Professional Documents

Culture Documents

1 Exemplary Technical Report 2012

1 Exemplary Technical Report 2012

Uploaded by

MKPashaPashaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Exemplary Technical Report 2012

1 Exemplary Technical Report 2012

Uploaded by

MKPashaPashaCopyright:

Available Formats

GEOSERVEX s.c.

Zbigniew i Boleslaw

Krystowczyk

office:

ul. Kociuszki 27/19A

85-079 Bydgoszcz, POLAND

tel: (+4852) 345 62 50

fax: (+4852) 345 62 55

e-mail: office@geoservex.com.pl

http://www.geoservex.com.pl

EU VAT ID No:

PL 554-039-43-18

ENGINEERING MEASUREMENTS ENTERPRISE LTD.

TECHNICAL REPORT

RESULTS OF DEVIATION MEASUREMENTS

AND

GEOMETRY OF ROTARY KILN

AT

GEOCEMENT PLANT

Period of survey: February 2012

Page

Rotary Kiln

Inspection

February 2012

(Hot condition)

EXEMPLARY CEMENT PLANT

2

Index

1. Cover Page 1

2. Index 2

3. Written Report 3

4. Coordinating System, Symbols and Terms 7

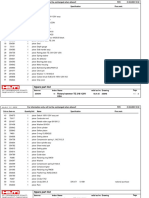

5. Measurements Data 8

6. Axial Deviations in Horizontal Plane 9

7. Axial Deviations in Vertical Plane 10

8. Rollers Skewing in Horizontal Plane 11

9. Rollers Skewing in Vertical Plane 12

10. Adjustment Program 13

11. Control Check after Adjustment in Horizontal Plane 14

12. Control Check after Adjustment in Vertical Plane 15

13. Base Plates Elevation 16

14. Skewing Corrections in Vertical Plane 17

15. Position of Supporting Rollers (up - down) 18

16. Recommendation for Future Thrust Correction 19

17. Tires ans Shell Temperatures 20

18. Tires and Rollers Diameters 21

19. Rollers Mechanical Wear 22

20. Roller Shafts Condition and Lubrication Efficiency 23

21. Tires and Girth Gear Wobbling 24

22. Girth Gear Runout 28

23. Deflection Values Changes of Roller Shaft 29

24. Drive Axial Position 35

25. Thrust Roller Position 37

26. Shelltest 38

27. Mechanical Inspection 46

28. Sections Position Diagram for Kiln Shell Deviation Survey 52

29. Shell Profile - Axonometric View 53

30. Radial Diagrams of Shell Deformation 57

31. Kiln Mechanical Parameters

3

FINAL REPORT OF ROTARY KILN

ALIGNMENT AND INSPECTION

AT GEOCEMENT PLANT.

I. SCOPE OF WORK:

1. Setting up the surveying bases around the kiln.

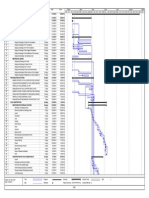

2. Measurement of kiln axis deformation in horizontal and vertical plane.

3. Measurements of rollers axis position, rollers skewing, inclination and

operating angles.

4. Measurements of rollers profiles (mechanical wear of rollers profiles).

5. Measurements of rollers shafts deflection (indication of shell crank formation).

6. Measurements of thrust roller position in reference to the kiln axis.

7. Measurements of tires and shell temperatures.

8. Measurements of tire migration (circumferential tire movement) and

calculation of shell ovality.

9. Measurements of shell profile (circularity deviation and eccentricity of cross

sections), preparation of shell polar diagrams and shell 3D animation model.

10. Measurement of tires and girth gear wobbling and run-out.

11. General mechanical inspection of drive mesh, bearings and shafts condition,

lubrication efficiency, inlet and outlet sealing, thrust unit, adjustment bolts

and housing.

12. Calculation of axial deviations in horizontal and vertical plane and the kiln

slope.

13. Preparation of optimal version of adjustment program and schedule.

14. Supervision over adjustment procedure carried out by technicians of the

Cement Plant.

15. Control survey of final kiln axis position and rollers skewing after the

adjustment.

16. Preparation of completed report on measurement and adjustment.

17. Preparation of recommendation for future preventive maintenance actions,

routines, necessary repairs and replacements.

18. Presentation and submission of the report to the Customer.

19. Optional 1: Shelltest elastic shell deformation survey, shell ovality check.

20. Optional 2: Measurement of kiln drive assembly geometry.

21. Optional 3: Recalculation of kiln mechanical parameters (current loads on

piers, pressure on bearings, Hertz pressures, bending stress in the shell,

stress in the tires, calculation of stiffness matrix, optimization of kiln vertical

axis position considering load distribution).

4

II. SURVEY OF THE ROTARY KILN No. 1

1. All measurements have been taken by GEOSERVEX Hot Kiln Alignment Team

Bydgoszcz, Poland from February 21, 2012 to February 29, 2012.

2. After completing all measurements for the kiln, technical documentation has

been presented to the cement plant representatives.

3. Coordinating system:

x Piers are numbered from outlet to inlet side

x Left and right sides are orientated, looking from inlet to outlet end

x Starting point for all measurements is a reference line; shim placed on

this line is shown as shim No. 1 ( see page 7 ).

