Professional Documents

Culture Documents

CBC Dressmaking NC II

CBC Dressmaking NC II

Uploaded by

Melitz EvaristoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CBC Dressmaking NC II

CBC Dressmaking NC II

Uploaded by

Melitz EvaristoCopyright:

Available Formats

Sector :

GARMENTS

Qualification :

DRESSMAKING NC II

Technical Education and Skills Development Authority

East Service Road South Superhi!h"ay Ta!ui! City

TA#$E %& C%NTENTS

'a!e

A( C%)RSE DESIGN ..

*

#( M%D)$ES %& INSTR)CTI%NS ..

M%D)$ES +#asic Competencies,

Participating in workplace communication .. -

Working in a team environment .... .*

Practicing career professionalism ./

Practicing occupational health and safety procedures .... .0

M%D)$ES +Common Competencies,

Carrying out Measurements and Calculations ... *1

Applying Quality Standards ...

Performing asic Maintenance .

Setting!up and "perating Machines

23

M%D)$ES +Core Competencies,

#rafting and Cutting Pattern for Casual Apparel . 20

Preparing and Cutting Materials for Casual Apparel .. 41

Sewing Casual Apparel .. /*

Applying $inishing %ouches on Casual Apparel .. /-

_______________________________________________________________________________

CBC Dressmaking NC II - 2 -

C%)RSE DESIGN

Dressmakin! NC II

_______________________________________________________________________________

CBC Dressmaking NC II - 3 -

C%)RSE DESIGN

C%)RSE TIT$E 5 DRESSMAKING NC II

N%MINA$ D)RATI%N 5 *436ours

C%)RSE DESCRI'TI%N 5 %his course is designed to enhance the

knowledge& skills and attitudes of a trainee'student in

accordance with industry standards. (t covers the )asic&

common and core competencies.

TRAINEE ENTR7 RE8)IREMENTS5

%rainees or students should possess the following re*uirements+

Can communicate oral and written

Physically and mentally fit

With good moral character, and

Can perform )asic mathematical computations

_______________________________________________________________________________

CBC Dressmaking NC II - 4 -

C%)RSE STR)CT)RE

)NIT %&

C%M'ETENC7

M%D)$E TIT$E $EARNING %)TC%ME

Nomi

nal

6rs(

#ASIC .-

-. Participate in

workplace

communication

-.-. Participating in

workplace

communication

-.-.-. ")tain and convey

workplace information

-.-... Participate in workplace

meeting and discussion

-.-./. Complete relevant work

related documents

0

.. Work in a team

environment

..-. Working with

others

..-.-. #escri)e and identify team

role and responsi)ility in a

team

..-... Work as a team mem)er

0

/. Practice career

professionalism

/.-. Practicing

career

professionalism

/.-.-. (ntegrate personal

o)1ectives with

organi2ational goals

/.-... Set and meet work priorities

3

0. Practice

occupational

health and

safety

procedures

0.-. Practicing

occupational

health and

safety

procedures

0.-.-. (dentify ha2ards and risks

0.-... 4valuate ha2ards and risks

0.-./. Control ha2ards and risks

0.-.0. Maintain occupational

health and safety

awareness

3

C%MM%N .9

-. Carry "ut

Measurements

and

Calculations

-.- Carrying!out

Measurements

and

Calculations

-.-.-. 5ead and interpret drawing

-.-... ")tain measurements

-.-./. Perform simple calculations

-.-.0. 4stimate appropriate

*uantities

0

.. Apply Quality

Standards

..- Applying

Quality

Standards

..-.-. Assess own work )ased on

workplace standards

..-... Assess *uality of component

parts and take corrective

actions

..-./. Measure parts using

appropriate instrument.

..-.0. 5ecord information in

accordance to workplace

procedures.

..-.3. Study causes of *uality

deviation and recommend

preventive action.

3

_______________________________________________________________________________

CBC Dressmaking NC II - 5 -

/. Perform asic

Maintenance

Performing asic

Maintenance

"perate machine and assess its

performance

Clean and lu)ricate machine

Check machine operation.

/

0. Set 6p and

"perate

Machines

Setting!up and

"perating

Machines

0.-.- Set machine

0.-.. Conduct sample run

0.-./ %est machine output

0.-.0 5e!ad1ust machine setting to

meet re*uirements

0.-.3 Maintain records and prepare

report

3

C%RE *43

-. #raft and Cut

Pattern for Casual

Apparel

-.- #rafting and

Cutting Pattern for

Casual Apparel

-.-.-.- Plan garment design

-.-.. %ake clients )ody

measurement

-.-./ #raft )asic')lock pattern

-.-.0 Manipulate pattern

-.-.3 Cut final pattern

78

.. Prepare and

Cut Materials for

Casual Apparel

..- Preparing and

Cutting Materials

for Casual Apparel

..-.- Prepare materials 9fa)ric:

..-.. ;ay!out and mark pattern on

materials

..-./ Cut materials

08

/. Sew Casual

Apparel

/.- Sewing casual

apparel

/.-.- Prepare cut parts

/.-.. Prepare sewing machine for

operation

/.-./ Sew and assem)le garment

parts

/.-.0 Alter completed garments

78

0. Apply

$inishing

%ouches on

Casual Apparel

0.- Applying

$inishing %ouches

on Casual Apparel

0.-.- Apply finishing touches

0.-.. %rim e<cess threads

0.-./ Press $inished garment

0.-.0 Package the $inished garment

08

ASSESSMENT MET6%DS5

Written e<amination

#emonstration'Actual Performance

(nterview

C%)RSE DE$I:ER75 +Methodolo!y,

Self!paced'Modular

=roup #iscussion

$ilm >iewing

RES%)RCES5

_______________________________________________________________________________

CBC Dressmaking NC II - -

%"";S 4Q6(PM4?% MA%45(A;S

%ape Measure Single ?eedle ;ockstitch

machines

Pencil

@ip Curve @igh Speed Machines

Attachment

Pattern Paper

Meter Stick / %hread "ver lock Machine %ailorAs chalk

$rench curve $lat (ron #ressmakerAs %racing

Paper

Scissors Steam Press %hread 9Assorted colors:

Cutting shears (roning oard uttons

;!S*uare Cutting ta)le Bipper 7C

%ransparent ruler 9with grid:

D .0C

Stools 5ecord )ook

asin'pail utton @oler Bipper .8C

Sewing )o< Model ody $orm $usi)le (nterlining

%racing wheel Calculator and 5oll

@anger @anger 5ack @ook E 4ye 9)ig E small:

Screw driver $lat 9medium: o))in Case Machine "il

%riangle -FC 03GH8 o))in Spool 4raser

@and spray utton holer Attachments ?eedle #G- I-0

Seam 5ipper Bipper $oot ?eedle #CG- I--

Pin Cushion Bipper $oot (nvisi)le ?eedle #PG- I-0

Shirring $oot ?eedle #PG3 I-0

Sleeve oard'@am @and ?eedles

#isplay Ca)inet $a)ric for louse

$a)ric for Skirt

$a)ric for #ress

Clothes ;ine

Pins

TRAINERS 8)A$I&ICATI%NS ;

Must )e a holder of ?C (((

Must have undergone training on %M ((

Must )e physically and mentally fit.

JMust have at least . years 1o)'industry e<perience

J"ptional D only when re*uired )y hiring institution.

_______________________________________________________________________________

CBC Dressmaking NC II - ! -

M%D)$ES %& INSTR)CTI%NS

#ASIC C%M'ETENCIES

_______________________________________________________________________________

CBC Dressmaking NC II - " -

)NIT %& C%M'ETENC7 5 'ARTICI'ATE IN <%RK'$ACE

C%MM)NICATI%N

M%D)$E TIT$E 5 'ARTICI'ATING IN <%RK'$ACE

C%MM)NICATI%N

M%D)$E DESCRI'TI%N 5 This module covers the kno"led!e

skills and attitudes re=uired to o>tain

interpret and convey in?ormation in

response to "orkplace re=uirements(

N%MINA$ D)RATI%N 5 4 hours

CERI&ICATE $E:E$ 5 NC II

'RERE8)ISITE 5 Receive and Respond to "orkplace

Communication( +NC I,

$EARNING %)TC%MES5

6pon completion of this module the students' trainees will )e a)le to+

;.".-. ")tain and convey workplace information

;."... Complete relevant work related documents

;."./. Participate in workplace meeting and discussion

_______________________________________________________________________________

CBC Dressmaking NC II - # -

$%.( %#TAIN AND C%N:E7 <%RK'$ACE IN&%RMATI%N

ASS4SSM4?% C5(%45(A+

-. Specific relevant information is accessed from appropriate sources.

