Professional Documents

Culture Documents

13851

13851

Uploaded by

govimanoCopyright:

Available Formats

You might also like

- Ed Soja ThirdspaceDocument193 pagesEd Soja Thirdspacepoemadelsol69% (13)

- 4 HorloverDocument418 pages4 HorloverCiel Phantomhive100% (2)

- K-12 School Presentation PDFDocument28 pagesK-12 School Presentation PDFDinabandhu PatraNo ratings yet

- A Guide To Classroom Observartion - Rob Walker & Clem Adelman PDFDocument159 pagesA Guide To Classroom Observartion - Rob Walker & Clem Adelman PDFKatia ManeroNo ratings yet

- Is 7226 1974Document14 pagesIs 7226 1974Santosh KumarNo ratings yet

- Is 2041 2009Document12 pagesIs 2041 2009Katie RamirezNo ratings yet

- Disclosure To Promote The Right To InformationDocument27 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- Is 10096-1-1 (1983)Document14 pagesIs 10096-1-1 (1983)slamienkaNo ratings yet

- Is 5986-2011Document14 pagesIs 5986-2011oneakshay100% (1)

- Is 2480-1Document20 pagesIs 2480-1TPM BMPNo ratings yet

- Disclosure To Promote The Right To Information: IS 11100 (1984) : Sweeping Brooms (CED 9: Timber and Timber Stores)Document14 pagesDisclosure To Promote The Right To Information: IS 11100 (1984) : Sweeping Brooms (CED 9: Timber and Timber Stores)arindam_chowdhu1926No ratings yet

- Is 15560 - 2005Document12 pagesIs 15560 - 2005kalpanaadhiNo ratings yet

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationRebecca FrancisNo ratings yet

- Is 6913 1973Document11 pagesIs 6913 1973diwakar1978No ratings yet

- Is 1897 2008Document12 pagesIs 1897 2008Santosh KumarNo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationSanje1024No ratings yet

- Emirates Steel: Pre QualificationDocument36 pagesEmirates Steel: Pre Qualificationnyuvraj2001No ratings yet

- Disclosure To Promote The Right To InformationDocument16 pagesDisclosure To Promote The Right To InformationCristian WalkerNo ratings yet

- Is 6755 1980Document7 pagesIs 6755 1980sarath6725No ratings yet

- Is 1079 (2009) - Hot Rolled Carbon Steel Sheet and StripDocument13 pagesIs 1079 (2009) - Hot Rolled Carbon Steel Sheet and StripJeetu GosaiNo ratings yet

- Is 3618 1966 PDFDocument19 pagesIs 3618 1966 PDFLakhwant Singh KhalsaNo ratings yet

- Is 10343 1999Document11 pagesIs 10343 1999Arjuna ReddyNo ratings yet

- Is 276 2000Document12 pagesIs 276 2000gotosudNo ratings yet

- 4853 1982Document20 pages4853 1982govimanoNo ratings yet

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- Disclosure To Promote The Right To InformationDocument21 pagesDisclosure To Promote The Right To InformationJaisree Balu PydiNo ratings yet

- Is 7666 1988Document9 pagesIs 7666 1988chepurthiNo ratings yet

- Disclosure To Promote The Right To InformationDocument22 pagesDisclosure To Promote The Right To Informationchitti409No ratings yet

- Copper PowderDocument4 pagesCopper Powderfsgitaly2011No ratings yet

- Is 513 StandardsDocument18 pagesIs 513 StandardsEr Abhijeet Kamble0% (1)

- Investment Casting CalculationsDocument7 pagesInvestment Casting CalculationsRawendrraw KuriNo ratings yet

- Is 3074 2005Document16 pagesIs 3074 2005Kuldeep SinghNo ratings yet

- Is 11802 (1986) - Method of Determination of Diffusible Hydrogen Content of Deposited Weld Metal From Covered Electrodes in Welding Mild and Low Alloy SteelsDocument19 pagesIs 11802 (1986) - Method of Determination of Diffusible Hydrogen Content of Deposited Weld Metal From Covered Electrodes in Welding Mild and Low Alloy SteelsBerk ÖzdirikNo ratings yet

- Thermocouple Documentation Temp-Pro IncDocument13 pagesThermocouple Documentation Temp-Pro IncCrls Armnd CNo ratings yet

- Is 1570 6 1996Document9 pagesIs 1570 6 1996Kiran KumarNo ratings yet

- Is 6392 1971Document62 pagesIs 6392 1971Chandra SekharNo ratings yet

- IS 460 Part 1Document19 pagesIS 460 Part 1Muhammed NoufalNo ratings yet

- Datasheet DMV 304 HCu 20081118Document4 pagesDatasheet DMV 304 HCu 20081118Anuj ShahiNo ratings yet