III. RESULTS OF MEASUREMENTS

1. Kiln axis, tire migration.

Kiln axis position in horizontal plane is within the tolerance and does not require

any correction at the moment, but the kiln axis in vertical plane is 3.5 mm lower

and requires some adjustment. Measurement data is shown on page 8 and kiln axes

deviations are shown on pages 9 and 10.

Under-tire clearance values are shown on pages 8 and 10, the clearance at tires

No. III and No. I slightly exceeds recommended value, which is 3 to 6 mm.

Kiln slope is 3.50 % and it is correct (See page 8 and 10).

2. Rollers parameters and the kiln thrust

Skewing of rollers is not high. Rollers inclination is within the tolerance only for

two rollers ( see rollers inclination and rollers skewing correction drawings on pages

12 and 17 ).

Rollers operating angles are correct for all stations ( see page 8 and 10 ).

No angle exceeds the tolerance (60

o

00 +/- 1

o

30).

Rollers mechanical wear is quite low ( see page 22 ). Also diameters of all rollers are

not far from nominal values. The rollers low wear is a result of proper lubrication

routine.

3. Drive station

The drive system has been working with a lot of vibrations caused by improper

girth gear and pinion meshing ( the girth gear teeth are worn out ). Gear wobbling is

+/- 1.4 mm and slightly exceeds the tolerance (+/- 1 mm for a brand new kiln). Gear

radial run-out is +/- 2.0 mm and is acceptable at the moment.

5

4. Kiln shell

Survey of shell deviation has been taken at 30 cross sections shown on page 52.

Maximum shell eccentricity is 14 mm at section No. 1, second biggest eccentricity is

11 mm at cross-section No. 25 ( The tolerance for shell eccentricity and shell local

deformations given by most kiln producers is 12 mm for the eccentricity and 15 mm

for local deformations ).

Some shell cross-sections radial deformations are quite significant and they do

exceed the acceptable range, take a look at sections No. 12,13 and 14 in this report.

Tires wobbling is not high for stations No. II and III, but the tire wobbling at the

first station exceeds the tolerance.

The kiln shell has been examined for mechanical and thermal hidden crank formation

presence. Mechanical crank formation can be examined by measuring of roller shaft

deflection change. The measurement results are shown on pages 29-34. None of

roller shaft deflection exceeds the tolerance ( 0.30 mm for total deflection ).

5. Shell-test measurement

The expected maximum ovality for a kiln of this diameter would be 0,58%.

Summary graph is shown on page 39.

For all measured piers ovality results are quite low. The measured ovality for

pier No. I was 0,30%, creep value was approximately 20 mm. For pier No. II

measured ovality was 0,32%, creep was around 12 mm.

The ovality at pier No. III was 0,22%, creep value was 20 mm.

All presented ovality values are perfectly within the tolerance.

For more details see pages 39 45.

6. Mechanical inspection (visual)

The kiln is in satisfactory mechanical condition. All rollers bearing condition is

good. Lubrication system is complete and works properly, there is proper oil film on

all shafts. Rollers shaft condition is also good.

Rollers housing and adjustment bolts are well maintained. Rollers and tires are in

good condition, the graphite lubrication device works properly, shimming bolts and

nuts were inspected and they are complete.

The contact between tires, supporting rollers and thrust roller is acceptable.

7. Adjustment

The adjustment has been carried out in stages within three days ( February 25-27

2012 ). The above mentioned adjustment has been made due to the fact that the

kiln axis in vertical plane required adjustment and the girth gear and pinion meshing

was improper and it was necessary to decrease vibrations appearing at the inlet side

pier. The whole adjustment has produced the desired result and the vibration level

has been significantly reduced ( please, see page 13 for more details ).

6

IV. CONCLUSION

We have been informed about the kiln tendency for high amperage,

especially during start-up, in our opinion the main reason for this was:

kiln axis misalignment in vertical plane, improper girth gear and pinion meshing

and also shell deformation crank.

To prolong the life of shell and refractory lining is important to:

- correct tire clearance regularly,

- monitor tire creep, temperature of tire and shell,

- avoid rapid heating and cooling of kiln,

- check alignment of kiln every two years.

According to our measurements some geometrical parameters such as kiln axes

in horizontal and vertical plane do not require any further correction,

however, some actions should be performed in the future to improve the kiln

operation.

Actions to be taken in the nearest future:

- skewing correction in vertical plane and bearing thickness check ( page 17 ),

- repair works on outlet seal, a lot of material drops on pier No. I,

which has a bad influence on tire and rollers surface ( page 51 ),

- thrust roller position correction ( 5 mm move towards the right side of the

kiln viewing from inlet side - page 37 ).

- thrust correction (only if necessary) according to our proposal described on

page 19,

- careful monitoring of under-tire clearances at all tires, the most recommended

clearance value is 3 to 6 mm.

Actions to be taken later:

- take under consideration the girth gear reversal and centering,

- consider shell section replacement between cross-sections No.12 and 14,

due to significantly big shell local deformations which may cause frequent

lining problems.

Geoservex, Hot Kiln Alignment Team would like to thank the Plant Crew and

Management for cooperation and assistance during our visit. In case of any problems

with the kiln geometry do not hesitate to contact us.

GEOCEMENT Plant: 29

th

of February 2012.

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

P

i

e

r

N

o

.

