Professional Documents

Culture Documents

Mel Series Rev.005 - Mmel r.52 - Mei 2008

Mel Series Rev.005 - Mmel r.52 - Mei 2008

Uploaded by

Aditya RahmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mel Series Rev.005 - Mmel r.52 - Mei 2008

Mel Series Rev.005 - Mmel r.52 - Mei 2008

Uploaded by

Aditya RahmanCopyright:

Available Formats

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

GENERAL CONTENTS

GENERAL CONTENTS

I ssued : Mei , 2008 Revi si on : 005 Page: GC 1

THE CONTENTS OF THI S MEL ARE:

I NTRODUCTI ON

DEFI NI TI ON

ATA 21 : AI R CONDI TI ONI NG

ATA 22 : AUTO FLI GHT

ATA 23 : COMMUNI CATI ON

ATA 24 : ELECTRI CAL POWER

ATA 25 : EQUI PMENT AND FURNI SHI NG

ATA 26 : FI RE PROTECTI ON

ATA 27 : FLI GHT CONTROL

ATA 28 : FUEL

ATA 29 : HYDRAULI C POWER

ATA 30 : I CE AND RAI N PROTECTI ON

ATA 31 : I NDI CATI NG / RECORDI NG SYSTEM

ATA 32 : LANDI NG GEAR

ATA 33 : LI GHTS

ATA 34 : NAVI GATI ON

ATA 35 : OXYGEN

ATA 36 : PNEUMATI C

ATA 38 : WATER & WASTE

ATA 49 : AI RBORNE AUXI LLI ARY POWER

ATA 52 : DOORS

ATA 73 : ENGI NE FUEL AND CONTROL

ATA 74 : I GNI TI ON

ATA 75 : BLEED AI R

ATA 77 : ENGI NE I NDI CATI NG

ATA 78 : THRUST REEVERS

ATA 79 : ENGI NE OI L

ATA 80 : STARTI NG

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

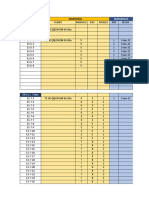

REVI SI ON RECORDS

REVI SI ON RECORDS

REVI SI ON

( I SSUE)

REVI SI ON

DATE

ENTERED

DATE

Remar ks

000 Nov, 1

st

2002 Nov, 1

st

2002 Or i gi nal

001 J ul y, 9

t h

2004 J ul y, 9

t h

2004

002 J ul y, 21

st

2005 J ul y, 21

st

2005

Re- i ssued

MMEL R. 47

003 Oct ober , 2006 Oct ober , 2006 MEL + CDL

004 Febr uar y, 2007 Febr uar y, 2007 MEL + CDL

005 Mei , 2008 Mei , 2008 MEL + CDL

Aut hor i t y Accept at i on

P. O. I

P. M. I

I ssued : Mei , 2008 Revi si on : 005 Page: RR 1

MI NI MUM EQUI PMENT LI ST

LI ST OF EFFECTI VE

( MEL)

BOEI NG 737- 300/ 400

PAGES

LIST OF EFFECTIVE PAGE

ITEM PAGE

REV

NO.

DATE ITEM PAGE

REV

NO.

DATE

I ssued : Mei , 2008 Revi si on : 005 Page: LOEP 1

STATEMENT - - Mei , 2008 ATA 21 21 12 005 Mei , 2008

ACCEPTANCE ACC 1 005 Mei , 2008 ATA 21 21 13 005 Mei , 2008

CONT. PAGE CP 1 005 Mei , 2008 ATA 21 21 14 005 Mei , 2008

PREAMBLE PRE 1 005 Mei , 2008 ATA 21 21 15 005 Mei , 2008

PREAMBLE PRE 2 005 Mei , 2008 ATA 21 21 16 005 Mei , 2008

GEN. CONT GC 1 005 Mei , 2008 ATA 21 21 17 005 Mei , 2008

REV. REC RR 1 005 Mei , 2008 ATA 21 21 18 005 Mei , 2008

ATA 21 21 19 005 Mei , 2008

LOEP LOEP 1 005 Mei , 2008 ATA 21 21 20 005 Mei , 2008

LOEP LOEP 2 005 Mei , 2008 ATA 21 21 21 005 Mei , 2008

LOEP LOEP 3 005 Mei , 2008 ATA 21 21 22 005 Mei , 2008

LOEP LOEP 4 005 Mei , 2008 ATA 21 21 23 005 Mei , 2008

LOEP LOEP 5 005 Mei , 2008 ATA 21 21 24 005 Mei , 2008

LOEP LOEP 6 005 Mei , 2008 ATA 21 21 25 005 Mei , 2008

ATA 21 21 26 005 Mei , 2008

LNAI LNAI 1 005 Mei , 2008 ATA 21 21 27 005 Mei , 2008

LNAI LNAI 2 005 Mei , 2008 ATA 21 21 28 005 Mei , 2008

LNAI LNAI 3 005 Mei , 2008 ATA 21 21 29 005 Mei , 2008

LNAI LNAI 4 005 Mei , 2008 ATA 21 21 30 005 Mei , 2008

LNAI LNAI 5 005 Mei , 2008 ATA 21 21 31 005 Mei , 2008

LNAI LNAI 6 005 Mei , 2008 ATA 21 21 32 005 Mei , 2008

LNAI LNAI 7 005 Mei , 2008 ATA 21 21 33 005 Mei , 2008

ATA 21 21 34 005 Mei , 2008

DEFI NI TI ONS D - 1 005 Mei , 2008 ATA 21 21 35 005 Mei , 2008

DEFI NI TI ONS D - 2 005 Mei , 2008 ATA 21 21 36 005 Mei , 2008

DEFI NI TI ONS D - 3 005 Mei , 2008 ATA 21 21 37 005 Mei , 2008

DEFI NI TI ONS D - 4 005 Mei , 2008 ATA 21 21 38 005 Mei , 2008

ATA 21 21 39 005 Mei , 2008

ATA 21 21 a 005 Mei , 2008 ATA 21 21 40 005 Mei , 2008

ATA 21 21 b 005 Mei , 2008 ATA 21 21 41 005 Mei , 2008

ATA 21 21 c 005 Mei , 2008 ATA 21 21 42 005 Mei , 2008

ATA 21 21 d 005 Mei , 2008 ATA 21 21 43 005 Mei , 2008

ATA 21 21 e 005 Mei , 2008 ATA 21 21 44 005 Mei , 2008

ATA 21 21 f 005 Mei , 2008 ATA 21 21 45 005 Mei , 2008

ATA 21 21 1 005 Mei , 2008 ATA 21 21 46 005 Mei , 2008

ATA 21 21 2 005 Mei , 2008 ATA 21 21 47 005 Mei , 2008

ATA 21 21 3 005 Mei , 2008 ATA 21 21 48 005 Mei , 2008

ATA 21 21 4 005 Mei , 2008 ATA 21 21 49 005 Mei , 2008

ATA 21 21 5 005 Mei , 2008 ATA 21 21 50 005 Mei , 2008

ATA 21 21 6 005 Mei , 2008 ATA 21 21 51 005 Mei , 2008

ATA 21 21 7 005 Mei , 2008 ATA 21 21 52 005 Mei , 2008

ATA 21 21 8 005 Mei , 2008 ATA 21 21 53 005 Mei , 2008

ATA 21 21 9 005 Mei , 2008 ATA 21 21 54 005 Mei , 2008

ATA 21 21 10 005 Mei , 2008 ATA 21 21 - 55 005 Mei , 2008

ATA 21 21 11 005 Mei , 2008

MI NI MUM EQUI PMENT LI ST

LI ST OF EFFECTI VE

( MEL)

BOEI NG 737- 300/ 400

PAGES

LIST OF EFFECTIVE PAGE

ITEM PAGE

REV

NO.

DATE ITEM PAGE

REV

NO.

DATE

I ssued : Mei , 2008 Revi si on : 005 Page: LOEP 2

ATA 22 22 a 005 Mei , 2008 ATA 24 24 b 005 Mei , 2008

ATA 22 22 b 005 Mei , 2008 ATA 24 24 1 005 Mei , 2008

ATA 22 22 1 005 Mei , 2008 ATA 24 24 2 005 Mei , 2008

ATA 22 22 2 005 Mei , 2008 ATA 24 24 3 005 Mei , 2008

ATA 22 22 3 005 Mei , 2008 ATA 24 24 4 005 Mei , 2008

ATA 22 22 4 005 Mei , 2008 ATA 24 24 5 005 Mei , 2008

ATA 22 22 5 005 Mei , 2008 ATA 24 24 6 005 Mei , 2008

ATA 22 22 6 005 Mei , 2008 ATA 24 24 7 005 Mei , 2008

ATA 22 22 7 005 Mei , 2008 ATA 24 24 8 005 Mei , 2008

ATA 22 22 8 005 Mei , 2008 ATA 24 24 9 005 Mei , 2008

ATA 22 22 9 005 Mei , 2008 ATA 24 24 10 005 Mei , 2008

ATA 22 22 10 005 Mei , 2008 ATA 24 24 11 005 Mei , 2008

ATA 22 22 11 005 Mei , 2008 ATA 24 24 12 005 Mei , 2008

ATA 22 22 12 005 Mei , 2008 ATA 24 24 13 005 Mei , 2008

ATA 22 22 13 005 Mei , 2008 ATA 24 24 14 005 Mei , 2008

ATA 22 22 14 005 Mei , 2008 ATA 24 24 15 005 Mei , 2008

ATA 22 22 15 005 Mei , 2008 ATA 24 24 16 005 Mei , 2008

ATA 22 22 16 005 Mei , 2008 ATA 24 24 17 005 Mei , 2008

ATA 22 22 17 005 Mei , 2008 ATA 24 24 18 005 Mei , 2008

ATA 22 22 18 005 Mei , 2008 ATA 24 24 19 005 Mei , 2008

ATA 22 22 19 005 Mei , 2008 ATA 24 24 20 005 Mei , 2008

ATA 22 22 20 005 Mei , 2008 ATA 24 24 21 005 Mei , 2008

ATA 22 22 21 005 Mei , 2008

ATA 25 25 1 005 Mei , 2008

ATA 23 23 a 005 Mei , 2008 ATA 25 25 2 005 Mei , 2008

ATA 23 23 b 005 Mei , 2008 ATA 25 25 3 005 Mei , 2008

ATA 23 23 c 005 Mei , 2008 ATA 25 25 4 005 Mei , 2008

ATA 23 23 1 005 Mei , 2008 ATA 25 25 5 005 Mei , 2008

ATA 23 23 2 005 Mei , 2008 ATA 25 25 6 005 Mei , 2008

ATA 23 23 3 005 Mei , 2008 ATA 25 25 7 005 Mei , 2008

ATA 23 23 4 005 Mei , 2008 ATA 25 25 8 005 Mei , 2008

ATA 23 23 5 005 Mei , 2008 ATA 25 25 9 005 Mei , 2008

ATA 23 23 6 005 Mei , 2008 ATA 25 25 10 005 Mei , 2008

ATA 23 23 7 005 Mei , 2008 ATA 25 25 11 005 Mei , 2008

ATA 23 23 8 005 Mei , 2008 ATA 25 25 12 005 Mei , 2008

ATA 23 23 9 005 Mei , 2008 ATA 25 25 13 005 Mei , 2008

ATA 23 23 10 005 Mei , 2008 ATA 25 25 14 005 Mei , 2008

ATA 23 23 11 005 Mei , 2008 ATA 25 25 15 005 Mei , 2008

ATA 23 23 12 005 Mei , 2008

ATA 23 23 13 005 Mei , 2008 ATA 26 26 a 005 Mei , 2008

ATA 23 23 14 005 Mei , 2008 ATA 26 26 b 005 Mei , 2008

ATA 23 23 15 005 Mei , 2008 ATA 26 26 c 005 Mei , 2008

ATA 23 23 16 005 Mei , 2008 ATA 26 26 1 005 Mei , 2008

ATA 26 26 2 005 Mei , 2008

ATA 24 24 a 005 Mei , 2008 ATA 26 26 3 005 Mei , 2008

MI NI MUM EQUI PMENT LI ST

LI ST OF EFFECTI VE

( MEL)

BOEI NG 737- 300/ 400

PAGES

LIST OF EFFECTIVE PAGE

ITEM PAGE

REV

NO.

