Professional Documents

Culture Documents

GB 2585 - 2007 Hot-Rolled Steel Rails For Railway

GB 2585 - 2007 Hot-Rolled Steel Rails For Railway

Uploaded by

tran_lamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GB 2585 - 2007 Hot-Rolled Steel Rails For Railway

GB 2585 - 2007 Hot-Rolled Steel Rails For Railway

Uploaded by

tran_lamCopyright:

Available Formats

ICS 77.140.60.

45

H 52

National Standards of the People's Republic of China

GB 25852007

Hot-rolled steel rails for railway

2007-07-12 Issue

2008-02-01 Implement

General Admi ni st rat i on of Qual i t y Supervi si on, I nspect i on

and Quarant i ne of t he Peopl e' s Republ i c of Chi na

Issue

Hot rolled steel rails for railway

1 Scope

This standard specifies the terms and definitions, ordering information, dimensions, shapes, masses and

tolerance, technical requirements, testing methods, inspection rules, marking and quality certificate, quality

assurance for hot rolled steel rails for railway.

This standard apply to railway that was manufactured by continuous casting billet and speed not more than

160 km/h, not apply to that full-length heat treatment.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute

provisions of this standard. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this standard are encouraged to

investigate the possibility of applying the most recent editions of the normative documents indicated below.

For undated references, the latest edition of the normative document referred to applies.

GB/T 222 Permissible tolerances for chemical composition of steel products

GB/T 223 Method for chemical analysis of iron, steel and alloy

GB/T 224 Determination of depth of decarburization of steel (eqv ISO 3887)

GB/T 226 Etch test for macrostructure and defect of steelseqv ISO 4969

GB/T 228 Metallic materials Tensile testing at ambient temperature (eqv ISO 6892)

GB/T 230.1 Metallic Rockwell hardness test-Part 1:Test methodscales A,B,C,D,E,F,G,H,K,N, T

eqv ISO 6508

GB/T 231.1 Metallic materials-Brinell hardness test-Part 1:Test method (neq ISO6506-1)

GB/T 2101 General requirements of acceptance, packaging, marking and certification for section steel

GB/T 3075 Method of axial force controlled fatigue testing of metals(neq ISO 1099)

GB/T 4161 Standard test method for plane-strain fracture toughness of metallic materials

GB/T 4336 Standard test method for spark discharge atomic emission spectrometric analysis of carbon

and low-alloy steel (Routine method)

GB/T10561 Steel-Determination of content of non-metallic inclusions micrographic method using standards

diagrams

GB/T 13298 Metal-Inspection method of microstructure

GB/T 17505 Steel and steel products-General technical delivery requirements (eqv ISO 404)

GB/T 19001 Quality management systems-Requirements eqv ISO9001\ISO9002

GB/T 20066 Steel and iron-Sampling and preparation of samples for the determination of chemical

compositionISO142841998 IDT

YB/T 951 Method of the ultrasonic inspection for rails

3 Terms and definitions

For the purposes of this standard, the following terms and definitions apply.

3.1

heat

All billets cast by one heat of liquid steel, until one certain billet cast by next heat of liquid steel ( the

extension of this billet ).

3.2

sequence

Any number of heats, of the same steel grade, which undergo continuous casting in tundishes.

3.3

GB 2585-2007

transition area

Any part of steel mixed by two heats.

4 Order information

The purchaser shall provide the supplier with the following information at the time of order:

a)the number of this standard;

b) the rail profiles and indicated drilled rail or welded rail;

c) the steel grades;

d) end quenching ;

e) quantity, lengths(cut length or not);

f) any other special requirements.

5 Dimensionshapeweight and tolerance

5.1 Dimension and tolerance

5.1.1 Rail profiles and their cross section dimensions and holes dimensions are given in annex A. Other

profiles can be supplied when agreed by purchaser and supplier and specify in the contract.

5.1.2 The tolerances of railway dimensions shall be as given in Table 1.

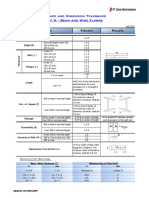

Table1 Dimensionshape tolerances mm

items Profile class kg/m

3843 506075

Gauge

figure

number

Width of rail head

WH

0.5 0.5 Figure C3

Thickness of rail

web

a

WT

+1.0

-0.5

+1.0

-0.5

Figure C6

Height of fishing

HF

0.6

+0.6

-0.5

Figure C5

Height of railH 0.8 0.6 Figure C8

Width of rail foot

WF

+1.0

-2.0

+1.0

-1.5

Figure C9

Profiles

Foot toe thickness

b

+0.75

-0.5

Figure C7

GB 25852007

Rail asymmetry

1.5

1.2

Figure C4-1

Figure C4-2

Vertical

Squareness of end

Horizontal

1.0 0.8

Vertical

straightness-up

0.8 0.5

Vertical

straightness-down

0.2 0.2

End curvature

1m from each rail

ends

Horizontal

straightness

0.5 0.5

Figure C11

Vertical flatness

0.5mm/3m

0.4mm/1m

Body

except 1m from

each rail ends

Horizontal flatness 0.7mm/1.5m

Whole rail twist 1/10000 of whole length

s

h

a

p

e

Whole rail sweep 0.5/1000 of whole length

Inclination of fishing surfaceson the basis of

14mm parallel to the inclined theoretical fishing

surfaces

+1.0

-0.5

+1.0

-0.5

Figure C5

Diameter 0.8 0.8

Drilling holes

Location 0.8 0.8

Figure C10

a

Thickness of rail web shall be measured at the point of minimum thickness.

b

Assurance when pass design. In case of dispute, gauge given in figure C7 is apply.

5.2 Shape tolerances

5.2.1 The tolerances of shape shall be as given in Table 1.

5.2.2 The foot base concavity shall not exceed 0.4mm.

5.2.3 Finished roller straightened rails shall not have curve like wave or rigidity.

5.2.4 The chamfer angle of drilling hole shall be 45 and 0.8mm2.0mm in depth.

5.3 Length and length tolerance

5.3.1 Length

5.3.1.1 The cut length of standard rail shall be 12.5m25m50m and 100m.

5.3.1.2 Curve shorten length of rail

GB 2585-2007

12.5m 12.46m12.42m12.38m.

25m 24.96m24.92m24.84m

5.3.1.3 Shorten length of rail

12.5m 9m9.5m11m11.5m12m

25m 21m22m23m24m24.5m

The quantities of short length rails shall be agreed by purchaser and supplier and specify in the contract. The

weight of short length rails shall not exceed 10% of ordering gross( include drilled rail and welded rail ). To

the rail of 50 kg/m, 60 kg/m, 75 kg/m shorten length of rail shall not included.

5.3.1.4 To the curve shorten length of 50m, 100m cut length rails and short length rail, the length shall be

agreed by purchaser and supplier, and the quantities of short length rails shall specified in the contract.

5.3.1.5 Rails of other length can be supplied when agreed by purchaser and supplier.

5.3.2 Length tolerance

The length tolerance of rail shall be as given in table 2.

