Professional Documents

Culture Documents

J Oncol Pharm Pract 2013 Sadeghipour 57 64

J Oncol Pharm Pract 2013 Sadeghipour 57 64

Uploaded by

Abdul Rakhmat MuzakkirOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

J Oncol Pharm Pract 2013 Sadeghipour 57 64

J Oncol Pharm Pract 2013 Sadeghipour 57 64

Uploaded by

Abdul Rakhmat MuzakkirCopyright:

Available Formats

http://opp.sagepub.

com/

Journal of Oncology Pharmacy Practice

http://opp.sagepub.com/content/19/1/57

The online version of this article can be found at:

DOI: 10.1177/1078155212452764

2013 19: 57 originally published online 9 July 2012 J Oncol Pharm Pract

F Sadeghipour, K Ing Lorenzini, C Ziewitz, M Dobrinas, M Fleury and P Bonnabry

hospital pharmacies

Chemical contamination during the preparation of cytotoxics: Validation protocol for operators in

Published by:

http://www.sagepublications.com

can be found at: Journal of Oncology Pharmacy Practice Additional services and information for

http://opp.sagepub.com/cgi/alerts Email Alerts:

http://opp.sagepub.com/subscriptions Subscriptions:

http://www.sagepub.com/journalsReprints.nav Reprints:

http://www.sagepub.com/journalsPermissions.nav Permissions:

What is This?

- Jul 9, 2012 OnlineFirst Version of Record

- Feb 23, 2013 Version of Record >>

by guest on May 18, 2014 opp.sagepub.com Downloaded from by guest on May 18, 2014 opp.sagepub.com Downloaded from

Oncology

Pharmacy

Practice

Journal of

Original Article

Chemical contamination during the

preparation of cytotoxics: Validation

protocol for operators in hospital

pharmacies

F Sadeghipour

Pharmacy, Hospitals of University of Geneva (HUG), Switzerland; School of Pharmaceutical

Sciences, University of Geneva, University of Lausanne, Switzerland

K Ing Lorenzini

Pharmacy, Hospitals of University of Geneva (HUG), Switzerland; School of Pharmaceutical

Sciences, University of Geneva, University of Lausanne, Switzerland

C Ziewitz

Pharmacy, Hospitals of University of Geneva (HUG), Switzerland

M Dobrinas

Pharmacy, Hospitals of University of Geneva (HUG), Switzerland

M Fleury

Pharmacy, Hospitals of University of Geneva (HUG), Switzerland; School of Pharmaceutical

Sciences, University of Geneva, University of Lausanne, Switzerland

P Bonnabry

Pharmacy, Hospitals of University of Geneva (HUG), Switzerland; School of Pharmaceutical

Sciences, University of Geneva, University of Lausanne, Switzerland

Abstract

Background and objectives: The chemical contamination during the preparation of cytotoxics remains a serious

problem in hospital pharmacies and the operators could contribute to this risk during their manipulations. A validation

protocol was developed using a non-toxic, highly detectable tracer, quinine dihydrochloride.

Method: Further, a method for a high recovery extraction and quantification of this marker, and a protocol covering the

critical operations of cytotoxic preparation, was developed and validated. Various devices were used to fill the syringes

and perfusion bags. All the filled containers and used materials were collected at the end of the protocol and the tracer

was extracted in water. The contaminated water was analyzed by fluorimetry. The number of spots on the working pads

was counted under ultraviolet light. During a total of 28 sessions, the procedure was applied by 20 different operators.

Results: The mean cumulated quantities of contamination were 6.2 mL (0.623.8) and >10 spots (020), which was

considered as high. No correlation was observed between the contamination rate and the operators experience.

Conclusion: This validation protocol facilitates controlling the operators working cleanliness and helps to improve the

initial and continuing training. This simple test presents an effective answer for the important issue of the chemical safety

of operators.

Keywords

Operators validation, cytotoxics, chemical contamination, fluorescent marker, quinine

Corresponding author:

Farshid Sadeghipour, Hospitals of University of Geneva (HUG), Rue

Gabrielle Perret-Gentil, 4, CH 1211, Geneva 14, Switzerland.

Email: farshid.sadeghipour@hcuge.ch

J Oncol Pharm Practice

19(1) 5764

! The Author(s) 2012

Reprints and permissions:

sagepub.co.uk/journalsPermissions.nav

DOI: 10.1177/1078155212452764

opp.sagepub.com

by guest on May 18, 2014 opp.sagepub.com Downloaded from

Introduction

Since the early 1980s, the preparation of injectable

antineoplastic drugs and other cytotoxic products for

adult and pediatric oncology units has been regularly

performed in hospital pharmacies. This trend is based

on two core rationales. It is aimed for a better protection

for the nursing and the medical sta, who previously

prepared these toxic medications in unprotected condi-

tions, as well as ensuring better safety for the patients,

supported by the quality assurance system implemented

in the production units of hospital pharmacies.

14

However, an important problem remained after the

transfer of this activity from the nurses to the pharma-

cists. A number of studies have actually reported a con-

tamination of the operators with the cytotoxics,

529

with

two possible sources. These sources include a production

residue on the primary packaging of antineoplastic

drugs

13,16,17,30

or a contamination by the operator

during the production of the nal drug for patients at

the pharmacy.

7,13,28

These mechanisms led to a contam-

ination of the syringes and infusion bags or the work

area in the pharmacy. The follow up to this contamin-

ation has been tended by various methods. These con-

trols can be performed by directly determining the

cytotoxic levels on the working surfaces

7,8,15,20,29

or

from the biological uids (blood and urine) of the oper-

ators.

5,1012,22,27,31

However, the latter techniques pre-

sent several drawbacks, such as the complexity of the

analytical methods

3234

as well as the theoretical risk

of contamination during the analytical process itself.

Moreover, the above mentioned approaches do not dif-

ferentiate between the contamination due to the manu-

facturer and the one related to the manipulation in the

hospital pharmacy. Therefore, it would be interesting to

estimate the contamination produced during the prep-

aration process. This would facilitate taking adequate

measures to improve the teaching of the operators, if

necessary. The selection of a non-toxic, sensitive, and

easily quantiable tracer would make it easier to

bypass these problems. This would allow easy simula-

tion of the routine operations as well as validation of the

procedures and the operators. Several markers have

been proposed in the literature for tracing the contam-

inations. Radioactive substances, such as technetiumare

very sensitive tracers.

