Professional Documents

Culture Documents

2 Design of Machine Elements Mech

2 Design of Machine Elements Mech

Uploaded by

Sachi DhanandamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 Design of Machine Elements Mech

2 Design of Machine Elements Mech

Uploaded by

Sachi DhanandamCopyright:

Available Formats

www.vidyarthiplus.

com

www.vidyarthiplus.com

Design of machine elements

Semester: V

Subject Code: ME 2303

MODEL QUESTION PAPER

PART A (10 X 2 = 20 Marks)

1. What is adaptive design? Where it is used? Give examples.

2. State the difference between straight beam and curved beam.

3. Why hollow shaft has greater strength and stiffness than solid shaft?

4. What are mechanical properties of metals? List any four.

5. Define stress concentration

6. What is meant by equivalent bending moment?

7. Sketch the cross section of splined shaft?

8. Define poissons ratio.

9. What is factor of safety for brittle materials?

10. Name the stresses induced in the shaft.

PART B (5X16=80 Marks)

11. i) Discuss in detail about the factors influencing machine design

ii) Write short notes on preferred numbers, fits and types of fits (June

2012)

12. A 50 mm diameter shaft is made from carbon steel having ultimate tensile strength of

600 Mpa. It is subjected to a torque which fluctuates between 2000N-m to -900 N-m.

Using soderberg method calculate the factor of safety.

(Dec 2010)

13. A C-clamp is subjected to a maximum load of W, as shown in figure. If the maximum

tensile stress in the clamp is limited to 140 Mpa. Find the value of load W.

(Nov 2012)

www.vidyarthiplus.com

www.vidyarthiplus.com

14. A pulley is keyed to a shaft midway between two bearings. The shaft is made of cold

drawn steel, for which the ultimate strength is 550 Mpa and the yield strength is 400

Mpa.. The bending moment at the pulley varies from -150Nm to 400Nm, as the torque on

the shaft varies from -50Nm to 150 Nm. Obtain the diameter of the shaft for an indefinite

life. The stress concentration factors for the keyway at the pulley in bending and in

torsion are 1.6 and 1.3 respectively. Take the following values, factor of safety = 1.5;

load correction factors 1.0 in bending and 0.6 in torsion, size effect factor = 0.85; surface

effect factor = 0.88.

(Nov 2012)

15. Design a shaft to transmit power from an electric motor to a lathe head stock through

a pulley by means of belt drive. The pulley weighs 200N and is located at 300 mm from

the centre of the bearing. The diameter of the pulley is 200mm and the maximum power

transmitted is 1KW at 120 rpm. The angle of lap of the belt is 180 and coefficient of

friction between the belt and the pulley is 0.3. The shock arid fatigue factors for bending

and twisting are 1.5 and 2 respectively. The allowable shear stress in the shaft may be

taken as 35 Mpa. (Dec 2011)

You might also like

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Dme-22 6 15Document8 pagesDme-22 6 15VIGNESH L RNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Sa 278Document5 pagesSa 278AnilNo ratings yet

- Lab Tensile UTHMDocument27 pagesLab Tensile UTHMMuhd Farhan Bin Ibrahim100% (1)

- 072 - ME8593, ME6503 Design of Machine Elements DEM - Question BankDocument16 pages072 - ME8593, ME6503 Design of Machine Elements DEM - Question BankalhaggagiNo ratings yet

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiNo ratings yet

- DMEDocument4 pagesDMEManivannanNo ratings yet

- Design of Machine ElementDocument11 pagesDesign of Machine ElementVenkat RajaNo ratings yet

- Q Bank PDFDocument16 pagesQ Bank PDFAthisayaraj RajNo ratings yet

- QB Unit-1,2Document5 pagesQB Unit-1,2Agranshu BhardwajNo ratings yet

- Macine Element I Worksheet For Final ExamDocument4 pagesMacine Element I Worksheet For Final Examdagimawgchew777No ratings yet

- Dom Gtu ImpDocument8 pagesDom Gtu ImpSwastik PanchalNo ratings yet

- ME-6503 Design of Machine Elements - 16 MarksDocument12 pagesME-6503 Design of Machine Elements - 16 MarksMadhu MithaNo ratings yet

- ME2303Document5 pagesME2303balameckNo ratings yet

- DME Question BankDocument4 pagesDME Question BankILAYAPERUMAL KNo ratings yet

- DME QB All UnitsDocument11 pagesDME QB All UnitsPrakash ThangavelNo ratings yet

- DME - Assignment - IDocument3 pagesDME - Assignment - ISathis KumarNo ratings yet

