Professional Documents

Culture Documents

FS One

FS One

Uploaded by

Dario SantosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FS One

FS One

Uploaded by

Dario SantosCopyright:

Available Formats

7

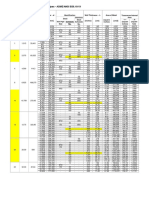

Firestop Systems

Saving Lives throgh innovation & education I Hilti Firestop Guide 2008-2009 I 1800-88-0985 I www.hilti.com.my

Technical data (at 73F(23 C )and 50% relative humidity)

Chemical basis Water-based intumescent

acrylic dispersion

Density: Approx. 1.5 g/cm

3

Colour: Red

Working time: Approx. 20-30 min

Curing time: Approx. 2mm / 3 days

Shore A Hardness: Approx. 35

Movement capability: Max. 10%

Intumescent Activation: Approx. 482F (250C)

Expansion rate (unrestricted): Approx. 4 times original volume

Temperature resistance (cured): 40F to 212F (40C to 100C)

Application temperature: 41F to 104F (5C to 40C

Surface burning characteristics Flame Spread: 0

(ASTM E 84-96): Smoke Development: 5

Sound transmission classification (ASTM E 90-99): 56

Shelf life at 25C(77F) and store at dry place: 9 months

Approvals:

ICBO (International Conference of Building Officials) Report No. 5071

California State Fire Marshal: Listing No. 4485-1200:108

City of New York: MEA 326-96-M

Tested in accordance with: UL 1497

ASTM E 814

ASTM E 84

Packaging contents Ordering designation Colour Item no.

Intumescent firestop mastic 5gallon(19 liter) FS-ONE, pail Red 259578

Internationally tested and approved

FS ONE

High Performance Intumescent firestop sealant

Product description

Intumescent (expands when exposed to fire) firestop sealant that

helps protect combustible and non-combustible penetrations for

up to 4 hours fire rating.

Product features

Smoke, gas and water resistant after material has cured.

Contains no halogen, solvents or asbestos.

High fire rating properties.

Water based, easy to clean.

Areas of application*

Insulated and non-insulated steel, cast iron, steel conduit, copper

and EMT pipes.

Cable trays and cable bundles. (various cables)

Closed or vented plastic pipes. (PVC, CPVC, ABS)

HVAC penetrations. (Insulated and non-insulated metal dusts)

Electrical busways.

For use with*

Concrete, masonry, gypsum, drywall and wood floor assemblies.

Wall and floor assemblies rated up to 4 hours.

Example*

Sealing around cable bundles in fire rated construction.

Sealing around combustible and non-combustible penetrations

in fire rated construction.

FS-ONE

High Performance intumescent firestop sealant

System advantages / Customer Benefits

Protects most typical firestop penetration applications

Easy to work with and fast clean up

Can be painted

Age tested for 30 years

Single component system available

Meet LEED requirements for indoor environmental quality credit 4.1 Low

Emiting Materials, Sealants and Adhesive and 4.2 Paints and Coatings

Opening

Clean the opening. Surfaces to which FS-ONE will be

applied should be cleaned of loose debris, dirt, oil ,

moisture, frost and wax. Structures supporting penetrating

items must be installed in compliance with local building

and electrical standards.

Application of firestop sealant

Install the prescribed backfilling material type and depth

to obtain the desired rating (if required). Leave sufficient

depth for applying FS-ONE.

Application of firestop sealant: Apply FS-ONE to the

required depth in order to obtain the desired fire rating.

Make sure FS-ONE contact al l surfaces to provi de

maximum adhesion. For application of FS-ONE use a

standard caulking gun, foil pack gun, bulk loader and bulk

gun. With FS-ONE buckets, Graco type sealant pumps may

be use. (Contact pump manufacturer for proper selection).

Smoothing of firestop sealant: To complete the seal, tool

immediately to give a smooth appearance. Excess sealant,

prior to curing, can be cleaned away from adjacent

surfaces and tools with water.

Leave completed seal undisturbed for 48 hours.

For maintenance reasons, a penetration seal could be

permanently marked with an identification plate. In such a

case, mark the identification plate fasten it in a visible

position next to the seal.

