Professional Documents

Culture Documents

Disclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)

Disclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)

Uploaded by

Tanmoy DuttaCopyright:

Available Formats

You might also like

- Structure Loadbearing Crosswall PDFDocument41 pagesStructure Loadbearing Crosswall PDFSKhandelwalNo ratings yet

- Is-909 Underground Fire HydrantDocument9 pagesIs-909 Underground Fire HydrantCharls JamesNo ratings yet

- 8931 PDFDocument27 pages8931 PDFPawan Kumar100% (1)

- Disclosure To Promote The Right To InformationDocument18 pagesDisclosure To Promote The Right To InformationNayan VyasNo ratings yet

- Is 3063-Spring WashersDocument11 pagesIs 3063-Spring Washerspbp2956No ratings yet

- Specification For Fire MonitorDocument4 pagesSpecification For Fire Monitorromdhan88No ratings yet

- Is 13095 1991Document15 pagesIs 13095 1991Surendra MalasaneNo ratings yet

- Is 13349Document20 pagesIs 13349raji357100% (1)

- Is-903 Couplings, Branch Pipe, NozzlesDocument13 pagesIs-903 Couplings, Branch Pipe, NozzlesCharls JamesNo ratings yet

- Is 3063Document11 pagesIs 3063Sumit ShyamalNo ratings yet

- Is 14845-2000Document18 pagesIs 14845-2000Sarbendu Paul100% (1)

- Is 6848 1979Document31 pagesIs 6848 1979ShirishNo ratings yet

- Manual For Glued Insulated Rail Joints (1998) : Government of India Ministry of RailwaysDocument13 pagesManual For Glued Insulated Rail Joints (1998) : Government of India Ministry of RailwaysbinodNo ratings yet

- Is - 14845Document17 pagesIs - 14845mechftpNo ratings yet

- IS 8442.2008.-Water MonitorDocument10 pagesIS 8442.2008.-Water MonitorNikhil GoyalNo ratings yet

- Bureau OF Indian Standards: ( Roup 3Document10 pagesBureau OF Indian Standards: ( Roup 3leua_690001837No ratings yet

- Is 6595 2 1993Document10 pagesIs 6595 2 1993mishraenggNo ratings yet

- Specification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02Document9 pagesSpecification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02GopalMahantaNo ratings yet

- Is 1626 Part 2Document11 pagesIs 1626 Part 2Sheetal JindalNo ratings yet

- Is - 11855 - Guidelines For Design and Use of Different Types of Rubber Seals For Hydraulic GatesDocument8 pagesIs - 11855 - Guidelines For Design and Use of Different Types of Rubber Seals For Hydraulic Gateskiranrauniyar100% (1)

- Is 7332 1 1991 PDFDocument12 pagesIs 7332 1 1991 PDFDeepak AroraNo ratings yet

- Is 14845 2000 PDFDocument21 pagesIs 14845 2000 PDFmethusalakannanNo ratings yet

- Suction Hose Couplings For Fire Fighting Purposes - SpecificationDocument9 pagesSuction Hose Couplings For Fire Fighting Purposes - SpecificationDebajani DekabaruahNo ratings yet

- Is 12943 Brass Cable GlandsDocument10 pagesIs 12943 Brass Cable Glandsnirbhay111No ratings yet

- Is 902 Fire Suction Hose CouplingDocument12 pagesIs 902 Fire Suction Hose CouplingNanu PatelNo ratings yet

- Is.628.1993 Pedal AssemblyDocument10 pagesIs.628.1993 Pedal AssemblydamansidhuNo ratings yet

- Butterfly Valves For General Purposes (: Indian StandardDocument12 pagesButterfly Valves For General Purposes (: Indian Standardrahul caddNo ratings yet

- 5290 Landing ValveDocument11 pages5290 Landing ValveSachin KumarNo ratings yet

- Disclosure To Promote The Right To InformationDocument12 pagesDisclosure To Promote The Right To Informationhumayun mdNo ratings yet

- 1729Document52 pages1729praj24083302No ratings yet

- Is 10611 1983Document16 pagesIs 10611 1983Rakesh RanjanNo ratings yet

- Double-Acting Spring Hinges - Specification (Third Revision)Document10 pagesDouble-Acting Spring Hinges - Specification (Third Revision)ssaurav89No ratings yet

- Specification For Air Cylinders: IPSS: 1-02-026-18Document13 pagesSpecification For Air Cylinders: IPSS: 1-02-026-18AzifahNo ratings yet

- GangwayDocument14 pagesGangwaysurnaikNo ratings yet

- Mil F 6218CDocument11 pagesMil F 6218CHabu1zeroNo ratings yet

- Disclosure To Promote The Right To InformationDocument23 pagesDisclosure To Promote The Right To InformationSantosh KumarNo ratings yet

- Specification For Machine For AbrasionDocument3 pagesSpecification For Machine For AbrasionSajidAliKhanNo ratings yet

- 510 Open ExamDocument17 pages510 Open Examariyamanjula2914100% (1)

- Valves SpecificationDocument13 pagesValves Specificationkselvan_1No ratings yet

- 1601366241948-5 Glued Joint Manual 1998Document33 pages1601366241948-5 Glued Joint Manual 1998Piyush MauryaNo ratings yet

- Is 9890 (Specification For General Purpose Ball Valves)Document3 pagesIs 9890 (Specification For General Purpose Ball Valves)Selvakpm06No ratings yet

- MNL 043 02Document70 pagesMNL 043 02George Iankov100% (2)

- Is 13095 1991 PDFDocument15 pagesIs 13095 1991 PDFrahul caddNo ratings yet

- MEDC13 (4938) P3 - Specification For First Aid Hose-Reel For Fire FightingDocument6 pagesMEDC13 (4938) P3 - Specification For First Aid Hose-Reel For Fire FightingKg Chit ZawNo ratings yet

- Manual For Fusion Welding of Rails by The Alumino-Thermic ProcessDocument49 pagesManual For Fusion Welding of Rails by The Alumino-Thermic ProcesskrischaeverNo ratings yet

- Specification - 2023 02 01 09 02 41Document10 pagesSpecification - 2023 02 01 09 02 41Chinnaraj SNo ratings yet

- IS 2486 Part-2 (1989)Document28 pagesIS 2486 Part-2 (1989)tanto_deep_15No ratings yet

- Disclosure To Promote The Right To InformationDocument34 pagesDisclosure To Promote The Right To InformationKashyap PatelNo ratings yet

- BFV STD - SpecdamperDocument39 pagesBFV STD - Specdamperkselvan_1No ratings yet