- Dme Quest Ut-2Document9 pagesDme Quest Ut-2aadhithyarajasekaranNo ratings yet

- Yt Yc 2 Ut 2Document2 pagesYt Yc 2 Ut 2ManivannanNo ratings yet

- M.D-I Final Tutorial and AssignmentDocument16 pagesM.D-I Final Tutorial and AssignmentnageshNo ratings yet

- Me2303 - Design of Machine ElementsDocument14 pagesMe2303 - Design of Machine ElementsGowtham RajNo ratings yet

- Tutorial Sheet-II MEC3110/317 (Machine Design II)Document4 pagesTutorial Sheet-II MEC3110/317 (Machine Design II)Prateeksha ShakyaNo ratings yet

- ME2303Document5 pagesME2303Galih PramuditaNo ratings yet

- Me6503 Dme Mech VST Au Unit IIDocument37 pagesMe6503 Dme Mech VST Au Unit IISiva Raman100% (2)

- Machine Design Answer KeyDocument16 pagesMachine Design Answer KeyK.KESAVARAJ HICET STAFF MCTSNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- Design of Machine ElementsDocument10 pagesDesign of Machine ElementsMahalingam NanjappanNo ratings yet

- Me2303 PDFDocument5 pagesMe2303 PDFBas RamuNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- ME6503 DME Question PapersDocument27 pagesME6503 DME Question PapersSaravanan KumarNo ratings yet

- Assignment No-01 MEPC-301Document6 pagesAssignment No-01 MEPC-301SANDEEP BUDANIANo ratings yet

- QuestionsDocument11 pagesQuestionsSundara MoorthyNo ratings yet

- Me2303 - Design of Machine ElementsDocument14 pagesMe2303 - Design of Machine Elementsdsathiya0% (1)

- Internal Test 1Document3 pagesInternal Test 1Sathish KumarNo ratings yet

- ME2303-Design of Machine ElementsDocument17 pagesME2303-Design of Machine ElementsSith AnanthanNo ratings yet

- ME 1302 - MACHINE DESIGN (5th Mech)Document7 pagesME 1302 - MACHINE DESIGN (5th Mech)Madhu MithaNo ratings yet

- 13 ME AssignmentDocument2 pages13 ME AssignmentMuhammad Sharif JamaliNo ratings yet

- Question For IcDocument4 pagesQuestion For IcPrem MNo ratings yet

- MDDocument5 pagesMDYogesh DanekarNo ratings yet

- 34412501-Design of MC ElementDocument8 pages34412501-Design of MC Elementsmg26thmayNo ratings yet

- UNIT-1: Department of Mechanical EngineeringDocument14 pagesUNIT-1: Department of Mechanical EngineeringManivannan JeevaNo ratings yet

- ME6503-Design of Machine Elements PDFDocument15 pagesME6503-Design of Machine Elements PDFkarthikNo ratings yet

- Imp Qoestions MDDocument3 pagesImp Qoestions MDvenuedNo ratings yet

- Dme Model QuestionDocument2 pagesDme Model QuestiondharaniventhanNo ratings yet

- Kings: Department of Mechanical EngineeringDocument14 pagesKings: Department of Mechanical EngineeringAdam AhmadNo ratings yet

- Integrated Mechanical Design Question: Fundamentals and Design of ShaftsDocument4 pagesIntegrated Mechanical Design Question: Fundamentals and Design of Shafts9944805552No ratings yet

- Me 331Document5 pagesMe 331arumugam_rNo ratings yet

- Docs MEDMMIAssignments2013 PDFDocument13 pagesDocs MEDMMIAssignments2013 PDFHafiz Mahar28No ratings yet

- Snist Dom Previous PaperDocument9 pagesSnist Dom Previous PaperKapil Siddhant DevulapalliNo ratings yet

- Assignment 02Document2 pagesAssignment 02adhnan_rasheed0% (1)

- 9A03504 Design of Machine Elements 21Document8 pages9A03504 Design of Machine Elements 21slv_prasaadNo ratings yet

- DME Question Bank - 3171917Document4 pagesDME Question Bank - 3171917fgyjnsv786No ratings yet

- Machine Design Important QuestionsDocument17 pagesMachine Design Important Questionssharmaparivaar07No ratings yet

- Design of Machine Elements IDocument8 pagesDesign of Machine Elements Imesab100No ratings yet

- EMM7241-Advanced Machine Design Examination June 2016Document8 pagesEMM7241-Advanced Machine Design Examination June 2016Charles OndiekiNo ratings yet

