Professional Documents

Culture Documents

Design (Imperial) 7.23

Design (Imperial) 7.23

Uploaded by

Pol Cesar Vega ChavezCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Jack Up Rig Design PDFDocument91 pagesJack Up Rig Design PDFAhmed Rehim50% (2)

- GP 110: Engineering Mechanics Dynamics of Particles: Problem Sheet 2Document3 pagesGP 110: Engineering Mechanics Dynamics of Particles: Problem Sheet 2Crypto Faucet100% (1)

- Small Clear Specimens of Timber: Standard Test Methods ForDocument31 pagesSmall Clear Specimens of Timber: Standard Test Methods ForCaro ChasipantaNo ratings yet

- Forensic Sci Bibliography, ExplosivesDocument4 pagesForensic Sci Bibliography, ExplosivesSusan ColemanNo ratings yet

- Crane SpecififctaionDocument2 pagesCrane SpecififctaionGandhi elumalaiNo ratings yet

- 1 s2.0 S0041624X21002389 MainDocument7 pages1 s2.0 S0041624X21002389 MainMohamedNo ratings yet

- DR.M.G.R Educational and Research Institute University: Entrance Examination For PH.D Admission (March 2012)Document3 pagesDR.M.G.R Educational and Research Institute University: Entrance Examination For PH.D Admission (March 2012)Krishna ChaitanyaNo ratings yet

- SHAFT Couplings - Catalogue - 2Document448 pagesSHAFT Couplings - Catalogue - 2Tom TamponNo ratings yet

- Abstracts Book 23rd PAC ConferenceDocument219 pagesAbstracts Book 23rd PAC ConferenceJeroenNo ratings yet

- Magnetic CircuitDocument4 pagesMagnetic CircuitBea Monique RoblesNo ratings yet

- Lecture 17 - Signalized Intersection DelayDocument34 pagesLecture 17 - Signalized Intersection DelayBasoz Arif AhmadNo ratings yet

- Definition of Chi-Square TestDocument8 pagesDefinition of Chi-Square TestDharshu Rajkumar100% (1)

- PropCalc ManualDocument5 pagesPropCalc ManualDemetrio Hinojosa ENo ratings yet

- Biswas 2011Document6 pagesBiswas 2011brar_harmanpreet01No ratings yet

- Fluid Mechanics 2 - Practical 1 Discharge Through An OrificeDocument13 pagesFluid Mechanics 2 - Practical 1 Discharge Through An OrificeShivesh Sohawan50% (4)

- Projeto Hover CraftDocument85 pagesProjeto Hover CraftTomas Hermes SbrisseNo ratings yet

- 17 4ph PDFDocument1 page17 4ph PDFMalavikaVarmaNo ratings yet

- Chapter 6 PID ControlDocument56 pagesChapter 6 PID ControlHana Muhammad100% (1)

- Refrigeration and Air-Conditioning - Unit 4 - Week-3Document4 pagesRefrigeration and Air-Conditioning - Unit 4 - Week-3Kali DassNo ratings yet

- ASDA A2 ManualDocument583 pagesASDA A2 ManualClaudio Lourenço da Silva100% (1)

- Product Line Horiba - Te 01-06-2014 v2 0Document36 pagesProduct Line Horiba - Te 01-06-2014 v2 0Carlos PalominoNo ratings yet

- Theodolite Field Observation Data and Its Calculation: Corrected Interior Angle BearingsDocument2 pagesTheodolite Field Observation Data and Its Calculation: Corrected Interior Angle BearingsSuman JyotiNo ratings yet

- CVof BsebsuDocument12 pagesCVof Bsebsubsebsu7901100% (3)

- The Bacterial FlagellumDocument1 pageThe Bacterial Flagellummferra100% (1)

- CapacitorDocument296 pagesCapacitorTomtopNo ratings yet

- Training On Dry Fog Dust Suppression SystemDocument10 pagesTraining On Dry Fog Dust Suppression SystemPriyatham GangapatnamNo ratings yet

- Midterm Review 2012-2013Document7 pagesMidterm Review 2012-2013Demi YangNo ratings yet

- R19 2019 20 Mechanical Engineering-1-134Document134 pagesR19 2019 20 Mechanical Engineering-1-134Praneeth RubenNo ratings yet