- Is 458 2003Document39 pagesIs 458 2003somnathjoyNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Glenfield Air ValvesDocument16 pagesGlenfield Air ValvesTanmoy DuttaNo ratings yet

- CI Tamper Proffe-ModelDocument1 pageCI Tamper Proffe-ModelTanmoy DuttaNo ratings yet

- Non Return Valve: Type 4010 and 4010HDDocument3 pagesNon Return Valve: Type 4010 and 4010HDTanmoy DuttaNo ratings yet

- STI/14846/1 Dec.2000Document8 pagesSTI/14846/1 Dec.2000Tanmoy DuttaNo ratings yet

- Product Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Document5 pagesProduct Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Tanmoy DuttaNo ratings yet

- K.P.Mondal & Sons: Works: Dasnagar, Howrah Amta Road, Howrah, West BengalDocument1 pageK.P.Mondal & Sons: Works: Dasnagar, Howrah Amta Road, Howrah, West BengalTanmoy DuttaNo ratings yet

- PM Is 13095Document5 pagesPM Is 13095Tanmoy DuttaNo ratings yet

- Datasheet Type 40104010HD enDocument3 pagesDatasheet Type 40104010HD enTanmoy DuttaNo ratings yet

- IS 5312 Part 1 Product ManualDocument6 pagesIS 5312 Part 1 Product ManualTanmoy DuttaNo ratings yet

- CI Foot Valve-ModelDocument1 pageCI Foot Valve-ModelTanmoy DuttaNo ratings yet

- Dual Plate 800 NB-ModelDocument1 pageDual Plate 800 NB-ModelTanmoy DuttaNo ratings yet

- CI Sluice Valve With ActuatorDocument1 pageCI Sluice Valve With ActuatorTanmoy DuttaNo ratings yet

- Stud Details: K.P.Mondal & SonsDocument1 pageStud Details: K.P.Mondal & SonsTanmoy DuttaNo ratings yet

- DI Air Release Valve-ModelDocument1 pageDI Air Release Valve-ModelTanmoy DuttaNo ratings yet

- K.P.Mondal&Sons: N No. of Hole H Hole DiaDocument1 pageK.P.Mondal&Sons: N No. of Hole H Hole DiaTanmoy DuttaNo ratings yet

- 300 NRV ModelDocument1 page300 NRV ModelTanmoy DuttaNo ratings yet

- MaskDocument1 pageMaskTanmoy DuttaNo ratings yet

- Spec For Sluice GatesDocument4 pagesSpec For Sluice GatesTanmoy Dutta100% (1)

- Air Valve Kinetic 80 MM With ISVDocument1 pageAir Valve Kinetic 80 MM With ISVTanmoy DuttaNo ratings yet

- Data Sheet: (Approved by ClientDocument3 pagesData Sheet: (Approved by ClientTanmoy DuttaNo ratings yet

- Air Valve Kinetic 80 MM SS-ModelDocument1 pageAir Valve Kinetic 80 MM SS-ModelTanmoy DuttaNo ratings yet

- Air Valve Kinetic-ModelDocument1 pageAir Valve Kinetic-ModelTanmoy DuttaNo ratings yet

- Is 3589Document2 pagesIs 3589Tanmoy DuttaNo ratings yet

- Guarantee Certificate: (AN ISO 9001: 2008 COMPANY)Document1 pageGuarantee Certificate: (AN ISO 9001: 2008 COMPANY)Tanmoy DuttaNo ratings yet

- Tendernotice 2Document222 pagesTendernotice 2Tanmoy DuttaNo ratings yet

- Rising Type Sluice Valve With Hand Wheel Operated: Upto 150Mm SizeDocument1 pageRising Type Sluice Valve With Hand Wheel Operated: Upto 150Mm SizeTanmoy DuttaNo ratings yet

- NRV ModelDocument1 pageNRV ModelTanmoy DuttaNo ratings yet

- Functional Specification For Deck CraneDocument31 pagesFunctional Specification For Deck Craneaiyubi20% (1)

- NEW Sales Tax Invoice - 2023-07-27T164634.549Document1 pageNEW Sales Tax Invoice - 2023-07-27T164634.549Saadat IrfanNo ratings yet

- Final Firefly Reading & Writing AnswerDocument70 pagesFinal Firefly Reading & Writing AnswerVamshidhar ReddyNo ratings yet

- Spider-81 Hardware Spec 7.7Document7 pagesSpider-81 Hardware Spec 7.7KonradNo ratings yet

- SOM016 - Hook Release System For Life Boats. Norsafe TOR mk2.Document20 pagesSOM016 - Hook Release System For Life Boats. Norsafe TOR mk2.arfaoui salimNo ratings yet

- 4.phases in Agricultural DevelopmentDocument16 pages4.phases in Agricultural Developmentakuril100% (3)

- 9852 1880 01 Maintenance Instructions ROC L7CR IIDocument102 pages9852 1880 01 Maintenance Instructions ROC L7CR IIphongNo ratings yet

- NT Seq DatabaseDocument4 pagesNT Seq DatabaseDevinder KaurNo ratings yet

- Synchronous Generators: Instructional ObjectivesDocument18 pagesSynchronous Generators: Instructional Objectivessanthosh2009No ratings yet

- (12942) Sheet Chemical Bonding 4 Theory eDocument8 pages(12942) Sheet Chemical Bonding 4 Theory eAnurag SinghNo ratings yet

- Gas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11ADocument4 pagesGas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11AĐình Sơn HoàngNo ratings yet

- Bata Shoe Company (Bangladesh) Ltd.Document6 pagesBata Shoe Company (Bangladesh) Ltd.Vurdalack666No ratings yet

- Ebffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full ChapterDocument53 pagesEbffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full Chapterkevin.carter759100% (3)

- Control of Spinal Anesthesia-Induced Hypotension in Adults - PMCDocument14 pagesControl of Spinal Anesthesia-Induced Hypotension in Adults - PMCAkash SharmaNo ratings yet

- AAB2000C1Document11 pagesAAB2000C1marcos morillo0% (1)

- Palliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Document10 pagesPalliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Dante Nathaniel FajardoNo ratings yet

- Carbohydrates Lecture Bio024Document17 pagesCarbohydrates Lecture Bio024mike angelo albacieteNo ratings yet

- Behaviour of Hollow Core Slabs Under Point LoadsDocument17 pagesBehaviour of Hollow Core Slabs Under Point LoadsVálter LúcioNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Absolute Priority Based Cell ReselectionDocument11 pagesAbsolute Priority Based Cell ReselectionNeoRa Ndivo RamsNo ratings yet

