Professional Documents

Culture Documents

Xylem AC Fire Pump Systems

Xylem AC Fire Pump Systems

Uploaded by

fredguy0 ratings0% found this document useful (0 votes)

120 views8 pagesFor over 80 years, A-C Fire pump systems has been on the forefront in developing, designing and custom-building a wide range of fire pump systems. One of the first built fire trucks in the late 1800's was equipped with an A-C Fire pump. To protect the space shuttle launch facilities, NASA installed a fail-safe fire suppression system utilizing A-C Fire pumps.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFor over 80 years, A-C Fire pump systems has been on the forefront in developing, designing and custom-building a wide range of fire pump systems. One of the first built fire trucks in the late 1800's was equipped with an A-C Fire pump. To protect the space shuttle launch facilities, NASA installed a fail-safe fire suppression system utilizing A-C Fire pumps.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

120 views8 pagesXylem AC Fire Pump Systems

Xylem AC Fire Pump Systems

Uploaded by

fredguyFor over 80 years, A-C Fire pump systems has been on the forefront in developing, designing and custom-building a wide range of fire pump systems. One of the first built fire trucks in the late 1800's was equipped with an A-C Fire pump. To protect the space shuttle launch facilities, NASA installed a fail-safe fire suppression system utilizing A-C Fire pumps.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 8

52C11829

Fire Pump Systems

For the protection of life and property, A-C Fire Pump offers

package systems that meet every fire protection need.

2

A-C Fire Pump Systems and

Professional Fire Protection...

A Shared Tradition

of Excellence

One of the first fire trucks built in the late

1800s was equipped with an A-C Fire Pump.

For over 80 years, A-C Fire Pump Systems

has been on the forefront in developing,

designing and custom-building a wide range

of fire pump systems including prefabricated

packages and house units that meet every fire

protection need. A-C Fire Pump is not only

rich in history, but on the cutting edge of

new technology as demonstrated with our

contribution to the fire protection systems

for launch pads 39A and 39B for NASA at the

Kennedy Space Center. A-C Fire Pump

Systems furnished a package of four 12x8x22

9100 series horizontal splitcase pumps driven

by huge 1065 horsepower diesel engines

including state-of-the-art control systems.

Each pump is rated at 3,500 gallons per

minute at 250 psi pressure. We will continue

to be the leader in the fire protection industry

providing both excellent service and superior

products for years to come. You can always

count on A-C Fire Pump Systems to solve

your pumping problems.

One of the first built fire

trucks in the late 1800s was

equipped with an

A-C Fire pump.

To protect the space

shuttle launch facilities,

NASA installed a fail-safe

fire suppression system

utilizing A-C Fire pumps.

In-Line Pumps

n Top pullout design allows for fast

and easy servicing. The rotating

element is easily removed

without disturbing suction and

discharge piping.

n Self-venting design eliminates the

need for an automatic air release

valve.

n Bronze impeller is dynamically

balanced and keyed direct to the

motor shaft.

Capacity to 1500 GPM

(5,678 L/min)

Pressures to 165 PSI (116 m)

Working Pressures to 150 PSI

n Space saving design

n No foundation or pads required.

n Suction and discharge flanges are

on a common centerline, 180

apart for inline mounting in piping.

Vertical Turbine Pumps

problem free operation.

n Open lineshaft design provides for

product lubrication of the bearings.

n Available in electric motor or diesel

engine driven configuration.

n Provided with a bronze suction

strainer as standard.

n Provided with an oversized air

release valve as standard.

n Available in special materials

of construction for salt water

applications.

Capacity to 5000 GPM

(18,925 L/min)

Pressures to 350 PSI (247 m)

Working Pressures

up to 200 PSI with

125 lb. A.S.A. flanges

up to 550 PSI with

250 lb. A.S.A. flanges

n Required by NFPA when

operating under a static suction lift

condition.

n Dynamically balanced impellers

secured to the shaft with steel

locking collets to assure proper

End Suction Pumps

Capacity to 500 GPM

(1,892 L/min)

Pressures to 150 PSI (106 m)

Working Pressures to 250 PSI

n Top centerline discharge with

foot supported casing.

