Professional Documents

Culture Documents

Acct Moi 6 Unitplan Latheoperations

Acct Moi 6 Unitplan Latheoperations

Uploaded by

sanu7bly0 ratings0% found this document useful (0 votes)

11 views9 pagesThere is nothing to upload right now

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThere is nothing to upload right now

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

11 views9 pagesAcct Moi 6 Unitplan Latheoperations

Acct Moi 6 Unitplan Latheoperations

Uploaded by

sanu7blyThere is nothing to upload right now

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 9

PATHWAY: Metals Technology

COURSE: Machining Operations I

UNIT : ACCT!MOI! "athe Operations

Annotation:

In this unit, students will learn the basics of lathe operations. Students will explore lathe applications and

learn essential safety precautions and protocols.

Grade(s):

9

th

X 10

th

X 11

th

X 12

th

Time:

40 Hours

Author:

r. !hesley !ha"bers

Students with Disabilities:

#or students with disabilities, the instructor should refer to the student$s I%& to be sure that the

acco""odations specified are bein' pro(ided. Instructors should also fa"iliari)e the"sel(es

with the pro(isions of *eha(ior Inter(ention &lans that "ay be part of a student$s I%&. #re+uent

consultation with a student$s special education instructor will be beneficial in pro(idin'

appropriate differentiation.

!,-% .esource /etwor0 1achinin' 2perations 1 3 4rades 10512 3 6nit 7 &a'e 1 of 9

- . ! H I , % ! , 6 . % , !2 / S , . 6 ! , I 2 / ,

!2 1 1 6 / I ! - , I 2 / S 8 , . - / S & 2 . , - , I 2 /

GPS Focus Standards:

ACCT-MO-!" Students will #er$orm the $ollowin% o#erations usin% the lathe"

a. Identify the parts of an en'ine lathe

b. !hec0 oil reser(oirs and cuttin' fluid le(els

c. !alculate feeds and speeds for (arious "aterials and "aterial dia"eters

d. Set up a lathe for (arious feeds and speeds.

e. 4rind 'eneral lathe cuttin' tools with a pedestal 'rinder.

f. e"onstrate set5up and ali'n"ent of the tool post.

'. e"onstrate set5up of the three59aw chuc0.

h. &erfor" facin' operations.

i. &erfor" center drillin' operations

GPS Academic Standards:

MM&P'" Students will sol(e #roblems (usin% the a##ro#riate technolo%))

b. *uild new "athe"atical 0nowled'e throu'h proble" sol(in'.

c. -pply and adapt a (ariety of appropriate strate'ies to sol(e proble"s.

SPS*" The students will relate trans$ormations and $low o$ ener%) within a s)stem"

b. In(esti'ate "olecular "otion as it relates to ther"al ener'y chan'es in ter"s of

conduction, con(ection, and radiation.

SPS+" Students will determine relationshi#s amon% $orce, mass, and motion"

a. !alculate (elocity and acceleration.

c. !alculate a"ounts of wor0 and "echanical ad(anta'e usin' si"ple "achines.

-ational . /ocal Standards . ndustr) . ST0:

/I1S, 2SH-, /!!%.

0ndurin% 1nderstandin%s:

.ound ob9ects all ha(e one thin' in co""on: they are lin0ed to an i"a'inary center line. 1any

re(ol(e around that center. ,he lathe has an i"a'inary center line that all the parts "ade on it

should re(ol(e true with the center.

0ssential 2uestions:

If a lathe is used to "a0e the co"ponents of a lathe, then how was the first lathe built;

<hat is a =thin'5a5"a59i'> or a =what5cha5"a5call5it>;

How low does the oil le(el need to be to start da"a'e to a car en'ine;

<hat are the effects of i"proper feeds and speeds on a lathe;

<hy does settin' the feeds and speeds on each indi(idual lathe ha(e to be so co"plicated;

How can a pedestal 'rinder eat the tool;

<hat happens if the tool post is not set at the correct an'le;

<hat would cause a ? 9aw chuc0 not to run true;

How can usin' a 4 9aw chuc0 be "ore accurate than usin' a ? 9aw chuc0;

<hy is facin' so critical;

How is hi'h accuracy achie(ed with lathe turnin';

<hat are the dan'ers of usin' a center drill;

3nowled%e $rom this 1nit:

Students will be able to:

!,-% .esource /etwor0 1achinin' 2perations 1 3 4rades 10512 3 6nit 7 &a'e 2 of 9

Identify the parts of an en'ine lathe.