.. 4ffective *uestioning& active listening and speaking skills are used to gather and

convey information.

/. Appropriate medium is used to transfer information and ideas.

0. Appropriate non!ver)al communication is used.

3. Appropriate lines of communication with superiors and colleagues are identified

and followed.

F. #efined workplace procedures for the location and storage of information are

used.

K. Personal interaction is carried out clearly and concisely.

C"?%4?%S+

Parts of speech

Sentence construction

4ffective communication

C"?#(%("?S+

%he students' trainees must )e provided with the following+

Writing materials 9pen E paper:

5eferences 9)ooks:

Manuals

M4%@"#";"=(4S+

=roup discussion

(nteraction

;ecture

5eportorial

ASS4SSM4?% M4%@"#S+

Written test

Practical'performance test

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - $% -

$%*( 'ARTICI'ATE IN <%RK'$ACE MEETINGS AND DISC)SSI%NS

ASS4SSM4?% C5(%45(A+

-. %eam meetings are attended on time.

.. "wn opinions are clearly e<pressed and those of others are listened to without

interruption.

/. Meeting inputs are consistent with the meeting purpose and esta)lished

protocols.

0. Workplace interactions are conducted in a courteous manner appropriate to

cultural )ackground and authority in the enterprise procedures.

3. Questions a)out simple routine workplace procedures and matters concerning

conditions of employment are asked and responded.

F. Meeting outcomes are interpreted and implemented.

C"?%4?%S+

Sentence construction

%echnical writing

5ecording information

C"?#(%("?S+

%he students'trainees must )e provided with the following+

Paper

Pencils')all pen

5eferences 9)ooks:

Manuals

M4%@"#";"=(4S+

=roup discussions

(nteraction

;ecture

ASS4SSM4?% M4%@"#S+

Written test

Practical'performance test

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - $$ -

$%2( C%M'$ETE RE$E:ANT <%RK RE$ATED D%C)MENTS

ASS4SSM4?% C5%45(A+

-. 5anges of forms relating to conditions of employment are completed accurately

and legi)ly.

.. Workplace data is recorded on standard workplace forms and documents.

/. asic mathematical processes are used for routine calculations.

0. 4rrors in recording information on forms and documents are identified and

rectified.

3. 5eporting re*uirements to superior are completed according to enterprise

guidelines.

C"?%4?%S+

asic mathematics

%echnical writing

%ypes of forms

C"?#(%("?S+

%he students'trainees must )e provided with the following+

Paper

Pencils')all pen

5eference )ooks

Manuals

M4%@"#";"=(4S+

=roup discussion

(nteraction

;ecture

ASS4SSM4?% M4%@"#S+

Written test

Practical'performance test

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - $2 -

)NIT %& C%M'ETENC7 5 <%RK IN A TEAM EN:IR%NMENT

M%D)$E TIT$E 5 <%RKING IN A TEAM EN:IR%NMENT

M%D)$E DESCRI'TI%N 5 This module covers the kno"led!e

skills and attitudes re=uired to relate

in a "ork >ased environment(

N%MINA$ D)RATI%N 5 4 hours

CERTI&ICATE $E:E$ 5 NC II

'RERE8)ISITE 5

$EARNING %)TC%MES5

6pon completion of this module& the students' trainees will )e a)le to+

;"-. #escri)e and identify team role and responsi)ility in a team

;".. #escri)e work as a team

_______________________________________________________________________________

CBC Dressmaking NC II - $3 -

$% .( DESCRI#E AND IDENTI&7 TEAM R%$E AND RES'%NSI#I$IT7 IN A TEAM

ASS4SSM4?% C5(%45(A+

-. 5ole and o)1ective of the team is identified.

.. %eam parameters& relationships and responsi)ilities are identified.

/. (ndividual role and responsi)ilities within team environment are identified.

0. 5oles and responsi)ilities of other team mem)ers are identified and recogni2ed.

3. 5eporting relationships within team and e<ternal to team are identified.

C"?%4?%S+

%eam role

5elationship and responsi)ilities

5ole and responsi)ilities with team environment

5elationship within a team

C"?#(%("?S+

%he students' trainees must )e provided with the following+

Standard operating procedure 9S"P: of workplace

Lo) procedures

Client'supplier instructions

Quality standards

"rgani2ational or e<ternal personnel

M4%@"#";"=(4S+

=roup discussion'interaction

Case studies

Simulation

ASS4SSM4?% M4%@"#S+

Written test

")servation

Simulation

5ole playing

_______________________________________________________________________________

CBC Dressmaking NC II - $4 -

$%*( <%RK AS A TEAM MEM#ER

ASS4SSM4?% C5(%45(A+

-. Appropriate forms of communication and interactions are undertaken.

.. Appropriate contri)utions to complement team activities and o)1ectives were

made.

/. 5eporting using standard operating procedures followed.

0. #evelopment of team work plans )ased from role team is contri)uted.

C"?%4?%S+

Communication process

%eam structure'team roles

=roup planning and decision making

C"?#(%("?S+

%he students'trainees must )e provided with the following+

S"P of workplace

Lo) procedures

"rgani2ation or e<ternal personnel

M4%@"#";"=(4S+

=roup discussion'interaction

Case studies

Simulation

ASS4SSM4?% M4%@"#S+

")servation of work activities

")servation through simulation or role play

Case studies and scenarios.

_______________________________________________________________________________

CBC Dressmaking NC II - $5 -

)NIT %& C%M'ETENC7 5 'RACTICE CAREER 'R%&ESSI%NA$ISM

M%D)$E TIT$E 5 'RACTICING CAREER 'R%&ESSI%NA$ISM

M%D)$E DESCRI'TI%N 5 This module covers the kno"led!e

skills and attitudes in promotin! career

!ro"th and advancement speci?ically to

inte!rate personal o>@ectives "ith

or!aniAational !oals set and meet "ork

priorities and maintain pro?essional

!ro"th and development(

N%MINA$ D)RATI%N 5 / hours

CERTI&ICATE $E:E$ 5 NC II

'RERE8)ISITE 5 none

$EARNING %)TC%MES5

6pon completion of this module& the trainee'student must )e a)le to+

;"-. (ntegrate personal o)1ectives with organi2ational goals

;".. Set and meet work priorities

;"/. Maintain professional growth and development

_______________________________________________________________________________

CBC Dressmaking NC II - $ -

$%.( INTEGRATE 'ERS%NA$ %#BECTI:ES <IT6 %RGANICATI%NA$ G%A$S

ASS4SSM4?% C5(%45(A+

-. Personal growth and work plans towards improving the *ualifications set for

professionalism are evident.

.. (ntra and interpersonal relationship in the course of managing oneself )ased on

performance evaluation is maintained.

/. Commitment to the organi2ation and its goal is demonstrated in the performance

of duties.

0. Practice of appropriate personal hygiene is o)served.

3. Lo) targets within key result areas are attained.

C"?%4?%S+

Personal development!social aspects+ intra and interpersonal development

"rgani2ational goals

Personal hygiene and practices

Code of ethics

C"?#(%("?S+

%he students' trainees must )e provided with the following+

Workplace

Code of ethics

"rgani2ational goals

@and outs and Personal development!social aspects

C#As& >@S tapes& transparencies

M4%@"#";"=(4S+

(nteractive !lecture

Simulation

#emonstration

Self paced instruction

ASS4SSM4?% M4%@"#S+

5ole play

(nterview

Written e<amination

_______________________________________________________________________________

CBC Dressmaking NC II - $! -

$%*( SET AND MEET <%RK 'RI%RITIES

ASS4SSM4?% C5(%45(A+

-. Competing demands to achieve personal& team and organi2ational goals and

o)1ectives are prioriti2ed.