DATE ITEM PAGE

REV

NO.

DATE

I ssued : Mei , 2008 Revi si on : 005 Page: LOEP 3

ATA 26 26 4 005 Mei , 2008 ATA 28 28 8 005 Mei , 2008

ATA 26 26 5 005 Mei , 2008 ATA 28 28 9 005 Mei , 2008

ATA 26 26 6 005 Mei , 2008 ATA 28 28 10 005 Mei , 2008

ATA 26 26 7 005 Mei , 2008 ATA 28 28 11 005 Mei , 2008

ATA 26 26 8 005 Mei , 2008 ATA 28 28 12 005 Mei , 2008

ATA 26 26 9 005 Mei , 2008 ATA 28 28 13 005 Mei , 2008

ATA 26 26 10 005 Mei , 2008 ATA 28 28 14 005 Mei , 2008

ATA 26 26 11 005 Mei , 2008 ATA 28 28 15 005 Mei , 2008

ATA 26 26 12 005 Mei , 2008 ATA 28 28 16 005 Mei , 2008

ATA 26 26 13 005 Mei , 2008 ATA 28 28 17 005 Mei , 2008

ATA 26 26 14 005 Mei , 2008 ATA 28 28 18 005 Mei , 2008

ATA 26 26 15 005 Mei , 2008 ATA 28 28 19 005 Mei , 2008

ATA 26 26 16 005 Mei , 2008 ATA 28 28 20 005 Mei , 2008

ATA 28 28 21 005 Mei , 2008

ATA 27 27 a 005 Mei , 2008 ATA 28 28 22 005 Mei , 2008

ATA 27 27 b 005 Mei , 2008 ATA 28 28 23 005 Mei , 2008

ATA 27 27 c 005 Mei , 2008 ATA 28 28 24 005 Mei , 2008

ATA 27 27 1 005 Mei , 2008 ATA 28 28 25 005 Mei , 2008

ATA 27 27 2 005 Mei , 2008 ATA 28 28 26 005 Mei , 2008

ATA 27 27 3 005 Mei , 2008 ATA 28 28 27 005 Mei , 2008

ATA 27 27 4 005 Mei , 2008 ATA 28 28 28 005 Mei , 2008

ATA 27 27 5 005 Mei , 2008 ATA 28 28 29 005 Mei , 2008

ATA 27 27 6 005 Mei , 2008 ATA 28 28 30 005 Mei , 2008

ATA 27 27 7 005 Mei , 2008

ATA 27 27 8 005 Mei , 2008 ATA 29 29 a 005 Mei , 2008

ATA 27 27 9 005 Mei , 2008 ATA 29 29 b 005 Mei , 2008

ATA 27 27 10 005 Mei , 2008 ATA 29 29 c 005 Mei , 2008

ATA 27 27 11 005 Mei , 2008 ATA 29 29 1 005 Mei , 2008

ATA 27 27 12 005 Mei , 2008 ATA 29 29 2 005 Mei , 2008

ATA 27 27 13 005 Mei , 2008 ATA 29 29 3 005 Mei , 2008

ATA 27 27 14 005 Mei , 2008 ATA 29 29 4 005 Mei , 2008

ATA 27 27 15 005 Mei , 2008 ATA 29 29 5 005 Mei , 2008

ATA 27 27 16 005 Mei , 2008 ATA 29 29 6 005 Mei , 2008

ATA 27 27 17 005 Mei , 2008 ATA 29 29 7 005 Mei , 2008

ATA 27 27 18 005 Mei , 2008 ATA 29 29 8 005 Mei , 2008

ATA 29 29 9 005 Mei , 2008

ATA 28 28 a 005 Mei , 2008 ATA 29 29 10 005 Mei , 2008

ATA 28 28 b 005 Mei , 2008 ATA 29 29 11 005 Mei , 2008

ATA 28 28 1 005 Mei , 2008 ATA 29 29 12 005 Mei , 2008

ATA 28 28 2 005 Mei , 2008 ATA 29 29 13 005 Mei , 2008

ATA 28 28 3 005 Mei , 2008 ATA 29 29 14 005 Mei , 2008

ATA 28 28 4 005 Mei , 2008

ATA 28 28 5 005 Mei , 2008 ATA 30 30 1 005 Mei , 2008

ATA 28 28 6 005 Mei , 2008 ATA 30 30 2 005 Mei , 2008

ATA 28 28 7 005 Mei , 2008 ATA 30 30 3 005 Mei , 2008

MI NI MUM EQUI PMENT LI ST

LI ST OF EFFECTI VE

( MEL)

BOEI NG 737- 300/ 400

PAGES

LIST OF EFFECTIVE PAGE

ITEM PAGE

REV

NO.

DATE ITEM PAGE

REV

NO.

DATE

I ssued : Mei , 2008 Revi si on : 005 Page: LOEP 4

ATA 30 30 4 005 Mei , 2008 ATA 33 33 5 005 Mei , 2008

ATA 30 30 5 005 Mei , 2008 ATA 33 33 6 005 Mei , 2008

ATA 30 30 6 005 Mei , 2008 ATA 33 33 7 005 Mei , 2008

ATA 30 30 7 005 Mei , 2008 ATA 33 33 8 005 Mei , 2008 |

ATA 30 30 8 005 Mei , 2008 ATA 33 33 9 005 Mei , 2008

ATA 30 30 9 005 Mei , 2008 ATA 33 33 10 005 Mei , 2008

ATA 30 30 10 005 Mei , 2008 ATA 33 33 11 005 Mei , 2008

ATA 30 30 11 005 Mei , 2008 ATA 33 33 12 005 Mei , 2008

ATA 30 30 12 005 Mei , 2008 ATA 33 33 13 005 Mei , 2008

ATA 30 30 13 005 Mei , 2008 ATA 33 33 14 005 Mei , 2008

ATA 30 30 14 005 Mei , 2008 ATA 33 33 15 005 Mei , 2008

ATA 30 30 15 005 Mei , 2008 ATA 33 33 16 005 Mei , 2008

ATA 30 30 16 005 Mei , 2008 ATA 33 33 17 005 Mei , 2008

ATA 30 30 17 005 Mei , 2008 ATA 33 33 18 005 Mei , 2008

ATA 30 30 18 005 Mei , 2008 ATA 33 33 19 005 Mei , 2008

ATA 30 30 19 005 Mei , 2008 ATA 33 33 20 005 Mei , 2008

ATA 30 30 20 005 Mei , 2008 ATA 33 33 21 005 Mei , 2008

ATA 30 30 21 005 Mei , 2008

ATA 30 30 22 005 Mei , 2008 ATA 34 34 1 005 Mei , 2008

ATA 30 30 - 23 005 Mei , 2008 ATA 34 34 2 005 Mei , 2008

ATA 34 34 3 005 Mei , 2008

ATA 31 31 1 005 Mei , 2008 ATA 34 34 4 005 Mei , 2008

ATA 31 31 2 005 Mei , 2008 ATA 34 34 5 005 Mei , 2008

ATA 31 31 3 005 Mei , 2008 ATA 34 34 6 005 Mei , 2008

ATA 31 31 4 005 Mei , 2008 ATA 34 34 7 005 Mei , 2008

ATA 31 31 - 5 005 Mei , 2008 ATA 34 34 8 005 Mei , 2008

ATA 34 34 9 005 Mei , 2008

ATA 32 32 a 005 Mei , 2008 ATA 34 34 10 005 Mei , 2008

ATA 32 32 b 005 Mei , 2008 ATA 34 34 11 005 Mei , 2008

ATA 32 32 1 005 Mei , 2008 ATA 34 34 13 005 Mei , 2008

ATA 32 32 2 005 Mei , 2008 ATA 34 34 14 005 Mei , 2008

ATA 32 32 3 005 Mei , 2008 ATA 34 34 15 005 Mei , 2008

ATA 32 32 4 005 Mei , 2008 ATA 34 34 16 005 Mei , 2008

ATA 32 32 5 005 Mei , 2008 ATA 34 34 17 005 Mei , 2008

ATA 32 32 6 005 Mei , 2008 ATA 34 34 18 005 Mei , 2008

ATA 32 32 7 005 Mei , 2008 ATA 34 34 19 005 Mei , 2008

ATA 32 32 8 005 Mei , 2008 ATA 34 34 20 005 Mei , 2008

ATA 32 32 9 005 Mei , 2008 ATA 34 34 21 005 Mei , 2008

ATA 32 32 10 005 Mei , 2008 ATA 34 34 22 005 Mei , 2008

ATA 34 34 23 005 Mei , 2008

ATA 33 33 a 005 Mei , 2008 ATA 34 34 24 005 Mei , 2008

ATA 33 33 1 005 Mei , 2008 ATA 34 34 25 005 Mei , 2008

ATA 33 33 2 005 Mei , 2008 ATA 34 34 26 005 Mei , 2008

ATA 33 33 3 005 Mei , 2008 ATA 34 34 27 005 Mei , 2008

ATA 33 33 4 005 Mei , 2008 ATA 34 34 28 005 Mei , 2008

MI NI MUM EQUI PMENT LI ST

LI ST OF EFFECTI VE

( MEL)

BOEI NG 737- 300/ 400

PAGES

LIST OF EFFECTIVE PAGE

ITEM PAGE

REV

NO.

DATE ITEM PAGE

REV

NO.

