Professional Documents

Culture Documents

P2325

P2325

Uploaded by

dsiucOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P2325

P2325

Uploaded by

dsiucCopyright:

Available Formats

tecsis GmbH DE 232 i

Carl-Legien Str. 40

D-63073 Offenbach / Main Sales national Sales international e-Mail: info@tecsis.de p. 1 / 3

Tel.: +49 69 5806-0 Fax: +49 69 5806-170 Fax: +49 69 5806-177 Internet: www.tecsis.de

| Force | Pressure | Temperature | Switch

All stainless steel pressure gauges

with Bourdon tube, with and without glycerine filling

Accuracy class 1.0

Nominal sizes ND 100

Connection position bottom, radial or back, eccentric

Description

The all stainless steel pressure gauges are ideal for

the hard conditions and the resulting high demands

on pressure measurement in production facilities in

chemical industry and other comparable branches.

Resistance to aggressive media and environments

is achieved by using highgrade materials such as

stainless steel both for the measuring system and

the case.

The glycerin-filled version is damped for wear-

protection should pulsating pressures and

mechanical vibrations occur. The measuring system

is of accuracy class 1.0, has overrange protection

amounting to 1.3 times the max. rating and can be

loaded up to the full scale value.

A series of installation possibilities enables adaption

to special requirements and installation conditions.

Features

o Stainless steel case and measuring system

o Protection IP 65

o Accuracy class 1.0

o For use up to full scale value

o Overrange protection 1.3 times max.

o Case with or without filling

Measuring ranges

0 ... 0.6 bar to 0 ... 1000 bar

Applications

Chemical and petrochemical industry;

Foodstuffs and beverages industry;

Plastics and paper industry;

Machine and apparatus construction

License:

Models: P2324, P2325, P2328, P2329

DE 232 i

p. 2 / 3

Technical data

Models P2324 P2325 P2328 P2329 Options

Nominal size 100

Symbol

Accuracy class 1.0 to EN 837-1

Ranges 0 ... 0.6 bar to 0 ... 1000 bar

negative gauge pressure or negative/positive gauge pressure

Application Constant load: up to full scale value

Alternating load: up to 0.9 x fullscale value

Overpressure protection

1.3 x , short-time

1.5 to 2 x max. rating depending on

range

Liquid filling none Glycerine none Glycerine

Case Stainless steel 1.4301 , bare

Pressure relief opening (sealed with rubber cover)

Stainless steel 1.4301, polished,

Bezel Stainless steel 1.4301

Mounting

without

Front flange, ss 1.4301 polished

Rear flange stainless steel 1.4301,

blank

Triangular bezel, ss polished with U-

clamp, steel zinc plated

Window Laminated safety glass Plexiglass

Dial Alumimium, white, scale and imprint black Dual scale

Pointer Aluminium, black microadjustable pointer,

red Al marker pointer on dial

marker pointer on plexiglass with key

adjustment or fixed knob

Movement Stainless steel plastic gearing and bearing; oil-

damped

pointer spindle (Manocont)

Measuring element

Stainless steel 316 L

(Bourdon tube up to 60 bar, helical tube from 100 bar)

Monel: Model P2200 and P2201

Connection

- position

Stainless steel 316 L

bottom

back eccentric

Monel: Model P2200 and P2201

- thread G 1/2 B; (1/2-14 NPT; 1/4-18 NPT; M 20 x 1.5)

Other threads on request,

protective cap for thread

Temperatures

- Medium

- Ambient

Tmin. -20C, Tmax. 100C

Tmin. -25C, Tmax. 60C

media temp. 200C on request

(only unfilled gauges)

Temperature drift 0.4%/10K if deviation from normal temperature 20C

Orifice without 0,3; 0.4; 0.8

Protection IP 65 to EN 60 529/IEC 529

Weight 0.6 kg 1.0 kg 0.6 kg 1.0 kg

DE 232 i

p. 3 / 3

Dimensions

Modifications reserved

Model P2324 / P2325

hole pattern for front

and rear flanges

Model P2324 / P2325

rear flange

Model P2328 / P2329

front flange

Model P2328 / P2329

with triangular bezel

and U-clamp

You might also like

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- CIE Publist 2011 FebruaryDocument11 pagesCIE Publist 2011 FebruaryMido AbdoNo ratings yet