.. 5esources are utili2ed efficiently and effectively to manage work priorities and

commitments.

/. Practices and economic use and maintenance of e*uipment and facilities are

followed as per esta)lished procedures.

0. Lo) targets within key result areas are attained.

C"?%4?%S+

"rgani2ational Mey 5esult Areas 9M5A:

Work values and ethical standards

Company policies on the use and maintenance of e*uipment

C"?#(%("?S+

%he students' trainees must )e provided with the following

@and outs on

"rgani2ational M5A

Work values and ethics

Company policies and standards

Sample 1o) targets

;earning guides

C#As& >@S tapes& transparencies

M4%@"#";"=(4S+

(nteractive lecture

=roup discussion

Structured activity

#emonstration

ASS4SSM4?% M4%@"#S+

5ole play

(nterview

Written e<amination

_______________________________________________________________________________

CBC Dressmaking NC II - $" -

$%2( MAINTAIN 'R%&ESSI%NA$ GR%<T6 AND DE:E$%'MENT

ASS4SSM4?% C5(%45(A+

-. %raining and career opportunities relevant to the 1o) re*uirements are identified

and availed.

.. ;icenses and'or certifications according to the re*uirements of the *ualifications

are ac*uired and maintained

/. $undamental rights at work including gender sensitivity are manifested' o)served

0. %raining and career opportunities )ased on the re*uirements of industry are

completed and updated.

C"?%4?%S+

Qualification standards

=ender and development 9=A#: sensitivity

Professionalism in the workplace

;ist of professional licenses

C"?#(%("?S+

%he students'trainees must )e provided with the following

Quality standards

=A# handouts

C#As& >@S tapes on professionalism in the workplace

Professional licenses samples

M4%@"#";"=(4S+

(nteractive lecture

$ilm viewing

5ole play'simulation

=roup discussion

ASS4SSM4?% M4%@"#S+

#emonstration

(nterview

Written e<amination

Portfolio assessment

_______________________________________________________________________________

CBC Dressmaking NC II - $# -

)NIT %& C%M'ETENC7 5 'RACTICE %CC)'ATI%NA$ 6EA$T6 AND

SA&ET7 'R%CED)RES

M%D)$E TIT$E 5 'RACTICING %CC)'ATI%NA$ 6EA$T6

AND SA&ET7 'R%CED)RES

M%D)$E DESCRI'TI%N 5 This module covers the kno"led!e

skills and attitudes re=uired to comply

"ith the re!ulatory and or!aniAational

re=uirements ?or occupational health

and sa?ety such as identi?yin!

evaluatin! and maintainin!

occupational health and sa?ety +%6S,

a"areness(

N%MINA$ D)RATI%N 5 / hours

CERTI&ICATE $E:E$ 5 NC II

'RERE8)ISITE 5 none

$EARNING %)TC%MES5

6pon completion of this module& the trainee'student must )e a)le to+

;"-. (dentity ha2ards and risks

;".. 4valuate ha2ards and risks

;"/. Control ha2ards and risks

;"0. Maintain occupational health and safety awareness

_______________________________________________________________________________

CBC Dressmaking NC II - 2% -

$%.( IDENTI&7 6ACARDS AND RISKS

ASS4SSM4?% C5(%45(A+

-. Workplace ha2ards and risks are identified and clearly e<plained.

.. @a2ards'risks and its corresponding indicators are identified in with the company

procedures.

/. Contingency measures are recogni2ed and esta)lished in accordance with

organi2ational procedures.

C"?%4?%S+

@a2ards and risks identification and control

"rgani2ational safety and health protocol

%hreshold limit value 9%;>:

"@S indicators

C"?#(%("?S+

%he students' trainees must )e provided with the following+

Workplace

Personal protective e*uipment 9PP4:

;earning guides

@and!outs

"rgani2ational safety and health protocol

"@S indicators

%hreshold limit value

@a2ards'risk identification and control

C#As& >@S tapes& transparencies

M4%@"#";"=(4S+

(nteractive !lecture

Simulation

Symposium

=roup dynamics

ASS4SSM4?% M4%@"#S+

Situation analysis

(nterview

Practical e<amination

Written e<amination

_______________________________________________________________________________

CBC Dressmaking NC II - 2$ -

$%*( E:A$)ATE 6ACARDS AND RISKS

ASS4SSM4?% C5(%45(A+

-. %erms of ma<imum tolera)le limits are identified )ased on threshold limit values

9%;>:

.. 4ffects of ha2ards are determined.

/. "@S issues and concerns are identified in accordance with workplace

re*uirements and relevant workplace "@S legislation.

C"?%4?%S+

%;> ta)le

Philippine "@S standards

4ffects of ha2ards in the workplace

4rgonomics

4CC 5egulations

C"?#(%("?S+

%he students'trainees must )e provided with the following

@and outs on

Philippine "@S standards

4ffects of ha2ards in the workplace

4rgonomics

4CC regulations

%;> ta)le

C#As& >@S tapes& transparencies

M4%@"#";"=(4S+

(nteractive lecture

Situation analysis

Symposium

$ilm viewing

=roup dynamics

ASS4SSM4?% M4%@"#S+

(nterview

Written e<amination

Simulation

_______________________________________________________________________________

CBC Dressmaking NC II - 22 -

$%2( C%NTR%$ 6ACARDS AND RISKS

ASS4SSM4?% C5(%45(A+

-. "@S procedures for controlling ha2ards and risk are strictly followed.

.. Procedures in dealing with workplace accidents& fire and emergencies are

followed in accordance with the organi2ationAs "@S policies.

/. Personal protective e*uipment 9PP4: is correctly used in accordance with

organi2ationAs "@S procedures and practices.

0. Procedures in providing appropriate assistance in the event of workplace

emergencies are identified in line with the esta)lished organi2ational protocol.

C"?%4?%S+

Safety regulations

Clean air act

4lectrical and fire safety code

Waste management

#isaster preparedness and management

Contingency measures and procedures

C"?#(%("?S+

%he students'trainees must )e provided with the following+

@and outs on

Safety 5egulations

Clean air act

4lectrical and fire safety code

Waste management

#isaster preparedness and management

Contingency measures and procedures

"@S personal records

PP4

C#As& >@S tapes& transparencies

M4%@"#";"=(4S+

(nteractive lecture

Symposium

$ilm viewing

=roup dynamics

Self!paced instruction

ASS4SSM4?% M4%@"#S+

Written e<amination

(nterview

Case'situation analysis

_______________________________________________________________________________

CBC Dressmaking NC II - 23 -

Simulation

_______________________________________________________________________________

CBC Dressmaking NC II - 24 -

$%4( MAINTAIN %CC)'ATI%NA$ 6EA$T6 AND SA&ET7 A<ARENESS

ASS4SSM4?% C5(%45(A+

-. Procedures in emergency related drill are strictly followed in line with the

esta)lished organi2ation guidelines and procedures.

.. "@S personal records are filled up in accordance with workplace re*uirements.

/. PP4 are maintained in line with organi2ation guidelines and procedures.

C"?%4?%S+

"perational health and safety procedure& practices and regulations

4mergency!related drills and training

C"?#(%("?S+

%he students'trainees must )e provided with the following

Workplace

PP4

"@S personal records

C#As& >@S tapes& transparencies

@ealth record

M4%@"#";"=(4S+

(nteractive lecture

Simulation

Symposium

$ilm viewing

=roup dynamics

ASS4SSM4?% M4%@"#S+

#emonstration

(nterview

Written e<amination

Portfolio assessment

_______________________________________________________________________________

CBC Dressmaking NC II - 25 -

M%D)$ES %& INSTR)CTI%NS

C%MM%N C%M'ETENCIES

_______________________________________________________________________________

CBC Dressmaking NC II - 2 -

6?(% "$ C"MP4%4?CN + CA55N "6% M4AS654M4?%S A?#

CA;C6;A%("?S

M"#6;4 %(%;4 + Carrying! "ut measurements and calculations

M"#6;4 #4SC5(P%("?

%his module covers the knowledge and skills re*uired in taking

accurate measurement of the client and calculating'estimating the

materials re*uirement cost.

