Professional Documents

Culture Documents

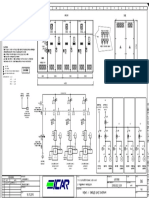

Intreruptor Schneider VCB-MG

Intreruptor Schneider VCB-MG

Uploaded by

Razvan MaresCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intreruptor Schneider VCB-MG

Intreruptor Schneider VCB-MG

Uploaded by

Razvan MaresCopyright:

Available Formats

MV Vacuum circuit-breaker

12-24 KV

Catalogue

2004

1

General contents

Evolis 12-24 kV

Presentation

Evolis circuit breakers 2-3

The very best of vacuum technology 4-6

Extended products offer 7

Circuit breaker

Performance tables 12-17.5KV 8-9

Function descriptions 10-17

Dimensions 18-19

Performance tables 24KV 20-21

Function descriptions 22-29

Dimensions 30-31

Option

LPCT sensors 32

2

Evolis circuit breakers are used to protect and control public or industrial medium

voltage electrical distribution networks.

Evolis is indoor switchgear that is particularly suited to the production and renovation

of HV/MV, MV/MV and MV/LV substations.

It is suitable for the protection of all types of applications:

cables, lines, motors, capacitors, transformers, bus sectioning of sources, etc.

2

0

0

4

6

1

2

0

0

4

6

0

Evolis circuit-breaker

Presentation

3

Presentation Evolis circuit-breaker

A safe, easy to integrate

and comprehensive range

for demanding installations.

P

E

5

5

1

0

1

Evolis 12 kV withdrawable

P

E

6

0

0

5

2

Evolis 24 kV withdrawable

b Evolis is a vacuum circuit-breaker that meets current and future standards in terms

of electrical installation dependability, in compliance with standards and

environmental protection.

It is the quintessential expression of Merlin Gerins know-how.

b Evolis is intended for all network applications, either new or renovation

installations, for utilities companies, infrastructures, process industry and

tertiary building.

4

D

E

6

0

1

6

3

Fig. 1: vacuum interrupter components

D

E

6

0

1

6

4

Fig. 2: cross-section of AMF contact

P

E

6

0

0

4

2

Fig. 3: diffuse vacuum arc AMF technology

Ceramic chamber

Shield

Fixed contact

Mobile contact

Metal bellows

Electrode

AMF coil

Contact disk

Arc plasma

Axial magnetic field

Current

Presentation

As a specialist in breaking technologies,

Merlin Gerin took naturally an interest in

vacuum breaking techniques.

A major R&D investment was made to

develop and engineer Evolis, providing

customers with the very best of vacuum

technology.

Make-up of a vacuum interrupter

b Vacuum interrupters basically have two electrical contacts, one xed and the other

mobile, and a sealed enclosure. The latter enables a high level of vacuum to be

maintained inside the interrupter (less than 10-7 bar) to provide insulation between

the open contacts.

b The dielectric strength of the vacuum allows the contact-to-contact distance to be

reduced. This short distance together with the low opening speed allow the use of a

low energy control mechanism. A metal bellows provides the link between the mobile

contact and the enclosure.

b In order to keep the vacuum level required for the correct operation of the

interrupter for 30 years, the enclosure must be perfectly sealed, and the various

components have to be fully degased. This is achieved by:

v choosing materials that are specically selected for this application

(metals and ceramics),

v choosing an appropriate assembly process (vacuum, high temperature brazing),

v the use of a "getter" material to absorb the residual gas.

Current breaking in a vacuum interrupter

b In vacuum breaking, the electrical arc generated on separation of the contacts is

made up of a plasma of metal vapors produced by the vaporization of the contact

material.

b At low values of current, these vapors very quickly condense on the shield and

contacts when the arc disappears, thus allowing:

v the vacuum to be re-established,

v a contact-to-contact dielectric strength to be restored that is greater than

the recovery voltage: breaking is then complete.

b At high currents, the electrical arc in the vacuum switches to a concentrated mode

which causes high, localized temperature rises on the contacts. The existence of

these hot spots is detrimental to the quick restoring of the dielectric strength.

Two techniques can be used in order to avoid this stagnation of the static

concentrated arc:

v the so called RMF (Radial Magnetic Field) technique, involves rotating the arc

thanks to an electromagnetic effect generated by a radial magnetic eld; this

therefore limits contact erosion.

v a more recent technique called AMF (Axial Magnetic Field) involves applying an

axial magnetic eld parallel to the axis of the two contacts (g. 2) which allows a

diffuse arc to be maintained (g. 3) even at high current values. The arc energy is

spread over the whole contact surface area, therefore causing very low levels of

erosion.

v Merlin Gerin has chosen this last technique for the Evolis range.

The very best of vacuum technology

5

2

0

0

1

1

0

Fig 4: 17.5 kV external coil type interrupter

D

E

6

0

1

6

2

Fig 5: 24 kV internal coil type interrupter

Merlin Gerins choices for Evolis

combined with its industrial expertise

provides customer with a highly reliable

range of circuit-breakers. These products

are suitable for the most demanding

conditions with the guarantee of full

compliance with international standards.

AMF technology

b Evolis circuit-breakers use AMF type vacuum interrupters.

According to technical and economic optimization considerations, the axial magnetic

eld is generated:

v either by a coil outside of the interrupter (g. 4), for rated voltages up to 17.5 kV,

v or by a coil integrated in the interrupter contact structure (g. 5), for the 24 kV

voltage level.

b In both cases the AMF vacuum interrupters feature low arc voltages (Uarc of

around 50 V) and maximum usage of the contact surface for very low contact erosion.

The advantages provided

b The above choices provide customers with the following advantages in

MV circuit-breaker applications:

v simple and compact vacuum interrupters,

v CuCr materials as main contacts in the interrupter for lower chopping current

and low surge during breaking,

v high electrical endurance meaning that there is no need for contact wear

inspection in normal network protection applications including highly disturbed

overhead line feeders.

Presentation The very best of vacuum technology

Presentation The very best of vacuum technology

6

P

E

6

0

0

6

2

Vacuum interrupter

P

E

6

0

0

6

1

Industrial process expertise

Systematic advanced control

The main components of the circuit-breaker, such as vacuum interrupter and

operating mechanism, are produced by Schneider Electric. The vacuum interrupters

are manufactured in an ultra-modern production unit in France.

During manufacture, each circuit-breaker is subjected to systematic advanced

testing.

Vacuum interrupter testing

b The level of vacuum in each interrupter is tested using the "magnetron discharge

method".

b Using this sophisticated procedure, measurement is very precise and does not

require access to the inside of the interrupter, thus not affecting the airtight seal.

Circuit-breaker testing

b A rigorous set of tests and measurements is carried out on each circuit-breaker.

b The results are reported and signed off by the quality control department on each

device's test certicate to ensure product traceability.