Notice about approvals

Check that the penetration has been sealed according to

the specified drawing in the UL Fire Resistance Directory

or Hilti Firestop Manual. For further advice, please contact

Hilti customer service. Refer to Hilti product literature and

UL fire resistance directory for specific application details.

Not for use...

High movement expansion joints

Underwater

On materials where oil, Plasticizers or solvents may bleed

i.e. impregnated wood, oil based seals, green or partially

vulcanized rubber

In any penetration other than those specifically described

in this manual or the text reports

Safety precautions

Before handling, read the product and Material Safety

Data Sheet for detailed use and health information

Keep out of reach of children

Wear suitable gloves and eye protection

Storage

Store only in the original packaging in a location protected

from moisture at temperatures between 41F (5C) and

86F (30C)

Observe expiration date on the packaging

Installation instructions for FS-ONE

1.

2.

3.

4.

5.

6.

* For installation criteria according to UL / BS 476-20, please contact Hilti Fire Protection Specialist for advice.

CABLE

PIPE

AGE TESTED

30 YEARS

You might also like

- Proposed Renovation of Residential Development Boq July 2016Document9 pagesProposed Renovation of Residential Development Boq July 2016Aliyu Shehu62% (13)

- Manual FireStopDocument148 pagesManual FireStopTimothy Hancock100% (1)

- CP 601S CP 601S: Elastomeric Firestop SealantDocument4 pagesCP 601S CP 601S: Elastomeric Firestop Sealantrichard_qrNo ratings yet

- Jotun Hardtop XP - Technical Data SheetDocument5 pagesJotun Hardtop XP - Technical Data Sheetamarican100% (1)

- CP 606Document1 pageCP 606Jonathan ChavezNo ratings yet

- TDS Tankguard Storage GB English ProtectiveDocument5 pagesTDS Tankguard Storage GB English ProtectiveAdverNo ratings yet

- Jotun-Penguard Primer - Tech DataDocument4 pagesJotun-Penguard Primer - Tech Dataanwarali1975No ratings yet

- Hardtop CA Technical Data Sheet JotunDocument5 pagesHardtop CA Technical Data Sheet JotunSam JoseNo ratings yet

- Penguard PrimerDocument5 pagesPenguard PrimerPutroedidohNo ratings yet

- Complete Top-of-Wall Firestopping Solution!: CP 672 CP 672Document4 pagesComplete Top-of-Wall Firestopping Solution!: CP 672 CP 672Gökhan GülhanNo ratings yet

- Hilti Firestop Submittal - Balamand UniversityDocument32 pagesHilti Firestop Submittal - Balamand UniversitybasbousrNo ratings yet

- Interthane 990: Product DescriptionDocument4 pagesInterthane 990: Product Descriptionsorion61No ratings yet

- Sikaflex®-11 FC: Product Data SheetDocument3 pagesSikaflex®-11 FC: Product Data SheetHaradhon DattaNo ratings yet

- Interzone 101Document0 pagesInterzone 101hennawijayaNo ratings yet

- Sikaflex 2c NS EZ Mix UsDocument3 pagesSikaflex 2c NS EZ Mix Usتوان امتياس سامسدينNo ratings yet

- Pyroplex Fire Rated Expanding Foam Datasheet enDocument4 pagesPyroplex Fire Rated Expanding Foam Datasheet enrmbalcobiaNo ratings yet

- Internationa Paint MSDSDocument4 pagesInternationa Paint MSDStsoheil100% (1)

- Hardtop XP: Technical Data SheetDocument5 pagesHardtop XP: Technical Data Sheetadeoye_okunoyeNo ratings yet

- Fiber WrapDocument2 pagesFiber WrapStephen WilberNo ratings yet

- Marthon Jotun Marine PaintDocument5 pagesMarthon Jotun Marine PaintNishanthNo ratings yet

- PC-5 Neoprene CoatingDocument2 pagesPC-5 Neoprene Coatingbello imamNo ratings yet

- Jotafloor SL UniversalDocument4 pagesJotafloor SL UniversalSlamat Parulian SimamoraNo ratings yet

- Penguard Express Datasheet " AzadJotun"Document5 pagesPenguard Express Datasheet " AzadJotun"AzadAhmadNo ratings yet