Table 2 length toleranceAmbient temperature :20

Length

m

Tolerance mm

Drilled rail 25 6

25 10

Welded rail

25 Agreed by purchaser and supplier

5.4 Weight

Rails shall be delivered in theoretical weight, the calculate data is given in annex A.

6 Technical requirements

6.1 Manufacture methods

6.1.1 Continuous casting blooms made from basic oxygen killed steel or electric arc furnace killed steel shall

be used for the manufacture of rails.

6.1.2 To descaling during the rolling a processes, the high-pressure injection method shall be used.

6.1.3 The cross-sectional area of the rail shall not exceed one ninth that of the bloom from which the rail is

rolled.

6.1.4 For the avoidance of hydrogen flakes, liquid steel shall be conducted vacuum degassing or blooms

and rails shall be conducted slowly cooling.

6.1.5 Welded rails do not need heat treatment of rail ends; it is shall specified in the contract , provided that

U74, U 71Mn, U70Mn drilled rails do not need heat treatment of rail ends.

6.2 Steel grades and chemical composition

GB 25852007

6.2.1 Steel grades, chemical composition and residual elementsheat analysisshall apply to table 3,

table 4 and requirements of 6.2.1.1 and 6.2.1.2The residual elements may not tested if the supplier can

make an assurance.

Table3 Steel grades and chemical composition

Chemical composition %

Steel grades

C Si Mn S P V

a

Nb

a

RE

U74 0.68~0.79 0.13~0.28 0.70~1.00 0.030 0.030

U71Mn 0.65~0.76 0.15~0.35 1.10~1.40 0.030 0.030

U70MnSi 0.66~0.74 0.85~1.15 0.85~1.15 0.030 0.030

U71MnSiCu 0.64~0.76 0.70~1.10 0.80~1.20 0.030 0.030

0.030

U75V 0.71~0.80 0.50~0.80 0.70~1.05 0.030 0.030 0.04~0.12

0.010

U76NbRE 0.72~0.80 0.60~0.90 1.00~1.30 0.030 0.030 0.02~0.05 0.02~0.05

U70Mn 0.61~0.79 0.10~0.50 0.85~1.25 0.030 0.030

0.030

0.010

a

Except V in U75V and Nb in U76NbRe are additional elements , Nb and V are residual elements in other

steel grades.

Table 4 Maximums residual elementsmass, %

Cr Mo Ni Cu

a

Sn Sb Ti Cu+10Sn Cr+Mo+Ni+Cu

0.15 0.02 0.10 0.15 0.040 0.020 0.025 0.35 0.35

a

the content of Cu in U71MnSiCu is 0.10~0.40%

6.2.1.1 The hydrogen contents of the liquid steel shall not exceed 2.510

-4

. If the hydrogen contents of

the liquid steel exceed 2.510

-4

the blooms shall be slowly cooled. The hydrogen contents of the liquid

steel need not test when the blooms are slowly cooled. The hydrogen contents of product rails shall not

exceed 2.010

-4

%.

6.2.1.2 Total oxygen content of liquid steel or product rail shall not exceed 3010

4

. Total oxygen content

need not test when the supplier can make an assurance that non-metallic inclusions in rails conform to the

requirements of this standard.

6.2.2 Product analysis

If purchaser requires the product analysis, the composition tolerance which described in table 3 shall apply to

requirements of GB/T222.

6.3 Delivery condition

The rail shall be supplied in hot rolled condition.

6.4 Mechanical properties

Mechanical properties of rails shall be as given in table 5.

GB 2585-2007

Table5 Mechanical properties

Mechanical properties

Steel grade Tensile strength R

m

N/mm

2

min.

Elongation A

% min.

U74 780 10

U71Mn

U70MnSi

U71MnSiCu

880 9

U75V

U76NbRE

980

U70Mn 880

9

When the test pieces is taken from hot saw sample rails, the results of A

can smaller 1% (absolute value) than the given value.

6.5 Heat treatment of rail ends

The rails need to heat treatment of rail ends, quenching layer shall be like a cap and free of quenching

cracks. The requirements shall comply with requirements of annex B.

6.6 Macrostructure

6.6.1The transverse macrostructures of acid etch rail test pieces shall comply with requirements of annex F.

6.6.2 The rails shall be free of hydrogen flakes.

6.7 Microstructure

The microstructure shall be pearlite but grain boundary ferrite may occur, there shall be no martensite,

bainite or grain boundary cementite.

6.8 Decarburization

The decarburization depth of rail shall below 0.5mm.

6.9 Non-metallic inclusions

Non-metallic inclusions of rails shall comply with the following requirements: group A shall not exceed level

2.5, group Baluminate type, group Csilicate type and group Dglobular oxide typeshall not

exceed level 2.0 respectively.

6.10 Drop weight test

Rails shall be conducted drop weight test. The specimens shall not fracture after one break. Deflection shall

be noted in the certification as reference.

6.11 Ultrasonic test

6.11.1 All rails shall be ultrasonically tested by a continuous process.

6.11.2 The minimum cross-sectional area examined by the ultrasonic technique shall be:

At least 70% of the head;

At least 60% of the web;

The area of the foot to be tested shall be as shown in Figure 1.

GB 25852007

figure1 Area to be tested in rail footshadow

6.12 Surface quality

6.12.1 The rail surface shall be free of crack, fold and transverse guide marks. The imperfections that comply

with the criteria below is permitted:

6.12.1.1 The longitudinal hot formed scratches, longitudinal cracks, scale which depth not exceed 0.5mm.

6.12.1.2 The depth of longitudinal and transverse cold formed scratches do not larger than 0.4mm for the rail

running surface and underside of foot; 0.5mm for the rest of rail.

6.12.2 Drilled holes and rail ends shall be deburred and without surface lamination and crack.

6.12.3 Any bulge on running surfaces, rail foot surfaces and 1m from end of the rail which affects fishing

surfaces shall be dressed.

6.12.4 Surface imperfections can be dressing by grinding. Dressing shall along the longitudinal direction and

the dressing width shall not less than 5 times of dressing depth. The dimensions of rails after dressing shall

comply with requirements of Table 1. The rail microstructure shall not be affected by the operation and the

work is contour blended.

6.13 Residual stress

The maximum longitudinal residual stress in the foot shall not great than 250MPa.

6.14 Fatigue

For a total strain amplitude of 1350, the fatigue life ( i.e circle times when the specimen completely

separation ) of each specimen shall be greater than 5

10

6

cycles.

6.15 Fracture toughness

The fracture toughness K

1C

of rails tested at -20the minimum single value shall be 26MPam

1/2

and the

minimum mean value shall be 29MPam

1/2

.