Ease of installation.

Simplifies piping layout.

Reduces problems associated

with piping strain.

n Self-venting design eliminates the

need for automatic air release valve.

n Rear pullout design supplied

as standard with spacer coupling.

Ease of maintenance,

eliminates disturbing

driver or piping when

removing rotating element.

n Hydraulically balanced impeller

extends bearing life and assures

smoother operation.

n Available in electric motor

or diesel engine driven

configuration.

8100 Series

n Space saving design.

n Available in horizontal or vertical

configuration.

n Suction and discharge flanges are

on a common centerline.

n Bearing span is kept to a minimum.

n Available in electric motor driven or

engine driven configuration.

n Available in clockwise or

counter-clockwise rotation to

simplify pump room layout.

Capacity to 3000 GPM

(11,355 L/min)

Pressures to 255 PSI (179 m)

Working Pressures

up to 250 PSI (176 m) with

125 lb. A.S.A. flanges

up to 375 PSI (264 m) with

250 lb. A.S.A. flanges

9100 Series

n Space saving design.

n Suction and discharge flanges are

on a common centerline.

n Dual volute casing balances radial

forces on the shaft and bearings.

n Available in electric motor driven or

engine driven configuration.

n Available in clockwise or

counter-clockwise rotation to

simplify pump room layout.

Capacity to 5000 GPM

(18,925 L/min)

Pressures to 208 PSI (146 m)

Working Pressures

up to 175 PSI (123 m) with

125 lb. A.S.A. flanges

up to 255 PSI (180 m) with

250 lb. A.S.A. flanges

8200 Series

n Bearing span is kept to a minimum.

n Compact pump design.

n Dual volute casing balances radial

forces on the shaft and bearings.

n Available in electric motor driven or

engine driven configuration.

n Two stage pump with two impellers

threaded together.

n Dynamic balanced impellers.

n Available in clockwise or

counter-clockwise rotation to

simplify pump room layout.

Capacity to 1000 GPM

(3,785 L/min)

Pressures to 640 PSI (450 m)

Working Pressures

up to 500 PSI (352 m) with

250 lb. A.S.A. flanges

up to 800 PSI (563 m) with

800 lb. A.S.A. flanges

n Space saving design.

n Suction and discharge flanges are

on a common centerline.

5

1

2

3

4

5

6

7

With A-C Fire Pump

Systems you can rest

assured of start-up and

future product support

being available locally,

worldwide.

n Components of A-C Fire Pump

Systems are labeled by one or

more of the following testing

laboratories: Underwriters

Laboratories (UL), Underwriters

Laboratories Canada (ULC),

Factory Mutual (FM)

n The equipment is completely

manufactured at our ISO 9001

facility.

n Packaged systems are

performance and hydrostatically

tested at our manufacturing facility

prior to shipment.

n Certified welding is available per

ASME section IX.

n Our fire pump packages have been

seismic qualification tested.

n Computer and CAD Design

capabilities assist you in the

design of a system custom built

to your specification. Complete

drawings are furnished for your

approval prior to manufacture.

n International distribution and

start up capabilities.

8

9

10

11

12

13

14

Select A-C Fire Pumps with confidence...

12

9

8

7

5

2

Skid Packages

Pressure sensing lines installed

per code requirements

UL Listed/FM Approved diesel

engine

Flowmeter loop

Listed OS and Y valve

Listed butterfly valve

Listed main relief valve

Single point electrical connection

(all electrical components

pre-wired at the factory)

Pre-piped fuel system

UL Listed FMapproved fire pump

controller

Closed waste cone

Listed check valve

Stuffing box and engine raw

water drain

UL Listed fuel tank sized per

NFPA #20

UL Listed FMapproved fire pump

4

1

11

5

14

10

6

13

3

1

2

3

4

5

6

House Packages

6

5

Big House

The largest pre-packaged

complete house unit ever built.

