Professional Documents

Culture Documents

Genset Installation and Start

Genset Installation and Start

Uploaded by

Muhammad Arslan Khurshid BhattiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Genset Installation and Start

Genset Installation and Start

Uploaded by

Muhammad Arslan Khurshid BhattiCopyright:

Available Formats

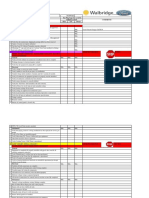

Applications requirements Liquid cooled generator sets

Generator set start-

up checklist

Open & enclosed generator sets

This checklist should be used to validate the completion of

generator set start-up procedure. A check-list should be

completed for each generator set of a multiple installation.

Project Details

Project Name ...

....

!ustomer "#nd $ser%......

....

Address ....

...

!ustomer representative....

Tel. No ..

#mail.

Generator set details

&enerator set model...

&enerator set serial number.'et no.

!ontrol t(pe...

!ontrol serial number..

'(stem control t(pe "if applicable%

Generator set environment and services

Precommissioning )ork * checklist complete D

'urroundings clean * clear from obstruction D

Lighting + heating, etc., s(stems operational D

-bservations....

!oolant heater

operational D

Leak check D

.!A dosing cartridges fitted * valves open D

/emote mounted radiator s(stems

/adiator, engine * pipe)ork checked for leaks D

!oolant heater operational D

0ans, pumps and controls checked D

Leak check D

.!A dosing cartridges fitted * valves open D

1eat e2changer * cooling to)er s(stems

'(stem, engine * pipe)ork checked for leaks D

!oolant heater operational D

'econdar( cooling s(stem checked D

0ans, pumps and controls checked D

.!A dosing cartridges fitted * valves open D

Legionnella dosing checked )here applicable D

/ecord dosing chemical * concentration.............................

