Professional Documents

Culture Documents

R-22 en Chillers

R-22 en Chillers

Uploaded by

vickersOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R-22 en Chillers

R-22 en Chillers

Uploaded by

vickersCopyright:

Available Formats

Overview

HCFC-22 is the worlds most widely used

refrigerant. It serves in both residential and

commercial applications, from small window

units to large water chillers, and everything in

between. Its particular combination of efficien-

cy, capacity and pressure has made it a popu-

lar choice for equipment designers.

Recently, extensive use of HCFC-22 has

made it possible to reduce the use of CFC

refrigerants, because its Ozone Depletion

Potential (ODP) is as much as 95% lower than

CFCs. Nevertheless, it does have some ODP,

so international law set forth in the Montreal

Protocol and its Copenhagen and Vienna

amendments have put HCFC-22 on a phase-

out schedule. In developed countries, produc-

tion of HCFC-22 will end no later than the year

2030. In intervening years, production is

reduced in a series of specified steps.

Detailed phaseout schedules vary from

country to country. In the U.S., HCFC-22 pro-

duction will be frozen at baseline levels on

January 1, 2010, and the production of virgin

refrigerant will be banned unless it is used as

a feedstock for other refrigerants, or in equip-

ment manufactured prior to January 1, 2010.

The countries of the European Community

have adopted even stricter measures.

After the phaseout dates, supplies of

HCFC-22 should still be plentiful thanks to

conservation and recycling techniques devel-

oped for CFCs. For instance, CFC-11 hasnt

been produced since January 1996, but

because of recycling, it is still widely available.

Recycled HCFC-22 should be even more plen-

tiful, because it is more widely used than CFC-

11. It is important to remember that the phase-

out affects only production, not use.

Direct-expansion (DX) chillers are among

the many products that have traditionally uti-

lized HCFC-22. Therefore, owners and speci-

fiers of DX chillers have an obvious interest as

to how the phaseout will impact such chillers.

After all, chillers purchased today will have a

service-life well into the 21st century, when the

phaseout will have begun to take effect.

The impact will vary from country to coun-

try. In countries with a late phaseout date, DX

chillers will be sold with HCFC-22 for some

time to come. In countries with an early phase-

out date, existing DX chillers may never have

to switch refrigerants because of the plentiful

supply of recycled HCFC-22. However, for

new DX chillers to be sold in countries with an

early phaseout date, chiller manufacturers are

developing units which utilize refrigerants other

than HCFC-22.

HCFC-22 Substitutes for DX Chillers

Obviously, new substitutes should possess

what HCFC-22 lacks from an environmental

standpoint, while retaining its good thermody-

namic characteristics. Environmentally, the

ideal candidate must have an ODP of zero

and a low Global Warming Potential (GWP).

Thermodynamic similarity is important when

retrofitting existing chillers; otherwise, capacity

and efficiency may be lost. In new chiller

designs, thermodynamic similarity is less of an

issue because the equipment can be specifi-

cally designed for the replacement refrigerants

particular characteristics.

Several HCFC-22 substitutes have been

identified by the Alternative Refrigerant

Evaluation Program (AREP). This internation-

al, industry-backed program was developed by

major refrigerant suppliers and HVAC manu-

facturers to ensure a broad-based assessment

of HCFC-22 alternatives. Refrigerant data was

shared among the participants to speed test-

ing and replacement recommendations.

Currently, there are four leading replace-

ment candidates: HFC-407C, HFC-404A,

HFC-134a, and HFC-410A.

As an AREP participant, YORK believes all

four HCFC-22 alternatives have merits. Its no

surprise, then, that each refrigerant has been

chosen by at least one manufacturer to

replace HCFC-22 in new DX chillers.

The Impact of the HCFC-22 Phaseout

on Direct-Expansion Chillers

YORK believes

all four HCFC-22

alternatives have

merits.

Unfortunately, having made their refrigerant

choice, some chiller manufacturers are bad-

mouthing the choices of others. At this early

stage of implementing HCFC-22 alternatives,

these disparaging claims cause undue confu-

sion and are a disservice to chiller owners and

specifiers. The evaluation that follows attempts

to give an even-handed analysis of the HCFC-

22 alternatives, so chiller owners and speci-

fiers can make informed decisions.

