Professional Documents

Culture Documents

Latihan Cad Part

Latihan Cad Part

Uploaded by

AvyadhanieCopyright:

Available Formats

You might also like

- Parametric Modeling With SOLIDWORKS 2023 Solution ManualDocument31 pagesParametric Modeling With SOLIDWORKS 2023 Solution ManualbradhakemanNo ratings yet

- Chapter 4 - Isometric DrawingDocument14 pagesChapter 4 - Isometric DrawingEvioKim0% (1)

- TR - Construction Painting NC IIDocument68 pagesTR - Construction Painting NC IIRonaldo HertezNo ratings yet

- Operation Manual - URW295C UNICDocument107 pagesOperation Manual - URW295C UNICHeverzonYairPeñalozaLozanoNo ratings yet

- Mdid Assignment: 1. Introduction About Machine Drawing?Document6 pagesMdid Assignment: 1. Introduction About Machine Drawing?JAY KACHANo ratings yet

- MT 8711 Cad Lab Univ QP Set 1Document9 pagesMT 8711 Cad Lab Univ QP Set 1Gopinath NNo ratings yet

- ME113 Wk10&11 Ch08Document128 pagesME113 Wk10&11 Ch08Atthapol YuyaNo ratings yet

- Chapter 6 - Assembly DrawingsDocument87 pagesChapter 6 - Assembly DrawingsAnonymous ohCM2ktv100% (1)

- Mod 7 Book 7 Engineering DrawingDocument48 pagesMod 7 Book 7 Engineering Drawingranjit prasadNo ratings yet

- DEMONSTRATION - Const. of A HelixDocument2 pagesDEMONSTRATION - Const. of A HelixNitin B maskeNo ratings yet

- Assembly Drawing Examples PDF - Google Search6Document2 pagesAssembly Drawing Examples PDF - Google Search6JebDesNo ratings yet

- CONSTRUCT Assembly Drawing 8Document24 pagesCONSTRUCT Assembly Drawing 8JOSEPH ONGNo ratings yet

- CAD in Robotics1 PDFDocument20 pagesCAD in Robotics1 PDFSugumaran MurugesanNo ratings yet

- 1 58503 283 2 2Document65 pages1 58503 283 2 2marcelo_adcampNo ratings yet

- Computer Aided Machine DrawingDocument9 pagesComputer Aided Machine DrawingChetan Gowda0% (1)

- Oblique Cone DevelopmentDocument9 pagesOblique Cone DevelopmentkarthimeenaNo ratings yet

- Assembly Drawing Example A0002Document1 pageAssembly Drawing Example A0002Dudeboy Nautic100% (1)

- Production Drawing & Pracctice Lab ManualDocument23 pagesProduction Drawing & Pracctice Lab ManualVenkateswar Reddy Mallepally88% (8)

- 3 View Orthographic DrawingDocument3 pages3 View Orthographic DrawingMuhammad FitriNo ratings yet

- Skill Builder-Derived Parts3Document3 pagesSkill Builder-Derived Parts3Ndianabasi UdonkangNo ratings yet

- Auto CadDocument50 pagesAuto CadGanesh DongreNo ratings yet

- CorelDraw Training For Laser Cutting Machines With Many Examples Learn and Master Many Example You Can Do With Coreldraw.... (Kaşoğlu, Abdulkadir Kaşoğlu, Abdulkadir)Document59 pagesCorelDraw Training For Laser Cutting Machines With Many Examples Learn and Master Many Example You Can Do With Coreldraw.... (Kaşoğlu, Abdulkadir Kaşoğlu, Abdulkadir)MirelaMilanNo ratings yet

- Shop Data - Fitting Layout For HVACDocument2 pagesShop Data - Fitting Layout For HVACDaniel AustinNo ratings yet

- Mechanisms Notes 2012Document12 pagesMechanisms Notes 2012kookwfNo ratings yet

- Construction Drawings Rev4Document12 pagesConstruction Drawings Rev4api-301270531No ratings yet

- #1 Pendahuluan - Gambar RakitanDocument12 pages#1 Pendahuluan - Gambar RakitanRinaldiFirdausNo ratings yet

- Machine Drawing With CADDocument227 pagesMachine Drawing With CADAhmed BdairNo ratings yet

- Computer Aided Machine Drawing Laboratory: Lab ManualDocument31 pagesComputer Aided Machine Drawing Laboratory: Lab ManualGiridharadhayalanNo ratings yet

- mt01419 PDFDocument606 pagesmt01419 PDFsouzaNo ratings yet

- SolidWorks Motion AnalysisDocument37 pagesSolidWorks Motion AnalysisAnonymous rI9NBeE5No ratings yet

- Tutorial Catia - Dmu KinematicsDocument27 pagesTutorial Catia - Dmu KinematicsLuis Felipe Grin100% (1)

- MCAD ManualDocument38 pagesMCAD ManualsureshrnalNo ratings yet

- Chapter 9 Geometric Dimensioning & Tolerancing (GD&T) : FPOLR-52332Document12 pagesChapter 9 Geometric Dimensioning & Tolerancing (GD&T) : FPOLR-52332Jackie HwangNo ratings yet

- Engineering Drawing and CADDocument53 pagesEngineering Drawing and CADpajarillo0100% (1)

- How To Create A Propeller BladeDocument16 pagesHow To Create A Propeller BladeStelistul SorinNo ratings yet

- ED7111Document117 pagesED7111palaniappan_pandianNo ratings yet

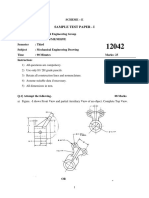

- 12042-Mechanical Engineering Drawing PDFDocument13 pages12042-Mechanical Engineering Drawing PDFIshara Sanjeewa PereraNo ratings yet

- Tut01 SW e ExcavatorDocument74 pagesTut01 SW e Excavatorxerx195100% (2)

- Metalwork: University of Cambridge International Examinations General Certificate of Education Ordinary LevelDocument12 pagesMetalwork: University of Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456No ratings yet

- Machine Draw inDocument2 pagesMachine Draw inLankipalli HemanthNo ratings yet

- Drafting ConventionsDocument20 pagesDrafting ConventionsQubit SizedNo ratings yet

- DrawingpackagerobotarmDocument12 pagesDrawingpackagerobotarmapi-244906204No ratings yet

- Engeering Graphic 1st YearDocument64 pagesEngeering Graphic 1st YearRajpurohit Samundra0% (1)

- What Do You Mean by CATIA and The Scope of The Application?Document3 pagesWhat Do You Mean by CATIA and The Scope of The Application?HarishNo ratings yet

- Model Machine DrawingDocument15 pagesModel Machine Drawingசெல்வ குமார்No ratings yet

- Ppt02-TypesOfProjectionSheet BBDocument27 pagesPpt02-TypesOfProjectionSheet BBMinh NguyenNo ratings yet

- Me 8381 - Computer Aided Machine DrawingDocument44 pagesMe 8381 - Computer Aided Machine DrawingJayaram R S [MECH]No ratings yet

- c15 Catia v5r17Document76 pagesc15 Catia v5r17Shubham HarleNo ratings yet

- CATIA Fry BasketDocument135 pagesCATIA Fry BasketSimona SimoneNo ratings yet

- Inventor Pro 2010Document32 pagesInventor Pro 2010bdi_ro100% (1)

- Advanced AutoCAD® 2017: Exercise WorkbookFrom EverandAdvanced AutoCAD® 2017: Exercise WorkbookRating: 1 out of 5 stars1/5 (1)

- Autodesk 3ds Max 2024 for Beginners: A Tutorial Approach, 24th EditionFrom EverandAutodesk 3ds Max 2024 for Beginners: A Tutorial Approach, 24th EditionNo ratings yet

- AutoCAD 2016 and AutoCAD LT 2016 No Experience Required: Autodesk Official PressFrom EverandAutoCAD 2016 and AutoCAD LT 2016 No Experience Required: Autodesk Official PressRating: 4 out of 5 stars4/5 (1)

- SolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)From EverandSolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)Rating: 4.5 out of 5 stars4.5/5 (5)

- Mastering Autodesk Inventor 2015 and Autodesk Inventor LT 2015: Autodesk Official PressFrom EverandMastering Autodesk Inventor 2015 and Autodesk Inventor LT 2015: Autodesk Official PressNo ratings yet

- Latihan CAD PART PDFDocument101 pagesLatihan CAD PART PDFNajihutsaqfan Hana AfanNo ratings yet

- Pengukuran Coating Thickness PraktikumDocument4 pagesPengukuran Coating Thickness PraktikumAvyadhanieNo ratings yet

- Tugas Part - BenchviceDocument9 pagesTugas Part - BenchviceAvyadhanieNo ratings yet

- HFAM Chp-5 Physical Environment (2014)Document41 pagesHFAM Chp-5 Physical Environment (2014)AvyadhanieNo ratings yet

- O P T I CDocument6 pagesO P T I CAvyadhanieNo ratings yet

- A Manual of Carpentry and Joinery 1905Document511 pagesA Manual of Carpentry and Joinery 1905xumontyNo ratings yet

- Spare Parts Manual H3N - 174 File-IDocument124 pagesSpare Parts Manual H3N - 174 File-Ikomalinternational5No ratings yet

- Catalog Isopan GB 7 2011Document88 pagesCatalog Isopan GB 7 2011Jonathan SmithNo ratings yet

- FabPod - Designing With Temporal Flexibility & Relationships PDFDocument8 pagesFabPod - Designing With Temporal Flexibility & Relationships PDFjrstockholmNo ratings yet

- Pipe Hanger & SupportsDocument220 pagesPipe Hanger & SupportsK.S.MAYILVAGHANANNo ratings yet

- Lecture NotesDocument34 pagesLecture Notesaparna baburajNo ratings yet

- Ascdc-Man-Op-Concrete Pouring & Testing Monitoring02Document15 pagesAscdc-Man-Op-Concrete Pouring & Testing Monitoring02aristeo garzonNo ratings yet

- Ceramic Tile CAD - Detail Document2Document46 pagesCeramic Tile CAD - Detail Document2داروین پرزNo ratings yet

- Catalogue For YJ31502G TORQUE CONVERTERDocument5 pagesCatalogue For YJ31502G TORQUE CONVERTERBandeira PartsNo ratings yet

- MDS Y20Document1 pageMDS Y20von18No ratings yet

- Introduction To ANSYS MechanicalDocument31 pagesIntroduction To ANSYS MechanicalKevin TsuiNo ratings yet

- 6 Unit 3 Storeyed RCC Staff Housing (120' X 30') Material SpecificationDocument4 pages6 Unit 3 Storeyed RCC Staff Housing (120' X 30') Material SpecificationZinmin PaingNo ratings yet

- Roman ArchitectureDocument28 pagesRoman ArchitectureShinjiNo ratings yet

- Min-Com Installation GuideDocument2 pagesMin-Com Installation GuideAmy ChanNo ratings yet

- Lecico CatalogueDocument99 pagesLecico CataloguemaiNo ratings yet

- Short Biography of Kengo KumaDocument2 pagesShort Biography of Kengo KumaMarija PopcevskaNo ratings yet

- Paper On Calculating Loads On Suspension SystemDocument31 pagesPaper On Calculating Loads On Suspension SystemAbhishek yadavNo ratings yet

- SPPDocument9 pagesSPPJANELLA JOY DULATRENo ratings yet

- Revit-MEP ARCH (005-102)Document98 pagesRevit-MEP ARCH (005-102)Ragul0042No ratings yet

- Bill of QuantityDocument11 pagesBill of QuantityFy PurnamaNo ratings yet

- Seismic Load: Prepared By: Placio, Princess AngelDocument21 pagesSeismic Load: Prepared By: Placio, Princess AngelRuf FethNo ratings yet

- 21-19700-120 Reintjes Product Guide 2021 - Final - LowDocument186 pages21-19700-120 Reintjes Product Guide 2021 - Final - LowLaodenovriNo ratings yet

- Piping Mat - L SpecificationDocument56 pagesPiping Mat - L SpecificationCua TranNo ratings yet

- 602 LCM Riggers Card 5.5x3.5 092619 V12Document12 pages602 LCM Riggers Card 5.5x3.5 092619 V12ICON LIFTINGNo ratings yet

- WIESLAW EDWARD LOBODA - Doc1Document2 pagesWIESLAW EDWARD LOBODA - Doc1Wieslaw Edward LobodaNo ratings yet

- Vittalkumar Ponnusamy ResumeDocument3 pagesVittalkumar Ponnusamy ResumevittalNo ratings yet

- JBP Company Profile - 2023Document25 pagesJBP Company Profile - 2023naomi.manaNo ratings yet

- Corporación Multi Negocios MG, Fundador Dilan Eduardo Mendez Guerra, Co Fundador Fraterno Vila BetoretDocument23 pagesCorporación Multi Negocios MG, Fundador Dilan Eduardo Mendez Guerra, Co Fundador Fraterno Vila BetoretEDWARD MGNo ratings yet

Latihan Cad Part

Latihan Cad Part

Uploaded by

AvyadhanieOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Latihan Cad Part

Latihan Cad Part

Uploaded by

AvyadhanieCopyright:

Available Formats

3-D Solid Part Models and Multiview

Documentation from Technical Sketches

The technical sketches in Figures 10.160 through 10.168

are designed to be used to construct fully constrained 3-D

solid part models. Any available parametric solid mod-

eling software may be used. Refer to Chapter 9 Three-

Dimensional Modeling as needed for a review of con-

struction or datum plane set up, profles, and part bodies

using standard extrusion, revolution, or lofting methods.

Use appropriate geometric and dimensional constraints

to fully constrain each part. Apply 3-D features, such as

holes, fllets, chamfers, ribs, and thin wall operations (as

required) to create a logical, easy to edit history tree.

Use the fnished part model to generate associated

multiview drawings containing appropriate drawing views

to fully describe the part (ie; front, top, right side, isomet-

ric views). As an option, make parametric changes to key

dimensions and features in the part model and use these

revisions to the model to update the associated multiview

drawing.

Problems designated FOR 3-D ASSEMBLY

MODEL are designed to be used as parts within 3-D

Assembly Models contained at the end of chapter prob-

lems for Chapter 20 Working Drawings.

Figure 10.160

Hoist Hook

572 PART 2 Fundamentals of Technical Graphics

ber28376_ch10.indd 572 1/2/08 3:06:50 PM

Figure 10.161

Robotic Arm E-01for 3-D assembly model

Figure 10.162

Faucet Basefor 3-D assembly model

573

ber28376_ch10.indd 573 1/2/08 3:06:56 PM

Figure 10.163

Cordless Cover

Figure 10.164

Carabiner Clip Body

574

ber28376_ch10.indd 574 1/2/08 3:07:02 PM

Figure 10.165

Faucet Tubefor 3-D assembly model

Figure 10.166

Soap Mold Form

575

ber28376_ch10.indd 575 1/2/08 3:07:14 PM

Figure 10.167

Intake Wand

576

Figure 10.168

Crank Shaftfor 3-D assembly model

ber28376_ch10.indd 576 1/2/08 3:07:20 PM

Figure 13.47

Dovetail angle slide

3-D Solid Part Models and Auxiliary View

from Technical Sketches

The technical sketches in Figures 13.47 through 13.53 con-

tain inclined and oblique surfaces and features that may re-

quire auxiliary views, to show true sizes and shapes. Con-

struct accurate, fully constrained 3-D solid part models for

each. Any available parametric solid modeling software

may be used. As required with your solid modeling soft-

ware, determine the appropriate method to creating, rotat-

ing, and positioning compound angle datum/construction

planes needed to correctly model inclined and oblique sur-

faces and features. Refer to Chapter 9 Three-Dimensional

Modeling as needed for a review of construction or datum

plane set up, profles, and part bodies using standard ex-

trusion, revolution, or lofting methods. Use appropriate

geometric and dimensional constraints to fully constrain

each part. Apply 3-D features, such as holes, fllets, cham-

fers, ribs, and thin wall operations (as required) to create a

logical, easy to edit history tree.