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- Price List 2018Document20 pagesPrice List 2018Imml TasbiNo ratings yet

- Stages of SleepDocument2 pagesStages of SleepCamilia Hilmy FaidahNo ratings yet

- Mec R2018Document227 pagesMec R2018Kishore Kumar RNo ratings yet

- Base On Solid-Works Design of Compact High EfficieDocument15 pagesBase On Solid-Works Design of Compact High EfficieGorgeNo ratings yet

- Nepra ManualDocument60 pagesNepra Manualabdulwasay_bzuNo ratings yet

- Maharastra State Board of Technical Education MumbaiDocument23 pagesMaharastra State Board of Technical Education MumbaiMayuresh PadekarNo ratings yet

- Case 621F, 721F Tier 4 Wheel Loader AxelDocument15 pagesCase 621F, 721F Tier 4 Wheel Loader AxelJose CarmonaNo ratings yet

- BEL PE Question Papers For ECE With Answers - 6 Knowledge AddaDocument14 pagesBEL PE Question Papers For ECE With Answers - 6 Knowledge AddaVishwanand ThombareNo ratings yet

Disclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)

Disclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)

Uploaded by

Tanmoy DuttaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Disclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)

Disclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)

Uploaded by

Tanmoy DuttaCopyright:

Available Formats

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 5290 (1993): Specification for landing valves [CED 22:

Fire Fighting]

I S 62.80 : 1993

1

\

hdian Standard

LANDING VALVES - SPECIFICATION

f Third Revision )

UDC 621*646*2 : 614.843~3

BURE

MANAK

AU OF INDIAN STANDARDS

BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

0 BI S 1993

November 1993

Price Group 4

( Reaffirmed 2003 )

Fire Fighting Sectional Committee, CED 22

FOREWORD

This Indian Standard ( Third Revision ) was adopted by the Bureau of Indian Standards, after the draft

finalized by the Fire Fighting Sectional Committee had been approved by the Civil Engineering Division

Council.

The landing valves are sometimes also referred to as internal hydrants because these are usually fitted

inside the buildings for wet hydrant system. These are primarily intended for being installed at the

staircase landing at each floor level, from where fire-hose could be laid out by the fire brigade or trained

men for fighting fire on the concerned floor. Because of this, the design of these valves has to be

compact so as not to cause any obstruction to the passage where these may be installed.

Landing valves may be installed in different ways and altitudes and for yielding varying output of water,

requiring different shape and sizes. Two types which are mostly used have been covered in this standard.

The landing valves when used for sea water should not be made of aluminium alloy.

This standard was first published in 1969 and revised subsequently in 1977 and 1983. This revision has

been prepared in order to update the provisions of the standard which has been done for incorporating

the amendments and modified figures.

The composition of committee responsible for the preparation of this standard is given in Annex B.

For the purpose of deciding whether a particular requirement of this standard is complied with, the

final value, observed or calculated, expressing the result of a test or analysis, shall be rounded off in

accordance with IS 2 : 1960 Rules for rounding off numerical values ( revised). The number of sign&

cant places retained in the rounded off value should be the same as that of the specified value in this

standard.

IS 5290 : 1993

I ndian Standard

LANDING VALVES - SPECIFICATION

( Third Revision )

1 SCOPE 3 GENERAL

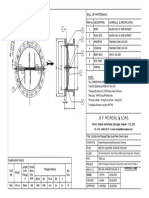

This standard lays down the requirements regard-

ing materials, shape, dimensions, and The landing valves assembly shall consist of

performance requirements of two types

of valve(s) (see Fig. 1 and 2 ), instantaneous female

landing valves. outlet(s) ( see Fig. 3 ) and blank cap(s) ( see

2 REFERENCES

Fig. 4).

The Indian Standards listed in Annex A are

necessary adjuncts to this standard.

NOTE - The instantaneous female outlets may also

be manufactured as a part of landing valves.

G

THREADS AS l$s,G l$ OF

1S. 2643CPtI '

THREADS AS PER SO 24x5

OF fS :4694 -1966 FOR

LENGTH OF 50mm min.

A LENGTH OF

,-Ck!ECH

NUT

NOTES

I Outlet is fixed with instantaneous female coupling with blank cap ( see Fig. 3 and 4 1.

2 Tolerance where not specified shall be f 05 mm.

3 Pre-circle diameter of flange shall match with respective diameter of pipe that is, 75 mm and 100 mm

respectively.

All dimensions in millimetres.

FIG. 1 LANDING VALVE SINGLE OUTLET ( TYPE A )

1

JS 5290 : 1993

HANDWHEEL J

iHREADS G3 AS PER

15??61? ( PI I )- 1975

Imm min.

OF IS: 1643 (Pt il-iQi5

FOR A LENGTH OF

+-- e 100------d

G 2x------~ j 1.

NOTES

1 Both outlets are fixed with instantaneous female coupling with blank caps ( see Fig. 3 and 4 ).

2 Dimensions of the component parts, that is, handwheel, spindle and other attachments are

same as in Fig. 1.

3 Tolerance where not specified shall be 1 05 mm.

All dimensions in millimetres.

FIG. 2 LANDING VALVE DOUBLE HEAD OU~LBT ( TYPE B )

4 MATERIALS

4.1 The valve body, bonnet, stop valve, check

nut, instantaneous female outlet and blank cap

shall be made either of leaded-tin-bronze eon-

forming to Grade LTB-2 of IS 318 : 1981 or

aluminium alloy conforming to 19 designation

4225, 4450 and 4600 of IS 617 : 1975. All alumi-

nium and zinc alloy shall be of die casting only.

4.X.1 Zinc-aluminium alloy ( copper 0.5 to 1.5

percent, aluminium 10.5 to 11.5 percent, mag-

nesium 0.015 to 0.03 percent and balance zinc )

or stainless steel designatton 04Cr17NiMOa con-

forming to IS 6529 : 1972. All aluminium and

zinc alloy shall be of die casting only.

4.2 The valve spindle shall be made of brass rod

conforming to IS 320 : 1980 or IS 319 : 1989 for

use with body of leaded-tin-bronze and of

stainless steel conforming to IS 6603 : 1972 for

use with body of aluminium or zinc alloy or

stainless steel.

4.3 The handwheel shall be made of mild steel

conforming to IS 1030 : 1989 or cast irou con-

forming to IS 210 : 1978.

4.4 Washers, gaskets shall be made of rubber

conforming to IS 937 : 1981 or leather conform-

ing to IS 581 : 1976. Gland packing shall be of

asbestos thread conforming to IS 4687 : X980.