Diesel Fuel System

3ulk storage facilit(

4solating valves correctl( positioned D

Transfer pump * controls operational D

Pipeline + tank heating s(stem operational D

0ill point alarm operational D

Leaks check D

'torage facilit( secure D

.a( tank

4solating and solenoid valves checked D

Tank filled D

'pillage containment * alarms operational D

Transfer pump operational D

Leak check D

Safety

Checks

0ire valves * release tested and operational D

#nsure starting is inhibited until start-up is required D

'et clean and full( assembled D

No loose materials near set D

Air ducts clear and clean D

Access * egress routes unobstructed * labelled D

!ontrol * maintenance positions unobstructed D

/oom secure no unauthorised access D

Personnel )arned of start-up process D

Gas Fuel System

4solating valves correctl( positioned D

/egulator set to correct pressure D

&as leak detection equipment operational D

.ouble shut-off device operational D

Leak test complete D

Purging complete D

.ocument Number5 P&6 0!. 78-79:8

1

'tart-up checklist ;9.7

< =778 !ummins Po)er &eneration Ltd

Applications requirements Liquid cooled generator sets

Cooling System

'et mounted radiator

/adiator, engine * pipe)ork checked for leaks D

3elts * guards checked for securit( + slipping D

Fire alarm / suppression system

0ire alarm + suppression s(stem operational D

'uppression s(stem lock-off operational D

-perator instructed in fire s(stem operation D

.ocument Number5 P&6 0!. 78-79:8

2

'tart-up checklist ;9.7

< =778 !ummins Po)er &eneration Ltd

u!rication system

#ngine oil pan filled to correct level D

-il make up s(stem operational D

&enerator set voltage * frequenc( correct to order D

!ontrol s(stem calibrations checked D

Phase rotation checked D

Paralleling sets phase coincidence check D

Starting system

3atter( starting

3atteries installed, filled and connected D

&enerator set s)itchgear manual operation correct D

Local stop + emergenc( stop control checked D

/emote start + stop + emergenc( stop checked D

3atter( charger commissioned D

!ompressed air + h(draulic starting

4solating valves correctl( positioned D

!ompressor operational D

1P * LP air + h(draulic pressures checked D

!ondensate drained D

"#haust system

!heck securit( of pipe)ork * muffler D

!heck co)l and+or rain cap are operational D

!heck )ater drain pipe)ork and valves correct D

Leak check D

!heck for e2haust gas recirculation D

$entilation & attenuation

!heck louvers are clear and operational D

0orced ventilation s(stem operational if applicable D

!heck for hot air recirculation D

"lectrical system

!ontrol s(stems

Au2iliar( supplies energised D

&enerator set local controls checked D

&enerator set remote controls checked D

&enerator set s(stem controls checked D

!ustomer remote indication + controls checked D

!hangeover s)itchgear + transfer s)itch

Au2iliar( supplies energised D

$tilit( suppl( energised D

;oltage + phase rotation checked D

4ndications correct D

All covers in position D

Paralleling s)itchgear

Au2iliar( supplies energised D

4ndications correct D

All covers in position D

%nitial start&up

>anual start-up, idle * full speed checks complete D

Generator set load test

Note: Load test is carried out on customers site load

unless agreed in writing prior to start-up. Artificial load

bank test will be performed using resistive load unless

otherwise specified.

Load test completed using customer?s load D

/ecord load achievedk@

Load bank test "if applicable%

!heck load bank voltage * po)er capabilit( D

!heck cables installed correctl( * tightened D

#nergise au2iliar( supplies and check functionalit( D

Load test completed D

/esult sheet completed D

/ecord load achievedk@

/ecord po)er factor

System start&up completion

&enerator set operational D

!hangeover + transfer s)itch operational D

Paralleling s)itchgear operational D

Automatic operations checked D

>aster control operational D

All safet( shutdo)ns and )arnings operational D

#lectrical 1;+>;+L; rules and procedures in place D

!omments on an( item that ma( affect acceptance5

!hecklist completed b( .

.ate...

Print Name

!ompan(..

Note5 !ompletion of this checklist does not relieve the installer of contract obligations.

You might also like

- Human Biology 16th Mader Test Bank PDFDocument28 pagesHuman Biology 16th Mader Test Bank PDFkuldeep saini100% (1)

- 2010 CC 3.6 Engine Schematic R36Document19 pages2010 CC 3.6 Engine Schematic R36Dungani AllanNo ratings yet

- Zenith mx60Document18 pagesZenith mx60jorge100% (2)

- Precommissioning Procedures of Testing & CommissioningDocument96 pagesPrecommissioning Procedures of Testing & CommissioningTasawar Hussain85% (34)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Chillers Daily Preventive MaintenanceDocument2 pagesChillers Daily Preventive MaintenanceEhteshem Mazhari0% (1)

- Emergency Power Supply System (Epss) Test QCDD Form: Pin No. Date Location Application Number Project Name OwnerDocument4 pagesEmergency Power Supply System (Epss) Test QCDD Form: Pin No. Date Location Application Number Project Name OwnerRonie Padua100% (1)

- Socioeconomic Issues in The PhilippinesDocument5 pagesSocioeconomic Issues in The PhilippinesRiannie BonajosNo ratings yet

- Generator Set Start-Up Checklist: Open Enclosed Generator SetsDocument6 pagesGenerator Set Start-Up Checklist: Open Enclosed Generator SetsEng Mamon StiNo ratings yet

- Greenheck DOAS Start-Up Report June2019Document19 pagesGreenheck DOAS Start-Up Report June2019DurgaNo ratings yet

- 4.module Chiller CommissioningDocument33 pages4.module Chiller CommissioningyeyasiniabduNo ratings yet

- 74046a02e Manual Tool PresetterDocument6 pages74046a02e Manual Tool PresetterAndy MossNo ratings yet

- HVAC ValidationDocument57 pagesHVAC ValidationJohny DoeNo ratings yet

- National Transmission and Despatch Company Mechanicalchecks, Visualinspections and ElectricaltestsDocument22 pagesNational Transmission and Despatch Company Mechanicalchecks, Visualinspections and Electricaltestsmirmunum100% (1)

- Air Handling Units COB AHU-10ADocument3 pagesAir Handling Units COB AHU-10AHernan RomeroNo ratings yet