DATE

I ssued : Mei , 2008 Revi si on : 005 Page: LOEP 5

ATA 34 34 29 005 Mei , 2008 ATA 49 49 6 005 Mei , 2008

ATA 34 34 30 005 Mei , 2008 ATA 49 49 7 005 Mei , 2008

ATA 34 34 31 005 Mei , 2008 ATA 49 49 8 005 Mei , 2008

ATA 34 34 32 005 Mei , 2008 ATA 49 49 9 005 Mei , 2008

ATA 34 34 33 005 Mei , 2008 ATA 49 49 10 005 Mei , 2008

ATA 34 34 34 005 Mei , 2008 ATA 49 49 11 005 Mei , 2008

ATA 34 34 35 005 Mei , 2008 ATA 49 49 12 005 Mei , 2008

ATA 34 34 36 005 Mei , 2008 ATA 49 49 13 005 Mei , 2008

ATA 34 34 37 005 Mei , 2008 ATA 49 49 14 005 Mei , 2008

ATA 34 34 38 005 Mei , 2008 ATA 49 49 15 005 Mei , 2008

ATA 34 34 39 005 Mei , 2008

ATA 34 34 40 005 Mei , 2008 ATA 52 52 1 005 Mei , 2008

ATA 52 52 2 005 Mei , 2008

ATA 35 35 1 005 Mei , 2008 ATA 52 52 3 005 Mei , 2008

ATA 35 35 2 005 Mei , 2008 ATA 52 52 4 005 Mei , 2008

ATA 35 35 3 005 Mei , 2008 ATA 52 52 5 005 Mei , 2008

ATA 35 35 4 005 Mei , 2008 ATA 52 52 6 005 Mei , 2008

ATA 35 35 5 005 Mei , 2008 ATA 52 52 7 005 Mei , 2008

ATA 35 35 6 005 Mei , 2008 ATA 52 52 8 005 Mei , 2008

ATA 35 35 7 005 Mei , 2008 ATA 52 52 9 005 Mei , 2008

ATA 52 52 10 005 Mei , 2008

ATA 36 36 a 005 Mei , 2008 ATA 52 52 11 005 Mei , 2008

ATA 36 36 b 005 Mei , 2008 ATA 52 52 12 005 Mei , 2008

ATA 36 36 c 005 Mei , 2008 ATA 52 52 13 005 Mei , 2008

ATA 36 36 1 005 Mei , 2008 ATA 52 52 14 005 Mei , 2008

ATA 36 36 2 005 Mei , 2008

ATA 36 36 3 005 Mei , 2008 ATA 73 73 1 005 Mei , 2008

ATA 36 36 4 005 Mei , 2008 ATA 73 73 2 005 Mei , 2008

ATA 36 36 5 005 Mei , 2008 ATA 73 73 3 005 Mei , 2008

ATA 36 36 6 005 Mei , 2008 ATA 73 73 4 005 Mei , 2008

ATA 36 36 7 005 Mei , 2008 ATA 73 73 5 005 Mei , 2008

ATA 36 36 8 005 Mei , 2008

ATA 36 36 9 005 Mei , 2008 ATA 74 74 1 005 Mei , 2008

ATA 36 36 10 005 Mei , 2008 ATA 74 74 2 005 Mei , 2008

ATA 36 36 11 005 Mei , 2008

ATA 36 36 12 005 Mei , 2008 ATA 75 75 1 005 Mei , 2008

ATA 38 38 1 005 Mei , 2008 ATA 77 77 1 005 Mei , 2008

ATA 38 38 2 005 Mei , 2008 ATA 77 77 2 005 Mei , 2008

ATA 77 77 3 005 Mei , 2008

ATA 49 49 1 005 Mei , 2008 ATA 77 77 4 005 Mei , 2008

ATA 49 49 2 005 Mei , 2008 ATA 77 77 5 005 Mei , 2008

ATA 49 49 3 005 Mei , 2008 ATA 77 77 6 005 Mei , 2008

ATA 49 49 4 005 Mei , 2008 ATA 77 77 7 005 Mei , 2008

ATA 49 49 5 005 Mei , 2008

MI NI MUM EQUI PMENT LI ST

LI ST OF EFFECTI VE

( MEL)

BOEI NG 737- 300/ 400

PAGES

LIST OF EFFECTIVE PAGE

ITEM PAGE

REV

NO.

DATE ITEM PAGE

REV

NO.

DATE

I ssued : Mei , 2008 Revi si on : 005 Page: LOEP 6

ATA 78 78 1 005 Mei , 2008 ATA 79 79 2 005 Mei , 2008

ATA 78 78 2 005 Mei , 2008 ATA 79 79 3 005 Mei , 2008

ATA 78 78 3 005 Mei , 2008

ATA 78 78 4 005 Mei , 2008 ATA 80 80 1 005 Mei , 2008

ATA 80 80 2 005 Mei , 2008

ATA 79 79 1 005 Mei , 2008 ATA 80 80 3 005 Mei , 2008

COMPANY APPROVAL

DATE :

NAME & TITLE : HILMAN ZAIDAN

QA MANAGER

SIGN :

DGAC APPROVAL

DATE :

NAME & TI TLE : BONAR P. MANURUNG

PMI METRO BATAVIA

SIGN :

MI NI MUM EQUI PMENT LI ST

LI ST OF

( MEL)

BOEI NG 737- 300/ 400

NOT APPLI CABLE I TEMS

I TEM REMARKS

ATA 21

( 21- 1) 1) b) 700I GW/ - 800

( 21- 1) 1) c) - 900

( 21- 1) 1) d) - 100/ - 200

( 21- 1) 1) f ) - 600/ - 700/ - 800

( 21- 1) 1) g) - 900

( 21- 1) 2) Combi and Al l Car go Conf i gur at i ons

( 737C, QC, and STC ST01566LA)

( 21- 1) 3) Car go Conf i gur at i on ( - 700C)

( 21- 1) 4) COMBI and Al l Car go Conf i gur at i ons

( 21- 4) 2) Combi and Al l Car go Conf i gur at i ons

( 737C, QC)

( 21- 6) 2) Combi and Al l Car go Conf i gur at i ons

( 737C, QC)

( 21- 10) 2) Di gi t al Cont r ol Syst em

( - 300/ - 400/ - 500/ - 600/ - 700/ - 800/ - 900)

( 21- 12) 2) Di gi t al Cont r ol Syst em

( - 300/ - 400/ - 500/ - 600/ - 700/ - 800/ - 900)

( 21- 13) 2) Di gi t al Cont r ol Syst em

( - 300/ - 400/ - 500/ - 600/ - 700/ - 800/ - 900)

( 21- 14) 1) Anal og Cont r ol Syst emAut omat i c/ St andby Modes

( - 100/ - 200/ - 300/ - 400/ - 500)

( 21- 14) 3) Di gi t al Cont r ol Syst emAut omat i c Modes

( - 300/ - 400/ - 500/ - 600/ - 700/ - 800/ - 900)

( 21- 14) 4) Di gi t al Cont r ol Syst emManual Mode

( - 300/ - 400/ - 500/ - 600/ - 700/ - 800/ - 900)

( 21- 15) 2) Di gi t al Cont r ol Syst emOut f l ow Val ve Aut omat i c Mode

Act uat or s

( 21- 15) 3) Di gi t al Cont r ol Syst emOut f l ow Val ve Manual Mode Act uat or

( 21- 16) 2) Di gi t al Cont r ol Syst em

( - 300/ - 400/ - 500/ - 600/ - 700/ - 800/ - 900)

( 21- 19) 2) c) - 900

( 21- 20) I ncor por at ed i nt o i t em21- 17, Revi si on 34a.

( 21- 21) 2) c) - 900

( 21- 23) - 100/ - 200

( 21- 26) 2) Di gi t al Cont r ol Syst em

( 21- 27) 3) - 600/ - 700/ - 800/ - 900

( 21- 28) - 100/ - 200

( 21- 30) - 200

( 21- 31) 3) - 600/ - 700

( 21- 31) 4) - 800/ - 900

( 21- 31) 5) - 300QC/ F, - 400F

( 21- 35) 2) - 900

( 21- 36) 2) - 900

( 21- 40) 2) Di gi t al Cont r ol Syst em

( 21- 41) Door Ar ea Heat er Syst ems

( 21- 42) - 600/ - 700/ - 800/ - 900

( 21- 43) - 600/ - 700/ - 800/ - 900

( 21- 44) - 600/ - 700/ - 800/ - 900

( 21- 45) - 700C

( 21- 46) - 300RB

( 21- 47) - 800EF

( 21- 48) - 800EF

( 21- 49) - 600/ - 700/ - 800/ - 900

I ssued : Mei , 2008 Revi si on : 005 Page: LNAI 1

MI NI MUM EQUI PMENT LI ST

LI ST OF

( MEL)

BOEI NG 737- 300/ 400

NOT APPLI CABLE I TEMS

I TEM REMARKS

ATA 22

( 22- 3) 2) - 600/ - 700/ - 800/ - 900

( 22- 6) 2) - 100/ - 200

( 22- 12) - 100/ - 200

( 22- 16) 1) d) - 600/ - 700- 800/ - 900

( 22- 16) 1) e) - 600/ - 700- 800/ - 900

( 22- 20) 2) - 600/ - 700- 800/ - 900

ATA 23

( 23- 2) 2) Car go Conf i gur at i on

( 23- 2) 2) Car go Conf i gur at i on

( 23- 5) Del et ed by Revi si on 27. Rel i ef i ncor por at ed i nt o I t em23- 4.

( 23- 7) 1) Del et ed by Revi si on 33. Rel i ef i ncor por at ed i nt o I t em25-

11.

( 23- 7) 2) Del et ed by Revi si on 45, r el i ef i ncor por at ed i nt o I t em23- 4.

( 23- 8) Del et ed r evi si on 33, r el i ef i ncor por at ed i nt o I t em25- 11.

( 23- 9) N/ A t o BTV B737 Fl eet .

( 23- 14) 1) b) N/ A t o BTV B737 300/ 400 Fl eet .

( 23- 15) N/ A t o BTV B737 Fl eet .

( 23- 16) 3) N/ A t o BTV B737- 300/ 400 Fl eet .

( 23- 16) 4) N/ A t o BTV B737- 300/ 400 Fl eet .

( 23- 18) N/ A t o BTV B737 Fl eet .

( 23- 19) 2) Car go Conf i gur at i on

( 23- 20) 2) Car go Conf i gur at i on

( 23- 21) N/ A t o BTV B737 Fl eet .

( 23- 22) N/ A t o BTV B737 Fl eet .

( 23- 23) N/ A t o BTV B737 Fl eet .

( 23- 24) N/ A t o BTV B737 Fl eet .

( 23- 25) STC ST10345SC

( 23- 26) N/ A t o BTV B737 Fl eet .

ATA 24

( 24- 1) 2) - 600/ - 700/ - 800/ - 900

( 24- 1) 3) - 600/ - 700/ - 800/ - 900

( 24- 1) 4) - 600/ - 700/ - 800/ - 900

( 24- 4) 2) - 600/ - 700/ - 800/ - 900

( 24- 6) 1) - 100/ - 200

( 24- 16) 2) - 600/ - 700/ - 800/ - 900

( 24- 20) N/ A t o BTV B737 Fl eet

ATA 25

( 25- 2) Del et ed Revi si on 33, r el i ef i ncor por at ed i nt o I t em25- 11.

( 25- 3) 3) N/ A t o BTV 737 Fl eet

( 25- 3) 4) N/ A t o BTV 737 Fl eet

( 25- 5) 1) 737C, - 300 QC, and - 700C

( 25- 5) 2) Pemco 737 F/ QC and COMBI

( 25- 6) 3) N/ A t o BTV 737 Fl eet

( 25- 6) 4) DELETED REV 49.

( 25- 7) Moved t o I t em25- 11 pr i or t o Revi si on 30.

( 25- 8) Moved t o I t em52- 8 pr i or t o Revi si on 30.

( 25- 10) N/ A t o BTV 737 Fl eet

( 25- 11) 3) N/ A t o BTV 737 Fl eet

( 25- 13) N/ A t o BTV 737 Fl eet

( 25- 14) Car go

( 25- 15) Moved t o I t em21- 41 i n Revi si on 33.

( 25- 17) 3) DELETED REVI SI ON 46.

( 25- 17) 4) N/ A t o BTV 737 Fl eet

( 25- 19) Moved t o I t em25- 6 i n Revi si on 39.

( 25- 23) N/ A t o BTV B737 f l eet

( 25- 24) N/ A t o BTV B737 f l eet

( 25- 25) N/ A t o BTV B737 f l eet

I ssued : Mei , 2008 Revi si on : 005 Page: LNAI 2

MI NI MUM EQUI PMENT LI ST

LI ST OF

( MEL)

BOEI NG 737- 300/ 400

NOT APPLI CABLE I TEMS

I TEM REMARKS

I ssued : Mei , 2008 Revi si on : 005 Page: LNAI 3

( 25- 26) N/ A t o BTV B737 f l eet

( 25- 27) N/ A t o BTV B737 f l eet

( 25- 28) N/ A t o BTV B737 f l eet

( 25- 29) N/ A t o BTV B737 f l eet

( 25- 30) N/ A t o BTV B737 f l eet

ATA 26

( 26- 2) 1) - 100/ - 200

( 26- 11) Del et ed pr i or t o Revi si on 27.

( 26- 14) N/ A t o BTV B737- 300/ 400 f l eet

( 26- 17) - 100/ - 200

( 26- 19) N/ A t o BTV 737 f l eet

( 26- 20) I ncor por at ed i nt o i t em26- 19 i n Revi si on 39.