?"M(?A; #65A%("? + 0 hours

C45%($(CA%4 ;4>4; + ?C ((

;4A5?(?= "6%C"M4S+

6pon completion of this module the students'trainees will )e a)le to+

;"-. ")tain measurements

;".. Perform simple calculations.

;"/ 4stimate appropriate *uantities.

_______________________________________________________________________________

CBC Dressmaking NC II - 2! -

$%.( %>tain measurements

Assessment Criteria+

-. Parts to )e measurements identified and recogni2ed.

.. Appropriate measuring tools selected for 1o).

/. 5eading of measurements practiced with accuracy.

0. Accurate measurements are o)tained.

3. Measuring tools cleaned )efore and after using.

F. Measuring tools kept on racks after using.

Contents+

Measurements

Measuring devices

Conditions+

%he students'trainees must )e provided with the following+

Practice e<ercises for o)taining measurements

5eferences

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 2" -

$%*( 'er?orm simple calculations(

Assessment Criteria+

-. Calculations needed to estimate complete task are performed using the 0

fundamentals 9M#AS:

.. ?umerical Computations are accurate.

Contents+

$undamental arithmetical operations 9M#AS:

Conversions

$ormulas

Conditions+

%he students'trainees must )e provided with the following+

Practice e<ercises for simple calculations

5eferences

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 2# -

$%2 Estimate appropriate =uantities(

Assessment Criteria+

-. 4nglish and metric measurements identified and recogni2ed.

.. 5eading of measurements practiced with accuracy.

/. %he fundamentals of arithmetic operations 9M#AS: practiced with accuracy.

Contents+

4stimates *uantities of pattern paper&

$a)rics& threads& )uttons& accessories& lu)ricants

Conditions+

%he students'trainees must )e provided with the following+

Practice e<ercises for materials estimate

5eferences

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 3% -

6?(% "$ C"MP4%4?CN + S4% 6P A?# "P45A%4 MAC@(?4S

M"#6;4 %(%;4 + S4%%(?=!6P A?# "P45A%(?= MAC@(?4S

M"#6;4 #4SC5(P%("? +

%his module covers the knowledge and skills re*uired in setting up and

operating machines.

?"M(?A; #65A%("? + 0 hours

C4#5%($(CA%4 ;4>4; + ?C ((

;4A5?(?= "6%C"M4S +

6pon completion of this module the students'trainees will )e a)le to+

;"-. Set machines

;".. Conduct sample run

;"/. %est machine output

;"0. 5e!ad1ust machine setting to meet re*uirements

;"3. Maintain records.

_______________________________________________________________________________

CBC Dressmaking NC II - 3$ -

$%.( Set machines

Assessment Criteria+

-. Machines needed for garments production operation are identified and

recogni2ed.

.. Machine oil levels are checked.

/. Machine motors& power switches and plugs are installed.

0. Machine threading& stitch lengths and tensions checked.

Contents+

(dentification of machines

Setting of machines

Conditions+

%he students'trainees must )e provided with the following+

ManufacturerAs instruction on setting of machines

Machine Manuals

5eferences and handouts

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 32 -

$%*( Conduct sample run

Assessment Criteria+

-. #ifferent machines needed for garments production operation and tested

following manufacturerAs instructions.

.. Sewing machine motors& switches& plugs functions smoothly.

/. $using machines motors& switches& plugs functions smoothly.

0. Pressing machines motors& switches& plugs functions smoothly.

3. Proper handling of machines is o)served.

Conditions+

%he students'trainees must )e provided with the following+

ManufacturerAs instruction of machines operation

Machine Manuals

5eferences and handouts

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 33 -

$%2( Test machine output

Assessment Criteria+

-. Safety use of machine operation is o)served.

.. Machine stitching& tensions of regular lengths.

/. $using machine temperature correctly regulated.

0. Pressing machine temperatures correctly regulated.

Contents+

Machine "peration'%esting

Conditions+

%he students'trainees must )e provided with the following+

ManufacturerAs instruction on machine operation

Machine Manuals

5eferences and handouts

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 34 -

$%4( ReDad@ust machine settin! to meet re=uirements

Assessment Criteria+

-. Proper handling techni*ues in re!ad1ustment of machine settings are

o)served.

.. Machines re!ad1usted to meet re*uirements for other fa)rics and designs are

identified.

/. $using machine temperature ad1usted to meet fa)ric re*uirements is

recogni2ed.

0. Pressing machine temperature ad1usted to meet fa)ric re*uirements is

recogni2ed.

3. Appropriate tools for re!ad1usting machine setting are identified.

Contents+

5e!ad1ustment of machine settings

%emperature chart for different fa)rics

Conditions+

%he students'trainees must )e provided with the following+

ManufacturerAs instruction on re!setting of machines

Machine Manuals

5eferences and handouts

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 35 -

$%/( Maintain records(

Assessment Criteria+

-. Parts ad1usted and replaced recorded on maintenance card.

.. Maintenance schedules identified and followed correctly.

Contents+

5ecords Management for machines

Conditions+

%he students'trainees must )e provided with the following+

ManufacturerAs instruction maintenance of machines

Machine Manuals

5eferences and handouts

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 3 -

6?(% "$ C"MP4%4?CN + P45$"5M AS(C MA(?%4?A?C4

M"#6;4 %(%;4 + P45$"5M(?= AS(C MA(?%4?A?C4

M"#6;4 #4SC5(P%("? +

%his module covers the knowledge& skills and attitudes re*uired

in performing minor maintenance of the machines used )y

dressmaker.

?"M(?A; #65A%("? , 0 hours

C45%($(CA%4 ;4>4; , ?C ((

;4A5?(?= "6%C"M4S +

6pon completion of this module the students'trainees will )e a)le to+

;"-. "perate machine and assess its performance

;".. Clean and lu)ricate machine

;"/. Check machine operation

_______________________________________________________________________________

CBC Dressmaking NC II - 3! -

$%.( %perate machine and assess its per?ormance

Assessment Criteria+

-. Proper handling of machines is o)served.

.. Correct procedures in machine operation are identified.

/. $unctional performance of machine is recogni2ed.

Contents+

Machine operation

Quality of stitches and tensions

Conditions+

%he students'trainees must )e provided with the following+

ManufacturerAs instruction

Manuals

5eferences

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 3" -

$%*( Clean and lu>ricate machine

Assessment Criteria+

-. 5egular cleaning of machine is o)served

.. Safety procedures in machine cleaning are followed.

/. 5egular maintenance schedules are o)served.

Contents+

Machine Cleanliness

Cleaning Procedures

;u)ricants and their uses

Conditions+

%he students'trainees must )e provided with the following+

Maintenance charts'cleaning guides

5eferences

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 3# -

$%2( Check machine operation(

Assessment Criteria+

-. Safety procedures on machine operation are o)served.

.. Machine functional operations are identified and o)served.

/. #ysfunctional operations are recogni2ed.

0. Correct Procedures for checking machine operations are followed.

Contents+

Safety on Machine "peration

")servation reports on machine operation

Conditions+

%he students'trainees must )e provided with the following+

=uides on machine checking

5eferences

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 4% -

6?(% "$ C"MP4%4?CN + APP;N Q6A;(%N S%A?#A5#S

M"#6;4 %(%;4 + APP;N(?= Q6A;(%N S%A?#A5#S

M"#6;4 #4SC5(P%("? +

%his module covers the knowledge& skills and attitudes re*uired in applying

*uality standards to work operations in the industry.

?"M(?A; #65A%("? + 0 hours

C45%($(CA%4 ;4>4; + ?C ((

;4A5?(?= "6%C"M4S +

;"-. Assess own work

;".. Assess *uality of received component parts

;"/. Measure parts

;"0. 5ecord information

;"3. Study causes of *uality deviations

_______________________________________________________________________________

CBC Dressmaking NC II - 4$ -

$%.( Assess o"n "ork

Assessment Criteria+

-. Standards of good *uality are identified.

.. Assessment procedures are esta)lished.

/. Criteria for comparisons )etween standards and finished work are esta)lished

and applied.