Use the fnished part model to generate associated

multiview drawings containing appropriate drawing

views to fully describe the part, i.e., front, top, right side,

and required auxiliary views. As an option, make para-

metric changes to key dimensions and features in the part

model and use these revisions to the model to update the

associated multiview drawing.

Problems designated FOR ASSEMBLY are de-

signed to be used as parts within 3-D Assembly Models

contained at the end of chapter problems for Chapter 20

Working Drawings.

CHAPTER 13 Auxiliary Views 683

ber28376_ch13.indd 683 1/2/08 3:11:56 PM

Figure 13.48

Angle block B-slot

Figure 13.49

Angle block N

684

ber28376_ch13.indd 684 1/2/08 3:12:01 PM

Figure 13.51

Holder 2J-METRIC

Figure 13.50

Shaft brace

685

ber28376_ch13.indd 685 1/2/08 3:12:06 PM

Figure 13.52

Corner connector

686

ber28376_ch13.indd 686 1/2/08 3:12:10 PM

Figure 13.53

Particle chamber

687

ber28376_ch13.indd 687 1/2/08 3:12:13 PM

810 PART 4 Standard Technical Graphics Practices

3D Solid Part Models and Auxiliary View from Technical Sketches

The technical sketches in Figures 16.82 through 16.93

contain a variety of section views required to show com-

plex interior details and features. Sample illustrations are

included with each sketch to help in visualizing the part.

Construct accurate, fully constrained 3-D solid part mod-

els for each. Any available parametric solid modeling soft-

ware may be used. As required with your solid modeling

software, determine the appropriate method to creating,

rotating, and positioning compound angle datum/con-

struction planes needed to correctly model inclined and

oblique surfaces and features. Refer to Chapter 9 Three-

Dimensional Modeling as needed for a review of construc-

tion or datum plane set up, profles, and part bodies using

standard extrusion, revolution, or lofting methods. Use ap-

propriate geometric and dimensional constraints to fully

constrain each part. Apply 3-D features, such as holes, fl-

lets, chamfers, ribs, and thin wall operations (as required)

to create a logical, easy to edit history tree.

Use the fnished part model to generate associated

multiview and pictorial drawings containing appropriate

views to fully describe the part, ie; front, top, right side,

and sectional cutaway views. As an option, make para-

metric changes to key dimensions and features in the part

model and use these revisions to the model to update the

associated multiview drawing fle.

Problems designated FOR 3-D ASSEMBLY

MODEL are designed to be used as parts within 3-D

Assembly Models contained at the end of chapter prob-

lems for Chapter 20 Working Drawings.

Figure 16.81

RollerDeere: for 3-D assembly model

ber28376_ch16.indd 810 1/2/08 3:15:49 PM

Figure 16.82

Rollermodel TX

Figure 16.83

HandwheelAluminum

811

ber28376_ch16.indd 811 1/2/08 3:15:56 PM

Figure 16.84

Ceiling fan cover

812

Figure 16.85

Blade hub

ber28376_ch16.indd 812 1/2/08 3:16:11 PM

813

Figure 16.86

Base E-01: for 3-D assembly model

ber28376_ch16.indd 813 1/2/08 3:16:19 PM

814

Figure 16.87

Wheel layout

Figure 16.88

Valve handwheel

ber28376_ch16.indd 814 1/2/08 3:16:24 PM

815

Figure 16.89

Housing shell

Figure 16.90

Shift link

ber28376_ch16.indd 815 1/2/08 3:16:40 PM

816

Figure 16.91

Tester housing

Figure 16.92

Piston: for 3-D assembly model

ber28376_ch16.indd 816 1/2/08 3:16:54 PM

817

Figure 16.93

Apparatus clamp

ber28376_ch16.indd 817 1/2/08 3:17:09 PM

SWING ARM

HANDLE

ITEM QTY NAME DESCRIPTION

ALUMINIUM

STEEL

BASE

MOVABLE JAW

SCREW

WASHER

1

1

2

2

2

2

1

2

3

4

5

6

ALUMINIUM

ALUMINIUM

STEEL

STEEL

1

4

4

5

6

2

3

5

3

6

BURNEY CUTTING JIG

Figure 20.43

Burney jig

981

ber28376_ch20.indd 981 1/2/08 3:23:22 PM

Figure 20.43

Burney jig (Continued)

982

.283

.18

.13

90

2.511

.03

R .57

.19

2X 45

PART NAME: BASE

PART NUMBER: 1

ALL FILLETS AND ROUNDS R.0625

BOTTOM DETAIL

2

X

.

5

0

.3

4

.

0

2

1

.

0

0

.

5

0

R

.

1

8

.

3

1

.

1

6

.

4

4

.

0

6

.

2

5

.

2

2

.

5

0

R

1

.

0

0

1

.

9

4

3

.

8

8

1

.

7

5

.

1

2

.

3

8

1

.1

2

R

.2

7

R

1

.

9

0

R

2

.

6

3

R

2

.

2

5

1

.

0

0

0

.

0

3

.

1

8

.3

8

.

1

9

S

.

1

8

R

2

.

5

3

.

1

2

.

2

5

.1

6

.

0

9

.

0

6

.

1

2

.

2

5

2

.

5

0

2

X

.1

9

0

.3

3

5

X

9

0

.

2

5

0

0

.

2

5

0

9

R

.

3

8

R

.

1

2

R

.

5

0

R

.

0

6

R

2

.0

3

R

1

.8

4

R

2

.4

1

.

3

1

3

.

3

8

2

.

2

0

9

1

1

8

4

1

2

1

.

6

5

6

C

L

9

0

4

5

.

2

5

.

2

9

0

0

.

2

9

0

6

1

.

0

0

.

7

5

.

0

6

ber28376_ch20.indd 982 1/2/08 3:23:22 PM

983

Figure 20.43

Burney jig (Continued)

.1

9

5

0

.1

9

5

2

1

.

9

4

R

.0

6

.

2

2

.

1

6

.1

2

.

5

0

0

R

.

1

8

.

3

8

.

2

5

.

0

8

.

7

5

0

.

7

5

0

.

5

0

.

3

1

2

S

.2

5

P

E

E

N

E

D

A

T

A

S

S

E

M

.

1

8

.

2

5

R

.2

5

R

.1

2

2

.

2

0

0

2

.

7

3

5

1

.

0

0

0

.1

5

6

.2

5

0

.

2

5

R

1

.

0

0

2

.

0

0

0

.

5

0

1

.

0

0

.3

0

9

3

.

8

8

PART NAME: SWING ARM

PART NUMBER: 2

ALL FILLETS & ROUNDS R .0625

4

5

.

6

3

7

6

.

2

9

0

0

.

2

9

6

0

.3

1

3

X

R

.

1

8

.1

2

1

.

7

5

4

X

R

.

1

2

.

5

6

R

.

2

2

.

2

5

-

2

0

U

N

C

.

8

8

2

X

R

.

0

6

R

.1

2

.1

8

.6

2

PART NAME: MOVABLE JAW

PART NUMBER: 3

ALL FILLETS & ROUNDS R .03

U.O.S.

.

2

5

.

8

2

5

.

2

8

9

5

.

2

8

9

1

.

1

2

5

0

.

1

2

8

0

P

E

E

N

A

T

A

S

S

E

M

B

L

Y

.

3

1

2

.