( 26- 21) N/ A t o BTV 737 f l eet

( 26- 22) N/ A t o BTV 737 f l eet

( 26- 23) N/ A t o BTV 737 f l eet ( STC ST09977)

( 26- 24) N/ A t o BTV 737 f l eet

ATA 27

( 27- 1) - 100/ - 200

( 27- 2) Del et ed pr i or t o Revi si on 27.

( 27- 3) 1) - 100/ - 200

( 27- 4) 1) - 100/ - 200

( 27- 4) 4) - 600/ - 700

( 27- 4) 5) - 800

( 27- 4) 6) - 900

( 27- 5) - 100/ - 200

( 27- 6) Moved t o I t em22- 5 pr i or t o Revi si on 27.

( 27- 7) 2) - 800/ - 900

( 27- 8) 1) - 100/ - 200

( 27- 8) 3) - 600

( 27- 8) 4) - 700

( 27- 8) 5) - 800

( 27- 8) 6) - 800 wi t h Shor t Fi el d Per f or mance ( SFP) Opt i on

( 27- 8) 7) - 900

( 27- 18) 2) - 700/ 800

( 27- 18) 3) - 700/ 800

( 27- 14) - 600/ - 700/ - 800/ - 900

( 27- 15) - 100/ - 200

( 27- 16) - 600/ - 700/ - 800/ - 900

( 27- 17) - 600/ - 700/ - 800/ - 900

( 27- 20) 1) - 700/ - 800

( 27- 22) 1) - 200

ATA 28

( 28- 1) 3) - 600/ - 700/ - 800/ - 900

( 28- 7) 1) - 100 and 600/ - 700/ - 800/ - 900

( 28- 7) 4) 600/ - 700/ - 800/ - 900

( 28- 13) Del et ed pr i or t o Revi si on 27.

( 28- 15) 1) N/ A t o BTV 737 f l eet

( 28- 22) 2) - 600/ - 700/ - 800/ - 900

( 28- 24) I ncor por at ed as a sub- i t emi n 28- 10 Rev 47a.

( 28- 100) PATS, - 600/ - 700/ - 800

( 28- 101) PATS, - 600/ - 700/ - 800

( 28- 102) PATS, - 600/ - 700/ - 800

( 28- 103) PATS, - 600/ - 700/ - 800

( 28- 104) PATS, - 600/ - 700/ - 800

( 28- 105) PATS, - 600/ - 700/ - 800

( 28- 106) PATS, - 600/ - 700/ - 800

( 28- 107) PATS, - 600/ - 700/ - 800

( 28- 108) PATS, - 600/ - 700/ - 800

MI NI MUM EQUI PMENT LI ST

LI ST OF

( MEL)

BOEI NG 737- 300/ 400

NOT APPLI CABLE I TEMS

I TEM REMARKS

I ssued : Mei , 2008 Revi si on : 005 Page: LNAI 4

( 28- 109) PATS, - 600/ - 700/ - 800

( 28- 110) PATS, - 600/ - 700/ - 800

( 28- 111) PATS, - 600/ - 700/ - 800

( 28- 112) PATS, - 600/ - 700/ - 800

( 28- 113) PATS, - 600/ - 700/ - 800

( 28- 114) PATS, - 600/ - 700/ - 800

( 28- 115) PATS, - 600/ - 700/ - 800

( 28- 116) PATS, - 600/ - 700/ - 800

( 28- 117) PATS, - 600/ - 700/ - 800

( 28- 118) PATS, - 600/ - 700/ - 800

( 28- 119) PATS, - 600/ - 700/ - 800

ATA 29

( 29- 1) - 100/ - 200

( 29- 2) 1) - 100/ - 200

( 29- 3) 1) - 100/ - 200

( 29- 6) Moved t o i t em32- 13, Revi si on 33.

( 29- 7) 1) - 100/ - 200

( 29- 7) 2) - 100/ - 200

( 29- 8) - 100/ - 200

( 29- 11) 1) - 100/ - 200

( 29- 14) I ncor por at ed i nt o I t em29- 7, i n Revi si on 39.

ATA 30

( 30- 1) 1) - 100/ - 200

( 30- 3) 1) - 100/ - 200

( 30- 3) 3) - 600/ - 700/ - 800/ - 900

( 30- 4) 1) - 100/ - 200

( 30- 4) 3) - 600/ - 700/ - 800/ - 900

( 30- 5) 2) - 600/ - 700/ - 800/ - 900

( 30- 9) 1) - 100/ - 200

( 30- 14) N/ A t o BTV 737 Fl eet

( 30- 15) N/ A t o BTV 737 Fl eet

( 30- 16) - 100/ - 200

( 30- 20) N/ A t o BTV 737 Fl eet

ATA 31

( 31- 1) N/ A t o BTV 737 Fl eet

( 31- 3) Moved t o MMEL I t em34- 41.

( 31- 4) 100/ - 200

( 31- 5) Moved t o MMEL I t em23- 10.

( 31- 6) N/ A t o BTV 737 Fl eet

( 31- 7) N/ A t o BTV 737 Fl eet

( 31- 8) - 600/ - 700/ - 800/ - 900

( 31- 10) - 600/ - 700/ - 800/ - 900

( 31- 11) N/ A t o BTV 737 Fl eet

( 31- 13) 1) N/ A t o BTV 737 Fl eet

( 31- 13) 2) N/ A t o BTV 737 Fl eet

( 31- 13) 3) N/ A t o BTV 737 Fl eet

( 31- 14) 2) - 600/ - 700/ - 800/ - 900

ATA 32

( 32- 1) - 100/ - 200

( 32- 2) 2) 1) - 600/ - 700/ - 800/ - 900

( 32- 4) 1) - 100/ - 200

( 32- 5) - 100/ - 200

( 32- 6) 1) Pemco F/ QC and COMBI

( 32- 9) N/ A t o BTV 737 Fl eet

( 32- 11) N/ A t o BTV 737 Fl eet

( 32- 13) 1) - 100/ - 200

( 32- 14) - 600/ - 700/ - 800/ - 900

MI NI MUM EQUI PMENT LI ST

LI ST OF

( MEL)

BOEI NG 737- 300/ 400

NOT APPLI CABLE I TEMS

I TEM REMARKS

I ssued : Mei , 2008 Revi si on : 005 Page: LNAI 5

( 32- 15) - 600/ - 700/ - 800/ - 900

( 32- 16) - 600/ - 700/ - 800/ - 900

( 32- 17) - 600/ - 700/ - 800/ - 900

( 32- 18) - 600/ - 700/ - 800/ - 900

( 32- 20) - 600/ - 700/ - 800/ - 900

( 32- 21) - 600/ - 700/ - 800/ - 900

( 32- 22) - 800

ATA 33

( 33- 4) 2) - 600/ - 700/ - 800

( 33- 4) 3) - 600/ - 700/ - 800

( 33- 5) 2) STCs ST01821LA and ST01873LA

( 33- 6) 1) a) - 700

( 33- 6) 1) b) Del et ed Revi si on 45 a. I ncor por at ed i nt o I t em33- 6.

( 33- 6) 1) c) N/ A t o BTV B737- 300 Fl eet

( 33- 6) 2) N/ A t o BTV 737 Fl eet

( 33- 11) 2) a) DELETED REVI SI ON 49a

( 33- 13) Del et ed pr i or t o Rev. 27.

( 33- 15) 1) Mi xed or Al l - Car go Conf i gur at i on

( 33- 15) 2) - 600/ - 700/ - 800/ - 900

( 33- 15) 3) ATI

( 33- 18) 2) b) - 600/ - 700/ - 800/ - 900

( 33- 21) 737C

( 33- 22) 737- 300 QC, PEMCO Aer opl ex, I nc. - 300/ - 400, and STC

ST01566LA

( 33- 24) N/ A t o BTV 737 Fl eet

ATA 34

( 34- 1) 1) a) - 600/ - 700/ - 800/ - 900

( 34- 2) 2) a) - 100/ - 200

( 34- 6) Del et e pr i or t o r evi si on 27.

( 34- 7) 2) N/ A t o BTV 737 Fl eet

( 34- 8) N/ A t o BTV 737 Fl eet |

( 34- 10) Del et e pr i or t o r evi si on 27.

( 34- 15) 2) N/ A t o BTV 737 Fl eet

( 34- 17) 2) N/ A t o BTV 737 Fl eet

( 34- 17) 3) - 600/ - 700/ - 800/ - 900

( 34- 18) 1) - 600/ - 700/ - 800/ - 900

( 34- 20) 1) a) - 100/ - 200

( 34- 20) 1) c) - 600/ - 700/ - 800/ - 900

( 34- 21) - 200

( 34- 22) - 100/ - 200

( 34- 24) Del et ad Rev 50 50 Moved t o 34- 1 Sub- i t em( 2)

( 34- 33) - 100/ - 200

( 34- 34) Moved t o I t em34- 3 pr i or t o Revi si on 30.

( 34- 36) 1) - 200 CMA- 900 FMS/ GPS

( 34- 36) 2) b) ( 2) N/ A t o BTV 737 Fl eet

( 34- 36) 2) d) ( 2) N/ A t o BTV 737 Fl eet

( 34- 38) N/ A t o BTV 737 Fl eet

( 34- 39) Del et ad Rev 50 50 Moved t o 34- 1 Sub- i t em

( 34- 41) - 100/ - 200

( 34- 42) 1) - 100/ - 200

( 34- 42) 3) - 600/ - 700/ - 800/ - 900

( 34- 44) N/ A t o BTV 737 Fl eet

( 34- 46) N/ A t o BTV 737 Fl eet

( 34- 48) 2) - 600/ - 700/ - 800/ - 900

( 34- 50) Del et ed i n Revi si on 37, r el i ef i ncor por at ed i nt o I t em34-

17.

( 34- 51) N/ A t o BTV 737 Fl eet

( 34- 52) STC

( 34- 53) N/ A t o BTV 737 Fl eet

( 34- 54) N/ A t o BTV 737 Fl eet

MI NI MUM EQUI PMENT LI ST

LI ST OF

( MEL)

BOEI NG 737- 300/ 400

NOT APPLI CABLE I TEMS

I TEM REMARKS

I ssued : Mei , 2008 Revi si on : 005 Page: LNAI 6

( 34- 55) - 600/ - 700/ - 800/ - 900

( 34- 56) - 600/ - 700/ - 800/ - 900

ATA 35

( 35- 1) Del et ed pr i or t o Revi si on 27.

( 35- 3) 3) - 100/ - 200

( 35- 3) 4) - 700C

ATA 36

( 36- 1) 1) - 100/ - 200

( 36- 1) 3) - 600/ - 700/ - 800/ - 900

( 36- 3) 1) - 100/ - 200

( 36- 5) 1) - 100/ - 200

( 36- 7) - 100/ - 200

ATA 49

( 49- 5) 2) GTCP36- 280, APS- 2000 and AS 131- 9B

( 49- 9) 2) - 600/ - 700/ - 800/ - 900

( 49- 14) - 100/ - 200

( 49- 15) - 600/ - 700/ - 800/ - 900

( 49- 16) - 600/ - 700/ - 800/ - 900

ATA 52

( 52- 2) - 100/ - 200

( 52- 3) 2) - 600/ - 700/ - 800/ - 900

( 52- 3) 3) - 800EF

( 52- 6) 3) - 600/ - 700/ - 800

( 52- 6) 4) - 600/ - 700/ - 800

( 52- 10) PEMCO Aer opl ex, I nc. STC SA2969SO

( 52- 11) PEMCO Aer opl ex, I nc. STC SA2969SO

( 52- 12) PEMCO F, QC and COMBI model s onl y

( 52- 13) N/ A t o BTV 737 Fl eet

( 52- 15) - 600/ - 700/ - 800/ - 900

( 52- 16) Car go Conf i gur at i on

( 52- 17) N/ A t o BTV 737 Fl eet

( 52- 18) N/ A t o BTV 737 Fl eet

( 52- 19) N/ A t o BTV 737 Fl eet

( 52- 20) N/ A t o BTV 737 Fl eet

( 52- 21) N/ A t o BTV 737 Fl eet

( 52- 22) N/ A t o BTV 737 Fl eet

ATA 73

( 73- 1) - 100/ - 200

( 73- 2) - 100/ - 200

( 73- 3) - 100/ - 200

( 73- 4) 1) - 100/ - 200

( 73- 9) Del et ed i n Revi si on 30.