I

I

C

o

o

r

d

i

n

a

t

i

n

g

S

y

s

t

e

m

,

S

y

m

b

o

l

s

a

n

d

T

e

r

m

s

xyahd

y

d

z

d

s

a

x

i

a

l

c

o

o

r

d

i

n

a

t

e

s

r

o

l

l

e

r

s

o

p

e

r

a

t

i

n

g

a

n

g

l

e

s

l

o

p

e

o

f

a

x

i

s

h

o

r

i

z

o

n

t

a

l

a

x

i

s

c

o

r

r

e

c

t

i

o

n

h

o

r

i

z

o

n

t

a

l

c

o

o

r

d

i

n

a

t

e

s

z

v

e

r

t

i

c

a

l

c

o

o

r

d

i

n

a

t

e

s

v

e

r

t

i

c

a

l

a

x

i

s

c

o

r

r

e

c

t

i

o

n

s

k

e

w

i

n

g

c

o

r

r

e

c

t

i

o

n

r

e

a

l

a

x

i

s

a

d

j

u

s

t

m

e

n

t

a

x

i

s

r

e

f

e

r

e

n

c

e

a

x

i

s

s

u

n

d

e

r

t

i

r

e

c

l

e

a

r

a

n

c

e

c

r

o

o

t

c

l

e

a

r

a

n

c

e

O

U

T

L

E

T

I

N

L

E

T

S

t

a

r

t

i

n

g

p

o

i

n

t

f

o

r

a

l

l

m

e

a

s

u

r

e

m

e

n

t

s

.

R

e

f

e

r

e

n

c

e

l

i

n

e

.

7

z

x

y

x

R

I

G

H

T

S

I

D

E

L

E

F

T

S

I

D

E

T

i

r

e

N

o

.

I

I

I

T

i

r

e

N

o

.

I

I

T

i

r

e

N

o

.

I

P

i

e

r

N

o

.

I

I

I

P

i

e

r

N

o

.

I

D

r

i

v

e

G

e

a

r

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

8

y

1

=

x

1

=

M

e

a

s

u

r

e

m

e

n

t

s

D

a

t

a

h

=

3

.

5

0

%

a

3

=

a

2

=

a

1

=

,

o

,

o

,

o

,

o

[

]

[

m

]

x

2

=

x

3

=

0

.

0

0

y

2

=

[

m

m

]

y

3

=

0

.

0

[

m

m

]

z

2

=

z

3

=

0

.

0

z

1

=

s

1

=

s

2

=

[

m

m

]

s

3

=

C

o

o

r

d

i

n

a

t

e

s

"

z

"

C

o

o

r

d

i

n

a

t

e

s

"

x

"

I

N

L

E

T

O

U

T

L

E

T

U

n

d

e

r

t

i

r

e

c

l

e

a

r

a

n

c

e

"

s

"

I

N

L

E

T

O

U

T

L

E

T

I

N

L

E

T

O

U

T

L

E

T

I

N

L

E

T

O

U

T

L

E

T

I

N

L

E

T

O

U

T

L

E

T

R

o

l

l

e

r

s

o

p

e

r

a

t

i

n

g

a

n

g

l

e

"

a

"

C

o

o

r

d

i

n

a

t

e

s

"

y

"

S

l

o

p

e

o

f

a

x

i

s

0

.

0

2

9

.

0

8

5

4

.

1

5

-

4

.

0

0

.

0

+

5

.

0

7

.

0

4

.

0

7

.

0

5

9

4

8

5

9

5

6

5

9

4

7

(

A

v

e

r

a

g

e

)

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

9

t

o

l

e

r

a

n

c

e

z

o

n

e

+

/

-

1

.

5

m

m

A

x

i

a

l

D

e

v

i

a

t

i

o

n

s

i

n

H

o

r

i

z

o

n

t

a

l

P

l

a

n

e

D

E

F

O

R

M

A

T

I

O

N

S

C

A

L

E

:

1

:

1

0

.

0

m

m

0

.

0

m

m

x

y

OUTLET

INLET

r

e

f

e

r

e

n

c

e

a

x

i

s

r

e

a

l

a

x

i

s

-

4

.

0

m

m

l

e

f

t

s

i

d

e

r

i

g

h

t

s

i

d

e

P

r

e

c

i

s

i

o

n

o

f

f

i

n

d

i

n

g

k

i

l

n

a

x

i

s

:

+

/

-

1

m

m

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

A

x

i

a

l

D

e

v

i

a

t

i

o

n

s

i

n

V

e

r

t

i

c

a

l

P

l

a

n

e

P

r

e

c

i

s

i

o

n

o

f

f

i

n

d

i

n

g

k

i

l

n

a

x

i

s

:

+

/

-

1

m

m

0

.

0

m

m

D

E

F

O

R

M

A

T

I

O

N

S

C

A

L

E

:

1

:

1

O U T L E T

I N L E T

0

.

0

m

m

x

z

s

=

7

.

0

m

m

s

=

4

.

0

m

m

s

=

7

.

0

m

m

s

a

r

e

a

l

a

x

i

s

+

5

.

0

m

m

3

.

5

0

%

t

o

l

e

r

a

n

c

e

z

o

n

e

+

/

-

1

.