2

5

-

2

0

U

N

C

4

.4

3

2

.3

1

2

.4

3

3

.3

1

3

PART NAME: SCREW

PART NUMBER: 4

.1

5

6

.

1

2

0

5

.

1

1

9

0

P

I

N

C

H

E

A

C

H

E

N

D

A

T

A

S

S

E

M

B

L

Y

2

.

0

0

0

PART NAME: HANDLE

PART NUMBER: 5

.0

3

.

3

1

2

5

.

2

5

0

0

PART NAME: WASHER

PART NUMBER: 6

R

.1

2

5

.

5

2

ber28376_ch20.indd 983 1/2/08 3:23:23 PM

KU-BAND PARABOLIC DISH

PARABOLIC DISH

FOCUSING RING

CONNECTING RING

REAR BRACE

SUPPORT BAR

FLAT WASHER

BACKING PLATE

MOUNTING SLIDE

BUTTON HEAD HEX SOCKET CAP SCR.

ITEM QTY NAME DESCRIPTION

STEEL

STEEL

STEEL

STEEL

.201 X .3340 X .0625

STEEL

STEEL

#10-24UNC X .625

HEADLESS SLTD CUP POINT SET SCR.

HEX HEAD CAP SCREW

PARABOLIC ARM

FLAT WASHER

1

1

1

1

3

1

1

1

3

1

1

9

9

13

12

11

10

9

8

7

6

5

4

3

2

1

.3125-18UNC X 2.000

STEEL

#6-32UNC X .1875

STEEL

.5312 X 1.25 X .0625

9

10

11

12

13

DETAIL A

1

2

3

4

5

6

7

8 9

DETAIL A

Figure 20.44

Ku-band parabolic dish

9

8

4

b

e

r

2

8

3

7

6

_

c

h

2

0

.

i

n

d

d

9

8

4

1

/

2

/

0

8

3

:

2

3

:

2

3

P

M

.5

0

0

R

.

6

2

5

.

5

3

1

3

.2

5

0

.3

1

2

5

-

1

8

U

N

C

.7

5

.6

2

5

1

.

0

0

0

1

.2

5

0

.

0

6

2

5

.7

5

0

.

2

5

0

1

.0

0

0

1

.4

0

6

2

B

.C

.

3

X

#

1

0

-

2

4

U

N

C

.6

2

5

0

1

.8

1

2

5

1

.

1

0

9

4

1

.

8

1

2

5 .

3

7

5

.1

7

3

4

.3

7

5

1

.0

1

5

2

.5

0

0

#

8

-

3

2

U

N

C

.

7

5

.

1

8

7

5

3

X

#

1

0

-

2

4

U

N

C

1

.

2

5

.

1

8

7

5

1

.0

6

2

5

.

1

8

7

5

.

2

5

0

#

6

-

3

2

U

N

C

.

3

7

5

.7

5

0

1

.8

1

2

5

.6

5

6

5

1

.3

1

3

3

X

.2

0

1

1

2

0

.2

6

0

.5

2

0

.3

6

2

2

R

.2

6

0

.3

3

2

3

.8

7

5

.

0

6

2

5

.

2

5

0

PART NAME: WASHER

PART NAME: MOUNTING SLIDE

PART NAME: BACKING PLATE

PART NAME: REAR BRACE

PART NAME: FOCUSING RING

PART NAME: CONNECTING RING

.3

1

2

5

.0

6

2

5

Figure 20.44

Ku-band parabolic dish (Continued)

985

ber28376_ch20.indd 985 1/2/08 3:23:23 PM

.1

8

7

5

.6

2

3

2

R

.4

3

7

5

R

.2

5

0

1

0

5

.1875

.375

2X

.201

.3789

1

3

.3

3

5

6

R

.2

5

.1

8

7

5

R

.4

3

7

5

.4

9

8

8

.2

5

0

1

4

2

PART NAME: SUPPORT BAR

R

.1

2

5

.

3

1

8

4

.3

7

5

.1

5

0

2

#

1

0

-

2

4

U

N

C

.6

2

5

.

1

8

7

5

B

O

T

H

S

I

D

E

S

.

8

3

5

7

R

.2

5

8

.7

2

6

3

.

5

0

0

R

.1

2

5

2

1

1

.

1

3

5

7

2

.

2

2

9

3

1

0

.1

1

6

2

.

2

5

0

.3

6

7

5

#

1

0

-

2

4

U

N

C

P

E

R

P

E

N

D

I

C

U

L

A

R

T

O

P

A

R

A

B

O

L

I

C

S

U

R

F

A

C

E

PART NAME: PARABOLIC ARM

C

L

4.6764

14.8281

3 PLACES

EQ SP

4.9954

R .0962

R .1562

SECTION A-A

PART NAME: PARABOLIC DISH

A

A

.3438

.2041

Figure 20.44

Ku-band parabolic dish (Continued)

986

ber28376_ch20.indd 986 1/2/08 3:23:23 PM

ARM

HINGE A

HANDLE

PIN B

ITEM QTY NAME DESCRIPTION

STEEL

STEEL

STEEL

STEEL

SUPPORT (LEFT & RIGHT)

GRIP

PIN A

HINGE B

SHAFT

1 EA.

2

1

1

1

1

1

1

2

1

2

3

4

5

6

7

8

9

STEEL

STEEL

STEEL

STEEL

STEEL

1

2

3

4

5

6

7

8

9

QUICK-ACTING HOLD-DOWN CLAMP

PIN C STEEL 1 10

10

Figure 20.45

Quick acting hold-down clamp

987

ber28376_ch20.indd 987 1/2/08 3:23:24 PM

.

2

8

1

2

.

2

5

0

P

E

E

N

A

T

A

S

S

E

M

B

L

Y

B

O

T

H

E

N

D

S

2

X

.

1

8

7

5

.

7

5

0

.

3

7

5

1

.

1

2

5 .

3

7

5

P

E

E

N

A

T

A

S

S

E

M

B

L

Y

B

O

T

H

E

N

D

S

.

2

5

0

.

3

1

2

5

R

.0

3

1

2

5

A

L

L

E

D

G

E

S

.3

1

2

5

.7

5

0

.3

7

5

.3

7

5

1

.3

7

5

.

2

5

0

PART NAME: HINGE A

PART NAME: SUPPORT

RIGHT & LEFT NEEDED

PART NAME: GRIP

PART NAME: PIN A

PART NAME: PIN C

PART NAME: ARM

.

1

2

5

R

.3

1

2

5

.

3

7

5

.2

5

0

R

.1

5

6

2

.2

1

8

7

6

X

.2

5

0 .2

5

0

.7

5

0

1

.2

5

0

.8

7

5

0

1

.2

5

0

.5

0

0

.3

7

5

1

.2

5

0

2

.5

0

0

1

.

0

0

0

4

5

.3

7

5

.1

2

5

.3

7

5

R

.

2

5

R

.1

0

R

.1

0

.

2

3

4

3

.

7

5

0

P

E

E

N

A

T

A

S

S

E

M

B

L

Y

B

O

T

H

E

N

D

S

.

2

5

0

B

O

T

H

S

I

D

E

S

.

1

8

7

5 B

O

T

H

S

I

D

E

S

.

7

5

0

R

.

0

3

1

2

F

I

L

L

E

T

B

O

T

H

S

I

D

E

S

R

.5

0

0

2

.2

5

0

R

.3

1

2

5

3

X

.2

5

0

R

.3

1

2

5

4

1

.3

7

5

.

1

2

5

R

.2

5

PART NAME: PIN B

.

3

1

2

5

.

2

5

0

P

E

E

N

A

T

A

S

S

E

M

B

L

Y

B

O

T

H

E

N

D

S .

1

8

7

5

.

7

5

0

1

.

1

2

5

C

E

N

T

E

R

E

D

O

N

F

E

A

T

U

R

E

Figure 20.45

Quick acting hold-down clamp (Continued)

988

ber28376_ch20.indd 988 1/2/08 3:23:24 PM

.6

2

5

0

.