Properties of HCFC-22 Substitutes

Because all four replacement candidates

are HFCs, their molecules do not include chlo-

rine, so their ODP is zero.

As far as GWP, however, the numbers do

vary. According to the Dupont Internet site,

the GWP ratings are:

HFC-134a: 1300 GWP

HFC-407C: 1600 GWP

HCFC-22: 1700 GWP

HFC-410A: 1890 GWP

HFC-404A: 3750 GWP

While there is a variance in these numbers,

it is not significant. According to the TEWI

(Total Equivalent Warming Impact) formula

being proposed by GWP researchers, there

are two ways in which a water chiller can

affect global warming: refrigerant leaks and

electric-energy consumption. Of the two fac-

tors, electric-energy consumption (or more

specifically, the CO

2

created by the power

plant supplying the electricity) is far more sig-

nificant, accounting for 98 to 99% of a chillers

TEWI. So the refrigerant GWP differences

shown above have such a minuscule impact

on TEWI that they can be effectively ignored.

According to refrigerant manufacturers, all

HCFC-22 substitutes will be available for the

long-term. All are non-flammable and have low

toxicities like HCFC-22. However, their capaci-

ties, efficiencies, and pressures vary, which

affects their application.

Retrofitting Existing Chillers

To be successful in a retrofit situation, a

replacement refrigerant needs to have capaci-

ty, efficiency, and pressure comparable to

HCFC-22. These thermodynamic characteris-

tics will ensure satisfactory equipment capacity

and efficiency.

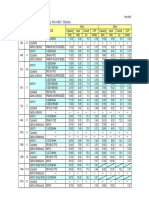

How do the replacement candidates mea-

sure up thermodynamically? Figure 1 shows

their efficiency, capacity, and pressure as com-

pared to HCFC-22.

HFC-407C is very similar to HCFC-22 in all

thermodynamic respects, which makes it a

good retrofit candidate. Consequently, HFC-

407C is being used for retrofits in some areas

now.

The capacity of HFC-134a is much lower

than HCFC-22, so it is not a good retrofit can-

didate.

The pressures of HFC-404A and HFC-410A

are much higher than HCFC-22, so they are

not good retrofit candidates either.

Designing New Chillers

Because new chillers can be designed

around a refrigerants properties, all of the

above refrigerants are candidates for use in

new DX-chiller designs. Obviously, the chiller

design will differ from HCFC-22 chillers to a

greater or lesser degree, according to the

properties of the particular refrigerant choice.

For HFC-134a DX chillers, the design is

affected by the refrigerants lower capacity and

pressure. Lower capacity means more refriger-

ant will have to be circulated, which necessi-

tates larger or faster compressors. Lower pres-

sure means that cost can be taken out of

some chiller components because they dont

have to be built as ruggedly.

For HFC-410A DX chillers, the designer

must deal with much higher refrigerant pres-

sure. As a result, heat exchangers and com-

pressors will have to be designed to withstand

that pressure. The higher pressure also means

the refrigerant gas will be more dense. Higher

density means less gas will have to be circu-

lated to provide the same amount of refrigera-

tion. So compared to HCFC-22 chillers, small-

er or slower compressors can be used.

For HFC-404A DX chillers, there is a lower

refrigerant efficiency and higher refrigerant

pressure to deal with. To counter the lower effi-

ciency, bigger heat exchangers may be

required. The higher pressure may require that

the heat exchangers and relief devices be

redesigned.

For HFC-407C DX chillers, the design pre-

ferred by YORK, the refrigerants slightly high-

er pressure is not high enough to require dif-

ferent chiller components than used for HCFC-

22 chillers. The refrigerants capacity and effi-

ciency are very similar to HCFC-22. There are,

R

e

l

a

t

i

v

e

P

e

r

f

o

r

m

a

n

c

e

Refrigerant

1.60

1.55

1.50

1.45

1.40

1.35

1.30

1.25

1.20

1.15

1.10

1.05

1.00

0.95

0.90

0.85

0.80

0.75

0.70

0.65

0.60

Figure 1: Thermodynamic Characteristics of HFC-134a, HFC-407C,

HFC-404A, and HFC-410A Relative to HCFC-22

R-134a R-22 R-407C R-404A R-410A

Efficiency

Capacity

Pressure

Thermodynamic Performance Assumptions:

Isentropic Compressor Efficiency = 0.65

Mean Condensing Temperature = 120F

Subcooling = 15F

Mean Evaporating Temperature = 38F

Superheat = 10F

Pressure Determined at the Mean Condensing Temperature

GWP differences

have such a

minuscule

impact on TEWI

that they can be

effectively

ignored.

however, intriguing design implications for one

unique feature of HFC-407C the property

known as temperature glide.