Contents+

Quality Work Standards

Conditions+

%he students'trainees must )e provided with the following+

Standards for good *uality

5eferences

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 42 -

$%*( Assess =uality o? received component parts

Assessment Criteria+

-. Quality of received componentsA parts esta)lished and recogni2ed.

.. Assessment procedures are defined.

/. %olerance level for accepta)le *uality identified.

Contents+

$ault Analysis on products Quality

Conditions+

%he students'trainees must )e provided with the following+

Samples of good *uality products

Samples of poor *uality products

5eferences

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 43 -

$%2( Measure parts

Assessment Criteria+

-. Parts for *uality measurements identified.

.. Quality assurance procedures esta)lished and followed.

/. %olera)le percentage of acceptance defined.

Contents+

Quality assurance measurements

Conditions+

%he students'trainees must )e provided with the following+

Samples of *uality assured products

5eferences

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 44 -

$%4( Record in?ormation

Assessment Criteria+

-. #ata are recorded accurately.

Contents+

5ecords Management

Conditions+

%he students'trainees must )e provided with the following+

5ecording samples

5eferences

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 45 -

$%/( Study causes o? =uality deviations

Assessment Criteria+

-. #efects and deviations to product *uality recogni2ed.

.. Caused of defects identified.

/. Causes of deviation analy2ed.

Contents+

#efects'deviations

Causes of #efects'deviations

Conditions+

%he students'trainees must )e provided with the following+

Samples of defects

5eferences

Writing materials

Methodologies+

;ecture

#emonstration

=roup #iscussion'interaction

Assessment Methods+

Written e<amination

")servation

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 4 -

M%D)$ES %& INSTR)CTI%NS

C%RE C%M'ETENCIES

_______________________________________________________________________________

CBC Dressmaking NC II - 4! -

)NIT %& C%M'ETENC7 5 #5A$% A?# C6% PA%%45? "5

CAS6A; APPA54;

M%D)$E TIT$E 5 #rafting and cutting pattern for

casual apparel

M%D)$E DESCRI'TI%N 5 %his module covers the knowledge&

skills and attitudes in drafting and cutting patterns

of casual apparel. (t details the re*uirements for planning

garment design& taking )ody measurements& drafting

)asic')lock pattern& manipulating and cutting final pattern.

N%MINA$ D)RATI%N 5 -3 6ours

CERTI&ICATE $E:E$ 5 ?C ((

'RERE8)ISITE 5

$EARNING %)TC%MES +

6pon completion of this module the trainees'students must )e a)le to+

;" -. Plan garment design

;" .. %ake clients )ody measurements

;" /. #raft )asic')lock pattern

;" 0. Manipulate pattern

;" 3. Cut final pattern

_______________________________________________________________________________

CBC Dressmaking NC II - 4" -

$% .( 'lan !arment desi!n(

ASSESSMENT CRITERIA+

-. CustomerAs 1o) re*uirements are determined in accordance with companyAs practice.

.. =arment design is prepared in accordance with the clientAs re*uirements.

/. #esign and fa)ric are discussed and selected according to clientAs specifications.

0. Special needs of the client are incorporated into the design )ased on procedures.

C%NTENTS +

=armentAs design

Classification of fa)rics

Company procedures and practices

%ypes of fa)rics

CompanyAs standard operating procedures

C%NDITI%NS +

Catalogue

Samples of fa)ric

Samples of finished product

arong

;ong Sleeves

Pants'%rouser

Coat

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

ASSESSMENT MET6%D +

#emonstration

(nterview

Written

_______________________________________________________________________________

CBC Dressmaking NC II - 4# -

$% * ( Take clients >ody measurements

ASSESSMENT CRITERIA+

-. Measuring tools are prepared in accordance with 1o) re*uirements

.. ody measurements are taken )ased on procedures

/. ody measurements of clients are taken in se*uence according to 1o) re*uirements

and standard )ody measurements.

0. ody measurements are recorded in line with company re*uirements'practice.

C%NTENT +

4nglish System of measurement

Metric System of measurement

;inear Measurement

ody parts to )e measured

Correct positioning in taking )ody measurements.

Correct positioning of measuring tools.

Procedure and se*uence in taking )ody measurements.

5ecording of )ody measurements )ased on companyAs

re*uirements'practice.

C%NDITI%NS +

%ape Measure

;!s*uare

Meter Stick

Pencil

5ecord ?ote)ook

Model'ody $orm

Procedure Manual

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

$ilm >iewing

ASSESSMENT MET6%D 5

#emonstration

(nterview

Written

_______________________________________________________________________________

CBC Dressmaking NC II - 5% -

$% 2( Dra?t >asicE>lock pattern

ASSESSMENT CRITERIA+

-. #rafting pattern tools are selected in accordance with 1o) re*uirements.

.. asic'lock pattern is drafted using appropriate tools and customerAs specifications.

/. #rafted )asic')lock is checked for accuracy against customerAs specifications .

C%NTENT +

Selection of Pattern %ools

Procedures in #rafting lock Pattern

C%NDITI%NS +

Pencil

%ailorAs Chalk

Pattern Paper

Pencil

%riangle

@ip Curve

5uler with =rid

$rench Curve

Procedure Manual

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

$ilm >iewing

ASSESSMENT MET6%D 5

#emonstration

(nterview

Written

_______________________________________________________________________________

CBC Dressmaking NC II - 5$ -

$% 4( Manipulate 'attern

ASSESSMENT CRITERIA+

-. lock pattern is laid out in accordance with company procedures.

.. lock pattern is manipulated in accordance with customerAs specifications.

/. $inal pattern is la)eled& filed and secured as per standard operating

procedure

C%NTENT +

#art Manipulation

Procedures in Pattern Making

C%NDITI%NS +

%ape Measure

lock pattern

;!s*uare

Meter Stick

Pencil

5ecord ?ote)ook

Model'ody $orm

Procedure Manual

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

$ilm >iewing

ASSESSMENT MET6%D 5

#emonstration

(nterview

Written

_______________________________________________________________________________

CBC Dressmaking NC II - 52 -

$% /( Cut ?inal pattern

ASSESSMENT CRITERIA+

-. %ools for cutting patterns are selected in accordance with 1o)

re*uirements.

.. Pattern is cut in accordance with customerAs specifications'

measurements.

C%NTENT +

Selection of Cutting Pattern %ools

Procedures in Pattern Cutting

C%NDITI%NS +

Scissors

Pencil

Procedure Manual

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

$ilm >iewing

ASSESSMENT MET6%D 5

#emonstration

(nterview

Written

_______________________________________________________________________________

CBC Dressmaking NC II - 53 -

)NIT %& C%M'ETENC7 5 P54PA54 A?# C6% A%45(A;S

$"5 CAS6A; APPA54;

M%D)$E TIT$E 5 Preparing and Cutting

Materials for Casual Apparel

M%D)$E DESCRI'TI%N 5 %his module covers the

knowledge& skills and attitudes re*uired in

preparing and cutting materials and

accessories of casual apparel. (t includes

the re*uirements for preparing materials&

lay!outing and marking pattern on materials

and cutting materials.

N%MINA$ D)RATI%N 5 43 6ours

CERTI&ICATE $E:E$ 5 ?C ((

'RERE8)ISITE 5

$EARNING %)TC%MES+

6pon completion of this module the trainees'students must )e a)le to+

;" -. Prepare materials 9fa)ric:

;" .. ;ay!out and mark pattern on material

;" /. Cut materials

_______________________________________________________________________________

CBC Dressmaking NC II - 54 -

$% .( 'repare materials +?a>ric,

ASSESSMENT CRITERIA5

-. $a)ric is collected and checked in accordance to 1o) specification.

.. $a)ricAs width and *uality are checked according to instructions and appropriate actions

are taken in accordance with work re*uirements.

/. $a)ric is checked for *uality& faults& width& selvedges& dye lot and marking re*uirement

according to workplace procedures.

0. $a)ric is soaked'drip dried and pressed in accordance with standard fa)ric care.

3. Accessories and accents are selected and prepared in accordance with specified

garment style'design.