- Polysafe Wood FX AcoustixDocument1 pagePolysafe Wood FX AcoustixFloorkitNo ratings yet

- Jotafloor Topcoat - English (Uk) - Issued.06.12.2007Document4 pagesJotafloor Topcoat - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Jotachar 1709 PDFDocument5 pagesJotachar 1709 PDFBiju_PottayilNo ratings yet

- Jotachar 1709: Technical Data SheetDocument5 pagesJotachar 1709: Technical Data SheetAndi BagusNo ratings yet

- Interthane 990 HS DatasheetDocument4 pagesInterthane 990 HS DatasheetBalasubramanian Ananth100% (1)

- Jotacote Universal AluminiumDocument5 pagesJotacote Universal AluminiumAnirbanNo ratings yet

- AG 24400 Jota Etch Euk GBDocument5 pagesAG 24400 Jota Etch Euk GBchusnadiantyNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data Sheetajuhaseen100% (1)

- Polyflex UltrachemDocument2 pagesPolyflex UltrachemBraulio Candela NoriegaNo ratings yet

- Jotun Resist 5WFDocument4 pagesJotun Resist 5WFSergio SmithNo ratings yet

- PDS Terostat PCFRi enDocument2 pagesPDS Terostat PCFRi enDherbecourtNo ratings yet

- Penguard Express ZPDocument5 pagesPenguard Express ZPMustafa Al-YasseriNo ratings yet

- CP 601selastic Firestop Sealant: Product DescriptionDocument122 pagesCP 601selastic Firestop Sealant: Product Descriptionbramakumar.sudhakarNo ratings yet

- MasterEmaco ADH 326 (Concresive Liq)Document4 pagesMasterEmaco ADH 326 (Concresive Liq)RodCorniNo ratings yet

- TankGuard Plus Product DescDocument5 pagesTankGuard Plus Product DescAbrar HussainNo ratings yet

- Tyfo SCH-41 Composite: Using Tyfo S EpoxyDocument2 pagesTyfo SCH-41 Composite: Using Tyfo S EpoxyPE EngNo ratings yet

- Product Data 232 Ceilcote FlakelineDocument3 pagesProduct Data 232 Ceilcote FlakelineMohd MustafhaNo ratings yet

- Interline 399Document4 pagesInterline 399pinky_y2kNo ratings yet

- TDS - Tankguard HBDocument5 pagesTDS - Tankguard HBRedzuanNo ratings yet

- Penguard FC - English (Uk) - Issued.06.12.2007Document4 pagesPenguard FC - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Hardtop Flexi - English (Uk) - Issued.06.12.2007Document3 pagesHardtop Flexi - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- TDS 2280 Penguard+FC Euk GB PDFDocument5 pagesTDS 2280 Penguard+FC Euk GB PDFRyukiNo ratings yet

- Jotafloor SL UniversalDocument6 pagesJotafloor SL UniversalrogandatambunanNo ratings yet

- Jotafloor TopcoatDocument4 pagesJotafloor TopcoatrogandatambunanNo ratings yet

- Date Sheet For PaintingDocument5 pagesDate Sheet For PaintingAws MohamedNo ratings yet

- Sika PDS - E - Sarnafil G 410 L FeltDocument4 pagesSika PDS - E - Sarnafil G 410 L Feltlwin_oo2435No ratings yet

- Interline 1012+ds+engDocument4 pagesInterline 1012+ds+engSUBHOMOYNo ratings yet

- Pitt Tech 90 712aDocument7 pagesPitt Tech 90 712aPablo PuebloNo ratings yet

- Jotun Resist 86Document5 pagesJotun Resist 86Ansar AliNo ratings yet

- Interline 850Document4 pagesInterline 850shameelNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Family Handyman Quick & Easy ProjectsFrom EverandFamily Handyman Quick & Easy ProjectsFamily HandymanNo ratings yet

- Family Handyman HacksFrom EverandFamily Handyman HacksFamily HandymanNo ratings yet

- PROFINET - The Industrial Ethernet Standard: © Siemens AG 2013. Alle Rechte VorbehaltenDocument22 pagesPROFINET - The Industrial Ethernet Standard: © Siemens AG 2013. Alle Rechte VorbehaltenKhaled Ouni100% (2)

