Professional Documents

Culture Documents

Ijmet: ©iaeme

Ijmet: ©iaeme

Uploaded by

IAEME PublicationCopyright:

Available Formats

You might also like

- Carrier Service ManualDocument40 pagesCarrier Service ManualMetalloy67% (9)

- Variolink+Esthetic DC - Composite - Glass Ceramic Restorations - Flow Chart - enDocument2 pagesVariolink+Esthetic DC - Composite - Glass Ceramic Restorations - Flow Chart - engmacaneata100% (1)

- Lab Report EEE111 Exp 1Document23 pagesLab Report EEE111 Exp 1Hazizi Khairy75% (4)

- Science Lab Equipment Study SheetDocument2 pagesScience Lab Equipment Study Sheetapi-314843596100% (1)

- Ijmet: ©iaemeDocument8 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- Parameter Optimization of Electro Discharge Machine of AISI 304 Steel by Using Taguchi MethodDocument5 pagesParameter Optimization of Electro Discharge Machine of AISI 304 Steel by Using Taguchi MethodInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Comparative Performance of Wet and Near-Dry Edm Process For Machining of Oil Hardned Non Sinking Steel MaterialDocument10 pagesComparative Performance of Wet and Near-Dry Edm Process For Machining of Oil Hardned Non Sinking Steel MaterialIAEME PublicationNo ratings yet

- 1114meij04 PDFDocument9 pages1114meij04 PDFAli RazaNo ratings yet

- Optimization of EDM Process Parameters in Machining of 17-4 PH Steel Using Taguchi MethodDocument8 pagesOptimization of EDM Process Parameters in Machining of 17-4 PH Steel Using Taguchi Method317-Darpan SatijaNo ratings yet

- Application of GRA For Optimal Machining Parameter Selection in EDMDocument8 pagesApplication of GRA For Optimal Machining Parameter Selection in EDMBrijKishoreSinghNo ratings yet

- A Case Study On Quality and ProductivityDocument10 pagesA Case Study On Quality and ProductivityG Hitesh ReddyNo ratings yet

- Optimization of Process Parameters in Wedm Process On Two Workpieces of Materials Hardox-400 and Hardox-500Document12 pagesOptimization of Process Parameters in Wedm Process On Two Workpieces of Materials Hardox-400 and Hardox-500TJPRC PublicationsNo ratings yet

- Comparison of Intelligent Optimization Algorithms For Wire Electrical Discharge Machining ParametersDocument7 pagesComparison of Intelligent Optimization Algorithms For Wire Electrical Discharge Machining Parametersmanhtuankt90No ratings yet

- Optimization of Edm Parameters Using Taguchi Method and Grey Relational Analysis For Mild Steel Is 2026Document10 pagesOptimization of Edm Parameters Using Taguchi Method and Grey Relational Analysis For Mild Steel Is 2026irinuca12No ratings yet

- Experimental Investigation and Multi-Objective Optimization of Wire Electrical Discharge Machining (WEDM) of 5083 Aluminum AlloyDocument7 pagesExperimental Investigation and Multi-Objective Optimization of Wire Electrical Discharge Machining (WEDM) of 5083 Aluminum AlloyÐɤ Suman ChatterjeeNo ratings yet

- Parametric Optimization of Machining Parameters of AISI D3 Tool Steel Using Wire Cut Electric Discharge Machining - A Taguchi Based ApproachDocument7 pagesParametric Optimization of Machining Parameters of AISI D3 Tool Steel Using Wire Cut Electric Discharge Machining - A Taguchi Based ApproachjanakNo ratings yet

- Materials Today: Proceedings: M. Subrahmanyam, T. NancharaiahDocument5 pagesMaterials Today: Proceedings: M. Subrahmanyam, T. NancharaiahakashNo ratings yet

- Materials Today: Proceedings: M. Subrahmanyam, T. NancharaiahDocument5 pagesMaterials Today: Proceedings: M. Subrahmanyam, T. NancharaiahakashNo ratings yet

- Parametric Study Along With Selection of Optimal Solutions in Wire Cut Machining of Titanium (Gr2)Document4 pagesParametric Study Along With Selection of Optimal Solutions in Wire Cut Machining of Titanium (Gr2)SundaraPandiyanNo ratings yet

- Ijmet: ©iaemeDocument9 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- Optimization of Electrical Discharge Machining Process Parameters Using Taguchi MethodDocument10 pagesOptimization of Electrical Discharge Machining Process Parameters Using Taguchi MethodRajapandian TNo ratings yet

- 67 Ijmperdaug201867Document6 pages67 Ijmperdaug201867TJPRC PublicationsNo ratings yet

- Msword&Rendition 1Document22 pagesMsword&Rendition 1ashwini yewaleNo ratings yet

- Optimization of WEDM Machining Process Parameters With Modified TLBO Method PDFDocument8 pagesOptimization of WEDM Machining Process Parameters With Modified TLBO Method PDFSubbu SuniNo ratings yet

- Multi-Responses Optimization of Edm Sinkingprocess of Aisi D2 Tool Steel Using Taguchi Grey-Fuzzy MethodDocument7 pagesMulti-Responses Optimization of Edm Sinkingprocess of Aisi D2 Tool Steel Using Taguchi Grey-Fuzzy MethodArief RachmanNo ratings yet

- Simultaneous Optimisation of Multiple Performance Characteristics in micro-EDM Drilling of Titanium AlloyDocument9 pagesSimultaneous Optimisation of Multiple Performance Characteristics in micro-EDM Drilling of Titanium AlloyAnnada Prasad MoharanaNo ratings yet

- Analysis of EDM Process Parameters On Inconel 718 Using The Grey-Taguchi and Topsis MethodsDocument8 pagesAnalysis of EDM Process Parameters On Inconel 718 Using The Grey-Taguchi and Topsis MethodsuniquetechvideosNo ratings yet

- Parametric Study of Dry WEDM Using Taguchi Method: S.Boopathi, K.Sivakumar, R.KalidasDocument6 pagesParametric Study of Dry WEDM Using Taguchi Method: S.Boopathi, K.Sivakumar, R.KalidasIJERDNo ratings yet

- Optimization of The Welding Parameters in Resistance Spot WeldingDocument6 pagesOptimization of The Welding Parameters in Resistance Spot WeldingIAEME PublicationNo ratings yet

- PCD Wire Edm TechnologyDocument6 pagesPCD Wire Edm Technologyyorf1989No ratings yet

- Analysis of Influence of micro-EDM Parameters On MRR, TWR and Ra in Machining Ni-Ti Shape Memory AlloyDocument6 pagesAnalysis of Influence of micro-EDM Parameters On MRR, TWR and Ra in Machining Ni-Ti Shape Memory AlloyJanak ValakiNo ratings yet

- Multi-Response Optimization of CNC Wedm Process Taguchi Grey Relational AnalysisDocument7 pagesMulti-Response Optimization of CNC Wedm Process Taguchi Grey Relational AnalysisAmanpreet SinghNo ratings yet

- International Journal of Industrial Engineering ComputationsDocument12 pagesInternational Journal of Industrial Engineering ComputationsVarun Tech-GeekNo ratings yet

- IMECS2009 pp1803-1808Document6 pagesIMECS2009 pp1803-1808neerajNo ratings yet

- Optimization of Wire Edm Process Parameters For Machining of Amcs (413/B C) Using Taguchi TechniqueDocument8 pagesOptimization of Wire Edm Process Parameters For Machining of Amcs (413/B C) Using Taguchi TechniqueTJPRC PublicationsNo ratings yet

