Professional Documents

Culture Documents

P-12 IK Strippers in Amine Sweetening Systems

P-12 IK Strippers in Amine Sweetening Systems

Uploaded by

Na-na OktaviaCopyright:

Available Formats

You might also like

- Lab2 MEE30004 - Lab2 - 2021 - Sem2 - Raw DataDocument6 pagesLab2 MEE30004 - Lab2 - 2021 - Sem2 - Raw DataAbidul IslamNo ratings yet

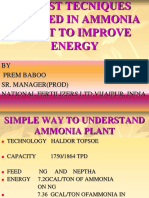

- BY Prem Baboo Sr. Manager (Prod) National Fertilizers LTD, Vijaipur, IndiaDocument74 pagesBY Prem Baboo Sr. Manager (Prod) National Fertilizers LTD, Vijaipur, IndiaAlbertoNo ratings yet

- Amine Regenerator ControlDocument14 pagesAmine Regenerator ControlGloria Margarita López100% (1)

- System Dynamics, Third Edition: Using Simscape ™ For Modeling Hydraulic Systems: Dynamics of A Hydraulic Piston and LoadDocument40 pagesSystem Dynamics, Third Edition: Using Simscape ™ For Modeling Hydraulic Systems: Dynamics of A Hydraulic Piston and LoadredwaneNo ratings yet

- 5471Document3 pages5471Mihai-Eugen Popa100% (2)

- Thermal Processing of Food & Aseptic ConditionsDocument20 pagesThermal Processing of Food & Aseptic Conditionstenguria samriddhNo ratings yet

- Session VI - Petrochemical Processing: A. PropyleneDocument5 pagesSession VI - Petrochemical Processing: A. PropyleneMallela Sampath KumarNo ratings yet

- Rac ExpDocument44 pagesRac ExpAkash Kumar DevNo ratings yet

- Tech Paper - Reheat Steam Temperature Control Concept in Once-Through Boilers - A ReviewDocument5 pagesTech Paper - Reheat Steam Temperature Control Concept in Once-Through Boilers - A ReviewQen Zyg EizernNo ratings yet

- Rankine CycleDocument6 pagesRankine CyclenabeelNo ratings yet

- Knowledge Troubleshooting AC SystemDocument13 pagesKnowledge Troubleshooting AC SystemRupak KumarNo ratings yet

- TE - 2 Unit - 1 NotesDocument37 pagesTE - 2 Unit - 1 NotesKrishna VamsiNo ratings yet

- Basic RefrigerationDocument9 pagesBasic RefrigerationDarren Jeff Manuel MicumaoNo ratings yet

- Steam Consumption at Sulphitation / Raw Sugar Factories (Boiling House - Recent Trends)Document6 pagesSteam Consumption at Sulphitation / Raw Sugar Factories (Boiling House - Recent Trends)Yadav ShwetaNo ratings yet

- Unit Lightup Synchronisation & ShutdownDocument42 pagesUnit Lightup Synchronisation & ShutdownAshvani ShuklaNo ratings yet

- Optimize Sour Water Stripper Feed Preheating For Low Capital PDFDocument6 pagesOptimize Sour Water Stripper Feed Preheating For Low Capital PDFDaniel Gonzalez RodriguezNo ratings yet

- Turbine Rolling and SynchronizationDocument54 pagesTurbine Rolling and Synchronizationsanjeev kushwaha67% (3)

- Flash Steam Recovery Calculation What Is Flash Steam?: Blow Down From BoilersDocument3 pagesFlash Steam Recovery Calculation What Is Flash Steam?: Blow Down From BoilersBeicha100% (1)

- Interview Questions For Chemical EngineeringDocument6 pagesInterview Questions For Chemical EngineeringNikunj PatelNo ratings yet

- 11 Refrigeration CyclesDocument18 pages11 Refrigeration CyclesHussamNo ratings yet

- Rules of Thumb For TroubleshootingDocument2 pagesRules of Thumb For TroubleshootingkktayNo ratings yet

- Chapter 17 Absorption Refrigeration ExercisesDocument2 pagesChapter 17 Absorption Refrigeration ExercisesAndrew PantaleonNo ratings yet

- Process Description of Ammonia PlantDocument12 pagesProcess Description of Ammonia PlantSridharNo ratings yet

- Improvement To RankineDocument10 pagesImprovement To RankineRitika SinghNo ratings yet

- The Importance of A Clean CondenserDocument5 pagesThe Importance of A Clean CondenserD HarNo ratings yet

- Good Operating Practices For Amine Treating SystemsDocument30 pagesGood Operating Practices For Amine Treating Systemsblah_0079681No ratings yet

- Improving Performance of Rankine Cycle: Thermodynamics - IIDocument9 pagesImproving Performance of Rankine Cycle: Thermodynamics - IIsamhameed2No ratings yet

- Power Plant Engineering Week 2-3Document39 pagesPower Plant Engineering Week 2-3Shoaib IlyasNo ratings yet

- Falling Film Evaporators in The Food IndustryDocument4 pagesFalling Film Evaporators in The Food IndustryAgung SiswahyuNo ratings yet

- REFRIGERATIONDocument24 pagesREFRIGERATIONDark ShadyNo ratings yet

- Refrigeration 1Document13 pagesRefrigeration 1Vishwanathan RishanthNo ratings yet

- Improvement To Rankine CycleDocument11 pagesImprovement To Rankine Cyclegjanklesaria100% (2)

- Pipe Elements 1Document310 pagesPipe Elements 1Ryan Llona FernandezNo ratings yet

- Troubleshooting of Amine RegnDocument8 pagesTroubleshooting of Amine RegnSekarNTutyNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- Performance of The Vapour Compression Cycle As A Refrigerator and As A Heat PumpDocument7 pagesPerformance of The Vapour Compression Cycle As A Refrigerator and As A Heat Pumptatoo1No ratings yet

- Vapour and Combined Power CyclesDocument37 pagesVapour and Combined Power CyclesTarvesh KumarNo ratings yet

- SPE 71471 Large Scale Field Gathering of Oil-Water-Gas at Temperature Below The Pour Point of Crude Oil SuccessfulDocument12 pagesSPE 71471 Large Scale Field Gathering of Oil-Water-Gas at Temperature Below The Pour Point of Crude Oil SuccessfuldanielmcaeNo ratings yet

- Geothermal Power Plant Cycles and Main ComponentsDocument24 pagesGeothermal Power Plant Cycles and Main ComponentsÅwink BeêNo ratings yet

- 5 200 PDFDocument12 pages5 200 PDFDee RajaNo ratings yet

- Low-Temperature ProcessingDocument5 pagesLow-Temperature ProcessingAlberto Fonseca UribeNo ratings yet

- Mud TestingDocument35 pagesMud TestingHarits Pamitran100% (1)

- Thumb RuleDocument4 pagesThumb RulenishadNo ratings yet

- Plate Freezer Performance.Document4 pagesPlate Freezer Performance.Behnam AshouriNo ratings yet

- The Pressure - Enthalpy ChartDocument12 pagesThe Pressure - Enthalpy ChartJohnMerrNo ratings yet

- Principles of Mash Conditioning 1706535501Document6 pagesPrinciples of Mash Conditioning 1706535501surya PrakashNo ratings yet

- The Contactor: Amine Regenerator Feed Temperature: How Hot Is Hot Enough?Document2 pagesThe Contactor: Amine Regenerator Feed Temperature: How Hot Is Hot Enough?mohamed senoussiNo ratings yet