- Descriptive Statistics W2Document29 pagesDescriptive Statistics W2Khusairi AnwarNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityPARMAR MAHENDRANo ratings yet

Design (Imperial) 7.23

Design (Imperial) 7.23

Uploaded by

Pol Cesar Vega ChavezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design (Imperial) 7.23

Design (Imperial) 7.23

Uploaded by

Pol Cesar Vega ChavezCopyright:

Available Formats

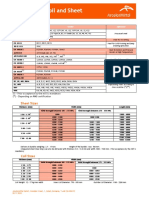

Specifier Sheet and Recommendation Summary

e-mail

Conveyor Length (ft) 100 7.3 HP

Tonnage Rate (tons/hour) 500

Belt Speed (fpm) 300 Force (lbs)

Standard Loading Belt Pull 731

Ambient temperature (F) Min -10 Extra pull for Hopper (if any)

Ambient temperature (F) Max 100 Extra pull for Slider Bed (if any)

Extra pull for Diverter or Tripper (if any)

Number of Belt Cleaners 1 TOTAL Required Belt Pull (Te): 731

Number of Return Belt Scrapers

Length of Skirt Zone (ft) 12

3

Number of Non-driven Pulleys 4

Elev. Above Sea Level (ft) 3300 ft

Minimum allowable belt width for lump size is 12 in

Minimum Acceptable Diameter is 10 in. *

Size Consist

Max. Lump Size (in) 2 *A smaller pulley diameter may cause belt carcass or fastener damage.

25 deg.

Belt Width 36 in Power: 7.5HP

Belt Carcass Type Fabric Belt Speed: 300 FPM

Idler Roll diameter 5 in Face Width: 37.4 in.

C

Troughing Idler Spacing 4 ft

Type of Lagging Power: 5.5 HP/each

Type of Take-up Belt Speed: 300 FPM

Type of Belt Face Width: 37.4 in.

Power savings - 1 shift and 3 shift per day:

(Motorized Pulley compared to exposed motor, gearbox, V-belt conveyor drives)

Save: 1180 Kw-Hrs/Yr, 1 shift/day or 3541 Kw-Hrs/Yr, 3 shifts/day

** This parameter is for either single or dual drive arrangement. Save: $94 /Yr, 1 shift/day or $283 /Yr, 3 shifts/day @ $0.08/Kw-Hr

4. Sidewall & Cleated Belt Parameters:

Sidewall & cleat height (in)

Thickness of sidewall (in)

Distance between cleats (in)

Thickness of cleats (in)

Extra Sidewall & Cleat Wt (incl above)

1. Hopper Feeder Design Parameters

Hopper opening width (in) 5. Tripper Design Parameters

Hopper opening length (in) Tripper length (ft)

Number of Hopper Openings Material lift height on tripper (ft)

2. Slider Bed Design Parameters No. of belt cleaners on tripper

Slider Bed Length (ft) Length of tripper skirt zone (ft)

Type of Slider Bed Material None Depth of material in skirt zone (in)

Slider Bed Frictional Coefficient No. of non-driven pulleys on tripper

Estimated belt tension, Te (lbs)

3. Drive Pulley Location ("return run" drive only) Estimated factor, Ky 0.03

Conveyor Length, tail to drive snub (ft)

Height, top of tail to bottom of drive (ft) 6. Material Diverter (Belt Plow)

No. of diverters that work simultaneously

05/20/14

Date

Mat'l, friction coeff Limestone, pulv.,dry, 0.128

Bulk Density (pcf)

6508-B Windmill Way

Wilmington, NC 28405

Special Loading Conditions:

Material Flow

Project Name

Telephone

Standard Loading Conditions:

Condition of Idlers & Pulleys well maintained

Angle of Wrap**

1. For hopper feeder specify opening dimensions below.

Elevating or Horizontal

Copyright - Rulmeca Corp.