( 73- 10) - 600/ - 700/ - 800/ - 900

( 73- 11) 1) - 600/ - 700/ - 800/ - 900

ATA 74

( 74- 1) 1) - 100/ - 200

ATA 75

( 75- 1) - 100/ - 200

ATA 77

( 77- 1) - 100/ - 200

( 77- 2) 1) - 100/ - 200

( 77- 3) - 100/ - 200

( 77- 4) Moved t o I t em73- 5 pr i or t o Revi si on 30.

( 77- 5) 1) - 100/ - 200

MI NI MUM EQUI PMENT LI ST

LI ST OF

( MEL)

BOEI NG 737- 300/ 400

NOT APPLI CABLE I TEMS

I TEM REMARKS

I ssued : Mei , 2008 Revi si on : 005 Page: LNAI 7

( 77- 7) Moved t o I t em34- 41 i n Revi si on 30.

( 77- 8) Moved t o I t em73- 6 pr i or t o Revi si on 30.

ATA 78

( 78- 1) 1) - 100/ - 200

( 78- 1) 3) - 600/ - 700/ - 800/ - 900

( 78- 3) Del et ed i n Revi si on 30.

( 78- 5) - 100/ - 200

( 78- 6) - 100/ - 200

ATA 79

( 79- 3) Del et ed pr i or t o Revi si on 27.

( 79- 5) Del et ed pr i or t o Revi si on 27.

ATA 80

( 80- 1) 1) - 100/ - 200

( 80- 2) 1) - 100/ - 200

( 80- 2) 3) - 600/ - 700/ - 800/ - 900

( 80- 3) 1) - 100/ - 200

( 80- 3) 3) - 600/ - 700/ - 800/ - 900

( 80- 4) - 100/ - 200

MI NI MUM EQUI PMENT LI ST

ATA : 21

( MEL)

BOEI NG 737- 300/ 400

AI R CONDI TI ONI NG

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - a

MI NI MUM EQUI PMENT LI ST

ATA : 21

( MEL)

BOEI NG 737- 300/ 400

AI R CONDI TI ONI NG

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - b

MI NI MUM EQUI PMENT LI ST

ATA : 21

( MEL)

BOEI NG 737- 300/ 400

AI R CONDI TI ONI NG

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - c

MI NI MUM EQUI PMENT LI ST

ATA : 21

( MEL)

BOEI NG 737- 300/ 400

AI R CONDI TI ONI NG

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - d

MI NI MUM EQUI PMENT LI ST

ATA : 21

( MEL)

BOEI NG 737- 300/ 400

AI R CONDI TI ONI NG

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - e

MI NI MUM EQUI PMENT LI ST

ATA : 21

( MEL)

BOEI NG 737- 300/ 400

AI R CONDI TI ONI NG

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - f

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 1

1. ( 21- 1) Ai r Condi t i oni ng Packs

1) Al l Passenger Conf i gur at i on

( Al l Model s)

a) ( - 300/ - 400) Wi t hout

PATS Auxi l i ar y Fuel

Tanks)

C 2 1 ( O) One may be i noper at i ve pr ovi ded

f l i ght al t i t ude r emai ns at or bel ow

FL 250.

|

e) ( - 300/ - 400) C 2 0 ( M) ( O) Bot h may be i noper at i ve

pr ovi ded:

a) Fl i ght i s conduct ed i n an

unpr essur i zed conf i gur at i on, and

b) Pr ocedur es ar e est abl i shed and

used t o ensur e l ower car go

compar t ment s r emai n empt y or ar e

ver i f i ed t o cont ai n onl y empt y

car go handl i ng equi pment , bal l ast

( bal l ast may be l oaded i n ULDs) ,

and/ or Fl y Away Ki t s.

NOTE: Oper at or MELs must def i ne

whi ch i t ems ar e appr oved f or

i ncl usi on i n Fl y Away Ki t s and

whi ch mat er i al s can be used as

bal l ast .

|

|

|

NOTE 3: For an i noper at i ve ai r condi t i oni ng pack, t he associ at ed pack ai r f l ow shut of f

val ve may be deact i vat ed cl osed per MMEL I t em21- 2 Mai nt enance pr ocedur e.

PLACARD

Af f ect ed pack swi t ch( es) - I NOP

MAI NTENANCE ( M)

TWO PACKS I NOP ( Unpr essur i zed)

- 300/ - 400:

1. Manual l y posi t i on out f l ow val ve f ul l open.

2. Advi se di spat ch f or unpr essur i zed f l i ght . Maxi mum al t i t ude f or f l i ght pl anni ng wi l l

be af f ect ed.

OPERATI ONS ( O)

For empt y car go compar t ment s:

Oper at or s must est abl i sh and use pr ocedur es t o ver i f y t he associ at ed compar t ment r emai ns

empt y or cont ai ns onl y bal l ast , empt y car go handl i ng equi pment ( bal l ast may be l oaded i n

ULDs) , or f l y away ki t s. The oper at or ' s MEL must def i ne whi ch i t ems ar e appr oved f or

i ncl usi on i n t he f l y away ki t s and whi ch mat er i al s can be used as bal l ast .

ONE PACK I NOP ( Pr essur i zed)

When di spat chi ng wi t h t he oper at i ng pack suppl i ed by engi ne bl eed ai r f or t akeof f , VMCG

shoul d be det er mi ned based on AC packs OFF ( not appl i cabl e t o - 100/ - 200 si nce VMCG i s not

dependent on pack st at us) . Takeof f per f or mance shoul d be based on AC packs ON/ AUTO.

|

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 2

- 300/ - 400:

a. Li mi t al t i t ude t o FL 250.

b. Onl y one gal l ey 4B f ood car t chi l l er ( i f i nst al l ed) may be used i nf l i ght .

c. ER oper at i ons ar e not al l owed.

d. Posi t i on t he associ at ed pack swi t ch t o OFF ( except - 900) . To mai nt ai n i sol at ed bl eed

sour ces, posi t i on t he i sol at i on val ve swi t ch t o CLOSE.

e. I f desi r ed, i ncr eased ai r f l ow can be obt ai ned when f l aps ar e ext ended ( t akeof f and

l andi ng) i f t he APU i s used i nst ead of engi ne bl eed t o suppl y bl eed ai r t o t he

oper at i ng pack. The f ol l owi ng pr ocedur e can be used t o accompl i sh t hi s.

1. Ri ght Pack I noper at i ve: Use t he Boei ng Oper at i ons Manual Suppl ement ar y

Pr ocedur e, No Engi ne Bl eed Takeof f and Landi ng Pr ocedur e. Per St ep 4, t he

r i ght pack swi t ch i s t o r emai n OFF ( except - 900) and t he i sol at i on val ve swi t ch

CLOSED.

2. Lef t Pack I noper at i ve:

1) Pr i or t o t akeof f or l andi ng, posi t i on engi ne no. 1 bl eed ai r swi t ch t o OFF,

r i ght pack swi t ch t o AUTO ( l ef t pack shoul d be OFF, except f or - 900) ,

i sol at i on val ve swi t ch t o OPEN, engi ne no. 2 bl eed ai r swi t ch t o OFF and APU

bl eed ai r swi t ch t o ON.

2) Af t er t akeof f or l andi ng, posi t i on t he APU bl eed ai r swi t ch t o OFF, engi ne

no. 2 bl eed ai r swi t ch t o ON, i sol at i on val ve swi t ch t o CLOSE and engi ne no.

1 bl eed ai r swi t ch t o ON.

TWO PACKS I NOP ( Unpr essur i zed)

- 300/ - 400:

1. Li mi t al t i t ude t o 10, 000 f t . f or passenger f l i ght s. Non- passenger f l i ght s above

10, 000 f t . r equi r e f l i ght cr ew t o be on oxygen.

2. Except f or di t chi ng, mai nt ai n out f l ow val ve i n t he f ul l open posi t i on.

3. To avoi d passenger di scomf or t , l i mi t cl i mb and descent r at es t o 500 FPM.

4. Wi t h pack deact i vat ed and t he i sol at i on val ve swi t ch i n t he AUTO posi t i on, t he

i sol at i on val ve wi l l r emai n cl osed when t he associ at ed pack swi t ch i s i n t he ON or

AUTO/ HI GH posi t i on. I f t he pack has not been deact i vat ed and t he af f ect ed pack swi t ch

i s i n t he OFF posi t i on, t he i sol at i on val ve wi l l open when t he i sol at i on val ve swi t ch

i s i n t he AUTO posi t i on. To mai nt ai n i sol at ed bl eed sour ces, posi t i on t he i sol at i on

val ve swi t ch t o CLOSE.

5. The f ol l owi ng st eps can be t aken t o i mpr ove bot h passenger cabi n and cr ew compar t ment

t emper at ur es:

A. I f possi bl e, pr e- condi t i on t he cabi n t o a l ow t emper at ur e pr i or t o di spat ch. A

l ow i ni t i al cabi n t emper at ur e wi l l r esul t i n a l ower peak t emper at ur e.

B. Mai nt ai n t he hi ghest al l owabl e f l i ght al t i t ude.

C. Mi ni mi ze cabi n heat by pul l i ng t he shades down and t ur ni ng of f unnecessar y

l i ght s.

D. Posi t i on Gasper Fan/ Reci r cul at i on Fan swi t ches as f ol l ows:

1) - 300/ - 400: Reci r cul at i on Fan( s) - AUTO.

E. Because of r educed vent i l at i on r at e ( appr oxi mat el y 1/ 6 of nor mal ) , consi der at i on

shoul d be gi ven t o f l i ght dur at i on and passenger l oad so t hat excessi ve cabi n

t emper at ur es may be avoi ded. Est i mat ed st abi l i zed t emper at ur es at t he end of 30

mi nut es of f l i ght ar e shown i n t he f ol l owi ng t abl es:

|

|

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 3

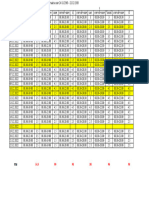

1) - 300/ - 400:

NO. PASS. CABI N CREWCABI N

TAT OF TEMPERATURE TEMPERATURE

C PASS F C F C

- 1 0 45 7 70 21

- 1 100 75 24 75 24

10 0 65 18 85 29

10 100 85 29 95 35

21 0 85 29 100 38

21 100 95 35 105 40

32 0 105 40 120 49

32 100 105 40 120 49

6. Pr ol onged oper at i on at TAT col der t han 10C may cause f r eezi ng of unheat ed wat er

syst ems l ocat ed i n t he af t l ower l obe.

7. Oper at i on at TAT hot t er t han 32C i s not r ecommended due t o t he r esul t i ng hi gh

t emper at ur es i n t he passenger and cr ew cabi ns.

|

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 4

2. ( 21- 2) Pack Ai r Fl ow/ Shut - of f

Val ves

C 2 0 ( M) ( O) May be i noper at i ve

deact i vat ed Cl osed.

1) Hi gh Fl ow Mode ( - 300/ - 400)

C 2 0 |

2) APU Hi gh Fl ow Mode C 2 0

NOTE: MMEL I t em 21- 1 r est r i ct i ons f or i noper at i ve pack( s) must be obser ved i f pack

ai r f l ow shut - of f val ve i s deact i vat ed cl osed.