35

However, their use is dicult

because of the necessary protective measures to be

taken for their manipulation. Another alternative

solution is the use of uorescent markers.

3638

Fluoresceine, for instance has a higher sensitivity in

comparison to other uorescent tracers, but is incon-

veniently visible (yellow-orange solution). Thus, the

operator could be abnormally attentive during the val-

idation process. Quinine dihydrochloride (QdHCl) is

natively uorescent, non-toxic, invisible to the naked

eye, soluble in water, and relatively easy to detect

under ultraviolet (UV) rays, with a high selectivity and

detectability.

39,40

Thus, it appears to be an ideal tracer

for measuring the contamination during the preparation

procedures.

The present study included two main objectives.

First, it aimed to develop and validate a simple

method using the QdHCl as a tracer. This would facili-

tate evaluating the contamination level by simulating

the preparation of the injectable cytotoxic drugs.

Second, the method was applied through a practical

standard operating procedure (SOP) to dierent oper-

ators for checking their ability to work in a clean

manner. This could help to avoid spreading the con-

tamination in the environment or on the nal prepar-

ation to be delivered to the wards. Based on the

obtained results, new specic training has to be orga-

nized for the operators with the most contamination to

correct their working methods.

Materials

QdHcl BP (Courtin & Warner LTD, UK and Duchefal

Farma, The Netherlands); Luer Lock Syringes 10, 20

and 50 mL (Becton, Dickinson & Co, NJ, USA); syringe

for vesical instillation, Omnix 100 mL (B.Braun,

Germany); needles (Terumo, Belgium); chemo dispen-

sing pin (B.Braun, Germany); transfer-set (Sintetica-

Bioren, Switzerland); tamper evident cap (B.Braun,

Germany); combi stopper (B.Braun, Germany); admin-

istration tubing set, Chemoprotect

gloves (Codan,

Germany); original Perfusor-Leitung PE (B.Braun,

Germany); infusion bag NaCl 0.9% 50 mL (Sintetica-

Bioren, Switzerland); gloves Micro-Touch PF

2

(Ansell,

NJ, USA); Fluorescence Spectrometer LS 50 (Perkin

Elmer, USA); and UV lamp (Camag, Switzerland).

Methods

Development and validation of the quantification

of the tracer

A 0.1 mM solution of QdHCl in water for injection

(WFI) was prepared to establish its uorimetric spec-

trum. An excitation wavelength and an emission wave-

length at 330 nm and 380 nm, respectively, were

determined. The limits of detection and quantication

were determined by the Eurachem approach based on

the use of a target value for the area of the relative

standard deviation (RSD).

41

The calibration curves

were carried out at concentrations between 0.1 and

1 mM in WFI to test the linearity at ve points. This

was done three times for each point (0.10, 0.15, 0.25,

0.50, 0.75, and 1.0 mM). Precision and accuracy were

tested at 0.1 and 1.0 mM.

58 Journal of Oncology Pharmacy Practice 19(1)

by guest on May 18, 2014 opp.sagepub.com Downloaded from

Development and validation of recovery of the

tracer from the contaminated devices

The contamination of the working pads was evaluated

semi-quantitatively by counting the number of stains

found under the UV light, owing mainly to the

absorbent nature of the liners. It was necessary to

develop a simple and ecient quantitative extraction

method to recover the contaminant (QdHCl) dropped

on the gloves and the infusion bags. A number of

previous studies have been based on wiping pads

7,8,42

wetted with organic solvents (methanol) or alkaline

solutions, where the contaminants were later extracted

in another solvent.

In the present study, the tracer being used was well

soluble in water. Thus, the extraction method was

tested by complete immersion of the gloves, bags, and

other contaminated devices in a glass beaker, contain-

ing 500 mL of WFI. This solution was stirred for 5 min.

The contaminated water was directly analyzed by

uorimetry. The recovery was tested at two dierent

levels of contamination: low (1 mL) and high (5 mL)

and on two dierent devices: 50 mL NaCl 0.9% infu-

sion bags and sterile non-powdered gloves. Either 1 or

5 mL of the 0.1 M solution of QdHCl was placed on

each device. Subsequent to drying of the solution, the

device was immerged in 500 mL of WFI.

To control the recovery rate, the uorescence mea-

sured on the devices was compared with the standard

solutions of 0.1 and 1.0 mM of QdHCl. The test on each

device was repeated six times per day, for 3 days.

Development of the operators validation protocol

To simulate the preparation of the lyophilized cyto-

toxics, 10 mL vials were lled with 10 mL of a 0.1 M

solution of QdHCl. Later, they were placed in an oven

at 90

C and their content was completely desiccated.

After the vials were sealed with stoppers and capsu-

lated, they were washed and checked under UV light

for absence of any outside contamination.

A preliminary test was developed to check the

feasibility of the operators protocol. A laboratory

chemical fume hood was used to simulate the working

conditions in the negative pressure biological safety

cabinets class III.

For the preliminary test, a working pad was installed

with all the necessary materials. For the entire test, the

operator wore Chemprotect

gloves covered by a pair

of other sterile non-powdered surgical gloves. Three

vials of desiccated QdHCl were reconstituted with

5 mL of WFI. Overall, 2 mL of the solution was

removed from each vial and added to a separate

50 mL NaCl 0.9% infusion bag. The covering gloves

were changed after each bag.

At the end of the procedure, the working pads were

observed under UV light to count the number of spots

(only the number and not the dimensions were con-

sidered). A semi-quantitative scale was used to deter-

mine the contamination rate: low (05 spots), medium

(610 spots), and high (>10 spots). The diameter of the

spots was not taken into account as the average size of

the spots was less than 3 mm.

The contamination on the covering gloves and the

infusion bags were separately measured by the previ-

ously developed quantitative method.

Operators validation protocol

The developed method was nally implemented in the

real working environment, that is, the negative pressure

biological safety cabinets class III placed in a class C

GMP (ISO 7) clean room. Every operators validation

session was performed in the presence of another val-

idation operator, a junior hospital pharmacist, who

controlled all the manipulations and the process

timing (not exceeding 1 h).

All pharmacists and pharmacy technicians working

in the cytotoxic preparation unit were required to pre-

pare a xed number of syringes and infusion bags in the

isolator with a solution of QdHCl in a limited period of

time. They were asked to follow precise instructions

and adopt the same working procedures such as those

used for the cytotoxics preparations.