- Black Liquor EvaporationDocument3 pagesBlack Liquor EvaporationAktharNo ratings yet

- STC GS 2 Air ConditioningDocument788 pagesSTC GS 2 Air ConditioningSayeed HvacNo ratings yet

- Warm Light Up (Mahendra Singh)Document35 pagesWarm Light Up (Mahendra Singh)vinamrataNo ratings yet

- High Condensing TemperatureDocument3 pagesHigh Condensing TemperatureluffydsiniNo ratings yet

- Introduction To RefrigerationDocument25 pagesIntroduction To RefrigerationFuture HazeNo ratings yet

- Solving Hydraulic System Overheating ProblemsDocument9 pagesSolving Hydraulic System Overheating Problemsmahadev100% (1)

- Lecture 08 Vapor and Combined Power CyclesDocument19 pagesLecture 08 Vapor and Combined Power CyclesDawood BajwaNo ratings yet

- Boiler Efficiency CalculationDocument17 pagesBoiler Efficiency CalculationSolai100% (4)

- Heat Recovery Presentation Rev 130213Document32 pagesHeat Recovery Presentation Rev 130213Budhi SaputraNo ratings yet

- 1 Falling Film Evaporators in The Food Industry DesignDocument4 pages1 Falling Film Evaporators in The Food Industry DesignIvan Ruben Capuñay IzquierdoNo ratings yet

- Introduction To Vapour Compression RefrigerationDocument9 pagesIntroduction To Vapour Compression RefrigerationmdmarufurNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Process Engineering: Facts, Fiction and FablesFrom EverandProcess Engineering: Facts, Fiction and FablesRating: 3 out of 5 stars3/5 (2)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- 7.flash DistilerDocument35 pages7.flash DistilerNa-na OktaviaNo ratings yet

- Academic Guidebook FT UI English VersionDocument546 pagesAcademic Guidebook FT UI English VersionpanduhusnantoNo ratings yet

- Academic Guidebook FT UI English VersionDocument546 pagesAcademic Guidebook FT UI English VersionpanduhusnantoNo ratings yet

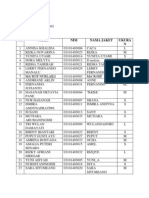

- NO Nama NIM Nama Jaket Ukura NDocument3 pagesNO Nama NIM Nama Jaket Ukura NNa-na OktaviaNo ratings yet

- Accumulator (Pilot) - Test and Charge - 084543Document4 pagesAccumulator (Pilot) - Test and Charge - 084543Juan LopezNo ratings yet

- Chapter 9 - Tennessee Eastman Plant-Wide Industrial Process Challenge ProblemDocument31 pagesChapter 9 - Tennessee Eastman Plant-Wide Industrial Process Challenge Problemkim haksongNo ratings yet

- Thermodynamics Lab 1 UpdatedDocument19 pagesThermodynamics Lab 1 UpdatedndumisoNo ratings yet

- A Tutorial On Initialising An Eclipse Reservoir ModelDocument19 pagesA Tutorial On Initialising An Eclipse Reservoir ModelDhiaa LaMiNo ratings yet

- Tubing Performance VLPDocument4 pagesTubing Performance VLPDhiaa LaMiNo ratings yet

- Lesson 61-Derivation of Bernoullis Equation PDFDocument6 pagesLesson 61-Derivation of Bernoullis Equation PDFSaravanan MathiNo ratings yet

- Installation, Operation and Maintenance Instructions: Penberthy Model Tme MixerDocument4 pagesInstallation, Operation and Maintenance Instructions: Penberthy Model Tme MixerGuillermo MartinezNo ratings yet

- Manometer NotesDocument5 pagesManometer NotesRaju100% (1)

- Technical - 2-01 SO Cirugía General Op. A - DM2-0404Document5 pagesTechnical - 2-01 SO Cirugía General Op. A - DM2-0404ALEX MIRANDANo ratings yet

- Unique Mixproof ValveDocument8 pagesUnique Mixproof ValveyapwaieeNo ratings yet

- System Description Fuel Gas Draining PDFDocument4 pagesSystem Description Fuel Gas Draining PDFsivamNo ratings yet

- PARAMETRIC STUDY ON EFFICIENCY OF ARCHIMEDES SCREW TURBINE DESIGN - UpdatedDocument4 pagesPARAMETRIC STUDY ON EFFICIENCY OF ARCHIMEDES SCREW TURBINE DESIGN - UpdatedRoberto Zambrano SepulvedaNo ratings yet

- Ear PrintDocument33 pagesEar PrintSeema Kotalwar100% (11)

- Gas Properties Laws Student DirectionsDocument3 pagesGas Properties Laws Student DirectionsKali stringsNo ratings yet

- PIL 140 Dry Gas Face Seals For Solar Compressors Rev 13aDocument22 pagesPIL 140 Dry Gas Face Seals For Solar Compressors Rev 13aYusri FakhrizalNo ratings yet

- Approval Standard For Explosion Venting SystemsDocument15 pagesApproval Standard For Explosion Venting Systemsrafael1978No ratings yet

- GMV5 Service Manual 2014Document120 pagesGMV5 Service Manual 2014Артур БобкинNo ratings yet

- Pore Pressure Prediction Using Seismic Velocity Modeling: Case Study, Sefid Zakhor Gas Field in Southern IranDocument12 pagesPore Pressure Prediction Using Seismic Velocity Modeling: Case Study, Sefid Zakhor Gas Field in Southern IranAhmedNo ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- 4c Radial Flow Semi Steady StateDocument41 pages4c Radial Flow Semi Steady StateDheeraj KumarNo ratings yet

- Laboratory Workshop in General Physics 2020, AllDocument138 pagesLaboratory Workshop in General Physics 2020, AllsalomeNo ratings yet

- Hydraulics TerminologiesDocument3 pagesHydraulics TerminologiesKrisleen Elyzel GullasNo ratings yet

- John Andre Cagampang - Gphy1 - q2 - Module7 - wk7 AnswersDocument18 pagesJohn Andre Cagampang - Gphy1 - q2 - Module7 - wk7 AnswersAndrejohn CagampangNo ratings yet

- 5TR CondenserDocument1 page5TR CondenserbevarsiNo ratings yet

- AGR 102 TheoryDocument140 pagesAGR 102 TheoryKuttyNo ratings yet

- Grade 10first TQDocument3 pagesGrade 10first TQJerbs PacundoNo ratings yet

- Note06. HGL & EGLDocument8 pagesNote06. HGL & EGLMohd Azhari Mohd RodziNo ratings yet

P-12 IK Strippers in Amine Sweetening Systems

P-12 IK Strippers in Amine Sweetening Systems

Uploaded by

Na-na OktaviaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P-12 IK Strippers in Amine Sweetening Systems

P-12 IK Strippers in Amine Sweetening Systems

Uploaded by

Na-na OktaviaCopyright:

Available Formats

T

H

E

F

U

N

C

T

I

O

N

O

F

T

H

E

S

T

R

I

P

P

E

R

O

R

S

T

I

L

L

I

S

T

O

R

E

M

O

V

E

T

H

E

H

2

S

A

N

D

/

O

R

C

O

2

F

R

O

M

T

H

E

A

M

I

N

E

S

O

L

U

T

I

O

N

.