4.5 The spring shall be of phosphor wire con-

forming to IS 7608 : 1987 for copper alloy

landing valve and stainless steel wire conform-

ing to IS 6528 : 1972 for aluminium alloy, zinc

alloy and stainless steel landing valves.

5 TYkS AND DIMENSIONS

5.1 The landing valves shall be of two types as

under:

a) Type A - Landing valve single outlet

( see Fig. 1 ).

b) Type B

- Landing valve double head

with double outlet ( see Fig. 2 ).

5.2 The shane and dimensions of each type are

given in Fig: 1 to 4.

5.2.1 Tooth shall be

material conforming

1985.

forged from forged brass

to grade FLB of IS 6912 :

2

IS 5290 : 1993

RELEASE TYPE

4 CAM -TOOTH

NOTES

*Rectangular Hole 128_!:2 . 254 + $i

GO

I The tolerance where not specified shall be i 05 mm.

2 The lug may also be the part of the main body.

All dimensions in miilimetres.

FIG. 3 INSTANTANEOUS FBMALB OUTLJW

8

6 FINISH

7 PERFORMANCE REQUIREMENTS

6.1 All parts shall be of good finish, clear of

7.1 Water Tightness Test for the Valve

burrs and sharp edges. All castings shall be of

clean and sound and shall be free from plugging,

The stop valve shall be fully closed by screwing

down the spindle. A hydrostatic pressure of

welding or repair of any defects.

1.4 MN/m* ( 14 kgf/cma ) shall then be applied

6.2 The valve top except the face of the flange

to each valve on its inlet side. There shall be-no

leakage through the valve and its seat.

and the instantaneous outlet shall be painted

fire red of shade No. 536 of IS 5 : 1978. The 72 Hydrostatic Pressure Test

outside of instantaneous outlet shall be highly Each assembled unit shall be subjected to a

polished. The handwheel shall be painted black.

Paints shall conform to IS 2932 : 1974.

hydrostatic pressure of 2-I MN/mms ( 21 kgf/

cm3 ) with the valve open and outlet closed for

3

IS 5290 : 1993

VENT HOLE 962

R I.5 APPROX

NOTE - The tolerances where not specified shall be i. 05 mm.

.411 dimensions in millimetres.

FIG. 4 BLAKK CAP

a period of 2.4 minutes for the purpose of locat-

ing porosity III the casting. When so tested, it

shall not fail or show any sign of leakage either

through the valve body or through the gland of

the spindle.

NOTE -During the hydrostatic pressure test, the

initial drops of water should be allowed up to the

period of proper rubber sealing with the male blank

cap.

7.3 Flow Test

Water shall be discharged through Ihe valve

assembly and its flow shall be measured using a

flow meter or V-notch. The flow shall be not less

than 900 litres per minute at 0.7 MN/m ( 7 kgf/

ema ) for Type A and 1 800 litres per minute at

Q-7 MN/m2 ( 7 kgf/cmP ) for Type B provided

the feed to the valves, for the purpose of this

test, is not less than these figures. It shall be a

type test.

8 MARKING

8.1 Each assembled valve shall be cEearly and

rel;E;;ently marked on the valve body, as

-0 :

a) Manufacturers name or trade-mark,

b) Code letter indicating the rype of valve

( inscribing type of instantaneous female

outlet ), and

c) Year of manufacture.

8.1.1 BI S Certification Marking

The valve astembly may also be marked with the

Standard Mark. Details are available with the

Bureau of Indian Standards.

4

IS No.

5 : 1978

210 : 1978

318 : 1981

319 : 1989

320 : 1980

581 : 1976

617 : 1975

937 : 19s1

ANNEX A

( Clause 2 ).

LIST OF REFERRED INDIAN STANDARDS

Title

Colours for ready mixedpaints

and enamels ( third revision )

Specification for grey iron

castings ( third revision )

Specification for leaded-tin-

bronze ingots and castings

( seconn revision )

Specifi cation for free cutting

brass bars, rods and sections

( fourfh revision )

Specification for high tensile

brass rods and sections (other

than forgings stock ) ( second

rev&ion )

Specification for vegetable

tanned hydraulic leather

( second revision )

Specification for aluminium

and aluminium alloy ingots

and castings for general engi-

neering purposes ( second

revision )

Specification for washers for

water fittings for fire fighting

purposes ( second revisian )

1s 5290!. 19!%3

IS No.

1030 : 1989

2643

( Fart 1 ) : 1975

2932 : 1974

4687 : 1980

6528 : 1972

6529 : 1972

6603 : 1972

6912 : 1985

7608 : 1987

Title

Specification for carbon steel

castings for general engineer;

ing purposes (fourth rej Mm ) ,

Dimensions for. pipe threads

for fastening purposes: Part 1

Basic profile and dimensions

(first revision )

Specification for enamel, syn-

thetic, exterior (a) undercoat-

ing, (b) finishing ( jTrst revi-

sion )

Specification for gland pack-

ing asbestos (Jirst revision,)

Specification for stain!ess

steel wire

Specification for sta@iess

steel blooms, billets and slabs

for forging

Specification for stainbxs

steel bars and flats

Specification for copper and

copper alloy forgings .stock

and forgings ( firsr revision )

Specification for. phosphor

bronze wrre for general engi-

neering purposes (fjrst revi-

sion )

Ifls 5290 : 1993

ANNEX B

( Foreword )

COMMITTEE COMPOSITION

Fire Fighting Sectional Committee, CED 22

RGpreSell~i~g

Ministry of Home Affairs

hssrsT~~'f INSPMJ'~OIL~ENEBAL( RPSF) Ministry of Railways

AS~IEITADTT SEUUKITY OEEIUE~ ( A6rarcnlc )

SIIHI S. N. CIX~XRAX~ORTY

Tariff Advisory Committee, Madras

SHRI B. L. CHOWDIII~Y

Shea B. K. SIPPY c Allernole 1

Oil and Natural Gas Commission, Dehra Dua

DEE+JTY DIUEUTOR ( Alternate )

DIEEU~O~ 0~ EQuIP&%J%!