Compliance with standards

b Evolis complies with IEC 62271-100.

b Design and production are certied to ISO 9000 (version 2000).

b Production sites are certied to ISO 14001 (environmental standard).

Certification

b The certicate of conformity provides guarantees that the circuit-breaker:

v has been subject to type tests according to EN 45001 standards procedures in

accredited laboratories by independent organizations,

v is in conformity with recognized international standards

b Evolis is currently being certied by external EN 45011 accredited organizations,

members of the STL (Short circuit Testing Liaison)

v EN 45001: general requirements for the competence of testing and calibration

laboratories,

v EN 45011: general requirements for bodies of operating product certication

systems.

Environmental care

b Product design takes account of the environmental constraints described in a

"Product Environment Prole" dossier (PEP).

b An end-of-service-life manual details procedures for dismantling and processing

components.

Ics = 100% Icu

220/440

525

690

100

100

85

Icw 85kA/1s

DV2

cat.B

IEC 947-2

UTE VDE BS CEI UNE AS NEMA

EN 60947-2

50/60Hz

Ue

Icu

(V)

(kA)

LV cubicle

components

b Mcb

b protection relay

b lamp

b push button

b terminal blocks

connector

MV cubicle

components

b capacitor insulator

b earthing switch

b heating resistor

b voltage presence

indicator

b crank

b extraction table

Instrument

transformer

Circuit-breaker

b pilot

b cradle

Protection

and control

b UMI

Metering

b VPIS

b PM500

7

D

E

6

0

1

2

9

Extended products offer

8

Full version

Performance tables

12KV-17.5KV

Common characteristics according to IEC 62271-100

rated frequency fr (Hz) 50 & 60

short-time withstand current Ik for tk = 3 s (kA) rms Ik = Isc

rated peak withstand current Ip peak (kA) Ip = 2.5 & 2.6 Ik

rated short circuit making current peak (kA) = 2.5 & 2.6 Isc

operating sequence O - 3 mn - CO - 3 mn - CO

O - 0.3 s - CO - 3 mn - CO

O - 0.3 s - CO - 15 s - CO

operating times opening ms < 50

breaking ms < 60

closing ms < 65

mechanical endurance class M2

number of operations 10000 (30000 upon request)

electrical endurance class E2

number of operations 25 kA 100

31.5 kA 100

40 kA 100

capacitive current breaking class C1-C2 (for some applications)

Electrical characteristics according to IEC 62271-100

circuit breaker 12P1 12P1 12P1 12P3 12P3 12P3 17P2 17P2 17P2

630 1250 2500 630 1250 2500 630 1250 2500

rated voltage Ur (kV) rms 12 12 12 12 12 12 17.5 17.5 17.5

rated insulation voltage Ud (kV) rms 28 28 28 28 28 28 38 38 38

rated insulation voltage Up (kV) peak 75 75 75 75 75 75 95 95 95

rated short-circuit breaking current Isc (kA) rms 25 25 25 40 40 40 31.5 31.5 31.5

rated normal current (-25 +40C) Ir (A) rms 630 1250 2500 630 1250 2500 630 1250 2500

climatic version -25 +40C b b b b b b b b b

Installation and connections

phase distance:

between poles (mm) 145 145 240 240 240 240 185 185 240

dimensions C.B. and cradle (mm) width (W) 576 576 866 866 866 866 686 686 866

depth (D) 1140 1140 1140 1140 1140 1140 1140 1140 1140

height (H) 965 965 965 965 965 965 965 965 965

mass C.B. and cradle (kg) 165 165 272 272 272 272 174 174 272

Withdrawable type

Humidity:

average relative humidity

24-hours period < 95%

1 month < 90%

9

Fixed version

12P1 12P1 12P1 12P3 12P3 12P3 17P2 17P2 17P2

630 1250 2500 630 1250 2500 630 1250 2500

12 12 12 12 12 12 17.5 17.5 17.5

28 28 28 28 28 28 38 38 38

75 75 75 75 75 75 95 95 95

25 25 25 40 40 40 31.5 31.5 31.5

630 1250 2500 630 1250 2500 630 1250 2500

b b b b b b b b b

145 145 240 240 240 240 185 185 240

470 470 660 660 660 660 550 550 660

429 429 429 429 429 429 429 429 429

535 535 535 535 535 535 535 535 535

51 51 79 79 79 79 55 55 79

Fixed

Withdrawable

Ics = 100% Icu

220/440

525 690

100 100 85

Icw 85kA/1s

DV2

cat.B

IEC 947-2

UTE VDE BS CEI UNE AS NEMA EN 60947-2 50/60Hz

Ue Icu (V) (kA)

Ics = 100% Icu

220/440 525 690

100 100 85

Icw 85kA/1s

DV2

cat.B

IEC 947-2

UTE VDE BS CEI UNE AS NEMA EN 60947-2

50/60Hz

Ue Icu (V) (kA)

Fixed type

10

Evolis 12 kV withdrawable

Function description

power circuit

Composition

b The power circuit comprises:

v mobile contacts made up of disconnecting clusters and arms mounted on the

circuit breaker,

v xed ngers located on the cradle and insulated by bushings and metal shutters.

b This unit gives perfect control of dielectric, short time withstand current and

temperature rise considerations.

All of these characteristics have been validated by testing.

Connection

b Customer connection is easily achieved outside the cradle:

v on vertical copper terminals integrated in the bushing,

v through a set of connectors, also used on the basic circuit breaker unit.

Connection variants described on page 26 are possible.

Comments:

The dielectric withstand values shown in the performance tables are guaranteed excluding these

connectors.

The panel builder should check the overall cubicle connection configuration.

b For Ur = 17.5 kV CBs with 185 mm phase-to-phase distance, the eld deectors

are used to increase the dielectric withstand from 75 kV to 95 kV.

D

E

3

0

1

1

8

Power circuit

2

0

0

1

5

9

3 sets of connectors

2

0

1

2

5

2

Field deflectors

Evolis 12 kV withdrawable

Function description

racking in

11

Composition

The racking in function is provided by:

b The racking truck supporting the circuit breaker (mobile part).

b The cradle including the bushings (xed part).

b The LV plug.

Operating procedure

b The circuit breaker moves through 3 stable states:

v service: circuit breaker racked in and locked in place; low voltage plug connected,

v test: circuit breaker racked out and locked in place; low voltage connected,

v extracted: the circuit breaker can be unlocked and extracted from the cubicle.

3 stable states for manual operation

Comments:

Arrows indicate the lock-in-positions for the circuit breaker and the low voltage connector.

Functions

b A propulsive system combined with a screw-shaft makes racking in and racking

out easier. The racking mechanism can be operated with the door closed.

Interlocking prevents the user from inserting the lever until the racking base selector

has been positioned to the racking in/racking out position.

b Interlocking between circuit breaker position and cradle makes operation safer:

racking in or out only when the circuit breaker is open.

b Interlocking is also provided between the low voltage connector and the circuit

breaker. Racking in is only possible when the low voltage connector is connected.