A

M

I

N

E

S

U

S

E

D

I

N

S

W

E

E

T

E

N

I

N

G

P

L

A

N

T

C

O

N

C

E

N

T

R

A

T

I

O

N

O

F

T

Y

P

E

O

F

A

M

I

N

E

A

B

B

R

E

V

I

A

T

I

O

N

A

M

I

N

E

I

N

S

O

L

U

T

I

O

N

M

O

N

O

E

T

H

A

N

O

L

A

M

I

N

E

M

E

A

1

5

-

2

0

%

D

I

E

T

H

A

N

O

L

A

M

I

N

E

D

G

A

2

0

-

3

0

%

D

I

G

L

Y

C

O

L

A

M

I

N

E

D

G

A

5

0

-

7

0

%

M

E

T

H

Y

L

D

I

E

T

H

A

N

O

L

A

M

I

N

E

M

D

E

A

4

0

-

6

0

%

S

U

L

F

O

L

A

N

E

&

D

I

S

O

P

R

O

P

Y

L

A

M

I

N

E

S

U

L

F

I

N

O

L

5

0

-

7

0

%

1

STRIPPER FLOW DIAGRAM

2

STRIPPER

FC

LEAN

AMINE

RICH

AMINE

LEAN-RICH

AMINE EXCHANGER

LEVEL

CONTR

REBOILER

HEAT

SOURCE

OUT

STRIPPING STEAM

HEAT

SOURCE

IN

STRIPPER

TOWER

FLOW

RECORDER

REFLUX

PUMP

REFLUX

ACCUMULATOR

CONDENSER

PRES

CONTR

H2S

VALVE TRAY

BUBBLE

CAP

TRAY

DOWNCOMER

TRAY INSTALLATION

IN TOWER

STRIPPER TRAYS

3

TRAYS USED STRIPPER

VALVE TRAY

BUBBLE CAP

TRAY

PACKING USED IN STRIPPERS

4

SLOTTED RINGS

RASHIG

RINGS

BERYL SADDLES

PLASTIC SADDLES

RING & SADDLE TYPE PACKING

STRUCTURED TOWER PACKING

GAS OUT

LIQUID

IN

SHELL

LIQUID

DISTRIBUTOR

PACKING

RESTRAINER

RANDOM

TOWER

PACKING

LIQUID

REDISTRIBUTOR

GAS IN

LIQUID

OUT

PACKING

SUPPORT

DOWNCOMER

BUBBLE CAP

RETAINING

BOLT AND NUT

WEIR

LIQUID

FLOW

DOWNCOMER

RISER

VAPOR

FLOW

VALVE

TRAY

VALVE RETAINING

EAR

FLOW ON TRAYS

5

FLOW ON STRIPPER TRAYS

PRINCIPLES OF STRIPPING

6

H

2

S AND CO

2

ARE ACID GASES.

THEY CHEMICALLY REACT WITH ALKALINE AMINE IN THE CONTACTOR.

H

2

S + AMINE V AMINE SULFIDE

C0

2

+ AMINE V AMINE CARBONATE

THE REACTION IS REVERSED IN THE STRIPPER.

AMINE SULFIDE + HEAT V AMINE + H

2

S

AMINE CARBONATE + HEAT V AMINE + CO2

H

2

S AND CO

2

FLOW OUT THE TOP OF THE STRIPPER. AMINE IS THE BOT-

TOM PRODUCT.

ABOUT 90% OF ACID GAS IS REMOVED FROM RICH AMINE IN THE STRIP-

PER. THE 10% THAT REMAINS IN THE AMINE IS CALLED RESIDUAL ACID

GAS.

RESIDUAL CONTENT IS LOWERED BY STRIPPING MORE ACID GAS FROM

THE RICH AMINE. THIS REQUIRES MORE REBOILER HEAT.

IF RESIDUAL IS LOWERED FROM 10% TO 0%, AMINE FLOW CAN BE REDUCED

10%. ADDITIONAL HEAT TO LOWER RESIDUAL IS FAR MORE THAN HEAT

REDUCTION BY LOWERING AMINE FLOW RATE.

STRIPPING IN PLANTS USING MEA AND DEA

7

THE PRIMARY FACTOR AFFECTING THE REVERSAL OF THE AMINE-SUL-

FIDE OR AMINE CARBONATE REACTION IS THAT OF TEMPERATURE IN

THE STRIPPER REBOILER.

THE SECONDARY FACTOR IS STRIPPING STEAM RATE, WHICH IS

CHANGED BY CHANGING THE HEAT INPUT TO THE REBOILER.

REBOILER TEMPERATURE IS FIXED BY THE AMINE CONCENTRATION AND

STRIPPER PRESSURE. RAISING THE CONCENTRATION OR PRESSURE WILL

INCREASE THE TEMPERATURE.

WATER BOILS AT 100C [212F] TO RAISE BOILING TEMPERATURE, PRES-

SURE MUST BE INCREASED.

1 KPA OF PRESSURE INCREASE WILL RAISE BOILING POINT 0.25C

1 PSI OF PRESSURE INCREASE WILL RAISE BOILING POINT 3F

EXAMPLE

DETERMINE THE BOILING TEMPERATURE OF WATER AT 70 KPA [10 PSI].

SI UNITS ENGLISH UNITS

BOILING PRESSURE 70 KPA 10 PSI

UNIT TEMPERATURE RISE 0.25 PER KPA 3 PER PSI

TEMPERATURE RISE IN BOILER 70 X 0.25 = 17.5C 3 X 10 = 30F

BOILER TEMPERATURE 100 + 17.5 = 117.5C 212 + 30 = 242F

STRIPPER REBOILER TEMPERATURE

SI UNITS

8A

THE EFFECT OF PRESSURE ON THE BOILING TEMPERATURE OF MEA AND

DEA IS:

1 KPA WILL EFFECT TEMPERATURE 0.16C

EXAMPLE

DETERMINE REBOILER TEMPERATURE WHEN PRESSURE IS RAISED 34 KPA

IN A 30% DEA REBOILER OPERATING AT 115.6C AT A PRESSURE OF 55 KPA.

TEMPERATURE INCREASE AT 34 KPA PRESSURE INCREASE

= 34 X 0.16 = 5.4C

TEMPERATURE AT 55 KPA 115.6C

TEMPERATURE AT (55 + 34 = 89 KPA) = 121C

REBOILER TEMPERATURE IS CHANGED AT A CONSTANT PRESSURE BY

CHANGING CONCENTRATION. CONCENTRATION IS CHANGED BY OPERA-

TOR. IT IS INCREASED BY ADDING FRESH AMINE TO SYSTEM IN THE

SURGE TANK. IT IS REDUCED BY ADDING WATER TO THE SYSTEM.

CONCENTRATION IS NORMALLY HELD CONSTANT:

15 - 20% FOR MEA

20 - 30% FOR DEA

HIGHER CONCENTRATION WILL RAISE REBOILER TEMPERATURE AND ALSO

INCREASE AMOUNT OF ACID GAS EACH LITER OF AMINE WILL REMOVE

FROM PROCESS FLUID IN THE CONTACTOR.

THE DOWN SIDES OF INCREASING CONCENTRATION ARE:

1. CORROSION RATE WILL INCREASE SIGNIFICANTLY.

2. HIGHER REBOILER TEMPERATURE WILL INCREASE DECOMPOSITION

OF AMINE WHICH MAY REQUIRE A RECLAIMER TO REMOVE THE DE-

COMPOSED MATERIAL OR REPLACEMENT OF AMINE SOLUTION.

PRESSURE IS USUALLY HELD BETWEEN 40 - 80 KPA.

THE DEGREE OF STRIPPING IS INCREASED BY RAISING THE HEAT INPUT

TO THE REBOILER.