Temperature Glide Explained

HFC-407C, HFC-404A, and HFC-410A are

all blends of other refrigerants.

HFC-407C is a ternary blend, comprised of

HFC-32, HFC-125 and HFC-134a, with a com-

position by weight of 23%, 25% and 52%

respectively. HFC-404A is ternary blend of

HFC-125 (44%), HFC-143a (52%), and HFC-

134a (4%). HFC-410A is a binary blend of

HFC-32 and HFC-125 in a 50%-50% ratio.

Each of these HCFC-22 alternatives is a

zeotropic blend, meaning that the resulting

blend does not react as a single substance. At

a given pressure, they evaporate and con-

dense over a range of temperatures, rather

than at a single temperature. The expression

temperature glide was coined to describe this

phenomenon.

HFC-410A and 404A have temperature

glides of 1F or less, which is small enough

that we can overlook the effect. However,

HFC-407C has a temperature glide of 7 to 8F.

Impact of Temperature Glide

The phenomenon of temperature glide,

when fully understood, holds tremendous

promise for chiller designers and customers as

a means of improving chiller efficiency.

Unfortunately, some manufacturers using other

HFCs are obscuring this benefit by spreading

several misconceptions.

Misconception # 1: Any refrigerant leak

will alter the blend percentages of the remain-

ing HFC-407C and degrade chiller perfor-

mance.

As stated above, the components of a

zeotropic blend evaporate at different tempera-

tures for a given pressure. Consequently, it is

perceived that an HFC-407C refrigerant leak

will cause the more volatile components

HFC-32 and HFC-125 to escape first. This

phenomenon is known as fractionation.

But it is wrongly thought that a refrigerant

leak invariably changes the proportion of the

remaining constituents, thereby degrading

chiller performance. In real-world applications,

there are few conditions where fractionation is

a factor. During chiller operation, any refriger-

ant-gas or refrigerant-liquid leaks will not result

in fractionation because the refrigerant blend is

still thoroughly mixed.

Only if there is a refrigerant-gas leak during

chiller shutdown will the more volatile compo-

nents escape first. But calculations and tests

show that the effect on performance is slight.

To empirically test the impact of refrigerant-

gas leaks during shutdown, an independent

test laboratory (Intertek Testing Services, for-

merly ETL) ran an experiment on a 100-ton

chiller. During chiller shutdown, 35% of the

HFC-407C gas was purposefully leaked from

the point in the system where the fractionation

effect would be most pronounced.

The leaked refrigerant was replaced with a

make-up quantity of fresh HFC-407C. This

leakage/recharge cycle was repeated 4 times.

In the end, the amount of gas lost and

replaced simulated a refrigerant leak of 140%

of the original charge. While such repeated,

massive leaks would be highly unusual in real-

life, they do serve as an extreme test of frac-

tionation.

What was the impact on chiller perfor-

mance? In spite of massive refrigerant leakage

and replacement, the laboratory found that

capacity went down only 4.5%, while efficiency

went up 1.1%.

This test illustrates that it would take a

near-catastrophic refrigerant leak to produce

any discernable loss in capacity, at which point

the seriousness of the leak would far over-

shadow the performance issues.

Misconception # 2: The temperature glide

of HFC-407C will result in refrigerant tempera-

tures below 32F, which will freeze the chilled

water.

A typical DX evaporator has a 7F small dif-

ference, which is defined as chilled-water tem-

perature minus refrigerant temperature at the

evaporator location where the temperature dif-

ference is smallest (usually where the refriger-

ant and water exit the evaporator, but not

always). Now charge this evaporator with

HFC-407C, with its temperature glide of 7 to

8F. At first glance, it would appear that this

combination might expose the chilled water to

near-freezing temperatures. As shown in

Figure 2, if the design leaving-chiller-water

temperature is 44F, then the HFC-407C refrig-

erant might enter the evaporator at 33F.