PLACARD

Af f ect ed Pack Swi t ch( es) - I NOP or HI GH FLOWI NOP or APU HI GH FLOWI NOP as appr opr i at e

MAI NTENANCE ( M)

- 300/ - 400:

Deact i vat e and cl ose t he af f ect ed pack ai r f l ow shut - of f val ve( s) .

1. Remove pr essur e f r omt he pneumat i c syst em.

2. Gai n access t o t he i noper at i ve pack shut - of f val ve l ocat ed i n t he ai r condi t i oni ng

bay.

3. Di sconnect , cap and st ow t he el ect r i cal connect or ( s) D488 ( l ef t pack) and/ or D492

( r i ght pack) .

4. I f t he pack ai r f l ow shut - of f val ve l i mi t swi t ch has f ai l ed i n t he OPEN posi t i on:

A. Di sconnect t he el ect r i cal connect or ( s) D486 ( l ef t pack) and/ or D490 ( r i ght pack) ,

j umper pi n 1 t o pi n 3, and ver i f y cont i nui t y t o ai r pl ane gr ound at pi n 3.

B. Cap and st ow t he el ect r i cal connect or ( s) D486 ( l ef t pack) and/ or D490 ( r i ght

pack) .

5. Push i n t he manual cont r ol shaf t . I f al r eady i n, pul l out and push back i n t o ver i f y

t hat t he assembl y i s i n.

6. For bot h shut - of f val ves i noper at i ve ( Unpr essur i zed Fl i ght ) onl y, manual l y posi t i on

out f l ow val ve f ul l open.

7. Advi se di spat ch. Maxi mumal t i t ude f or f l i ght pl anni ng wi l l be af f ect ed.

OPERATI ONS ( O)

1. For di spat ch wi t h one Pack Ai r f l ow/ Shut - Of f Val ve i noper at i ve ( pr essur i zed) , use MMEL

I t em21- 1 One Pack I noper at i ve ( Pr essur i zed) Oper at i ons pr ocedur e.

2. For di spat ch wi t h bot h Pack Ai r f l ow/ Shut - Of f Val ves i noper at i ve, use MMEL I t em 21- 1

Two Packs I noper at i ve ( Unpr essur i zed) Oper at i ons pr ocedur e.

|

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 5

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 6

3. ( 21- 3) Pack Tr i p War ni ng

Syst ems

C 2 0 ( M) ( O) May be i noper at i ve pr ovi ded

associ at ed pack i s not used.

|

NOTE: MMEL I t em 21- 1 r est r i ct i ons f or i noper at i ve pack( s) must be obser ved. On 737C

ai r pl anes, t he l ef t pack must oper at e nor mal l y f or mai n cabi n smoke evacuat i on

pr ocedur es when t he ai r pl ane i s oper at ed i n a passenger / car go or al l car go

conf i gur at i on and car go i s car r i ed on t he mai n deck.

PLACARD

Associ at ed Pack Swi t ch( es) - I NOP

MAI NTENANCE ( M)

Use MMEL I t em21- 1 Mai nt enance pr ocedur e f or one or t wo packs i noper at i ve, as appl i cabl e.

OPERATI ONS ( O)

1. For di spat ch wi t h one Pack Tr i p War ni ng Syst em i noper at i ve ( pr essur i zed) , use MMEL

I t em21- 1 One Pack I noper at i ve ( Pr essur i zed) Oper at i ons pr ocedur e.

2. For di spat ch wi t h bot h Pack Tr i p War ni ng Syst ems i noper at i ve, use MMEL I t em 21- 1 Two

Packs I noper at i ve ( Unpr essur i zed) Oper at i ons pr ocedur e.

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 7

4. ( 21- 4) Pack Tur bof an ( - 300/ -

400)

|

1) Al l Passenger Conf i gur at i on

( Al l Model s)

C 2 0 ( O) May be i noper at i ve pr ovi ded

associ at ed pack( s) i s oper at ed onl y

i n f l i ght wi t h f l aps r et r act ed.

PLACARD

Pack swi t ch( es) - PACK TURBOFAN I NOP - USE PACK( S) ONLY I N FLI GHT WI TH FLAPS UP

OPERATI ONS ( O)

For empt y car go compar t ment s:

Oper at or s must est abl i sh and use pr ocedur es t o ver i f y t he associ at ed compar t ment r emai ns

empt y or cont ai ns onl y bal l ast , empt y car go handl i ng equi pment ( bal l ast may be l oaded i n

ULDs) , or f l y away ki t s. The oper at or ' s MEL must def i ne whi ch i t ems ar e appr oved f or

i ncl usi on i n t he f l y away ki t s and whi ch mat er i al s can be used as bal l ast .

NOTE: The t ur bi ne ai r suppl y val ve i s act i vat ed el ect r i cal l y when t he associ at ed pack i s

t ur ned on and t he ai r gr ound saf et y sensor or t he f l ap l i mi t swi t ch i s act i vat ed.

When f l aps ar e ext ended, posi t i on af f ect ed pack swi t ch( es) t o OFF. Wi t h af f ect ed pack

swi t ch( es) i n OFF posi t i on, t he i sol at i on val ve wi l l be open when i sol at i on val ve swi t ch

i s i n t he AUTO posi t i on. To mai nt ai n i sol at ed bl eed sour ces, posi t i on t he i sol at i on val ve

swi t ch t o CLOSE.

When di spat chi ng wi t h a si ngl e oper at i ng pack suppl i ed by engi ne bl eed ai r f or t akeof f ,

VMCG shoul d be det er mi ned based on AC packs OFF. Takeof f per f or mance shoul d be based on

AC packs ON/ AUTO.

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 8

5. ( 21- 5) Pack RamAi r Syst ems C 2 0 ( M) ( O) May be i noper at i ve i n FLI GHT

OPEN posi t i on pr ovi ded:

a) Oper at i ons ar e not conduct ed on

r unways cover ed wi t h sl ush, or on

gr avel r unways, and

b) Associ at ed pack i s not oper at ed

dur i ng t akeof f or l andi ng on wet

r unways or r unways wi t h st andi ng

wat er .

|

*** 1) Exhaust Louver Assembl i es

( - 300/ - 400)

C 2 0 ( M) ( O) May be i noper at i ve pr ovi ded:

a) Act uat or ( s) i s di sconnect ed, and

b) Louver ( s) i s secur ed i n f ul l open

posi t i on.

|

PLACARD

Af f ect ed pack swi t ch( es) - PACK RAM AI R SYSTEM - I NOP

MAI NTENANCE ( M)

- 300/ - 400:

RAM AI R MODULATI NG SYSTEM I NOPERATI VE

1. Gai n access t o t he r amai r act uat or l ocat ed adj acent t o t he r amai r exi t .

2. Di sconnect , cap and st ow t he el ect r i cal connect or t o t he r amai r act uat or .

3. Remove at t achi ng bol t and separ at e act uat or shaf t r od end bear i ng f r om t or que shaf t

quadr ant ar m. Rei nst al l and secur e bol t i n t or que shaf t quadr ant ar m.

4. By hand, r ot at e t or que shaf t quadr ant and cabl e syst em t o al i gn r i g pi n hol es ( 1/ 4

i nch di amet er ) f or t he FLI GHT OPEN posi t i on. Ref er t o f ol l owi ng dr awi ng.

5. I nser t a bol t ( NAS6704U10 or equi val ent ) t hr ough t he r i g pi n hol e i n t he pul l ey and

t hr ead i t i nt o t he nut pl at e ( NAS1068- A4) on t he suppor t assembl y.

6. Secur e t he act uat or shaf t r od end bear i ng t o t he at t ach bol t at t he end of t he t or que

shaf t quadr ant ar musi ng saf et y wi r e.

7. Cl ose and secur e access panel s.

|

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 9

RAM AI R EXHAUST LOUVER ASSEMBLY I NOPERATI VE

1. Gai n access t o t he r amai r exhaust modul at i on l ouver assembl y.

2. Remove exhaust l ouver act uat i ng shaf t f r om t he t or que shaf t quadr ant at t he out boar d

uni ver sal j oi nt . Tape shaf t down t o pr event vi br at i on.

3. Al i gn t he r i g pi n hol e and boss and i nst al l a bol t ( AN4H7A or equi val ent ) t hr ough t he

ar mr i ggi ng pi n hol e i nt o t he r i ggi ng pi n boss.

4. Secur e t he bol t i n pl ace by r unni ng saf et y wi r e t hr ough t he dr i l l ed head bol t and

t hen ar ound t he act uat i ng ar m.

5. Cl ose and secur e access panel s.

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 10

OPERATI ONS ( O)

NOTE: For t he - 300/ - 400, di spat chi ng wi t h one pack i noper at i ve ( MMEL I t em 21- 1) and t he

ot her pack s r am ai r syst em i noper at i ve ( r am ai r i nl et door i n t he FLI GHT OPEN

posi t i on) may l ead t o i ci ng i n t he oper at i ng pack s wat er separ at or , af f ect i ng pack

per f or mance.

When oper at i ng on wet r unways or r unways wi t h st andi ng wat er wi t h t he r am ai r i nl et door

i noper at i ve i n t he FLI GHT OPEN posi t i on, pl ace af f ect ed pack( s) t o OFF posi t i on dur i ng

t akeof f and l andi ng. Wi t h af f ect ed pack swi t ch( es) i n OFF posi t i on, t he i sol at i on val ve

wi l l be open when i sol at i on val ve swi t ch i s i n AUTO posi t i on. To mai nt ai n i sol at ed bl eed

sour ces, pl ace t he i sol at i on val ve swi t ch t o CLOSE.

When di spat chi ng wi t h a si ngl e oper at i ng pack suppl i ed by engi ne bl eed ai r f or t akeof f ,

VMCG shoul d be det er mi ned based on AC packs OFF. Takeof f per f or mance shoul d be based on

AC packs ON/ AUTO.

For each pack r amai r syst emaf f ect ed, t he f ol l owi ng per f or mance penal t i es can be used t o

account f or t he i ncr eased dr ag associ at ed wi t h; ( 1) t he r amai r i nl et door i noper at i ve i n

t he FLI GHT OPEN posi t i on, ( 2) t he exhaust l ouver s i noper at i ve i n t he f ul l open posi t i on.

ENROUTE CLI MB FUEL MI LEAGE

MODEL

I NLET DOOR

EXHAUST

LOUVERS

I NLET DOOR

EXHAUST

LOUVERS

- 300/ - 400 480 Lbs. 140 Lbs. 1. 2% 0. 4%

|

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 11

6. ( 21- 6) Pack Tur bof an Val ves

( - 300/ - 400)

|

1) Al l Passenger Conf i gur at i on

( Al l Model s)

C 2 0 ( M) ( O) May be i noper at i ve Cl osed

pr ovi ded associ at ed pack( s) i s

oper at ed onl y i n f l i ght wi t h f l aps

r et r act ed.

PLACARD

Pack swi t ch( es) - TURBOFAN VALVE I NOP - USE PACK( S) ONLY I N FLI GHT WI TH FLAPS UP

MAI NTENANCE ( M)

1. Gai n access t o t he val ve. Ri ght val ve i s l ocat ed i n t he r i ght equi pment bay at t he

f or war d end wher e t he val ve duct connect s t o t he r i ght pack col d ai r suppl y duct . The

l ef t val ve i s l ocat ed i n t he l ef t equi pment bay i nboar d of t he t ur bof an.

2. Di sconnect and st ow t he t ur bof an val ve sol enoi d el ect r i cal connect or .

3. Push i n t he sol enoi d manual over r i de pl unger . I f al r eady i n, pul l out and push back

i n t o ver i f y t hat t he pl unger i s i n t he cl osed posi t i on.