Depth of Mat'l in skirt zone (in)

Material Surcharge Angle

5. If conveyor has a tripper, define tripper below.

4. If belt has cleats and/or sidewalls show dimensions below.

2. For slider bed, specify bed length & type of bed mat'l below.

6. If conveyor has diverter(s), define below.

220, 320, 400, 500, 630

CEMA Type

Drive Location

3. If belt is driven on return run, specify drive pulley location.

180 degrees

Full Lagging

SPECIAL NOTES:

Models Available:

RECOMMENDED OPTIONS:

www.rulmecacorp.com

Conveyor Reference

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23

Material Lift Height (ft)

Initial Velocity of Material (fpm)

Telefax

Ph 910-794-9294

Fax 910-794-9296

RECOMMENDED "DUAL DRIVE" MOTORIZED PULLEY:

Models Available:

220, 320, 400, 500

RECOMMENDED "SINGLE DRIVE" MOTORIZED PULLEY:

REQUIRED POWER:

BELT PULL SUMMARY:

Head

none Type of Dual Drive, if any

Manual

Limestone, crushed, 90 pcf

2 ply, 225 piw

Avg is 50% Max Lump Size

\\vboxsrv\conversion_tmp\scratch_6\229681129.xls.ms_office, Specifier, Page 1 of 8 5/20/2014 2:46 PM

Model Selector

REQUIRED POWER:

BELT PULL SUMMARY:

Standard Loading Belt Pull

Extra pull for Hopper (if any)

Extra pull for Slider Bed (if any)

Extra pull for Diverter or Tripper (if any)

TOTAL Required Belt Pull (Te):

RECOMMENDED OPTIONS (if any):

Minimum allowable belt width for lump size is 12 in

Minimum Acceptable Diameter is 10 in. *

*A smaller pulley diameter may cause belt carcass or fastener damage.

RECOMMENDED "SINGLE DRIVE" MOTORIZED PULLEY:

Te, effective belt tension

T2, to prevent belt/pulley slippage

T2, to limit belt sag to 2 %

T1, maximum belt tension

**Measured at Drive A in Dual Drive, if applicable.

Calculation for "Dual Drive on Carry Side" is under construction.

RECOMMENDED "DUAL DRIVE" MOTORIZED PULLEY:

Models Available:

Models Available:

Check Maximum Belt Tension (to

prevent belt damage)

300 FPM

220, 320, 400, 500, 630

7.3 HP

731

Force (lbs)

Check Radial Load (to prevent

internal damage to pulley)

Check Pulley Diameter

(to prevent belt damage.)

731

Power:

Belt Speed:

Face Width:

5.5 HP/each

300 FPM

Telephone Telefax

SPECIAL NOTES (if any):

Project Name

Face Width:

7.5HP

320M

Belt Tension Calculation Summary

e-mail

Fax 910-794-9296

Ph 910-794-9294

Select Model

Maximum Allowable Radial Load

Minimum Acceptable Diameter is 10 in.

Selected Diameter is 12.64 in

Selected diameter is appropriate for specified belt.

37.4 in.

Power:

Belt Speed:

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23

05/20/14

Date

2,366 Maximum Belt Tension (T1)

Allowable Fabric Belt Tension

6508-B Windmill Way

Wilmington, NC 28405

www.rulmecacorp.com

Copyright - Rulmeca Corp.

8,100

Force (lbs)

731

Force (lbs)

Selected model is appropriate for estimated radial load.

Estimated Maximum Radial Load**

220, 320, 400, 500

Conveyor Reference

Force (lbs)

4,496

4,001

37.4 in.

585

1,635

2,366

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23

Bulk Handling Trajectory Calculator and Plotter

5/20/14

Date

Phone Fax

Project Name

Conveyor Ref.

System Design Parameters:

Belt Width 36 in

Troughing Idler Angle 35

Diameter Pulley (in) 13.26 in

Lagging Thickness (in) 0.31 in

Belt Speed 300 fpm

25 deg.

Tonnage Rate (TPH) 500

Material Density (pcf) 90

Belt Thickness (in) 0.75

Distance to Chute Plate (in) 24

Angle of Conv. Inclination (deg)

Alternate Belt Speed (fpm) 350

Design Trajectory - red line; Alternate speed - blue.

Calculated Results:

Calc'd mat'l height at centerline 5 in

Calc'd actual height of C.O.G.* 2 in

84.7 sq ft

CEMA Max Allow. height at center 7 in

CEMA Max Height of C.O.G.* 3 in

CEMA Max Allow. cross section 152.6 sq ft

Note:

This program uses actual C.O.G.* height above

top of belt (based on actual cross section) to plot

trajectory. Height of C.O.G. for CEMA

max. allow. cross section is given for ref. only. Design Cross Section - red line; CEMA max allow. - black line.