4

3

7

5

.2

6

6

C

E

N

T

E

R

E

D

O

N

F

E

A

T

U

R

E

.3

7

5

-

1

6

U

N

C

.2

5

0

4

.

1

8

7

5

5

.

0

6

2

5

.3

7

5

-

1

6

U

N

C

.

7

0

0

.

3

1

2

5

B

O

T

H

E

N

D

S

.

1

2

5

B

O

T

H

S

I

D

E

S

1

.

0

0

0

R

.

0

3

1

2

F

I

L

L

E

T

B

O

T

H

E

N

D

S

P

E

E

N

A

T

A

S

S

E

M

B

L

Y

B

O

T

H

S

I

D

E

S

.

2

5

0

3

.

0

0

0

PART NAME: HINGE B

PART NAME: SHAFT

PART NAME: HANDLE

Figure 20.45

Quick acting hold-down clamp (Continued)

989

ber28376_ch20.indd 989 1/2/08 3:23:25 PM

1

2

3

4

BASE

ITEM QTY NAME DESCRIPTION

STEEL

BUSHING

CAP

HEX HEAD BOLT

2

1

1

6

1

2

3

4

BRONZE

STEEL

.50-13UNC X 2.00

DOUBLE BEARING

Figure 20.46

Double bearing

990

ber28376_ch20.indd 990 1/2/08 3:23:25 PM

PART NAME: BASE

.5

0

0

3

.0

0

0

3

.0

0

0

1

.2

5

0

3

.0

0

0

4

.0

0

0

.5

0

0

2

X

R

1

.2

5

7

.0

0

0

3

.5

0

0

2

X

R

.7

5

0

.5

0

1

.5

0

0

.7

5

0

6

X

.5

1

6

PART NAME: CAP

PART NAME: BUSHING

2

.

0

0

4

.5

0

0

.5

0

0

1

.

1

2

5

1

.

5

0

2

.5

0

0

.7

5

0

6

X

.5

0

0

-

1

3

U

N

C

1

.1

2

5

1

.5

0

0

.5

0

0

9

.0

0

4

.0

0

1

.5

0

4

5

.5

0

0

1

.2

5

0

1

.7

5

0 3

.5

0

0

1

.2

5

0

1

.5

0

2

.5

0

.5

0

0

3

.0

0

4

.0

0

R

.7

5

0

R

1

.2

5

C

L

.5

0

0

1

.0

0

.5

0

0

Figure 20.46

Double bearing (Continued)

991

ber28376_ch20.indd 991 1/2/08 3:23:25 PM

2

.

7

5

1

.

2

5

.

7

5

.

6

3

2

.

5

6

2

.

0

0

1

.

2

5

.

2

5

2

.

7

5

1

.

8

8

1

.

5

0

1

.

2

5

2

.

0

0

1

.

7

5

1

.

1

3

.

8

7

2

.

0

0

2

.

4

4

1

.

9

7

.

4

7

.

2

2

2

.

7

5

1

.

2

5

2

.

0

0

.

3

7

5

-

1

6

U

N

C

T

H

R

U

T

O

H

O

L

E

.

5

0

4

.

0

0

.

6

3

.

6

2

R

.

9

7

.

3

1

3

-

1

8

U

N

C

.

3

7

5

1

6

U

N

C

.

6

2

5

.

5

0

X

.

5

0

.

2

5

.

1

3

.

3

1

3

-

1

8

U

N

C

X

1

.

7

5

.

2

5

X

.

1

9

DOUBLE V-BLOCK

1

2

3

FASTENER

BASE

U-CLAMP

1 REQ.

2 REQ.

2 REQ.

9

0

.

2

5

R

.

2

5

R

.

1

2

5

R

1

.

2

.

6

3

.

2

5

1

.

2

5

2

.

3

5

0

Figure 20.47

Double V-block

992

ber28376_ch20.indd 992 1/2/08 3:23:25 PM

.

2

8

1

.

8

8

1

.

5

9 1

.

4

7

1

.

0

0 .

8

7

.

4

1

1

.

5

0

1

.

0

6

.

8

7

.

1

2

2

.

0

0

1

.

3

1

2

.

1

3

1

.

0

6

.

1

3

S

Q

1

.

6

9

1

.

5

0

1

.

2

5

1

.

0

0

.

7

5

1

.

8

8

1

.

3

8

1

.

0

0

4

5

1

.

2

5

R

.

1

2

5 .

0

3

S

T

A

M

P

N

A

M

E

C

E

N

T

E

R

E

D

.

3

8

-

1

6

U

N

C

1

.

0

0

.

3

1

3

/

8

-

1

6

U

N

C

.

6

3

F

R

O

M

B

O

T

T

O

M

.

5

0

1

.

0

0

.

8

8

1

.

1

3

R

.

6

9

R

.

9

0

5

9

0

1

.

8

1

1

.

0

6

.

5

0

4

X

R

.

0

5

1

0

-

3

2

U

N

F

.

2

5

.

3

8

X

.

5

0

.

0

6

2

5

X

4

5

#

1

0

-

3

2

U

N

F

X

1

.

8

8

.

1

6

1

.

4

0

.

1

9

X

.

1

2

M

E

D

I

U

M

K

N

U

R

L

V-BLOCK

1 BASE

1 REQ.

2

FASTENER

1 REQ.

3 U-CLAMP

1 REQ.

FILLETS & ROUNDS R .125

.

3

7

5

Figure 20.48

V-block

993

ber28376_ch20.indd 993 1/2/08 3:23:25 PM

1

1

.

5

0

6

.

5

0

2

.

5

0

1

.0

0

3

.

0

0

.

7

5

4

.0

0

4

X

.

5

0

0

-

1

3

U

N

C

4

.

0

0

2

.

0

0

1

.

0

0

1

.

5

0

4

.

0

0

2

.

0

0

1

.

5

0

R

.

1

2

5

.

5

0

F

N

2

F

IT

R

.

6

2

5

SOCKET HEAD SHOULDER SCREW 5/8" DIAMETER

2.50" SHOULDER LENGTH RC1 STEEL

WASHER

INNER DIAMETER 5/8"

BRONZE

BUSHING

OUTER DIAMETER 1.00" FN2

INNER DIAMETER 5/8" RC1

THICKNESS 1/2"

BRONZE

WHEEL

DIAMETER 4.00"

WIDTH 1.00" BODY .50" THICK

HUB WIDTH 1.50" X .75" O.D.

GROOVE 45

AND CENTERED

CAST IRON

SUPPORT COLD

ROLLED STEEL

HEX HEAD NUT

1/2" - 13NC

BASE

COLD ROLLED STEEL

DETAIL WHEEL

.50

HEX HEAD MACHINE SCREW

.50013UNC X 1.00

WHEEL SUPPORT

3

.

2

5

4

.

0

0

.

2

5

Figure 20.49

Wheel support

994

ber28376_ch20.indd 994 1/2/08 3:23:25 PM

SHOCK ASSEMBLY

PIVOT

U-SUPPORT

BRACKET

FLAT WASHER

ITEM QTY NAME DESCRIPTION

STEEL

STEEL

STEEL

1.50 X .750 X .125

CASTLE NUT

BUSHING

HEX HEAD BOLT

SHAFT

SPACER

SELF-LOCKING NUT

1

1

2

1

1

1

1

1

1

1

10

9

8

7

6

5

4

3

2

1

STEEL

BRONZE

STEEL

C.R.S.

11 COTTER PIN 1

.625-11UNC

STEEL

1

2

3

4

5

6

7

8

9

8

10

11

WELD TO BRACKET

WELD TO U-SUPPORT

Figure 20.50

Shock assembly

995

ber28376_ch20.indd 995 1/2/08 3:23:25 PM

.6

2

5

-

1

1

U

N

C

X

1

.0

0

H

E

IG

H

T

O

F

S

H

A

F

T

D

E

T

E

R

M

IN

E

D

B

Y

U

S

E

R

.7

5

0

.1

2

5

X

.1

2

5

.2

5

0

2

.