SENXOR FIRE OR~ICIER ( Alternate )

DIREQT~TR GFHERAL OF FIRESERVICE

,' ;

DE~.TW DLRE~~TOR ( Allernatc)

SHRI P. N. Gnoslr

S.&I 0.. P. GOS~IN

SHBIJ. S._J~Xsnm*dl

Snsl G:, GNANRAJ ( AUernate)

M& C&N B. $. BATAVIA

.!$&I A.. K. Snnr ( Aflernate )

SHKI P. k.f~hNhT~

SHR~ D. .J. Iior_~rnriv~

SHIU ASIIOK SIIAEMA

SJ IRI A. K. NANDI ( Alternate )

SIII:~R. c. SEfARMA

Lh:, T. P. SHAEMA

DJ; A. 1;. GLPTA ( Atterna!e )

SXRX Sux-rr, DAS

S~inr M. C. P. S~sna ( AIternate ;

SL!ILI Tun>T SUR

&cl D. N~oc+r ( .4itJrnnte )

Sllllr<J. N. VAKIL

STTUI K. R~rr ( dl!crcale j

S-r!r,X T. \ OC+ESWA11A

Srr~iJoa~ TAIWY ( L4!l~t?tair )

SUIII Y. R. TANEJ A

Director ( cliv Engg )

Eureka Firetech Pvt Ltd, Bombay

Urban Development Departmt nt, Govemr;ent of Maharashtra,

Bombay

Municipal Corporation of Deihi, Delhi

Bhabha Atomic Research Centre ( Fire Service 1, Bombay

Home Department ( Fire Service ), Government of Tamil ~aJu

National Airport Authority, New Delhi

Home ( Police Department 1. Government of Andhra Pradt2!:.

Hyderabad

In personal capacity (J-1916 Chitranjan Park, &L Delhi j

CPWD ( Electrical ), New Delhi

Steelnge Industries Ltd ( Minimax Division !, Bombay

Ministry of Defence ( DIFR :

Jaya Shree Textiles 6: Industriq Kishra

Municipal Corporation of Greater Bombay ( Bon1 bay Fire Brigade ) I

Bombay

Fire & Safety Applicanceo Co, Calcutta

Avon Services ( Production and Agencies ) Pvt Ltd, Bombay

In personal capacity ( C..231 &Yamashar Aparlments, Ma~ur Bihar, Ptia .c lj

.New Delhi )

Steel Authority of India ( Bokaro Steel Plant ), New Delhi

Central Industrial Security Force, Ministry of Home Affairs

West Bengal Fire Services, Calcutta

The Institution of Fire Engineers ( India j. Neir Delhi

Ministry of Defence ( DGI 1

Vijay Fire Protection Systems Pvt Ltd, Bomba)

Directorate General of Technical Development, Ntaw Delhi

Kooverji Devshi & Co Pvt Ltd. Bombay

Newagr Industries, Gujarat

Mathar Er Platt ( India ) Ltd, Bombay

Directorate General of Supplies and Disposals, New Delhi

Central Building Research Institute ( CSIR ), Roorkee

Metallurgical & Engineering Consultants ( India ) Ltd, Ranchi

Surex Production Rc Sales Pvt Ltd, Calcutta

Tariff Advisory Committee, Bombay

Steel Authority of India Ltd ( Rourkela Steel Plant ), Rourke1.r

Director Gei:eral, BIS ( Ex-@is Member )

Swr HFMST KUMAK

Joint Director , Civil l?ngg ), 1:li

( Continued on pase I ;

IS 5290 : 1993

Water Fittir;g for Fire Fighting Purposes Subcommittee, CED 22 : 1

Snn~ 2. U. Is7,,4x ( dlfernale )

SHRI S. 1~. DI~ERX

Ministr:u of Befence, R & D Organization, New Delhi

Madras Refineries Ltd, Manali, Madras

Tariff Advisory Committee, Madras

Municipal Corporation of Delhi ( Delhi Fire Service j, Nc;v Delhi

Ministry of Home Affairs, New Delhi

Chhatriya Rubber & Chemical Industries, Bombay

jaya Shree Textiles, Rishra ( West Bengal )

Municipal Corporation of Bombay ( Bombay Fire Brigado ).

Bombay

The Institution of Fire Engineers ( India ), New Delhi

Directorate of Standardization, Ministry of Defense, New Delhi

Engineers India Ltd, New Delhi

Indian Petrochemicals Corporation Ltd, bombay

Kooverji Devshi & Co Pvt Ltd, Bombay

Newage Industries, Surender Nagar, Gujarat

Devraj Engineers, Abmadabad

Mather & Platt India Etd, Bombay

Steel Authority of India Ltd I Rorrrkela Steel Plant ), Roiirb*:la

--

Standard Mark

The use of the Standard Mark is governed by the provisions of the Bureau of I ndian

Standards Act, 1986 and the Rules and Regulations made thereunder. The Standard Mark on

products covered by an Indian Standard conveys the assurance that they have been

produced to comply with the requirements of that standard under a well defined system of

inspection, testing and quality control which is devised and supervised by BIS and operated

by the producer. Standard marked products are also continuously checked by BIS for con-

formity to that standard as a,further safeguard. Details of conditions under which a licence

for the use of the Standard Mark may be granted to manufacturers or producers may be

obtained from the Bureau of Indian Standards,

Ba+ytu of Iudifn Standards

RIS is a statutory i,nstjtuii.on established under the &reau OJ &&VI Standards Act, 19&6 t.o promote

harmonious development of the activities of standardization, marking and quality certification of goods

and attending to connected matters in the country.

Coppright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any

form without the prior permission in writing of BIS. This does not preclude the free use, in the course

of implementing the standard, of necessary details, such as symbols and sizes, type or grade

designations. Enquiries relating to copyright be addressed to the Director ( Publications ), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also

reviewed periodically; a standard along with amendments is reaffirmed when such review indicates that

no than es are needed; if the review indicates that changes are needed, it is taken up for revision.

Users of f ndian Standards should ascertain that they are in possession of the latest amendments or

edition by referring to the latest issue of BIS Handbook and Standards Monthly Additions.

Comments on this Indian Standard may be sent to BIS giving the following reference:

Dot No. CED 22 ( 5274 )

Amendments Issued Since Yublication

Amend No. Date of Issue Text Affected

.

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002

Telephones : 331 01 31, 331 13 75

Regional Officer I

Central I Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Telegrams : Manaksanstha .

( Common to all office8 )

Telephone

I

331 01 31 I

331 13 75 _

Eastern : l/14 C. I. T. Scheme VII M, V. I. P. Road, Maniktola

CALCUTTA 700054

Northern ; SC0 445-446, Sector 35-C, CHANDIGARH 160036

I?

Southern : C. I. T. Campus, IV Croor Road, MADRAS 600113

1

31 84 99, 37 85 61

37 86 26, 37 86 62

I

53 38 43, 53 16 40 r

53 23 84 .

I

235 02 16, 235 04 42

235 15 19, 235 23 15

Western t Manakalaya, E9 MIDC, Marol, An8heri ( East )

BOMBAY 400093

632 92 95, 632 78 58

632 78 91, 632 78 92

Brancha r AHMADABAD. BANGALORE. BHOPAL. BHUBANESHWAR.