STILL REBOILER HEAT INPUT FOR MEA OR DEA PLANTS

HEAT REQUIRED PER

HEAT SOURCE LITER OF AMINE CIRCULATION

STEAM 0.14 - 0.17 KG/L

FUEL GAS 0.010 - 0.013 M

3

/L

STRIPPER REBOILER TEMPERATURE

ENGLISH UNITS

8B

THE EFFECT OF PRESSURE ON THE BOILING TEMPERATURE OF MEA AND

DEA IS:

1 PSI WILL EFFECT TEMPERATURE 2F

EXAMPLE

DETERMINE REBOILER TEMPERATURE WHEN PRESSURE IS RAISED 8 PSI

IN A 30% DEA REBOILER OPERATING AT 240F AT A PRESSURE OF 5 PSI.

TEMPERATURE INCREASE AT 5 PSI PRESSURE INCREASE

= 5 X 2 = 10F

TEMPERATURE AT 8 PSI 240F

TEMPERATURE AT (8 + 5 = 13 PSI) = 250F

REBOILER TEMPERATURE IS CHANGED AT A CONSTANT PRESSURE BY

CHANGING CONCENTRATION. CONCENTRATION IS CHANGED BY OPERA-

TOR. IT IS INCREASED BY ADDING FRESH AMINE TO SYSTEM IN THE

SURGE TANK. IT IS REDUCED BY ADDING WATER TO THE SYSTEM.

CONCENTRATION IS NORMALLY HELD CONSTANT:

15 - 20% FOR MEA

20 - 30% FOR DEA

HIGHER CONCENTRATION WILL RAISE REBOILER TEMPERATURE AND ALSO

INCREASE AMOUNT OF ACID GAS EACH GALLON OF AMINE WILL REMOVE

FROM PROCESS FLUID IN THE CONTACTOR.

THE DOWN SIDES OF INCREASING CONCENTRATION ARE:

1. CORROSION RATE WILL INCREASE SIGNIFICANTLY.

2. HIGHER REBOILER TEMPERATURE WILL INCREASE DECOMPOSITION

OF AMINE WHICH MAY REQUIRE A RECLAIMER TO REMOVE THE DE-

COMPOSED MATERIAL OR REPLACEMENT OF AMINE SOLUTION.

PRESSURE IS USUALLY HELD BETWEEN 6 - 12 PSI.

THE DEGREE OF STRIPPING IS INCREASED BY RAISING THE HEAT INPUT

TO THE REBOILER.

STILL REBOILER HEAT INPUT FOR MEA OR DEA PLANTS

HEAT REQUIRED PER

HEAT SOURCE LITER OF AMINE CIRCULATION

STEAM 1.15 - 1.40 LB/GAL

FUEL GAS 1.40 - 1.75 CF/GAL

STRIPPING IN PLANTS USING MDEA, DGA, SULFINOL

9

DEGREE OF STRIPPING H

2

S AND C0

2

FROM RICH AMINE IS INCREASED BY

RAISING STRIPPING STEAM.

THIS IS DONE BY RAISING HEAT INPUT TO THE REBOILER.

HEAT INPUT IN MDEA, DGA AND SULFINOL REBOILERS

HEAT HEAT INPUT PER LITER HEAT INPUT PER GALLON

SOURCE AMINE FLOW OF AMINE FLOW

STEAM 0.1 - 0.13 KG 0.83 - 1.0 LB

FUEL TO HEATER 0.008 - 0.01 M 1.04 - 1.22 CU FT

ABOVE ALSO APPLIES TO SPECIALLY FORMULATED AMINES SUCH AS

UCARSO AND GAS SPEC.

PROBLEM

FLOW OF AMINE IS 100 L/MIN [250 GPM]

SI UNITS ENGLISH UNITS

STRIPPING GAS @

MAX RATE W/DEA ______ X ______ ______ X ______

= ________ = ________

STRIPPING GAS @

MAX RATE W/DGA ______ X ______ ______ X ______

= ________ = ________

REFLUX IN AMINE STRIPPER

10

FUNCTION OF REFLUX

REFLUX FLOW RATE

SI UNITS ENGLISH UNITS

REFLUX FLOW RATE, R = 0.0125 X (REB STM) 0.0015 X (REB STM)

REBOILER STEAM RATE KG/HR LB/HR

REFLUX FLOW L/M GPM

EXAMPLE

DETERMINE THE REFLUX FLOW RATE IN A STRIPPER IN WHICH THE

REBOILER STEAM RATE IS 6350 KG/HR [14 000 LB/HR].

SI UNITS ENGLISH UNITS

REFLUX FLOW EQUATION, R = 0.0125 X (REB STM) 0.0015 X (REB STM)

REBOILER STEAM RATE 6350 KG/HR 14 000 LB/HR

SUBSTITUTE IN EQUATION, 4 = 0.0125 X 6350 0.0015 X 14 000

= 79.4 L/MIN = 21 GPM

ACID GASES

REMOVED FROM

RICH SOLUTION

REFLUX

ACCUMULATOR

REFLUX

PUMP

REFLUX

REFLUX

CONSENSER

Liquid entering the accumulator

drops to the bottom and is

pumped to the top of the tower.

Upflowing vapor

bubbles through

cool reflux on the

top trays. Amine

in the vapor is

absorbed in the

reflux.

Hot vapor flowing up tower

contains some amine.

Vapor from the top of the tower

flows through the condenser

where part of the stream con-

denses.

S

T

R

I

P

P

I

N

G

S

T

E

A

M

S

T

E

A

M

F

L

O

W

C

O

N

T

R

L

E

V

E

L

C

O

N

T

R

S

T

R

I

P

P

I

N

G

S

T

E

A

M

F

L

O

W

C

H

A

N

G

E

D

B

Y

C

H

A

N

G

I

N

G

S

E

T

P

O

I

N

T

I

N

F

L

O

W

C

O

N

T

R

O

L

L

E

R

.

R

E

B

O

I

L

E

R

L

E

A

N

A

M

I

N

E

S

T

E

A

M

C

O

N

D

E

N

S

A

T

E

11

S

T

R

I

P

P

I

N

G

S

T

E

A

M

F

L

O

W

C

O

N

T

R

O

L

S

T

I

L

L

R

E

B

O

I

L

E

R

W

I

T

H

S

T

E

A

M

E

X

C

H

A

N

G

E

R

12

S

T

R

I

P

P

I

N

G

S

T

E

A

M

F

L

O

W

C

O

N

T

R

O

L

S

T

I

L

L

R

E

B

O

I

L

E

R

W

I

T

H

I

N

D

I

R

E

C

T

F

I

R

E

D

H

E

A

T

E

R

S

T

R

I

P

P

I

N

G

S

T

E

A

M

S

T

R

I

P

P

I

N

G

S

T

E

A

M

F

L

O

W

C

H

A

N

G

E

D

B

Y

C

H

A

N

G

I

N

G

S

E

T

P

O

I

N

T

I

N

F

L

O

W

C

O

N

T

R

O

L

L

E

R

.