The oor of the cradle includes all necessary xing holes to position properly the

operating mechanism and the power circuit of the earthing switch. This allows

reliable operations of the earthing switch and guarantees the interlocking between

circuit breaker and earthing switch.

b Earthing is automatically achieved throughout the whole racking in operation.

b Protective shutters placed on the cradle prevent access to the racking ngers

when the device is extracted (protection index: IP2X).

b For maintenance operations, it is possible to:

v padlock the shutters in the closed position,

v unlock the shutters mechanism to access the racking ngers.

b A full proof protection enables cradle and circuit breaker to be matched up.

This system is mounted on the racking base.

Part of it has to be assembled by the panel builder on the cubicle floor.

Accessories

b A set of auxiliary contacts:

v 4 racked in/racked out circuit breaker position contacts,

v 1 contact indicating that the circuit breaker is locked in place in the cradle.

b The earthing for the base is provided by a copper brush.

b A key locking system (Ronis or Profalux) for the racked out position

on the circuit breaker will provide increased safety when working downstream

of the circuit breaker. This system is combined with an earthing switch

(refer to page 43).

b Circuit breaker compartment door interlocking.

b The device allows circuit breaker operation only when the door is closed

for full version with truck.

D

E

3

0

1

1

9

2

0

0

1

4

6

D

E

3

0

1

2

1

Shutters

D

E

3

0

1

2

2

M

T

6

6

0

4

9

Locked C.B.

position

contact

Racked in/

racked out

contacts

Earthing device

D

E

3

0

1

3

6

Cubicle door interlocking mechanism

Propulsive system

D

E

3

0

1

2

4

D

E

3

0

1

2

5

D

E

3

0

1

2

6

Service position Test position Extracted position

Function description

LV connections

Evolis 12 kV withdrawable

12

Main functions

This plug and socket system provides an auxiliary supply connection with a high level

of electrical safety.

Interlocking function

It is possible to connect and disconnect the plug only if the breaker is in racked out

position. It is not possible during the racking in operation.

Two versions of plug and socket

An 18 pin version

This version allows you to connect:

bbb b For remote control

v 1 electric motor,

v 1 shunt closing release,

v 1 shunt opening release,

v 1 contact ready to close.

bbb b For auxiliary contacts

v 2 changeover contacts,

v 1 normally-open contact,

v 1 normally-closed contact.

A 42 pin version

This version allows you to connect:

bbb b For remote control

v 1 electric motor,

v 1 shunt closing release,

v 2 shunt opening releases

or 1 shunt opening release + 1 undervoltage release,

v 1 contact ready to close,

v 1 low energy release,

v 1 fault-trip indication contact,

v 1 SDE contact remote reset.

bbb b For auxiliary contacts

v 2 changeover contacts,

v 5 normally-open contacts,

v 4 normally-closed contacts.

D

E

3

0

1

2

7

Plug and socket 18 pin version

D

E

3

0

1

2

8

Plug and socket 42 pin version

Function description

opening circuit

13

Low voltage accessories

Composition

The basic circuit breaker equipment includes a shunt trip release unit (MX).

b It may also include the following options:

v a second MX release,

v or an undervoltage release (MN),

v or an undervoltage release with time delay (MN + time delay unit),

v and a low energy release (MITOP).

Opening mechanism circuit diagram

Shunt opening release (MX)

This enables the instant opening of the circuit breaker when energised.

The permanent energising of the MX locks the circuit breaker in the open position.

2

0

0

2

0

2

Circuit breaker equipped with an opening release

2

0

0

2

1

3

MX shunt opening release

2

0

0

4

7

6

E

N

Characteristics

supply V AC 50/60 Hz 24 48 100-130 200-250

V DC 24-30 48-60 100-130 200-250

threshold 0.7 to 1.1 Un (DC) 0.85 to 1.1 Un (AC)

consumption (VA or W) pick-up: 200 hold: 4.5

opening

order

opening

order

delayed

opening order

time delay unit

MN MN MX

Function description

opening circuit

14

Low voltage accessories

Undervoltage release (MN)

An undervoltage release operates to open the circuit breaker when the voltage at the

terminals of the release decreases below 35% of its rated voltage, even in case of

slow and gradual decrease.

It doesnt operate the circuit breaker when the voltage at its terminals exceeds 70%

of its rated apply voltage.

The closing of the circuit breaker is possible when the values of the voltage at the

terminals of the release are equal to, or higher than 85% of its rated voltage.

Its closing is impossible when the voltage of the terminals is lower than 35%

of its rated supply voltage.

Time delay unit for MN

To eliminate spurious tripping of the circuit breaker during momentary voltage drops

MN's action is time-delayed. This function is achieved by adding an external time

delay to the MN release circuit (delay is ajustable).

This unit is placed outside of the circuit breaker and can be inhibited by an

emergency stop button to obtain instant opening.

Low energy release (MITOP)

This specific coil actuates the opening mechanism of the poles to trip the circuit

breaker. It is characterized by a low energy consumption.

Any tripping caused by the Mitop release is indicated momentarily by an SDE type

changeover contact. This Release Unit also includes a coil enabling the remote

rearming of the SDE contact.

Comment:

To use the MITOP release requires the adjustment of a time delay to be set by the protection relay

in order to ensure a circuit breaker operating time of 45-50 ms.

2

0

0

2

1

3

MN undervoltage release

2

0

0

2

1

4

Time delay unit for MN

2

0

0

2

6

8

MITOP low energy release

Characteristics

supply V AC 50/60 Hz 24 48 100-130 200-250

V DC 24-30 48-60 100-130 200-250

threshold opening 0.35 to 0.7 Un

closing 0.85 Un

consumption (VA or W) pick-up: 200 hold: 4.5

Characteristics

supply V AC 50/60 Hz 48-60 100-130 200-250

V DC 48-60 100-130 200-250

threshold opening 0.35 to 0.7 Un

closing 0.85 Un

consumption (VA or W) pick-up: 200 hold: 4.5

time delay 0.5 s - 0.9 s - 1.5 s - 3 s

Characteristics

supply direct current

threshold 0.6 A < I < 3 A

response time of the circuit breaker at Un 11 ms

15

Low voltage accessories

Function description

remote control

Function

b The remote control enables remote opening and closing of the circuit breaker.

b In the case of continuous opening and closing orders, the remote control unit

blocks the device in the open position as standard: the anti-pumping function.

This function gives absolute priority to the opening order, but and also it stops closing

order and thus avoids the device being locked in an indefinite opening-closing cycle:

v the opening and closing coils may be fed power on a constant basis to achieve an

electrical type locking: there is no self-breaking contact inside the device,

v the interlocking between the opening and closing orders, whatever their causes,

is achieved as standard within the device's control mechanism.