- Design and Analysis of Process Parameters On Multistage Wire Drawing Process-A ReviewDocument10 pagesDesign and Analysis of Process Parameters On Multistage Wire Drawing Process-A ReviewTJPRC PublicationsNo ratings yet

- Analysis and Optimization of Process Parameters in EDM of RENE 80 Using Taguchi MethodDocument6 pagesAnalysis and Optimization of Process Parameters in EDM of RENE 80 Using Taguchi MethodBONFRINGNo ratings yet

- Effect of Machining Parameters On Surface Roughness of H13 Steel in Edm Process Using Powder Mixed FluidDocument3 pagesEffect of Machining Parameters On Surface Roughness of H13 Steel in Edm Process Using Powder Mixed FluidNguyễn Hữu PhấnNo ratings yet

- Multi-Objective Optimization of The Dry Electric Discharge Machining ProcessDocument29 pagesMulti-Objective Optimization of The Dry Electric Discharge Machining Processirinuca12No ratings yet

- Seminar 1Document22 pagesSeminar 1ashwini yewaleNo ratings yet

- Modeling and Analysis of The Effects of Machining Parameters On The Performance Characteristics in The Edm Process of Al O +tic Mixed CeramicDocument11 pagesModeling and Analysis of The Effects of Machining Parameters On The Performance Characteristics in The Edm Process of Al O +tic Mixed CeramicusbkitsNo ratings yet

- Fuzzy Logic Research PaperDocument15 pagesFuzzy Logic Research PaperBhartish AchutaraoNo ratings yet

- 1 s2.0 S1018364717303336 Main PDFDocument8 pages1 s2.0 S1018364717303336 Main PDFMathias BoldtNo ratings yet

- Prediction of Material Removal Rate For Aluminum BIS-24345 Alloy in Wire-Cut EDMDocument11 pagesPrediction of Material Removal Rate For Aluminum BIS-24345 Alloy in Wire-Cut EDMGopinath GangadhariNo ratings yet

- Ijaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)Document9 pagesIjaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)IAEME PublicationNo ratings yet

- Optimization of wire-EDM Process of Titanium Alloy-Grade 5 Using Taguchi's Method and Grey Relational AnalysisDocument10 pagesOptimization of wire-EDM Process of Titanium Alloy-Grade 5 Using Taguchi's Method and Grey Relational Analysismustafa sertNo ratings yet

- Materials Today: Proceedings: S.S. Shirguppikar, M.S. PatilDocument6 pagesMaterials Today: Proceedings: S.S. Shirguppikar, M.S. PatilShailesh ShirguppikarNo ratings yet

- CPIE-2016 Paper 21 PDFDocument9 pagesCPIE-2016 Paper 21 PDFAtul ChauhanNo ratings yet

- Investigation On Electro Discharge Machining of H13Document10 pagesInvestigation On Electro Discharge Machining of H13Nguyễn Hữu PhấnNo ratings yet

- Optimalisasi Hasil Proses Wire-Cut Edm Dengan Metode Principal Component Analysis (Pca) (Studi Kasus Di CV - Catur Prasetya Packindo) Mulyadi, Agus Puji SuryantoDocument6 pagesOptimalisasi Hasil Proses Wire-Cut Edm Dengan Metode Principal Component Analysis (Pca) (Studi Kasus Di CV - Catur Prasetya Packindo) Mulyadi, Agus Puji SuryantoSigit BagusNo ratings yet

- 3980 1 7841 1 10 20170130Document6 pages3980 1 7841 1 10 20170130Sigit Juniarto PrabaowoNo ratings yet

- Sharma 2021 IOP Conf. Ser. - Mater. Sci. Eng. 1116 012030Document13 pagesSharma 2021 IOP Conf. Ser. - Mater. Sci. Eng. 1116 012030Areeb HasanNo ratings yet

- IMECS2009 pp1803-1808Document6 pagesIMECS2009 pp1803-1808Ratan KumarNo ratings yet

- Experimental Investigation of Material Removal Rate in CNC Turning Using Taguchi MethodDocument10 pagesExperimental Investigation of Material Removal Rate in CNC Turning Using Taguchi MethodVidyanand Kumar YadavNo ratings yet

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNo ratings yet

- NSGA and TaguchiDocument9 pagesNSGA and TaguchiRahulKumarNo ratings yet

- Experimental Investigation On Surface Integrity in Machining of Inconel X750 With WEDM Using Taguchi TechniqueDocument15 pagesExperimental Investigation On Surface Integrity in Machining of Inconel X750 With WEDM Using Taguchi TechniqueRiddhijit ChattopadhyayNo ratings yet

- Machining ResearchDocument11 pagesMachining ResearchdeesingNo ratings yet

- IJTech ME 870 Modeling of WEDM Parameters While Machining MgSiCDocument9 pagesIJTech ME 870 Modeling of WEDM Parameters While Machining MgSiCAlagar SamyNo ratings yet

- Optimization of Process Parameters in Wire-EDM of AL6063-T6 Alloy Using Taguchi DOEDocument12 pagesOptimization of Process Parameters in Wire-EDM of AL6063-T6 Alloy Using Taguchi DOEIJRASETPublicationsNo ratings yet

- Submitted By:-Vikram Singh Roll No:-2511666 Mechanical Engineering DeptDocument45 pagesSubmitted By:-Vikram Singh Roll No:-2511666 Mechanical Engineering DeptManjeet BohatNo ratings yet

- Selection of Wire Electrical Discharge Machining Process Parameters Using Non-Traditional Optimization AlgorithmsDocument11 pagesSelection of Wire Electrical Discharge Machining Process Parameters Using Non-Traditional Optimization AlgorithmsBrijKishoreSinghNo ratings yet

- An Overview of Major Research Areas in Wire Cut EDDocument16 pagesAn Overview of Major Research Areas in Wire Cut EDĐặng Tiến LâmNo ratings yet

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNo ratings yet

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 pagesBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationNo ratings yet

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 pagesAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationNo ratings yet

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 pagesImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationNo ratings yet

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 pagesA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationNo ratings yet

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 pagesVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationNo ratings yet

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 pagesInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationNo ratings yet

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 pagesA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationNo ratings yet

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 pagesA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationNo ratings yet

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 pagesRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationNo ratings yet

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 pagesApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationNo ratings yet

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 pagesVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationNo ratings yet

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 pagesOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationNo ratings yet

- Analyzability Metric For Maintainability of Object Oriented Software SystemDocument14 pagesAnalyzability Metric For Maintainability of Object Oriented Software SystemIAEME PublicationNo ratings yet

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 pagesA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationNo ratings yet

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 pagesFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationNo ratings yet

- Investment Strategies in NBFCS: An Over ViewDocument9 pagesInvestment Strategies in NBFCS: An Over ViewIAEME PublicationNo ratings yet

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 pagesDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationNo ratings yet

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 pagesQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationNo ratings yet

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 pagesKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationNo ratings yet

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 pagesA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationNo ratings yet

- Camel Analysis of NBFCS in TamilnaduDocument7 pagesCamel Analysis of NBFCS in TamilnaduIAEME PublicationNo ratings yet

- Ipc2010 31293Document10 pagesIpc2010 31293Sriven ReddyNo ratings yet

- Air Pollution From Fertilizer Industries Roll No.61Document4 pagesAir Pollution From Fertilizer Industries Roll No.61umarNo ratings yet