F

L

O

W

C

O

N

T

R

R

E

B

O

I

L

E

R

L

E

V

E

L

C

O

N

T

R

L

E

A

N

A

M

I

N

E

F

U

E

L

G

A

S

13

L

E

A

K

I

N

L

E

A

N

-

R

I

C

H

S

O

L

U

T

I

O

N

E

X

C

H

A

N

G

E

R

C

O

O

L

L

E

A

N

S

O

L

U

T

I

O

N

O

U

T

H

O

T

L

E

A

N

S

O

L

U

T

I

O

N

I

N

C

O

O

L

R

I

C

H

S

O

L

U

T

I

O

N

I

N

H

O

T

R

I

C

H

S

O

L

U

T

I

O

N

O

U

T

W

h

e

n

l

e

a

k

o

c

c

u

r

s

,

h

i

g

h

e

r

p

r

e

s

s

u

r

e

r

i

c

h

s

o

l

u

t

i

o

n

w

i

l

l

l

e

a

k

i

n

t

o

l

e

a

n

s

o

l

u

t

i

o

n

.

T

h

e

t

e

m

p

e

r

a

t

u

r

e

o

f

l

e

a

n

s

o

l

u

t

i

o

n

f

l

o

w

i

n

g

o

u

t

o

f

t

h

e

E

x

c

h

a

n

g

e

r

w

i

l

l

b

e

l

o

w

e

r

t

h

a

n

n

o

r

m

a

l

,

a

n

d

i

t

s

r

e

s

i

d

u

a

l

c

o

n

t

e

n

t

w

i

l

l

b

e

h

i

g

h

e

r

t

h

a

n

t

h

a

t

o

f

l

e

a

n

s

o

l

u

t

i

o

n

e

n

t

e

r

i

n

g

t

h

e

E

x

c

h

a

n

g

e

r

.

14

OPERATION AND CONTROL START-UP PROCEDURE

START-UP PROCEDURE

LEAN

AMINE

RICH

AMINE

LEAN-RICH

AMINE EXCHANGER

LEVEL

CONTR

REBOILER

HEAT

SOURCE

OUT

STRIPPING STEAM

HEAT

SOURCE

IN

STRIPPER

TOWER

FLOW

RECORDER

REFLUX

PUMP

REFLUX

ACCUMULATOR

CONDENSER

PRES

CONTR

H2S

7

2

6

5

1

3

4

Fill Reboiler with

lean solution.

Start

feed.

Start

Amine

Pump.

Open heat to Reboiler and

bring it up to operating

temperature

Star t Refl ux Pump

when level appears

in Accumulator.

Set pressure

controller.

Put condenser

in service.

LEAN

AMINE

RICH

AMINE

LEAN-RICH

AMINE EXCHANGER

LEVEL

CONTR

REBOILER

HEAT

SOURCE

OUT

STRIPPING STEAM

HEAT

SOURCE

IN

STRIPPER

TOWER

FLOW

RECORDER

REFLUX

PUMP

REFLUX

ACCUMULATOR

CONDENSER

PRES

CONTR

H2S

SHUT DOWN PROCEDURE

15

SHUT DOWN PROCEDURE

3

4

2

Stop

feed.

Stop Reflux

Pump.

Shut down

condenser.

1

Close

heat.

16

ROUTINE OPERATING CHECKS

CAUSE FOR CHANGE AND

PROCESS CONDITION CORRECTIVE ACTION

INCREASE IN STRIPPER 1. FAILURE OF PRESSURE CONTROLLER. REPAIR

PRESSURE CONTROLLER.

2. PRESSURE CONTROL VALVE STUCK CLOSED. STROKE

VALVE SEVERAL TIMES.

3. OBSTRUCTION IN OUTLET GAS LINE. CHECK FOR

CLOSED VALVE IN LINE OR FREEZE-UP IN COLD

WEATHER.

DECREASE IN STRIPPER 1. FAILURE OF PRESSURE CONTROLLER. REPAIR

PRESSURE CONTROLLER.

2. PRESSURE CONTROL VALVE STUCK OPEN. STROKE

VALVE SEVERAL TIMES.

3. BREAK OR LEAK IN OUTLET GAS LINE.

INCREASE IN 1. AERIAL TYPE CONDENSER.

TEMPERATURE OUT a. FAN MOTOR HAS STOPPED. DETERMINE CAUSE

OF CONDENSER AND CORRECT.

b. FAN BELTS ARE SLIPPING OR BROKEN. TIGHTEN

OR REPLACE BELTS.

c. FAN BLADES ARE BROKEN OR HAVE CHANGED

PITCH. CHECK AND REPAIR.

d. COOLER FINS ARE OBSTRUCTED. CLEAN FINS.

2. WATER COOLER.

a. LOW WATER FLOW RATE. OUTLET WATER TEMPERA-

TURE IS HIGH. OPEN VALVES IN WATER LINES, OR

CHECK FOR OBSTRUCTIONS IN WATER LINES.

LEVEL VARIES IN 1. FAULTY LEVEL CONTROL SYSTEM. CHECK & REPAIR.

REFLUX ACCUMULATOR 2. TOWER IS BURPING. SEE PAGE 7.

3. REBOILER HEAT INPUT CHANGES. SEE BELOW.

REBOILER HEAT INPUT GAS FIRED REBOILER

CHANGES a. FUEL PRESSURE CHANGES. CHECK FUEL GAS

SYSTEM AND CORRECT.

b. FAULTY FUEL FLOW CONTROL SYSTEM.

c. FUEL CONTAINS LIQUID. DRAIN FUEL SCRUBBER.

STEAM OR HOT OIL REBOILER

a. PRESSURE CHANGES IN HEATING FLUID.

CHECK AND CORRECT.

b. FAULTY FLOW CONTROL SYSTEM ON HEATING

FLUID. CHECK AND REPAIR.

c. TEMPERATURE OF HEATING FLUID CHANGES.

DETERMINE CAUSE AND CORRECT.

PROCESS CHECKS

17

CAUSE FOR CHANGE AND

PROCESS CONDITION CORRECTIVE ACTION

RESIDUAL ACID GAS 1. RICH AMINE FEED RATE HAS INCREASED. LOWER

CONTENT OF LEAN FEED RATE OR RAISE HEAT INPUT TO REBOILER.

AMINE GOES UP. 2. LEAK IN LEAN-RICH EXCHANGER. CONFIRM BY CHECK-

ING RESIDUAL CONTENT OF LEAN AMINE IN AND OUT

OF EXCHANGER. PLUG LEAKING TUBES.

3. ACID GAS CONTENT OF RICH AMINE FEED IS UP. THIS

MAY BE DUE TO INCREASE IN FLOW OF SOUR GAS TO

THE PLANT. RAISE LEAN AMINE FLOW RATE AND HEAT

INPUT TO REBOILER.

4. FOAMING IS OCCURRING. SEE PAGE 26

5. TRAYS ARE FOULED. SHUT DOWN AND CLEAN.

6. REBOILER HEAT INPUT HAS DECREASED. RAISE TO

NORMAL.

LEVEL VARIES IN DRAW- 1. FAULTY LEVEL CONTROL SYSTEM. CHECK AND REPAIR.

OFF CHAMBER ON 2. PRESSURE IN TOWER IS LOW. RAISE TO NORMAL.

REBOILER. 3. RICH FEED IS FLOWING IN SLUGS. ADJUST LEVEL CON-

TROL SYSTEM THAT REGULATES FLOW OF RICH FEED.

TEMPERATURE OF 1. TEMPERATURE OF RICH AMINE TO EXCHANGER HAS

LEAN AMINE OUT OF DECREASED. CHECK AND CORRECT.

LEAN-RICH EXCHANGER 2. LEAK IN EXCHANGER. CONFIRM LEAK AND PLUG

GOES DOWN. TUBES.

