoundationDocument22 pagesReinforced Strip FoundationGautam PaulNo ratings yet

- Lecture 10 Analysis and Design of Waffle Slabs - 2011Document62 pagesLecture 10 Analysis and Design of Waffle Slabs - 2011José Pablo Rosales Sánchez100% (1)

Gas - Adding or Extending Piping: Permit Requirements

Gas - Adding or Extending Piping: Permit Requirements

Uploaded by

Andrian WicaksonoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas - Adding or Extending Piping: Permit Requirements

Gas - Adding or Extending Piping: Permit Requirements

Uploaded by

Andrian WicaksonoCopyright:

Available Formats

Handout No.

6-2

Published: 8/21/00

Updated 9/16/04

Page 1 of 3

Gas - Adding or Extending Piping

Permit Requirements

A permit is required when installing new gas piping or when altering an existing gas line.

Permits are issued to either the owner or to a State-licensed contractor with a current City of San Jose

Business License.

Permits are obtained at the San Jose Building Division Permit Center, or 24/7 by the Internet:

The Permit Center is located in City Hall at 200 East Santa Clara Street.

Office hours are from 9:00 a.m. to 4:00 p.m., Monday through Friday.

Permits online: https://www.sjpermits.org/

Plans are usually not required. However, gas-sizing calculations may be required to verify

that the gas piping is sized per the minimum code requirements. [See Worksheet, page 3]

The calculations, if required, shall be made available at the time of inspection.

Installation Requirements

Unions [inline couplings] are not permitted in a gas piping system except as follows:

Unions are allowed downstream of [after] appliance shutoff valves, meter locations and

immediately downstream of building shutoff valves.

The use of right/left couplings and nipples are required in lieu of unions in all other locations.

Metallic gas piping is not allowed outdoors in or within six inches of the ground.

Exception: Only piping which has been factory coated with approved materials is acceptable for burial in

the ground.

Appliances and UPC-approved Flexible gas connectors from the gas pipe to the appliances shall be sized

and installed in accordance with code requirements and manufacturer's specifications.

The gas pipe must be firecaulked tightly where the pipe penetrates the exterior surface of the fire

chamber in a factory-built fireplace. Also, the interior void shall be filled with fiberglass insulation or

mineral wool. It must also be firecaulked at any penetrations through a garage or any other fire-rated wall.

Shutoff valve requirements are as follows:

1. Required in the gas piping system ahead of all gas appliances,

2. Must be accessible and in the same room as the appliance,

3. Must not leak,

4. Shall be within three feet of the appliance, except as follows:

Shutoff valves may be within six feet of the gas dryer or freestanding oven,

Shutoff valves for log lighters to be within four feet of the fireplace opening.

Note: Fireplace shutoff valves must be installed outside the firebox.

Pipe support is based on the size of the pipe. Protect pipes from damage.

UPC Table 12-2

Size of pipe Pipe Support Distance (max.)

6

to 1 8

1- or larger- Horizontal 10

1- or larger- Vertical Every Floor

Gas - Adding or Extending Piping Page 2 of 3

Inspection Requirements

All new piping shall be inspected prior to covering any portion of new piping.

The applicant must perform a gas test and have it witnessed by the inspector for all portions of new gas

piping, after all nailing of covering sheetrock and any other concealing is complete.

The person doing the work is responsible for performing the gas test and calling for inspection.

Inspections may be scheduled by calling (408) 535-3555 from 8:00 a.m. to 5:00 p.m, or over the Internet.

Any cancellations must be received by 2 p.m. the business day before the scheduled inspection.

Gas Test Requirements UPC 319, UPC 1204.3.2

The entire gas piping system shall be tested, with all appliances shut off at the valve or disconnected and

capped. Caution: Some of the older wedge-type shut-off valves tend to leak and then the pressure test can

damage the appliances; disconnection and pre-testing is recommended.

The inspection shall include an air pressure test. The gas piping shall stand a pressure of not less than

(10) pounds per square inch gauge pressure. The test gauge must be accurate to 1/10 of one pound and

have a pressure range of not more than twice the test pressure applied. The test must hold for at least 15

minutes with no perceptible drop in pressure while the Inspector waits.