COIMBATORE. FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD.

JAIPUR. KANPUR. LUCKNOW. PATNA. THIRUVANANTHAPURAM.

AMENDMENT NO. 1 JUNE 1994

TO

IS 5290 : 1993 LANDING VALVES - SPECIFICATION

( Third Revision )

( Page 2, clause 4.1.1, line 4 ) - Read 04Cr17Ni12MO~ for

04Cr17NiMOz.

(Pqy 3, clause 7.2, line 2 ) - Read 2.1 MN/m for 2.1

MN/mm

2,

.

(CED22)

Reprography Unit, BE. New Delhi. India

AMENDMENT NO. 2 AUGUST 1999

TO

IS 5290 : 1993 LANDING VALVES - SPECIFICATION

( Third He vision )

[ Page 2, clrrlrse 41.1 (we n/so Anzendnmt No. 1 ) ] - Substitute Grade

1 and 4 of IS 3444 : 1957 foi- 04017Ni12M02 conforming lo IS 6529 :

1972.

( Pflge 2, clr11se 4.4 ) - Substitute seat valvefor gaskets.

(Purge 2, clmse 52.1 ) -Substitute the following for the existing clause:

55.1 Tooth, seat valve shall be forged from forged brass material conComing

to grade FLB of IS 6912 : 19% or 1s 291 : 19S9. Blank cap shall be of ABS

plastics.

( Purge 5, Annex A ) - Insert the following at appropriate places:

IS 291 : 1989 Nav,al brass rods and sections for machining purposes.

IS 3444 : 19S7 Corrosion resistant alloy steel and nickel base castings for

general applications.

(CED22)

Kepropphy Unit, BIS, New Delhi, India

AMENDMENT NO. 3 FEBRUARY 2001

TO

IS 5290:1993 LANDING VALVES SPECIFICATION

(Pa ge 2 , clause 4 . 1 ):

a) Delete valve body from first line.

b) Insert the following at the end of clause:

Valve body shall be conforming to IS 3444: 1987 Corrosion resistant

alloy steel and nickel base castings for general applications .

( Page 2 , clause 4 . 1 . 1 ) Substitute Grade 1 and 4 of IS 3444:

1987 @ 04Cr17Ni12M02 conforming to IS 6529:1972.

(Page 2, clause 4.4) Substitute seat valve for gaskets.

(Page 2, clause 5 . 2 . 1 ) Substitute the following for the existing clause:

Tooth, seat valve shall be forged from forged brass material conforming to

Grade FLB of IS 6912: 1985 or IS 291:1989, Blank eap shall be of ABS

plastics.

(Page 5, Annex A ) Insert the following at the appropriate place

IS 291:1989 Naval brass rods and sections for machining purposes.

IS 3444:1987 Corrosion resistant alloy steel and nickel brass castings for

general applications

( CED 22 )

Reprography Unit, BIS, New Delhi, India

i-

AMENI)MENT NO. 4 OCTOBER 2002

~.

-

TO

IS 5290:1993 LANDING VALVES SPECIFICATION

}-

( Third Revision)

[ Page 2, clause 4.1, line 1 ( see also Amendment No. 3 )] Insert the

following in the beginning:

The valve body

( Page 2, clause 4.1, line 7 ) Delete and zinc alloy

( CED 22 )

ReprographyUniq BIS, New Delhi, India

,,>

.,.,

,..8

.,+=-

AMENDMENT NO. 5 MAY 2005

TO

IS 5290:1993 LANDING VALVES SPECIFICATION

( Third Revision)

[ Page 2, clause 4.1 (see also Amendments No. 3 and 4) ] Substitute the following for the existing:

The valve body, bonnet, stop valve, check nut, instantaneous female outlet and blank cap shall be made either of

leaded-tin-bronze conforming to Grade LTB 2 of IS 318 or aluminium alloy conforming to IS Designation 4225,4450 and

4600 ofIS617 or stainless steel Grade 1 and 4 of IS 3444. All aluminium and zinc alloy shall be of die casting only.

( Page 2, clause 4.4) Substitute seat washer for gaskets.

( Page 3, Fig. 3 ) Substitute the following figure for the existing:

LUG-TWIST RELEASE TYPE

(SEE B FOR PULL OUT TYPE)

71.+1

A f-min

T

I

25:;;

I

J_

14 min.

T

@8

K CAM TOOTH

r+l I

THREAOSG Ii

ASPER

w:

15 rein,

IS2643 (Pt. I): 1975 ,

I

-L

40 min.

?

-L

B PULL OUT TYPE LUG

(ALTERNATIVE )

*RwIangular Hole 12.8 +

0.2

x 25.4::;

-0.0

NOTES

1 The tolerance where not specified shall be* 0.5 mm.

2 The lug may also be the part of the main body.

All dimensionsin millirnetres.

FIG. 3 INSTANTANEOUS FEMALE OUTLET

( CED 22 )

,-.

Reprography Unit. BE. New Delhi. India

IS

>

AMENDMENT NO. 6 MAY 2 0 0 6

TO

5 2 9 0 :1 9 9 3 LAND~G VALVES SPEC~CATION

( Thud Rwki on )

Page 2, clause 4.1 ( see also Amendments A70. 3 and 4 ) 1 Add tie

followingat tie end of clau&:

,.

Bl~ cap may&of ABS plastic.

( CED 22 )

Reprography Uni~ BIS, New Delhi, Itiia

.,

6

You might also like

- Structure Loadbearing Crosswall PDFDocument41 pagesStructure Loadbearing Crosswall PDFSKhandelwalNo ratings yet

- Is-909 Underground Fire HydrantDocument9 pagesIs-909 Underground Fire HydrantCharls JamesNo ratings yet

- 8931 PDFDocument27 pages8931 PDFPawan Kumar100% (1)

- Disclosure To Promote The Right To InformationDocument18 pagesDisclosure To Promote The Right To InformationNayan VyasNo ratings yet

- Is 3063-Spring WashersDocument11 pagesIs 3063-Spring Washerspbp2956No ratings yet

- Specification For Fire MonitorDocument4 pagesSpecification For Fire Monitorromdhan88No ratings yet

- Is 13095 1991Document15 pagesIs 13095 1991Surendra MalasaneNo ratings yet

- Is 13349Document20 pagesIs 13349raji357100% (1)

- Is-903 Couplings, Branch Pipe, NozzlesDocument13 pagesIs-903 Couplings, Branch Pipe, NozzlesCharls JamesNo ratings yet