7 Test methods

7.1 Test items, sampling position, sampling numbers and test methods shall be as given in table 6.

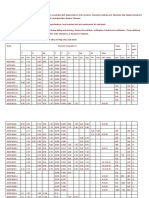

Table6 Test items, sampling position, sampling numbers and test methods

No. Test items sampling position

sampling

numbers

test methods

1 Dimension 300mm from each rail end Each

Gauge in annex C,

calipers

GB 2585-2007

2 Shape End Each

figureC11figureC4-

1figureC4-2

3

Chemical

composition

See figure2 1 / heat GB/T223GB/T4336

4 Oxygen

After vacuum degassed or finished

railsee figure4

1/ lot GB/T223.35

5 Hydrogen

7.2.2 or agreed by purchaser and

supplier

1 or 2 / heat

Agree by purchaser and

supplier

6 Macrostructure Any part except mixing zone 1/ heat GB/T226

7 Tensile strength

Any rails except mixing zonesee

figure2specimen diameter 10mm

1/ heat GB/T228

8 Microstructure See figure2 7.3 GB/T13298

9 Decarburisation See figure3 1/ lot 7.4, GB/T224

10

Non-metallic

inclusion

Head of rail 1/ lot 7.5

11

Drop-weight tear

test

Any part except mixing zone 1/ lot 7.6

12 Ultrasonic test Whole length Each YB/T 951

13 Surface quality Whole length Each Visualizing

14 Residual stress 3000mm from each rail end 7.8 Annex D

15 Fatigue

3000mm from each rail endSee

figure 5

7.9 GB/T 3075

16 Fracture toughness 3000mm from each rail end 7.10 GB/T 4161and annex E

38kg/ m and 43 kg/ m rails may not subject to items No. 8, No.9, No.10, No.14, No.15, No.16.

7.2 Chemical composition test

7.2.1 Product analysis can be performed if required by the purchaser. One test piece shall be taken from any

rail of each lot. Test pieces shall be sampled from whole profile of the rail or as shown in figure 2.

7.2.2The hydrogen content of the liquid steel shall be determined each heat when the blooms are not slowly

cooled. At least two liquid samples shall be taken from the first heat of any sequence using a new tundish

and one from each of the remaining heats and analyzed for hydrogen content. Hydrogen determination shall

be carried out on samples taken from the centre of the rail head. The first sample from the first heat in a

sequence shall be taken from the last rail rolled by the first bloom of any strand and determined by hydrogen

determinator.

GB 25852007

Figure 2 Location of tensile test piece , microstructure checks and product chemical composition

7.3 Microstructure

The sampling position in the rail head shall be as shown in Figure 2. The test shall be made once per 1000

tons or less and there of in accordance with GB/T 13298.

7.4 Decarburization

The testing position in the surface of rail head shall be as shown in Figure 3. The test shall be made to

measure the depth of closed ferrite network in accordance with GB/T 224.

Figure 3 Range of extent of rail head surface for decarburization checks

7.5 Determination of total oxygen content

The sampling position to determinate total oxygen content shall be as shown in Figure 4.

Figure4 Sampling positions for total oxygen determination

GB 2585-2007

7.6 Evaluation of nonmetal inclusions

One test piece shall be taken from each lot to evaluate nonmetal inclusions. Test pieces shall be longitudinal

cut from head of rails. The surface to be tested shall be 10mm~15mm from running surface and area not

less than 200mm

2

. The results shall be evaluated by method A of annex A of GB/T 10561.

7.7 Drop-weight test

7.7.1 Test pieces shall be at least 1300mm in length and without defects on surface.

7.7.2 Test temperature shall above 10. The drop weight tester shall be as that capable of supporting a rail

on two bears( the span shall be 1000mm), and dropping a weight 1000kg in mass freely on its center from a

height given in Table 7.

Table7 Dropping height

Profileskg/m 37 38 43 50 60 75

Height (m) 5.55 5.8 6.7 7.7 9.1 11.2

Height of the hammer also can be evaluated by the following formula:

m

r

M

M

H

150

HDropping heightm

M

r

liner mass of the railkg

M

m

weight of the hammerkg

7.8 Residual stress in rail foot

For residual stress tests there shall be 3 sample rails, which be removed from finished roller straightened

rails, and test pieces shall be taken at least 3000mm from each rail end. Test pieces from the rail section

shall be 1000mm in length. The residual stresses in the rail foot shall be determined in accordance with

annex D. Tests shall be make every 2 years or great changes happen in manufacture process.

7.9 Fatigue test

There shall be 3 sample rails removed from finished roller straightened rails from different heat and cast, and

2 specimens shall be taken at least 3000mm from each rail end. The specimen dimension and sampling

position shall be as shown in Figure5. Tests shall be make every 5 years or great changes happen in

manufacture process.

GB 25852007

a) Sampling position

notes:

1) R26 mm radius shall run tangential with gauge diameter (datum diameter A) without undercutting or

leaving a shoulder;

2) General tolerance shall be 0,2 mm unless otherwise stated;

3) Specimen to be identified on each end .

b) Specimen dimension

Figure 5 specimen for determining fatigue initiation life

7.10 Fracture toughness

There shall be 3 sample rails removed from finished roller straightened rails from different heat and cast, and

5 specimens shall be taken at least 3000mm from each rail end. The specimen dimension and sampling

position shall be as shown in Figure5. Tests shall be make every 5 years or great changes happen in

manufacture process. Fracture toughness shall be determined in accordance with GB/T 4161 and annex E.

8 Inspection requirements

8.1 Inspection and acceptance

The inspection and acceptance tests shall be response by supplier and the results shall in accordance with

GB/T 17505. The purchaser have right to retest in accordance with this standard.

8.2 Batch rules

Rails shall be tested by lot. A test lot shall consist of the rails from one grade, profile and blooms of one

sequence.

GB 2585-2007

8.3 Retest and justification

8.3.1 When the initial test of rails unqualified, retest and justification shall comply with the following

requirements.

8.3.1.1 Retest of chemical composition

The rails shall be rejected if the chemical composition unqualified.

8.3.1.2 Retest of tensile test

If any test result fails to meet the requirements, then two tests shall be performed on samples from other

rails of the same heat. One sample shall be taken from the rails of same strand with the original sample, the

other sample shall be taken from different strands. The rails of this heat shall be accepted when the results

of the tests both in accordance with this standard.

If the retest results both not in accordance with this standard, further test shall be made. That is rails from

one strand shall be rejected when two retest results from one strand unqualified. Should either retest fail then

the rails shall be progressively tested until acceptable material is found.

8.3.1.3 Retest of decarburization and nonmetallic inclusions

8.3.1.3.1 Decarburization

If the initial test result fails to meet the requirements, then retests shall be performed on samples by heat.

One sample shall be taken from two rails of the initial heat and one from each of the remaining heats. The

rails of the initial heat shall be accepted when the results of the tests both in accordance with this standard.

The rails of the initial heat shall be rejected when one of sample unqualified. The rails of other heats shall be

accepted when the result of the test in accordance with this standard. If the test result fails to meet the

requirements then two more samples shall be taken from other two rails of one heat individually. The rails of

this heat shall be accepted when the results of the tests both in accordance with this standard. The rails of

this heat shall be rejected when one of the test unqualified.