- Contradictions of Plato's IdeasDocument6 pagesContradictions of Plato's Ideaskissinger2020No ratings yet

- All Stainless Steel Pressure Gauges With Bourdon Tube, With and Without Glycerine FillingDocument3 pagesAll Stainless Steel Pressure Gauges With Bourdon Tube, With and Without Glycerine FillingRolando Jara YoungNo ratings yet

- Standard Pressure Gauges: Description Special FeaturesDocument2 pagesStandard Pressure Gauges: Description Special FeaturesFlorian_AngererNo ratings yet

- Bourdon 1Document2 pagesBourdon 1Dick D. JucarNo ratings yet

- Bourdon Tube Caisson Pressure Gauges Room Pressure Gauge Model 232.01, Stainless Steel VersionDocument2 pagesBourdon Tube Caisson Pressure Gauges Room Pressure Gauge Model 232.01, Stainless Steel VersionbehnamatgNo ratings yet

- 1020Document7 pages1020eeng_nnabilNo ratings yet

- Tescis GaugeDocument3 pagesTescis GaugeTejas MehtaNo ratings yet

- TECSIS Serie P1705-P1706-P1709Document3 pagesTECSIS Serie P1705-P1706-P1709Nebojsa IvinNo ratings yet

- DS PM0204 GB 3681Document2 pagesDS PM0204 GB 3681Anonymous 4MwmDaNbNo ratings yet

- Bourdon Tube Pressure Gauges Economical Stainless Steel Gauge Type 132.53 - Dry Case Type 133.53 - Liquid-Filled CaseDocument2 pagesBourdon Tube Pressure Gauges Economical Stainless Steel Gauge Type 132.53 - Dry Case Type 133.53 - Liquid-Filled CaseSholhan AzizNo ratings yet

- Differential Pressure Gauge Model 732.51, Stainless Steel Version, With Diaphragm Element All Welded ConstructionDocument4 pagesDifferential Pressure Gauge Model 732.51, Stainless Steel Version, With Diaphragm Element All Welded ConstructionClarence AG YueNo ratings yet

- Brochure Schuh Technology PT - LMIDocument17 pagesBrochure Schuh Technology PT - LMIRoderikus Rendy MNo ratings yet

- Bourdon Tube Pressure Gauges: Solid-Front Turret Style Thermoplastic Case Pressure GaugesDocument2 pagesBourdon Tube Pressure Gauges: Solid-Front Turret Style Thermoplastic Case Pressure Gaugeslcfigueroa1987No ratings yet

- Bourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Safety Version, NS 63, 100 and 160 Models 232.30, 233.30Document4 pagesBourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Safety Version, NS 63, 100 and 160 Models 232.30, 233.30Chau TranNo ratings yet

- Features: Explosion ProofDocument2 pagesFeatures: Explosion Proofhussein javanNo ratings yet

- s527 Pipe Temperature Sensor RtsDocument1 pages527 Pipe Temperature Sensor RtsYojan StibenNo ratings yet

- Diaphragm Pressure Gauge For The Process Industry Models 432.50, 433.50, Up To 10-Fold Overload Safety, Max. 40 BarDocument4 pagesDiaphragm Pressure Gauge For The Process Industry Models 432.50, 433.50, Up To 10-Fold Overload Safety, Max. 40 BarchauNo ratings yet

- 2324 TecsisDocument2 pages2324 TecsisRolando Jara YoungNo ratings yet

- TG-73, DS - TM7301 - en - Co - 2146Document15 pagesTG-73, DS - TM7301 - en - Co - 2146Paulkumar RamaiahNo ratings yet

- 232 50Document2 pages232 50musaismail8863No ratings yet

- Bimetal Thermometer With Pt100 Electrical Output Signal Model 54, Stainless Steel VersionDocument5 pagesBimetal Thermometer With Pt100 Electrical Output Signal Model 54, Stainless Steel VersionRajendra LabadeNo ratings yet