*C.O.G. = center of gravity of material, shown as and

(based on CEMA 5th Edition)

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

Calc'd actual mat'l cross section

www.rulmecacorp.com

Copyright - Rulmeca Corp.

Surcharge Angle

-3

0

3

6

9

-

1

8

-

1

5

-

1

2

-

9

-

6

-

3

03691

2

1

5

1

8

Mat'l Cross Section at Pulley Face:

Small Pulley (scale: inches)

-24

-21

-18

-15

-12

-9

-6

-3

0

3

6

9

12

15

18

-

2

7

-

2

4

-

2

1

-

1

8

-

1

5

-

1

2

-

9

-

6

-

3

03691

2

1

5

1

8

2

1

2

4

2

7

3

0

3

3

3

6

3

9

Material Trajectory:

Small Pulley (scale: inches)

\\vboxsrv\conversion_tmp\scratch_6\229681129.xls.ms_office, trajectory, Page 3 of 8 5/20/2014 2:46 PM

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23

Material Cross Section Plotter

Reference Name

Conveyor Number

System Design Parameters:

Tonnage Rate (tph) 500

Belt Speed (fpm) 300

Bulk Density (lbs/cu ft) 90

Material Surcharge Angle

25 degrees

Belt Width

36 in.

Idler Angle

35 degrees

Material Geometry in Troughing Idler:

CEMA Max. Allow. Cross Section 1.1 sq ft

Calculated Cross Section 0.6 sq ft

Calc'd Xsec/CEMA Xsec 58%

CEMA Standard Edge Distance 2.9 in

Calculated Edge Distance 6 in

Calc'd Material Height at Centerline 5.4 in

Material Geometry at Pulley Discharge:

Calculated Cross Section 0.6 sq ft

Material Height at Centerline 4.4 in

Height of Center of Gravity (A1) 1.8 in

Assumed Edge Distance 3.02 in

Calculated Surcharge Angle 33 deg

CEMA Max. Allow height at center 6.6 in.

CEMA Max Height of C.O.G. 2.7 in.

CEMA Standard Edge Distance 1.44 in

Note:

This program calculates height of actual C.O.G.*

by assuming that actual edge distance at pulley

face equals 1/2 of actual edge distance in troughed

section. Height of C.O.G.* for CEMA maximum

allowable cross section pulley face is given for

reference only.

* C.O.G. = center of gravity of material

Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

Phone Fax

www.rulmecacorp.com

Copyright - Rulmeca Corp.

Fax 910-794-9296

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

5/20/14

Date

1.80

2.7

-3

0

3

6

9

-

1

8

-

1

5

-

1

2

-

9

-

6

-

3

03691

2

1

5

1

8

Cross Section at Pulley Face:

Narrow Belt (scale: inches)

-3

0

3

6

9

12

15

-

1

5

-

1

2

-

9

-

6

-

3

03691

2

1

5

Cross Section at Troughing Idler:

Narrow Belt (scale: inches)

\\vboxsrv\conversion_tmp\scratch_6\229681129.xls.ms_office, Page 4 of 8 5/20/2014 2:46 PM

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23

Material Cross Section Plotter

Reference Name

Conveyor Number

System Design Parameters:

Tonnage Rate (tph) 500

Belt Speed (fpm) 300

Bulk Density (lbs/cu ft) 90

Material Surcharge Angle

25 degrees

Belt Width

36 in.

Idler Angle

35 degrees

Material Geometry in Troughing Idler:

CEMA Max. Allow. Cross Section 1.1 sq ft

Calculated Cross Section 0.6 sq ft

Calc'd Xsec/CEMA Xsec 58%

CEMA Standard Edge Distance 2.9 in

Calculated Edge Distance 6 in

Calc'd Material Height at Centerline 5.4 in

Material Geometry at Pulley Discharge:

Calculated Cross Section 0.6 sq ft

Material Height at Centerline 4.4 in

Height of Center of Gravity (A1) 1.8 in

Assumed Edge Distance 3.02 in

Calculated Surcharge Angle 33 deg

CEMA Max. Allow height at center 6.6 in.

CEMA Max Height of C.O.G. 2.7 in.