8.3.1.3.2 Nonmetallic inclusions

If the initial test result fails to meet the requirements, then two tests shall be performed on samples from

other rails of one heat. One sample shall be taken from the rails of same strand with the initial sample, the

other sample shall be taken from different strands. The rails of this heat shall be accepted when the results

of the tests both in accordance with this standard. Rails from one strand shall be rejected when two retest

results from one strand unqualified; Should either retest fail then the rails shall be progressively tested until

acceptable material is found.

8.3.1.4 Macrostructures

8.3.1.4.1 The rails shall be rejected if Hydrogen Flakes appears.

8.3.1.4.2 If the macrostructures initial test result fails to meet the requirements of this standard, the following

method shall be used to retest.

Two samples shall be taken from the before and back the sampling position of initial test. One sample shall

be taken from the rails of same strand with the initial sample. The rails of this heat shall be accepted when

the results of the tests both in accordance with this standard. Should either retest fail then the rails shall be

progressively tested until acceptable material is found.

8.3.1.5 Retest of drop weight test

If the initial test result fails to meet the requirements then one test shall be performed on samples from rails

of each heat. Two sample shall be taken from the before and back the sampling position of initial test. One

sample shall be taken from the rails of same strand with the initial sample. The rails of this heat shall be

accepted when the results of the tests both in accordance with this standard. Should either retest fail then

the rails shall be progressively tested until acceptable material is found.

GB 25852007

9 Brand marks and Certification

9.1 Brand marks

9.1.1 Brand marks shall be rolled in relief on one side and in the middle of the webof each rail at least once

every 4 m, the brand marks on the rails shall be clearly and convex, and shall be 20 mm to 28 mm high,

convex height between 0.5mm to 1.5mm.

The brand marks shall include:

a) the identification of the mill;

b) the rail profile identification;

c) the steel grade;

d) the year( the last two figures) and month of manufacture.

9.1.2 Each rail shall be identified clearly by hot stamped(cold stamped is not permitted) on the rail web and

each rail shall be hot stamped at least twice every 25m from the end of 2m. The surface of characters shall

have a flat or radius face, and shall be 10mm~16mm in high, 0.5mm~1.5mm in depth, 1mm~1.5mm in width.

a) the number of the heat;

b) the number of the strand;

c) the number of the sequence (A, B ,C...).

9.1.3 In the event of identification marks having been removed, omitted or requiring alteration, re-

identification of such marks shall be made by hot stamped or painted.

9.1.4 After packed up, on one end of rails tags shall be attached or get steel seal which includes profiles,

steel grades, heat and length etc.

9.1.5 The rail shall not consignment when no mark or mark cant be clearly identified.

9.1.6 Painting of rails shall be agreed by purchaser and supplier.

9.2 Certification

When specified in the purchase order or contract, a certification shall be furnished, include:

aname of manufactory

bname of purchaser;

cthe rail profilesdrilled rails and welded rails

dthe number of contract;

ethe number of this standard;

fthe steel grades

gquantity, the length of rail;

hheat

iall the test results specified in this standard

GB 2585-2007

jex-factory date.

10 Quality assurance system

10.1 Quality system

Quality system that certified and verified by national certification body and in accordance with GB/T19001

shall be applied by the supplier.

10.2 Period of quality assurance

10.2.1 Supplier shall assurance that the rails are free of harmful defects form manufacture date N to 31th

December of N+5. In the meantime, if the rails due to fracture or other defects cannot be applied, supplier

and purchaser shall check the product, to carry out laboratory test when necessary.

10.2.2 In case of dispute, the arbitration organization shall be agreed between supplier and purchaser.

GB 25852007

Annex A

Normative

Rail profiles

A.1 The rail profiles dimensions of 38kg/m75kg/m is as given in figure A.1A.5The theoretical weight of

rail and metal distribution see table A.1table A.2

Figure A.1 Rail profile 38kg/m

GB 2585-2007

Figure A.2 Rail profile 43kg/m

GB 25852007

Figure A.3 Rail profile 50kg/m

GB 2585-2007

Figure A.4 Rail profile 60kg/m

GB 25852007

Figure A.5 Rail profile 75kg/m

GB 2585-2007

Table A.1 Calculate data of rail

Rail style

kg/m

Section

area

cm

2

Center of

gravity from

bottom of

rail

cm

Center of

gravity from

ends of rail

cm

moment

inertia of

Horizontal

axiscm

4

Moment inertia

of vertical axis

cm

4

Cross-

section

coefficient

of bottom

cm

3

Cross-

section

coefficient

of top

cm

3

Cross-

section

coefficient

of bottom

side edge

cm

3

38 49.5 6.67 6.73 1204.4 209.3 180.6 178.9 36.7

43 57.0 6.90 7.10 1489.0 260.0 217.3 208.3 45.0

50 65.8 7.10 8.10 2037.0 377.0 287.2 251.3 57.1

60 77.45 8.12 9.48 3217 524 369.0 339.4 69.9

75 95.037 8.82 10.38 4489 665 509 432 89

Table A.2 Metal distribution of rail

Profilekg/m 38 43 50 60 75

Rail head 43.68 42.68 38.68 37.47 37.42

Rail web 21.63 21.31 23.77 25.29 26.54 Metal distribution of rail

Rail foot 34.69 35.86 37.55 37.24 36.04

GB 25852007

Annex B

(Normative)

Technical requirements of End hardened rails

B.1 Shapes and dimensions of Hardened Region on Rail Sections

The shapes and dimensions of the hardened region in the lateral and longitudinal sections of a rail shall be

as specified in Figure B1.

Dimensions in millimeters

a) Hardened region in the lateral sections bHardened region in the longitudinal sections

Figure B1 Shapes and Dimensions of Hardened Region

B.2 Hardness of Hardened Region of Rail Section

B.2.1 Surface hardness of Rail head top

The surface hardness of the stationary hardened part at the rail head top of U74U71Mn shall be

HBW302~388HRC32.5~42.0

B.2.2 The hardness of hardened depth of rail section

The hardness of stationary hardened part of the rail 7mm from the centre of head top shall HB280

HRC28.0.

B.2.3 Hardness distribution of hardened region in the longitudinal sections and rail section

a) The hardness of the stationary hardened part of the rail shall decrease gradually inward from the rail

surface, and there shall be no sudden change and discontinuity;

b) The hardness of the transition part of the rail shall decrease gradually in proportion as the hardened

depth decreases.

B.3 Microstructure of hardened layer

Microstructure of hardened layer shall be shred pearlite and a little ferrite, but no martensite and bainite.

B.4 Appearance

The rail shall be free from injurious defects such as quenching cracks, flaws and distorsions.

B.5 Tests

B.5.1 Surface hardness test on head top of rail

GB 2585-2007

The test shall be located in a place approximately 50mm from the quenched end and the surface layer shall

be ground. The test method shall be in accordance with GB/T 231.1 or GB/T 230.