3. EXCHANGER IS FOULED. CLEAN TUBES.

STRIPPER CONTROL

18

PRIMARY CONTROL POINTS:

1. PRESSURE

2. REBOILER HEAT INPUT

IF STRIPPER OVERHEAD GAS FLOWS TO INCINERATOR OR SULFUR PLANT

OR COMPRESSOR, STRIPPER PRESSURE MUST BE HIGH ENOUGH FOR

ACID GAS TO ENTER DOWNSTREAM EQUIPMENT.

IF GAS FLOWS TO AIR, PRESSURE SHOULD BE MINIMUM REQUIRED FOR

LEAN AMINE OUT THE REBOILER TO FLOW TO THE BOOSTER PUMP OR

SURGE TANK.

REBOILER HEAT INPUT IS USUALLY THE MAIN OPERATING EXPENSE. IT

SHOULD BE HELD TO A MINIMUM.

A. TROUBLESHOOTING PROCEDURE FOR EXCESSIVE RESIDUAL COMPO-

NENT IN THE LEAN SOLUTION (TOO MUCH ACID GAS IN LEAN AMINE).

CAUSE OF EXCESSIVE TROUBLESHOOTING

RESIDUAL PROCEDURE

1. HIGH STRIPPER PRESSURE CHECK PRESSURE AND LOWER TO DESIGN

2. LOW HEAT INPUT TO REBOILER. CHECK FLOW RATE. RAISE IF NECESSARY.

RATE IS INDICATED BY FLOW OF HEAT

SOURCE TO REBOILER.

3. LOW STRIPPER FEED CHECK TEMPERATURE. FIND CAUSE OF LOW

TEMPERATURE. TEMPERATURE. LEAN-RICH SOLUTION EX-

CHANGER MAY BE FOULED.

4. LEAK IN LEAN-RICH EXCHANGER. CHECK SOLUTION EXCHANGER FOR LEAK

IN TUBE AND PLUG IT.

5. STRIPPER TRAYS OR PACKING IS CONFIRM WITH HIGH PRESSURE DROP

FOULED. MEASUREMENT. INTERNALLY INSPECT AND

CLEAN.

B. TROUBLESHOOTING PROCEDURE FOR FOAMING OR CARRYOVER IN

STRIPPER.

CAUSE OF FOAMING OR TROUBLESHOOTING

CARRYOVER PROCEDURE

1. RICH SOLUTION CONTAINS SOLID SOLUTION WILL BE DISCOLORED OR

PARTICLES. CLOUDY. CHANGE OR CLEAN FILTER ELE-

MENTS.

2. HYDROCARBONS ARE PRESENT HYDROCARBONS WILL ENTER IN THE RICH

IN THE FEED. SOLUTION.

a. CHECK A SAMPLE OF SOLUTION FOR

OIL FILM.

b. CHECK FLASH TANK OR OTHER

SEPARATORS IN RICH SOLUTION FLOW

FOR OPERATION OF HYDROCARBON

DRAW-OFF FACILITIES OR LOSS OF

LIQUID LEVEL THAT WILL ALLOW GAS TO

PASS OUT THE LIQUID LINE.

3. HIGH LIQUID FLOW IN TOWER. CHECK FLOW OF REFLUX AND FEED. LOWER

TO DESIGN RATES.

4. HIGH VAPOR FLOW IN TOWER. CHECK STRIPPING GAS FLOW RATE. LOWER

TO DESIGN.

5. TRAYS OR PACKING FOULED. INTERNALLY INSPECT AND CLEAN.

TOWER HAS HIGH PRESSURE

DROP.

TROUBLESHOOTING

19

D. REBOILER WILL NOT SUPPLY ENOUGH HEAT

1. FOR REBOILER WITH FIRETUBE HEATER.

TROUBLESHOOTING

CAUSES PROCEDURE

1. LOW FUEL RATE. CHECK RATE. RAISE TO DESIGN.

2. LOW FUEL GAS PRESSURE. CHECK PRESSURE. RAISE TO NORMAL.

3. IMPROPER COMBUSTION. a. CHECK FLAME ARRESTOR FOR

PLUGGING. CLEAN IF NECESSARY.

b. ADJUST PRIMARY AND SECONDARY

AIR TO GIVE GOOD FLAME PATTERN.

4. LIQUID LEVEL BELOW TOP CHECK LEVEL AND RAISE ABOVE

OF FIRE TUBE. FIRETUBE.

5. FOULED FIRETUBE. REMOVE AND CLEAN.

2. FOR REBOILER WITH HEATING TUBE FLUID.

TROUBLESHOOTING

CAUSES PROCEDURE

1. LOW TEMPERATURE OF CHECK TEMPERATURE. RAISE TO DESIGN.

HEATING FLUID.

2. LOW FLOW OF HEATING FLUID. a. CHECK FLOW RATE. RAISE IF POSSIBLE.

b. CHECK PRESSURES OF HEATING FLUID

IN AND OUT OF REBOILER. IF PRESSURE

DIFFERENCE IS HIGH, TUBES ARE

PLUGGED AND MUST BE CLEANED.

3. LIQUID LEVEL BELOW TOP OF CHECK LEVEL AND RAISE ABOVE TUBE

TUBES. BUNDLE.

4. TUBES ARE FOULED. REMOVE BUNDLE AND CLEAN.

TROUBLESHOOTING

20

VALIDATION

SI UNITS

STRIPPER IN

SWEETENING PLANT

Name ____________________

1. Refer to the drawing.

a. Reboiler steam rate is

__________ kg/hr.

b. Residual H

2

S content is

_______ m

3

/L.

c. Reflux rate is _______ L/min.

d. Flow of H

2

S out the top of

the Reflux Accumulator is

________ m

3

/d.

Answers

FC

LEAN

AMINE

110 L/min

0.004 m H2S/L

RICH

MEA

LEAN-RICH

AMINE EXCHANGER

LEVEL

CONTR

REBOILER

HEAT

SOURCE

OUT

STRIPPING STEAM

HEAT

SOURCE

IN

TOWER

FLOW

RECORDER

REFLUX

PUMP

REFLUX

ACCUMULATOR

REFLUX

CONDENSER

PRES

CONTR

H2S

LC

STEAM IN

0.15 kg/L MEA

No. of trays = 20

Tray Eff = 60%

110 L/min 0.025 m H2S/L

3

3

Check the correct item or items to each of the following statements.

2. The function of reflux is to:

______ Dilute rich solution ______ Add reboiler duty

______ Scrub amine from vapors ______ Cool top of Stripper

3. The Reboiler supplies heat to:

______ Vaporize reflux ______ Vaporize Stripped components

______ Heat liquid in tower ______ Heat stripping gas

4. When checking the performance of a Stripper, the most important item is:

______ Feed rate ______ Residual content of lean solution

______ Reflux rate ______ Stripping gas flow rate

5. List the order of events to start up a Stripper.

______ Start Reboiler Heat ______ Start Reflux Pump

______ Start Feed ______ Start Amine Pump

990 (0.15)(110)(60)

0.004

12.375

(0.0125)(990)

3325.4

(0.025 - 0.004)(110)(1440)

e e

e e

e

e

3 4

2 1

Scoring

10

5

10

10

Scoring

3 for

each

correct

answer

Total

65

VALIDATION

ENGLISH UNITS

STRIPPER IN

SWEETENING PLANT

Name ____________________

1. Refer to the drawing.

a. Reboiler steam rate is

__________ lb/hr.

b. Residual H

2

S content is

_______ cu ft/gal.

c. Reflux rate is ____ gpm.

d. Flow of H

2

S out the top of

the Reflux Accumulator is

____ Mcf/d.

Answers

FC

LEAN

AMINE

25 gpm

0.3 cu ft H2S/gal RICH

MEA

LEAN-RICH

AMINE EXCHANGER

LEVEL

CONTR

REBOILER

HEAT

SOURCE

OUT

STRIPPING STEAM

HEAT

SOURCE

IN

TOWER

FLOW

RECORDER

REFLUX

PUMP

REFLUX

ACCUMULATOR

REFLUX

CONDENSER

PRES

CONTR

H2S

LC

STEAM IN

1.25 lb/gal MEA

No. of trays = 20

Tray Eff = 60%

3 cu ft H2S/gal

Check the correct item or items to each of the following statements.