CEMA Standard Edge Distance 1.44 in

Note:

This program calculates height of actual C.O.G.*

by assuming that actual edge distance at pulley

face equals 1/2 of actual edge distance in troughed

section. Height of C.O.G.* for CEMA maximum

allowable cross section pulley face is given for

reference only.

* C.O.G. = center of gravity of material

Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

Fax

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Phone

www.rulmecacorp.com

Copyright - Rulmeca Corp.

Fax 910-794-9296

5/20/14

Date

1.80

2.7

-6

0

6

12

18

-

4

8

-

4

2

-

3

6

-

3

0

-

2

4

-

1

8

-

1

2

-

6

061

2

1

8

2

4

3

0

3

6

4

2

4

8

Cross Section at Pulley Face:

Wide Belt (scale: inches)

-6

0

6

12

18

24

30

36

42

-

4

2

-

3

6

-

3

0

-

2

4

-

1

8

-

1

2

-

6

061

2

1

8

2

4

3

0

3

6

4

2

Cross Section at Troughing Idler:

Wide Belt (scale: inches)

\\vboxsrv\conversion_tmp\scratch_6\229681129.xls.ms_office, Page 5 of 8 5/20/2014 2:46 PM

Design Parameter Summary

e-mail

Calculated power to drive conveyor belt: 6.6 HP

Drive pulley bearing friction: 0.2 HP

Power at motor: 6.9 HP

Gear loss in motorized pulley: 0.4 HP

Calculated power 7.3 HP

Derate for high elevation HP

Derate for high temperature HP

Required Power for motorized pulley: 7.3 HP

Symbol Value Definition of Terms

Te 731 lbs Te = effective belt tension at drive.

ang 180 degrees ang = angle of belt wrap around drive pulley(s).

Cw 0.8 Cw = "wrap factor", to determine slack side tension to prevent belt slippage on drive pulley.

T2 1635 lbs.

T1 2366 lbs T1 = Te + T2

T1 + T2 4001 lbs T1 + T2 = Sum of belt forces on drive pulley. NOTE: This is not a vector sum.

T_L Full Lagging T_L = type of lagging specified for drive pulley(s).

Tatype Manual Tatype = type of take-up specified to apply "slack-side tension".

Beltype 2 ply, 225 piw Beltype = type of belt carsass specified.

w 36 in. w = belt width

str 8100 lbs.

pstr 16 % pstr = percentage of available belt tensile strength used.

btr 3/16 to 7/16 in. btr = thickness range of specified belt

Ai 1.8 lbs Ai = belt tension required to overcome frictional resistance and rotate idlers.

Cs 0.128 Cs = skirtboard friction factor.

H 0 ft H = vertical distance that material is lifted or lowered.

Kt 1.59 Kt = ambient temperature correction factor.

Kx 0.49 lbs/ft

Ky 0.04 Ky = factor to calculate resistance of belt and resistance of load to flexure as they move over idlers.

L 100 ft L = length of conveyor.

Q 500 tph Q = tons per hour conveyed.

Si 4 ft Si = troughing idler spacing.

Tac 266 lbs Tac = total of the tensions from conveyor accessories.

Tam 43 lbs Tam = tension required to accelerate the material continuously as it is fed onto belt.

Tb 0 lbs Tb = tension required to lift or lower the belt.

Tbc 180 lbs Tbc = tension required to overcome belt cleaner drag.

Te 731 lbs Te = effective belt tension at drive.

Tm 0 lbs Tm = tension required to lift or lower conveyed material.

Tp 78 lbs

Tpl 0 lbs Tpl = tension required to overcome belt plow drag.

Tsb 86 lbs Tsb = tension required to overcome skirtboard drag.

Ttr 0 lbs Ttr = tension required to overcome special loading condition(s.)

Tx 78 lbs Tx = tension required to overcome carrying and return idler friction.

Tyb 71 lbs Tyb = total of tensions due to resistance of belt to flexure as it rides over carrying and return idlers.

Tyc 50 lbs Tyc = tension due to resistance of belt to flexure as it rides over carrying idlers.

Tym 194 lbs Tym = tension due to resistance of material to flexure as it rides over carrying idlers.

Tyr 21 lbs Tyr = tension due to resistance of belt to flexure as it rides over return idlers.

V 300 fpm V = design belt speed.

Wb 9 lbs/ft Wb = weight of belt per unit of length of conveyor.