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 12

OPERATI ONS ( O)

For empt y car go compar t ment s:

Oper at or s must est abl i sh and use pr ocedur es t o ver i f y t he associ at ed compar t ment r emai ns

empt y or cont ai ns onl y bal l ast , empt y car go handl i ng equi pment ( bal l ast may be l oaded i n

ULDs) , or f l y away ki t s. The oper at or ' s MEL must def i ne whi ch i t ems ar e appr oved f or

i ncl usi on i n t he f l y away ki t s and whi ch mat er i al s can be used as bal l ast .

NOTE: The t ur bi ne ai r suppl y val ve i s act i vat ed el ect r i cal l y when t he associ at ed pack i s

t ur ned on and t he ai r gr ound saf et y sensor or t he f l ap l i mi t swi t ch i s act i vat ed.

When f l aps ar e ext ended, posi t i on af f ect ed pack swi t ch( es) t o OFF. Wi t h af f ect ed pack

swi t ch( es) i n OFF posi t i on, t he i sol at i on val ve wi l l be open when i sol at i on val ve swi t ch

i s i n t he AUTO posi t i on. To mai nt ai n i sol at ed bl eed sour ces, posi t i on t he i sol at i on val ve

swi t ch t o CLOSE.

When di spat chi ng wi t h a si ngl e oper at i ng pack suppl i ed by engi ne bl eed ai r f or t akeof f ,

VMCG shoul d be det er mi ned based on AC packs OFF ( not appl i cabl e t o - 100/ - 200 si nce VMCG

i s not dependent on pack st at us) . Takeof f per f or mance shoul d be based on AC packs

ON/ AUTO.

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 13

7. ( 21- 7) RAM DOOR FULL OPEN

I ndi cat i ng Li ght s

C 2 0

PLACARD

Associ at ed RamDoor Ful l Open Li ght - I NOP

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 14

8. ( 21- 8) Ai r Mi x Val ves ( - 300)

C 2 0 ( M) ( O) May be i noper at i ve pr ovi ded

associ at ed pack i s not used.

|

NOTE: MMEL I t em21- 1 r est r i ct i ons f or i noper at i ve pack( s) must be obser ved.

PLACARD

Associ at ed Pack Swi t ch( es) - AI R MI X VLV I NOP - LEAVE PACK OFF

MAI NTENANCE ( M)

Use MMEL I t em21- 1 Mai nt enance pr ocedur e f or one or t wo packs i noper at i ve, as appl i cabl e.

OPERATI ONS ( O)

1. For di spat ch wi t h one Ai r Mi x Val ve i noper at i ve ( pr essur i zed) , use MMEL I t em21- 1 One

Pack I noper at i ve ( Pr essur i zed) Oper at i ons Pr ocedur e.

2. For di spat ch wi t h bot h Ai r Mi x Val ves i noper at i ve, use MMEL I t em 21- 1 Two Packs

I noper at i ve ( Unpr essur i zed) Oper at i ons Pr ocedur e.

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 15

9. ( 21- 9) Ai r Mi x Val ve Posi t i on

I ndi cat or s ( - 300)

C 2 0

|

PLACARD

Associ at ed Ai r Mi x Val ve Posi t i on I ndi cat or - I NOP

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 16

10. ( 21- 10) Cabi n Rat e of Cl i mb

I ndi cat or

1) Anal og Cont r ol Syst em

( - 300/ - 400)

C 1 0 May be i noper at i ve pr ovi ded AUTO and

STBY cont r ol modes oper at e nor mal l y.

|

C 1 0 ( M) ( O) May be i noper at i ve pr ovi ded

f l i ght i s conduct ed i n unpr essur i zed

conf i gur at i on.

PLACARD

Cabi n Rat e of Cl i mb I ndi cat or - I NOP

MAI NTENANCE ( M)

Conf i gur e ai r pl ane f or unpr essur i zed f l i ght .

1. Manual l y posi t i on t he out f l ow val ve i n t he f ul l / par t i al open posi t i on as appl i cabl e.

A. For Anal og Syst em, posi t i on t he out f l ow val ve i n t he f ul l open posi t i on as

f ol l ows.

1) Pl ace t he Pr essur i zat i on Mode Sel ect or i n t he AC MAN or DC MAN posi t i on.

2) Hol d t he VALVE t oggl e swi t ch i n t he OPEN posi t i on unt i l val ve posi t i on

i ndi cat or i ndi cat es f ul l open

2. Advi se di spat ch. Maxi mumal t i t ude f or f l i ght pl anni ng wi l l be af f ect ed.

OPERATI ONS ( O)

1. Li mi t al t i t ude t o 10, 000 f t . f or passenger f l i ght s. Non- passenger f l i ght s above

10, 000 f t . r equi r e f l i ght cr ew t o be on oxygen.

2. Except f or di t chi ng, mai nt ai n out f l ow val ve i n t he f ul l open ( Anal og Syst em) posi t i on

as appl i cabl e.

3. For - 300/ - 400:

A. Onl y one A/ C Pack may be used i nf l i ght .

When di spat chi ng wi t h t he oper at i ng pack suppl i ed by engi ne bl eed ai r f or

t akeof f , VMCG shoul d be det er mi ned based on AC packs OFF. Takeof f

per f or mance shoul d be based on AC packs ON/ AUTO.

B. Onl y one gal l ey 4B f ood car t chi l l er ( i f i nst al l ed) may be used i nf l i ght .

4. To avoi d passenger di scomf or t , l i mi t cl i mb and descent r at es t o 500 FPM.

For empt y car go compar t ment s:

Oper at or s must est abl i sh and use pr ocedur es t o ver i f y t he associ at ed compar t ment r emai ns

empt y or cont ai ns onl y bal l ast , empt y car go handl i ng equi pment ( bal l ast may be l oaded i n

ULDs) , or f l y away ki t s. The oper at or ' s MEL must def i ne whi ch i t ems ar e appr oved f or

i ncl usi on i n t he f l y away ki t s and whi ch mat er i al s can be used as bal l ast .

|

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 17

11. ( 21- 11) Cabi n Al t i t ude War ni ng

Syst em

C 1 0 May be i noper at i ve pr ovi ded f l i ght

al t i t ude r emai ns at or bel ow 10, 000

f eet MSL.

*** 1) Hi gh Al t i t ude War ni ng

Syst em

C 1 0 May be i noper at i ve pr ovi ded

pr ocedur es do not r equi r e i t s use.

*** 2) CABI N ALTI TUDE Li ght

|

|

a) - 300/ - 400 ( Upon

i ncor por at i on of Boei ng

Ser vi ce Bul l et i n 737-

31A1325)

C 1 0 May be i noper at i ve pr ovi ded TAKEOFF

CONFI G war ni ng l i ght oper at es

nor mal l y.

|

|

|

|

PLACARD

Pr essur i zat i on Cont r ol Panel - CABI N ALTI TUDE WARNI NG SYSTEM or HI GH ALTI TUDE WARNI NG

SYSTEM - I NOP

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 18

12. ( 21- 12) Cabi n Al t i t ude

I ndi cat or

1) Anal og Cont r ol syst em

( 300/ - 400)

C 1 0 May be i noper at i ve pr ovi ded:

a) Cabi n di f f er ent i al pr essur e

i ndi cat or oper at es nor mal l y, and

b) A char t i s pr ovi ded t o cr ew t o

conver t di f f er ent i al pr essur e t o

cabi n al t i t ude.

|

|

C 1 0 ( M) ( O) May be i noper at i ve pr ovi ded

f l i ght i s conduct ed i n an

unpr essur i zed conf i gur at i on.

PLACARD

Cabi n Al t i t ude I ndi cat or - I NOP

MAI NTENANCE ( M)

Conf i gur e ai r pl ane f or unpr essur i zed f l i ght .

1. Manual l y posi t i on t he out f l ow val ve i n t he f ul l / par t i al open posi t i on as appl i cabl e.

A. For Anal og Syst em, posi t i on t he out f l ow val ve i n t he f ul l open posi t i on as

f ol l ows.

1) Pl ace t he Pr essur i zat i on Mode Sel ect or i n t he AC MAN or DC MAN posi t i on.

2) Hol d t he VALVE t oggl e swi t ch i n t he OPEN posi t i on unt i l val ve posi t i on

i ndi cat or i ndi cat es f ul l open.

2. Advi se di spat ch. Maxi mumal t i t ude f or f l i ght pl anni ng wi l l be af f ect ed.

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 19

OPERATI ONS ( O)

1. Li mi t al t i t ude t o 10, 000 f t . f or passenger f l i ght s. Non- passenger f l i ght s above

10, 000 f t . r equi r e f l i ght cr ew t o be on oxygen.

2. Except f or di t chi ng, mai nt ai n out f l ow val ve i n t he f ul l open ( Anal og Syst em) or 25%

open ( Di gi t al Syst em) posi t i on as appl i cabl e.

3. For - 300/ - 400:

A. Onl y one A/ C Pack may be used i nf l i ght .

When di spat chi ng wi t h t he oper at i ng pack suppl i ed by engi ne bl eed ai r f or

t akeof f , VMCG shoul d be det er mi ned based on AC packs OFF. Takeof f

per f or mance shoul d be based on AC packs ON/ AUTO.

B. Onl y one gal l ey 4B f ood car t chi l l er ( i f i nst al l ed) may be used i nf l i ght .

4. To avoi d passenger di scomf or t , l i mi t cl i mb and descent r at es t o 500 FPM.

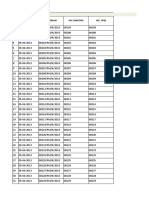

NOTE: The f ol l owi ng char t can be used t o f i nd Cabi n Al t i t ude.

For empt y car go compar t ment s:

Oper at or s must est abl i sh and use pr ocedur es t o ver i f y t he associ at ed compar t ment r emai ns

empt y or cont ai ns onl y bal l ast , empt y car go handl i ng equi pment ( bal l ast may be l oaded i n

ULDs) , or f l y away ki t s. The oper at or ' s MEL must def i ne whi ch i t ems ar e appr oved f or

i ncl usi on i n t he f l y away ki t s and whi ch mat er i al s can be used as bal l ast .

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 20

13. ( 21- 13) Cabi n Di f f er ent i al

Pr essur e I ndi cat or

1) Anal og Cont r ol Syst em ( -

300/ - 400)

C 1 0 May be i noper at i ve pr ovi ded:

a) Cabi n al t i t ude i ndi cat or oper at es

nor mal l y, and

b) A char t i s pr ovi ded t o cr ew t o

conver t cabi n al t i t ude t o

di f f er ent i al pr essur e.

|

|

C 1 0 ( M) ( O) May be i noper at i ve pr ovi ded

f l i ght i s conduct ed i n an

unpr essur i zed conf i gur at i on.

PLACARD

Cabi n Di f f er ent i al Pr essur e I ndi cat or - I NOP

MAI NTENANCE ( M)

Conf i gur e ai r pl ane f or unpr essur i zed f l i ght .

1. Manual l y posi t i on t he out f l ow val ve i n t he f ul l / par t i al open posi t i on as appl i cabl e.

A. For Anal og Syst em, posi t i on t he out f l ow val ve i n t he f ul l open posi t i on as

f ol l ows.

1) Pl ace t he Pr essur i zat i on Mode Sel ect or i n t he AC MAN or DC MAN posi t i on.

2) Hol d t he VALVE t oggl e swi t ch i n t he OPEN posi t i on unt i l val ve posi t i on

i ndi cat or i ndi cat es f ul l open.

2. Advi se di spat ch. Maxi mumal t i t ude f or f l i ght pl anni ng wi l l be af f ect ed.

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 21

OPERATI ONS ( O)

1. Li mi t al t i t ude t o 10, 000 f t . f or passenger f l i ght s. Non- passenger f l i ght s above

10, 000 f t . r equi r e f l i ght cr ew t o be on oxygen.