Remote control circuit diagram

Composition

b The remote control comprises:

v electrical motor and associated mechanism (MCH) equipped

with a spring-loaded limit switch (CH),

v two shunt trip releases:

- a closing release (XF),

- an opening release (MX).

b It can be added with:

v a ready to close contact PF,

v a second block of 4 contacts for indication of the O/C position of the device.

2

0

0

2

0

3

Circuit breaker equipped with remote control

2

0

0

4

8

5

E

N

closed open

OF

ready

to close

PF

closing

order

XF

opening

order

MX

charged

springs

CH

MCH

OF OF

16

Low voltage accessories

Function description

remote control

Electric motor (MCH)

The MCH unit arms and rearms the energy storage springs as soon as the circuit

breaker is closed. This enables instant reclosing of the device after opening.

The arming lever is only used as back up control in the absence of an auxiliary

voltage.

The MCH is equipped as standard with a CH limit switch. This contact indicates the

armed position of the mechanism (spring charged).

Shunt release (XF and MX)

Closing release (XF)

This enables the remote closing of the circuit breaker when the control mechanism

is charged.

Opening release (MX)

This enables the opening of the circuit breaker when energised.

2

0

0

2

1

5

2

0

0

2

1

3

Shunt release XF/MX

Characteristics

supply V AC 50/60 Hz 48-60 100-130 200-240

V DC 24-30 48-60 100-125 200-250

threshold 0.85 to 1.1 Un

consumption (VA or W) 180

motor overcurrent 2 to 3 In during 0.1 s

charging time 6 s. max.

switching rate 3 cycles per minute max.

CH contact 10 A at 240 V

Characteristics XF/MX

supply V AC 50/60 Hz 24 48 100-130 200-250

V DC 24-30 48-60 100-130 200-250

threshold 0.85 to 1.1 Un (DC/AC)

consumption (VA or W) pick-up: 200 pick-up: 200

hold: 4.5 hold: 4.5

17

Low voltage accessories

Function description

indication and locking / interlocking

Push button disabling

This transparent screen prevents access to the circuit breaker opening and

closing push buttons.

The device enables independent locking of the opening or closing button, it is often

associated with an electrical motor (MCH).

b Locking is achieved either by:

v 2 screws,

v 3 padlocks, not supplied,

v sealing.

Locking of the circuit breaker in the open

position

b The circuit breaker is locked in the open position by blocking the opening push

button in the pushed-in position:

v using padlocks: 1 to 3 padlocks not supplied,

v using key locks: 1 or 2 different key locks supplied.

b The key locks are of Profalux or Ronis type captive keys, that become free

once locked, and are offered according to the following options, either:

v 1 single key lock,

v 1 single key lock mounted on the device + 1 identical one delivered, separately for

interlocking with another device,

v 2 different key locks for double locking.

b Profalux and Ronis key locks are inter-compatible.

Cubicle door interlocking mechanism

b The device allows C.B. operation only when the door is closed for full version

with truck.

2

0

0

2

1

9

Push button disabling

2

0

0

2

0

0

Padlocking the circuit breaker in open position

2

0

0

2

0

1

Key locking the circuit breaker in open position

D

E

3

0

1

3

6

Cubicle door interlocking mechanism

R O N I S

D

E

3

0

1

3

5

2

0

0

2

7

0

2

0

0

2

6

9

Padlocking Sealing

Full version

18

Dimensions

Phase distance between poles 145 mm

circuit breakers

12P1-630

12P1-1250

D

E

3

0

1

3

7

D

E

3

0

1

4

0

Phase distance between poles 185 mm

circuit breakers

17P2-630

17P2-1250

D

E

3

0

1

3

8

D

E

3

0

1

4

0

Phase distance between poles 240 mm

circuit breakers

12P1-2500

12P3-630

12P3-1250

12P3-2500

17P2-2500

D

E

3

0

1

3

9

D

E

3

0

1

4

1

Fixed version

Dimensions

19

Phase distance between poles 145 mm

circuit breakers

12P1-630

12P1-1250

2

0

0

1

0

8

2

0

0

1

0

9

Phase distance between poles 185 mm

circuit breakers

17P2-630

17P2-1250

2

0

0

1

1

3

2

0

0

1

0

9

Phase distance between poles 240 mm

circuit breakers

12P1-2500

12P3-630

12P3-1250

12P3-2500

17P2-2500

2

0

0

1

1

6

2

0

0

1

0

9

145

470

535

145 90

185

550

535

185 90

240

660

535

240 90

20

Full version

Performance tables

24KV

Common characteristics according to IEC 62271-100

rated frequency fr (Hz) 50 & 60

short-time withstand current Ik for tk = 3 s (kA) rms Ik = Isc

rated peak withstand current Ip peak (kA) Ip = 2.5 & 2.6 Ik

rated short circuit making current peak (kA) = 2.5 & 2.6 Isc

operating sequence O - 3 mn - CO - 3 mn - CO

O - 0.3 s - CO - 3 mn - CO

O - 0.3 s - CO - 15 s - CO

operating times opening ms < 50

breaking ms < 65

closing ms < 70

mechanical endurance class M2

number of operations 10000 (30000 upon request)

electrical endurance class E2

number of operations 12.5&16 kA 100

25 kA

31.5 kA

capacitive current breaking class C1-C2 (for some applications)

Electrical characteristics according to IEC 62271-100

circuit breaker

rated voltage Ur (kV) rms 24 24 24 24 24 24 24 24 24 24 24 24

rated insulation voltage Ud (kV) rms 50 50 50 50 50 50 50 50 50 50 50 50

rated insulation voltage Up (kV) peak 125 125 125 125 125 125 125 125 125 125 125 125

rated short-circuit breaking current Isc (kA) rms 12.5 12.5 12.5 16 16 16 25 25 25 31.5 31.5 31.5

rated normal current (-25 +40C) Ir (A) rms 630 1250 2500 630 1250 2500 630 1250 2500 630 1250 2500

climatic version -25 +40C b b b b b b b b b b b b

Installation and connections

phase distance:

between poles (mm) 230 230 250 230 230 250 230 230 250 250 250 250

dimensions C.B. and cradle (mm) width (W) 786 786 886 786 786 886 786 786 886 886 886 886

depth (D) 1309 1309 1309 1309 1309 1309 1309 1309 1309 1309 1309 1309

height (H) 1188 1188 1188 1188 1188 1188 1188 1188 1188 1188 1188 1188

mass C.B. and cradle (kg) 270 270 354 270 270 354 270 270 354 354 354 354

100

100

Humidity:

average relative humidity

24-hours period < 95%

1 month < 90%

Withdrawable type

21

Fixed version

24 24 24 24 24 24 24 24 24 24 24 24

50 50 50 50 50 50 50 50 50 50 50 50

125 125 125 125 125 125 125 125 125 125 125 125

12.5 12.5 12.5 16 16 16 25 25 25 31.5 31.5 31.5

630 1250 2500 630 1250 2500 630 1250 2500 630 1250 2500

b b b b b b b b b b b b

230/250 230/250 250 230/250 230/250 250 230/250 230/250 250 250 250 250

655/734 655/734 745 655/734 655/734 745 655/734 655/734 745 745 745 745

712.5 712.5 712.5 712.5 712.5 712.5 712.5 712.5 712.5 712.5 712.5 712.5

593 593 593 593 593 593 593 593 593 593 593 593

97 97 135 97 97 135 97 97 135 135 135 135

Fixed Withdrawable

Fixed type

22

Function description

MV connections

Connection

b Customer connection is easily achieved outside the cradle:

v on vertical copper terminals integrated in the bushing.