F. Measuring tools are prepared in accordance with 1o) re*uirements.

K. 4*uipment and tools are prepared according to procedures.

C%NTENT +

Principles of design

Procedures in drafting and cutting pattern

Selection of $a)ric E Accessories

$a)ric Care

C%NDITI%NS +

%ape Measure

;!s*uare

Meter Stick

Pencil

$a)ric

Accessories

Procedure Manual

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

ASSESSMENT MET6%D +

#emonstration

(nterview

Written

_______________________________________________________________________________

CBC Dressmaking NC II - 55 -

$% *( $ayDout and mark pattern on material(

ASSESSMENT CRITERIA+

-. Cutting ta)le is prepared and set!up in accordance with companyAs

procedures.

.. Patterns are prepared and checked in accordance with companyAs

specifications

/. Patterns are laid out and pinned on the fa)ric in accordance with fa)ric

grain line.

0. $a)ric is laid Dup and alignment with pattern is checked as per procedure.

3. Pattern pieces are positioned manually in accordance with companyAs

procedures.

F. Seam allowances are marked on the fa)ric in accordance with 1o)

re*uirements.

K. #arts E pocket locations are traced 'marked on the fa)ric in accordance

with specified garment style or design.

7. Mark is placed in accordance with companyAs procedures.

C%NTENTS+

Preparation of fa)ric )efore cutting

$a)ric manufacturing and design

Pattern lay!out and marking

Procedure in cutting materials

C%NDITI%NS + Students'%rainees must )e provided with the following+

%ape Measure

;!s*uare

Meter Stick

Pencil

5ecord ?ote)ook

Model'ody $orm

Procedure Manual

Pins

Pattern Paper

%ailorAs chalk

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

ASSESSMENT MET6%D +

#emonstration

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 5 -

Written

$% 2( Cut materials

ASSESSMENT CRITERIA+

-. =arment style or design is interpreted in accordance with customerAs

specification.

.. $a)ric is cut to meet design re*uirements and measurements of the pattern.

/. =arment parts are checked for completeness in accordance with specified

garment design or styles.

C%NTENTS+

Preparation of the fa)ric )efore cutting

$a)ric manufacturing and design

Pattern lay!out and marking

Procedure in cutting materials

C%NDITI%NS + Students'%rainees must )e provided with the following+

%ape Measure

;!s*uare

Meter Stick

Pencil

5ecord ?ote)ook

Model'ody $orm

Procedure Manual

Pins

Pattern Paper

%ailorAs chalk

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

ASSESSMENT MET6%D +

#emonstration

(nterview

Written

_______________________________________________________________________________

CBC Dressmaking NC II - 5! -

)NIT %& C%M'ETENC7 5 S4W CAS6A; APPA54;

M%D)$E TIT$E 5 Sewing casual apparel

M%D)$E DESCRI'T%R 5 %his module covers the

knowledge& skills and attitudes re*uired in

sewing casual apparel. (t includes the

re*uirements for preparing cut parts&

preparing sewing machines for operations

and sewing garment.

N%MINA$ D)RATI%N 5 -3 6ours

CERTI&ICATE $E:E$ 5 ?C ((

'RERE8)ISITE 5

$EARNING %)TC%MES +

6pon completion of this module the trainees'students must )e a)le to+

;" -. Prepare cut parts

;".. Prepare sewing machine for operation

;" /. Sew and assem)le garment parts

;" 0. Alter completed garment

_______________________________________________________________________________

CBC Dressmaking NC II - 5" -

$% .( 'repare cut parts

ASSESSMENT CRITERIA5

-. Cut parts are prepared in accordance with the specified garment design'style.

.. Cut parts are pressed in accordance with fa)ric specifications.

/. Cut parts are pinned together in accordance with garment design or style

0. Accessories and accents are prepared in accordance with garment design or

style.

C%NTENT5

$a)ric manufacturing procedures

=arments designs and styles

%echni*ues in pressing

C%NDITI%NS + Students'%rainees must )e provided with the following+

Pencil

Cutting shears

5uler with =rid

Pins

;!s*uare

Pin cushion

%ape Measure

4mery )ag

Curve 5uler

$a)ric

$rench curve

Clothes line

asic Pattern

$lat iron

Pattern Paper

(roning )oard

Scissors

Paper weight

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

ASSESSMENT MET6%D +

#emonstration

(nterview

_______________________________________________________________________________

CBC Dressmaking NC II - 5# -

Written

$%*( 'repare se"in! machine ?or operation(

ASSESSMENT CRITERIA5

-. Machine parts are cleaned and lu)ricated in accordance with companyAs

re*uirements and manufacturerAs cleaning and lu)ricating instructions.

.. Machines are threaded in accordance with the companyAs work procedure

/. Machines are set!up and ad1usted in accordance with fa)ric specification.

0. Speed of machine and work handling are controlled in accordance with

companyAs procedures.

3. Minor machines pro)lem or fault is identified and repaired in accordance to

manufacturerAs manuals.

F. Machine operations is monitored.

K. CompanyAs health and safety practices and procedures are followed as per

standard operating procedures

C%NTENTS+

%ypes and functions of sewing machine

Machine trou)les and remedies

?eedle types and their application

C%NDITI%NS+

?eedles

%esting fa)ric

%hread

Working tools

Shears

@igh speed sewing machine

@igh speed sewing machine attachments

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

ASSESSMENT MET6%D+

Written %est

Actual performance

_______________________________________________________________________________

CBC Dressmaking NC II - % -

$%2( Se" and assem>le !arment parts

ASSESSMENT CRITERIA5

-. =arments parts are assem)led in accordance with garment assem)ly

instruction and pattern specifications.

.. =arments are sewn in accordance with sewing standard procedures and

companyAs time frames

/. Sleeves& collars and pockets are identified and sewn in terms of customerAs

specification

0. %he neckline and corners are sewn evenly and sharp according to sewing

procedures

3. Pocket flaps and pieces had clean corners with no raw edges

F. Bipper is sewn without puckered according to sewing instructions

K. Seams& edges are finished in accordance with the 1o) re*uirements

7. Waist)and width are evenly sewn from end!to!end according to standard

operating procedure.

C%NTENTS+

Procedure in assem)ling garments such as )louse& skirts and dress

Complete finishing touches

Procedure in pressing

C%NDITI%NS+

?eedles

Cut fa)rics

Pins

%esting fa)rics

%hreads

Cutting ta)le

%ailors chalk'pencil

Cutting tool

%ape measure

Steam (ron

Cutting shears

(roning )oard

Specification sheet

Model'dress form

Seam ripper

Sleeve )oard'ham

%esting fa)ric

=arment sample

_______________________________________________________________________________

CBC Dressmaking NC II - $ -

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

ASSESSMENT MET6%D+

Written %est

Actual performance

_______________________________________________________________________________

CBC Dressmaking NC II - 2 -

$%4( Alter completed !arment

ASSESSMENT CRITERIA5

-. Alteration'modifications are determined'undertaken in accordance with the

clientAs specifications

.. $inal fitting is conducted to ensure clientAs satisfaction

/. =arments alteration is completed as per clients satisfaction.

C%NTENTS+

Procedure on final fitting

%ypes of packaging

Procedure on packaging

C%NDITI%NS+

?eedles

Cut fa)rics

Pins

%esting fa)rics

%hreads

Cutting ta)le

%ailors chalk'pencil

Cutting tool

%ape measure

Steam (ron

Cutting shears

(roning )oard

Specification sheet

Model'dress form

Seam ripper

Sleeve )oard'ham

%esting fa)ric

=arment sample

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

ASSESSMENT MET6%D+

Written %est

Actual performance

_______________________________________________________________________________

CBC Dressmaking NC II - 3 -

)NIT %& C%M'ETENC7 5 APP;N $(?(S@(?= %"6C@4S "?

CAS6A; APPA54;

M%D)$E TIT$E 5 Applying $inishing %ouches on

Casual Apparel

M%D)$E DESCRI'TI%N 5 %his module covers the

knowledge& skills and attitude on applying

finishing touches& trimming e<cess threads&

pressing finished garment and packaging

the finished garment.