- Is 3063Document11 pagesIs 3063Sumit ShyamalNo ratings yet

- Is 14845-2000Document18 pagesIs 14845-2000Sarbendu Paul100% (1)

- Is 6848 1979Document31 pagesIs 6848 1979ShirishNo ratings yet

- Manual For Glued Insulated Rail Joints (1998) : Government of India Ministry of RailwaysDocument13 pagesManual For Glued Insulated Rail Joints (1998) : Government of India Ministry of RailwaysbinodNo ratings yet

- Is - 14845Document17 pagesIs - 14845mechftpNo ratings yet

- IS 8442.2008.-Water MonitorDocument10 pagesIS 8442.2008.-Water MonitorNikhil GoyalNo ratings yet

- Bureau OF Indian Standards: ( Roup 3Document10 pagesBureau OF Indian Standards: ( Roup 3leua_690001837No ratings yet

- Is 6595 2 1993Document10 pagesIs 6595 2 1993mishraenggNo ratings yet

- Specification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02Document9 pagesSpecification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02GopalMahantaNo ratings yet

- Is 1626 Part 2Document11 pagesIs 1626 Part 2Sheetal JindalNo ratings yet

- Is - 11855 - Guidelines For Design and Use of Different Types of Rubber Seals For Hydraulic GatesDocument8 pagesIs - 11855 - Guidelines For Design and Use of Different Types of Rubber Seals For Hydraulic Gateskiranrauniyar100% (1)

- Is 7332 1 1991 PDFDocument12 pagesIs 7332 1 1991 PDFDeepak AroraNo ratings yet

- Is 14845 2000 PDFDocument21 pagesIs 14845 2000 PDFmethusalakannanNo ratings yet

- Suction Hose Couplings For Fire Fighting Purposes - SpecificationDocument9 pagesSuction Hose Couplings For Fire Fighting Purposes - SpecificationDebajani DekabaruahNo ratings yet

- Is 12943 Brass Cable GlandsDocument10 pagesIs 12943 Brass Cable Glandsnirbhay111No ratings yet

- Is 902 Fire Suction Hose CouplingDocument12 pagesIs 902 Fire Suction Hose CouplingNanu PatelNo ratings yet

- Is.628.1993 Pedal AssemblyDocument10 pagesIs.628.1993 Pedal AssemblydamansidhuNo ratings yet

- Butterfly Valves For General Purposes (: Indian StandardDocument12 pagesButterfly Valves For General Purposes (: Indian Standardrahul caddNo ratings yet

- 5290 Landing ValveDocument11 pages5290 Landing ValveSachin KumarNo ratings yet

- Disclosure To Promote The Right To InformationDocument12 pagesDisclosure To Promote The Right To Informationhumayun mdNo ratings yet

- 1729Document52 pages1729praj24083302No ratings yet

- Is 10611 1983Document16 pagesIs 10611 1983Rakesh RanjanNo ratings yet

- Double-Acting Spring Hinges - Specification (Third Revision)Document10 pagesDouble-Acting Spring Hinges - Specification (Third Revision)ssaurav89No ratings yet

- Specification For Air Cylinders: IPSS: 1-02-026-18Document13 pagesSpecification For Air Cylinders: IPSS: 1-02-026-18AzifahNo ratings yet

- GangwayDocument14 pagesGangwaysurnaikNo ratings yet

- Mil F 6218CDocument11 pagesMil F 6218CHabu1zeroNo ratings yet

- Disclosure To Promote The Right To InformationDocument23 pagesDisclosure To Promote The Right To InformationSantosh KumarNo ratings yet

- Specification For Machine For AbrasionDocument3 pagesSpecification For Machine For AbrasionSajidAliKhanNo ratings yet

- 510 Open ExamDocument17 pages510 Open Examariyamanjula2914100% (1)

- Valves SpecificationDocument13 pagesValves Specificationkselvan_1No ratings yet

- 1601366241948-5 Glued Joint Manual 1998Document33 pages1601366241948-5 Glued Joint Manual 1998Piyush MauryaNo ratings yet

- Is 9890 (Specification For General Purpose Ball Valves)Document3 pagesIs 9890 (Specification For General Purpose Ball Valves)Selvakpm06No ratings yet

- MNL 043 02Document70 pagesMNL 043 02George Iankov100% (2)

- Is 13095 1991 PDFDocument15 pagesIs 13095 1991 PDFrahul caddNo ratings yet

- MEDC13 (4938) P3 - Specification For First Aid Hose-Reel For Fire FightingDocument6 pagesMEDC13 (4938) P3 - Specification For First Aid Hose-Reel For Fire FightingKg Chit ZawNo ratings yet

- Manual For Fusion Welding of Rails by The Alumino-Thermic ProcessDocument49 pagesManual For Fusion Welding of Rails by The Alumino-Thermic ProcesskrischaeverNo ratings yet

- Specification - 2023 02 01 09 02 41Document10 pagesSpecification - 2023 02 01 09 02 41Chinnaraj SNo ratings yet

- IS 2486 Part-2 (1989)Document28 pagesIS 2486 Part-2 (1989)tanto_deep_15No ratings yet

- Disclosure To Promote The Right To InformationDocument34 pagesDisclosure To Promote The Right To InformationKashyap PatelNo ratings yet

- BFV STD - SpecdamperDocument39 pagesBFV STD - Specdamperkselvan_1No ratings yet

- Is 458 2003Document39 pagesIs 458 2003somnathjoyNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Glenfield Air ValvesDocument16 pagesGlenfield Air ValvesTanmoy DuttaNo ratings yet

- CI Tamper Proffe-ModelDocument1 pageCI Tamper Proffe-ModelTanmoy DuttaNo ratings yet

- Non Return Valve: Type 4010 and 4010HDDocument3 pagesNon Return Valve: Type 4010 and 4010HDTanmoy DuttaNo ratings yet

- STI/14846/1 Dec.2000Document8 pagesSTI/14846/1 Dec.2000Tanmoy DuttaNo ratings yet

- Product Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Document5 pagesProduct Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Tanmoy DuttaNo ratings yet

- K.P.Mondal & Sons: Works: Dasnagar, Howrah Amta Road, Howrah, West BengalDocument1 pageK.P.Mondal & Sons: Works: Dasnagar, Howrah Amta Road, Howrah, West BengalTanmoy DuttaNo ratings yet

- PM Is 13095Document5 pagesPM Is 13095Tanmoy DuttaNo ratings yet

- Datasheet Type 40104010HD enDocument3 pagesDatasheet Type 40104010HD enTanmoy DuttaNo ratings yet