Type tested connection configuration are shown in the Installation Guide.

Field deflectors

The field deflectors are to be fitted at the end of the bushings. They are necessary in

case of installation of the cradle within a compartmented cubicle.

For other applications, tested configurations are described in the Installation Guide.

D

E

6

0

1

5

8

D

E

6

0

1

3

4

Evolis 24 kV withdrawable

23

Composition

b

The "racking in" function is provided by:

v

the racking truck supporting the circuit-breaker (mobile part),

v

v

the cradle including the bushings (xed part),

the LV plug.

Operating procedure

b

The circuit-breaker moves through 3 stable positions:

v

service position:

circuit-breaker racked in and locked in place; low voltage plug connected,

v

test position:

circuit-breaker racked out and locked in place; low voltage plug connected,

v

extracted position:

the circuit-breaker can be unlocked and extracted from the cubicle,

with no interlocking.

Safety functions

A propulsive system combined with a screw-shaft makes racking in and racking out

easier.

b

Interlocking

In accordance with IEC standards 62271-100 and 62271-200, the following

interlockings are provided:

v

v

racking in or out are impossible unless the circuit-breaker is in the open position,

racking in the circuit-breaker is impossible unless the LV plug is connected,

v

disconnecting the LV plug is impossible unless the circuit-breaker is racked out.

In addition the truck is equipped with a device that allows circuit-breaker racking in

to be interlocked with the cubicle door (which must be specially designed):

v

v

It is only possible to rack in the circuit-breaker if the door is closed,

the door can only be opened with the circuit-breaker racked out.

b

Earthing

is achieved throughout the whole racking in operation by the mean of the

wheels of the racking truck. Additional earthing device can be supplied as an option.

b

Protective shutters

on the cradle prevent access to the racking ngers when the

device is extracted (protection index: IP2X).

b

For maintenance or test purposes, it is possible to:

v

padlock the shutters in the closed position,

v

unlock the shutters mechanism to access the xed contacts, and insert a screen

to prevent the lived set of xed contacts being exposed.

b

A fool-proof

protection

enables cradle and circuit-breaker to be matched up.

This system is mounted on the circuit-breaker. Part of it has to be assembled by

the panel builder on the cradle side.

b

Earthing switch

It can be xed on the cradle, allowing proper interlocking between the circuit-breaker

and the earthing switch, (see detailed description in "Earthing switch and cubicle

components" catalogue).

b Anti-drop function

This function ensures the safety of the operator during the extraction of the

circuit-breaker.

Accessories

b 4 racked in/racked out position contacts.

b Additional earthing device (copper brush).

b Core sensors LPCT type, directly tted on the bushings of the cradle.

b Auto-discharge function:

the spring of the circuit-breaker operating mechanism is automatically discharged

when the circuit-breaker is extracted from the cubicle. This feature avoids

unexpected closing of the circuit-breaker.

2

0

0

1

2

8

Service position

2

0

0

1

4

9

Test position

2

0

0

0

1

4

8

Extracted position

D

E

6

0

1

1

4

D

E

6

0

1

3

8

Auto-discharge function

D

E

5

5

1

3

7

M

T

6

6

0

4

9

Racked in/out position Earthing sliding device

Evolis 24 kV withdrawable

Function description

racking in

24

Function description

LV connections

Main functions

b With the basic withdrawable circuit-breaker, LV wiring is produced via an

LV plug.

b The LV plug includes:

v the xed part (male) tted on the circuit-breaker and fully wired to the terminal

block of the operating mechanism,

v the mobile part (female) compatible with the male part.

Two versions of LV plug are available

b A 21-pin LV plug, allowing to connection of

v

v

a shunt opening release YO1,

a remote control mechanism (electrical motor, shunt closing release YF,

antipumping relay),

v

v

the Pilot monitoring device,

maximum number of auxiliary contacts: 3 NC - 3 NO - 1 CHG

(see details in chapter "Open/closed auxiliary contacts").

b A 42-pin LV plug, allowing to connect

v

v

an opening release (shunt opening release or under-voltage release),

a second opening release (shunt opening release YO2, under-voltage release YN

or low energy release MITOP),

v a remote control mechanism (electrical motor, shunt closing release,

antipumping relay)

v

v

the Pilot monitoring device,

maximum number of auxiliary contacts: 5 NC - 6 NO - 1 CHG

(see details in chapter "Open/closed auxiliary contacts").

b Interlocking function

In order to comply with IEC standard 62271-200, an interlocking feature prevents:

v racking in when the LV plug is not connected.

v disconnection of the LV plug when the circuit-breaker is in racking in position.

LV wiring kit

b A kit including 21 wires (2 meters long) tted with pin suitable for the plug can be

supplied for connection to the LV compartment of the cubicle.

This arrangement provides an auxiliary supply connection with a high level of

electrical safety.

D

E

6

0

1

5

5

Evolis 24 kV withdrawable

25

Function description

opening circuit

Composition

b The opening circuit can be achieved by the followings units:

v

v

shunt opening release (YO1),

second shunt opening release (YO2),

v

v

under voltage release (YN),

low energy release (MITOP).

Please check in the combination table the right associations of different releases.

Note: this table is present in order form at the end of this catalogue.

Shunt opening release (YO1 et YO2)

b This causes the instant opening of the circuit-breaker when energised.

Under voltage release (YN)

b An under voltage release operates to open the circuit-breaker when the voltage at

the terminals of the release falls below 35% of its rated voltage, even if the fall is slow

and gradual.

On the other hand, it does not operate the circuit-breaker when the voltage at its

terminals exceeds 70% of its rated supply voltage.

Circuit-breaker closing is possible when the values of the voltage at the terminals of

the release are greater than or equal to 85% of its rated voltage.

Closing is impossible when the voltage at the terminals is lower than 35% of its

rated supply voltage.

Low energy release (MITOP)

b This specic release comprises a low energy consumption unit and is used

specically with self-powered relay SEPAM 100LA ("REFLEX MODULE"), or VIP

relay.