- Wika-233 30Document2 pagesWika-233 30meyssamkNo ratings yet

- Gas-Actuated Thermometer Stainless Steel Version Model 73: ApplicationsDocument8 pagesGas-Actuated Thermometer Stainless Steel Version Model 73: ApplicationslpczyfansNo ratings yet

- DS PM332 30 en Us 15970Document2 pagesDS PM332 30 en Us 15970Sukddesh RagavanNo ratings yet

- Bourdon Tube Pressure Gauge Model 332.34 LM-All Stainless Steel Wetted PartsDocument2 pagesBourdon Tube Pressure Gauge Model 332.34 LM-All Stainless Steel Wetted PartsbehnamatgNo ratings yet

- Bourdon Tube Pressure Gauges Solid-Front Test Gauge - Direct Drive Type 332.34DDDocument2 pagesBourdon Tube Pressure Gauges Solid-Front Test Gauge - Direct Drive Type 332.34DDbehnamatgNo ratings yet

- Lluisma Pressure and Temperature ExamDocument11 pagesLluisma Pressure and Temperature ExamMaxine GarcesNo ratings yet

- PBT Pressure Transmitter: The PBT Is A Universal Electronic Pressure Transmitter Used in General Industrial ApplicationsDocument12 pagesPBT Pressure Transmitter: The PBT Is A Universal Electronic Pressure Transmitter Used in General Industrial ApplicationsMarco AbrilNo ratings yet

- Unitrans Universal Pressure Transmitters Type Ut-10, Ut-11: ApplicationsDocument4 pagesUnitrans Universal Pressure Transmitters Type Ut-10, Ut-11: ApplicationsbehnamatgNo ratings yet

- Bourdon Tube Pressure Gauges: Solid-Front Turret Style Thermoplastic Case Pressure GaugesDocument2 pagesBourdon Tube Pressure Gauges: Solid-Front Turret Style Thermoplastic Case Pressure GaugesFabro CoronelNo ratings yet

- 134 189Document56 pages134 189api-208855872No ratings yet

- Servinox Product DatasheetDocument2 pagesServinox Product DatasheetHakan TekelNo ratings yet

- Product Overview UK BDDocument28 pagesProduct Overview UK BDNaser Jahangiri100% (1)

- P3251 TecsisDocument4 pagesP3251 TecsisJHONNJANNo ratings yet

- Bourdon Tube Pressure Gauges Stainless Steel Series Type 232.50 - Dry Case Type 233.50 - Liquid-Filled CaseDocument2 pagesBourdon Tube Pressure Gauges Stainless Steel Series Type 232.50 - Dry Case Type 233.50 - Liquid-Filled CaseSachin GuptaNo ratings yet

- M09. WIKA Pressure GaugeDocument2 pagesM09. WIKA Pressure GaugepsatyasrinivasNo ratings yet

- Differential Pressure Gauge Stainless Steel Version, With Diaphragm Element Model 732.51, All Welded ConstructionDocument4 pagesDifferential Pressure Gauge Stainless Steel Version, With Diaphragm Element Model 732.51, All Welded ConstructionPaulkumar RamaiahNo ratings yet

- Bourdon Tube Pressure Gauges Stainless Steel, Safety Pattern Version, High Overpressure Safety Model 232.36/233.36, Without/with Liquid FillingDocument2 pagesBourdon Tube Pressure Gauges Stainless Steel, Safety Pattern Version, High Overpressure Safety Model 232.36/233.36, Without/with Liquid FillingRichard EVNo ratings yet

- Tecsis 3251Document4 pagesTecsis 3251dsiucNo ratings yet

- Pressure Switch CatalogueDocument0 pagesPressure Switch CatalogueMilosglNo ratings yet

- Wika F73.100 DS TM7301 en Co 2146Document15 pagesWika F73.100 DS TM7301 en Co 2146NCNo ratings yet

- TR-62-Technical Information PDFDocument10 pagesTR-62-Technical Information PDFAlaa RamadanNo ratings yet

- Pressure Gauge ClassDocument2 pagesPressure Gauge ClassYougchu LuanNo ratings yet

- Temperature Transmitter TR45Document16 pagesTemperature Transmitter TR45cysautsNo ratings yet