This system includes three

electric motor driven fire pumps,

16' x 53' and weighs 57,000 lbs.

1

4

3

6

Rigid I-beam base with optional

lifting provisions.

UL Listed motor for fire protection.

Pre-fabricated house designed for

specific geographic location.

Custom engineered piping system

designed for project requirements.

Listed control equipment pre-wired

to job driver and power distribution

panel...one electrical connection.

Listed control valves.

2

7

We realize that each customer

has different fire protection

needs, specific to each fire

hazard. We can design

a system around your needs,

just like the Saturn automotive

plant...special buildings, pump

materials and custom floor

arrangements. You need it

well provide it.

Versatility

a key word at

A-C Fire Pump Systems.

NFPA #20 requires the use of a

vertical turbine on systems operating

under a static suction lift condition

requirement. A-C Fire Pump Systems

offers the complete pre-packaged

system, pump, driver, controller,

low measuring device, control

valves, check valves, sensing lines and

power distribution panel. This system

requires one electrical connection and

a water supply. Its ready to provide

immediate, reliable fire protection.

Complete House Units pre-wired and

pre-pipedinstant fire suppression

n Engine combustion air intake vent

n Battery operated emergency lights

n A115V thermostat control

ventilating fan

n Single point power connection

n Exterior photocell sodium vapor

light

n Pre-piped sprinkler systems for

pump house interior

n GFCI utility electrical outlets

provided

n Base is provided with optional

lifting provisions

n Building heater

All A-C Fire Pumps are

performance and hydrostatically

tested in accordance with the

requirements of NFPA #20 and

are supplied as standard with a

packed stuff box, grease

lubricated bearings and cast

iron/bronze fitted materials of

construction.

For more information visit our website at

www.completewatersystems.com/brands/a-c-fire-pump

Vertical TurbinePackage

Xylem Applied Water Systems

a division of Xylem Canada Company

55 Royal Road, Guelph, Ontario

N1H 1T1, Canada

Phone: (519) 821-1900

Fax: (519) 821-5316

Package Systems

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.completewatersystems.com/brands/a-c-fire-pump

A-C Fire Pump is a trademark of Xylem Inc. or one of its subsidiaries.

2012 Xylem, Inc. 52C11829 August 2004

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Flygt MultiSmart - Release PresentationDocument46 pagesFlygt MultiSmart - Release PresentationfredguyNo ratings yet

- 802 1ad-2005Document74 pages802 1ad-2005lipe_sr100% (1)

- Serval Aviation Manufacturing CapabilitiesDocument4 pagesServal Aviation Manufacturing Capabilitiesapi-278922320No ratings yet

- TLF 2019 Catalog193Document252 pagesTLF 2019 Catalog193fredguy100% (1)

- Xylem AC-13D Home DefenderDocument2 pagesXylem AC-13D Home DefenderfredguyNo ratings yet

- Pop Up Menu ExamplesDocument1 pagePop Up Menu ExamplesfredguyNo ratings yet

- UV Lamp ELR30-1 EnglDocument1 pageUV Lamp ELR30-1 EnglfredguyNo ratings yet

- Uv-Ecoray en InetDocument3 pagesUv-Ecoray en InetfredguyNo ratings yet

- STEP7 V12 Migration Von AWL-Programmen Nach S7-1500 eDocument13 pagesSTEP7 V12 Migration Von AWL-Programmen Nach S7-1500 efredguyNo ratings yet

- 2.2l Ranger Fx4 at PMDocument2 pages2.2l Ranger Fx4 at PMooiNo ratings yet

- 36 มยผ.8116-52 มาตรฐานแผงควบคุมเครื่องสูบน้ำดับเพลิงDocument21 pages36 มยผ.8116-52 มาตรฐานแผงควบคุมเครื่องสูบน้ำดับเพลิงappril26No ratings yet