0

0

0

.

5

0

0

1

.

5

0

0

1

.2

5

0

PART NAME: SPACER

PART NAME: BUSHING PART NAME: BUSHING

PART NAME: SHAFT

1

.

5

0

0

9

.5

0

0

2

X

.5

0

0

.7

5

0

C

E

N

T

E

R

E

D

IN

O

B

J

E

C

T

4

.7

5

0

2

.8

7

5

1

.1

8

8

2

.3

7

5

3

.

0

0

0

PART NAME: BRACKET

ALL FILLETS R .313

ALL ROUNDS R .625

.3

1

3

2

X

R

1

.

4

0

0

3

.5

0

0

3

.

8

1

3

2

X

.

5

0

0

.3

1

3

PART NAME: U-SUPPORT

ALL FILLETS R .313

ALL ROUNDS R .625

.

7

5

2

.5

0

0

.

3

1

3

1

.2

5

0

.6

2

5

6

.

5

0

0

5

.

0

0

0

1

.

3

1

3

3

.

2

5

0

R

1

.

0

6

3

1

.

5

0

0 4

X

.

2

5

0

PART NAME: PIVOT

R

.

5

0

0

D

E

T

E

R

M

IN

E

D

B

Y

U

S

E

R

1

.7

5

2

.2

5

4

.7

5

0

2

.8

7

5

1

.1

8

8

1

.

5

0

0

Figure 20.50

Shock assembly (Continued)

996

ber28376_ch20.indd 996 1/2/08 3:23:25 PM

BILL OF MATERIALS

QTY. PART NAME DESCRIPTION ITEM

1

2

3

4

1

1

SHOULDER

SUPP. SHAFT

V-SUPPORT

WASHER

STEEL

5

1

1

1 CAP SCREW

STEEL

STEEL

STEEL

SCREW JACK

3

2

1

4

5

#10 SC. HD.

Figure 20.51

Screw jack

997

ber28376_ch20.indd 997 1/2/08 3:23:26 PM

1

.0

0

.4

5

3

1

.2

5

.5

0

0

-

2

0

U

N

F

1

.2

5

F

R

O

M

B

O

T

T

O

M

.6

2

5

1

.0

9

4

1

.1

2

5

.0

9

4

R

.0

6

2

5

F

IL

L

E

T

2

.

0

0

.

5

0

0

.

0

6

2

5

X

4

5

.

0

5

x

4

5

1

.5

0

.

2

0

3

.

5

0

0

.0

6

2

5

1

.6

8

7

5

2

.7

6

5

6

.6

2

5

1

.1

8

7

5

.2

6

6

0

1

.0

0

.3

7

5

0

#

1

0

-

3

2

U

N

F

X

.5

7

8

D

P

3

X

.0

3

1

X

4

5

.

5

0

0

-

2

0

-

U

N

F

-

3

A

.

2

1

8 2

H

O

L

E

S

9

0

A

P

A

R

T

C

E

N

T

E

R

.

5

7

8

5

F

R

O

M

T

O

P

O

F

P

A

R

T

.4

0

6

.5

6

2

5

.5

6

2

5

9

0

V

C

U

T

.2

1

8

.8

1

2

5

.5

6

3

1

.2

5

0

1

.0

0

3

X

.0

3

1

X

4

5

PART NAME: SUPPORT SHAFT

PART NAME: V-SUPPORT

PART NAME: WASHER

PART NAME: SHOULDER

Figure 20.51

Screw jack (Continued)

998

ber28376_ch20.indd 998 1/2/08 3:23:26 PM

ROUND HEAD MACHINE SCREW

WOODRUFF KEY

ARM

HEX HEAD NUT

ITEM QTY NAME DESCRIPTION

#4-48UNF X .250

STEEL

.375-24UNF

BODY

PLATE

SHAFT

RETAINER

ROUND HEAD MACHINE SCREW

1

2

1

1

1

1

3

1

1

1

2

3

4

5

6

7

8

9

CAST IRON

ALUMINIUM

STEEL

STEEL

#10-32UNF X .500

BUTTERFLY VALVE

ASSEMBLED

SECTION

1

2

3

4

6

7

8

9

1

2

3

4

5

6

7

8

9

Figure 20.52

Valve

9

9

9

b

e

r

2

8

3

7

6

_

c

h

2

0

.

i

n

d

d

9

9

9

1

/

2

/

0

8

3

:

2

3

:

2

6

P

M

6

X

.

4

7

0

2

.2

5

0

1

.

5

0

1

.1

2

5

1

.5

9

4

.3

1

3

1

2

0

.

5

6

2

2

.

8

1

3

.

8

7

5

.

7

5

0

3

X

#

1

0

-

3

2

U

N

F

.

3

7

5

1

.

9

3

8

R

1

.

4

0

6

1

.

7

5

0

R

.

5

0

0

3

.

2

5

0

6

X

1

2

0

.2

5

0

.

5

6

3

1

2

0

2

.

0

0

0

3

X

.

2

0

3

1

.

5

0

.

0

6

3

2

X

.1

2

5

1

.0

0

0

.0

0

0

.7

0

3

.9

4

9

1

.0

7

2

1

.1

0

9

.

0

0

0

.

2

5

0

.

5

0

0

.

7

5

0

.

9

6

9

PART NAME: BODY

PART NAME: RETAINER

PART NAME: ARM

PART NAME: SHAFT

PART NAME: PLATE

(ELLIPTICAL)

.6

2

5

.1

8

7

1

.

1

2

5

.

5

6

3

.

0

7

7

X

.

1

2

6

K

E

Y

W

A

Y

3

.

0

0

.

4

3

8

.

8

7

5

W

O

O

D

R

U

F

F

K

E

Y

W

A

Y

.5

0

0

.

0

3

X

4

5

B

O

T

H

E

N

D

S

.

8

7

2

.

5

6

0

.

5

6

0

.

3

7

5

-

2

4

U

N

F

.8

9

8

.2

4

0

3

.8

9

8

1

.0

0

0

.

1

2

5

.

4

7

2

.

3

7

5

1

.9

3

7

.

3

1

1

2

X

#

4

-

4

8

U

N

F

.

1

2

5

2

.

0

0

0

.

2

5

0

Figure 20.52

Valve (Continued)

1000

ber28376_ch20.indd 1000 1/2/08 3:23:26 PM

8

7

4

1

3

5

6

2

9

BILL OF MATERIALS

QTY. PART NAME DESCRIPTION ITEM

1

2

3

4

1

1

1

1

5

6

7

8

9

2

1

1

2

1

INDEX

INDEX PLATE

GENEVA

BUSHING

WASHER

FLAT HEX NUT

CAP SCREW

SHAFT

SET SCREW

BRASS

STEEL

STEEL

STEEL

STEEL

STEEL

#3 SC. HD.

STEEL

STEEL

GENEVA CAM

Figure 20.53

Geneva cam

1001

ber28376_ch20.indd 1001 1/2/08 3:23:26 PM

2

.2

5

8

X

.3

7

5

.1

1

1

.5

2

1

.7

9

.5

0

.

1

3

.5

0

2

.4

7

.2

5

5X

.2

1

.2

5

.

4

4

.

2

5

.2

5

.1

3

.

1

1

.

0

3

.1

9

.1

3

2

.

5

0

.2

5

2

X

.0

3

1

X

4

5

1

.2

5

.5

0

.2

5

R

1

.2

5

#

1

0

-

3

2

U

N

F

.

2

5

.

2

5

.

1

3

PART NAME: INDEX PLATE

PART NAME: INDEX

PART NAME: GENEVA

PART NAME: BUSHING

PART NAME: WASHER

PART NAME: SHAFT

.2

8

7

0

.3

5

0

1

.