- 1121 1122 1122BC 1123 ATEX VersionDocument1 page1121 1122 1122BC 1123 ATEX VersionNazrul IslamNo ratings yet

- ST 3000 Smart Transmitter Series 100 Remote Diaphragm Seals Models Specifications 34-ST-03-64 March 2013Document44 pagesST 3000 Smart Transmitter Series 100 Remote Diaphragm Seals Models Specifications 34-ST-03-64 March 2013ruzzo2003No ratings yet

- Wika Wallace Tiernan Series 1500 85 Pressure GaugeDocument2 pagesWika Wallace Tiernan Series 1500 85 Pressure Gaugerodruren01No ratings yet

- Mix Mim UkDocument4 pagesMix Mim Ukprihartono_diasNo ratings yet

- YCA.23X.34 Bourdon GageDocument2 pagesYCA.23X.34 Bourdon Gagejanvierhotben3983No ratings yet

- TSS70 130 PDFDocument12 pagesTSS70 130 PDFararrefNo ratings yet

- Differential Pressure Gauges Model A2G-10, Air2guide: ApplicationsDocument2 pagesDifferential Pressure Gauges Model A2G-10, Air2guide: ApplicationsbehnamatgNo ratings yet

- Ffifudenberg: Model:726 Classic Process GaugeDocument1 pageFfifudenberg: Model:726 Classic Process Gaugevasudeva yasasNo ratings yet

- Ds Uhp Wuc 1x en Us 20710Document10 pagesDs Uhp Wuc 1x en Us 20710behnamatgNo ratings yet

- Drying Ovens: FD 115 - Drying Oven With Forced ConvectionDocument4 pagesDrying Ovens: FD 115 - Drying Oven With Forced ConvectionSamehibrahemNo ratings yet

- Pce 28Document3 pagesPce 28Pop-Coman SimionNo ratings yet

- Securisens Adw 535: Product InformationDocument2 pagesSecurisens Adw 535: Product Informationanak1n888No ratings yet

- OverpressureDocument2 pagesOverpressureampowersidNo ratings yet

- General CatalogueDocument144 pagesGeneral CataloguePhilipMDMNo ratings yet

- Panasonic Basic User Guide: Your Extension Number Is: .. . Your Direct Number IsDocument4 pagesPanasonic Basic User Guide: Your Extension Number Is: .. . Your Direct Number IsdsiucNo ratings yet

- Buhl MannDocument2 pagesBuhl ManndsiucNo ratings yet

- Homelite UT70131Document22 pagesHomelite UT70131dsiucNo ratings yet

- Stari Tecsis ManometriDocument24 pagesStari Tecsis ManometridsiucNo ratings yet

- TecsisDocument42 pagesTecsisdsiucNo ratings yet

- XOMOX JacketedPlugValveDocument14 pagesXOMOX JacketedPlugValvedsiucNo ratings yet

- Tecsis 3251Document4 pagesTecsis 3251dsiucNo ratings yet

- DS Ac0905 GB 5382Document6 pagesDS Ac0905 GB 5382dsiucNo ratings yet

- MB500 Complete ManualDocument12 pagesMB500 Complete ManualdsiucNo ratings yet

- API 6A Appendix GDocument2 pagesAPI 6A Appendix GdsiucNo ratings yet

- Xi Topswtg enDocument1 pageXi Topswtg endsiucNo ratings yet

- An Intelligent Black Widow Optimization On Image Enhancement With Deep Learning Based Ovarian Tumor Diagnosis ModelDocument16 pagesAn Intelligent Black Widow Optimization On Image Enhancement With Deep Learning Based Ovarian Tumor Diagnosis ModelAgnesNo ratings yet

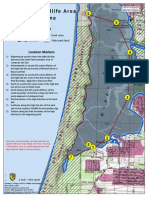

- Morro Bay Wildlife Area Hunt Zone: Map LegendDocument1 pageMorro Bay Wildlife Area Hunt Zone: Map LegendZarahNo ratings yet

- Documentação OpenpyxlDocument35 pagesDocumentação Openpyxlbottaluan20No ratings yet