For each operator, 10 desiccated vials of 0.1 M

QdHCl were prepared, as previously described. The

rst step for the operator involved dissolving the

desiccated QdHCl powder with 5 mL of WFI for all

the 10 vials. Subsequently, the entire contents (50 mL

in total) were transferred into an empty 50 mL sterile

and clean vial. A short administration tubing set was

installed on an infusion bag, and 15 mL of the QdHCl

solution was transferred using a 20 mL syringe into

the bag. A 100 mL vesical instillation syringe was

lled with 15 mL of quinine solution and locked

with a special cap. Another 50 mL infusion bag was

completely emptied with a 50 mL syringe and the

remaining QdHCl solution in the 50 mL vial was

transferred with the help of a transfer-set into this

bag. Finally, all the materials were collected in seven

separate plastic bags (quinine vials, two infusion bags,

vesical instillation syringe, other operational syringes,

covering gloves, absorbent working pad and small

wipes used to avoid aerosolization during solution

retrieval from the vials).

The spots of the QdHCl solution on the working pad

were counted under UV light. The contamination on

the external surface of the objects was measured by the

previously developed quantitative method. The correl-

ation between rates of contamination (expressed in

Sadeghipour et al. 59

by guest on May 18, 2014 opp.sagepub.com Downloaded from

cumulated quantities of contamination in mL) and the

operators years of experience was evaluated.

Results

Development and validation of the quantification

of the tracer

The LOD and the LOQ of the spectrouorimetric

method were determined at 0.008 mM and 0.025 mM,

corresponding to a contamination of 0.05 and 0.15 mL

of a 0.1 M solution of QdHCl, respectively.

The linearity was tested in the range of 0.11 mM.

The correlation coecients (r) obtained from the plot

of experimental values as a function of theoretical

values were always greater than 0.9985. It was observed

that the intercepts and the slopes were not signicantly

dierent from 0.00 and 1.00, respectively (Student t-

test, P<0.05). Thus, the method provided a linear

response without systematic errors (xed or relative).

Repeatability and reproducibility were calculated as

relative standard deviations (RSD): repeatability results

were in the range of 2.15.0% (0.1 mM) and 0.82.0%

(1.0 mM) and reproducibility results were in the range of

2.6% (0.1 mM) and 1.1% (1.0 mM) for the six replicate

determinations.

Development and validation of the recovery of the

tracer from the contaminated devices

For the immersion method, with a contamination of 1

or 5 mL of the 0.1 M solution diluted in 500 mL, the

nal concentration remained in the linearity limits vali-

dated previously. The recovery rates for each device are

presented in Table 1.

Development of the operators validation protocol

The rst tests were performed with nine operators in

simulated working conditions (fume hood). They con-

rmed the feasibility of the recovery method, while

giving a preliminary overview of the contamination

rate for each operator. Further, they also permitted

the improvement of the protocol for the validation of

the operators in the real conditions of a sterile BSC

class III.

The preliminary results for the rate of contamin-

ations extracted from the bags and the gloves (mL) as

well as the spots detected on the working pad are pre-

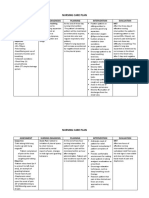

sented in Figure 1.

Operators validation protocol

The procedure was applied by 20 dierent operators

during 28 validation sessions. Some operators per-

formed twice the full procedure. For each session, the

total contamination rates measured on the surfaces of

the material and the number of spots left observed on

the working pad is presented in Figure 2.

The mean cumulated quantities of contamination at

the end of the whole procedure (duration: minimum

45 min, maximum 60 min) were 6.2 mL (0.623.8) and

>10 spots (020), which was considered as high.

No signicant correlation was observed between the

contamination rate (mL) and the operators experience

(years) (Figure 3).

Discussion

A simple method was developed to measure the rates of

contamination during the preparation of cytotoxics

using a novel tracer, which targeted the spillage

during the production process. It was observed that

the protocol was easy to implement in any facility

and was an important support to the quality assurance

of the operators training.

The results showed signicant contamination rates

with a large inter-individual variability, which con-

rmed the interest of the conducted experiment. In

most of the validation sessions (22/28), the contamin-

ation rates on the devices were less than the mean value.

However, for the spots, only seven of them could be

considered as clean (zero spot) and more than half had

a high contamination. In the real-life scenario, the

working pads were changed after each production ses-

sion (maximum of 1.5 h), according to the operating

procedures. There was no strong relationship between

the contaminant quantity collected on the surface of the

dierent devices and the number of spots detected on

the working pad, as shown in Figure 2. The number of

spots was high for one third of the operators having

Table 1. Recovery rates of the tracer from the contaminated

devices at low and high contamination levels.

Day

1 mL (n 6) 5 mL (n 6)

Recovery

(%)

RSD

(%)

Recovery

(%)

RSD

(%)

Infusion bags

1 96 2.0 97 1.3

2 107 2.3 99 2.3

3 101 6.2 100 4.9

Mean recovery (%) 101 99

Gloves

1 103 6.3 100 4.8

2 108 6.1 102 1.2

3 102 6.1 97 2.8

Mean recovery (%) 104 100

RSD: relative standard deviation.

60 Journal of Oncology Pharmacy Practice 19(1)

by guest on May 18, 2014 opp.sagepub.com Downloaded from

0

.

6

0

.

6

0

.

7

1

.

1

1

.

2

1

.

7

1

.

7

1

.

8

2

.

0

2

.

3

2

.

83

.

3

4

.

2

4

.

3

4

.

5

4

.

7

4

.

7

5

.

0

5

.

2

5

.

3

5

.

4

6

.

17

.

4

1

3

.

3

1

7

.

3

2

0

.

0

2

3

.

5

2

3

.

8

6

.

2

0.0

5.0

10.0

15.0

20.0

25.0

1 2 5 3 4 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

C

o

n

t

a

m

i

n

a

t

i

o

n

q

u

a

n

t

i

t

y

[

L

]

M

e

a

n

c

o

n

t

a

m

n

a

t

i

o

n

Validation Sessions

SPOTS

MEDIUM

LOW

ZERO

HIGH

SPOTS : Low : 1 -5 ; Medium : 6 -10 ; High : 11-20

Figure 2. Contamination rate of the operators for the validation sessions (20 different operators participated to these 28 validation

sessions).

0

.

4

4

.

0

5

.

4

7

.

9

0

.

0

0

.

0

0

.

0

0

.

0

2

.