But actual applications show there is no

freezing problem. Most major HVAC equip-

ment suppliers already allow their HCFC-22

DX evaporators to operate with refrigerant-inlet

temperatures below 32F, and there are no

freezing problems.

T

e

m

p

e

r

a

t

u

r

e

(

F

)

Location in Evaporator

HFC-407C Refrigerant

HFC-407C Refrigerant

Water

54

33

37

41

44

Figure 2: HFC-407C Temperatures in a Two-pass Evaporator

Water Inlet

Refrigerant Inlet & Outlet

Water Outlet

7F Small

Difference

Refrigerant

in Tubes

Water in Shell

Two-pass Evaporator

8F Temp.

Glide

Temperature glide

holds tremendous

promise as a

means of

improving chiller

efficiency.

The reasons are simple. First, the coldest

refrigerant is typically in contact with the

warmest water, as shown in Figure 2.

Secondly, ice-crystal formation is inhibited by

the high velocity and turbulence present in the

water side of the evaporator. If ice crystals did

form on the tube or tubesheet surfaces, the

scrubbing action of the turbulence would pull

them back into the warm bulk flow.

Benefit of Temperature Glide

At first glance, the phenomenon of tempera-

ture glide looks like an unwanted side effect in

an HCFC-22 substitute. However, closer

examination reveals that the temperature glide

of HFC-407C holds a promising benefit

major improvement in chiller efficiency.

If the DX evaporator is designed as a

counter-flow heat exchanger, then the refriger-

ant and the water enter at opposite ends, as

shown in Figure 3. In this configuration, the

leaving refrigerant temperature is 45F.

Compare this temperature with an HCFC-22

chiller using the same evaporator. The leaving

refrigerant temperature would be 37F.

The higher leaving-refrigerant temperature

with a counter-flow evaporator and HFC-407C

means the compressor does less work to raise

the refrigerant to the condensing temperature.

And less compressor work means lower ener-

gy consumption.

Thanks to temperature glide, HFC-407C

promises to be an outstanding HCFC-22 sub-

stitute, not just from the perspective of ODP

and GWP, but from an efficiency viewpoint as

well.

Conclusion

A variety of HFC refrigerants have been

developed as alternatives to HCFC-22 in DX

chillers. All are viable candidates, and all are

being used by one or more chiller manufactur-

ers. YORK has chosen HFC-407C because of

its performance characteristics in real-world

applications. Its capacity, efficiency, and pres-

sure similarities to HCFC-22 make it a logical

choice for retrofits. And its temperature glide

promises significant efficiency improvements in

new chillers.

When the HVAC industry eliminated its use

of CFC refrigerants, some chiller manufactur-

ers confused owners and specifiers with

claims and counter-claims as to which was the

best replacement refrigerant. In the end, sev-

eral refrigerants turned out to be worthy

replacements, and the focus of chiller evalua-

tions turned away from refrigerants and toward

the more important factors of value and perfor-

mance. At YORK, we hope this paper has

cleared up some misconceptions, and results

in a speedy acceptance of all HCFC-22 alter-

natives.

T

e

m

p

e

r

a

t

u

r

e

(

F

)

Location in Evaporator

54

37

44

45

Figure 3: HFC-407C Temperatures in a Counter-flow Evaporator

Water Inlet

Refrigerant Outlet

Water Outlet

Refrigerant Inlet

7F Small

Difference

Refrigerant

in Tubes

Water in Shell

Counter-flow Evaporator

8F Temperature

Glide and Reduced

Compressor Head

H

F

C

-407C

R

efrig

eran

t

HCFC-22 Refrigerant

W

a

te

r

We hope this

paper results

in a speedy

acceptance of

all HCFC-22

alternatives.