N%MINA$ D)RATI%N 5 43 6ours

CERTI&ICATE $E:E$ 5 ?C ((

'RERE8)ISITE 5

$EARNING %)TC%MES +

6pon completion of this module the trainees'students must )e a)le to+

;" -. Apply finishing touches

;" .. %rim e<cess threads

;" /. Press finished garment

;" 0. Package the finished garment

_______________________________________________________________________________

CBC Dressmaking NC II - 4 -

$% .( Apply ?inishin! touches

ASSESSMENT CRITERIA5

-. $inishing touches are checked in accordance with garments design'style

specifications

.. Accessories and accents position are marked and attached in accordance

with garment design'style specification

/. =arment is checked for loose threads& missing )uttons and attachments

0. odice hems allowances and sleeves are folded and pinned in accordance

with customerAs specifications

3. @emline allowances are sewn in accordance with the given stitch'seam

specifications

F. Accessories and accents are sewn )y hand or machine in accordance to

garment design'style specifications

K. $inishing operations are performed in accordance with customerAs

specifications and companyAs procedures.

C%NTENT+

%ypes and functions of finishing touches

Procedure in pressing

C%NDITI%NS+

?eedles

Cut fa)rics

Pins

%esting fa)rics

%hreads

Cutting ta)le

%ailors chalk'pencil

Cutting tool

%ape measure

Steam (ron

Cutting shears

(roning )oard

Specification sheet

Model'dress form

Seam ripper

Sleeve )oard'ham

%esting fa)ric

=arment sample

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

ASSESSMENT MET6%D+

Written %est

Actual performance

_______________________________________________________________________________

CBC Dressmaking NC II - 5 -

$% *( Trim eFcess threads

ASSESSMENT CRITERIA5

-. =arments are trimmed of e<cess threads in accordance with sewing

procedures

.. =arments are reversed and hanged in accordance with companyAs

procedures

/. %rimming tools are prepared in accordance with companyAs procedures

C%NTENT5

Procedure in trimming

6se of trimming tools

C%NDITI%NS5

%rimming scissors

Cutting shears

Specification sheet

Model'dress form

Seam ripper

=arment sample

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

ASSESSMENT MET6%D5

Written %est

Actual performance

_______________________________________________________________________________

CBC Dressmaking NC II - -

$% 2( 'ress ?inished !arment

ASSESSMENT CRITERIA5

-. Pressing machines are set!up& cleaned and checked in accordance with

companyAs procedures

.. @eat'pressure is applied in accordance with product re*uirements& fa)ric

specifications and companyAs procedures

/. Pressing is se*uenced in accordance with work specifications and companyAs

procedures

C%NTENT5

Procedure in pressing

Application of heat and pressure on garments

"perating pressing machines

C%NDITI%NS5

Steam (ron

(roning )oard

Model'dress form

)oard'ham

=arment sample

MET6%D%$%G7 +

Self!paced'Modular

=roup #iscussion

ASSESSMENT MET6%D5

Written %est

Actual performance

_______________________________________________________________________________

CBC Dressmaking NC II - ! -

$% 4( 'acka!e the ?inished !arment

ASSESSMENT CRITERIA5

-. =arments are finished and met specification and appropriate la)els

.. $inished garments are packed in accordance with packaging standards and

procedures

C%NTENT5

#ifferent kinds of packaging materials

Procedures in la)eling and packaging finished garments

C%NDITI%NS+

$inished garments

Packaging materials

;a)eling materials

Specification sheet

MET6%D%$%G7 5

Self!paced'Modular

=roup #iscussion

ASSESSMENT MET6%D+

Written %est

Actual performance

_______________________________________________________________________________

CBC Dressmaking NC II - " -

You might also like

- CBLM DressmakingDocument36 pagesCBLM DressmakingNovi Ember78% (27)

- Pagnitoan Session Plan For g11 DressmakingDocument11 pagesPagnitoan Session Plan For g11 Dressmakingiries jabines86% (7)

- Maintain Training FacilitiesDocument13 pagesMaintain Training FacilitiesAngelou Tingson100% (1)

- Session Plan (Dressmaking NC II)Document4 pagesSession Plan (Dressmaking NC II)Noemi Bautista91% (11)

- CBLM and Assessment ToolDocument56 pagesCBLM and Assessment ToolKrystyn Camille Madrigal Sevillano100% (2)

- CBLM FINAL (PREPARING AND CUTTING MATERIALS For CASSUAL APPAREL) March 24,2021Document33 pagesCBLM FINAL (PREPARING AND CUTTING MATERIALS For CASSUAL APPAREL) March 24,2021Lady ann Concepcion Ragay92% (13)

- Wendy Institutional Assessment ToolsDocument18 pagesWendy Institutional Assessment ToolsWendy Arnido100% (1)

- Registration and Shop Orientation: Division Skills Training For TLE Teachers by SpecializationDocument3 pagesRegistration and Shop Orientation: Division Skills Training For TLE Teachers by Specializationlissalawas88% (8)

- UtilizeDocument22 pagesUtilizeJeff Ubana Pedrezuela40% (5)

- Competency Based Learning Materials-DressmakingDocument19 pagesCompetency Based Learning Materials-Dressmakinglissalawas100% (10)

- Guide To Fire Protection in MalaysiaDocument3 pagesGuide To Fire Protection in MalaysiaFadilah Ansari0% (2)

- A Mini Project Report ON Web Based College Admission System: Bachelor of Computer ApplicationsDocument48 pagesA Mini Project Report ON Web Based College Admission System: Bachelor of Computer ApplicationsAbhimanyu Pandey100% (1)

- TR - Dressmaking (Casual) NC IIDocument60 pagesTR - Dressmaking (Casual) NC IIBibi Chem Jones MillaNo ratings yet

- Evidence Plan: Competency Standard: Dressmaking Ncii Unit of Competency: Draft and Cut Pattern For Casual ApparelDocument2 pagesEvidence Plan: Competency Standard: Dressmaking Ncii Unit of Competency: Draft and Cut Pattern For Casual ApparelmaristellaNo ratings yet

- Module 1 Draft and Cut Pattern of Casual ApparelDocument79 pagesModule 1 Draft and Cut Pattern of Casual Appareljazzy mallari100% (1)

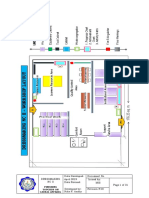

- Dressmaking Shop LayoutDocument1 pageDressmaking Shop Layoutnina andoy50% (2)

- PortfolioDocument106 pagesPortfolioshiena mae liberto100% (5)

- RA IN EE: Progress Chart Dressmaking NC Ii 275 HoursDocument3 pagesRA IN EE: Progress Chart Dressmaking NC Ii 275 Hoursnimfa cielo toribio50% (2)

- MTFDocument21 pagesMTFnina andoy100% (2)

- Manipon CBLM FinalDocument52 pagesManipon CBLM FinalTRISTAN MARTINEZNo ratings yet

- Maintain Training FacilitiesDocument12 pagesMaintain Training FacilitiesMerlita JuanNo ratings yet

- Wendy CBLM FINAL EditedDocument37 pagesWendy CBLM FINAL EditedWendy ArnidoNo ratings yet

- 1 - Training Activity MatrixDocument5 pages1 - Training Activity MatrixMashelet Valle33% (3)

- Competency Based Learning Material - Borja, Kathleen B.Document77 pagesCompetency Based Learning Material - Borja, Kathleen B.Kathleen BorjaNo ratings yet

- SWBL DocumentsDocument38 pagesSWBL DocumentsJeffrey Ryan Alonsagay83% (6)

- Dressmaking NC Ii Trainingactivitymatrix: CBLM Dressmaking Ncii Draft and Cut Pattern For Casual ApparelDocument3 pagesDressmaking NC Ii Trainingactivitymatrix: CBLM Dressmaking Ncii Draft and Cut Pattern For Casual ApparelJexylon TenederoNo ratings yet

- CBLM DressmakingDocument37 pagesCBLM DressmakingRYDEN100% (1)

- Portfolio SampleDocument103 pagesPortfolio SampleMaher ArakamaNo ratings yet

- TM CBLM - Copy 2.odtDocument98 pagesTM CBLM - Copy 2.odtVenus Ballesteros100% (2)

- Facilitate Learning SessionDocument7 pagesFacilitate Learning Sessionroselyn ayensaNo ratings yet