- Development of A Signal-Free Intersection Control System For CAVs and Corridor Level Impact AssessmentDocument16 pagesDevelopment of A Signal-Free Intersection Control System For CAVs and Corridor Level Impact AssessmentChristian Kyle BeltranNo ratings yet

- Assignment 3 11-5-23Document3 pagesAssignment 3 11-5-23Haider khan100% (2)

- UAV Flight ChecklistDocument3 pagesUAV Flight ChecklistLuXi LuXiNo ratings yet

- Aplicación Manual DiasysDocument63 pagesAplicación Manual DiasysbetsabevegaaNo ratings yet

- Getting The Most Out of RootsMagic-7-BookDocument398 pagesGetting The Most Out of RootsMagic-7-Booksuntzu1869No ratings yet

- Redis Cluster Specification-12Document1 pageRedis Cluster Specification-12Kajaruban SurendranNo ratings yet

- Drug Calculations Practice NCLEX Questions (100+Document2 pagesDrug Calculations Practice NCLEX Questions (100+obedidomNo ratings yet

- Course Information For Current Semester/Term: Maklumat Kursus Untuk Semester/Penggal SemasaDocument6 pagesCourse Information For Current Semester/Term: Maklumat Kursus Untuk Semester/Penggal SemasaCamila HalikNo ratings yet

- Statically Indeterminate Shaft-Bearing Systems: D Cos DDocument14 pagesStatically Indeterminate Shaft-Bearing Systems: D Cos DIvelin ValchevNo ratings yet

- Lecture 7Document28 pagesLecture 7Nkugwa Mark WilliamNo ratings yet

- Solution Manager 7Document24 pagesSolution Manager 7Md Abdullah Al MamunNo ratings yet

- MScFE 620 DTSP - Compiled - Notes - M1 PDFDocument25 pagesMScFE 620 DTSP - Compiled - Notes - M1 PDFRocApplyNo ratings yet

- ACER - Rasakan Performa OPTIMAL Dengan SSDDocument11 pagesACER - Rasakan Performa OPTIMAL Dengan SSDRika SaputriNo ratings yet

- Basic Service Purchase Order Process - DIEN MaterialDocument6 pagesBasic Service Purchase Order Process - DIEN MaterialDanielleNo ratings yet

- Humphree Course StabilisingDocument8 pagesHumphree Course StabilisingMatNo ratings yet

- MicropaleontologyDocument20 pagesMicropaleontologyMUHAMMAD FAUZI RODZEENo ratings yet

- Absurdity Incongruity and LaughterDocument24 pagesAbsurdity Incongruity and LaughterMHardt1No ratings yet

- Quasi TurbineDocument29 pagesQuasi TurbineArun N MukundanNo ratings yet

- TESOL Journal - 2022 - Uludag - Exploring EAP Instructors Evaluation of Classroom Based Integrated EssaysDocument20 pagesTESOL Journal - 2022 - Uludag - Exploring EAP Instructors Evaluation of Classroom Based Integrated EssaysAy IsNo ratings yet

- Derivative of Logarithmic and Exponential FunctionDocument3 pagesDerivative of Logarithmic and Exponential FunctionPrincessdy CocadizNo ratings yet

- PAKEDMON Pendahuluan Telematika 2019 PDFDocument13 pagesPAKEDMON Pendahuluan Telematika 2019 PDFkhashina afiffNo ratings yet

- PG 26 W FACTOR BPVC-I - 2015-068-069Document2 pagesPG 26 W FACTOR BPVC-I - 2015-068-069Eka WahyuNo ratings yet

- Operation Slew A.R.V. and Anti-Cavitation Operation: Section E - HydraulicsDocument20 pagesOperation Slew A.R.V. and Anti-Cavitation Operation: Section E - HydraulicsMarcelo Elói De Amorim SilvaNo ratings yet

- 2021 Main Residency Match® by The Numbers: PositionsDocument1 page2021 Main Residency Match® by The Numbers: Positionsyogitha dadiNo ratings yet

- Standards and Competency of 5 Years Old ChildrenDocument14 pagesStandards and Competency of 5 Years Old ChildrenFrancis kevin Parre�oNo ratings yet