Welded piping and those pipes holding gas at over 14 inches water column pressure shall be tested at not

less than 60 psi with a gauge with 1 psi increments for at least 30 minutes.

Note that the test gauge requirements have changed slightly from the prior requirements and policies.

UPC Table 12-1: Average Gas Use

Minimum demand per hour

Appliance (typical)* Btu/hr Watts Cubic Ft/Hr

Barbecue (residential) 50,000 14,650 50

Bunsen Burner 3,000 879 3

Domestic Clothes Dryer 35,000 10,255 35

Domestic Gas Range 65,000 19,045 65

Domestic Recessed Oven Section 25,000 7,325 25

Domestic Gas Cooktop 40,000 11,720 40

Fireplace Log Lighter (commercial) 50,000 14,650 50

Fireplace Log Lighter (residential) 25,000 2,930 25

Gas Engines (per Horsepower) 10,000x Hp 2,930 x Hp 10 x Hp

Gas Refrigerator 3,000 879 3

Mobile Home (single)** 250,000 73,275 250

Steam Boilers (per horsepower) 50,000 x Hp 14,650 x Hp 50 x Hp

Storage Water Heater up to 30 gallons 30,000 8,790 30

Storage Water Heater 40-50 gallons 50,000 14,650 50

Furnace See Manufacturers Specifications

Pool Heater See Manufacturers Specifications

Instantaneous Water Heater See Manufacturers Specifications

* See manufacturers specifications or the Rating Plate attached to the appliance for the exact usage.

**See UPC Appendix Table E-3 for multiple lot mobile home parks.

Bold: most common residential uses (225 CFH combined + FAU)

Note: Cubic Feet per Hour (CFH) x 1000 = BTU capacity; 10,000 BTU=10 CFH

Additional information can be obtained by calling our Information Inspector's voice mail at:

(408) 535-3555 and leaving a detailed message, or by visiting our website at:

http://www.sanjoseca.gov/building/ or https://www.sjpermits.org/ > Building Home

Gas - Adding or Extending Piping Page 3 of 3

Sizing Worksheet

Table 12-3: Size of Gas Piping (Low Pressure) CFH

Maximum Length of pipe section in Feet

Pipe

Size

(inches) 10 20 30 40 50 60 70 80 90 100 125 150

174 119 96 82 73 66 61 56 53 50 44 40

363 249 200 171 152 138 127 118 111 104 93 84

1 684 470 377 323 286 259 239 222 208 197 174 158

1- 1404 965 775 663 588 532 490 456 428 404 358 324

1- 2103 1445 1161 993 880 798 734 683 641 605 536 486

2 4050 2784 2235 1913 1696 1536 1413 1315 1234 1165 1033 936

2- 6455 4437 3563 3049 2703 2449 2253 2096 1966 1857 1646 1492

3 11,412 7843 6299 5391 4778 4329 3983 3705 3476 3284 2910 2637

1. Maximum Delivery Capacity of Cubic Feet of Gas per Hour (CFH) of IPS Pipe carrying Natural Gas of 0.60 Specific Gravity, based on a

Pressure Drop 0.5 inch Water Column. 10,000 BTU= 10 CFH Divide Watts by 293 = CFH

2. and pipe is most common residential size (in bold), with 1 to 1- at the meter. May install larger meter to allow for future pool

heater.

Sample Sizing Chart

Sizing Worksheet

Diagram

1. Furthest Outlet (feet) : ____+____+____+____+____+____=_____ ft

2. Use Table 12-3 Column for _______ feet (round up, circle above)

3. Section sizes from Furthest to Meter; (divide BTUs by 1000 for CFH)

Furthest: _______________ CFH = ____pipe ( typ.)

(1) ____+_____ CFH = _____CFH = ____ pipe

(2) ____+____+____= _____CFH = ____ pipe

(3) ____+____+____= _____CFH =_____ pipe

(4) ____+____+____= _____CFH =_____ pipe

Min. Meter Size =______; to Use: _______

4. Branch sizes- mark on diagram per Table 12-3

(SFR: typ.)