- Jindal Seamless Pipe Price List - Jindal Seamless Pipe Price List - Jindal Pipes Price List - Jindal Pipes Prices - Jindal Seamless Pipe Suppliers - Trident SteelDocument4 pagesJindal Seamless Pipe Price List - Jindal Seamless Pipe Price List - Jindal Pipes Price List - Jindal Pipes Prices - Jindal Seamless Pipe Suppliers - Trident Steelkaruna0% (1)

- Whirlpool ADG689 - Ix DishwasherDocument13 pagesWhirlpool ADG689 - Ix Dishwasherairwolf4226No ratings yet

- Fired Heaters and Boilers InspectionDocument31 pagesFired Heaters and Boilers Inspectionriysall100% (1)

- Desaireador GKMOSS - Tray - Deaerator - Brochure PDFDocument6 pagesDesaireador GKMOSS - Tray - Deaerator - Brochure PDFCdMoraSNo ratings yet

- Leser PSV Type 447Document4 pagesLeser PSV Type 447santhoshkumarplNo ratings yet

- Toyota Case StudyDocument22 pagesToyota Case StudySavinder SachdevNo ratings yet

- Ammonia ScrubbersDocument7 pagesAmmonia Scrubbersangelo pascuaNo ratings yet

- (A3) Cementitious Waterproofing Applicator ListDocument1 page(A3) Cementitious Waterproofing Applicator ListjimdabrondNo ratings yet

- Ji 2008 JB00 K NNLC 000 0001 PDFDocument41 pagesJi 2008 JB00 K NNLC 000 0001 PDFHamza ChemmamNo ratings yet

- Astm C642 97Document1 pageAstm C642 97teimimineNo ratings yet

- Heat Exchanger Aftercooler and SeparatorDocument16 pagesHeat Exchanger Aftercooler and Separatorjaskaran singhNo ratings yet

- 3 Electrical Component SpecificationDocument9 pages3 Electrical Component SpecificationqwureyquweryNo ratings yet

- Piston Ring PDFDocument3 pagesPiston Ring PDFArun SNo ratings yet

- Nuts and BoltsDocument27 pagesNuts and BoltsGaurav Kantrod100% (3)

- Howell Bunger Valve 05 HBGR Text New Cover PDFDocument4 pagesHowell Bunger Valve 05 HBGR Text New Cover PDFRoger Labra LlanoNo ratings yet

- Phocos Datasheet CML E-WebDocument2 pagesPhocos Datasheet CML E-WebRedHammerNo ratings yet

- Sigmazinc 158Document7 pagesSigmazinc 158JORGEALEXERNo ratings yet

- Boilers EmissionDocument2 pagesBoilers EmissionGopinath KaliyaperumalNo ratings yet

- Tutorial 9 - Brayton CycleDocument3 pagesTutorial 9 - Brayton CycleasdfsdjhNo ratings yet

- 15ME62T U1 PR. S3pptxDocument7 pages15ME62T U1 PR. S3pptxSeema PintoNo ratings yet

- JWB - AAL Engineering - Cabint Quotation - 15JUL22Document5 pagesJWB - AAL Engineering - Cabint Quotation - 15JUL22Alexander LiwanagNo ratings yet

- Pso Alpha GreaseDocument1 pagePso Alpha GreaseMuhammad EhsanNo ratings yet

- Discussion On Distribution Lines SlideDocument12 pagesDiscussion On Distribution Lines SlideErfan AhmedNo ratings yet

- ESAB Transportation Catalogue 201181132250 20118916190 PDFDocument68 pagesESAB Transportation Catalogue 201181132250 20118916190 PDFcengizarda1979No ratings yet

Ijmet: ©iaeme

Ijmet: ©iaeme

Uploaded by

IAEME PublicationOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijmet: ©iaeme

Ijmet: ©iaeme

Uploaded by

IAEME PublicationCopyright:

Available Formats

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print),

ISSN 0976 6359(Online), Volume 5, Issue 5, May (2014), pp. 180-188 IAEME

180

THE EFFECT OF DIFFERENT WIRE ELECTRODES ON THE MRR OF MS

WORKPIECE USING WEDM PROCESS

Manpreet Singh

1

, Amandeep Singh Bansal

2

, Sanjeev Kumar

3

1-3

(Dept of Mechanical Engg., CTIEMT, Shahpur, India,)

ABSTRACT

Wire electrical discharge machining (WEDM) is a specialized thermal machining process

which is capable of accurate machining of parts which have varying hardness, complex shapes and

sharp edges that are hard to be machined by the traditional machining processes. . Predictions on the

Material Removal Rate of workpieces in WEDM have been reported in the past. In the present study

an analysis has been done to evaluate the Material Removal Rate of MS workpiece using WEDM

process with different types of wire electrodes. It has been found that the effect of material of wire,

on percentage improvement in Material Removal Rate (MRR) is prominent. Result shows that

improvement in MRR is higher with copper wire as compared to other wire electrodes. Also MRR

reduces gradually as the value of current in the circuit was increased.

Keywords: Wire EDM, Material Removal Rate, Material of Wire Electrode, Brass Wire,

Zinc Coated Brass Wire.

1. INTRODUCTION

Wire electrical discharge machining (WEDM) is a specialized thermal machining process

which is capable of accurate machining of parts which have varying hardness, complex shapes and

sharp edges that are hard to be machined by the traditional machining processes. The technology of

WEDM process is based on the conventional EDM sparking principle utilizing the widely accepted

noncontact technique of material removal [1]. The main aim of the researchers is to obtain the

improved material removal rate with desired surface finish of the workpiece. Enormous research has

been carried out to maximize the material removal rate in the past.

Prasad beri et al. proposed that EDM researchers have explored a number of ways to progress

and optimize the MRR including some unique experimental models that depart from the traditional

INTERNATIONAL JOURNAL OF MECHANICAL ENGINEERING

AND TECHNOLOGY (IJMET)

ISSN 0976 6340 (Print)

ISSN 0976 6359 (Online)

Volume 5, Issue 5, May (2014), pp. 180-188

IAEME: www.iaeme.com/ijmet.asp

Journal Impact Factor (2014): 7.5377 (Calculated by GISI)

www.jifactor.com

IJMET

I A E M E

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print),

ISSN 0976 6359(Online), Volume 5, Issue 5, May (2014), pp. 180-188 IAEME

181

EDM sparking singularity. All the research work in this area is done to achieve more efficient MRR

coupled with decline in Tool Wear Rate (TWR) and improved surface finish. They conclude that in

order to increase the MRR and reduce TWR, best suitable dielectric is needed. They also concluded

that an optimum value of powder in dielectric is necessary to achieve the high MRR and reduced

TWR [2].

Lin and Lin, reported the use of an orthogonal array, grey relational generating, grey

relational coefficient, grey-fuzzy reasoning grade and analysis of variance to study the performance

characteristics of the WEDM machining process. The machining parameters (pulse on time, duty

factor and discharge current) with considerations of multiple responses (electrode wear ratio,

material removal rate and surface roughness) were effective. The grey-fuzzy logic approach helped

to optimize the electrical discharge machining process with multiple process responses. The process

responses such as the electrode wear ratio, material removal rate and surface roughness in the

electrical discharge machining process could be greatly improved [3].