5

2

8

7

5

X

R

.

6

3

Figure 20.53

Geneva cam (Continued)

1002

ber28376_ch20.indd 1002 1/2/08 3:23:26 PM

INTERNAL LUG

ROCKER

SURFACE ROLLER

CUSTOM SCREW

10-32 FILL. HD. SCR.

ITEM QTY NAME DESCRIPTION

DR. ROD

C.R.S.

BASE

EXTERNAL LUG

PEAN

CONICAL SPACER

RETURN SCREW

COMPRESSION SPG.

1

1

1

1

1

1

1

1

1

3

1

1

2

3

4

5

6

7

8

9

10

11

C.R.S.

C.R.S.

DR. ROD

C.R.S.

C.R.S.

C.R.S.

C.R.S.

SURFACE GAUGE

1

2

3

4

5

6

7

8

9

10

10

11

Figure 20.54

Surface gauge

1003

ber28376_ch20.indd 1003 1/2/08 3:23:26 PM

PART NUMBER: 1

FILLETS & ROUNDS R.125

BOTH 90 SLOTS CENTERED

R

.

2

5

R

.

5

0

0

G

R

O

O

V

E

C

E

N

T

E

R

E

D

2

.

3

8

.

5

0

0

2

.8

7

5

1

.4

3

7

5

.8

1

2

5

.9

3

7

5

1

.1

8

7

5

.3

1

2

5

-

.2

4

U

N

F

.4

3

7

5

.

0

6

2

5

9

0

9

0

.3

7

5

.2

5

.3

1

2

5

D

R

IL

L

T

O

R

E

M

A

IN

IN

G

T

H

IC

K

N

E

S

S

O

F

.1

2

5

R

.2

5

.

3

7

5

.5

0

.

2

5

0

+

.0

0

5 -

.0

0

0

.

5

0

0

.

8

7

5

1

.

2

5

0

2

.

0

0

0

8

-

3

2

X

.

6

8

8

.

3

1

2

5

+

.0

0

0 -

.0

0

5

.1

8

7

+

.0

0

2

- .0

0

0

.

3

1

2

+

.0

0

2 -

.0

0

0

.

1

4

0

6

2

X

.

0

3

1

3

X

4

5

PART NUMBER: 2

.

5

0

0

+

.0

0

0 -

.0

0

2

PART NUMBER: 4

S

.

3

1

2

5

.

1

2

5

.

2

1

8

8

9

.

0

0

1

0

-

3

2

U

N

F

.

5

0

0

.

3

1

2

+

.0

0

0

-

.0

0

2

.

0

3

X

4

5

.

6

2

5

1

.

0

9

4

.

1

5

6

.

1

8

8

X

6

0

.

3

1

2

.

1

4

1

.5

0

1

+

.0

0

2

- .0

0

0

.

1

9

0

+

.0

0

5 -

.0

0

0

.6

8

7

5

PART NUMBER: 3

.

3

0

.

4

5

2

X

Figure 20.54

Surface gauge (Continued)

1004

ber28376_ch20.indd 1004 1/2/08 3:23:27 PM

Figure 20.54

Surface gauge (Continued)

R

1

.0

0

B

L

E

N

D

.

2

4

8

.8

1

3

1

.0

0

.5

0

0

1

.4

3

7

.5

0

0

.2

5

0

8

-

3

2

U

N

C

T

H

R

U

P

A

R

A

L

L

E

L

T

O

E

N

D

C

E

N

T

E

R

E

D

O

N

.2

4

8

T

H

IC

K

N

E

S

S

.1

8

7

.0

3

X

4

5

B

O

T

H

S

ID

E

S

R

.4

3

8

.3

1

2

5

.1

8

8

X

6

0

O

N

B

A

C

K

S

ID

E

+

.0

0

5

- .0

0

0

+

.0

0

0 -

.0

0

2

R

.2

5

0

.

3

1

2

5

+

.0

0

2

- .0

0

0

PART NUMBER: 5

.

4

3

8

.

0

6

3

.

1

8

8

.

3

1

5

.

1

2

5

+

.0

0

5

- .0

0

0

.

6

8

7

5

.

1

9

0

+

.0

0

5

-

.0

0

0

PART NUMBER: 6

.

6

2

5

D

I

A

M

O

N

D

K

N

U

R

L

.

1

8

8

1

.

1

2

5

8

-

3

2

X

.

8

1

2

5

3

X

.

0

3

1

2

5

X

4

5

R

.

0

6

2

5

PART NUMBER: 7

PART NUMBER: 8

.

4

3

7

5

.

1

8

7

5

.

5

6

3

8

-

3

2

U

N

C

.2

8

1

.3

1

2

5

F

R

O

M

B

A

C

K

S

ID

E

1

.0

0

D

IA

M

O

N

D

K

N

U

R

L

2

X

.0

3

1

2

5

X

4

5

PART NUMBER: 9

3

X

.

3

1

2

5

X

4

5

.

0

3

1

2

5

S

L

O

T

.

0

6

2

5

.

3

1

2

5

-

2

4

U

N

F

.

9

3

8

.

5

6

3

.

1

8

7

+

.0

0

0 -

.0

0

2

1005

ber28376_ch20.indd 1005 1/2/08 3:23:27 PM

DRILL GUIDE

SLIDE

DRILL ADAPTOR

ROD GUIDE

ITEM QTY NAME DESCRIPTION

ALUMINIUM

STEEL

STEEL

BASE

BUSHING

EXTERNAL RETAINING RING

COLLAR

THUMB SCREW

1

1

2

2

1

2

4

2

1

2

3

4

5

6

7

8

ALUMINIUM

BRONZE

SAE 1060

ALUMINIUM

ALUMINIUM

4

5

8

2

3

4

3

ASSEMBLY A

ASSEMBLY A

1

8

7

2

6

Figure 20.55

Drill guide

1006

ber28376_ch20.indd 1006 1/2/08 3:23:27 PM

.1

6

.

2

5

-

2

0

U

N

C

.

6

2

2

X

.

2

5

4

5

.

4

0

.

5

0

0

0

.

5

0

0

4

1

.5

3 .1

8

R

.

2

5

.

7

5

2

X

.

7

5

2

.

2

5

3

.

5

0

.6

2

1

.

4

4

.

8

8

4

.

7

5

.

1

2

5

PART NAME: BASE

PART NUMBER: 1

ALL FILLETS & ROUNDS R .0312

1

.

7

5

.

3

8

2

X

C

L

.

5

0

0

0

.

5

0

0

4

PART NAME: SLIDE

PART NUMBER: 2

ALL FILLETS & ROUNDS R .04

.1

8

1

.

7

5

0

.

8

8

.

2

5

.1

2

.5

6

1

.2

5

1

.8

8

1

.5

0

.7

5

0

.1

6

.

7

5

0

.

6

8

.

3

8

-

1

6

U

N

C

X

.

4

0

6

2

.7

8

1

6

2

.1

8

2

6

1

.9

9

7

6

.1

8

5

.

5

0

0

2

X

.

0

3

1

3

X

.

0

3

1

3

G

R

O

O

V

E

.

3

8

-

1

6

U

N

C

1

.

2

0

PART NAME: DRILL ADAPTOR

PART NUMBER: 5

.

5

0

0

0

.

5

0

0

4

.

3

8

1

.0

6

.4

3

8

.

2

5

-

2

0

U

N

C

1

.

0

0

PART NAME: COLLAR

PART NUMBER : 6

1

0

.0

0

0

2

X

.

0

4

X

4

5

.

5

0

0

0

.