- Appendix For Chiller MS Phase Rev.00 PDFDocument102 pagesAppendix For Chiller MS Phase Rev.00 PDFSamboy DionisioNo ratings yet

- Well Testing Procedure ExampleDocument15 pagesWell Testing Procedure ExampleMohamed MamdouhNo ratings yet

- AKSA Generator Startup Checklist - Editable PDFDocument2 pagesAKSA Generator Startup Checklist - Editable PDFTama42gmail.com AzryNo ratings yet

- PPM Task Sheet - MPGSDocument4 pagesPPM Task Sheet - MPGSJacobNo ratings yet

- 38aks Iom 60 HZDocument28 pages38aks Iom 60 HZJason FamilaranNo ratings yet

- Spec Upt Page 41Document58 pagesSpec Upt Page 41midhunvarNo ratings yet

- FAT Form Winch UnitDocument7 pagesFAT Form Winch UnitYadi KusmayadiNo ratings yet

- I11c Instrument Close Loop Check PG 1Document1 pageI11c Instrument Close Loop Check PG 1Momo ItachiNo ratings yet

- List of Checking - Test of HydroGenerator Set-1Document9 pagesList of Checking - Test of HydroGenerator Set-1Santosh MandalNo ratings yet

- Hvac Static Pressure Test: @T @S @D @SS @SSD @PDDocument2 pagesHvac Static Pressure Test: @T @S @D @SS @SSD @PDnayumNo ratings yet

- Operation Maintenance SOWDocument8 pagesOperation Maintenance SOWKiki Iswadi PrajamanggalaNo ratings yet

- Pre Commissioning Check List of GeneratorDocument26 pagesPre Commissioning Check List of GeneratorSUROHMAN ROHMANNo ratings yet

- Wiper Trip Opertion ProcedureDocument3 pagesWiper Trip Opertion ProcedureAlexander KlmNo ratings yet

- Prefunctional ChecklistsDocument37 pagesPrefunctional Checklistsrenjithv_4100% (1)

- Drives Td001 - en P Ultima VersionDocument6 pagesDrives Td001 - en P Ultima VersionCristian Yesid Pachon HernandezNo ratings yet

- Method Statement For Split AC Manufacturers Installation DetailsDocument77 pagesMethod Statement For Split AC Manufacturers Installation Detailsaaktgt MepNo ratings yet

- Barring GearDocument30 pagesBarring GearJeffrey MuellerNo ratings yet

- Maint. SchedulesDocument109 pagesMaint. SchedulesShahriyar Kabir RistaNo ratings yet

- Tripp Lite Owners Manual 772040Document32 pagesTripp Lite Owners Manual 772040InfraestructuraNo ratings yet

- Idoc - Pub - 13 Deluge Valve HD Fire PDFDocument17 pagesIdoc - Pub - 13 Deluge Valve HD Fire PDFĐinh TrọngNo ratings yet

- Hvacbms 190214045355Document57 pagesHvacbms 190214045355kksajjanamNo ratings yet

- 3/2-Way Solenoid Valve, Direct-Acting: Type 743Document4 pages3/2-Way Solenoid Valve, Direct-Acting: Type 743Francisco Mones RuizNo ratings yet

- Pre Commissioning ChecklistsDocument13 pagesPre Commissioning Checklistsmehul10941No ratings yet

- Standby GeneratorDocument11 pagesStandby Generatortecmak AngolaNo ratings yet

- Vacuum PumpsDocument2 pagesVacuum PumpsStefanVisNo ratings yet

- DPT Calibration FFDocument4 pagesDPT Calibration FFKram Alim VillonNo ratings yet

- Deluge Valve Model-H3Document16 pagesDeluge Valve Model-H3AJ MolinaNo ratings yet

- Tab Report Forms PRE TAB CHECK LIST (Systems Ready For TAB)Document21 pagesTab Report Forms PRE TAB CHECK LIST (Systems Ready For TAB)MMLNo ratings yet