You might also like

- CO2 IIAR HandbookDocument188 pagesCO2 IIAR HandbookOnofreHalberNo ratings yet

- CR Certificate (1465731)Document6 pagesCR Certificate (1465731)rampartnersbusinessllcNo ratings yet

- MM Refrigeration-IIAR 2006 Conference-CO2 Cascade Refrigeration SystemsDocument40 pagesMM Refrigeration-IIAR 2006 Conference-CO2 Cascade Refrigeration SystemsHarsha Vardhan BNo ratings yet

- Technical Papers: 34th Annual Meeting International Institute of Ammonia RefrigerationDocument40 pagesTechnical Papers: 34th Annual Meeting International Institute of Ammonia Refrigerationrohitkb09No ratings yet

- HVACR Service Trobleshooting With The Professor John TomczykDocument48 pagesHVACR Service Trobleshooting With The Professor John TomczykvickersNo ratings yet

- ThermostatCatalog 570-280Document12 pagesThermostatCatalog 570-280vickers0% (1)

- Speakout Elementary. Units 1 & 2 ExamDocument2 pagesSpeakout Elementary. Units 1 & 2 ExamDaniel Galotti33% (3)

- Heatcraft Evaluation HCF Alternative Refrigerants enDocument5 pagesHeatcraft Evaluation HCF Alternative Refrigerants enakhmad arifinNo ratings yet

- Vertiv Refrigerants - of - The - Future WP Uk Low Rev.1 09.2018 - 246049 - 0Document10 pagesVertiv Refrigerants - of - The - Future WP Uk Low Rev.1 09.2018 - 246049 - 0boombloomNo ratings yet

- Future Refrigerants Sales SheetDocument8 pagesFuture Refrigerants Sales SheetDaniel MachadoNo ratings yet

- Residential and Commercial Air Conditioning and Heating: Coordinating Lead Authors Lead AuthorsDocument26 pagesResidential and Commercial Air Conditioning and Heating: Coordinating Lead Authors Lead AuthorsAshok KumarNo ratings yet

- Refrigerant Mixtures As HCFC-22 AlternativesDocument11 pagesRefrigerant Mixtures As HCFC-22 Alternativesmani317No ratings yet

- Danfoss r290 en PDFDocument4 pagesDanfoss r290 en PDFAli Al-Sayyab100% (1)

- WP 025Document3 pagesWP 025Suthi Sae DanNo ratings yet

- Trends For Refrigerants in Compression Systems: Dr.-Ing. Jürgen SüssDocument3 pagesTrends For Refrigerants in Compression Systems: Dr.-Ing. Jürgen Süsshonghai_dlNo ratings yet

- Transcritical Co2 Refrigeration - PDFDocument11 pagesTranscritical Co2 Refrigeration - PDFHector Fabian Hernandez Algarra100% (1)

- Myths and Facts of Hvac Refrigerants: Fact: HCFCS, Including R123, Are Being Phased OutDocument4 pagesMyths and Facts of Hvac Refrigerants: Fact: HCFCS, Including R123, Are Being Phased OutSiva SivaNo ratings yet

- 12 Bucati Catalog Intreg-Technical Topic Refrigeration Oils (Jan 2011) - enDocument4 pages12 Bucati Catalog Intreg-Technical Topic Refrigeration Oils (Jan 2011) - enDiaconescu AdrianNo ratings yet

- Paper, Synthetic Refrigerants, 7966, 01.04 Cutmarks PDFDocument8 pagesPaper, Synthetic Refrigerants, 7966, 01.04 Cutmarks PDFAnamarija ŠkovrljNo ratings yet

- A 501 14Document40 pagesA 501 14fakhrealammmNo ratings yet

- Sroc 04Document44 pagesSroc 04ambuenaflorNo ratings yet

- 6 Things Plastics TechnologyDocument7 pages6 Things Plastics TechnologySubramanian gokulNo ratings yet

- 7877-E-Kigali FS02 Current UsesDocument4 pages7877-E-Kigali FS02 Current UsesOrlando Mican BuitragoNo ratings yet

- Technical Topic Refrigeration Oils (Jan 2011) - EN PDFDocument4 pagesTechnical Topic Refrigeration Oils (Jan 2011) - EN PDFPreeti gulatiNo ratings yet

- Refrigerant TypesDocument4 pagesRefrigerant Typesch pavan kumar0% (1)

- FS 3 Domestic Refrigeration Oct 15Document3 pagesFS 3 Domestic Refrigeration Oct 15Jitbahan MohantaNo ratings yet

- 258 Copeland CF and CS Compressor CatalogueDocument88 pages258 Copeland CF and CS Compressor Cataloguevacosteles100% (1)