4

9

9

7

PART NAME: ROD GUIDE

PART NUMBER: 8

Figure 20.55

Drill guide (Continued)

1007

ber28376_ch20.indd 1007 1/2/08 3:23:27 PM

WELDER ARM

FIXTURE

3/16 SLOTTED SPRING PIN

ARM

THONG

ITEM QTY NAME DESCRIPTION

STEEL

STEEL

STEEL

HEX HEAD MACHINE SCREW

MIDPIECE

SUPPORT

BRACE

HOLDER

3

1

1

2

1

1

1

1

2

1

1

2

3

4

5

6

7

8

9

10

STEEL

STEEL

1

2

3

4

5

6

7

8

9

11

10

WELD TO

ARM

WELD TO

MIDPIECE

CENTER AND WELD

TO HOLDER

1 11

STEEL

STEEL

3/16 SLOTTED SPRING PIN

1/8 SLOTTED SPRING PIN

Figure 20.56

Welder arm

1008

ber28376_ch20.indd 1008 1/2/08 3:23:27 PM

R

.2

5

0

.

1

2

5

0

.1

7

6

8

.5

6

2

5

2

.1

2

5

5

.0

6

2

5

5

.3

1

2

5

4

.5

6

2

5

.1

8

7

5

3

4

.3

7

5

.1

8

7

5

1

4

.2

4

0

R

.

1

7

6

8

1

4

R

.2

5

0

.1

0

0

3

.0

0

0

.5

0

0

1

.5

0

0

.3

7

5

.5

0

0

1

.3

7

5

.6

8

7

5

.6

8

7

5

.8

7

5

5

0

.9

3

7

5

.8

7

5

.5

0

0

1

.

3

1

2

5

.6

8

7

5

R

.

2

5

0

1

0

R

.2

5

0

.3

1

2

5

.4

7

6

2

X

.1

.1

7

6

8

9

0 .8

1

2

5

3

7

.1

2

5

.2

0

.3

7

5

3

4

1

1

.5

0

0

.5

0

0

.

6

2

5

.

1

2

5

.

5

0

0 .

1

2

5

.

2

5

0

.6

8

7

5

.25 X .1875 X .4375

GROOVE CENTERED

R

.2

5

0

R

.

1

2

5

.1

2

5

.1

2

5

.2

5

0

1

.2

5

0

3

.5

0

0

.0

6

2

5

X

4

5

.4

5

2

1

.1

9

0

.

5

0

0

.

5

0

0

.6

0

1

PART NAME: THONG

PART NAME: FIXTURE

PART NAME: HOLDER

PART NAME: BRACE

PART NAME: SUPPORT

PART NAME: MIDPIECE

.

5

0

0

.

4

2

5

.

2

5

0

.

2

5

0

1

.

5

0

0

.

5

0

0

1

1

X

#

5

-

4

0

U

N

C

2

.

1

2

5

1

.

8

0

0

9

X

R

.

1

2

5

R

.

0

6

2

5

.

5

0

0

3

X

1

2

0

.

3

7

5

.

2

5

0

.

5

6

2

5

.

3

7

5

3

X

.

1

3

6

#

5

-

4

0

U

N

C

.

7

5

1

.8

1

2

5 1

.

2

5

0

.

4

0

6

2

.

8

7

5

.

2

5

0

.

7

5

0

1

.3

7

5

.

6

2

5

Figure 20.56

Welder arm (Continued)

1009

ber28376_ch20.indd 1009 1/2/08 3:23:27 PM

.9

3

7

5

5

.1

8

7

5

2

.5

0

0

.2

5

0

3

.1

2

5

B

.C

.

9

X

.3

7

5

4

.0

0

0

2

.5

0

0

2

.1

2

5

1

3

2

7

1

.

5

0

0

1

.

2

5

0

1

.

5

6

2

5

.

8

1

2

5

1

.

1

2

5

.

1

2

5

1

.

5

0

0

1

.2

5

0

.0

4

X

4

5

1

.0

0

0

.1

2

5

X

4

5

2

.

7

5

0

1

.2

5

0

C

E

N

T

E

R

E

D

1

.

8

1

2

5

6

.

6

8

7

5

PART NAME: ARM

1

.

2

5

0

Figure 20.56

Welder arm (Continued)

1010

ber28376_ch20.indd 1010 1/2/08 3:23:28 PM

BRACE B

HANDLE

PIN B

GRIP A

SOCKET HEAD CAP SCREW

ITEM QTY NAME DESCRIPTION

10-32 X .375

BRACE A

PIN A

HINGE A

SHAFT

HINGE B

GRIP B

2

2

4

1

1

1

1

2

1

1

1

1

2

3

4

5

6

7

8

9

10

11

C.R.S.

C.R.S.

C.R.S.

C.R.S.

C.R.S.

C.R.S.

C.R.S.

C.R.S.

C.R.S.

C.R.S.

KANT-TWIST CLAMP

6

5

1

2

9

10

4

11

7

3

8

3

8

3

Figure 20.57

Kant-twist clamp

1011

ber28376_ch20.indd 1011 1/2/08 3:23:28 PM

R

.

3

8

.

5

6

4

.

5

0

1

.

4

4

.

1

2

5

X

.

2

5

.

7

5

2

.

5

0

R

.

3

1

R

.

5

6

R

.

3

8

1

.

7

5

.

6

9

2

.

0

0

R

.

3

1

PART NAME: BRACE A

PART NUMBER: 1

THICKNESS .125

PART NAME: BRACE B

PART NUMBER: 2

THICKNESS .125

2

X

.

2

5

.

3

7

5

-

1

6

U

N

C

C

E

N

T

E

R

E

D

O

N

P

A

R

T

1

.

0

0

.

7

5

.

1

3

.

7

5

PART NAME: HINGE A

PART NUMBER: 4

P

E

E

N

A

T

A

S

S

E

M

B

O

T

H

E

N

D

S

2

.

7

5

.

2

5

.

0

3

1

2

5

x

4

5

B

O

T

H

E

N

D

S

PART NAME: HANDLE

PART NUMBER: 5

.

6

2

C

E

N

T

E

R

E

D

O

N

P

A

R

T

.6

2

3

.8

8

.4

4

.

2

5 2

X

.

0

6

2

5

X

4

5

.

3

7

5

-

1

6

U

N

C

.

2

5

1

0

-

3

2

U

N

F

PART NAME: SHAFT

PART NUMBER: 6

.

3

1

2

.7

5

.

7

4

.

7

5

9

0

G

R

O

O

V

E

.

0

6

2

5

.

3

1

.2

5

.3

8

.2

5

C

E

N

T

E

R

E

D

O

N

P

A

R

T

.

5

0

.6

9

.

7

5

.

1

2

5

.

7

5

.2

5

PART NAME: HINGE B

PART NUMBER: 7

P

E

E

N

A

T

A

S

S

E

M

B

O

T

H

E

N

D

S

PART NAME: GRIP A

PART NUMBER: 9

2

X

.

2

5

.

3

1

2

X

.

1

8

7

5

.

5

0

P

E

E

N

A

T

A

S

S

E

M

B

O

T

H

E

N

D

S

PART NAME: PIN B

PART NUMBER: 8

9

0

G

R

O

O

V

E

.

0

6

2

5

.7

5

.4

9

.

3

1

2

.

7

5

.

1

8

PART NAME: GRIP B

PART NUMBER: 10

.

3

1

.

1

9

.

7

5

.

2

5 B

O

T

H

E

N

D

S

P

E

E

N

A

T

A

S

S

E

M

B

O

T

H

E

N

D

S

PART NAME: PIN A

PART NUMBER: 3

.

3

1 R

.

3

1

3

X

.

2

5

1

.

7

5

R

.

3

1

R

.

3

8

.

8

1

2

.

5

0

1

.

6

9

R

.

5

6

.

6

9

.

7

5

Figure 20.57

Kant-twist clamp (Continued)

1012

ber28376_ch20.indd 1012 1/2/08 3:23:28 PM

BELT TIGHTENER

.

2

6

6

.

2

5

0

1

.

0

0

0

.

5

0