- Generator Set Start-Up Checklist: Open Enclosed Generator SetsDocument2 pagesGenerator Set Start-Up Checklist: Open Enclosed Generator SetsEng Mamon StiNo ratings yet

- NFS2 3030 SpecificationDocument26 pagesNFS2 3030 SpecificationJC InquillayNo ratings yet

- Company Profile PT. Inako PersadaDocument22 pagesCompany Profile PT. Inako PersadaTiar_Rahman_9553No ratings yet

- Lec 10Document30 pagesLec 10ahmed EmadNo ratings yet

- Annexure To Start-Up & Commissioning of Fire Water PumpsDocument5 pagesAnnexure To Start-Up & Commissioning of Fire Water PumpsMina KhalilNo ratings yet

- Pneumatic P I DDocument12 pagesPneumatic P I Dmarine MukeshNo ratings yet

- Air Handling Unit QC Checklist: AHU InformationDocument5 pagesAir Handling Unit QC Checklist: AHU InformationRaheel AhmedNo ratings yet

- Generator Check ListDocument8 pagesGenerator Check Listtecmak AngolaNo ratings yet

- Compressor Autonomous ChecklistDocument1 pageCompressor Autonomous ChecklistsambasivammeNo ratings yet

- National Grid: Checklist For Commissioning of Oil-Immersed Power TransformerDocument8 pagesNational Grid: Checklist For Commissioning of Oil-Immersed Power TransformerSanthosh Kumar VinayagamNo ratings yet

- Mcti - CBF Current Check RelayDocument2 pagesMcti - CBF Current Check RelayTHILAKKUMARNo ratings yet

- Eot Ibl Crane Yearly ChecksheetDocument3 pagesEot Ibl Crane Yearly ChecksheetAmit ThakurNo ratings yet

- Contractor'S Material and Test Certificate Fire Sprinkler SystemsDocument4 pagesContractor'S Material and Test Certificate Fire Sprinkler SystemsToufik MedjNo ratings yet

- Execution of Hydro Power Plant - PLANNING AND OPERATIONDocument49 pagesExecution of Hydro Power Plant - PLANNING AND OPERATIONkapolaNo ratings yet

- DWLR, Bubbler Type (SW)Document7 pagesDWLR, Bubbler Type (SW)hydrologyproject0No ratings yet

- cOMMISSIONING 1 - WorksheetDocument60 pagescOMMISSIONING 1 - WorksheetPramod Dhir100% (1)

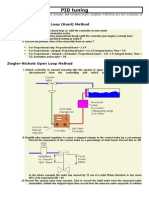

- PID TuningDocument4 pagesPID TuningJitendra Kumar100% (1)

- Soleusair Air Conditioner 10000 BtuDocument21 pagesSoleusair Air Conditioner 10000 BtuGreg JohnsonNo ratings yet

- Plumbing and Piping Systems Inspection Notes: Up to CodeFrom EverandPlumbing and Piping Systems Inspection Notes: Up to CodeRating: 3 out of 5 stars3/5 (2)

- Svensk Standard SS-EN 13438:2005: Fastställd 2005-11-11 Utgåva 1Document11 pagesSvensk Standard SS-EN 13438:2005: Fastställd 2005-11-11 Utgåva 1Muhammad Arslan Khurshid BhattiNo ratings yet

- Paints and Varnishes - Determination of Film Thickness (ISO 2808:2007)Document12 pagesPaints and Varnishes - Determination of Film Thickness (ISO 2808:2007)Muhammad Arslan Khurshid BhattiNo ratings yet

- Hra Panel SpecDocument4 pagesHra Panel SpecMuhammad Arslan Khurshid BhattiNo ratings yet

- Segmentation & Addressing Modes: Name Roll No Section MarksDocument6 pagesSegmentation & Addressing Modes: Name Roll No Section MarksMuhammad Arslan Khurshid BhattiNo ratings yet

- Roundtable - IEC 61850 Slides (20161115)Document157 pagesRoundtable - IEC 61850 Slides (20161115)Muhammad Arslan Khurshid BhattiNo ratings yet