Wm 56 lbs/ft Wm = weight of material per unit of length of conveyor.

Sag 2.0% Sag = recommended maximum sag percentage to avoid spillage in troughed section of belt.

Ls Ls = Length of conveyor from tail pulley to Drive snub (for return run drive only)

Hd Hd = Height of conveyor from top of tail pulley to bottom of drive pulley (for return run drive only)

Copyright - Rulmeca Corp.

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

www.rulmecacorp.com Telefax

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23

05/20/14

Date

T2 = estimated slack-side tension required to either keep belt from slipping on pulley surface or maintain trough at

allowable sag percentage, whichever is greater.

str = tensile strength of specified belt.

Telephone

Power Calculation Summary

Project Name Conveyor Reference

Kx = factor to calculate frictional resistance of the idlers and the sliding resistance between belt and idler rolls.

Tp = tension required to overcome resistance of belt to flexure around pulleys and resistance of pulleys to rotate on

their bearings.

\\vboxsrv\conversion_tmp\scratch_6\229681129.xls.ms_office, Design Parameters, Page 6 of 8 5/20/2014 2:46 PM

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23

Bulk Handling Belt Conveyor Terminology

Belt Width

Idler Type > A B C D E

Idler (deg) > 20 35 45 20 35 45 20 35 45 20 35 45 20 35 45

18 300 300 300 410 410 410 900 900 900 - - - - - -

24 300 300 289 410 410 410 900 900 900 1200 1200 1200 1800 1800 1800

30 300 280 270 410 410 410 900 900 900 1200 1200 1200 1800 1800 1800

36 275 256 248 410 410 396 900 837 810 1200 1200 1200 1800 1800 1800

42 - - - 390 363 351 850 791 765 1200 1200 1200 1800 1800 1800

48 - - - 380 353 342 800 744 720 1200 1200 1200 1800 1800 1800

54 - - - - - - 750 698 675 1200 1116 1080 1800 1800 1800

60 - - - - - - 700 650 630 1150 1070 1035 1800 1800 1800

72 - - - - - - - - - 1050 977 945 1800 1800 1800

84 - - - - - - - - - - - - 1800 1674 1620

96 - - - - - - - - - - - - 1750 1628 1575

*These ratings are for three-equal-roll idlers and are based on a 30,000 hour minimum

BU bearing life at 500 RPM. BU bearing life represents the statistical point in hours where

a minimum of 90% of the bearings will still be functional with no increase in torque or noise.

Surcharge

Angle

5

10

20

25

30

www.rulmecacorp.com

Conveyor Profile

6508-B Windmill Way

Ph 910-794-9294

Fax 910-794-9296

Wilmington, NC 28405

Copyright - Rulmeca Corp.

Initial Velocity of Material

Belt Conveyor with Two Diverter(s)

Conveyor Cross Section in Skirt Zone

Belt Conveyor with Tripper

40+

Uniform size, very small rounded particles, either very wet or very dry; such as dry

silica sand, cement, and wet concrete.

Irregular, stringy, fibrous, interlocking material, such as wood chips, bagasse, and

tempered foundry sand.

Angle of

Repose

0 to 19

20 to 29

Description of Material

Typical common materials such as bituminous coal, stone, and most ores.

30 to 34

35 to 39

Idler Load Ratings* (lbs)

"CEMA" Idler Type Definitions

(Based on Conveyor Equipment Manufacturers Association Manual)

(Based on Conveyor Equipment Manufacurters Association Manual)

Rounded, dry polished particles, of medium weight, such as whole grain and beans.

Irregular, granular or lumpy materials of medium weight, such as anthracite coal,

cottonseed meal, and clay.

Cleated Belt with Sidewalls

Material Surcharge Angle Guide

Hopper Feeder Conveyor

\\vboxsrv\conversion_tmp\scratch_6\229681129.xls.ms_office, Terminology, Page 7 of 8 5/20/2014 2:46 PM

Conveyor Height Calculator

Inclined conveyor length (ft)

Angle of inclination (degrees)

Material lift height (ft)

Copyright - Rulmeca Corp.