EN 31 steel, when machined with cryogenic treated brass wire, with three process parameters

namely type of wire electrode, pulse width, and wire tension, shows a significant improvement in

Surface Roughness than the untreated wire electrode. Strong interaction is observed between type of

wire and wire tension; pulse width and wire tension [4].

For determining the optimal parametric settings, lot of work has been done in the engineering

design. But mostly all of them concentrated on a single response problem. However, the WEDM

processes are having several important performance characteristics like MRR, SR, etc. The optimal

parametric settings with to different performance characteristics are different [5].

Scott et al. have presented a formulation and solution of a multi objective optimization

problem for the selection of the best parameter settings on a WEDM machine. The measures of

performance for the model were MRR and surface quality. In that study, a factorial design model has

been used to predict the measures of performance as a function of a variety of machining parameters

[6].

Fuzhu Han et al. have found that the material removal rate is much higher when short pulse

duration is used as compared to longer pulse duration. Moreover, from the single discharge

experiments, they found that when the pulse energy was reduced to a certain value; a long pulse

duration combined with a low peak value could not produce craters on the workpiece surface any

more [7]. Kodalagara Puttanarasaiah Somashekhar et al. have presented presents the formulation and

solution of optimization of various process parameters for the selection of the best control settings on

microwire electrical discharge machining. They have found that at discharge energy of 2,645 J,

maximum MRR of 0.0428 mm

3

/ min and an overcut value of 69 m are observed. With the value of

discharge energy changing from 32 to 4,500 J, the Ra value of slot surface varied from 1.17 to

4.25 m. After the analysis the average erosion efficiency is found to be around 27% [8]. S. S.

Mahapatra et al. have used Taguchis parameter design to find out the significant machining

parameters affecting the performance measures. With the help of nonlinear regression analysis they

have established the relationship between control factors and responses like MRR, SF and kerf. They

have concluded that the WEDM process parameters can be adjusted to achieve better metal removal

rate, surface finish [9]. Adeel Ikram et al. have reported the effect and optimization of selected eight

control factors on material removal rate (MRR), surface roughness and kerf in wire electrical

discharge machining (WEDM) process for tool steel D2.they have developed linear regression and

additive models for all the response factors. They have concluded that pulse on-time is the most

significant factor affecting the surface roughness, kerf and material removal rate [10]. Hari Singh el

al. have studied the effects of WEDM process parameters like pulse on time, pulse off time , gap

voltage, peak current, wire feed and wire tension; on material removal rate of hot die steel (H-11)

using one variable at a time approach. After a long series of experiments they have concluded that

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print),

ISSN 0976 6359(Online), Volume 5, Issue 5, May (2014), pp. 180-188 IAEME

182

the material removal rate increases with increase in pulse on time and peak current, while decreases

with increase in pulse off time and servo voltage [11].

2. SCHEME OF EXPERIMENTS

The experiments were performed on electronica sprint cut machine using a work piece of MS

of dimensions 25mm x 25mm of thickness 5 mm.

The selected parameters and their range for the detailed experiments are shown in Table 1.

Table 1: Process Parameters & their Range

S. No. Parameter Range Unit

1 Material of Wire Copper, Brass, Zinc Coated Brass ----

2 Current 3-7 Amp

3 T

on

110-130 Micro Sec

4 T

off

35 Micro Sec

5 Wire Tension 9 Grams

6 Servo Voltage 20 Volt

The experiments have to be designed so that we can study the effect of some selected

parameters on response characteristics of WEDM process. To study the effect of same Taguchi

parametric design methodology was adopted. The experiments were conducted using

appropriate orthogonal array (OA).

The non-linear behaviour exists among the process parameters, can only be studied if more

than two levels of the parameters are used. Therefore, each parameter was analyzed at three levels.

The selected number of process parameters and their levels are given in Table 2. For the sake of

simplification, the second order interactions among the parameters were not considered.

Each three level parameter has 2 degree of freedom (DOF = Number of levels-1), overall

mean has a degree of freedom of 1, and the total DOF required for three parameters each at three

levels is 7 =1+ [3 x (3-1)]. As per Taguchis method the total DOF of selected OA must be greater

than or equal to the total DOF required for the experiment. So an L

9

(a standard 3-level OA) having 8

= (9-1) degree of freedom was selected for the present analysis. Standard L

9

OA with the parameters

assigned by using linear graphs is given in Table 3.

Table 2: Process Parameters with Symbols and their Values at Different Levels

Symbol

Process

Parameters

Unit Level 1 Level 2 Level 3

M

Material of

Wire

---- Copper Brass

Zinc Coated

Brass

C Current A 3 5 7

T T

on

Micro Sec 110 120 130

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print),

ISSN 0976 6359(Online), Volume 5, Issue 5, May (2014), pp. 180-188 IAEME

183

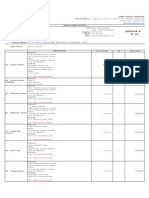

Table 3: Orthogonal array for L9 with responses (RAW data/ S/N Ratios)

Exp.

No.

Run

Order

Material Removal

S/N Ratio (dB)

R1 R2 R3

1 1 4.41 8.33 6.37 16.08

2 4 5.56 5.88 5.72 15.15

3 7 7.3 8.71 8.01 18.07

4 2 3.25 9.85 6.55 16.32

5 5 11.43 4.29 7.86 17.91

6 8 3.11 3.17 3.14 9.94

7 3 7.21 6.33 6.77 16.61

8 6 3.09 2.9 2.99 9.53

9 9 4.6 3.23 3.92 11.85

Total 49.96 52.69 51.33

T

MR

=Overall mean of MR

= 5.70

3. RESULTS & DISCUSSION

The average values of %age improvement in surface roughness and S/N ratio for each

parameter at Level L

1

, L

2

and L

3

are calculated and given in Table 4. These values have been plotted

in Fig. 1, Fig. 2, and Fig. 3.

Table 4: Average values & main effects: Material Removal Rate

Process

Parameter

Level Material of Wire Current T

on

Type of Data

Raw

Data

(mg)

S/N

Ratio

(dB)

Raw

Data

(mg)

S/N

Ratio

(dB)

Raw

Data

(mg)

S/N

Ratio

(dB)

Average

Values (MR)

L

1

6.70 16.12 6.56 15.16 4.17 11.55

L

2

5.85 13.16 5.53 13.50 5.40 13.47

L

3

4.56 12.56 5.02 13.17 7.55 16.80

Main Effects

(MR)

L

2

-L

1

-0.85 -2.96 -1.04 -1.66 1.23 1.92

L

3

-L

2

-1.29 -0.60 -0.51 -0.33 2.15 3.33

Difference

{( L

3

-L

2

)-( L

2

-L

1

)}

-0.44 2.36 0.53 1.33 0.92 1.42

L

1

, L

2

& L

3

represent levels 1, 2, & 3 respectively of parameters. L

2

-L

1

is the average

main effect when the corresponding parameter changes from level 1 to level 2. L

3

-L

2

is the main effect when the corresponding parameter changes from level 2 to level 3.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print),

ISSN 0976 6359(Online), Volume 5, Issue 5, May (2014), pp. 180-188 IAEME

184

12.5

13.5

14.5

15.5

16.5

Cu B ZB

Material of Wire

S

/

N

R

a

t

i

o

(

d

B

)

4

5

6

7

%

I

m

p

r

o

v

e

m

e

n

t

i

n

M

R

(

m

g

)

S/N Raw data

Fig. 1: Effect of Material of Wire on S/N Ratio & Material Removal.