- Mech-V-Design of Machine Elements I (10me52) - AssignmentDocument10 pagesMech-V-Design of Machine Elements I (10me52) - AssignmentArunNo ratings yet

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- 05-04 Machine Design & Cad-II (Me)Document2 pages05-04 Machine Design & Cad-II (Me)Abdul AhadNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- TMD, Flywheel ProblemsDocument2 pagesTMD, Flywheel ProblemsSachi DhanandamNo ratings yet

- Friction 2 Marks and Important ProblemsDocument2 pagesFriction 2 Marks and Important ProblemsSachi DhanandamNo ratings yet

- Problems On GyrocopeDocument1 pageProblems On GyrocopeSachi DhanandamNo ratings yet

- Mechanical Behaviour of Materials Model Question Paper PDFDocument2 pagesMechanical Behaviour of Materials Model Question Paper PDFSachi Dhanandam100% (1)

- Mechanical Behaviour of Materials Anna Tech Question Paper PDFDocument3 pagesMechanical Behaviour of Materials Anna Tech Question Paper PDFSachi DhanandamNo ratings yet

- List of Proposed Experiments For Simulation Lab Updated-30th SepDocument4 pagesList of Proposed Experiments For Simulation Lab Updated-30th SepSachi DhanandamNo ratings yet

- Mechanical Behaviour of Materials Questions PART 1Document3 pagesMechanical Behaviour of Materials Questions PART 1Sachi Dhanandam100% (2)

- Mechanical Behaviour of Materials PDFDocument6 pagesMechanical Behaviour of Materials PDFSachi DhanandamNo ratings yet

- Mechanical Behaviour and Testing of MaterialsDocument5 pagesMechanical Behaviour and Testing of MaterialsSachi DhanandamNo ratings yet

- Sciencedirect: Friction Stir Welded Butt Joints of Aa2024 T3 and Aa7075 T6 Aluminum AlloysDocument5 pagesSciencedirect: Friction Stir Welded Butt Joints of Aa2024 T3 and Aa7075 T6 Aluminum AlloysSachi DhanandamNo ratings yet

- Break Even AnalysisDocument20 pagesBreak Even AnalysisSachi DhanandamNo ratings yet

- Projection of SolidsDocument58 pagesProjection of SolidsSachi DhanandamNo ratings yet

- TRB PT2017 Tentative Answer KeyDocument26 pagesTRB PT2017 Tentative Answer KeySachi DhanandamNo ratings yet

- Ug Table 2017Document2 pagesUg Table 2017Sachi DhanandamNo ratings yet

- Fitting Workshop Manual2014Document35 pagesFitting Workshop Manual2014Sachi DhanandamNo ratings yet

- 15ME101 Model Exam QP BMEDocument2 pages15ME101 Model Exam QP BMESachi DhanandamNo ratings yet

- EG Week 12 (1) (Autosaved)Document36 pagesEG Week 12 (1) (Autosaved)Sachi DhanandamNo ratings yet

- Format For Stock Verification ReportDocument2 pagesFormat For Stock Verification ReportSachi DhanandamNo ratings yet

- Production or Working DrawingsDocument18 pagesProduction or Working DrawingsSachi DhanandamNo ratings yet

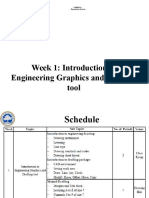

- Week 1: Introduction To Engineering Graphics and Drafting ToolDocument55 pagesWeek 1: Introduction To Engineering Graphics and Drafting ToolSachi DhanandamNo ratings yet

- Workshop: Brooklynn Innovative Research & DevelopmentDocument1 pageWorkshop: Brooklynn Innovative Research & DevelopmentSachi DhanandamNo ratings yet

- Prof. John Banhart Resume-FoamsDocument2 pagesProf. John Banhart Resume-FoamsSachi DhanandamNo ratings yet

- Cad SyllabusDocument5 pagesCad SyllabusSachi DhanandamNo ratings yet

- SRM University Faculty of Engineering and Technology Compensatory Courses For Even Semester 2015 - 2016 List of Registered Students (Ug & PG)Document6 pagesSRM University Faculty of Engineering and Technology Compensatory Courses For Even Semester 2015 - 2016 List of Registered Students (Ug & PG)Sachi DhanandamNo ratings yet

- Me1036 Dts Tutorial Note BookDocument176 pagesMe1036 Dts Tutorial Note BookSachi DhanandamNo ratings yet

- SRM University Department of Mechanical EngineeringDocument2 pagesSRM University Department of Mechanical EngineeringSachi DhanandamNo ratings yet