- En Ikk Hydrocarbon Cuba Proklima 2005Document28 pagesEn Ikk Hydrocarbon Cuba Proklima 2005maufinottiNo ratings yet

- HFC Phasedown Webinar Presentation - 508cDocument49 pagesHFC Phasedown Webinar Presentation - 508cChoi Fu ChuenNo ratings yet

- CAC 05 11 MurphyDocument12 pagesCAC 05 11 MurphyzetseatNo ratings yet

- Module 1 - Introduction To Alternative RefrigerantsDocument47 pagesModule 1 - Introduction To Alternative RefrigerantsMark BrewardNo ratings yet

- Out With The Old & in With The New:: Freon Vs Ammonia & Glycol Refrigeration SystemsDocument4 pagesOut With The Old & in With The New:: Freon Vs Ammonia & Glycol Refrigeration SystemsHarsha Vardhan BNo ratings yet

- 7884-E-Kigali FS09 High Ambient TempDocument3 pages7884-E-Kigali FS09 High Ambient TempOrlando Mican BuitragoNo ratings yet

- R134a PDFDocument6 pagesR134a PDFDaniel FernandezNo ratings yet

- Refrigerant Report: 15. EditionDocument40 pagesRefrigerant Report: 15. EditionPedro SilvaNo ratings yet

- Thermal Engineering Systems: Digital Assignment 1Document24 pagesThermal Engineering Systems: Digital Assignment 1Ramesh Kavitha Sanjit 18BME0677No ratings yet

- Northcutt, Inc HC Refrigerant Products Training ManualDocument50 pagesNorthcutt, Inc HC Refrigerant Products Training ManualLv RamanNo ratings yet

- CO2 Handbook IIARDocument190 pagesCO2 Handbook IIAROnofreHalberNo ratings yet

- Research Mentorship Program - Part-B: Project TitleDocument9 pagesResearch Mentorship Program - Part-B: Project TitleKaustubh GaikwadNo ratings yet

- Bock R410A Compressor GBDocument20 pagesBock R410A Compressor GBRodrigo GonçalvesNo ratings yet

- Refrigerant RetrofittingDocument54 pagesRefrigerant RetrofittingHarpreet Randhawa100% (1)

- Performance Analysis of R22 and Its Substitutes in Air ConditionersDocument13 pagesPerformance Analysis of R22 and Its Substitutes in Air ConditionersSuneel KallaNo ratings yet

- Co2 Heat Pump SystemsDocument7 pagesCo2 Heat Pump SystemsAmine Yahiaoui100% (1)

- Refrigeration Retrofitt GuidelinesDocument52 pagesRefrigeration Retrofitt GuidelinesAurelio Jr TambigaNo ratings yet

- Refrigeration PDFDocument10 pagesRefrigeration PDFkhaledppuNo ratings yet

- LEED Reference Guide For Green Building Design and ConstructionDocument1 pageLEED Reference Guide For Green Building Design and ConstructionHermanManruNo ratings yet

- Unit 1Document57 pagesUnit 1Naveen Prakash NoronhaNo ratings yet

- Technical Bulletin #R-100 Refrigerant: R410a vs. R407cDocument1 pageTechnical Bulletin #R-100 Refrigerant: R410a vs. R407cmunggangNo ratings yet

- Plate-Fin Heat Exchangers - An Ideal Platform For LNG Process Innovation-EnglishDocument12 pagesPlate-Fin Heat Exchangers - An Ideal Platform For LNG Process Innovation-EnglishjrfmlNo ratings yet

- Replacement of R22 in Existing Installations: Experiences From The Swedish Phase OutDocument13 pagesReplacement of R22 in Existing Installations: Experiences From The Swedish Phase OutDevi DeepkumarNo ratings yet

- R-22 Being Phased Out, Not EliminatedDocument6 pagesR-22 Being Phased Out, Not EliminatedAsad KhanNo ratings yet

- C r407c GuideDocument32 pagesC r407c Guidezam_ramliNo ratings yet

- R744 (CO2) Refrigerant Cooling Systems, The Finned Tube R744 (CO2) Evaporator and Gas CoolerDocument24 pagesR744 (CO2) Refrigerant Cooling Systems, The Finned Tube R744 (CO2) Evaporator and Gas CoolerSudersanSridhar100% (1)