The effect of the Material of Wire on S/N Ratio & Material Removal can be clearly seen in

the fig. 1. It can be seen from the figure that the Material Removal decreases directly as the Material

of Wire is changed from Copper to zinc coated brass. Highest Material Removal is obtained with

Copper wire. The decrease in Material Removal is observed when the Brass Wire is used, Material

Removal is further decreased when Zinc coated Brass Wire is used for cutting. This is due to the fact

that as the hardness of the electrode material is increased the material removal is increased. In the

present study zinc coated brass wire is the soft material and copper being the hardest from rest of

two. Thats why the material removal is higher when copper wire is used for cutting.

13

13.5

14

14.5

15

15.5

16

3 5 7

Current (A)

S

/

N

R

a

t

i

o

(

d

B

)

4.8

5

5.2

5.4

5.6

5.8

6

6.2

6.4

6.6

6.8

%

I

m

p

r

o

v

e

m

e

n

t

i

n

M

R

(

m

g

)

S/N Rawdata

Fig. 2: Effect of Current on S/N Ratio & Material Removal.

Another Parameter that affects the Material Removal with these parameters is Current. Fig. 2

shows the variation of Material Removal with respect to Current. Highest value of Material Removal

is observed at 3A, after that when the value of current is increased from 3A to 7A the decrease in

Material Removal is observed. Lowest value of Material Removal is shown at 7A current, as shown

in the figure 2. This is because of the fact that as the hardness of the electrode wire is decreased the

material removal is also decreased. The hardness of plain brass wire is probably less as compared to

the work piece material thats why material removal was decreased with the increase in current. Now

as the current during the cycle is increased more deterioration of wire takes place as compared to

work piece material.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print),

ISSN 0976 6359(Online), Volume 5, Issue 5, May (2014), pp. 180-188 IAEME

185

10

11

12

13

14

15

16

17

110 120 130

Ton(Micro Sec.)

S

/

N

R

a

t

i

o

(

d

B

)

3.8

4.3

4.8

5.3

5.8

6.3

6.8

7.3

7.8

%

I

m

p

r

o

v

e

m

e

n

t

i

n

M

R

(

m

g

)

S/N Rawdata

Fig. 3: Effect of Ton on S/N Ratio & Material Removal

One more parameter that was used in cutting was T

on

; Figure 3 shows the variation of

material removal with respect to various values of T

on

. The Figure show that the material removal is

increased directly as the value of T

on

is increased. Maximum value of material removal is observed at

the third value of T

on

(i.e.130 micro Sec). This is due to the fact that when the cycle time (i.e. T

on

) is

increased, the current is allowed to pass through the wire electrode to work piece for an increased

time interval as a result of that the material removal is increased.

Pooled ANOVA tables for raw data and S/N Ratio data of surface roughness are shown

below in the Tables 5 and 6 respectively.

Table 5: Pooled ANOVA (Raw Data, MR)

SOURCE SS DOF V F- RATIO P%

Material of Wire 20.86 2 10.43 3.43 10.17

Current 11.14 2 5.57 1.8 3.48

T

on

52.58 2 26.29 8.64 31.98

Error 60.79 20 3.03 54.36

Total (T) 145.40 26 -- 100

Significant at 95% confidence level, F

critical

=3.55

SS- Sum of Squares, DOF- Degree of Freedom, V- Variance

Table 6: Pooled ANOVA (S/N Ratio Data, MR)

SOURCE SS DOF V F- RATIO P%

Material of Wire 21.76 2 10.88 61.76 30.05

Current 6.78 2 3.39 19.25 9.03

T

on

42.36 2 21.18 120.19 58.95

Error 0.35 2 0.18 1.98

Total (T) 71.26 8 -- 100

Significant at 95% confidence level, F

critical

=3.55

SS- Sum of Squares, DOF- Degree of Freedom, V- Variance

4. ESTIMATION OF OPTIMUM RESPONSE CHARACTERISTICS

As observed the optimum values for maximum MR are M

1

C

1

T

3

for both raw and S/N data.

The mean at the optimal MR (optimal value of the response characteristic) is estimated as:

MR = T T C M 2

3 1 1

+ + (1)

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print),

ISSN 0976 6359(Online), Volume 5, Issue 5, May (2014), pp. 180-188 IAEME

186

T

= overall mean of the response = 5.70 (Table 3)

1 M = Average value of MR at the First level of Material of Wire = 6.70 (Table 6)

1

C = Average value of MR at the First level of Current = 6.56 (Table 6)

3

T = Average value of MR at the third level of T

on

= 7.55 (Table 6)

Substituting these values in equation (1), MR = 9.41

The confidence interval of confirmation experiments (CI

CE

) and of population (CI

POP

) is calculated

by using the following equations:

+ =

R

1

n

1

V ) f (1, F CI

eff

e e CE

eff

e e

POP

n

V ) f (1, F

CI =

Where, F

(1, f

e

) = The F-ratio at the confidence level of (1-) against DOF 1 and error degree of

freedom f

e

= 4.35 (Tabulated F value)

f

e

= error DOF = 20 (Table 5)

N = Total number of result = 27 (treatment = 9, repetition = 3)

R = Sample size for confirmation experiments = 3

V

e

= Error variance = 3.03 (Table 5)

n

eff

= = 3.86

So, CI

CE

= 12.49

And CI

POP

= 8.26

The 95% confirmation interval of predicted optimal range (for confirmation run of three

experiments) is:

Mean MR CI

CE

< MR > Mean MR + CI

CE

-3.09

< MR >

21.90

The 95% confirmation interval of the predicted mean is:

Mean MR CI

POP

< MR > Mean MR + CI

POP

1.14 < MR > 17.67

5. CONFORMATION EXPERIMENT

In order to validate the results obtained, three confirmation experiments have been conducted

for response characteristics of MR at the optimal levels of Material of Wire at level One (M

1

),

Current at level One (C

1

) and T

on

at level Three (T

3

). Result of conformation experiments is shown in

table 7.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print),

ISSN 0976 6359(Online), Volume 5, Issue 5, May (2014), pp. 180-188 IAEME

187

Table 7: Predicted Optimal Values, Confidence Intervals and Results of Confirmation Experiments

Response

Characteristics

Optimal

Process

Parameters

Predicted

Optimal

Value

Confidence Interval

95%

Actual Value (Avg.

of Confirmation

EXP.)

MR M

1

C

1

T

3

9.41

CI

CE

:-3.09<MR>21.90

CI

POP

:1.14<MR>17.70

CI

CE

: 15.86

CI

POP

: 12.46

% Improvement

in R

a

M

2

C

3

T

3

4.58

CI

CE

:2.77<R

a

>6.38

CI

POP

:3.79<R

a

>5.36

CI

CE

: 3.90

CI

POP

: 4.08

CI

CE

Confidence interval for the mean of the confirmation experiments

CI

POP

Confidence interval for the mean of the population

6. CONCLUSIONS

The important conclusions drawn from the present study are summarized below:

1. The effect of material of wire, on percentage improvement in Material Removal Rate (MRR) is

found to be prominent.

2. As the material of the wire is changed from copper to brass then to zinc coated brass Material

Removal Rate decreases.

3. Best result is obtained with plain copper wire with a maximum MRR of 6.7%. Also at the

maximum value of T

on

, MRR is found to be 7.55 %.

4. MRR reduces gradually as the value of current in the circuit was increased.

7. REFERENCES

[1] Technological Manual of Electronica Sprincut Wire-cut Electrical Discharge Machine.