7

0

1

2

3

4

5

6

7

8

9

10

3 4 5 6 1 2 7 8 9

C

o

n

t

a

m

i

n

a

t

i

o

n

q

u

a

n

t

i

t

y

[

L

]

Operators

SPOTS

LOW

ZERO

SPOTS : Low : 1 - 5 ; Medium : 6 - 10 ; High : 11-20

Figure 1. Preliminary results of the contamination rate of the operators for the validation development phase at low and high

contamination levels.

Sadeghipour et al. 61

by guest on May 18, 2014 opp.sagepub.com Downloaded from

low surfaces contamination. It showed that most of the

operators had to learn to manage the nal preparation

contamination and the working site contamination.

No signicant correlation was observed between the

years of experience of the operators and the contamin-

ation rate, even if all contamination quantities over

10 mL were related to the operators with 5 or less

years of experience (Figure 3). This suggested that spe-

cic individualized training is necessary to control

chemical contamination and that the working appro-

priateness is not automatically obtained after several

years of activity.

The present method in comparison to some of the

previous studies,

35,37,43

using tracers to set the general

scoring and validation of the sta, focused more on the

quantitative and detailed evaluation of their cleanli-

ness. The nal goal was to identify the more contam-

inating operators, review their training and through

comparison, decrease the mean contamination rate

over time. At rst glance, the results obtained could

be considered as an acceptable level of contamination.

However, according to the very strict 0.1 mL limit of the

Georgiadi et al. study, the results could be considered

to be extremely high.

35

As both conclusions remain

very subjective and as the protocols cannot be directly

compared, there is a diculty in interpreting the

observed contamination rates in terms of risk and

xing an acceptable limit. In the context of the Food

and Drug Administration specications for the estab-

lishment of cleaning validation methods, some limits

have been proposed by industry representatives.

44

These include analytical detection levels (10 PPM), bio-

logical activity levels (1/1000 of the normal therapeutic

dose), and organoleptic levels (no visible residue).

45

If

these limits are applied to the contamination levels of

the operators, the potential risk associated with the

mean value of 6.2 mL would depend on the pharmaco-

logical activity of the active ingredient of the prepared

cytotoxic drug.

For instance, for 5-uorouracil with a daily dose of

1000 mg, the acceptable 1/1000 limit corresponded to

1 mg or 20 mL of contamination for a usual 50 mg/mL

solution. For the tested operators, the contamination

was equal to ca. 0.031.2 mg. It should be noted that if

the measured contamination of a relatively low active

substance such as 5-uorouracil is acceptable for 90%

of the operators, then, for two operators, a new specic

training to learn cleaner working procedures and reval-

idation would be mandatory.

Conversely, with a highly active cytotoxic substance

such as vincristine with a daily dose of 2 mg, the accept-

able 1/1000 limit would correspond to 2 mg or 2 mL of

contamination for a usual 1 mg/mL solution. In the

present case, the contamination is below the acceptance

limit for only 8 of 28 sessions. Thus, the training of a

majority of the operators would have to be revised.

The two examples are helpful for evaluating

the limits of the acceptance criteria for the contamin-

ation levels. However, an absolute risk level for the

operators could not be clearly set up. Large-scale stu-

dies such as Monitoring-Eekt-Studie fu r Wischproben

in Apotheken (MEWIP

46

or monitoring-eect study for

wiping samples in pharmacies) are used for evaluating

the surface contamination of Carcinogenic, mutagenic,

toxic for reproduction (CMR) substances in pharma-

cies preparing cytotoxic injectable drugs in Germany.

25.0

20.0

15.0

10.0

5.0

0.0

0 2 4 6

Experience (Years)

C

o

n

t

a

m

i

n

a

n

t

Q

u

a

n

t

i

t

y

(

m

L

)

y = 0.3727x + 8.1294

R

2

= 0.0488

8 10 12 14

Figure 3. Correlation between years of experience and contamination rate of the operators.

62 Journal of Oncology Pharmacy Practice 19(1)

by guest on May 18, 2014 opp.sagepub.com Downloaded from

These help to establish the average limits and the

statistical milestones by benchmarking. This is an inter-

esting approach that can be applied to the present pro-

cedure when a larger number of results will be

accumulated.

The present validation protocol oers an eective

answer for the important issue of chemical security of

the operators by following the well-known schemes of

media-ll tests for microbiological contamination.

Thus, the implementation of such validation protocols

in other hospital pharmacies preparing cytotoxic inject-

able drugs parallel to the mandatory media-ll valid-

ation tests for operators would help to standardize the

preparation methods. Further, it would also help to

decrease the contamination levels through the improve-

ment of the operating procedures, not only from a

microbiological point of view but also regarding the

hazardous drugs contamination.

This protocol can also be used to check the appro-

priateness of the devices used for preparing the inject-

able cytotoxic drugs. Further, it can be used to easily

evaluate whether some of these devices could be con-

sidered as a closed-system, as regard the chemical

contamination.

The present study does not set any objective limit for

the acceptable level of contamination. Thus, the ana-

lysis of these results cannot be directly correlated to the

risks for the operators health. However, they provide

rather a quantitative indicator for the contamination

level and a tool available to conduct education pro-

grams, in a continuing improvement spirit. In our set-

ting, we considered that any operator having a

contamination level above the mean level is a candidate

for a new training program.

Conclusion

QdHcl solution, as a simulating working solution, is

an ideal tracer for testing the contamination during

the preparation of cytotoxic injectable drugs. As

a non-hazardous marker, it is easy to detect using a

sensitive method. Further, it is also invisible to the

naked eye.

The present validation method helps in testing all

operators at least once per year. The obtained results

show how the hospital pharmacy sta has successfully

or not mastered the control of the chemical contam-

ination. Every new operator should also be tested after

the initial training to verify the ability to prepare cyto-

toxic drugs in a safe and professional manner.

In future, applying this protocol to other hospitals

could facilitate better evaluation of the mean contam-

ination level. In addition, this benchmarking could also

permit the standardization and improvement of the

operating procedures to decrease the chemical

contamination of the nal preparation and the produc-

tion sites.

Funding

This research received no specic grant from any funding

agency in the public, commercial, or not-for-prot sectors.

References

1. Takada S. Principles of chemotherapy safety procedures.

Clin Tech Small Anim Pract 2003; 18: 7374.

2. Baldo P, Bertola A, Basaglia G, et al. A centralized

pharmacy unit for cytotoxic drugs in accordance with

italian legislation. J Eval Clin Pract 2007; 13: 265271.