You might also like

- Design of Water Based Fire Protection SystemsDocument43 pagesDesign of Water Based Fire Protection SystemsKumararaja Konikki94% (33)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- ASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 5 Optimized Control SequencesDocument20 pagesASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 5 Optimized Control Sequencesmdalt9180No ratings yet

- Manual SylberDocument72 pagesManual Sylberniladam2002No ratings yet

- SOP For Duct Leak TestingDocument8 pagesSOP For Duct Leak TestingSubodh Murkewar50% (2)

- Sleeperwall 1Document6 pagesSleeperwall 1John SmithNo ratings yet

- BS EN ISO 527-4-Plastics PDFDocument20 pagesBS EN ISO 527-4-Plastics PDFShezad Ali100% (1)

- GE-1 Weights Building MaterialsDocument2 pagesGE-1 Weights Building Materialsreset00No ratings yet

- ReticulationDocument118 pagesReticulationIzzul Hazim100% (1)

- Chapter 4 - Gas Piping Installations PDFDocument14 pagesChapter 4 - Gas Piping Installations PDFGeorge_Wabag_2014No ratings yet

- Residential Gas Pipe InstallationDocument1 pageResidential Gas Pipe InstallationFrancisco GonzalezNo ratings yet

- Plumbing Installations: A Homeowner Guide To The City of Winnipeg Plumbing Requirements For A Single-Family DwellingDocument20 pagesPlumbing Installations: A Homeowner Guide To The City of Winnipeg Plumbing Requirements For A Single-Family DwellingLai Huynh VanNo ratings yet

- Sprinkler 001Document66 pagesSprinkler 001Kevin Tsui100% (1)

- Dunkirk PSB Boiler Installation ManualDocument28 pagesDunkirk PSB Boiler Installation ManualaprichNo ratings yet

- Gas Reticulation Project Group 8Document13 pagesGas Reticulation Project Group 8Mohd Hafiz50% (2)

- Module 10 Q&ADocument7 pagesModule 10 Q&ACorin FramptonNo ratings yet

- Wayne Combustion Hsg200 Owners ManualDocument23 pagesWayne Combustion Hsg200 Owners Manualwotm28No ratings yet

- Bosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualDocument36 pagesBosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualMerlin1950No ratings yet

- Gas Load Calculations: City of Vacaville Community Development Building DivisionDocument2 pagesGas Load Calculations: City of Vacaville Community Development Building DivisionHammad MalikNo ratings yet

- Saunier Duval Thema C23 Installation ManualDocument20 pagesSaunier Duval Thema C23 Installation ManualZmarandoiu SorinaNo ratings yet

- Instructions For Installation and Servicing: Vaillant Combined AppliancesDocument62 pagesInstructions For Installation and Servicing: Vaillant Combined AppliancesCristina TibulcaNo ratings yet

- Burnham Corp Nstallation Operating and Service Instructions Gas Boilers Series 2 Model B For Burnham Series 2 BoilerDocument52 pagesBurnham Corp Nstallation Operating and Service Instructions Gas Boilers Series 2 Model B For Burnham Series 2 BoilerjjamerNo ratings yet

- Quote 1311 r2 Poly Gulf Unit 3Document5 pagesQuote 1311 r2 Poly Gulf Unit 3Evin VargheseNo ratings yet

- IBRDocument33 pagesIBRBrijraj Pandey100% (5)

- Baxi Solo 2 40rs Gcno.41-077-77Document42 pagesBaxi Solo 2 40rs Gcno.41-077-77sjallandNo ratings yet

- Ductwork&PressureLosses GreenhackDocument5 pagesDuctwork&PressureLosses GreenhackAdarshNo ratings yet

- SECTION 02660 Pipeline Testing: Hcss 02660-1 June 2008Document8 pagesSECTION 02660 Pipeline Testing: Hcss 02660-1 June 2008moyassine7139No ratings yet