B.5.2 Quenching equipments

The quenching equipments shall work well before quenching so that the shape of the harden layer is proper

and without quenching cracks. If the quenching equipments appear abnormal phenomena during the

manufacture process, the equipments shall be adjusted immediately and test the longitudinal test pieces

until the test results qualified.

B.5.3 Test on shapes of hardened region of rail sections

B.5.3.1 Test rails

From the same profile, grade and heat treatment conditions, take one rails 500mm in length to heat treat

under the same conditions as the products.

B.5.3.2 Test pieces

Test pieces shall be made by the following requirements:

aTest piece of the lateral section of the rail

Cut off the cross-section sample from approximately 20mm the heat-treated end of the test rail and grind its

inside surface to finish

bTest piece of the longitudinal section of the rail

Split the head of the rail which is the remainder of the test rail from which the lateral section test piece has

been cut off, longitudinally along the center line of the width of head into two, and then grind the longitudinal

section of either portion to finish.

B.5.3.3 Test method

The ground test pieces shall be etched by solution of 5% nitric acid and alcohol to reveal the shape of

hardened layer.

B.5.4 Hardness distribution test of hardened region of rail section

B.5.4.1 Test rail and test piece

Test rail and test piece shall in accordance with B5.3.1 and 5.3.2.

B.5.4.2 Test method

Test method shall in accordance with GB/T230.

B.5.4.3 Measuring positions

The measuring positions shall be the positions marked with X in figure 2.

B.5.5 Microstructure test

The test pieces shall be taken from the softened part and transition part individually.

GB 25852007

Dimensions in millimeters

Figure B.2 Measuring position of lateral section and longitudinal section of the rail

B.6 Record

The manufacturer of the rail shall test the rail as the requirements of B.5 and supply the results to purchaser.

B.7 Reheat-treated

The manufacturer have right to reheat-treated any unqualified rails but not exceed 2 times. The rails appears

quenching cracks is not permitted to reheat-treated.

GB 2585-2007

Annex C

Normative

Profile and drilling gauges

Figure C.1 Datum references for tolerances

GB 25852007

Figure number

0 Height, (must not), (must pass ) C7

1 Width of rail head must notmust touch C2

1 Rail asymmetrymust notmust touch C3

2 Inclination of fishing surfaces C4

3 Height of fishplatingmust notmust touch C4

3 Width of rail web must notmust touch C5

4 Width of rail footmust notmust touch C8

Figure C.2 Datum references for decision

GB 2585-2007

Figure C.3 Width of rail head

GB 25852007

Figure C.4-1 Rail asymmetry

GB 2585-2007

Figure C.4-2 Rail asymmetry

GB 25852007

Note:

x1, x2, x3, x4 is distance between rail and guage;

The maximum difference between x1 and x2 is 0.35mm;

The maximum difference between x3 and x4 is 0.35mm;

The total difference is 0.35mm.

Figure C.5 Fishing height and inclination

GB 2585-2007

Figure C.6 web thickness

GB 25852007

key

1 Maximum

2 Minimum

3 Width of foot/2

4 Tolerance

Figure C.7 Foot toe thickness

GB 2585-2007

Figure C.8 Height of rail

GB 25852007

Figure C.9 Width of rail foot

GB 2585-2007

e Web thickness;

T

d

Tolerance of hole diameter;

T

c

Tolerance of hole location;

T

d/c

Total tolerance of hole diameter and location;

T

d/c

=2(T

d

+ T

d/c

)

Figure C.10 Gauge for checking distance between holes and rail end and hole diameter

GB 25852007

Figure C.11 Check on the deviation of rail ends

GB 2585-2007

Annex D

(normative)

Method for the determination of rail foot surface longitudinal residual stresses

D.1 Procedure

Residual stresses shall be estimated by first attaching an electrical strain gauge on the rail foot surface, then

the surface to which the gauge is attached shall be progressively isolated from the rail, and the relaxed

strains shall then be used to estimate the original residual stresses.

D.2 Strain gauges and their location

Electrical strain gauges of the encapsulated type shall be used, 3 mm in length with a gauge factor accuracy

of better than 1 %.

The strain gauge shall be attached to the surface of the rail foot in order to measure longitudinal strain at the

positions as shown in Figure D.1. The surface of the rail foot and the strain gauge attached shall be prepared

in accordance with the recommendations of the strain gauge manufacturer.(Note: Any surface preparation

shall not itself result in a change of the residual stresses in the rail foot.) The strain gauges shall locate at the

centre of sample rails 1m in length.

Cut a 20 mm40mm thick slice from the centre of the rail length (Figure C.2), measure stress value before

cut and after (Cooling properly shall be taken when cutting).The residual stresses shall be calculated from

the differences between cut before and after, then by multiplying by 2,07 10

5

MPa.

Strain gauge

Figure D.1 Location of strain gauge to measure rail foot surface longitudinal residual stresses

GB 25852007

Dimensions in millimetres

Key

1 Centreline

2 Saw cut

3 Strain gauge

4 Rail foot

Figure D.2 Location and width of cut for the determination of residual stress

GB 2585-2007

Annex E

(normative)

Test method for the determination of the plane strain fracture toughness (K

1c

) of rails

E.1 Test methods

In addition to the requirements in this standard, test shall be performed in accordance with the requirements

of GB/T 4161.

E.2 Test pieces

B.2.1 The location of the test piece in the rails transverse section is shown in Figure E.1.

E.2.2 The thickness B of all test pieces shall be 25 mm, the width W shall be 40 mm.

E.3 Number of tests

A minimum of 5 tests from each sample shall be performed.

E.4 Test conditions

E.4.1 Fatigue pre-cracking shall be carried out in the temperature range + 15 to + 20 using a stress

ratio in the range0+ 0,1, cyclic frequency in the range 15 Hz to 120 Hz.The final crack length to test

piece width ratio shall be in the range 0,45 to 0,55 and when the cracks growing to 1,25 mm, Kmax shall be

in the range 18 MPa m

1/2

to 22MPa m

1/2

.

E.4.2 The single edge notched bend test piece shall be loaded under displacement control using three point

bending with a loading span (S) equal to four times the test piece width (W).

E.4.3 Tests shall be performed at -20 2, test piece temperature may be measured using a beadless

thermocouple spot welded to the test piece at the location shown in Figure E.2. In order to avoid the front of

crack bend occur , the notch specified in GB/T 4161 is recommended.

E.5 Analysis of test data

E.5.1 The calculation of K

Q

shall be in accordance with GB/T 4161. In addition to the requirements of E.5.2

to E.5.6, the checks made to establish whether this value is a valid K

1c

shall be in accordance with GB/T

4161.

E.5.2 P

max

/P

Q

shall be less than 1,10 for force-crack mouth opening curves where pop-in does not occur

before the intersection of the curve with the 95 % secant. There shall be no P

max

/P

Q

criterion for other types

of curve.