3. Descoutures JM. Preparation of antineoplastic agents.

Ann Pharm Fr 2006; 64: 716.

4. Touroude P and Gosso F. The centralization of cytotoxic

preparations. Isolator technology. RBM News 1999; 21:

7683.

5. Baker ES and Connor TH. Monitoring occupational

exposure to cancer chemotherapy drugs. Am J Health

Syst Pharm 1996; 53: 27132723.

6. Bos RP and Sessink PJ. Biomonitoring of occupational

exposures to cytostatic anticancer drugs. Rev Environ

Health 1997; 12: 4358.

7. Connor TH, Anderson RW, Sessink PJ, et al. Surface

contamination with antineoplastic agents in six cancer

treatment centers in Canada and the United States. Am

J Health Syst Pharm 1999; 56: 14271432.

8. Crauste-Manciet S, Sessink PJ, Ferrari S, et al.

Environmental contamination with cytotoxic drugs in

healthcare using positive air pressure isolators. Ann

Occup Hyg 2005; 49: 619628.

9. Dranitsaris G, Johnston M, Poirier S, et al. Are health care

providers who work with cancer drugs at an increased risk

for toxic events? A systematic review and meta-analysis of

the literature. J Oncol Pharm Pract 2005; 11: 6978.

10. Ensslin AS, Huber R, Pethran A, et al. Biological moni-

toring of hospital pharmacy personnel occupationally

exposed to cytostatic drugs: urinary excretion and cyto-

genetics studies. Int Arch Occup Environ Health 1997; 70:

205208.

11. Ensslin AS, Stoll Y, Pethran A, et al. Biological monitor-

ing of cyclophosphamide and ifosfamide in urine of hos-

pital personnel occupationally exposed to cytostatic

drugs. Occup Environ Med 1994; 51: 229233.

12. Favier B, Gilles L, Desage M, et al. Analysis of cyclo-

phosphamide in the urine of antineoplastic drugs hand-

lers. Bull Cancer 2003; 90: 905909.

13. Hedmer M, Georgiadi A, Bremberg ER, et al. Surface

contamination of cyclophosphamide packaging and

surface contamination with antineoplastic drugs in a

hospital pharmacy in Sweden. Ann Occup Hyg 2005; 49:

629637.

14. Kiffmeyer T and Hadtstein C. Handling of chemothera-

peutic drugs in the OR: hazards and safety consider-

ations. Cancer Treat Res 2007; 134: 275290.

15. Leboucher G, Serratrice F, Bertholle V, et al. Evaluation

of platinum contamination of a hazardous drug

Sadeghipour et al. 63

by guest on May 18, 2014 opp.sagepub.com Downloaded from

preparation area in a hospital pharmacy. Bull Cancer

2002; 89: 949955.

16. Mason HJ, Morton J, Garfitt SJ, et al. Cytotoxic drug

contamination on the outside of vials delivered to a hos-

pital pharmacy. Ann Occup Hyg 2003; 47: 681685.

17. Monfort P, Georget S, Vigneron J, et al. Contamination

chimique du conditionnement primaire de me dicaments

cytotoxiques. J de PharmClin 2001; 20.

18. Nygren O and Lundgren C. Determination of platinum in

workroom air and in blood and urine from nursing staff

attending patients receiving cisplatin chemotherapy. Int

Arch Occup Environ Health 1997; 70: 209214.

19. Roberts S, Khammo N, Mcdonnell G, et al. Studies on

the decontamination of surfaces exposed to cytotoxic

drugs in chemotherapy workstations. J Oncol Pharm

Pract 2006; 12: 95104.

20. Schmaus G, Schierl R and Funck S. Monitoring surface

contamination by antineoplastic drugs using gas chroma-

tography-mass spectrometry and voltammetry. Am J

Health Syst Pharm 2002; 59: 956961.

21. Sessink PJ, Anzion RB, Van Den Broek PH, et al.

Detection of contamination with antineoplastic agents

in a hospital pharmacy department. Pharm Weekbl Sci

1992; 14: 1622.

22. Sessink PJ, Boer KA, Scheefhals AP, et al. Occupational

exposure to antineoplastic agents at several departments

in a hospital. Environmental contamination and excre-

tion of cyclophosphamide and ifosfamide in urine of

exposed workers. Int Arch Occup Environ Health 1992;

64: 105112.

23. Sessink PJ and Bos RP. Drugs hazardous to healthcare

workers. Evaluation of methods for monitoring occupa-

tional exposure to cytostatic drugs. Drug Saf 1999; 20:

347359.

24. Sessink PJ, Friemel NS, Anzion RB, et al. Biological and

environmental monitoring of occupational exposure of

pharmaceutical plant workers to methotrexate. Int Arch

Occup Environ Health 1994; 65: 401403.

25. Sessink PJ, Kroese ED, Van Kranen HJ, et al. Cancer

risk assessment for health care workers occupationally

exposed to cyclophosphamide. Int Arch Occup Environ

Health 1995; 67: 317323.

26. Sessink PJ, Van De Kerkhof MC, Anzion RB, et al.

Environmental contamination and assessment of expos-

ure to antineoplastic agents by determination of cyclo-

phosphamide in urine of exposed pharmacy technicians:

is skin absorption an important exposure route? Arch

Environ Health 1994; 49: 165169.

27. Turci R, Sottani C, Ronchi A, et al. Biological monitor-

ing of hospital personnel occupationally exposed to anti-

neoplastic agents. Toxicol Lett 2002; 134: 5764.

28. Ziegler E, Mason HJ and Baxter PJ. Occupational expos-

ure to cytotoxic drugs in two UK oncology wards. Occup

Environ Med 2002; 59: 608612.

29. Acampora A, Castiglia L, Miraglia N, et al. A case study:

surface contamination of cyclophosphamide due to work-

ing practices and cleaning procedures in two italian hos-

pitals. Ann Occup Hyg 2005; 49: 611618.

30. Connor TH, Sessink PJ, Harrison BR, et al. Surface con-

tamination of chemotherapy drug vials and evaluation of

new vial-cleaning techniques: results of three studies. Am

J Health Syst Pharm 2005; 62: 475484.

31. Pethran A, Schierl R, Hauff K, et al. Uptake of antineo-

plastic agents in pharmacy and hospital personnel. Part I:

Monitoring of urinary concentrations. Int Arch Occup

Environ Health 2003; 76: 510.