- Design of Water Supply For PlumbingDocument23 pagesDesign of Water Supply For PlumbingssgjmlimNo ratings yet

- Installers Manual ING 2010Document161 pagesInstallers Manual ING 2010Aminu IbrahimNo ratings yet

- Nordyne Line SizeDocument4 pagesNordyne Line SizeRay RavelNo ratings yet

- Aerco Boiler Design GuideDocument58 pagesAerco Boiler Design Guidemnt6176No ratings yet

- Water Cooled Fcu Piping DetailsDocument14 pagesWater Cooled Fcu Piping Detailsfernandoreyes893No ratings yet

- 330130Document7 pages330130Cool SharyNo ratings yet

- Gaspipe SizingDocument15 pagesGaspipe SizingmaxxhaloNo ratings yet

- p405 01Document8 pagesp405 01Utku KepcenNo ratings yet

- Gas ResInstallationSizingDocument3 pagesGas ResInstallationSizingLamHotNo ratings yet

- Fire Pump Installation GuideDocument3 pagesFire Pump Installation GuideJeff D. AgustinNo ratings yet

- Manual NXR4Document20 pagesManual NXR4libertysyndrome2010No ratings yet

- Wayne Hsg24 ManualDocument22 pagesWayne Hsg24 ManualGabrielle D'AnnvnzioNo ratings yet

- City Gas' Guidelines For The Installation of Gas Water HeaterDocument9 pagesCity Gas' Guidelines For The Installation of Gas Water HeaterDavid WeeNo ratings yet

- Pipe Sizing Steam Supply and Condensate Return Lines: DefinitionsDocument6 pagesPipe Sizing Steam Supply and Condensate Return Lines: Definitionsferdie14No ratings yet

- Kitchen HoodDocument10 pagesKitchen HoodkumarNo ratings yet

- Pentair Training Program: First Week Office LecturesDocument37 pagesPentair Training Program: First Week Office LecturesCobra_007No ratings yet

- Guidelines For Sizing: FeaturesDocument8 pagesGuidelines For Sizing: FeaturesApih Ibrahim100% (1)

- Amana Amvc95Document12 pagesAmana Amvc95Veljko MilasinovicNo ratings yet

- Attic HVAC UnitsDocument5 pagesAttic HVAC Unitsjonnee_nguyenNo ratings yet

- Appendices: Recommended Rules For Sizing The Water Supply SystemDocument21 pagesAppendices: Recommended Rules For Sizing The Water Supply Systemrex tanongNo ratings yet

- Watson McDaniel EngineeringDataDocument61 pagesWatson McDaniel EngineeringDataViswanathan DamodaranNo ratings yet

- Water Base ProtectionDocument42 pagesWater Base ProtectionandreasbudiNo ratings yet

- Optima 701 ManualDocument32 pagesOptima 701 ManualJonathan James ConwayNo ratings yet

- Worcester Greenstar Junior Instruction GuideDocument65 pagesWorcester Greenstar Junior Instruction GuidePeter ThomasNo ratings yet

- Duct & Vent EngineeringDocument70 pagesDuct & Vent Engineeringtop20202080% (5)

- Installers Manual ING 2010Document161 pagesInstallers Manual ING 2010aco1970No ratings yet

- Johnson & Starley Janus Water Heater Owner's GuideDocument8 pagesJohnson & Starley Janus Water Heater Owner's GuideMark WeatherillNo ratings yet

- STP PDFDocument7 pagesSTP PDFJames FernNo ratings yet

- Conveyor Ovens - Continuous ProcessDocument2 pagesConveyor Ovens - Continuous ProcessAmalina SolahuddinNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- MRI Philips Internal MeetingDocument2 pagesMRI Philips Internal Meetingm_johairieNo ratings yet

- Construction and Building Materials: Tayfun Çiçek, Yasin ÇinçinDocument7 pagesConstruction and Building Materials: Tayfun Çiçek, Yasin ÇinçinInzimam Ul haqNo ratings yet