2. The function of reflux is to:

______ Dilute rich solution ______ Add reboiler duty

______ Scrub amine from vapors ______ Cool top of Stripper

3. The Reboiler supplies heat to:

______ Vaporize reflux ______ Vaporize Stripped components

______ Heat liquid in tower ______ Heat stripping gas

4. When checking the performance of a Stripper, the most important item is:

______ Feed rate ______ Residual content of lean solution

______ Reflux rate ______ Stripping gas flow rate

5. List the order of events to start up a Stripper.

______ Start Reboiler Heat ______ Start Reflux Pump

______ Start Feed ______ Start Amine Pump

Scoring

10

5

10

10

1875 (25 gpm x 60) 1.25

0.3

2.81 1875 x 0.0015

97.2

(25 gpm x 1440 min/d)(3 - 0.3 cu ft/gal)

1000

e e

e e

e

e

3 4

2 1

You might also like

- Lab2 MEE30004 - Lab2 - 2021 - Sem2 - Raw DataDocument6 pagesLab2 MEE30004 - Lab2 - 2021 - Sem2 - Raw DataAbidul IslamNo ratings yet

- BY Prem Baboo Sr. Manager (Prod) National Fertilizers LTD, Vijaipur, IndiaDocument74 pagesBY Prem Baboo Sr. Manager (Prod) National Fertilizers LTD, Vijaipur, IndiaAlbertoNo ratings yet

- Amine Regenerator ControlDocument14 pagesAmine Regenerator ControlGloria Margarita López100% (1)

- System Dynamics, Third Edition: Using Simscape ™ For Modeling Hydraulic Systems: Dynamics of A Hydraulic Piston and LoadDocument40 pagesSystem Dynamics, Third Edition: Using Simscape ™ For Modeling Hydraulic Systems: Dynamics of A Hydraulic Piston and LoadredwaneNo ratings yet

- 5471Document3 pages5471Mihai-Eugen Popa100% (2)

- Thermal Processing of Food & Aseptic ConditionsDocument20 pagesThermal Processing of Food & Aseptic Conditionstenguria samriddhNo ratings yet

- Session VI - Petrochemical Processing: A. PropyleneDocument5 pagesSession VI - Petrochemical Processing: A. PropyleneMallela Sampath KumarNo ratings yet

- Rac ExpDocument44 pagesRac ExpAkash Kumar DevNo ratings yet

- Tech Paper - Reheat Steam Temperature Control Concept in Once-Through Boilers - A ReviewDocument5 pagesTech Paper - Reheat Steam Temperature Control Concept in Once-Through Boilers - A ReviewQen Zyg EizernNo ratings yet

- Rankine CycleDocument6 pagesRankine CyclenabeelNo ratings yet

- Knowledge Troubleshooting AC SystemDocument13 pagesKnowledge Troubleshooting AC SystemRupak KumarNo ratings yet

- TE - 2 Unit - 1 NotesDocument37 pagesTE - 2 Unit - 1 NotesKrishna VamsiNo ratings yet

- Basic RefrigerationDocument9 pagesBasic RefrigerationDarren Jeff Manuel MicumaoNo ratings yet

- Steam Consumption at Sulphitation / Raw Sugar Factories (Boiling House - Recent Trends)Document6 pagesSteam Consumption at Sulphitation / Raw Sugar Factories (Boiling House - Recent Trends)Yadav ShwetaNo ratings yet

- Unit Lightup Synchronisation & ShutdownDocument42 pagesUnit Lightup Synchronisation & ShutdownAshvani ShuklaNo ratings yet

- Optimize Sour Water Stripper Feed Preheating For Low Capital PDFDocument6 pagesOptimize Sour Water Stripper Feed Preheating For Low Capital PDFDaniel Gonzalez RodriguezNo ratings yet

- Turbine Rolling and SynchronizationDocument54 pagesTurbine Rolling and Synchronizationsanjeev kushwaha67% (3)

- Flash Steam Recovery Calculation What Is Flash Steam?: Blow Down From BoilersDocument3 pagesFlash Steam Recovery Calculation What Is Flash Steam?: Blow Down From BoilersBeicha100% (1)

- Interview Questions For Chemical EngineeringDocument6 pagesInterview Questions For Chemical EngineeringNikunj PatelNo ratings yet

- 11 Refrigeration CyclesDocument18 pages11 Refrigeration CyclesHussamNo ratings yet

- Rules of Thumb For TroubleshootingDocument2 pagesRules of Thumb For TroubleshootingkktayNo ratings yet

- Chapter 17 Absorption Refrigeration ExercisesDocument2 pagesChapter 17 Absorption Refrigeration ExercisesAndrew PantaleonNo ratings yet

- Process Description of Ammonia PlantDocument12 pagesProcess Description of Ammonia PlantSridharNo ratings yet

- Improvement To RankineDocument10 pagesImprovement To RankineRitika SinghNo ratings yet

- The Importance of A Clean CondenserDocument5 pagesThe Importance of A Clean CondenserD HarNo ratings yet

- Good Operating Practices For Amine Treating SystemsDocument30 pagesGood Operating Practices For Amine Treating Systemsblah_0079681No ratings yet

- Improving Performance of Rankine Cycle: Thermodynamics - IIDocument9 pagesImproving Performance of Rankine Cycle: Thermodynamics - IIsamhameed2No ratings yet

- Power Plant Engineering Week 2-3Document39 pagesPower Plant Engineering Week 2-3Shoaib IlyasNo ratings yet

- Falling Film Evaporators in The Food IndustryDocument4 pagesFalling Film Evaporators in The Food IndustryAgung SiswahyuNo ratings yet

- REFRIGERATIONDocument24 pagesREFRIGERATIONDark ShadyNo ratings yet

- Refrigeration 1Document13 pagesRefrigeration 1Vishwanathan RishanthNo ratings yet

- Improvement To Rankine CycleDocument11 pagesImprovement To Rankine Cyclegjanklesaria100% (2)

- Pipe Elements 1Document310 pagesPipe Elements 1Ryan Llona FernandezNo ratings yet

- Troubleshooting of Amine RegnDocument8 pagesTroubleshooting of Amine RegnSekarNTutyNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- Performance of The Vapour Compression Cycle As A Refrigerator and As A Heat PumpDocument7 pagesPerformance of The Vapour Compression Cycle As A Refrigerator and As A Heat Pumptatoo1No ratings yet

- Vapour and Combined Power CyclesDocument37 pagesVapour and Combined Power CyclesTarvesh KumarNo ratings yet

- SPE 71471 Large Scale Field Gathering of Oil-Water-Gas at Temperature Below The Pour Point of Crude Oil SuccessfulDocument12 pagesSPE 71471 Large Scale Field Gathering of Oil-Water-Gas at Temperature Below The Pour Point of Crude Oil SuccessfuldanielmcaeNo ratings yet