32. Guetens G, De Boeck G, Wood M, et al. Hyphenated

techniques in anticancer drug monitoring. I. Capillary gas

chromatography-mass spectrometry. J Chromatogr A

2002; 976: 229238.

33. Turci R, Sottani C, Spagnoli G, et al. Biological and

environmental monitoring of hospital personnel exposed

to antineoplastic agents: a review of analytical methods.

J Chromatogr B Analyt Technol Biomed Life Sci 2003;

789: 169209.

34. Tjaden UR and De Bruijn EA. Chromatographic analysis

of anticancer drugs. J Chromatogr 1990; 531: 235294.

35. Georgiadi A, Ramme E, Wretman C, et al. How to create

acceptable working conditions for hospital pharmacy

staff when preparing cytotoxic drugs. EJHP 2004; 10:

240242.

36. Smart PL and Laidlaw IMS. An evaluation of some

fluorescent dyes for water tracing. Water Resour Res

1977; 13: 1533.

37. Harrison BR, Godefroid RJ and Kavanaugh EA.

Quality-assurance testing of staff pharmacists handling

cytotoxic agents. Am J Health Syst Pharm 1996; 53:

402407.

38. Spivey SM and Connor TH. Determining sources of

workplace contamination with antineoplastic drugs and

comparing conventional IV drug preparation with a

closed system. Hosp Pharm 2003; 38: 5.

39. Geisler A, Andersen E and Vedso S. The cooperation of

patients with depression during drug treatment. A study

using quinine as a tracer. Ugeskr Laeger 1968; 130:

18031806.

40. Murphy KR, Ruiz GM, Dunsmuir WT, et al. Optimized

parameters for fluorescence-based verification of ballast

water exchange by ships. Environ Sci Technol 2006; 40:

23572362.

41. Vial J and Jardy A. Experimental comparison of the dif-

ferent approaches to estimate LOD and LOQ of an

HPLC method. Anal Chem 1999; 71: 26722677.

42. Mason HJ, Blair S, Sams C, et al. Exposure to antineo-

plastic drugs in two UK hospital pharmacy units. Ann

Occup Hyg 2005; 49: 603610.

43. Favier B, Gilles L and Latour J-F. Mise en place dun

syste` me de valuation des manipulateurs dans une unite de

reconstitution de cytotoxiques. J Pharm Clin 2003; 22:

107112.

44. Points to consider for cleaning validation. Technical report

no. 29. PDA, Parental Drug Association. PDA J Pharm

Sci Technol 1998; 52: 123.

45. Guide to inspections validation of cleaning processes. 1993,

US Food and Drug Administration.

46. Heinemann A, Kiffmeyer T, Stu tzer H, et al.

Monitoringeffekt-studie fu r wischproben in apotheken.

Ko ln: Berufsgenossenschaft fu r Gesundheitsdienst und

Wohlfahrtspflege (BGW), 2008.

64 Journal of Oncology Pharmacy Practice 19(1)

by guest on May 18, 2014 opp.sagepub.com Downloaded from

You might also like

- Medical Ethics and Law (Questions and Answers) Prof. Ahmed Ammar PDFDocument15 pagesMedical Ethics and Law (Questions and Answers) Prof. Ahmed Ammar PDFRabia Khaira100% (2)

- American Journal of Infection ControlDocument8 pagesAmerican Journal of Infection ControlRizky AdipratamaNo ratings yet

- Review Article: Pre-Analytical Phase in Clinical Chemistry LaboratoryDocument8 pagesReview Article: Pre-Analytical Phase in Clinical Chemistry Laboratorymuthia aninditaNo ratings yet

- Microbial Control and Monitoring in Aseptic Processing CleanroomsDocument13 pagesMicrobial Control and Monitoring in Aseptic Processing Cleanroomsmustea_ana9616100% (1)

- Asma Agentes LimpiezaDocument8 pagesAsma Agentes LimpiezaAnonymous GfPSYi4nNo ratings yet

- Formal I MetDocument38 pagesFormal I MetKomkep MHJSNo ratings yet

- Isothermal Nucleic Acid Amplification For Point of Care DevicesDocument27 pagesIsothermal Nucleic Acid Amplification For Point of Care DevicespascalcrawNo ratings yet

- Preanalytical Requirements of Urinalysis: Biochemia Medica February 2014Document17 pagesPreanalytical Requirements of Urinalysis: Biochemia Medica February 2014MARIO ALVARADONo ratings yet

- PHSS Annual Members Conference 2014: Book Online Phss - Co.uk/eventsDocument3 pagesPHSS Annual Members Conference 2014: Book Online Phss - Co.uk/eventsTim SandleNo ratings yet

- A Novel Outlook On Detecting Microbial Contamination in Cosmetic Products - AnalysDocument10 pagesA Novel Outlook On Detecting Microbial Contamination in Cosmetic Products - AnalysVioleta GrigorasNo ratings yet

- Cleaning Validation To Be Developed From This Article On Metformin TabletsDocument9 pagesCleaning Validation To Be Developed From This Article On Metformin TabletsPramba Kumar AhujaNo ratings yet

- Calibration and Use of Syringe PumpsDocument5 pagesCalibration and Use of Syringe PumpsJason SantosoNo ratings yet

- Direct Identification of Prohibited Substances in Cosmetics and Foodstuffs Using Ambient Ionization On A Miniature Mass Spectrometry SystemDocument21 pagesDirect Identification of Prohibited Substances in Cosmetics and Foodstuffs Using Ambient Ionization On A Miniature Mass Spectrometry SystemI. Sandoval TorresNo ratings yet

- Basic Laboratory Procedure in Clinical BacteriologyDocument175 pagesBasic Laboratory Procedure in Clinical BacteriologyWoro Hapsari WahyuningrumNo ratings yet

- Implementation and Use of Point of Care C R 2022 Journal of The American MedDocument11 pagesImplementation and Use of Point of Care C R 2022 Journal of The American MedPuttryNo ratings yet

- BFS-FRIEDMAN - Contamination Case Studies Paper PDFDocument9 pagesBFS-FRIEDMAN - Contamination Case Studies Paper PDFipatoffNo ratings yet

- Iupac Oos Oot PDFDocument33 pagesIupac Oos Oot PDFGATOMICONo ratings yet

- Covid-19 A Panoramic View (Part 3) : European Journal of Pharmaceutical and Medical ResearchDocument10 pagesCovid-19 A Panoramic View (Part 3) : European Journal of Pharmaceutical and Medical ResearchRuchiNo ratings yet