- ch21 PDFDocument13 pagesch21 PDFRodrigo S QuirinoNo ratings yet

- Fabrication of Water Cooler Cum Air ConditionerDocument3 pagesFabrication of Water Cooler Cum Air Conditionerpramo_dassNo ratings yet

- Carbon Alloy SteelsDocument4 pagesCarbon Alloy SteelsBeyzanur TepecikNo ratings yet

- Concrete Technology (Lab Manual)Document23 pagesConcrete Technology (Lab Manual)VipulShukla100% (3)

- Abandonment of Sewer MainsDocument5 pagesAbandonment of Sewer MainsbarouniamineNo ratings yet

- ISEO IDEA Kw12816 (Base - AntiGerm - DoP - Certifire - CE0497)Document16 pagesISEO IDEA Kw12816 (Base - AntiGerm - DoP - Certifire - CE0497)31863192No ratings yet

- Grade 6 Science Notes Term II Magnets LessonDocument4 pagesGrade 6 Science Notes Term II Magnets LessonShaik Md Shoaib Anas 5A (Shoaib Anas)No ratings yet

- 99 269 Testing of Plastics and Rubber e enDocument56 pages99 269 Testing of Plastics and Rubber e enFerryNo ratings yet

- Mechanics of Materials Equation SheetDocument3 pagesMechanics of Materials Equation SheetAramis Kelkelyan100% (1)

- Company Profile - EskayDocument4 pagesCompany Profile - EskayNarasimha PrasadNo ratings yet

- Ashish Industrial Training ReportDocument31 pagesAshish Industrial Training Reportprosperity facilitationNo ratings yet

- Dr. Shanza Rehan: Eng. Omar Farooq, Dr. FidaDocument23 pagesDr. Shanza Rehan: Eng. Omar Farooq, Dr. FidaMaheenNo ratings yet

- Aisi 4130Document2 pagesAisi 4130Ravi Chaitanya VelamarthyNo ratings yet

- #97753 Bonding Non Metallic Materials Using Indium and High Indium AlloysDocument1 page#97753 Bonding Non Metallic Materials Using Indium and High Indium AlloysEnrico PiccininiNo ratings yet

- Engineering Properties of Reactive Clay Earthworks in SE QueenslandDocument16 pagesEngineering Properties of Reactive Clay Earthworks in SE QueenslandKamesh KumarNo ratings yet

- Bonded Coatings For All Metal Surfaces.: Your Global SpecialistDocument16 pagesBonded Coatings For All Metal Surfaces.: Your Global Specialistghatiyas26No ratings yet

- Mechanical Properties of Solids: (Prepared by Ayyappan C, HSST Physics, GHSS Udma, Kasaragod, Mob: 9961985448)Document4 pagesMechanical Properties of Solids: (Prepared by Ayyappan C, HSST Physics, GHSS Udma, Kasaragod, Mob: 9961985448)sangeetha pNo ratings yet

- Chapter 1: Soft Condensed MatterDocument24 pagesChapter 1: Soft Condensed MatterbyonymousNo ratings yet

- Transport For NSW (TFNSW) Qa Specification 3051 Granular Pavement Base and Subbase MaterialsDocument45 pagesTransport For NSW (TFNSW) Qa Specification 3051 Granular Pavement Base and Subbase MaterialsroshanNo ratings yet

- Phase Transformation in SteelDocument5 pagesPhase Transformation in SteelBobby Yusuf HakaNo ratings yet

- Specific Requirements & Scope of Work For RCC PilingDocument38 pagesSpecific Requirements & Scope of Work For RCC PilingTauqueerAhmadNo ratings yet

- Training Manual Price ListDocument4 pagesTraining Manual Price ListvinviaNo ratings yet

- Reinforced Strip FoundationDocument22 pagesReinforced Strip FoundationGautam PaulNo ratings yet

- Lecture 10 Analysis and Design of Waffle Slabs - 2011Document62 pagesLecture 10 Analysis and Design of Waffle Slabs - 2011José Pablo Rosales Sánchez100% (1)