E.5.3 The linearity of force-crack mouth opening curves I

a

, I

b

, II

a

and III (see Figure E.3) shall be checked in

the following manner:

Measure the distance (v1) between the tangent OA and the force-crack mouth opening curve at a constant

force of 0,8 P

Q

. Measure the distance (v) between the tangent OA and the force-crack mouth opening curve

at a constant force of P

Q

. For a test result to be valid V

1

0,25 V.

E.5.4 The linearity of force - crack mouth opening curves II

b

and II

c

(see Figure E.3) shall be checked in the

following manner:

Measure the distance between the tangent OA and the force - crack mouth opening curve at constant forces

of 0,8 P

Q

and P

Q

recording these values as V

1

* and V* respectively.

Measure the crack mouth opening values arising from all pop-ins that occur up to P

Q

; this is done by

measuring the horizontal distance travelled along the crack mouth opening axis between the start and finish

GB 25852007

of each pop-in.Sum the values for pop-ins occurring below 0,8 P

Q

and for those occurring between 0,8 P

Q

and P

Q

recording them asV

1pi

and V

pi

respectively.

For a test result to be valid [V

1

*- V

1pi

] 0,25 [V* - ( V

pi

+ V

1pi

)]

E.5.5 The linearity criterion cannot be applied to force - crack mouth opening curve IV.

E.5.6 For all force - crack mouth opening curves the K

Q

value shall be subjected to the validity check that the

test piece thickness (B) and crack length (a) are equal to, or greater than, the value of 2,5 (K

Q

/R

p0,2

)

2

, where

Rp

0,2

is the 0,2 % proof stress at the fracture test temperature of - 20 .

E.6 Reporting of results

All measurements required to calculate the test result and to show that the test conditions were as specified

in the test procedure shall be recorded.

All results shall be reported as either K

Ic

values

*

Q

K

values or K

Q

values; where

*

Q

K

values are those K

Q

values which failed the validity criteria due only to one or more of the following:

1) P

max

/P

Q

> 1,1;

2) Exceed the 2,5 (K

Q

/R

p0,2

)

2

criterion;

3) Crack mouth opening displacement - force relationship.

The mean and standard deviation of both K

IC

and

*

Q

K

results shall be recorded in accordance with table E.1.

Table E.1 Mean and standard deviation of K

1C

and K

Q

*

grade

0.2

-20

(MPa)

Mean of K

1C

(MPam

1/2

)

K

1C

Measurement

times

standard

deviation

(MPam

1/2

)

Mean of K

Q

(MPam

1/2

)

K

Q

Measurement

times

standard

deviation

(MPam

1/2

)

The value to be used for the acceptance criteria is that of the mean K

IC

and shall be based on a minimum of

five K

IC

values. When five K

IC

values have not been obtained any

*

Q

K

values shall be included with any K

IC

values in the mean value to be used for the acceptance criteria. In this event the number of test results shall

be at least ten.

All values of K

IC

and

*

Q

K

shall be accordance with 6.15.

GB 2585-2007

Dimensions in millimetres

Key

1 Notch machined in this face

2 Section through rail head

3 Letter H to be stamped on end face of test piece as shown

B = 25

W = see B.2.2

For all other test piece proportions

see ASTM E399

Figure E.1 Location and section of fracture toughness test pieces

GB 25852007

Dimensions in millimetres

Key

1 Notch

2 Thermocouple to be placed in the shaded zone

3 Fatigue crack tip

Figure E.2 Location of thermocouple on fracture toughness specimens

Key

1 Force, P

2 Crack mouth opening displacement (v)

Figure E.3 Force - Crack mouth opening curves

GB 2585-2007

Annex F

(normative)

Standard diagrams for macrostructure of rails

F.1 Cross section of rail include 3 parts: head, wed, root, see figure F.1.

F.2 Failure conditions of macrostructure see table F.1.

Figure number Failure conditions

Figure F.2 F.3

Hydrogen flakes

Figure F.4F.5 Shrinkage

Figure F6F.7 Web centre cracks extend to head or root

Figure F.8 F.9 Cracks more than 64mm in length

Figure F.10 Web centre cracks scattered extend to head or root

Figure F.11 Segregation scattered extend to head or root

Figure F.12 Subsurface porosity

Figure F.13 Segregation more than 13mm in length and more than 6mm in width

extend to head or root

Figure F.14 Head cracks more than 3mm developed from radial cracks, middle

cracks and zigzag cracks

Figure F.15 Other defects (such as slag, refractory) cause rails failure early

Figure F.1 Cross section of rail

GB 25852007

Figure.2 Hydrogen flakes

GB 2585-2007

Figure.3 Shrinkage

GB 25852007

Figure.4 Shrinkage

GB 2585-2007

Figure.5 Shrinkage

GB 25852007

Figure.6 Web centre cracks extend to head or root

GB 2585-2007

Figure.7 Web centre cracks extend to head or root

GB 25852007

Figure F.8 Cracks more than 64mm in length

GB 2585-2007

Figure F.9 Cracks more than 64mm in length

GB 25852007

Figure F.10 Web centre cracks scattered extend to head or root

GB 2585-2007

Figure F.11 Segregation scattered extend to head or root

GB 25852007

Figure F.12 Subsurface porosity

GB 2585-2007

Figure F.13 Segregation more than 13mm in length and more than 6mm in width extend to head or root

GB 25852007

Figure F.14 Head cracks more than 3mm developed from radial cracks, middle cracks and zigzag cracks

GB 2585-2007

Figure F.15 Other defects (such as slag, refractory) cause rails failure early

You might also like

- National Standard of The People's Republic of China PDFDocument16 pagesNational Standard of The People's Republic of China PDFJCuchapin100% (1)

- Norma GB 2585 - 2007Document58 pagesNorma GB 2585 - 2007JeanMHoffNo ratings yet

- GBT 1591-2008 - High Strength Low Alloy Structural SteelDocument16 pagesGBT 1591-2008 - High Strength Low Alloy Structural SteelDarren ThoonNo ratings yet

- HighTens EN25Document2 pagesHighTens EN25Annamali Thiayagarajan0% (1)

- GB - T 10095.2-2008Document5 pagesGB - T 10095.2-2008taghdirimNo ratings yet

- Brass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForDocument9 pagesBrass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForarunjacobnNo ratings yet

- M 32-09 (Steel Wire, Plain, For Concrete Reinforcement)Document8 pagesM 32-09 (Steel Wire, Plain, For Concrete Reinforcement)tran_lamNo ratings yet

- M 140-08 (Emilsified Asphalt)Document1 pageM 140-08 (Emilsified Asphalt)tran_lamNo ratings yet

- IS:2062Document13 pagesIS:2062Rv VaghasiaNo ratings yet

- JBT6396 2006 (English Version)Document18 pagesJBT6396 2006 (English Version)Anonymous l5yF0V100% (1)

- GBT 24186Document5 pagesGBT 24186Cao Mạnh CườngNo ratings yet

- ASTM A36 MildLow Carbon SteelDocument3 pagesASTM A36 MildLow Carbon SteelAndrés MaiguaNo ratings yet

- Alloys DensityDocument4 pagesAlloys DensityArnold Melissa CollettNo ratings yet