Any tripping caused by the Mitop release is indicated momentarily by an SDE type

changeover contact.

D

E

6

0

1

6

1

Operating mechanism

D

E

6

0

0

9

4

(1) Shunt opening release

D

E

6

0

0

8

9

(2) Under voltage release

D

E

6

0

0

9

1

(3) Low energy release

(1) or (3) (2)

Characteristics

Supply see order form

Threshold VAC 0.7 to 1.1 Un

VDC 0.85 to 1.1 Un

Consumption VAC 160 VA

VDC 50 W

Characteristics

Supply see order form

Threshold opening 0.35 to 0.7 Un

closing 0.85 Un

Consumption pick-up VAC 400 VA

VDC 100 W

hold VAC 100 VA

VDC 10 W

Characteristics

Supply direct current

Threshold 0.6 A < I < 3 A

Low voltage accessories

Low voltage accessories

26

Function description

remote control

Function

b The remote control enables remote opening and closing of the circuit-breaker.

Composition

b The remote control comprises:

v

v

electrical motor and gear reducer,

a shunt closing release (YF),

v

v

an antipumping relay,

an operation counter.

Electric motor and gear reducer

b The electrical motor arms and rearms the energy storage springs as soon as the

circuit-breaker is closed. This enables instant reclosing of the device after opening.

The arming lever is only used as back up control in the absence of an auxiliary

voltage.

M3 contact indicates end of charging.

Shunt closing release (YF)

b This causes the remote closing of the circuit-breaker when the operating

mechanism is armed.

Antipumping relay

b The antipumping relay avoids unwanted closing and tripping within a short interval.

This function gives absolute priority to the opening order and blocks closing.

This prevents the device from being locked in an indenite opening-closing cycle.

D

E

6

0

1

6

0

Operating mechanism

D

E

6

0

0

9

3

(4) Electric motor and gear reducer

D

E

6

0

1

5

1

(5) Shunt closing release

D

E

6

0

0

9

5

(6) Antipumping relay

(8)

(7)

(9)

(4)

(5) (6)

Characteristics

Supply V AC 50/60 see order form

V DC see order form

Consumption V AC 380 VA

V DC 380 W

Characteristics YF

Supply VAC 50/60 Hz see order form

VDC see order form

Threshold 0.85 to 1.1 Un

Consumption VAC 160 VA

VDC 50 W

Operation counter

b The operation counter is visible from the front face.

It displays the number of operating cycles that the device has performed

D

E

6

0

0

8

7

(7) Operation counter

27

Function description

indication and locking / interlocking

Open/closed auxiliary contacts

b The number of available contacts depends on the tted options on the operating

mechanism.

v In its basic conguration, the operating mechanism of the circuit-breaker

comprises a total of:

v

v

5 normally closed contacts (NC),

6 normally open contacts (NO),

v 1 changeover contact (CHG).

b Use of auxiliary contacts is given in the following table:

To find out the final number of contacts available, the above quantity

must be deducted from the total quantity (5 NC + 6 NO + 1 CHG) included in the

circuit-breaker.

(Example: a circuit-breaker equipped with a remote control and a shunt opening release

has 4 NC + 4 NO + 1 CHG available contacts. With an under-voltage release instead of

a shunt release, this circuit-breaker has 4 NC + 5 NO + 1CHG available contacts).

b When the 21-pin LV plug is used, the maximum number of available contacts is:

v

v

3 NC,

3 NO,

v 1 changeover.

(Instead of 5NC-6NO-1CHG with the 42-pin LV plug).

Locking of the circuit-breaker

in the open position

b This key lock allows the locking of the circuit-breaker in the "open" position by

the means of a key.

b The circuit-breaker is locked in the "open" position by blocking the opening

pushbutton in the "pushed-in position".

b The key lock is of Profalux or Ronis captive key type.

D

E

6

0

1

5

2

(8) Auxiliary contacts

D

E

6

0

1

2

4

(9) Locking kit

Option NC contact NO contact

Remote control 1 1

Shunt opening release (each) 0 1

Undervoltage release 0 0

Low energy release MITOP 0 0

Trip circuit supervision 1 0

Contact characteristics

Rated current 10 A

Breaking capacity AC 220 V (cos

0.3) 1 A

DC 110/220 V (L/R 0.02 s) 0.3 A

Low voltage accessories

Auxiliary wiring diagram (principle)

M

YF +

anti-pumping

motor shunt closing

+ anti-pumping

system

remote control

monitoring

device pilot

shunt

opening

release

under-

voltage

release

low energy

release

(MITOP)

NO

contacts

changeover

contact

NC

contacts

CLOSE CB

OPEN CB

YO1

or

YO2

YM

MITOP

PILOT

28

Function description

Fitted on the circuit-breaker,

the Pilot monitors its operating

conditions.

The Pilot circuit-breaker monitoring device

has two specific features

Monitoring operating conditions

The device monitors external conditions and provides alarms if they are out of the

specified range.

Recording circuit-breaker operating data

Similarly to an aircraft black box the monitor device logs the circuit-breakers key data

over time, allowing a diagnosis on its mechanical conditions.

Pilot main characteristics

Detailed features

Monitoring operating conditions

b The module continuously monitors

v opening auxiliary voltage,

v circuit-breaker ambient temperature,

v

v

number of operations,

time between operations,

v

b

and sends alarms if the set points are exceeded.

Alarms are visible on the front of the device and can also be transferred to

the LV compartment, or supervision system.

b Operating conditions are recorded: minimum and maximum values of auxiliary

voltage and ambient temperature are time-tagged and stored every 24h.

Recording circuit-breaker data

b All circuit-breaker events are time-tagged and stored (opening, closing, motor

charging, energizing, voltage set point, temperature set point, number of operations,

time between operations).

b A circuit-breaker expert can analyse the stored data in order to check the correct

mechanical functioning of the circuit-breaker, 1000 events are stored in the

module.

Servicing note-pad

b The device incorporates this useful feature to record any information related to

servicing the circuit-breaker (250x250 - character note-pad).

D

E

6

0

0

5

3

D

E

6

0

0

5

8

D

E

6

0

0

5

5

YM

Energy

supply

Communication

YL

M

Characteristics

Supply V AC 50/60 Hz 100/250 -15% to +10%

V DC 24/250 -30% to +10%

Service temperature C -25C to +70C

Consumption VA or W > 3

Measurement inputs V AC 50/60 Hz 100/250 -15% to +10%

V DC 24/250 -30% to +10%

Events recording capacity 1000

Conditions record capability 1000

Maintenance notes record capacity 256 (x 256 characters)

Evolis Pilot monitoring

device

Pilot

ON OK

Reset alarm

N > 20000

Aux. voltage

Operating

C

55C

50C

40C

45C

I > 360j

b

29

Local or remote data collection

Local use

Alarms are displayed on the device itself.