%xplain the (arious functions of a lathe.

@now the proper oilin' procedure for "achine shop e+uip"ent.

eter"ine proper speeds and feeds for (arious "aterials.

ecide tool an'le for lathe bits.

escribe tool post ali'n"ent for facin' and turnin'.

1a0e clear how a ? 9aw chuc0 wor0s

S4ills $rom this 1nit:

Students will:

!hec0 and fill oil and fluid le(els.

Set up the lathe for desired feed and speed.

!han'e feeds and speeds on the lathe.

&roperly and safely 'rind lathe cuttin' tool.

-li'n cuttin' tool to lathe center.

Install ? 9aw chuc0.

#ace and center drill a part.

Assessment Method T)#e:

&re5test

2b9ecti(e assess"ent 5 "ultiple5choice, true5 false, etc.

AxA Bui))esC,ests

AA 6nit test

4roup pro9ect

x Indi(idual pro9ect

Self5assess"ent 5 1ay include practice +ui))es, 'a"es, si"ulations, chec0lists,

etc.

AA Self5chec0 rubrics

AA Self5chec0 durin' writin'Cplannin' process

AA Dab *oo0

AA .eflect on e(aluations of wor0 fro" teachers, business partners, and co"petition

9ud'es

AA -cade"ic pro"pts

AA &ractice +ui))esCtests

Sub9ecti(e assess"entCInfor"al obser(ations

AA %ssay tests

AA 2bser(e students wor0in' with partners

AA 2bser(e students role playin'

&eer5assess"ent

AA &eer editin' 8 co""entary of productsCpro9ectsCpresentations usin' rubrics

AA &eer editin' andCor criti+uin'

ialo'ue and iscussion

AA StudentCteacher conferences

AA &artner and s"all 'roup discussions

AA <hole 'roup discussions

AA Interaction withCfeedbac0 fro" co""unity "e"bersCspea0ers and business partners

!onstructed .esponses

AA !hart 'ood readin'Cwritin'Clistenin'Cspea0in' habits

AA -pplication of s0ills to real5life situationsCscenarios

&ost5test

Assessment Attachments and . or Directions:

-O-0

!,-% .esource /etwor0 1achinin' 2perations 1 3 4rades 10512 3 6nit 7 &a'e ? of 9

3 /0SSO- ': /athe denti$ication and Maintenance

1. Identify the standards. Standards should be posted in the classroo".

ACCT-MO-!" Students will #er$orm the $ollowin% o#erations usin% the lathe"

a. Identify the parts of an en'ine lathe

b. !hec0 oil reser(oirs and cuttin' fluid le(els

c. !alculate feeds and speeds for (arious "aterials and "aterial dia"eters

d. Set up a lathe for (arious feeds and speeds.

e. 4rind 'eneral lathe cuttin' tools with a pedestal 'rinder.

f. e"onstrate set5up and ali'n"ent of the tool post.

'. e"onstrate set5up of the three59aw chuc0.

h. &erfor" facin' operations.

i. &erfor" center drillin' operations

2. .e(iew %ssential Buestions. &ost %ssential Buestions in the classroo".

If a lathe is used to "a0e the co"ponents of a lathe, then how was the first lathe built;

<hat is a =thin'5a5"a59i'> or a =what5cha5"a5call5it>;

How low does the oil le(el need to be to start da"a'e to a car en'ine;

<hat are the effects of i"proper feeds and speeds on a lathe;

<hy does settin' the feeds and speeds on each indi(idual lathe ha(e to be so co"plicated;

How can a pedestal 'rinder eat the tool;

<hat happens if the tool post is not set at the correct an'le;

<hat would cause a ? 9aw chuc0 not to run true;

How can usin' a 4 9aw chuc0 be "ore accurate than usin' a ? 9aw chuc0;

<hy is facin' so critical;

How is hi'h accuracy achie(ed with lathe turnin';

<hat are the dan'ers of usin' a center drill;

?. Identify and re(iew the unit (ocabulary. ,er"s "ay be posted on word wall.