5

m

m

r

e

f

e

r

e

n

c

e

a

x

i

s

1

0

a

=

5

9

o

5

6

a

=

5

9

o

4

8

a

=

5

9

o

4

7

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

1

1

R

o

l

l

e

r

s

s

k

e

w

i

n

g

(

S

h

)

a

r

e

r

e

d

u

c

e

d

f

o

r

b

o

l

t

s

d

i

s

t

a

n

c

e

R

o

l

l

e

r

s

S

k

e

w

i

n

g

i

n

H

o

r

i

z

o

n

t

a

l

P

l

a

n

e

k

i

l

n

a

x

i

s

OUTLET

INLET

1

.

5

m

m

2

.

0

m

m

0

.

0

m

m

0

.

5

m

m

0

.

0

m

m

0

.

5

m

m

l

e

f

t

s

i

d

e

r

i

g

h

t

s

i

d

e

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

1

2

O U T L E T

I N L E T

R

o

l

l

e

r

s

S

k

e

w

i

n

g

i

n

V

e

r

t

i

c

a

l

P

l

a

n

e

R

o

l

l

e

r

s

s

k

e

w

i

n

g

(

S

v

)

a

r

e

r

e

d

u

c

e

d

f

o

r

b

o

l

t

s

d

i

s

t

a

n

c

e

k

i

l

n

a

x

i

s

C

a

u

t

i

o

n

!

R

o

l

l

e

r

s

k

e

w

i

n

g

v

a

l

u

e

i

s

r

e

d

u

c

e

d

f

o

r

a

d

j

u

s

t

m

e

n

t

b

o

l

t

s

d

i

s

t

a

n

c

e

0

.

5

m

m

a

d

j

u

s

t

m

e

n

t

b

o

l

t

s

d

i

s

t

a

n

c

e

0 . 5 m m

3

.

5

0

%

l

e

f

t

s

i

d

e

r

i

g

h

t

s

i

d

e

4

.

0

m

m

0

.

5

m

m

1

.

0

m

m

2

.

0

m

m

1

.

0

m

m

3

.

5

0

%

1

.

0

m

m

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

A

d

j

u

s

t

m

e

n

t

P

r

o

g

r

a

m

4

.

5

m

m

OUTLET

INLET

l

e

f

t

s

i

d

e

r

i

g

h

t

s

i

d

e

1

3

4

.

5

m

m

1

2

.

5

m

m

1

2

.

5

m

m

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

A

d

j

u

s

t

m

e

n

t

S

c

h

e

d

u

l

e

OUTLET

INLET

l

e

f

t

s

i

d

e

r

i

g

h

t

s

i

d

e

1

3

a

ds

dz

dy

ds

dz

dy

8.5

8.5

ds

dz

dy

ds

dz

dy

8.5

8.5

4.0

4.0

4.0

4.0

0.0

0.0

0.0

0.0

4

.

5

m

m

4

.

5

m

m

1

2

.

5

m

m

1

2

.

5

m

m

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

A

d

j

u

s

t

m

e

n

t

S

c

h

e

d

u

l

e

-

S

t

e

p

b

y

S

t

e

p

OUTLET

INLET

l

e

f

t

s

i

d

e

r

i

g

h

t

s

i

d

e

1

3

b

4

.

5

m

m

4

.

5

m

m

5 1

1.0

3

1.0 1.0

7

1.5

1.0

4

1.0

6

1.0

8

1.5

2

11

18

1.5

16

1.5

14

1.5

12

1.0

10

1.0

17

1.5

15

1.5

13

1.5 1.0

9

1.0

1

2

.

5

m

m

T

h

e

n

u

m

b

e

r

o

f

a

d

j

u

s

t

m

e

n

t

s

t

e

p

s

-

i

n

r

e

d

c

o

l

o

u

r

1

2

.

5

m

m

20

1.5

19

1.5

22

1.5

21

1.5

23

1.5

24

1.5

26

1.5

25

1.5

1

s

t

D

a

y

1

s

t

D

a

y

2

n

d

D

a

y

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

1

4

t

o

l

e

r

a

n

c

e

z

o

n

e

+

/

-

1

.

5

m

m

C

o

n

t

r

o

l

C

h

e

c

k

-

A

x

i

a

l

D

e

v

i

a

t

i

o

n

s

i

n

H

o

r

i

z

o

n

t

a

l

P

l

a

n

e

D

E

F

O

R

M

A

T

I

O

N

S

C

A

L

E

:

1

:

1

0

.

0

m

m

0

.

0

m

m

x

y

OUTLET

INLET

r

e

f

e

r

e

n

c

e

a

x

i

s

r

e

a

l

a

x

i

s

-

0

.

5

m

m

l

e

f

t

s

i

d

e

r

i

g

h

t

s

i

d

e

P

r

e

c

i

s

i

o

n

o

f

f

i

n

d

i

n

g

k

i

l

n

a

x

i

s

:

+

/

-

1

m

m

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

C

o

n

t

r

o

l

C

h

e

c

k

-

A

x

i

a

l

D

e

v

i

a

t

i

o

n

s

i

n

V

e

r

t

i

c

a

l

P

l

a

n

e

D

E

F

O

R

M

A

T

I

O

N

S

C

A

L

E

:

1

:

1

s

a

1

5

P

r

e

c

i

s

i

o

n

o

f

f

i

n

d

i

n

g

k

i

l

n

a

x

i

s

:

+

/

-

1

m

m

0

.