- Debug 1214Document3 pagesDebug 1214MuhammadPrayitoNo ratings yet

- Cloud ComputingDocument25 pagesCloud ComputingmanikeshNo ratings yet

- 04.020 Webercem Five Star Repair Concrete PDFDocument3 pages04.020 Webercem Five Star Repair Concrete PDFNuno FerreiraNo ratings yet

- Random MergedDocument839 pagesRandom MergedAnonymous WQZvNONo ratings yet

- 2018 Civilcast Brochure PDFDocument20 pages2018 Civilcast Brochure PDFariNo ratings yet

- Fire Escape DoorDocument25 pagesFire Escape DoorAhtesham KhanNo ratings yet

- Module 3 - Module 5 Cad-Cam & ROBOTICS-1Document53 pagesModule 3 - Module 5 Cad-Cam & ROBOTICS-1BASIL BENNYNo ratings yet

- The Pentium Pro Was Introduced in 1995 As The Successor To The PentiumDocument5 pagesThe Pentium Pro Was Introduced in 1995 As The Successor To The PentiumManpreetaaNo ratings yet

- Sheet PilesDocument58 pagesSheet Pilesamin alzuraikiNo ratings yet

- Jordan Odor Thesis DraftDocument22 pagesJordan Odor Thesis DraftrutkrtkNo ratings yet

- Project Wise Explorer V8i Client Installation-Step-By-StepDocument6 pagesProject Wise Explorer V8i Client Installation-Step-By-StepXai XiongNo ratings yet

- Physical Facilities Repair and Maintenance Needs Assessment FormDocument6 pagesPhysical Facilities Repair and Maintenance Needs Assessment FormJohn Orodio VillaseñorNo ratings yet

- Specifying Chain Link Fence: Standard Guide ForDocument3 pagesSpecifying Chain Link Fence: Standard Guide ForEnriqueVeNo ratings yet

- Public Realm Design ManualDocument234 pagesPublic Realm Design ManualØwięs MØhãmmedNo ratings yet

- OnDevice Facebook - User ManualDocument12 pagesOnDevice Facebook - User ManualSif Eddine SellamiNo ratings yet

- Install GCC 4.7 On RHEL 6Document3 pagesInstall GCC 4.7 On RHEL 6Zhou Yupeng PaulNo ratings yet

- NP Lab RecordDocument15 pagesNP Lab RecordNag RajNo ratings yet

- Fallingwater, - WPS OfficeDocument4 pagesFallingwater, - WPS OfficeAbdi TirfaNo ratings yet

- GD & GDSDocument16 pagesGD & GDSDota NgNo ratings yet

- Summer InteriorDocument36 pagesSummer Interiorjacob jacobNo ratings yet

- Azure Virtual Network Frequently Asked QuestionsDocument12 pagesAzure Virtual Network Frequently Asked QuestionsAjoy MondalNo ratings yet

- Auto LiftDocument22 pagesAuto LiftIshan RanganathNo ratings yet

- Content Matrix User Mapping From AD To Claims Including O365Document12 pagesContent Matrix User Mapping From AD To Claims Including O365BrizaNo ratings yet

- Ceragon Ip 10r1 Advanced Course Handbook v41 PDFDocument413 pagesCeragon Ip 10r1 Advanced Course Handbook v41 PDFAndreaLugliNo ratings yet

- English Manual Graitec DadvanceDocument36 pagesEnglish Manual Graitec DadvanceajinomotoNo ratings yet

- 1 Patil 2 30 GR - Floor/ Pour No-01 GR - Floor Bottom Slab: Name of Project: D Mart, BelgaumDocument20 pages1 Patil 2 30 GR - Floor/ Pour No-01 GR - Floor Bottom Slab: Name of Project: D Mart, BelgaumChandrakant KumbharNo ratings yet

- Carbon, Alloy and Stainless Steel Pipes - ASME/ANSI B36.10/19Document1 pageCarbon, Alloy and Stainless Steel Pipes - ASME/ANSI B36.10/19ElAleNo ratings yet

- Web-Development Using GWT + mvp4gDocument305 pagesWeb-Development Using GWT + mvp4gUlric WilfredNo ratings yet