- Properties of Q345B Steel For Plate Material - EhowDocument1 pageProperties of Q345B Steel For Plate Material - EhowchrtromNo ratings yet

- CD4 PDFDocument1 pageCD4 PDFMayrym Rey ConNo ratings yet

- En 10083 C50 Steel Plate High Carbon SteelDocument2 pagesEn 10083 C50 Steel Plate High Carbon SteelMatteo BuffoNo ratings yet

- All Unified PL On SR RequestDocument87 pagesAll Unified PL On SR RequestRohit Kumar SinghNo ratings yet

- Q345B PDFDocument2 pagesQ345B PDFAbdelkader DraïNo ratings yet

- Carbon and Carbon-Manganese Steel Seamless Steel Tubes and Pipes For ShipDocument10 pagesCarbon and Carbon-Manganese Steel Seamless Steel Tubes and Pipes For Shipvalli rajuNo ratings yet

- GBT1220 2007 Stainless Steel BarsDocument73 pagesGBT1220 2007 Stainless Steel BarsByron Erazo HermosaNo ratings yet

- National Standard of The People's Republic of China: High Strength Low Alloy Structural SteelsDocument15 pagesNational Standard of The People's Republic of China: High Strength Low Alloy Structural SteelsAnonymous uux1ScsNo ratings yet

- En-10031 - 2003 Semi Finished Products For Forging-Tolerances On Dimensions Shape and MassDocument12 pagesEn-10031 - 2003 Semi Finished Products For Forging-Tolerances On Dimensions Shape and MassmetropodikasNo ratings yet

- GB 1591 Q420 Steel PropertiesDocument6 pagesGB 1591 Q420 Steel Propertiespbp2956No ratings yet

- Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements ForDocument16 pagesSteel Bars, Carbon and Alloy, Hot-Wrought, General Requirements Forsharon blushteinNo ratings yet

- Din 1681-GS 60Document9 pagesDin 1681-GS 60Vishnu AgawaneNo ratings yet

- Jis 3192Document2 pagesJis 3192Angga KurniawanNo ratings yet

- Brass MaterialDocument2 pagesBrass Materialmaddy28No ratings yet

- ASTM A572 Grade 65: General Product DescriptionDocument1 pageASTM A572 Grade 65: General Product DescriptionRichard AubertNo ratings yet

- Steel IndexDocument24 pagesSteel IndexAnonymous AlhzFE9EVNNo ratings yet

- GBT-1220-2007-stainless Steel BarsDocument23 pagesGBT-1220-2007-stainless Steel BarsKepeNo ratings yet

- GB T 699 1988 Quality Carbon Structural SteelsDocument17 pagesGB T 699 1988 Quality Carbon Structural SteelsPHUONGNo ratings yet

- Din 1.4003Document2 pagesDin 1.4003Dhaniel100% (1)

- SM490 Ya-Yb ChemicalDocument1 pageSM490 Ya-Yb ChemicalJoko TrisnantoNo ratings yet

- Irs T 10 2023Document24 pagesIrs T 10 2023pp_mechNo ratings yet

- High Strength Structural Steel Plates in The Quenched and Tempered ConditionDocument10 pagesHigh Strength Structural Steel Plates in The Quenched and Tempered ConditionPeter KastroNo ratings yet

- 1570 (Part V)Document18 pages1570 (Part V)Kaushik SenguptaNo ratings yet

- Astm A572m PDFDocument4 pagesAstm A572m PDFrianaseptianiNo ratings yet

- GB - T 3274-2007Document7 pagesGB - T 3274-2007Dung HD0% (1)

- CI Properties TTT CompiledDocument8 pagesCI Properties TTT CompiledRajesh N Priya GopinathanNo ratings yet

- Alloy Structure Steel ComparisionDocument3 pagesAlloy Structure Steel ComparisionNenad TabandzelicNo ratings yet

- Alloy286 - ASTM A453 660 DatasheetDocument2 pagesAlloy286 - ASTM A453 660 Datasheetn1ghtfallNo ratings yet

- 1570 (Part II)Document20 pages1570 (Part II)Kaushik SenguptaNo ratings yet

- Interlloy Grade 1045 Carbon Steel BarDocument3 pagesInterlloy Grade 1045 Carbon Steel BarPRASHANT KANTENo ratings yet

- AMS5566NDocument8 pagesAMS5566Ngagalunar789No ratings yet

- Material - S45C NormalizedDocument1 pageMaterial - S45C NormalizedhanazahrNo ratings yet

- National Standard's China - Wrougth Aluminium Alloy ExtrudedDocument18 pagesNational Standard's China - Wrougth Aluminium Alloy ExtrudedMauricio RiquelmeNo ratings yet

- Specifications Casting PDFDocument1 pageSpecifications Casting PDFjahangir_alam44_6764No ratings yet

- AS2074 CastSteel Specifications PDFDocument5 pagesAS2074 CastSteel Specifications PDFZac NastNo ratings yet

- Astm A27 (2010) PDFDocument4 pagesAstm A27 (2010) PDFStuar TencioNo ratings yet

- ASTM A759-2000 Crane RailsDocument4 pagesASTM A759-2000 Crane Railsnkpong849005100% (1)

- The Mechanical and Microstructural Study of Welded Aa7075 Using Different Filler MetalsDocument17 pagesThe Mechanical and Microstructural Study of Welded Aa7075 Using Different Filler MetalsIndra SetiyadiNo ratings yet

- Quenching and TemperingDocument2 pagesQuenching and TemperingAnonymous VRspXsmNo ratings yet

- Wagon DetailDocument2 pagesWagon DetailShekher NikhilNo ratings yet

- En 10088 Steel NumberDocument3 pagesEn 10088 Steel Numberrvieira659No ratings yet

- Ansteel Product CatalogueDocument13 pagesAnsteel Product Cataloguerashid isaarNo ratings yet

- Sans 1431Document2 pagesSans 1431grincheu70100% (1)

- ASTM A656 Grade 50: General Product DescriptionDocument1 pageASTM A656 Grade 50: General Product DescriptionHarsh ChopraNo ratings yet

- Is 3930Document19 pagesIs 3930IPSITNo ratings yet

- 04Cr18Ni10 PDFDocument3 pages04Cr18Ni10 PDFAvishekNo ratings yet

- GB 2585 2007 Hot Rolled Steel Rails For RailwayDocument58 pagesGB 2585 2007 Hot Rolled Steel Rails For RailwayArthanari VaidyanathanNo ratings yet

- 4454 1 PDFDocument12 pages4454 1 PDFJessica Harrington0% (1)

- Steel wire rod for bridge cable wire 桥梁缆索钢丝用盘条: (English Translation)Document9 pagesSteel wire rod for bridge cable wire 桥梁缆索钢丝用盘条: (English Translation)Mada TetoNo ratings yet

- New Doc 2017-03-28Document1 pageNew Doc 2017-03-28tran_lamNo ratings yet

- Japan International Cooperation AgencyDocument6 pagesJapan International Cooperation Agencytran_lamNo ratings yet