0

m

m

O U T L E T

I N L E T

0

.

0

m

m

x

z

s

=

7

.

0

m

m

s

=

4

.

0

m

m

s

=

7

.

0

m

m

r

e

a

l

a

x

i

s

-

0

.

5

m

m

3

.

5

0

%

t

o

l

e

r

a

n

c

e

z

o

n

e

+

/

-

1

.

5

m

m

r

e

f

e

r

e

n

c

e

a

x

i

s

a

=

6

0

o

0

5

a

=

5

9

o

4

4

a

=

5

9

o

4

7

Page

Rotary Kiln

Inspection

February 2012

(Hot condition)

EXEMPLARY CEMENT PLANT

OUTLET

INLET

Base Plates Elevation

16

PIER No. I

PIER No. III

PIER No. II

+ 78.8 mm

(+ 83.3 mm)

- 4.5 mm

0.0 mm

2

3

8

0

m

m

3

.

4

8

%

2

3

8

0

m

m

(

3

.

5

0

%

)

2

6

8

0

m

m

3

.

4

5

%

2

6

8

0

m

m

(

3

.

5

0

%

)

+ 82.8 mm

(+ 83.3 mm)

- 0.5 mm

- 94.1 mm

(- 93.8 mm)

- 0.3 mm

0.0 mm

+ 92.5 mm

(+ 93.8 mm)

- 1.3 mm

0.0 mm

- 3.0 mm - measured elevation

(0.0 mm) - theoretical elevation

- 3.0 mm - deviation

3

.

3

1

%

(

3

.

5

0

%

)

3

.

5

1

%

(

3

.

5

0

%

)

(3.50 %) - theoretical slope

3.52 % - measured slope

0.0 mm

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

S

k

e

w

i

n

g

C

o

r

r

e

c

t

i

o

n

i

n

V

e

r

t

i

c

a

l

P

l

a

n

e

3

m

m

s

h

i

m

t

o

b

e

p

l

a

c

e

d

u

n

d

e

r

h

o

u

s

i

n

g

1

7

O U T L E T

I N L E T

R

o

l

l

e

r

s

s

k

e

w

i

n

g

(

S

v

)

a

r

e

r

e

d

u

c

e

d

f

o

r

b

o

l

t

s

d

i

s

t

a

n

c

e

k

i

l

n

a

x

i

s

C

a

u

t

i

o

n

!

R

o

l

l

e

r

s

k

e

w

i

n

g

v

a

l

u

e

i

s

r

e

d

u

c

e

d

f

o

r

a

d

j

u

s

t

m

e

n

t

b

o

l

t

s

d

i

s

t

a

n

c

e

0

.

5

m

m

a

d

j

u

s

t

m

e

n

t

b

o

l

t

s

d

i

s

t

a

n

c

e

0 . 5 m m

3

.

5

0

%

l

e

f

t

s

i

d

e

r

i

g

h

t

s

i

d

e

4

.

0

m

m

3

.

5

0

%

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

1

8

P

o

s

i

t

i

o

n

o

f

S

u

p

p

o

r

t

i

n

g

R

o

l

l

e

r

s

(

u

p

-

d

o

w

n

)

D

i

s

t

a

n

c

e

b

e

t

w

e

e

n

T

r

u

s

t

C

o

l

l

a

r

s

a

n

d

R

e

t

a

i

n

i

n

g

B

l

o

c

k

s

OUTLET

INLET

contact

gap

contact

gap

gap

c

o

n

t

a

c

t

g

a

p

r

o

l

l

e

r

s

h

a

f

t

b

e

a

r

i

n

g

r

e

s

i

s

t

a

n

c

e

r

i

n

g

contact

gap

contact

gap

s

h

a

f

t

l

e

f

t

s

i

d

e

r

i

g

h

t

s

i

d

e

contact

gap

contact

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

1

9

R

e

c

o

m

m

e

n

d

a

t

i

o

n

f

o

r

F

u

t

u

r

e

T

h

r

u

s

t

C

o

r

r

e

c

t

i

o

n

P

e

r

f

o

r

m

o

n

l

y

i

f

n

e

c

e

s

s

a

r

y

k

i

l

n

u

p

0 . 5 m m

k

i

l

n

a

x

i

s

OUTLET

INLET

l

e

f

t

s

i

d

e

r

i

g

h

t

s

i

d

e

k

i

l

n

u

p

0 . 5 m m

k

i

l

n

u

p

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

1

9

a

R

e

c

o

m

m

e

n

d

a

t

i

o

n

f

o

r

F

u

t

u

r

e

T

h

r

u

s

t

C

o

r

r

e

c

t

i

o

n

P

e

r

f

o

r

m

o

n

l

y

i

f

n

e

c

e

s

s

a

r

y

0 . 5 m m

k

i

l

n

d

o

w

n

k

i

l

n

d

o

w

n

0 . 5 m m

k

i

l

n

a

x

i

s

OUTLET

INLET

l

e

f

t

s

i

d

e

r

i

g

h

t

s

i

d

e

k

i

l

n

d

o

w

n

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

2

0

T

i

r

e

s

a

n

d

S

h

e

l

l

T

e

m

p

e

r

a

t

u

r

e

U

n

i

t

:

[

C

]

E

m

i

s

s

i

o

n

f

a

c

t

o

r

:

0

.