- Classification by Target ParameterDocument5 pagesClassification by Target ParametersansureNo ratings yet

- OB Module 5Document48 pagesOB Module 5Neena MolNo ratings yet

- Adult Education in Tanzania - A Review - 3611Document120 pagesAdult Education in Tanzania - A Review - 3611elia eliaNo ratings yet

- Stock 2014 DiopsDocument770 pagesStock 2014 DiopsHoàng Minh HuyềnNo ratings yet

- ANSWERS Module 4 - PRACTICE EXAMDocument66 pagesANSWERS Module 4 - PRACTICE EXAMMahesh Chandra DixitNo ratings yet

- Inductive and Deductive ReasoningDocument6 pagesInductive and Deductive Reasoningkiahjessie100% (3)

- HRM Concept PaperDocument6 pagesHRM Concept PaperAlexis Andrew Antonio100% (1)

- Why We Are Shallow by F. Sionil JoseDocument3 pagesWhy We Are Shallow by F. Sionil JosePrecy M AgatonNo ratings yet

- Student Spending BehaviorDocument4 pagesStudent Spending BehaviorIka GhozaliNo ratings yet

- Myhumandesign Analysis As A PseudoscienceDocument1 pageMyhumandesign Analysis As A PseudoscienceDavid HukomNo ratings yet

- DaturaDocument18 pagesDaturaSundara Veer Raju MEDNo ratings yet

- LAS 1A The Magic PomegranateDocument2 pagesLAS 1A The Magic PomegranateCherry Maravilla Basa MingoaNo ratings yet

- Orthopedics Prometric Mcq1 SamplesDocument7 pagesOrthopedics Prometric Mcq1 SamplesshaifNo ratings yet

- Unit 3.2 - Material HandlingDocument23 pagesUnit 3.2 - Material Handlinglamao123No ratings yet

- Pavalion Cum Convention Centre: Topic: Site AnalysisDocument7 pagesPavalion Cum Convention Centre: Topic: Site AnalysisNaitik JaiswalNo ratings yet

- 201806290521342834814ReadyReckonerJune2018web PDFDocument94 pages201806290521342834814ReadyReckonerJune2018web PDFahabasiNo ratings yet

- HSC Data AnalysisDocument8 pagesHSC Data Analysisapi-249729474No ratings yet

- Unit-1 Introduction To Management and OrganizationsDocument73 pagesUnit-1 Introduction To Management and OrganizationsGnanesh GNo ratings yet

- PDF Data Science and Machine Learning Mathematical and Statistical Methods Chapman Hall CRC Machine Learning Pattern Recognition 1St Edition Dirk P Kroese Ebook Full ChapterDocument54 pagesPDF Data Science and Machine Learning Mathematical and Statistical Methods Chapman Hall CRC Machine Learning Pattern Recognition 1St Edition Dirk P Kroese Ebook Full Chaptercatherine.cottingham887100% (5)

- PLANTILLA de Animales para PresentaciónDocument53 pagesPLANTILLA de Animales para PresentaciónoliNo ratings yet

- Interocclusal Records in Prosthodontic Rehabilitations - Materials and Techniques - A Literature ReviewDocument7 pagesInterocclusal Records in Prosthodontic Rehabilitations - Materials and Techniques - A Literature ReviewnandaNo ratings yet

- Business Studies 2021 HSC Exam Pack NSW Education StandardsDocument3 pagesBusiness Studies 2021 HSC Exam Pack NSW Education Standardsmxstiia10No ratings yet

- Data Analysis ProjectDocument18 pagesData Analysis ProjectDaylyn MosherNo ratings yet

- Filament SecurityDocument12 pagesFilament Securitymahdi el100% (1)

- HOA5 Question PapersDocument5 pagesHOA5 Question Papersrevathi hariharanNo ratings yet

- MTTRAPD Huaweii2000 cl2Document3,295 pagesMTTRAPD Huaweii2000 cl2Muhammad AdnanNo ratings yet

- Pro Thesis 1Document20 pagesPro Thesis 1Anh GiangNo ratings yet