!o"pound rest Headstoc0 Indexable insert cuttin' tool

#acin' 2 turnin' Sin'le5point cuttin' tool

,ailstoc0 ,ool post Di(e center

ead center ? 9aw chuc0 4 9aw chuc0

Dathe do' Dathe centerline !enter drill

4. Introduction:

Doo0 around and ta0e notice of all the round ob9ects. ,here are li'ht bulbs, door 0nobs, and

wheels 9ust to na"e a few. ,he thin' that all these ha(e in co""on is they see" to be lin0ed to

an i"a'inary center line.

Eou and a partner are assi'ned the tas0 of puttin' to'ether so"e play'round e+uip"ent for your

local recreation center.

Fust one s"all proble", you and your partner does not spea0 the sa"e lan'ua'e. /ot e(en

close. It will ta0e both of you to put it to'ether.

How would you proceed with the asse"bly;

!,-% .esource /etwor0 1achinin' 2perations 1 3 4rades 10512 3 6nit 7 &a'e 4 of 9

,he first ti"e you see a lathe, you probably donGt ha(e a clue what it is. Eou ha(e to learn the

parts of it before learnin' how to use it. Eou are learnin' the ="achine shop lan'ua'e>. Eou "ust

practice, practice, and practice so"e "ore.

H. Desson:

4i(e a brief introduction to the lathe and its uses. Ha(e so"e parts to show what can be "ade

with it.

Show the followin' (ideo on =*asic <ood Dathe 2perations>

http://www.youtube.com/watch?v=nk_rGxOZhZM

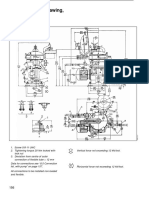

Show the /athe O#erations PowerPoint.

%xplain safety precautions and tips.

.e(iew the parts of a lathe. %xplain the functionIsJ of each part.

.e(iew oil and "aintenance procedures.

.e(iew Safety &rocedures:

o Stand to the side of the chuc0.

o o not lea(e the chuc0 0ey in the chuc0.

o ,uc0 in loose clothin' and hair.

o -(oid distractions.

7. -cti(ity:

Show the followin' (ideo on =Identification of Dathe &arts>

http://www.youtube.com/watch?v=tn7A9P!"t#

6se the /athe Part denti$ication Sheet to identify the parts of the lathe.

Ha(e each student identify and touch all correspondin' parts of the lathe.

Ha(e the" turn the 0nobs to see how they wor0.

!hec0 oil le(els and inspect for da"a'e.

K. Su""ary:

It is a 'ood thin' that the instructions for the play'round are in "any different lan'ua'es. It ta0es

a little while to learn the lan'ua'e, but the "ore you practice, the better you will be at it.

3 /0SSO- 5: Calculatin% Feeds and S#eeds

1. Introduction:

2n the ,L show =Ice .oad ,ruc0ers>, when "a0in' the cli"b up a steep icy road, they "ust

ha(e the truc0 in the correct 'ear usin' the ri'ht a"ount of .&1.

If this for"ula is not correct then it could lead to disaster.

Ha(in' the lathe set for the correct .&1 and feed rate is (ery i"portant.

If this is not correct you are li0ely to 0ill your part.

2. Desson and -cti(ity:

,he correct .&1 for "achinin' will i"pro(e the life of the cuttin' tool and help pre(ent da"a'e

to the part bein' "achined. e"onstrate how to find .&1 for (arious typesG "etals. Ha(e

students co"plete Calculatin% Feeds and S#eeds 6or4sheet. ,hen, set the "achine to that

specific .&1 alon' with rou'hin' and finishin' feed rate.