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

www.rulmecacorp.com

\\vboxsrv\conversion_tmp\scratch_6\229681129.xls.ms_office, Lift Height, Page 8 of 8 5/20/2014 2:46 PM

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Jack Up Rig Design PDFDocument91 pagesJack Up Rig Design PDFAhmed Rehim50% (2)

- GP 110: Engineering Mechanics Dynamics of Particles: Problem Sheet 2Document3 pagesGP 110: Engineering Mechanics Dynamics of Particles: Problem Sheet 2Crypto Faucet100% (1)

- Small Clear Specimens of Timber: Standard Test Methods ForDocument31 pagesSmall Clear Specimens of Timber: Standard Test Methods ForCaro ChasipantaNo ratings yet

- Forensic Sci Bibliography, ExplosivesDocument4 pagesForensic Sci Bibliography, ExplosivesSusan ColemanNo ratings yet

- Crane SpecififctaionDocument2 pagesCrane SpecififctaionGandhi elumalaiNo ratings yet

- 1 s2.0 S0041624X21002389 MainDocument7 pages1 s2.0 S0041624X21002389 MainMohamedNo ratings yet

- DR.M.G.R Educational and Research Institute University: Entrance Examination For PH.D Admission (March 2012)Document3 pagesDR.M.G.R Educational and Research Institute University: Entrance Examination For PH.D Admission (March 2012)Krishna ChaitanyaNo ratings yet

- SHAFT Couplings - Catalogue - 2Document448 pagesSHAFT Couplings - Catalogue - 2Tom TamponNo ratings yet

- Abstracts Book 23rd PAC ConferenceDocument219 pagesAbstracts Book 23rd PAC ConferenceJeroenNo ratings yet

- Magnetic CircuitDocument4 pagesMagnetic CircuitBea Monique RoblesNo ratings yet

- Lecture 17 - Signalized Intersection DelayDocument34 pagesLecture 17 - Signalized Intersection DelayBasoz Arif AhmadNo ratings yet

- Definition of Chi-Square TestDocument8 pagesDefinition of Chi-Square TestDharshu Rajkumar100% (1)

- PropCalc ManualDocument5 pagesPropCalc ManualDemetrio Hinojosa ENo ratings yet

- Biswas 2011Document6 pagesBiswas 2011brar_harmanpreet01No ratings yet

- Fluid Mechanics 2 - Practical 1 Discharge Through An OrificeDocument13 pagesFluid Mechanics 2 - Practical 1 Discharge Through An OrificeShivesh Sohawan50% (4)

- Projeto Hover CraftDocument85 pagesProjeto Hover CraftTomas Hermes SbrisseNo ratings yet

- 17 4ph PDFDocument1 page17 4ph PDFMalavikaVarmaNo ratings yet

- Chapter 6 PID ControlDocument56 pagesChapter 6 PID ControlHana Muhammad100% (1)

- Refrigeration and Air-Conditioning - Unit 4 - Week-3Document4 pagesRefrigeration and Air-Conditioning - Unit 4 - Week-3Kali DassNo ratings yet

- ASDA A2 ManualDocument583 pagesASDA A2 ManualClaudio Lourenço da Silva100% (1)

- Product Line Horiba - Te 01-06-2014 v2 0Document36 pagesProduct Line Horiba - Te 01-06-2014 v2 0Carlos PalominoNo ratings yet

- Theodolite Field Observation Data and Its Calculation: Corrected Interior Angle BearingsDocument2 pagesTheodolite Field Observation Data and Its Calculation: Corrected Interior Angle BearingsSuman JyotiNo ratings yet

- CVof BsebsuDocument12 pagesCVof Bsebsubsebsu7901100% (3)

- The Bacterial FlagellumDocument1 pageThe Bacterial Flagellummferra100% (1)

- CapacitorDocument296 pagesCapacitorTomtopNo ratings yet

- Training On Dry Fog Dust Suppression SystemDocument10 pagesTraining On Dry Fog Dust Suppression SystemPriyatham GangapatnamNo ratings yet

- Midterm Review 2012-2013Document7 pagesMidterm Review 2012-2013Demi YangNo ratings yet

- R19 2019 20 Mechanical Engineering-1-134Document134 pagesR19 2019 20 Mechanical Engineering-1-134Praneeth RubenNo ratings yet

- Descriptive Statistics W2Document29 pagesDescriptive Statistics W2Khusairi AnwarNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityPARMAR MAHENDRANo ratings yet