[2] Prasad Beri, Dielectric Fluid in Electro Discharge Machining, International Journal of

Manufacturing Technology, 2005.

[3] Lin, J.L., Lin, C.L., The use of grey-fuzzy logic for the optimization of the manufacturing

process, Journal of Materials Processing Technology, 160, 2004, 914.

[4] Kapoor J., Khamba J.S., Singh S., Effects of Cryogenic Treated Wire Electrode on the

Surface of EN31 Steel Machined by WEDM, International Journal of Surface Engineering

and Material Technology, Vol. 1, Issue 1, 2011, 43-47.

[5] M. Singh, H. Lal, R. Singh, Recent Developments in WEDM: A Review, IJRMET, Vol. 3,

Issue 2, 2013, 150-152.

[6] Scott D, Boniya S, Rajurkar KR, Analysis and optimization of parameter combination in wire

electrical discharge machining, International Journal of Production research, Vol. 29, Issue

11, 1991, 2189-2207.

[7] F. Han, J. Jiang, D. Yu, Influence of machining parameters on surface roughness in finish cut

of WEDM, The International Journal of Advanced Manufacturing Technology, Vol. 34, Issue

5-6, 2007, 538-546.

[8] K. P. Somashekhar, N. Ramachandran, J. Mathew, Material removal characteristics of

microslot (kerf) geometry in -WEDM on aluminum, The International Journal of Advanced

Manufacturing Technology, Vol. 51, Issue 5-8, 2010, 611-626.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print),

ISSN 0976 6359(Online), Volume 5, Issue 5, May (2014), pp. 180-188 IAEME

188

[9] S. S. Mahapatra, A. Patnaik, Optimization of wire electrical discharge machining (WEDM)

process parameters using Taguchi method, The International Journal of Advanced

Manufacturing Technology , Vol. 34, Issue 9-10, 2007, 911-925.

[10] A. Ikram, N. A. Mufti, M. Q. Saleem, A. R. Khan, Parametric optimization for surface

roughness, kerf and MRR in wire electrical discharge machining (WEDM) using Taguchi

design of experiment, Journal of Mechanical Science and Technology, Vol. 27, Issue 7,

2013, 2133-2141.

[11] H. Singh, R. Garg, Effects of process parameters on material removal rate in WEDM, Journal

of Achievements in Materials and Manufacturing Engineering, Vol. 32, 2009, 0-74.

[12] Y.S.Sable, R.B.Patil and Dr.M.S.Kadam, Investigation of MRR in WEDM for Wc-Co

Sintered Composite, International Journal of Mechanical Engineering & Technology

(IJMET), Volume 4, Issue 3, 2013, pp. 349 - 358, ISSN Print: 0976 6340, ISSN Online:

0976 6359.

[13] Shalaka Kulkarni and Manikrodge, Process Parameter Optimisation in WEDM of Hchcr

Steel using Taguhi Method and Utility Concept, International Journal of Mechanical

Engineering & Technology (IJMET), Volume 5, Issue 1, 2014, pp. 57 - 67, ISSN Print: 0976

6340, ISSN Online: 0976 6359.

[14] S V Subrahmanyam and M. M. M. Sarcar, WEDM Process Modeling with Data Mining

Techniques, International Journal of Advanced Research in Engineering & Technology

(IJARET), Volume 4, Issue 7, 2013, pp. 161 - 169, ISSN Print: 0976-6480, ISSN Online:

0976-6499.

[15] S V Subrahmanyam and M. M. M. Sarcar, Parametric Optimization for Cutting Speed A

Statistical Regression Modeling for WEDM, International Journal of Advanced Research in

Engineering & Technology (IJARET), Volume 4, Issue 1, 2013, pp. 142 - 150, ISSN Print:

0976-6480, ISSN Online: 0976-6499.

You might also like

- Carrier Service ManualDocument40 pagesCarrier Service ManualMetalloy67% (9)

- Variolink+Esthetic DC - Composite - Glass Ceramic Restorations - Flow Chart - enDocument2 pagesVariolink+Esthetic DC - Composite - Glass Ceramic Restorations - Flow Chart - engmacaneata100% (1)

- Lab Report EEE111 Exp 1Document23 pagesLab Report EEE111 Exp 1Hazizi Khairy75% (4)

- Science Lab Equipment Study SheetDocument2 pagesScience Lab Equipment Study Sheetapi-314843596100% (1)

- Ijmet: ©iaemeDocument8 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- Parameter Optimization of Electro Discharge Machine of AISI 304 Steel by Using Taguchi MethodDocument5 pagesParameter Optimization of Electro Discharge Machine of AISI 304 Steel by Using Taguchi MethodInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Comparative Performance of Wet and Near-Dry Edm Process For Machining of Oil Hardned Non Sinking Steel MaterialDocument10 pagesComparative Performance of Wet and Near-Dry Edm Process For Machining of Oil Hardned Non Sinking Steel MaterialIAEME PublicationNo ratings yet

- 1114meij04 PDFDocument9 pages1114meij04 PDFAli RazaNo ratings yet

- Optimization of EDM Process Parameters in Machining of 17-4 PH Steel Using Taguchi MethodDocument8 pagesOptimization of EDM Process Parameters in Machining of 17-4 PH Steel Using Taguchi Method317-Darpan SatijaNo ratings yet

- Application of GRA For Optimal Machining Parameter Selection in EDMDocument8 pagesApplication of GRA For Optimal Machining Parameter Selection in EDMBrijKishoreSinghNo ratings yet

- A Case Study On Quality and ProductivityDocument10 pagesA Case Study On Quality and ProductivityG Hitesh ReddyNo ratings yet

- Optimization of Process Parameters in Wedm Process On Two Workpieces of Materials Hardox-400 and Hardox-500Document12 pagesOptimization of Process Parameters in Wedm Process On Two Workpieces of Materials Hardox-400 and Hardox-500TJPRC PublicationsNo ratings yet

- Comparison of Intelligent Optimization Algorithms For Wire Electrical Discharge Machining ParametersDocument7 pagesComparison of Intelligent Optimization Algorithms For Wire Electrical Discharge Machining Parametersmanhtuankt90No ratings yet

- Optimization of Edm Parameters Using Taguchi Method and Grey Relational Analysis For Mild Steel Is 2026Document10 pagesOptimization of Edm Parameters Using Taguchi Method and Grey Relational Analysis For Mild Steel Is 2026irinuca12No ratings yet

- Experimental Investigation and Multi-Objective Optimization of Wire Electrical Discharge Machining (WEDM) of 5083 Aluminum AlloyDocument7 pagesExperimental Investigation and Multi-Objective Optimization of Wire Electrical Discharge Machining (WEDM) of 5083 Aluminum AlloyÐɤ Suman ChatterjeeNo ratings yet

- Parametric Optimization of Machining Parameters of AISI D3 Tool Steel Using Wire Cut Electric Discharge Machining - A Taguchi Based ApproachDocument7 pagesParametric Optimization of Machining Parameters of AISI D3 Tool Steel Using Wire Cut Electric Discharge Machining - A Taguchi Based ApproachjanakNo ratings yet

- Materials Today: Proceedings: M. Subrahmanyam, T. NancharaiahDocument5 pagesMaterials Today: Proceedings: M. Subrahmanyam, T. NancharaiahakashNo ratings yet