- IS 5312 Part 1 Product ManualDocument6 pagesIS 5312 Part 1 Product ManualTanmoy DuttaNo ratings yet

- CI Foot Valve-ModelDocument1 pageCI Foot Valve-ModelTanmoy DuttaNo ratings yet

- Dual Plate 800 NB-ModelDocument1 pageDual Plate 800 NB-ModelTanmoy DuttaNo ratings yet

- CI Sluice Valve With ActuatorDocument1 pageCI Sluice Valve With ActuatorTanmoy DuttaNo ratings yet

- Stud Details: K.P.Mondal & SonsDocument1 pageStud Details: K.P.Mondal & SonsTanmoy DuttaNo ratings yet

- DI Air Release Valve-ModelDocument1 pageDI Air Release Valve-ModelTanmoy DuttaNo ratings yet

- K.P.Mondal&Sons: N No. of Hole H Hole DiaDocument1 pageK.P.Mondal&Sons: N No. of Hole H Hole DiaTanmoy DuttaNo ratings yet

- 300 NRV ModelDocument1 page300 NRV ModelTanmoy DuttaNo ratings yet

- MaskDocument1 pageMaskTanmoy DuttaNo ratings yet

- Spec For Sluice GatesDocument4 pagesSpec For Sluice GatesTanmoy Dutta100% (1)

- Air Valve Kinetic 80 MM With ISVDocument1 pageAir Valve Kinetic 80 MM With ISVTanmoy DuttaNo ratings yet

- Data Sheet: (Approved by ClientDocument3 pagesData Sheet: (Approved by ClientTanmoy DuttaNo ratings yet

- Air Valve Kinetic 80 MM SS-ModelDocument1 pageAir Valve Kinetic 80 MM SS-ModelTanmoy DuttaNo ratings yet

- Air Valve Kinetic-ModelDocument1 pageAir Valve Kinetic-ModelTanmoy DuttaNo ratings yet

- Is 3589Document2 pagesIs 3589Tanmoy DuttaNo ratings yet

- Guarantee Certificate: (AN ISO 9001: 2008 COMPANY)Document1 pageGuarantee Certificate: (AN ISO 9001: 2008 COMPANY)Tanmoy DuttaNo ratings yet

- Tendernotice 2Document222 pagesTendernotice 2Tanmoy DuttaNo ratings yet

- Rising Type Sluice Valve With Hand Wheel Operated: Upto 150Mm SizeDocument1 pageRising Type Sluice Valve With Hand Wheel Operated: Upto 150Mm SizeTanmoy DuttaNo ratings yet

- NRV ModelDocument1 pageNRV ModelTanmoy DuttaNo ratings yet

- Functional Specification For Deck CraneDocument31 pagesFunctional Specification For Deck Craneaiyubi20% (1)

- NEW Sales Tax Invoice - 2023-07-27T164634.549Document1 pageNEW Sales Tax Invoice - 2023-07-27T164634.549Saadat IrfanNo ratings yet

- Final Firefly Reading & Writing AnswerDocument70 pagesFinal Firefly Reading & Writing AnswerVamshidhar ReddyNo ratings yet

- Spider-81 Hardware Spec 7.7Document7 pagesSpider-81 Hardware Spec 7.7KonradNo ratings yet

- SOM016 - Hook Release System For Life Boats. Norsafe TOR mk2.Document20 pagesSOM016 - Hook Release System For Life Boats. Norsafe TOR mk2.arfaoui salimNo ratings yet

- 4.phases in Agricultural DevelopmentDocument16 pages4.phases in Agricultural Developmentakuril100% (3)

- 9852 1880 01 Maintenance Instructions ROC L7CR IIDocument102 pages9852 1880 01 Maintenance Instructions ROC L7CR IIphongNo ratings yet

- NT Seq DatabaseDocument4 pagesNT Seq DatabaseDevinder KaurNo ratings yet

- Synchronous Generators: Instructional ObjectivesDocument18 pagesSynchronous Generators: Instructional Objectivessanthosh2009No ratings yet

- (12942) Sheet Chemical Bonding 4 Theory eDocument8 pages(12942) Sheet Chemical Bonding 4 Theory eAnurag SinghNo ratings yet

- Gas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11ADocument4 pagesGas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11AĐình Sơn HoàngNo ratings yet

- Bata Shoe Company (Bangladesh) Ltd.Document6 pagesBata Shoe Company (Bangladesh) Ltd.Vurdalack666No ratings yet

- Ebffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full ChapterDocument53 pagesEbffiledoc - 204download PDF Logic and Algebraic Structures in Quantum Computing 1St Edition Jennifer Chubb Ebook Full Chapterkevin.carter759100% (3)

- Control of Spinal Anesthesia-Induced Hypotension in Adults - PMCDocument14 pagesControl of Spinal Anesthesia-Induced Hypotension in Adults - PMCAkash SharmaNo ratings yet

- AAB2000C1Document11 pagesAAB2000C1marcos morillo0% (1)

- Palliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Document10 pagesPalliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Dante Nathaniel FajardoNo ratings yet

- Carbohydrates Lecture Bio024Document17 pagesCarbohydrates Lecture Bio024mike angelo albacieteNo ratings yet

- Behaviour of Hollow Core Slabs Under Point LoadsDocument17 pagesBehaviour of Hollow Core Slabs Under Point LoadsVálter LúcioNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Absolute Priority Based Cell ReselectionDocument11 pagesAbsolute Priority Based Cell ReselectionNeoRa Ndivo RamsNo ratings yet

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- Price List 2018Document20 pagesPrice List 2018Imml TasbiNo ratings yet

- Stages of SleepDocument2 pagesStages of SleepCamilia Hilmy FaidahNo ratings yet

- Mec R2018Document227 pagesMec R2018Kishore Kumar RNo ratings yet

- Base On Solid-Works Design of Compact High EfficieDocument15 pagesBase On Solid-Works Design of Compact High EfficieGorgeNo ratings yet

- Nepra ManualDocument60 pagesNepra Manualabdulwasay_bzuNo ratings yet

- Maharastra State Board of Technical Education MumbaiDocument23 pagesMaharastra State Board of Technical Education MumbaiMayuresh PadekarNo ratings yet

- Case 621F, 721F Tier 4 Wheel Loader AxelDocument15 pagesCase 621F, 721F Tier 4 Wheel Loader AxelJose CarmonaNo ratings yet

- BEL PE Question Papers For ECE With Answers - 6 Knowledge AddaDocument14 pagesBEL PE Question Papers For ECE With Answers - 6 Knowledge AddaVishwanand ThombareNo ratings yet