- Hicac 2024 Ky Yeu Hoi ThaoDocument292 pagesHicac 2024 Ky Yeu Hoi Thaotran_lamNo ratings yet

- 22 TCN 247 - 98 PDFDocument55 pages22 TCN 247 - 98 PDFtran_lamNo ratings yet

- 2nd MRB Workshop & Training - FinalDocument36 pages2nd MRB Workshop & Training - Finaltran_lamNo ratings yet

- M 54-07 (2011) (Welded Deformed Steel Bar Mats For Concrete Reinforcement)Document4 pagesM 54-07 (2011) (Welded Deformed Steel Bar Mats For Concrete Reinforcement)tran_lamNo ratings yet

- M 17-11 (Mineral Filler For Bituminous Paving Mixtures)Document1 pageM 17-11 (Mineral Filler For Bituminous Paving Mixtures)tran_lamNo ratings yet

- M 269-96 (2008) (Turnbuckles and Shackles)Document25 pagesM 269-96 (2008) (Turnbuckles and Shackles)tran_lamNo ratings yet

- T 044-96 Solubility of Bituminous MaterialsDocument2 pagesT 044-96 Solubility of Bituminous Materialstran_lamNo ratings yet

- T 30-10 (Mechanical Analysis of Extracted Aggregate)Document4 pagesT 30-10 (Mechanical Analysis of Extracted Aggregate)tran_lam100% (1)

- TCXD 45-78 TK Nen Nha Va Cong TrinhDocument74 pagesTCXD 45-78 TK Nen Nha Va Cong TrinhKienNguyenNo ratings yet

- Specification For Diaphragm WallDocument22 pagesSpecification For Diaphragm WallleodegarioporralNo ratings yet

- Laboratory Vane Shear TestDocument1 pageLaboratory Vane Shear Testtran_lamNo ratings yet

- IEC 60034-30 Technical NoteDocument2 pagesIEC 60034-30 Technical Notetran_lamNo ratings yet

- A 500 - 03 Qtuwmc1sruqDocument7 pagesA 500 - 03 Qtuwmc1sruqtran_lamNo ratings yet

- T 19-09 (Bulk Density (Unit Weight) and Voids in Aggregate)Document8 pagesT 19-09 (Bulk Density (Unit Weight) and Voids in Aggregate)tran_lamNo ratings yet

- T 11-05 (2009) (Materials Finer Than 75-Microm (No. 200) Sieve in Mineral Aggregates by Washing)Document5 pagesT 11-05 (2009) (Materials Finer Than 75-Microm (No. 200) Sieve in Mineral Aggregates by Washing)tran_lamNo ratings yet

- Jis G3016-2008Document1 pageJis G3016-2008Nguyễn TrườngNo ratings yet

- Metalwork Formulas and Tables MetalDocument238 pagesMetalwork Formulas and Tables MetalAvil100% (1)

- px5879 Pantex Product Weld Inspection Form (Visual) PDFDocument2 pagespx5879 Pantex Product Weld Inspection Form (Visual) PDFbambaeeroNo ratings yet

- Solids Liquids and GasesDocument25 pagesSolids Liquids and GasesJane Seymour100% (1)

- Miscellaneous List of Products Move To Other ProductsDocument17 pagesMiscellaneous List of Products Move To Other Productsbalagangadhar17No ratings yet

- Chemistry Unit 3B - by Maple Leaf International SchoolDocument36 pagesChemistry Unit 3B - by Maple Leaf International SchoolMohamed Muawwiz Kamil73% (15)

- Parr 239 MDocument32 pagesParr 239 MChau MaiNo ratings yet

- KGP Flamme Stright For BEI 221016Document4 pagesKGP Flamme Stright For BEI 221016oomoomNo ratings yet

- (PEJT5025-02) Reporting Particle Count by ISO CodeDocument12 pages(PEJT5025-02) Reporting Particle Count by ISO Codevictor.ciprianiNo ratings yet

- Astm B75M.11Document8 pagesAstm B75M.11Tiago SucupiraNo ratings yet

- SRB-BART Reaction PatternsDocument1 pageSRB-BART Reaction PatternszayedNo ratings yet

- HEAT TREATMENT of SteelDocument33 pagesHEAT TREATMENT of Steelparamaguru vNo ratings yet

- WPS Format PDFDocument2 pagesWPS Format PDFHimansu Sekhar JenaNo ratings yet

- ASME P-NumbersDocument9 pagesASME P-NumbersAamer MohammedNo ratings yet

- Lab Manual - BWPDocument23 pagesLab Manual - BWPAneesh KumarNo ratings yet

- Special Report Avoid Common Mistakes With VesselsDocument21 pagesSpecial Report Avoid Common Mistakes With VesselsAnonymous oVRvsdWzfB0% (1)

- Domestic Wiring DiagramsDocument19 pagesDomestic Wiring DiagramsKaran DesaiNo ratings yet

- A500 Tech. BulletinDocument3 pagesA500 Tech. BulletinIan McpheeNo ratings yet

- Stoody Super 20Document1 pageStoody Super 20JUAN DAVID ESPITIANo ratings yet

- HT Catalogue 2012Document194 pagesHT Catalogue 2012Vishal ReddyNo ratings yet

- HKDSE CHEMISTRY - Book 4B AnsDocument47 pagesHKDSE CHEMISTRY - Book 4B AnsSteven Chu100% (2)

- General Casting ToleranceDocument2 pagesGeneral Casting ToleranceMuhammad M ElhafidNo ratings yet

- Engineering MaterialsDocument197 pagesEngineering MaterialsSidiq BudhyNo ratings yet

- Science Five Third: PanimulaDocument4 pagesScience Five Third: PanimulaPrince CharlesNo ratings yet

- 2700-Series PRV - Intalacion MantenimientoDocument14 pages2700-Series PRV - Intalacion Mantenimientopgarces86100% (1)

- Metal Solid Nickel PDFDocument18 pagesMetal Solid Nickel PDFNur Indah KartikasariNo ratings yet

- The Design of Products To Be Hot Dip Galvanized After FabricationDocument24 pagesThe Design of Products To Be Hot Dip Galvanized After FabricationKrista Undeberg MercerNo ratings yet

- Kansas Department of Transportation Special Provision To The Standard Specifications, Edition 2015Document3 pagesKansas Department of Transportation Special Provision To The Standard Specifications, Edition 2015Vpln SarmaNo ratings yet

- Chemistry Investigatory Project - Study of Constituent of AlloysDocument19 pagesChemistry Investigatory Project - Study of Constituent of AlloyscaptainclockNo ratings yet

- DFMA On Desktop StaplerDocument15 pagesDFMA On Desktop Staplerranjithkraj100% (1)

- A Handbook of Art Smithing, F. S. Meyer, 1896 PDFDocument215 pagesA Handbook of Art Smithing, F. S. Meyer, 1896 PDFPGAChamp100% (2)