2. Except f or di t chi ng, mai nt ai n out f l ow val ve i n t he f ul l open ( Anal og Syst em) posi t i on

as appl i cabl e.

3. For - 300/ - 400:

A. Onl y one A/ C Pack may be used i nf l i ght .

When di spat chi ng wi t h t he oper at i ng pack suppl i ed by engi ne bl eed ai r f or

t akeof f , VMCG shoul d be det er mi ned based on AC packs OFF. Takeof f

per f or mance shoul d be based on AC packs ON/ AUTO.

B. Onl y one gal l ey 4B f ood car t chi l l er ( i f i nst al l ed) may be used i nf l i ght .

4. To avoi d passenger di scomf or t , l i mi t cl i mb and descent r at es t o 500 FPM.

NOTE: The f ol l owi ng char t can be used t o f i nd di f f er ent i al pr essur e.

For empt y car go compar t ment s:

Oper at or s must est abl i sh and use pr ocedur es t o ver i f y t he associ at ed compar t ment r emai ns

empt y or cont ai ns onl y bal l ast , empt y car go handl i ng equi pment ( bal l ast may be l oaded i n

ULDs) , or f l y away ki t s. The oper at or ' s MEL must def i ne whi ch i t ems ar e appr oved f or

i ncl usi on i n t he f l y away ki t s and whi ch mat er i al s can be used as bal l ast .

|

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 22

14. ( 21- 14) Cabi n Pr essur e Cont r ol

Syst em

2) Anal og Cont r ol Syst em

Aut omat i c/ St andby/ Manual

Modes ( - 300/ - 400)

C 3 0 ( M) ( O) May be i noper at i ve f or

unpr essur i zed f l i ght pr ovi ded:

a) Out f l ow val ve i s deact i vat ed open

or r emoved, and

b) Ext ended over wat er f l i ght i s

pr ohi bi t ed.

|

PLACARD

Pr essur i zat i on Mode Sel ect or posi t i on( s) - I NOP

MAI NTENANCE ( M)

For unpr essur i zed f l i ght , r ef er t o MMEL I t em 21- 15 ( Out f l ow Val ve) and accompl i sh t he

unpr essur i zed f l i ght Mai nt enance ( M) Pr ocedur es.

OPERATI ONS ( O)

For empt y car go compar t ment s:

Oper at or s must est abl i sh and use pr ocedur es t o ver i f y t he associ at ed compar t ment r emai ns

empt y or cont ai ns onl y bal l ast , empt y car go handl i ng equi pment ( bal l ast may be l oaded i n

ULDs) , or f l y away ki t s. The oper at or ' s MEL must def i ne whi ch i t ems ar e appr oved f or

i ncl usi on i n t he f l y away ki t s and whi ch mat er i al s can be used as bal l ast .

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 23

1. ANALOG CONTROL SYSTEM

A. Nor mal oper at i on of manual modes may be conf i r med as f ol l ows:

1) Sel ect MAN AC on t he Pr essur i zat i on Mode Sel ect or .

a. By appr opr i at e use of t he VALVE t oggl e swi t ch, obser ve t hat t he out f l ow

val ve posi t i on i ndi cat or moves t o f ul l open, t o f ul l cl osed and t hen back

t o f ul l open.

2) Sel ect MAN DC on t he Pr essur i zat i on Mode Sel ect or .

a. By appr opr i at e use of t he VALVE t oggl e swi t ch, obser ve t hat t he out f l ow

val ve posi t i on i ndi cat or moves t o f ul l open, t o f ul l cl osed and t hen back

t o f ul l open.

3) I f val ve posi t i on i ndi cat or f ai l s t o r espond i n ei t her MAN AC or MAN DC,

di spat ch must be i n accor dance wi t h MMEL I t em21- 15 f or unpr essur i zed f l i ght .

B. For pr essur i zed f l i ght when STBY Mode i s i noper at i ve, modi f y t he f ol l owi ng f l i ght

cr ew Non- Nor mal Pr ocedur es as f ol l ows.

1) DOOR ANNUNCI ATOR: I f MAI N CARGO l i ght i l l umi nat es or i f EQUI P, FWD/ AFT CARGO

or AI RSTAI R l i ght i l l umi nat es and pr essur i zat i on i s not nor mal :

a. Fol l owi ng descent t o 13, 000 f eet or MEA ( whi chever i s hi gher ) , set LAND

ALT t o 13, 000 f eet i f MEA i s not above 13, 000 f eet . I f MEA i a above 13, 000

f eet , set pr essur i zat i on mode sel ect or t o MAN and adj ust out f l ow val ve t o

i ncr ease cabi n al t i t ude t o MEA.

2) SMOKE REMOVAL: I f pack( s) ar e ON and smoke sour ce i s conf i r med t o be i n t he

cockpi t or mai n cabi n:

a. I ncr ease vent i l at i on r at e by set t i ng LAND ALT t o 10, 000 f eet .

3) ARCI NG/ DELAMI NATED/ SHATTERED OR CRACKED WI NDOW:

a. I f Wi ndow 3 i s NOT af f ect ed; Set LAND ALT t o 10, 000 f eet .

b. I f Wi ndow 3 i s af f ect ed; Set LAND ALT t o 13, 000 f eet .

C. For unpr essur i zed f l i ght , r ef er t o MMEL I t em21- 15 ( Out f l ow Val ve) and accompl i sh

t he unpr essur i zed f l i ght Oper at i ons ( O) Pr ocedur es.

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 24

15. ( 21- 15) Mai n Out f l ow Val ve

1) Anal og Cont r ol Syst em

Out f l ow Val ve Act uat or s ( AC

and/ or DC) ( - 300/ - 400)

C 2 1 One act uat or may be i noper at i ve f or

pr essur i zed car go- onl y f l i ght ,

pr ovi ded ai r pl ane i s depr essur i zed

bef or e l andi ng.

|

C 2 0 ( M) ( O) May be i noper at i ve f or

unpr essur i zed f l i ght pr ovi ded:

a) Out f l ow val ve i s deact i vat ed open

or r emoved, and

b) Ext ended over wat er f l i ght i s

pr ohi bi t ed.

PLACARD

UNPRESSURI ZED FLI GHT:

Pr essur i zat i on Mode Sel ect or - PRESS SYS I NOP

PRESSURI ZED FLI GHT:

1. For Anal og Syst em, pl acar d near t he Pr essur i zat i on Mode Sel ect or - MAN MODE AC/ DC

I NOP

2. I f Aut o Mode ( Di gi t al Syst em) i s i noper at i ve, sel ect ALTN on t he Pr essur i zat i on Mode

Sel ect or and pl acar d AUTO MODE I NOP

MAI NTENANCE ( M)

UNPRESSURI ZED FLI GHT

- 300/ - 400:

1. Manual l y posi t i on t he out f l ow val ve i n t he f ul l / par t i al open posi t i on as appl i cabl e.

A. For Anal og Syst em, posi t i on ( i f r equi r ed) t he out f l ow val ve i n t he f ul l open

posi t i on as f ol l ows.

1) Pl ace t he Pr essur i zat i on Mode Sel ect or i n t he AC MAN or DC MAN posi t i on.

2) Hol d t he VALVE t oggl e swi t ch i n t he OPEN posi t i on unt i l val ve posi t i on

i ndi cat or i ndi cat es f ul l open.

B. I f out f l ow val ve cannot be posi t i oned t o ei t her t he f ul l open ( Anal og Syst em) or

25% open ( Di gi t al Syst em) posi t i on as appl i cabl e, r emove val ve per AMM 21- 31- 11.

St ow el ect r i cal connect or s.

|

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 25

2. Open and col l ar t he f ol l owi ng P- 6 Panel out f l ow val ve ci r cui t br eaker s:

A. For Anal og Syst em: MANUAL AC, MANUAL DC, AUTO AC, AUTO DC, STBY AC and STBY DC.

B. For Di gi t al Syst em: PRESSURI ZATI ON CONTROL - MAN, PRESSURI ZATI ON CONTROL - AUTO

1, PRESSURI ZATI ON CONTROL - AUTO 2, PRESSURI ZATI ON CONTROL - I ND and

PRESSURI ZATI ON CONTROL - LCD LTG.

3. Advi se di spat ch. Maxi mumal t i t ude f or f l i ght pl anni ng wi l l be af f ect ed.

OPERATI ONS ( O)

For empt y car go compar t ment s:

Oper at or s must est abl i sh and use pr ocedur es t o ver i f y t he associ at ed compar t ment r emai ns

empt y or cont ai ns onl y bal l ast , empt y car go handl i ng equi pment ( bal l ast may be l oaded i n

ULDs) , or f l y away ki t s. The oper at or ' s MEL must def i ne whi ch i t ems ar e appr oved f or

i ncl usi on i n t he f l y away ki t s and whi ch mat er i al s can be used as bal l ast .

NOTE 1: For Anal og Syst em, pr essur i zed f l i ght al l owed f or car go- onl y f l i ght s. Ensur e

ai r cr af t i s depr essur i zed pr i or t o l andi ng.

NOTE 2: For pr essur i zed f l i ght wi t h t he Di gi t al Syst em i nst al l ed, i f AUTO mode i s

i noper at i ve, oper at e Cabi n Pr esur i zat i on Cont r ol l er i n ALTN mode f or aut omat i c

cabi n pr essur e cont r ol .

UNPRESSURI ZED FLI GHT

1. Li mi t al t i t ude t o 10, 000 f t . f or passenger f l i ght s. Non- passenger f l i ght s above

10, 000 f t . r equi r e f l i ght cr ew t o be on oxygen.

2. To avoi d passenger di scomf or t , l i mi t cl i mb and descent r at es t o 500 FPM.

3. Ext ended over wat er f l i ght i s not per mi t t ed.

4. For - 300/ - 400:

A. Onl y one A/ C Pack may be used i nf l i ght . On t he 737- 900 wi t h t he f or war d car go

heat duct secur ed cl osed, pl ace t he pack i n HI GH af t er compl et i ng t he AFTER

TAKEOFF checkl i st . When di spat chi ng wi t h t he oper at i ng pack suppl i ed by engi ne

bl eed ai r f or t akeof f , VMCG shoul d be det er mi ned based on AC packs OFF. Takeof f

per f or mance shoul d be based on AC packs ON/ AUTO.

B. Onl y one gal l ey 4B f ood car t chi l l er ( i f i nst al l ed) may be used i nf l i ght .

MI NI MUM EQUI PMENT LI ST

( MEL)

BOEI NG 737- 300/ 400

ATA : 21

AI R CONDI TI ONI NG

CATEGORY

NUMBER I NSTALLED

NUMBER REQUI RED FOR DI SPATCH

SEQ

NO

I TEM

REMARK AND / OR EXCEPTI ON

I ssued : Mei , 2008 Revi si on : 005 Page: 21 - 26

16. ( 21- 16) Pr essur e Rel i ef Val ves

1) Anal og Cont r ol Syst em

( - 300/ - 400)

C 2 1 ( M) One may be i noper at i ve cl osed

f or pr essur i zed f l i ght .

|

C 2 0 ( M) ( O) May be i noper at i ve pr ovi ded

f l i ght i s conduct ed i n an

unpr essur i zed conf i gur at i on.

PLACARD

Cabi n Al t i t ude/ Di f f er ent i al Pr essur e I ndi cat or - PRESS RELI EF VALVE( S) I NOP

MAI NTENANCE ( M)

PRESSURI ZED FLI GHT

Boei ng i s not awar e of any r el i abl e way t o secur e a saf et y r el i ef val ve i n t he cl osed

posi t i on. I f one val ve i s i noper at i ve and pr essur i zed f l i ght i s desi r ed, i nst al l a

bl anki ng pl at e per t he f ol l owi ng i nst r uct i ons.

1. Remove t he af t bul khead l i ner i n t he af t car go compar t ment .