- Is 7291 1981 PDFDocument38 pagesIs 7291 1981 PDFAnubhav LakhmaniNo ratings yet

- Is 432 2 1982 PDFDocument14 pagesIs 432 2 1982 PDFAnil Daniel HansNo ratings yet

- Is 1852 1985Document31 pagesIs 1852 1985pavan_03No ratings yet

- Is.437.1979 SIZE ANALYSIS of Coal and Coke For MarketingDocument16 pagesIs.437.1979 SIZE ANALYSIS of Coal and Coke For Marketingak_thimiriNo ratings yet

- Is 3018 1977 Specification For Standard Silica Sand For Raw Material Testing in FoundriesDocument14 pagesIs 3018 1977 Specification For Standard Silica Sand For Raw Material Testing in FoundriespsewagNo ratings yet

- Rubber Research Institute Testing FeeDocument15 pagesRubber Research Institute Testing FeemoumonaNo ratings yet

- 1405Document19 pages1405Neeraj Agrawal100% (1)

- Is 12776 2002 PDFDocument12 pagesIs 12776 2002 PDFVenkataLakshmiKorrapatiNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To Informationsarath6725No ratings yet

- Is 9417 1989Document15 pagesIs 9417 1989Ganesh RajaNo ratings yet

- CH 22Document5 pagesCH 22ProfNDAcharyaNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Ceramics for Environmental SystemsFrom EverandCeramics for Environmental SystemsLianzhou WangNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- Ut Rule of ThumbDocument1 pageUt Rule of ThumbTonyo Ayshiyu100% (6)

- Int QDocument103 pagesInt QgovimanoNo ratings yet

- Cbse - Biz: Paper Prepared byDocument3 pagesCbse - Biz: Paper Prepared bygopi_dey8649No ratings yet

- API 620 Vs API 650Document5 pagesAPI 620 Vs API 650govimanoNo ratings yet

- Surface Preparation For Carbon SteelDocument2 pagesSurface Preparation For Carbon Steelgovimano100% (1)

- DeaeratorDocument3 pagesDeaeratorNury RinjaniNo ratings yet

- Pressure Vessel and Heat Exchanger BooksDocument1 pagePressure Vessel and Heat Exchanger BooksgovimanoNo ratings yet

- Boiler Water TreatmentDocument4 pagesBoiler Water TreatmentgovimanoNo ratings yet

- Guide To The Fundamentals of Helium Leak TestingDocument4 pagesGuide To The Fundamentals of Helium Leak TestinggovimanoNo ratings yet

- Fluid Static PressureDocument1 pageFluid Static PressuregovimanoNo ratings yet

- Is 1387 1993Document10 pagesIs 1387 1993anilkumar18No ratings yet

- Laminar & Turbulent FlowDocument1 pageLaminar & Turbulent FlowgovimanoNo ratings yet

- Chloride Attack On Stainless SteelDocument10 pagesChloride Attack On Stainless SteelgovimanoNo ratings yet

- Is 1757 1988 PDFDocument7 pagesIs 1757 1988 PDFkarthikkandaNo ratings yet

- Detergent Colour CodeDocument1 pageDetergent Colour CodegovimanoNo ratings yet

- Disclosure To Promote The Right To InformationDocument23 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- Disclosure To Promote The Right To InformationDocument10 pagesDisclosure To Promote The Right To InformationrajmarathiNo ratings yet

- Disclosure To Promote The Right To InformationDocument14 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- 2643 2005Document14 pages2643 2005govimanoNo ratings yet

- Disclosure To Promote The Right To Information: IS 1751 (1984) : Fireclay Cupola Refrectories (MTD 15: Refractories)Document11 pagesDisclosure To Promote The Right To Information: IS 1751 (1984) : Fireclay Cupola Refrectories (MTD 15: Refractories)govimanoNo ratings yet

- Experiment No 16Document3 pagesExperiment No 16Usama MughalNo ratings yet

- Chapter 1 MergedDocument65 pagesChapter 1 MergedAdi SaputraNo ratings yet

- Bluedio R Manual PDFDocument2 pagesBluedio R Manual PDFAdalberto Orta Pozo0% (2)

- Artificial Neural Network Using PythonDocument3 pagesArtificial Neural Network Using PythonPoornima GhodkeNo ratings yet

- Refrigerant Suction Recovery UnitDocument4 pagesRefrigerant Suction Recovery UnitOmair FarooqNo ratings yet

- SAP SD Contract Creation User ManualDocument52 pagesSAP SD Contract Creation User ManualRayaseelan100% (1)

- NCERT G7 BOC Physics Ch-15-LightDocument6 pagesNCERT G7 BOC Physics Ch-15-LightTapan Kumar NayakNo ratings yet