?. Su""ary:

How is the correct 'ear and .&1 selected for the Ice .oad ,ruc0ers; ,his (aries fro" truc0 to

truc0. %xperience plays a bi' roll in the selection.

2ne 'ood way to tell if you ha(e the correct feed and speeds is when the cut is finished you

should be able to touch the part without it burnin' you. ,he heat should co"e out with the chips.

!,-% .esource /etwor0 1achinin' 2perations 1 3 4rades 10512 3 6nit 7 &a'e H of 9

3 /0SSO- 7: Selectin% Cuttin% Tools and Set 1#

1. Introduction:

4olfin' is a hi'h tech sport. 1any thin's will help i"pro(e your 'a"e, such as custo" fitted

clubs. 6sin' the correct club for the particular shot is i"portant. Eou donGt ha(e 9ust 1 club you

use for all the shots.

,his is the sa"e for "achinin'. ependin' on the situation, selectin' the correct cuttin' tool is

i"portant.

2. Desson:

,here are 2 co""on types of lathe cuttin' tools: carbide and hi'h speed steel.

<ithin these two, there are "any different "a0e ups of the cutters. 1ost all "achinin' text boo0s

show the (ariety of cutters and their uses.

,he hi'h speed steel cutters ha(e to be 'round to the appropriate shape for the particular

application.

,he carbide inserted cutters are "ore affecti(e than the hi'h speed cutters and last "uch lon'er.

,he insert is rotated for "ultiple uses. ,hese are easily chipped and da"a'ed if not used

properly.

#or be'innin' "achinin', the hi'h speed steel cutters are "ore durable.

?. Show the followin' (ideo on =Dathe Safety>

http://www.ehow.com/v$%eo_&9&'9()_*athe+,a"ety.htm*

4. .e(iew safety procedures for "etal wor0in' lab usin' the Sa$et) Chec4list 8andout.

H. Ha(e students co"plete the Turnin% and Facin% O#erations 6or4sheet before wor0in' with

tools.

7. e"onstrate the proper 'rindin' techni+ue for: rou'hin' cutter, facin' cutter, and finishin' cutter.

K. e"onstrate how to set the cutter for: turnin' and facin' operations. - (ery i"portant step is to

"a0e sure the cutter cuttin' tip hei'ht is on the lathe (ertical center line.

M. -cti(ity:

Ha(e students practice sharpenin' a lathe cutter.

Instead of usin' a lathe cutter for practice, use carbon steel s+uare stoc0. ,his is "uch cheaper

than hi'h speed steel cutters.

Ha(e students practice settin' up the cutter for turnin' and facin'. !hec0 to "a0e sure the

cutter is (ertical centered.

9. Su""ary:

@nowin' which 'olf club to use for each shot will "a0e you loo0 li0e you 0now what you are

doin'.

,his builds confidence.

@nowin' which cutter and how to set it up will i"pro(e your production and possible 'et you a

pay raise or better class 'rade.

3 /0SSO- &: Three-9aw Chuc4

1. Introduction:

!,-% .esource /etwor0 1achinin' 2perations 1 3 4rades 10512 3 6nit 7 &a'e 7 of 9

6sin' the ? 9aw chuc0 is one of the easiest ways to chuc0 a part in the lathe.

I"a'ine tryin' to pour water fro" a H 'allon buc0et into a 20 o) bottle without a funnel. It "a0es

a "ess.

,he ? 9aw chuc0 would be li0e ha(in' a lar'e funnel to use. ItGs that si"ple.

2. Desson:

,he ? 9aw chuc0 is desi'ned that all 9aws operate at the sa"e ti"e.

,his auto"atically centers round or hexa'onal shaped stoc0.

1ost chuc0s ha(e re(ersible 9aws to acco""odate for different part chuc0in' needs.

,he 9aws need to be clean of debris before chuc0in' the part. If debris is between the part and

chuc0, the part will run off center.

6se a dial indicator to chuc0 for run out. If there is a sli'ht run out, it can be ad9usted by tappin'

the part with a ha""er.