9

5

OUTLET

INLET

1

5

0

1

5

3

1

9

0

D

a

t

e

:

F

e

b

r

u

a

r

y

2

3

,

2

0

1

2

1

5

4

1

9

5

1

3

5

P

I

E

R

I

I

i

n

l

e

t

s

i

d

e

o

u

t

l

e

t

s

i

d

e

m

i

n

i

m

u

m

2

1

6

2

5

7

m

a

x

i

m

u

m

2

5

0

2

7

2

d

i

f

f

e

r

e

n

c

e

3

4

1

5

P

I

E

R

I

i

n

l

e

t

s

i

d

e

o

u

t

l

e

t

s

i

d

e

m

i

n

i

m

u

m

2

9

9

3

0

9

m

a

x

i

m

u

m

3

3

6

3

4

2

d

i

f

f

e

r

e

n

c

e

3

7

3

3

P

I

E

R

I

I

I

i

n

l

e

t

s

i

d

e

o

u

t

l

e

t

s

i

d

e

m

i

n

i

m

u

m

2

2

2

2

3

5

m

a

x

i

m

u

m

2

7

2

2

7

0

d

i

f

f

e

r

e

n

c

e

5

0

3

5

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

2

1

D

i

a

m

e

t

e

r

s

o

f

T

i

r

e

s

a

n

d

R

o

l

l

e

r

s

i

n

N

o

r

m

a

l

P

h

y

s

i

c

a

l

C

o

n

d

i

t

i

o

n

s

(

2

0

o

C

)

OUTLET

INLET

f = 5884

f = 5935

f = 5883

f

=

1

9

9

6

f

=

2

3

0

0

f

=

1

9

9

9

f

=

1

9

9

4

f

=

2

2

9

8

f

=

2

0

0

0

Page

Rotary Kiln

Inspection

February 2012

(Hot condition)

EXEMPLARY CEMENT PLANT

Rollers Mechanical Wear

22

INLET

OUTLET

Accuracy of measurements +/- 0.5 mm

devi ati on

[mm]

max. radius = 1001.0 mm

0.0

- 0.5

- 1.0

- 1.0

- 1.0

- 1.0

- 1.0

- 1.0

- 0.5

0.0

devi ati on

[mm]

max. radius = 1002.0 mm

P - I

r

o

l

l

e

r

a

x

i

s

max. radius = 999.0 mm

0.0

- 0.5

- 0.5

- 1.0

- 1.0

- 1.0

- 0.5

- 0.5

0.0

0.0

max. radius = 998.0 mm

P - III

max. radius = 1151.0 mm

- 1.0

- 0.5

- 0.5

0.0

0.0

- 1.0

- 0.5

0.0

0.0

0.0

max. radius = 1150.0 mm

P - II

DEFORMATION SCALE 1 : 1

r

o

l

l

e

r

a

x

i

s

r

o

l

l

e

r

a

x

i

s

r

o

l

l

e

r

a

x

i

s

r

o

l

l

e

r

a

x

i

s

r

o

l

l

e

r

a

x

i

s

Page

Rotary Kiln

Inspection

February 2012

(Hot condition)

EXEMPLARY CEMENT PLANT

shaft condition: good

lubrication: good

shaft condition: good

lubrication: good

shaft condition: good

lubrication: good

shaft condition: good

lubrication: good

shaft condition: good

lubrication: good

23

INLET

OUTLET

Roller Shafts Condition

and Lubrication Efficiency

shaft condition: good

lubrication: good

shaft condition: good

lubrication: good

shaft condition: good

lubrication: good

shaft condition: good

lubrication: good

shaft condition: good

lubrication: good

shaft condition: good

lubrication: good

shaft condition: good

lubrication: good

Page

Rotary Kiln

Inspection

February 2012

(Hot condition)

EXEMPLARY CEMENT PLANT

Tire Wobbling

24

TIRE No. III

0.4 mm

0.4 mm

(Point No. 12)

(Point No. 28)

O

U

T

L

E

T

I

N

L

E

T

TIRE No. II

TIRE No. I

Tire No. III

(VIEWING FROM INLET SIDE)

Y

Z

M

a

x

i

m

u

m

w

o

b

b

l

i

n

g

l

i

n

e

1

32

31

30

29

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Caution: reference line describing kiln position

- at the bottom

Page

Rotary Kiln

Inspection

February 2012

(Hot condition)

EXEMPLARY CEMENT PLANT

0.9 mm

(Point No. 2)

(Point No. 18)

Tire Wobbling

25

TIRE No. III

O

U

T

L

E

T

I

N

L

E

T

TIRE No. II

TIRE No. I

Tire No. II

(VIEWING FROM INLET SIDE)

0.9 mm

Y

Z

M

a

x

i

m

u

m

w

o

b

b

l

i

n

g

l

i

n

e

1

32

31

30

29

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Caution: reference line describing kiln position

- at the bottom

Page

Rotary Kiln

Inspection

February 2012

(Hot condition)

EXEMPLARY CEMENT PLANT

Tire Wobbling

26

Tire No. I

(VIEWING FROM INLET SIDE)

TIRE No. III

O

U

T

L

E

T

I

N

L

E

T

TIRE No. II

TIRE No. I

2.2 mm

2.2 mm (Point No. 20)