- Suva123 in ChillersDocument6 pagesSuva123 in ChillersSwiss WissNo ratings yet

- Comparacion 407c y 410aDocument5 pagesComparacion 407c y 410aAlan Q'amaháNo ratings yet

- R202 FluidDocument10 pagesR202 Fluidzoran_stevNo ratings yet

- Dupont Hcfc-123: Properties, Uses, Storage, and HandlingDocument24 pagesDupont Hcfc-123: Properties, Uses, Storage, and HandlingosamaNo ratings yet

- Ashrae Chill Water STDDocument8 pagesAshrae Chill Water STDKarthik Raj100% (1)

- 3 8 HFC-23 HCFC-22 Production PDFDocument13 pages3 8 HFC-23 HCFC-22 Production PDFsiva anandNo ratings yet

- Design and Analysis of The Different Refrigerants by Using Composite MaterialsDocument47 pagesDesign and Analysis of The Different Refrigerants by Using Composite MaterialsNationalinstituteDsnrNo ratings yet

- Application Bulletin 124Document13 pagesApplication Bulletin 124Vinod NairNo ratings yet

- Exploring The Differences Between R-410A and R-22Document4 pagesExploring The Differences Between R-410A and R-22aungwinnaingNo ratings yet

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- Danfoss Banana Ripening Application BrochureDocument6 pagesDanfoss Banana Ripening Application BrochurevickersNo ratings yet

- Danfoss Facts Worth Knowing About ACDrivesDocument208 pagesDanfoss Facts Worth Knowing About ACDrivesvickersNo ratings yet

- Thermal Applications CategoryDocument19 pagesThermal Applications CategoryvickersNo ratings yet

- ASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFDocument74 pagesASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFvickers100% (1)

- Building Sustainability AnalysisDocument25 pagesBuilding Sustainability AnalysisvickersNo ratings yet

- McQuay MCW-C-H Technical Manual EngDocument20 pagesMcQuay MCW-C-H Technical Manual EngCarlos Can PootNo ratings yet

- Direct Expansion (DX) and Secondary Loop (SN) SystemsDocument2 pagesDirect Expansion (DX) and Secondary Loop (SN) SystemsvickersNo ratings yet

- Temperature To Resistance Chart NTC Thermistor: Temp C Temp F Resistance OhmsDocument1 pageTemperature To Resistance Chart NTC Thermistor: Temp C Temp F Resistance OhmsvickersNo ratings yet

- Sanyo ScrollDocument24 pagesSanyo Scrollworker359567No ratings yet

- Replacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)Document10 pagesReplacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)vickersNo ratings yet

- Cooling Load Temperature Difference Calculation MethodDocument3 pagesCooling Load Temperature Difference Calculation Methodvickers50% (2)

- 6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandDocument10 pages6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandvickersNo ratings yet

- INT69 KRIWAN Diagnosis SystemDocument6 pagesINT69 KRIWAN Diagnosis Systemvickers100% (1)

- Comparative Table of ScrollsDocument11 pagesComparative Table of ScrollsvickersNo ratings yet

- Cypetherm SuiteDocument72 pagesCypetherm SuitevickersNo ratings yet

- Chiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonDocument152 pagesChiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonvickersNo ratings yet

- Fast, Easy Furnace TuningDocument2 pagesFast, Easy Furnace TuningvickersNo ratings yet

- Chiller Types and ApplicationsDocument73 pagesChiller Types and Applicationsvickers100% (3)

- Multi V Water PDB (08.04.10 - ) Final PDFDocument123 pagesMulti V Water PDB (08.04.10 - ) Final PDFMaxiaires RefrigeracionNo ratings yet

- Supco TimersDocument7 pagesSupco Timersvickers100% (1)

- Unilever Solar Assisted Ice Cream Cabinet With Danfoss Direct Current Operated Propane CompressorDocument2 pagesUnilever Solar Assisted Ice Cream Cabinet With Danfoss Direct Current Operated Propane CompressorvickersNo ratings yet

- Fasco Full Catalog PDFDocument184 pagesFasco Full Catalog PDFvickersNo ratings yet

- 30RB Opt28B Low Ambient OperationDocument1 page30RB Opt28B Low Ambient OperationvickersNo ratings yet