- Jurnal Internasional Aso PDFDocument8 pagesJurnal Internasional Aso PDFAffrilinaNo ratings yet

- Gerpac 2014 ReviewDocument3 pagesGerpac 2014 ReviewTim SandleNo ratings yet

- IntroductionDocument6 pagesIntroductionSheila LópezNo ratings yet

- Artículo BiochemDocument16 pagesArtículo BiochemViankis García100% (1)

- Environmental Monitoring by Surface Sampling For CytotoxicsDocument14 pagesEnvironmental Monitoring by Surface Sampling For CytotoxicsDarlianaMelloSouzaNo ratings yet

- 1 s2.0 S0026265X21002733 MainDocument8 pages1 s2.0 S0026265X21002733 MainArtem KulikovNo ratings yet

- 2009 JHI Methodstoevaluate RotterDocument10 pages2009 JHI Methodstoevaluate RotterAzizah Alya RaihanNo ratings yet

- EFLM WG Preanalytical Phase Opinion Paper Local Validation of Blood Collection Tubes in Clinical LaboratoriesDocument7 pagesEFLM WG Preanalytical Phase Opinion Paper Local Validation of Blood Collection Tubes in Clinical LaboratoriesSiskawati SuparminNo ratings yet

- Some Practical Examples of Method Validation in The Analytical LaboratoryDocument10 pagesSome Practical Examples of Method Validation in The Analytical LaboratoryImad AghilaNo ratings yet

- Ketin Sonja, Radmila Maksimovic, Rade Biocanin, Mithat AsoticDocument9 pagesKetin Sonja, Radmila Maksimovic, Rade Biocanin, Mithat Asoticstefanov_sonjaNo ratings yet

- эффективность УФ обработкиDocument23 pagesэффективность УФ обработкиGrigoryNo ratings yet

- Comparison of Four Skin Preparation Strategies To Prevent Catheter-Related Infection in Intensive Care Unit (CLEAN Trial) : A Study Protocol For A Randomized Controlled TrialDocument7 pagesComparison of Four Skin Preparation Strategies To Prevent Catheter-Related Infection in Intensive Care Unit (CLEAN Trial) : A Study Protocol For A Randomized Controlled TrialKanana AdiwijayaNo ratings yet

- Final Publishable JRP Summary For Hlt07 Medd Metrology For Drug DeliveryDocument6 pagesFinal Publishable JRP Summary For Hlt07 Medd Metrology For Drug DeliveryRocío NapanNo ratings yet

- Pharmacy 10 00101Document12 pagesPharmacy 10 00101bertNo ratings yet

- BJMP 2012 5 1 A512Document5 pagesBJMP 2012 5 1 A512maslikanNo ratings yet

- Evaluasi Nilai KritisDocument10 pagesEvaluasi Nilai KritisLaboratorium RSUD KEMAYORANNo ratings yet

- Impact of ATP Bioluminescence Cleaning VerificatioDocument10 pagesImpact of ATP Bioluminescence Cleaning Verificatiodyatlovvadim65No ratings yet

- Validation of Innovative Food Microbiological Methods According To The EN ISO 16140 StandardDocument11 pagesValidation of Innovative Food Microbiological Methods According To The EN ISO 16140 StandardVinay KumarNo ratings yet

- MentanceDocument8 pagesMentanceArt RemoNo ratings yet

- The Preanalytical Phase - Past Present and Future.: Annals of Clinical BiochemistryDocument9 pagesThe Preanalytical Phase - Past Present and Future.: Annals of Clinical BiochemistryArturo Eduardo Huarcaya OntiverosNo ratings yet

- Villacís2019 Article EfficacyOfPulsed-xenonUltravioDocument6 pagesVillacís2019 Article EfficacyOfPulsed-xenonUltravioByron JimenezNo ratings yet

- Development of A New Field-Deployable RTQPCR Workflow For COVID19 DetectionDocument10 pagesDevelopment of A New Field-Deployable RTQPCR Workflow For COVID19 DetectionGreater K. OYEJOBINo ratings yet

- Corticosteroids For Bacterial Keratitis - The Steroids For Corneal Ulcers Trial (SCUT)Document8 pagesCorticosteroids For Bacterial Keratitis - The Steroids For Corneal Ulcers Trial (SCUT)Bela Bagus SetiawanNo ratings yet

- Fs Reliability Operators Ejhp p07Document5 pagesFs Reliability Operators Ejhp p07marcelo1315No ratings yet

- External Ventriculostomy-Associated Infection Reduction After Updating A Care BundleDocument10 pagesExternal Ventriculostomy-Associated Infection Reduction After Updating A Care Bundled4rkgr455No ratings yet

- Neumaier 1998 Fundamentals Quality Assessment Molecular Ampli MethodDocument15 pagesNeumaier 1998 Fundamentals Quality Assessment Molecular Ampli MethodMaya RustamNo ratings yet

- (415 421) V9N3PTDocument8 pages(415 421) V9N3PTNasr Biomedical ImpexNo ratings yet

- Increasing The Robustness of Biopharmaceutical PrecipitationDocument9 pagesIncreasing The Robustness of Biopharmaceutical Precipitation6gtnsvdw72No ratings yet

- Molecular Diagnosis of Dermatophyte InfectionsDocument10 pagesMolecular Diagnosis of Dermatophyte Infectionsabznaim420No ratings yet

- Microbiological Pharmaceutical Quality Control Labs (7 - 93) - FDADocument8 pagesMicrobiological Pharmaceutical Quality Control Labs (7 - 93) - FDAArmando SaldañaNo ratings yet

- Alternative Microbiological Methods in The Pharmaceutical IndustryDocument9 pagesAlternative Microbiological Methods in The Pharmaceutical Industryltrevino100No ratings yet

- Gestión de Las Fases de Pre y Post-Analítica de La PDFDocument12 pagesGestión de Las Fases de Pre y Post-Analítica de La PDFUlises Saldías RoaNo ratings yet

- Microbiological Pharmaceutical Quality Control LabsDocument7 pagesMicrobiological Pharmaceutical Quality Control LabsDede Kizzy Black100% (1)

- Microbiology of Drinking Water Part 8 PseudomonasDocument40 pagesMicrobiology of Drinking Water Part 8 PseudomonasDavid WoodsNo ratings yet

- Pan American Society For Clinical Virology Position Statement On Fda Oversight of Laboratory-Developed Tests (LDTS)Document5 pagesPan American Society For Clinical Virology Position Statement On Fda Oversight of Laboratory-Developed Tests (LDTS)fdablogNo ratings yet