6se a tail stoc0 when the part is out fro" the chuc0 "ore than a few inches. ,his is for safety

and will increase the +uality of cut.

?. e"onstrate how to install a ? 9aw chuc0 onto the lathe.

e"onstrate the re"o(al and installation of the chuc0 9aws.

6se a dial indicator to chec0 for run out.

!huc0 to the outside of a round part.

!huc0 to the outside of a hexa'onal part.

!huc0 to the inside of a pipe.

4. -cti(ity:

Ha(e the students:

o Install a ? 9aw chuc0 onto the latheN

o .e"o(e and install chuc0 9awsN

o 6se a dial indicator to chec0 for run outN

o !huc0 to the outside of a round partN

o !huc0 to the outside of a hexa'onal partN

o !huc0 to the inside of a pipe.

H. Su""ary:

,he ? 9aw chuc0 "a0es chuc0in' a part easy as lon' at the chuc0 is in 'ood operatin' shape

and clean of debris. If not, itGs (ery difficult to use and be accurate. Di0e not usin' a funnel to

pour oil in the car, it "a0es a "ess.

3 /0SSO- :: Four-9aw Chuc4

1. Introduction:

6sin' a 4 9aw chuc0 so"eti"es is li0e tryin' to put a s+uare pe' into a round hole. Eou "ay

thin0 it will ne(er be center. So"eti"es you ha(e to stop, re"o(e the part, and start o(er.

2. Desson:

2n a four 9aw chuc0, each 9aw operates independently.

,his allows for cla"pin' irre'ular shapes and offset turnin'.

,hese 9aws can be re"o(ed fro" their slots and be re(ersed easily.

!enterin' the wor0 is achie(ed by ad9ustin' each 9aw independently while usin' an indicator to

chec0 center.

<hen one 9aw is "o(ed, the opposite 9aw is affected. ItGs li0e a 'a"e of pin5pon'.

%ach 9aw needs to sli'htly ad9ust until the part is runnin' true.

!,-% .esource /etwor0 1achinin' 2perations 1 3 4rades 10512 3 6nit 7 &a'e K of 9

S+uare stoc0 is centered "uch the sa"e way. ,he indicator rod needs to be pulled bac0 before

rotatin' to the next side. @eep note to the indicator .100 readin' "ar0s, so the part want be off

by incre"ents of .100.

?. -cti(ity:

Ha(e the students practice usin' a dial indicator to:

o !enterin' round stoc0 within .002

o !enterin' s+uare stoc0 within .002

4. Su""ary:

&atience and persistence is the 0ey. If you ha(e finally centered the part in the 4 9aw chuc0, be

proud of yourself. Eou "i'ht e(en choose to ha(e a contest to see who can center a part the

+uic0est.

3 /0SSO- !: Drillin% O#erations

1. Introduction:

rillin' on the lathe is li0e turnin' a drill press on its side, cla"pin' the drill bit in the (ise,

"ountin' the part in the chuc0, then drillin' the hole. ,hatGs how weird it is drillin' with a lathe.

2. Desson:

rillin' on the lathe is si"ilar to drillin' on a drill press.

,he "a9or difference is the part spins instead of the drill.

Dathe drillin' ta0e "ore ti"e than drill press drillin'.

,he .&1 is calculated the sa"e as with other drillin'.

,o drill in the center of the part, start with a center drill.

,he proper dept is about 2C? up the tapered shoulder.

If drilled up to the flat, the next drill will not center as well.

,his locates the center line of the "achine.

,he .&1 need to be hi'her and cuttin' fluid needs to be used for this operation.

?. -cti(ity:

e"onstrate and then ha(e students practice:

o Set up a part to center drill and drill. 6se coolant and drill with center drill.

o rill with a O> drill. 4o up to P> drill in the sa"e hole. 4o up to 1> drill in the sa"e hole.

o <hen the drill starts to 'o throu'h the end of the part, reduce the pressure on the drill.

o /otice the .&1 difference between each drill si)e.

4. Su""ary:

-fter drillin' for a while with the lathe, itGs not so weird after all. It is 0ind of li0e watchin' ,L lyin'

down instead of sittin' up.