- Course: CCNA-Cisco Certified Network Associate: Exam Code: CCNA 640-802 Duration: 70 HoursDocument7 pagesCourse: CCNA-Cisco Certified Network Associate: Exam Code: CCNA 640-802 Duration: 70 HoursVasanthbabu Natarajan NNo ratings yet

- Use Case + Activity Diagram + JawabanDocument4 pagesUse Case + Activity Diagram + JawabanMichael MikaruNo ratings yet

- Single Phase Induction Motor Speed ControlDocument35 pagesSingle Phase Induction Motor Speed ControlHarshit Sengar100% (2)

- Imperial Assault Game Log Lite V4.3Document33 pagesImperial Assault Game Log Lite V4.3Sherif NasratNo ratings yet

- Subject Code and name:16CP2201 /research Methodology Question BankDocument7 pagesSubject Code and name:16CP2201 /research Methodology Question BankRevathimuthusamyNo ratings yet

- Control StructuresDocument9 pagesControl StructuresSachin AroraNo ratings yet

- Business Partner - CVIDocument13 pagesBusiness Partner - CVIGuru Prasad100% (1)

- SJ-20100211152857-010-ZXWN MSCS (V3.09.21) MSC Server Common Configuration Operation GuideDocument299 pagesSJ-20100211152857-010-ZXWN MSCS (V3.09.21) MSC Server Common Configuration Operation GuideadeepcdmaNo ratings yet

- 8BK88PLUSDocument8 pages8BK88PLUSSwapnil PatilNo ratings yet

- CCTVDocument27 pagesCCTVRAGAVI BNo ratings yet

- Project Report: BOI, Ban of IndiaDocument52 pagesProject Report: BOI, Ban of IndiaNilaya Shanker SrivastavaNo ratings yet

- Commissioning Step of The Power PlantDocument3 pagesCommissioning Step of The Power Plantssheart_mind100% (1)

- Eryigit Goldberg 120sDocument2 pagesEryigit Goldberg 120sElom Djadoo-ananiNo ratings yet

- Electrodo Lincoln 7018Document2 pagesElectrodo Lincoln 7018Erick Quan Luna100% (1)

- Stem To Steam Visual Art Signature Program References Education Trends Subscribe To RssDocument3 pagesStem To Steam Visual Art Signature Program References Education Trends Subscribe To Rssapi-221015864No ratings yet

- Gold NanorodsDocument13 pagesGold NanorodsS Sri ReddyNo ratings yet

- T-920 User Manual v1.2Document11 pagesT-920 User Manual v1.2Aung Kyaw OoNo ratings yet

- PWC Digital Iq ReportDocument30 pagesPWC Digital Iq ReportAndrijana GolubovićNo ratings yet

- Rotary Dryer DesignDocument43 pagesRotary Dryer DesignsasitharNo ratings yet

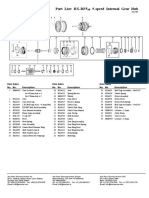

- Part List: RX-RF5 5-Speed Internal Gear HubDocument2 pagesPart List: RX-RF5 5-Speed Internal Gear HubTomislav KoprekNo ratings yet

- Transylvania County, North Carolina Mountain Real Estate Landslide Hazard DataDocument125 pagesTransylvania County, North Carolina Mountain Real Estate Landslide Hazard DataAnonymous rJ7m34No ratings yet

- South Gujarat University Format-ConfidentialDocument2 pagesSouth Gujarat University Format-ConfidentialRishi GargNo ratings yet

- Lesson Plan Art: Chalk Bat ShadowsDocument4 pagesLesson Plan Art: Chalk Bat Shadowsapi-301371005No ratings yet

- Danuhm Bush Air Cooled Split PACUDocument16 pagesDanuhm Bush Air Cooled Split PACUFalak KhanNo ratings yet

- De-119957 Diving SafetyDocument5 pagesDe-119957 Diving SafetyJithuJohnNo ratings yet

- Service-Oriented Computing:: State of The Art and Research ChallengesDocument19 pagesService-Oriented Computing:: State of The Art and Research Challengesapi-26748751No ratings yet