A dry contact relay collates the faults and can be wired to the low voltage

compartment.

A laptop user-machine Interface can be used to set parameters and to display

and upload data.

Remote use

The monitoring device can be connected to a supervisor or concentrator

for connection to the Web via a local RS485 Modbus network.

The supervisor can display, process and acknowledge alarms.

Data is then either processed in the supervision system or in the remote

web-enabled system.

Easy to install module

The module is inserted in the special housing reserved for it on the front of the

circuit-breaker.

This module may be added at any time

during the circuit-breaker's service life

b The module may be factory-mounted within the circuit-breaker: connection and

parameter setting, are done by Schneider Electric.

b The module may be added after circuit-breaker commissioning: connection,

parameter setting and testing, are done by a specialized service provider (Schneider

Electric or other).

The customer is provided with the product manual and the CDrom containing the

computerized manual and UMI PC software.

Operation and service

The "Pilot" monitoring device can be used on two levels:

b Information on operating conditions.

b Diagnosis of mechanical circuit-breaker conditions: performed by a circuit-breaker

expert (from Schneider Electric), by analyzing the recorded data.

P

E

6

0

0

3

7

D

E

6

0

0

5

6

D

E

6

0

0

5

7

R

S

4

8

5

E

th

ernet network W

e

b

s

e

r

v

e

r

Pilot

ON OK

Reset alarm

N > 20000

Aux. voltage

Operating

C

55C

50C

40C

45C

I > 360j

Function description

Evolis Pilot monitoring

device

30

Dimensions

230 mm phase distance

D

E

6

0

0

6

3

D

E

6

0

0

6

5

250 mm phase distance

D

E

6

0

0

6

4

D

E

6

0

0

6

5

1400

1309

288

400

473.5

1400

1309

288

400

473.5

Full version

230 230 163

1188

786

250 250 193

1188

886

31

Dimensions

3 sizes of width

D

E

6

0

0

6

0

D

E

6

0

0

6

2

W

712.5

97.5 D D

Dimensions (mm)

Phase distance 230 250 250

D W D W D W

16 kA 630 A 655 734

1250 A 655 734

2000 A 745

2500 A 745

25 kA 630 A 655 734

1250 A 655 734

2000 A 745

2500 A 745

31.5 kA 630 A 745

1250 A 745

2000 A 745

2500 A 745

Fixed type

593

32

Function description

LPCT sensors

The LPCTs are the best way to increase

the effectiveness of the protection chain

and simplify the selection.

Function

b These Low Power Current Transducers (LPCT) provide accurate current

measurement to the protection function when an Evolis circuit-breaker is associated

with the Sepam relay range.

b They comply with IEC 60044-8 standard.

Composition

b Two types of LPCT are available:

v

v

LPCT for bushings,

LPCT for cubicles.

b The sensor is delivered with 5m of cable and connector that allows direct

connection to the Sepam unit.

Mechanical characteristics

(LPCT for bushings)

b Mounted directly on the Evolis withdrawable circuit-breaker cradle.

The sensors are simply located on the bushings and fixed using three screws.

Each sensor covers the full operating range of the corresponding circuit-breaker.

b Connection to the Sepam is achieved using an shielded cable which is attached to

each sensor.

Electrical characteristics

b In compliance with IEC 60044-8 standard, dening Low Power current Transducer

with voltage output.

b Usable for nominal currents of 25 A to 2500 A.

b Class 0.5 throughout the range.

b Current sensors deliver a voltage output at a ratio of 100 A/22.5 mV.

D

E

6

0

0

9

9

LPCT for bushings (TLP Type)

D

E

6

0

0

9

7

LPCT for cubicle (CLP Type)

Common features

Rated primary current 100 A

Rated secondary output (at 100A) 22.5 mV

Accuracy class for measuring 0.5

Accuracy class for protection 5P

Burden 2 2 k

Frequency 50 / 60 Hz

Specific features CLP2 CLP3 TLP160 TLP190

Assembly In the cubicle In the cubicle On the bushings On the bushings

D

E

6

0

0

9

7

D

E

6

0

0

9

8

D

E

6

0

0

9

9

D

E

6

0

1

0

0

Rated extended primary current 1250 A 2500 A 1250 A 2500 A

Accuracy limit factor 250 315 250 315

Rated short time thermal current 25 kA / 3s 31.5 kA / 3s 25 kA / 3s 31.5 kA / 3s

Highest voltage for equipment 24 kV 24 kV 0.72 kV 0.72 kV

Rated power frequency withstand volt. 50 kV 50 kV 3 kV 3 kV

Rated lighting inpulse withstand voltage 125 kV 125 kV

Option

As standards, specifications and designs change from time to time, please ask for confirmation of

the information given in this publication.

Publishing: Schneider Electric SA

Technical writing: P. Andrani

Design, production: HeadLines

Printing: Imprimerie du Pont de Claix

Schneider Electric Industries SAS

04-05

T

W

E

V

O

L

I

S

E

N

2

0

0

4

S

c

h

n

e

i

d

e

r

E

l

e

c

t

r

i

c

-

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

Postal address

MV department

F-38050 Grenoble cedex 9

Tel: +33 (0)4 76 57 60 60

http://www.schneider-electric.com

RSC Nanterre B 954 503 439

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1208 ManualDocument33 pages1208 Manualmg victorNo ratings yet

- Structural Design of Steel Latticed TowersDocument13 pagesStructural Design of Steel Latticed Towersskumaran1100% (11)

- Bulletin 857 Protection System For Feeder and Motor Protection, Series ADocument516 pagesBulletin 857 Protection System For Feeder and Motor Protection, Series ARazvan MaresNo ratings yet

- Product Data Sheet 3RH1440-1BM40: Contactor Relay, Latched, 4-Pole, 4 NO, SIZE S00, DC 220VDocument5 pagesProduct Data Sheet 3RH1440-1BM40: Contactor Relay, Latched, 4-Pole, 4 NO, SIZE S00, DC 220VRazvan MaresNo ratings yet

- Graphical Symbols For Electrical Circuit Diagrams 20003 HQ enDocument4 pagesGraphical Symbols For Electrical Circuit Diagrams 20003 HQ enMohammed Mushtaha100% (1)

- Day-Ahead Hourly Forecasting of Power Generation From Photovoltaic PlantsDocument14 pagesDay-Ahead Hourly Forecasting of Power Generation From Photovoltaic PlantsRazvan MaresNo ratings yet

- Best Overhead Line Software - Power Line PDFDocument1 pageBest Overhead Line Software - Power Line PDFRazvan MaresNo ratings yet

- AN100.EN002 The Circuit Supervision For VAMP40 VAMP130 VAMP135 VAMP140 and VAMP150Document144 pagesAN100.EN002 The Circuit Supervision For VAMP40 VAMP130 VAMP135 VAMP140 and VAMP150Razvan MaresNo ratings yet