(Point No. 4)

Y

Z

M

a

x

i

m

u

m

w

o

b

b

l

i

n

g

l

i

n

e

1

32

31

30

29

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Caution: reference line describing kiln position

- at the bottom

Page

Rotary Kiln

Inspection

February 2012

(Hot condition)

EXEMPLARY CEMENT PLANT

Caution: reference line describing kiln position

- at the bottom

Girth Gear Wobbling

27

Girth Gear

(VIEWING FROM INLET SIDE)

TIRE No. III

O

U

T

L

E

T

I

N

L

E

T

TIRE No. II

TIRE No. I

1.4 mm

1.4 mm (Point No. 3)

(Point No. 19)

Z

GIRTH GEAR

m

a

x

.

w

o

b

b

l

i

n

g

l

i

n

e

1

12

11

10

9

8

7

6

5

4

3

2

Page

Rotary Kiln

Inspection

February 2012

(Hot condition)

EXEMPLARY CEMENT PLANT

Girth Gear Runout

28

Girth Gear

(VIEWING FROM INLET SIDE)

Z

Caution: reference line describing kiln

position - at the bottom

1

12

11

10

9

8

7

6

5

4

3

2

axis of

rotation

z

y

geometric

centre

Y

GEOMETRIC CENTRE

COORDINATES

Coordinate Y

Coordinate Z

ECCENTRICITY

mm

mm

mm

- 2.0

0.0

2.0

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

2

9

R

o

l

l

e

r

S

h

a

f

t

D

e

f

l

e

c

t

i

o

n

V

a

l

u

e

C

h

a

n

g

e

P

I

E

R

N

o

.

I

I

I

L

E

F

T

R

O

L

L

E

R

M

e

a

s

u

r

e

m

e

n

t

M

e

t

h

o

d

E

c

c

e

n

t

r

i

c

i

t

y

:

0

.

2

8

m

m

(

t

o

l

e

r

a

n

c

e

0

.

1

5

m

m

)

T

o

t

a

l

d

e

f

l

e

c

t

i

o

n

v

a

l

u

e

:

0

.

5

8

m

m

M

a

x

i

m

u

m

d

e

f

l

e

c

t

i

o

n

a

t

p

o

i

n

t

N

o

.

:

2

8

L

e

f

t

S

i

d

e

V

i

e

w

f

r

o

m

i

n

l

e

t

s

i

d

e

1

2

3

c h a n g e v a l u e

o f d e f l e c t i o n

R

o

l

l

e

r

S

h

a

f

t

D

e

f

l

e

c

t

i

o

n

V

a

l

u

e

C

h

a

n

g

e

-

0

.

3

0

-

0

.

2

0

-

0

.

1

0

0

.

0

0

0

.

1

0

0

.

2

0

0

.

3

0

Unit: [mm]

S

t

a

r

t

i

n

g

p

o

i

n

t

l

i

n

e

-

s

t

a

r

t

o

f

s

u

r

v

e

y

S

t

a

r

t

i

n

g

p

o

i

n

t

l

i

n

e

-

e

n

d

o

f

s

u

r

v

e

y

N

o

.

o

f

p

o

i

n

t

:

6

1

2

3

4

5

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

1

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

3

0

P

I

E

R

N

o

.

I

I

I

R

I

G

H

T

R

O

L

L

E

R

M

e

a

s

u

r

e

m

e

n

t

M

e

t

h

o

d

E

c

c

e

n

t

r

i

c

i

t

y

:

0

.

2

6

m

m

(

t

o

l

e

r

a

n

c

e

0

.

1

5

m

m

)

T

o

t

a

l

d

e

f

l

e

c

t

i

o

n

v

a

l

u

e

:

0

.

5

3

m

m

M

a

x

i

m

u

m

d

e

f

l

e

c

t

i

o

n

a

t

p

o

i

n

t

N

o

.

:

3

2

R

i

g

h

t

S

i

d

e

V

i

e

w

f

r

o

m

i

n

l

e

t

s

i

d

e

1

2

3

c h a n g e v a l u e

o f d e f l e c t i o n

R

o

l

l

e

r

S

h

a

f

t

D

e

f

l

e

c

t

i

o

n

V

a

l

u

e

C

h

a

n

g

e

-

0

.

3

0

-

0

.

2

0

-

0

.

1

0

0

.

0

0

0

.

1

0

0

.

2

0

0

.

3

0

Unit: [mm]

S

t

a

r

t

i

n

g

p

o

i

n

t

l

i

n

e

-

s

t

a

r

t

o

f

s

u

r

v

e

y

S

t

a

r

t

i

n

g

p

o

i

n

t

l

i

n

e

-

e

n

d

o

f

s

u

r

v

e

y

N

o

.

o

f

p

o

i

n

t

:

6

1

2

3

4

5

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

1

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

-

0

.

3

0

-

0

.

2

0

-

0

.

1

0

0

.

0

0

0

.

1

0

0

.

2

0

0

.

3

0

0

.

4

0

Unit: [mm]

S

t

a

r

t

i

n

g

p

o

i

n

t

l

i

n

e

-

s

t

a

r

t

o

f

s

u

r

v

e

y

S

t

a

r

t

i

n

g

p

o

i

n

t

l

i

n

e

-

e

n

d

o

f

s

u

r

v

e

y

N

o

.

o

f

p

o

i

n

t

:

6

1

2

3

4

5

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

1

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

1

P

I

E

R

N

o

.