- Geothermal Power Plant Cycles and Main ComponentsDocument24 pagesGeothermal Power Plant Cycles and Main ComponentsÅwink BeêNo ratings yet

- 5 200 PDFDocument12 pages5 200 PDFDee RajaNo ratings yet

- Low-Temperature ProcessingDocument5 pagesLow-Temperature ProcessingAlberto Fonseca UribeNo ratings yet

- Mud TestingDocument35 pagesMud TestingHarits Pamitran100% (1)

- Thumb RuleDocument4 pagesThumb RulenishadNo ratings yet

- Plate Freezer Performance.Document4 pagesPlate Freezer Performance.Behnam AshouriNo ratings yet

- The Pressure - Enthalpy ChartDocument12 pagesThe Pressure - Enthalpy ChartJohnMerrNo ratings yet

- Principles of Mash Conditioning 1706535501Document6 pagesPrinciples of Mash Conditioning 1706535501surya PrakashNo ratings yet

- The Contactor: Amine Regenerator Feed Temperature: How Hot Is Hot Enough?Document2 pagesThe Contactor: Amine Regenerator Feed Temperature: How Hot Is Hot Enough?mohamed senoussiNo ratings yet

- Black Liquor EvaporationDocument3 pagesBlack Liquor EvaporationAktharNo ratings yet

- STC GS 2 Air ConditioningDocument788 pagesSTC GS 2 Air ConditioningSayeed HvacNo ratings yet

- Warm Light Up (Mahendra Singh)Document35 pagesWarm Light Up (Mahendra Singh)vinamrataNo ratings yet

- High Condensing TemperatureDocument3 pagesHigh Condensing TemperatureluffydsiniNo ratings yet

- Introduction To RefrigerationDocument25 pagesIntroduction To RefrigerationFuture HazeNo ratings yet

- Solving Hydraulic System Overheating ProblemsDocument9 pagesSolving Hydraulic System Overheating Problemsmahadev100% (1)

- Lecture 08 Vapor and Combined Power CyclesDocument19 pagesLecture 08 Vapor and Combined Power CyclesDawood BajwaNo ratings yet

- Boiler Efficiency CalculationDocument17 pagesBoiler Efficiency CalculationSolai100% (4)

- Heat Recovery Presentation Rev 130213Document32 pagesHeat Recovery Presentation Rev 130213Budhi SaputraNo ratings yet

- 1 Falling Film Evaporators in The Food Industry DesignDocument4 pages1 Falling Film Evaporators in The Food Industry DesignIvan Ruben Capuñay IzquierdoNo ratings yet

- Introduction To Vapour Compression RefrigerationDocument9 pagesIntroduction To Vapour Compression RefrigerationmdmarufurNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Process Engineering: Facts, Fiction and FablesFrom EverandProcess Engineering: Facts, Fiction and FablesRating: 3 out of 5 stars3/5 (2)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- 7.flash DistilerDocument35 pages7.flash DistilerNa-na OktaviaNo ratings yet

- Academic Guidebook FT UI English VersionDocument546 pagesAcademic Guidebook FT UI English VersionpanduhusnantoNo ratings yet

- Academic Guidebook FT UI English VersionDocument546 pagesAcademic Guidebook FT UI English VersionpanduhusnantoNo ratings yet

- NO Nama NIM Nama Jaket Ukura NDocument3 pagesNO Nama NIM Nama Jaket Ukura NNa-na OktaviaNo ratings yet

- Accumulator (Pilot) - Test and Charge - 084543Document4 pagesAccumulator (Pilot) - Test and Charge - 084543Juan LopezNo ratings yet

- Chapter 9 - Tennessee Eastman Plant-Wide Industrial Process Challenge ProblemDocument31 pagesChapter 9 - Tennessee Eastman Plant-Wide Industrial Process Challenge Problemkim haksongNo ratings yet

- Thermodynamics Lab 1 UpdatedDocument19 pagesThermodynamics Lab 1 UpdatedndumisoNo ratings yet

- A Tutorial On Initialising An Eclipse Reservoir ModelDocument19 pagesA Tutorial On Initialising An Eclipse Reservoir ModelDhiaa LaMiNo ratings yet

- Tubing Performance VLPDocument4 pagesTubing Performance VLPDhiaa LaMiNo ratings yet

- Lesson 61-Derivation of Bernoullis Equation PDFDocument6 pagesLesson 61-Derivation of Bernoullis Equation PDFSaravanan MathiNo ratings yet

- Installation, Operation and Maintenance Instructions: Penberthy Model Tme MixerDocument4 pagesInstallation, Operation and Maintenance Instructions: Penberthy Model Tme MixerGuillermo MartinezNo ratings yet

- Manometer NotesDocument5 pagesManometer NotesRaju100% (1)

- Technical - 2-01 SO Cirugía General Op. A - DM2-0404Document5 pagesTechnical - 2-01 SO Cirugía General Op. A - DM2-0404ALEX MIRANDANo ratings yet

- Unique Mixproof ValveDocument8 pagesUnique Mixproof ValveyapwaieeNo ratings yet

- System Description Fuel Gas Draining PDFDocument4 pagesSystem Description Fuel Gas Draining PDFsivamNo ratings yet

- PARAMETRIC STUDY ON EFFICIENCY OF ARCHIMEDES SCREW TURBINE DESIGN - UpdatedDocument4 pagesPARAMETRIC STUDY ON EFFICIENCY OF ARCHIMEDES SCREW TURBINE DESIGN - UpdatedRoberto Zambrano SepulvedaNo ratings yet

- Ear PrintDocument33 pagesEar PrintSeema Kotalwar100% (11)

- Gas Properties Laws Student DirectionsDocument3 pagesGas Properties Laws Student DirectionsKali stringsNo ratings yet

- PIL 140 Dry Gas Face Seals For Solar Compressors Rev 13aDocument22 pagesPIL 140 Dry Gas Face Seals For Solar Compressors Rev 13aYusri FakhrizalNo ratings yet

- Approval Standard For Explosion Venting SystemsDocument15 pagesApproval Standard For Explosion Venting Systemsrafael1978No ratings yet

- GMV5 Service Manual 2014Document120 pagesGMV5 Service Manual 2014Артур БобкинNo ratings yet

- Pore Pressure Prediction Using Seismic Velocity Modeling: Case Study, Sefid Zakhor Gas Field in Southern IranDocument12 pagesPore Pressure Prediction Using Seismic Velocity Modeling: Case Study, Sefid Zakhor Gas Field in Southern IranAhmedNo ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- 4c Radial Flow Semi Steady StateDocument41 pages4c Radial Flow Semi Steady StateDheeraj KumarNo ratings yet

- Laboratory Workshop in General Physics 2020, AllDocument138 pagesLaboratory Workshop in General Physics 2020, AllsalomeNo ratings yet

- Hydraulics TerminologiesDocument3 pagesHydraulics TerminologiesKrisleen Elyzel GullasNo ratings yet

- John Andre Cagampang - Gphy1 - q2 - Module7 - wk7 AnswersDocument18 pagesJohn Andre Cagampang - Gphy1 - q2 - Module7 - wk7 AnswersAndrejohn CagampangNo ratings yet

- 5TR CondenserDocument1 page5TR CondenserbevarsiNo ratings yet

- AGR 102 TheoryDocument140 pagesAGR 102 TheoryKuttyNo ratings yet

- Grade 10first TQDocument3 pagesGrade 10first TQJerbs PacundoNo ratings yet

- Note06. HGL & EGLDocument8 pagesNote06. HGL & EGLMohd Azhari Mohd RodziNo ratings yet