- Progress SheetDocument5 pagesProgress SheetJexylon TenederoNo ratings yet

- CBLMDocument42 pagesCBLMDnca Alaan77% (43)

- CBLM 3Document33 pagesCBLM 3lyka joy silpao89% (9)

- Sample Session PlanDocument4 pagesSample Session PlanClarina BerganteNo ratings yet

- 1.7.1 CBLMDocument64 pages1.7.1 CBLMNovi Ember75% (4)

- Shop Layout Dressmaking NC IIDocument1 pageShop Layout Dressmaking NC IIAndrea Pabalinas100% (5)

- Session PlanDocument10 pagesSession PlanCherry Mae Claire Villanueva-GomezNo ratings yet

- Form 1.1 Self-Assessment Checks INSTRUCTIONS: This Self-Check Instrument Will Give The Trainer NecessaryDocument59 pagesForm 1.1 Self-Assessment Checks INSTRUCTIONS: This Self-Check Instrument Will Give The Trainer NecessaryMerlinda Jornales ElcanoNo ratings yet

- TM 2Document87 pagesTM 2Angelic-Denmark AcacioNo ratings yet

- Plan Training SessionDocument92 pagesPlan Training Sessionjoyce92% (12)

- Written Test: Qualification: Dressmaking NCII UNIT OF COMPETENCY: Draft and Cut Pattern For Casual ApparelDocument4 pagesWritten Test: Qualification: Dressmaking NCII UNIT OF COMPETENCY: Draft and Cut Pattern For Casual Apparelmaristella67% (3)

- CBLM - Dressmaking NciiDocument62 pagesCBLM - Dressmaking NciiRowelyn Linte100% (1)

- Module 2 Prepare and Cut Materials For Casual ApparelDocument80 pagesModule 2 Prepare and Cut Materials For Casual Appareljazzy mallari100% (2)

- TM Jumah CBLM GarmentsDocument96 pagesTM Jumah CBLM GarmentsAljubir Marrack100% (1)

- Output Arnel Lomocso 1Document67 pagesOutput Arnel Lomocso 1Arnel LomocsoNo ratings yet

- Training PlanDocument2 pagesTraining PlanShiela Mae Ceredon100% (3)

- Draft and Cut Final Pattern For Men'S Casual ApparelDocument13 pagesDraft and Cut Final Pattern For Men'S Casual ApparelJe-ann H. GonzalesNo ratings yet

- Assessor's GuideDocument7 pagesAssessor's Guidebenjaminrcojr0% (2)

- Sew Casual ApparelDocument36 pagesSew Casual ApparelJexylon Tenedero100% (1)

- CBLMDocument44 pagesCBLMMerlinda Jornales Elcano100% (4)

- CBLM PackageDocument20 pagesCBLM PackageMaila Calimpong Asim100% (1)

- TNA FormsDocument32 pagesTNA FormsMerlinda Jornales ElcanoNo ratings yet

- CBLM 3 1Document32 pagesCBLM 3 1Jexylon TenederoNo ratings yet

- F. Form 10 Record BookDocument4 pagesF. Form 10 Record BookArnel LomocsoNo ratings yet

- Welcome! !!: Pigcarangan Integrated School Dressmaking NC IiDocument30 pagesWelcome! !!: Pigcarangan Integrated School Dressmaking NC IiLeah UljerNo ratings yet

- CBC Dressmaking NC IIDocument68 pagesCBC Dressmaking NC IINing Erlano Triñanes75% (4)

- Complete CBLMDocument178 pagesComplete CBLMtagekykunsNo ratings yet

- TR - Dressmaking NC IIDocument60 pagesTR - Dressmaking NC IIMR. CHRISTIAN DACORONNo ratings yet

- CBLM PackageDocument38 pagesCBLM PackagePearl Anne ManilaNo ratings yet

- CBC Tailoring NC IIDocument48 pagesCBC Tailoring NC IInamasteamizadeNo ratings yet

- HEO (Wheel Loader) NC IIDocument63 pagesHEO (Wheel Loader) NC IIfilipetaveirosNo ratings yet

- Competency-Based Curriculum: Computer Hardware Servicing NC IiDocument78 pagesCompetency-Based Curriculum: Computer Hardware Servicing NC IiLznh EmtiroNo ratings yet

- Technical Data Book PDFDocument79 pagesTechnical Data Book PDFRuth Santos NaranjoNo ratings yet

- Compact Wideband Dual-Band Polarization and Pattern Diversity Antenna For Vehicle CommunicationsDocument6 pagesCompact Wideband Dual-Band Polarization and Pattern Diversity Antenna For Vehicle CommunicationsAnil NayakNo ratings yet

- Eclairage MaisonDocument147 pagesEclairage MaisonradaziNo ratings yet

- 1 Quarter TLE 7 Week 7 Lesson: Hazard and Risk in The WorkplaceDocument15 pages1 Quarter TLE 7 Week 7 Lesson: Hazard and Risk in The WorkplaceNazzer NacuspagNo ratings yet

- Good Colour Periodic TableDocument1 pageGood Colour Periodic TableDaizLee AhmadNo ratings yet

- Networx Nx-548E Receiver Installation Instructions: ContentDocument12 pagesNetworx Nx-548E Receiver Installation Instructions: ContentJefersom RodriguesNo ratings yet

- Parts Manual: FortensDocument554 pagesParts Manual: FortensHaradau AdrianNo ratings yet

- IcommsDocument4 pagesIcommsPercy Posadas BangononNo ratings yet

- 2012 Adams Adams Practical Guide Intellectual Property AfricaDocument715 pages2012 Adams Adams Practical Guide Intellectual Property AfricaThe Legal WhispersNo ratings yet

- Option B - BiochemistryDocument24 pagesOption B - BiochemistryRosaNo ratings yet

- Garden City University College: Department of I.C.TDocument3 pagesGarden City University College: Department of I.C.Trichardmawuli3593No ratings yet

- Solutions Manual For Introduction To RobDocument10 pagesSolutions Manual For Introduction To RobAndy Tan Fu YangNo ratings yet

- Replikasi, Transkripsi Dan Translasi DnaDocument19 pagesReplikasi, Transkripsi Dan Translasi DnaEllizabeth LilantiNo ratings yet

- Physiology of Normal Pueperium and Its ManagementDocument13 pagesPhysiology of Normal Pueperium and Its ManagementSandhya s100% (3)

- Ghost Usb Honeypot MasterDocument15 pagesGhost Usb Honeypot MasterVinamra MittalNo ratings yet

- The Definitive Airline Operations and KPI GuideDocument71 pagesThe Definitive Airline Operations and KPI Guidethanapong mntsaNo ratings yet

- Rob Cover - Identity and Digital Communication - Concepts, Theories, Practices-Routledge (2023)Document193 pagesRob Cover - Identity and Digital Communication - Concepts, Theories, Practices-Routledge (2023)Betül Önay DoğanNo ratings yet

- Adler Presentation Patio SABMA 1-ADocument9 pagesAdler Presentation Patio SABMA 1-Apaulo.m.patioNo ratings yet

- Profil Company 2017Document10 pagesProfil Company 2017Eno Ronaldfrank OguriNo ratings yet

- CYSTOSTOMYDocument60 pagesCYSTOSTOMYOepil KirickNo ratings yet

- COMESADocument15 pagesCOMESAchesca macaraigNo ratings yet

- INFO 4650 Prototype - Course OutlineDocument7 pagesINFO 4650 Prototype - Course OutlineMax PerronNo ratings yet

- Omkar TrustDocument156 pagesOmkar TrustAveline Dsouza100% (2)

- Jestine Seva - PEModuleWeek5&6Document5 pagesJestine Seva - PEModuleWeek5&6Mike AlbaNo ratings yet

- Tesol End Term AssignmentDocument7 pagesTesol End Term Assignmentakshita ramdasNo ratings yet

- Prayer For The Elderly and GrandparentsDocument2 pagesPrayer For The Elderly and GrandparentsRomain Garry Evangelista LazaroNo ratings yet

- Jurnal Farmasi PDFDocument7 pagesJurnal Farmasi PDFFiona ValenciaNo ratings yet

- Mathematics Actual SBaDocument8 pagesMathematics Actual SBaRohan lall100% (1)