- Materials Today: Proceedings: M. Subrahmanyam, T. NancharaiahDocument5 pagesMaterials Today: Proceedings: M. Subrahmanyam, T. NancharaiahakashNo ratings yet

- Parametric Study Along With Selection of Optimal Solutions in Wire Cut Machining of Titanium (Gr2)Document4 pagesParametric Study Along With Selection of Optimal Solutions in Wire Cut Machining of Titanium (Gr2)SundaraPandiyanNo ratings yet

- Ijmet: ©iaemeDocument9 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- Optimization of Electrical Discharge Machining Process Parameters Using Taguchi MethodDocument10 pagesOptimization of Electrical Discharge Machining Process Parameters Using Taguchi MethodRajapandian TNo ratings yet

- 67 Ijmperdaug201867Document6 pages67 Ijmperdaug201867TJPRC PublicationsNo ratings yet

- Msword&Rendition 1Document22 pagesMsword&Rendition 1ashwini yewaleNo ratings yet

- Optimization of WEDM Machining Process Parameters With Modified TLBO Method PDFDocument8 pagesOptimization of WEDM Machining Process Parameters With Modified TLBO Method PDFSubbu SuniNo ratings yet

- Multi-Responses Optimization of Edm Sinkingprocess of Aisi D2 Tool Steel Using Taguchi Grey-Fuzzy MethodDocument7 pagesMulti-Responses Optimization of Edm Sinkingprocess of Aisi D2 Tool Steel Using Taguchi Grey-Fuzzy MethodArief RachmanNo ratings yet

- Simultaneous Optimisation of Multiple Performance Characteristics in micro-EDM Drilling of Titanium AlloyDocument9 pagesSimultaneous Optimisation of Multiple Performance Characteristics in micro-EDM Drilling of Titanium AlloyAnnada Prasad MoharanaNo ratings yet

- Analysis of EDM Process Parameters On Inconel 718 Using The Grey-Taguchi and Topsis MethodsDocument8 pagesAnalysis of EDM Process Parameters On Inconel 718 Using The Grey-Taguchi and Topsis MethodsuniquetechvideosNo ratings yet

- Parametric Study of Dry WEDM Using Taguchi Method: S.Boopathi, K.Sivakumar, R.KalidasDocument6 pagesParametric Study of Dry WEDM Using Taguchi Method: S.Boopathi, K.Sivakumar, R.KalidasIJERDNo ratings yet

- Optimization of The Welding Parameters in Resistance Spot WeldingDocument6 pagesOptimization of The Welding Parameters in Resistance Spot WeldingIAEME PublicationNo ratings yet

- PCD Wire Edm TechnologyDocument6 pagesPCD Wire Edm Technologyyorf1989No ratings yet

- Analysis of Influence of micro-EDM Parameters On MRR, TWR and Ra in Machining Ni-Ti Shape Memory AlloyDocument6 pagesAnalysis of Influence of micro-EDM Parameters On MRR, TWR and Ra in Machining Ni-Ti Shape Memory AlloyJanak ValakiNo ratings yet

- Multi-Response Optimization of CNC Wedm Process Taguchi Grey Relational AnalysisDocument7 pagesMulti-Response Optimization of CNC Wedm Process Taguchi Grey Relational AnalysisAmanpreet SinghNo ratings yet

- International Journal of Industrial Engineering ComputationsDocument12 pagesInternational Journal of Industrial Engineering ComputationsVarun Tech-GeekNo ratings yet

- IMECS2009 pp1803-1808Document6 pagesIMECS2009 pp1803-1808neerajNo ratings yet

- Optimization of Wire Edm Process Parameters For Machining of Amcs (413/B C) Using Taguchi TechniqueDocument8 pagesOptimization of Wire Edm Process Parameters For Machining of Amcs (413/B C) Using Taguchi TechniqueTJPRC PublicationsNo ratings yet

- Design and Analysis of Process Parameters On Multistage Wire Drawing Process-A ReviewDocument10 pagesDesign and Analysis of Process Parameters On Multistage Wire Drawing Process-A ReviewTJPRC PublicationsNo ratings yet

- Analysis and Optimization of Process Parameters in EDM of RENE 80 Using Taguchi MethodDocument6 pagesAnalysis and Optimization of Process Parameters in EDM of RENE 80 Using Taguchi MethodBONFRINGNo ratings yet

- Effect of Machining Parameters On Surface Roughness of H13 Steel in Edm Process Using Powder Mixed FluidDocument3 pagesEffect of Machining Parameters On Surface Roughness of H13 Steel in Edm Process Using Powder Mixed FluidNguyễn Hữu PhấnNo ratings yet

- Multi-Objective Optimization of The Dry Electric Discharge Machining ProcessDocument29 pagesMulti-Objective Optimization of The Dry Electric Discharge Machining Processirinuca12No ratings yet

- Seminar 1Document22 pagesSeminar 1ashwini yewaleNo ratings yet

- Modeling and Analysis of The Effects of Machining Parameters On The Performance Characteristics in The Edm Process of Al O +tic Mixed CeramicDocument11 pagesModeling and Analysis of The Effects of Machining Parameters On The Performance Characteristics in The Edm Process of Al O +tic Mixed CeramicusbkitsNo ratings yet

- Fuzzy Logic Research PaperDocument15 pagesFuzzy Logic Research PaperBhartish AchutaraoNo ratings yet

- 1 s2.0 S1018364717303336 Main PDFDocument8 pages1 s2.0 S1018364717303336 Main PDFMathias BoldtNo ratings yet

- Prediction of Material Removal Rate For Aluminum BIS-24345 Alloy in Wire-Cut EDMDocument11 pagesPrediction of Material Removal Rate For Aluminum BIS-24345 Alloy in Wire-Cut EDMGopinath GangadhariNo ratings yet

- Ijaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)Document9 pagesIjaret: International Journal of Advanced Research in Engineering and Technology (Ijaret)IAEME PublicationNo ratings yet

- Optimization of wire-EDM Process of Titanium Alloy-Grade 5 Using Taguchi's Method and Grey Relational AnalysisDocument10 pagesOptimization of wire-EDM Process of Titanium Alloy-Grade 5 Using Taguchi's Method and Grey Relational Analysismustafa sertNo ratings yet

- Materials Today: Proceedings: S.S. Shirguppikar, M.S. PatilDocument6 pagesMaterials Today: Proceedings: S.S. Shirguppikar, M.S. PatilShailesh ShirguppikarNo ratings yet

- CPIE-2016 Paper 21 PDFDocument9 pagesCPIE-2016 Paper 21 PDFAtul ChauhanNo ratings yet

- Investigation On Electro Discharge Machining of H13Document10 pagesInvestigation On Electro Discharge Machining of H13Nguyễn Hữu PhấnNo ratings yet

- Optimalisasi Hasil Proses Wire-Cut Edm Dengan Metode Principal Component Analysis (Pca) (Studi Kasus Di CV - Catur Prasetya Packindo) Mulyadi, Agus Puji SuryantoDocument6 pagesOptimalisasi Hasil Proses Wire-Cut Edm Dengan Metode Principal Component Analysis (Pca) (Studi Kasus Di CV - Catur Prasetya Packindo) Mulyadi, Agus Puji SuryantoSigit BagusNo ratings yet

- 3980 1 7841 1 10 20170130Document6 pages3980 1 7841 1 10 20170130Sigit Juniarto PrabaowoNo ratings yet