I

I

L

E

F

T

R

O

L

L

E

R

E

c

c

e

n

t

r

i

c

i

t

y

:

0

.

2

9

m

m

(

t

o

l

e

r

a

n

c

e

0

.

1

5

m

m

)

T

o

t

a

l

d

e

f

l

e

c

t

i

o

n

v

a

l

u

e

:

0

.

5

8

m

m

M

a

x

i

m

u

m

d

e

f

l

e

c

t

i

o

n

a

t

p

o

i

n

t

N

o

.

:

1

4

c h a n g e v a l u e

o f d e f l e c t i o n

M

e

a

s

u

r

e

m

e

n

t

M

e

t

h

o

d

1

2

3

R

o

l

l

e

r

S

h

a

f

t

D

e

f

l

e

c

t

i

o

n

V

a

l

u

e

C

h

a

n

g

e

L

e

f

t

S

i

d

e

V

i

e

w

f

r

o

m

i

n

l

e

t

s

i

d

e

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

3

2

P

I

E

R

N

o

.

I

I

R

I

G

H

T

R

O

L

L

E

R

M

e

a

s

u

r

e

m

e

n

t

M

e

t

h

o

d

E

c

c

e

n

t

r

i

c

i

t

y

:

0

.

4

6

m

m

(

t

o

l

e

r

a

n

c

e

0

.

1

5

m

m

)

T

o

t

a

l

d

e

f

l

e

c

t

i

o

n

v

a

l

u

e

:

0

.

9

2

m

m

M

a

x

i

m

u

m

d

e

f

l

e

c

t

i

o

n

a

t

p

o

i

n

t

N

o

.

:

1

5

R

i

g

h

t

S

i

d

e

V

i

e

w

f

r

o

m

i

n

l

e

t

s

i

d

e

1

2

3

c h a n g e v a l u e

o f d e f l e c t i o n

R

o

l

l

e

r

S

h

a

f

t

D

e

f

l

e

c

t

i

o

n

V

a

l

u

e

C

h

a

n

g

e

-

0

.

5

0

-

0

.

4

0

-

0

.

3

0

-

0

.

2

0

-

0

.

1

0

0

.

0

0

0

.

1

0

0

.

2

0

0

.

3

0

0

.

4

0

0

.

5

0

0

.

6

0

Unit: [mm]

S

t

a

r

t

i

n

g

p

o

i

n

t

l

i

n

e

-

s

t

a

r

t

o

f

s

u

r

v

e

y

S

t

a

r

t

i

n

g

p

o

i

n

t

l

i

n

e

-

e

n

d

o

f

s

u

r

v

e

y

N

o

.

o

f

p

o

i

n

t

:

6

1

2

3

4

5

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

1

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

3

3

P

I

E

R

N

o

.

I

L

E

F

T

R

O

L

L

E

R

E

c

c

e

n

t

r

i

c

i

t

y

:

0

.

0

8

m

m

(

t

o

l

e

r

a

n

c

e

0

.

1

5

m

m

)

T

o

t

a

l

d

e

f

l

e

c

t

i

o

n

v

a

l

u

e

:

0

.

1

5

m

m

M

a

x

i

m

u

m

d

e

f

l

e

c

t

i

o

n

a

t

p

o

i

n

t

N

o

.

:

3

0

c h a n g e v a l u e

o f d e f l e c t i o n

M

e

a

s

u

r

e

m

e

n

t

M

e

t

h

o

d

L

e

f

t

S

i

d

e

V

i

e

w

f

r

o

m

i

n

l

e

t

s

i

d

e

1

2

3

R

o

l

l

e

r

S

h

a

f

t

D

e

f

l

e

c

t

i

o

n

V

a

l

u

e

C

h

a

n

g

e

-

0

.

1

5

-

0

.

1

0

-

0

.

0

5

0

.

0

0

0

.

0

5

0

.

1

0

0

.

1

5

Unit: [mm]

S

t

a

r

t

i

n

g

p

o

i

n

t

l

i

n

e

-

s

t

a

r

t

o

f

s

u

r

v

e

y

S

t

a

r

t

i

n

g

p

o

i

n

t

l

i

n

e

-

e

n

d

o

f

s

u

r

v

e

y

N

o

.

o

f

p

o

i

n

t

:

6

1

2

3

4

5

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

1

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

P

a

g

e

R

o

t

a

r

y

K

i

l

n

I

n

s

p

e

c

t

i

o

n

F

e

b

r

u

a

r

y

2

0

1

2

(

H

o

t

c

o

n

d

i

t

i

o

n

)

E

X

E

M

P

L

A

R

Y

C

E

M

E

N

T

P

L

A

N

T

3

4

P

I

E

R

N

o

.

I

R

I

G

H

T

R

O

L

L

E

R

M

e

a

s

u

r

e

m

e

n

t

M

e

t

h

o

d

E

c

c

e

n

t

r

i

c

i

t

y

:

0

.

0

8

m

m

(

t

o

l

e

r

a

n

c

e

0

.

1

5

m

m

)

T

o

t

a

l

d

e

f

l