- Tchol H Met CobasDocument22 pagesTchol H Met CobasGhaith MaaniNo ratings yet

- Automation in MicrobiologyDocument63 pagesAutomation in Microbiologytummalapalli venkateswara raoNo ratings yet

- ATP Meter TestDocument8 pagesATP Meter TestDirector ResearchNo ratings yet

- Point of Care TestingDocument40 pagesPoint of Care TestingPrincewill Seiyefa100% (1)

- Icmr-National Institute For Research in Tuberculosis-ChennaiDocument27 pagesIcmr-National Institute For Research in Tuberculosis-Chennaidhanya sriNo ratings yet

- JMV 25666Document5 pagesJMV 25666Nathalia LedesmaNo ratings yet

- Effective microbiological sampling of food processing environments (1999)From EverandEffective microbiological sampling of food processing environments (1999)No ratings yet

- Cleaning and disinfection of food factories: a practical guideFrom EverandCleaning and disinfection of food factories: a practical guideNo ratings yet

- Detail Produk Epson l360Document2 pagesDetail Produk Epson l360Abdul Rakhmat MuzakkirNo ratings yet

- Mr. RakhmatDocument4 pagesMr. RakhmatAbdul Rakhmat MuzakkirNo ratings yet

- 1215 2513 1 SM PDFDocument13 pages1215 2513 1 SM PDFtary_nuryanaNo ratings yet

- Set OkDocument1 pageSet OkAbdul Rakhmat MuzakkirNo ratings yet

- NCP BSN 3rd Yr Psychiatric WardDocument9 pagesNCP BSN 3rd Yr Psychiatric WardMary Margarett BoadoNo ratings yet

- Classification of Age-Related CataractDocument16 pagesClassification of Age-Related CataracttataNo ratings yet

- CINAHL With Full Text: Database Coverage ListDocument172 pagesCINAHL With Full Text: Database Coverage ListArisa VijungcoNo ratings yet

- "Sandwich" Bone Augmentation Technique-Rationale and Report of Pilot Cases PDFDocument14 pages"Sandwich" Bone Augmentation Technique-Rationale and Report of Pilot Cases PDFHector MurilloNo ratings yet

- MRCGP CSA Exam Quick Reference Guide Explaining A Diagnosis Communication Skills (CSAprep - CSA Course)Document4 pagesMRCGP CSA Exam Quick Reference Guide Explaining A Diagnosis Communication Skills (CSAprep - CSA Course)MRCGP CSA Prep Courses / CSA courseNo ratings yet

- Progressive Care Units - Different But The SameDocument9 pagesProgressive Care Units - Different But The SameJHNo ratings yet

- Technology in MedicineDocument2 pagesTechnology in MedicineMaría Alejandra Uparela CastroNo ratings yet

- Bruce and Naughton ProtocolDocument13 pagesBruce and Naughton ProtocolDheeraj RaiNo ratings yet

- Introduction To ChemotherapyDocument28 pagesIntroduction To ChemotherapyShivsharan B. DhaddeNo ratings yet

- Healthcare Quality Account 2021-22Document98 pagesHealthcare Quality Account 2021-22Adeuga ADEKUOYENo ratings yet

- Cipla LTDDocument6 pagesCipla LTDSana AnjumNo ratings yet

- A Drug Study On: Furosemide TabletDocument7 pagesA Drug Study On: Furosemide TabletRaijenne VersolaNo ratings yet

- Lamar State College - Port Arthur Upward Mobility Program RNSG 2361 Clinical Care PlanDocument5 pagesLamar State College - Port Arthur Upward Mobility Program RNSG 2361 Clinical Care PlanAlmaHernandezNo ratings yet

- Astasthana Pariksha - A Diagnostic Method of Yogaratnakara and Its Clinical ImportanceDocument17 pagesAstasthana Pariksha - A Diagnostic Method of Yogaratnakara and Its Clinical Importancenarayana asso100% (1)

- Lilley: Pharmacology and The Nursing Process, 7th EditionDocument8 pagesLilley: Pharmacology and The Nursing Process, 7th EditionthubtendrolmaNo ratings yet

- Chameli Devi Group of Institutions, IndoreDocument13 pagesChameli Devi Group of Institutions, IndoreVinay ProjectNo ratings yet

- Haemodynamic Monitoring: WWW - Vygon.co - UkDocument12 pagesHaemodynamic Monitoring: WWW - Vygon.co - UkJuita yuliarniNo ratings yet

- Special Beds For Positioning ClientDocument66 pagesSpecial Beds For Positioning ClientCarmela Lacsa DomocmatNo ratings yet

- Medical Form & Document ChecklistDocument2 pagesMedical Form & Document Checklistrjadhav0075No ratings yet

- 4th Quarter MAPEH (HEALTHDocument6 pages4th Quarter MAPEH (HEALTHaldrinepangilinan0111No ratings yet

- IBRDocument2 pagesIBRAde HermawanNo ratings yet

- Allergic Rhinitis and Its Impact On Asthma (Allergy, 2008)Document153 pagesAllergic Rhinitis and Its Impact On Asthma (Allergy, 2008)incaudasemperNo ratings yet

- Intubation ProcedureDocument5 pagesIntubation ProcedurePurwadi SujalmoNo ratings yet

- Nursing Care Plan: Assessment Nursing Diagnosis Planning Intervention EvaluationDocument4 pagesNursing Care Plan: Assessment Nursing Diagnosis Planning Intervention EvaluationGiddel Guerra PapellerasNo ratings yet

- Reimbursement Claim Form VidalDocument3 pagesReimbursement Claim Form Vidalsarv2kNo ratings yet

- Sumitted By: Jeanne Laicca M. de Guzman Sumitted To: Dr. M Yrna O. Balangue BSN: 1Y2-1 Teaching PlanDocument3 pagesSumitted By: Jeanne Laicca M. de Guzman Sumitted To: Dr. M Yrna O. Balangue BSN: 1Y2-1 Teaching PlanJanaica JuanNo ratings yet

- Financial Analysis of Ad Din FoundationDocument53 pagesFinancial Analysis of Ad Din FoundationMd. SaifullahNo ratings yet

- Beg Elem ReadingComprehensionDocument1 pageBeg Elem ReadingComprehensionHelefreitasNo ratings yet

- TotilacDocument4 pagesTotilacOliver Tabag100% (2)