- Sharma 2021 IOP Conf. Ser. - Mater. Sci. Eng. 1116 012030Document13 pagesSharma 2021 IOP Conf. Ser. - Mater. Sci. Eng. 1116 012030Areeb HasanNo ratings yet

- IMECS2009 pp1803-1808Document6 pagesIMECS2009 pp1803-1808Ratan KumarNo ratings yet

- Experimental Investigation of Material Removal Rate in CNC Turning Using Taguchi MethodDocument10 pagesExperimental Investigation of Material Removal Rate in CNC Turning Using Taguchi MethodVidyanand Kumar YadavNo ratings yet

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNo ratings yet

- NSGA and TaguchiDocument9 pagesNSGA and TaguchiRahulKumarNo ratings yet

- Experimental Investigation On Surface Integrity in Machining of Inconel X750 With WEDM Using Taguchi TechniqueDocument15 pagesExperimental Investigation On Surface Integrity in Machining of Inconel X750 With WEDM Using Taguchi TechniqueRiddhijit ChattopadhyayNo ratings yet

- Machining ResearchDocument11 pagesMachining ResearchdeesingNo ratings yet

- IJTech ME 870 Modeling of WEDM Parameters While Machining MgSiCDocument9 pagesIJTech ME 870 Modeling of WEDM Parameters While Machining MgSiCAlagar SamyNo ratings yet

- Optimization of Process Parameters in Wire-EDM of AL6063-T6 Alloy Using Taguchi DOEDocument12 pagesOptimization of Process Parameters in Wire-EDM of AL6063-T6 Alloy Using Taguchi DOEIJRASETPublicationsNo ratings yet

- Submitted By:-Vikram Singh Roll No:-2511666 Mechanical Engineering DeptDocument45 pagesSubmitted By:-Vikram Singh Roll No:-2511666 Mechanical Engineering DeptManjeet BohatNo ratings yet

- Selection of Wire Electrical Discharge Machining Process Parameters Using Non-Traditional Optimization AlgorithmsDocument11 pagesSelection of Wire Electrical Discharge Machining Process Parameters Using Non-Traditional Optimization AlgorithmsBrijKishoreSinghNo ratings yet

- An Overview of Major Research Areas in Wire Cut EDDocument16 pagesAn Overview of Major Research Areas in Wire Cut EDĐặng Tiến LâmNo ratings yet

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationNo ratings yet

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 pagesBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationNo ratings yet

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 pagesAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationNo ratings yet

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 pagesImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationNo ratings yet

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 pagesA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationNo ratings yet

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 pagesVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationNo ratings yet

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 pagesInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationNo ratings yet

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 pagesA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationNo ratings yet

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 pagesA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationNo ratings yet

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 pagesRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationNo ratings yet

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 pagesApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationNo ratings yet

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 pagesVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationNo ratings yet

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 pagesOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationNo ratings yet

- Analyzability Metric For Maintainability of Object Oriented Software SystemDocument14 pagesAnalyzability Metric For Maintainability of Object Oriented Software SystemIAEME PublicationNo ratings yet

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 pagesA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationNo ratings yet

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 pagesFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationNo ratings yet

- Investment Strategies in NBFCS: An Over ViewDocument9 pagesInvestment Strategies in NBFCS: An Over ViewIAEME PublicationNo ratings yet

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 pagesDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationNo ratings yet

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 pagesQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationNo ratings yet

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 pagesKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationNo ratings yet

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 pagesA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationNo ratings yet

- Camel Analysis of NBFCS in TamilnaduDocument7 pagesCamel Analysis of NBFCS in TamilnaduIAEME PublicationNo ratings yet

- Ipc2010 31293Document10 pagesIpc2010 31293Sriven ReddyNo ratings yet

- Air Pollution From Fertilizer Industries Roll No.61Document4 pagesAir Pollution From Fertilizer Industries Roll No.61umarNo ratings yet

- Jindal Seamless Pipe Price List - Jindal Seamless Pipe Price List - Jindal Pipes Price List - Jindal Pipes Prices - Jindal Seamless Pipe Suppliers - Trident SteelDocument4 pagesJindal Seamless Pipe Price List - Jindal Seamless Pipe Price List - Jindal Pipes Price List - Jindal Pipes Prices - Jindal Seamless Pipe Suppliers - Trident Steelkaruna0% (1)

- Whirlpool ADG689 - Ix DishwasherDocument13 pagesWhirlpool ADG689 - Ix Dishwasherairwolf4226No ratings yet

- Fired Heaters and Boilers InspectionDocument31 pagesFired Heaters and Boilers Inspectionriysall100% (1)

- Desaireador GKMOSS - Tray - Deaerator - Brochure PDFDocument6 pagesDesaireador GKMOSS - Tray - Deaerator - Brochure PDFCdMoraSNo ratings yet

- Leser PSV Type 447Document4 pagesLeser PSV Type 447santhoshkumarplNo ratings yet

- Toyota Case StudyDocument22 pagesToyota Case StudySavinder SachdevNo ratings yet

- Ammonia ScrubbersDocument7 pagesAmmonia Scrubbersangelo pascuaNo ratings yet

- (A3) Cementitious Waterproofing Applicator ListDocument1 page(A3) Cementitious Waterproofing Applicator ListjimdabrondNo ratings yet

- Ji 2008 JB00 K NNLC 000 0001 PDFDocument41 pagesJi 2008 JB00 K NNLC 000 0001 PDFHamza ChemmamNo ratings yet

- Astm C642 97Document1 pageAstm C642 97teimimineNo ratings yet

- Heat Exchanger Aftercooler and SeparatorDocument16 pagesHeat Exchanger Aftercooler and Separatorjaskaran singhNo ratings yet

- 3 Electrical Component SpecificationDocument9 pages3 Electrical Component SpecificationqwureyquweryNo ratings yet

- Piston Ring PDFDocument3 pagesPiston Ring PDFArun SNo ratings yet

- Nuts and BoltsDocument27 pagesNuts and BoltsGaurav Kantrod100% (3)

- Howell Bunger Valve 05 HBGR Text New Cover PDFDocument4 pagesHowell Bunger Valve 05 HBGR Text New Cover PDFRoger Labra LlanoNo ratings yet

- Phocos Datasheet CML E-WebDocument2 pagesPhocos Datasheet CML E-WebRedHammerNo ratings yet

- Sigmazinc 158Document7 pagesSigmazinc 158JORGEALEXERNo ratings yet

- Boilers EmissionDocument2 pagesBoilers EmissionGopinath KaliyaperumalNo ratings yet

- Tutorial 9 - Brayton CycleDocument3 pagesTutorial 9 - Brayton CycleasdfsdjhNo ratings yet

- 15ME62T U1 PR. S3pptxDocument7 pages15ME62T U1 PR. S3pptxSeema PintoNo ratings yet

- JWB - AAL Engineering - Cabint Quotation - 15JUL22Document5 pagesJWB - AAL Engineering - Cabint Quotation - 15JUL22Alexander LiwanagNo ratings yet

- Pso Alpha GreaseDocument1 pagePso Alpha GreaseMuhammad EhsanNo ratings yet

- Discussion On Distribution Lines SlideDocument12 pagesDiscussion On Distribution Lines SlideErfan AhmedNo ratings yet

- ESAB Transportation Catalogue 201181132250 20118916190 PDFDocument68 pagesESAB Transportation Catalogue 201181132250 20118916190 PDFcengizarda1979No ratings yet