- AN100.EN002 The Circuit Supervision For VAMP40 VAMP130 VAMP135 VAMP140 and VAMP150 PDFDocument2 pagesAN100.EN002 The Circuit Supervision For VAMP40 VAMP130 VAMP135 VAMP140 and VAMP150 PDFRazvan MaresNo ratings yet

- NT00381-02 - T300-OVR Installation Guide PDFDocument48 pagesNT00381-02 - T300-OVR Installation Guide PDFRazvan MaresNo ratings yet

- Tcs 7PA26 - 27 - 30 - Catalog - SIP-2008 - en PDFDocument7 pagesTcs 7PA26 - 27 - 30 - Catalog - SIP-2008 - en PDFBagus Permadi100% (1)

- CBCT PDFDocument1 pageCBCT PDFRazvan MaresNo ratings yet

- SG30KTL M Quick User ManualDocument34 pagesSG30KTL M Quick User ManualRazvan MaresNo ratings yet

- Catalogue - Control Relays and TimersDocument196 pagesCatalogue - Control Relays and TimersRazvan MaresNo ratings yet

- Batreii Cond ICARDocument1 pageBatreii Cond ICARRazvan MaresNo ratings yet

- Circuit Breaker LTB D 72.5 - 170 KV FSA Spring Operating MechanismsDocument8 pagesCircuit Breaker LTB D 72.5 - 170 KV FSA Spring Operating MechanismsRazvan Mares50% (2)

- MC MC: Multifunction Three Phase Overvoltage / Undervoltage RelayDocument4 pagesMC MC: Multifunction Three Phase Overvoltage / Undervoltage RelayRazvan Mares100% (1)

- Megger - The Complete Guide To Electrical Insulation TestingDocument24 pagesMegger - The Complete Guide To Electrical Insulation TestingHARISH ROHANNo ratings yet

- Electromagnetic Modeling of Anisotropic Ferrites-Application To Microstrip Y-Junction Circulator DesignDocument12 pagesElectromagnetic Modeling of Anisotropic Ferrites-Application To Microstrip Y-Junction Circulator Designmohamed_jemai1955No ratings yet

- How To Build A Tesla Coil PDFDocument14 pagesHow To Build A Tesla Coil PDFSanthosh KumarNo ratings yet

- Design of Rectenna For Energy Harvesting in ISM BandDocument4 pagesDesign of Rectenna For Energy Harvesting in ISM BandAbdullah AloglaNo ratings yet

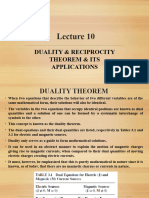

- 1 Duality & Reciprocity TheoremDocument15 pages1 Duality & Reciprocity TheoremChristy PollyNo ratings yet

- Curriculum Map SCIENCE 5 3rd QuarterDocument3 pagesCurriculum Map SCIENCE 5 3rd QuarterCrispin Daniel MuñozNo ratings yet

- Impedance Matching 1 Lecture For July 2, 2013Document91 pagesImpedance Matching 1 Lecture For July 2, 2013Alas Mallari DonatoNo ratings yet

- Topic 7 - TrigonometryDocument24 pagesTopic 7 - TrigonometryOtai EzraNo ratings yet

- 11th Physics Book Back Questions With Answers in EnglishDocument29 pages11th Physics Book Back Questions With Answers in EnglishsuryaNo ratings yet

- Fundamental ACDocument1 pageFundamental ACAaj AajNo ratings yet

- Click Here To Join To Download Our App Follow Us On Facebook Follow Us On InstagramDocument12 pagesClick Here To Join To Download Our App Follow Us On Facebook Follow Us On InstagramshilNo ratings yet

- 12 Physics Notes Ch02 Electrostatic Potential and CapacitanceDocument2 pages12 Physics Notes Ch02 Electrostatic Potential and CapacitanceTapankumar SanyalNo ratings yet

- LED System Light - SZ 2500.110: Date: Apr 20, 2021Document4 pagesLED System Light - SZ 2500.110: Date: Apr 20, 2021samim_khNo ratings yet

- Unit I Acoustics Planning For Noise, STC, NRCDocument9 pagesUnit I Acoustics Planning For Noise, STC, NRCKavya DesaiNo ratings yet

- Marco Trak Lighting Systems Catalog 1981Document56 pagesMarco Trak Lighting Systems Catalog 1981Alan MastersNo ratings yet

- Civil Services Examination (Mains) 2021 Physics Paper - I: Mechanics Tutorial Sheet: 1 Conservation LawsDocument39 pagesCivil Services Examination (Mains) 2021 Physics Paper - I: Mechanics Tutorial Sheet: 1 Conservation LawsPadhai wadhaiNo ratings yet

- Chemical Bonding ProjectDocument3 pagesChemical Bonding ProjectOtto Bauer0% (1)

- Introduction To Antennas: Dr. Bablu K. GhoshDocument76 pagesIntroduction To Antennas: Dr. Bablu K. GhoshNurulAnisAhmadNo ratings yet

- Nuclear Reaction and RadioactivityDocument12 pagesNuclear Reaction and RadioactivityHermae BuctonNo ratings yet

- Agilent Eesof Eda: Matching Network Yin-Yang - Part 1Document10 pagesAgilent Eesof Eda: Matching Network Yin-Yang - Part 1Steven PeñaNo ratings yet

- Nuclear Reactions (27th March 2023)Document15 pagesNuclear Reactions (27th March 2023)Giovanni SlackNo ratings yet

- WITCO - UT PresentationDocument51 pagesWITCO - UT PresentationJohn OLiverNo ratings yet

- Aes - Mcqs - Unit - 1 To 5Document9 pagesAes - Mcqs - Unit - 1 To 5KumarJinneNo ratings yet

- Schneider Electric - Altivar-21-Variable-Speed-Drives-Legacy-Product - ATV21HD55N4Document4 pagesSchneider Electric - Altivar-21-Variable-Speed-Drives-Legacy-Product - ATV21HD55N4sofianigniteNo ratings yet

- Careful For VFD Fed Small MotorsDocument2 pagesCareful For VFD Fed Small MotorsRabia akramNo ratings yet

- UCLA Mathematics of ComputationDocument2 pagesUCLA Mathematics of ComputationkensusantoNo ratings yet

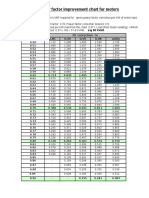

- Power Factor Improvement Chart For Motors: ExampleDocument1 pagePower Factor Improvement Chart For Motors: Examplealageshvijay100% (1)

- TN 01 Lot I BOQDocument17 pagesTN 01 Lot I BOQአረጋዊ ሐይለማርያምNo ratings yet

- Filtration in X-Ray RadiographyDocument2 pagesFiltration in X-Ray RadiographyTonmoy Paul100% (1)