3 ATTAC8M0-TS FO; /0SSO- P/A-S:

/athe O#erations PowerPoint

/athe Part denti$ication Sheet

/athe Part denti$ication Sheet Answer 3e)

Calculatin% Feeds and S#eeds 6or4sheet

Sa$et) Chec4list 8andout

Turnin% and Facin% O#erations 6or4sheet

3 -OT0S < ;0F/0CTO-:

!,-% .esource /etwor0 1achinin' 2perations 1 3 4rades 10512 3 6nit 7 &a'e M of 9

6se softer "aterials such as wood, alu"inu", and plastic to help reduce tool da"a'e. <ith the

Sa$et) Chec4list 8andout and the Turnin% and Facin% O#eration Practice 6or4sheet, chec0in'

students wor0 and si'nin' their na"e to a list after they ha(e co"pleted their wor0 will help reduce

later co"plications later in the unit. It will ensure the student 0nows what heCshe is doin'.

Culminatin% 1nit Per$ormance Tas4 Title:

,each 8 e"onstrate S0ill

Culminatin% 1nit Per$ormance Tas4 Descri#tion.Directions.Di$$erentiated nstruction:

,eachers should write tas0s learned on slips of paper and put into hat. Students should draw a tas0

and =teach 8 de"onstrate> s0ill. 6se the S4ill ;ubric to 'rade students.

Attachments $or Culminatin% Per$ormance Tas4:

S4ill ;ubric

6eb ;esources:

*asic <ood Dathe 2perations http://www.youtube.com/watch?v=nk_rGxOZhZM

Dathe &arts http://www.youtube.com/watch?v=tn7A9P!"t#

Dathe Safety http://www.ehow.com/v$%eo_&9&'9()_*athe+,a"ety.htm*

Materials < 0=ui#ment:

&ro9ection %+uip"ent

!o"puter with Internet access

Dathe

1achinin' oil

Hand tools

!alculators

5'

st

Centur) Technolo%) 1sed:

x Slide Show Software 4raphin' Software -udio #ileIsJ

Interacti(e <hiteboard x !alculator 4raphic 2r'ani)er

Student .esponse Syste" es0top &ublishin' I"a'e #ileIsJ

<eb esi'n Software *lo' x Lideo

-ni"ation Software <i0i %lectronic 4a"e or &u))le 1a0er

%"ail x <ebsite

!,-% .esource /etwor0 1achinin' 2perations 1 3 4rades 10512 3 6nit 7 &a'e 9 of 9

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Spring-Supported Thrust BearingsDocument4 pagesSpring-Supported Thrust BearingsZoebairNo ratings yet

- International Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsDocument9 pagesInternational Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsZoebairNo ratings yet

- Structures and Mechanisms ClassificationsDocument1 pageStructures and Mechanisms ClassificationsminakirolosNo ratings yet

- Installation and Operating Procedures: Manual Grease InterceptorsDocument8 pagesInstallation and Operating Procedures: Manual Grease InterceptorsZoebairNo ratings yet

- Indigenous ManufacturersDocument6 pagesIndigenous ManufacturersZoebairNo ratings yet

- Datasheet TurbineDocument2 pagesDatasheet TurbineZoebairNo ratings yet

- 8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0Document1 page8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0ZoebairNo ratings yet

- Construction Specification 71-Water Control Gates: Instructions For UseDocument2 pagesConstruction Specification 71-Water Control Gates: Instructions For UseZoebairNo ratings yet

- Hy 25 ValvesDocument3 pagesHy 25 ValvesZoebairNo ratings yet

- CEE 331: Fluid Mechanics, Homework Set 2, SolutionsDocument7 pagesCEE 331: Fluid Mechanics, Homework Set 2, SolutionsZoebairNo ratings yet

- DAMS CFD ModellingDocument2 pagesDAMS CFD ModellingZoebairNo ratings yet

- Pennsylvania: Lehigh University'Document5 pagesPennsylvania: Lehigh University'ZoebairNo ratings yet