- Bul-30RB Brine OptionDocument1 pageBul-30RB Brine OptionvickersNo ratings yet

- Spare Parts Catalog: 6 WG 200 (555/5) Material Number: 4644.026.333 Current Date: 27.02.2020Document74 pagesSpare Parts Catalog: 6 WG 200 (555/5) Material Number: 4644.026.333 Current Date: 27.02.2020GeorgiNo ratings yet

- MG-RTX3 ManualDocument2 pagesMG-RTX3 ManualAJ EmandienNo ratings yet

- Recurrent Psychotic Episodes With A Near - Monthly CycleDocument4 pagesRecurrent Psychotic Episodes With A Near - Monthly CycleNajia ChoudhuryNo ratings yet

- Ch06 Solations Brigham 10th EDocument32 pagesCh06 Solations Brigham 10th ERafay HussainNo ratings yet

- Documents - Pub Internship Report Presentation On Cloud ComputingDocument31 pagesDocuments - Pub Internship Report Presentation On Cloud ComputingYashvi KankarwalNo ratings yet

- Eaton Hydroline TS CylinderDocument8 pagesEaton Hydroline TS CylinderHanzil HakeemNo ratings yet

- DSP Question Bank With SolutionsDocument52 pagesDSP Question Bank With SolutionsRakesh Kumar DNo ratings yet

- Physical Science WHLP Week 3 N 4Document2 pagesPhysical Science WHLP Week 3 N 4Dave SedigoNo ratings yet

- C9 ICT Full BookDocument122 pagesC9 ICT Full BookTajtiné Bondár KatalinNo ratings yet

- Brainaid CaseDocument4 pagesBrainaid CaseJyotiraditya Kumar JhaNo ratings yet

- 5-Whys Guide& Template: Step-By-Step InstructionsDocument5 pages5-Whys Guide& Template: Step-By-Step InstructionsSudhakar Lakshmana RajNo ratings yet

- Barium StudiesDocument89 pagesBarium StudiesManuel PoncianNo ratings yet

- Po CDocument43 pagesPo CGeldo RivasNo ratings yet

- Digital Marketing Communicaton - Summative Brief CW2Document12 pagesDigital Marketing Communicaton - Summative Brief CW2cyrax 3000No ratings yet

- Adh DemolitionDocument10 pagesAdh Demolitionruel solteroNo ratings yet

- Society Law and Ethics NotesDocument12 pagesSociety Law and Ethics NotesTanishka100% (1)

- By Sin I Rise Part Two Sins - Cora ReillyDocument237 pagesBy Sin I Rise Part Two Sins - Cora ReillyNour Al-khatib50% (2)

- Critical Thinking Concepts and Tools - ADocument10 pagesCritical Thinking Concepts and Tools - ASigrid Cruz100% (1)

- DR Hanif Suhairi Cyberbullying Among AdolescentsDocument21 pagesDR Hanif Suhairi Cyberbullying Among AdolescentsnurulNo ratings yet

- Security Guard Training & OSHA Training NY Guardian Group ServicesDocument1 pageSecurity Guard Training & OSHA Training NY Guardian Group ServicesLochard BaptisteNo ratings yet

- Wateen TelecomDocument44 pagesWateen TelecomTalha MahboobNo ratings yet

- The History of Computers: Done by - Anandhu Raj, Albin Raphy, Anirudh C. VinayanDocument42 pagesThe History of Computers: Done by - Anandhu Raj, Albin Raphy, Anirudh C. Vinayanarjun rajNo ratings yet

- MFC-L9570CDW Brochure PDFDocument2 pagesMFC-L9570CDW Brochure PDFAnonymous n80oQosNo ratings yet

- SCM Final ReportDocument12 pagesSCM Final ReportSYED DANIYAL HASSAN SHAHNo ratings yet

- High Yield Topics MCATDocument5 pagesHigh Yield Topics MCATkarijaniNo ratings yet

- Red Hat System Administration I 3.4 PracticeDocument9 pagesRed Hat System Administration I 3.4 PracticestefygrosuNo ratings yet

- Genetics Linkage and Crossing OverDocument94 pagesGenetics Linkage and Crossing OverSurabhiNo ratings yet