- Process Planninng CompensatoryDocument3 pagesProcess Planninng CompensatorySachi DhanandamNo ratings yet

- Biomechnics Mids NotsDocument10 pagesBiomechnics Mids Notstalha.k.rajpootNo ratings yet

- As 1145.1-2001 Determination of Tensile Properties of Plastics Materials General PrinciplesDocument6 pagesAs 1145.1-2001 Determination of Tensile Properties of Plastics Materials General PrinciplesSAI Global - APACNo ratings yet

- A Review On Effect On Properties of Al-Sic Composites Fabricated by Stir Casting MethodDocument5 pagesA Review On Effect On Properties of Al-Sic Composites Fabricated by Stir Casting MethodesatjournalsNo ratings yet

- 893 - Effects of Manual Therapy Connective Tissue PDFDocument10 pages893 - Effects of Manual Therapy Connective Tissue PDFDiego EstradaNo ratings yet

- En 50182Document1 pageEn 50182pankajnbi100% (2)

- The Development of An Australian Standard For Stainless Steel StructuresDocument15 pagesThe Development of An Australian Standard For Stainless Steel Structureswaynectw100% (1)

- Ashby Materials Selection ChartsDocument18 pagesAshby Materials Selection Chartspeter_prabhat0% (1)

- Yield Strength TestingDocument6 pagesYield Strength TestingBoy Alfredo PangaribuanNo ratings yet

- PS1Document3 pagesPS1SKYE LightsNo ratings yet

- Afm E308-16 Afm E308h-16Document13 pagesAfm E308-16 Afm E308h-16Julio Cesar Lazcano PintoNo ratings yet

- Aço Estrutural Astm A570Document10 pagesAço Estrutural Astm A570galvaosilvaNo ratings yet

- Column Design 165Document25 pagesColumn Design 165Anonymous nwByj9LNo ratings yet

- SD 1 AssignmentDocument17 pagesSD 1 AssignmentAnuj Chandiwala100% (1)

- Seminar Report 2019-22 Carbon Fiber Used in ConstructionDocument11 pagesSeminar Report 2019-22 Carbon Fiber Used in ConstructionAdarsh SooryaNo ratings yet

- Gril Engineer URS Engineer: Manufacturer Guideline/QMS Protected Against Rain, Humidity, Dew Fall and DustDocument17 pagesGril Engineer URS Engineer: Manufacturer Guideline/QMS Protected Against Rain, Humidity, Dew Fall and Dustjitendra100% (1)

- Elastomeric BearingsDocument20 pagesElastomeric Bearingsalperen52No ratings yet

- Overcoming Residual Stresses and Machining Distortion in The Production of Aluminum Alloy Satellite BoxesDocument56 pagesOvercoming Residual Stresses and Machining Distortion in The Production of Aluminum Alloy Satellite BoxessleonNo ratings yet

- IS 8329-2000 CDI PipeDocument30 pagesIS 8329-2000 CDI Pipesunitkghosh1100% (1)

- AISI 1050 Steel, As RolledDocument2 pagesAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoNo ratings yet

- Test Certificate: CM/L-NO:5530357Document10 pagesTest Certificate: CM/L-NO:5530357TARUNKUMARNo ratings yet

- Astm A320 Rev ADocument8 pagesAstm A320 Rev AStalin Ayala GaiborNo ratings yet

- Uniaxial Tension - EVOCDDocument7 pagesUniaxial Tension - EVOCDanon_637246413No ratings yet

- ME6503 DME Question PapersDocument27 pagesME6503 DME Question PapersSaravanan KumarNo ratings yet

- Report BTP Final1Document22 pagesReport BTP Final1Vishnu NairNo ratings yet

- Certificate of Analysis Conveyor Belt PT. Mutiara Tanjung Lestari Order Tahun 2022Document29 pagesCertificate of Analysis Conveyor Belt PT. Mutiara Tanjung Lestari Order Tahun 2022RestuNo ratings yet

- Strength of Materials Lecture Notes Civil Engineering 12Document6 pagesStrength of Materials Lecture Notes Civil Engineering 12Ar Ayoushika AbrolNo ratings yet

- UL 746C SUN Rev 4 20 2020 ED 4 20 2022Document3 pagesUL 746C SUN Rev 4 20 2020 ED 4 20 2022Aritra DasguptaNo ratings yet

- Unibell Handbook - Chapter 2 Raw Materials PDFDocument9 pagesUnibell Handbook - Chapter 2 Raw Materials PDFDAVID GREGORIO FRANCO ANDRADENo ratings yet