- TM Family Lowres enDocument16 pagesTM Family Lowres enRui PratesNo ratings yet

- Quantel Optimis II Service Manual 51 60Document10 pagesQuantel Optimis II Service Manual 51 60Vladimir LevchenkoNo ratings yet

- Strategic Management - WalmartDocument7 pagesStrategic Management - WalmartKanika ShahNo ratings yet

- Quality Manual HETL FCS 17025 2017Document108 pagesQuality Manual HETL FCS 17025 2017Mohamed azarudeenNo ratings yet

- Charles LawDocument3 pagesCharles LawJohn Eliandrei Bañaga IINo ratings yet

- Good Things Come To Those Who Wait, But Only Those Things Left by Those Who Hustle' by Abraham LincolnDocument12 pagesGood Things Come To Those Who Wait, But Only Those Things Left by Those Who Hustle' by Abraham Lincolnsiva_mmNo ratings yet

- Environmental Audit Hand BookDocument70 pagesEnvironmental Audit Hand BookAnonymous ufxnMzUhKNo ratings yet

- Ôn DLKTDocument21 pagesÔn DLKTLinh DoanNo ratings yet

- EADS-Brochure VoltAir EnglishDocument6 pagesEADS-Brochure VoltAir EnglishHemesh AceNo ratings yet

- The Magic of Doing One Thing at A TimeDocument3 pagesThe Magic of Doing One Thing at A Timevenu4u498No ratings yet

- ShopeePay Payment Services Agreement - (Online Merchant) ESB LTE - (ESB Com) 23062022Document37 pagesShopeePay Payment Services Agreement - (Online Merchant) ESB LTE - (ESB Com) 23062022jessicaNo ratings yet

- Kromatografi TLCDocument24 pagesKromatografi TLCBloodySayeNo ratings yet

- Guidelines For Occlusion Strategy in Imp PDFDocument7 pagesGuidelines For Occlusion Strategy in Imp PDFpablogdv956No ratings yet

- Literary Analysis Final DraftDocument4 pagesLiterary Analysis Final Draftapi-645801422No ratings yet

- 17-619 Introduction To Real-Time Software and Systems: Carnegie MellonDocument7 pages17-619 Introduction To Real-Time Software and Systems: Carnegie Mellonbkit_n_haiNo ratings yet

- Evidence Based Dentistry - A Review: January 2014Document5 pagesEvidence Based Dentistry - A Review: January 2014Sitta Dea ViastiyaNo ratings yet

- PriyankaDocument2 pagesPriyankaPriyanka AmazonNo ratings yet

- Organizational Structure of PRDocument127 pagesOrganizational Structure of PRgopalmeb6368No ratings yet

- Multiple Intelligences InventoryDocument4 pagesMultiple Intelligences Inventorylape darwelNo ratings yet

13851

13851

Uploaded by

govimanoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

13851

13851

Uploaded by

govimanoCopyright:

Available Formats

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

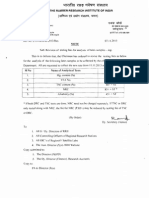

IS 13851 (1993): Storage and redrying of covered electrodes

before use - recommendations [MTD 11: Welding General]

AMENDMENT NO. 2 DECEMBER 2010

TO

IS 13851 : 1993 STORAGE AND REDRYING OF COVERED

ELECTRODES BEFORE USE RECOMMENDATIONS

[Page 3, Table 1 (see also Amendment No.1)] Substitute the following in place of the existing

Table 1:

Table 1 Temperature Time Cycle for Redrying of Electrodes

(Clause 4)

Redrying Condition Sl No. Electrode Type

Temp (

o

C) Time (min)

Holding Condition

Temp

o

C

Time Exposed

i) General purpose mild

steel cored:

a) Rutile (IS 814) coated 135 10 60 40-45 4 h

b) Cellulose coated Not recommended Not recommended Nil

c) Basic coated (for extra low hydrogen,

that is, less than 5 ml/100 g of weld)

300 10

or

360 10

120

60

130 10

130 10

9 h

(2 h for Basic

Coated only)

ii) Stainless steel electrode 300 10 120 130 10 1 h

iii) Hardfacing:

a) Basic 300 10 120 130 10 2 h

b) Rutile 100 10 60 4 h

iv) Cast iron 135 10 60 40-45 1 h

v) Ni & Ni based 360 10 60 130 10 1 h

vi) Non-ferrous:

a) Aluminium 180 10 60 Nil

b) Copper 230 10 120 1 h

NOTE Redrying to be done if the electrodes have remained exposed to humid condition (70 % RH and above) for a time as given

above. Whenever the welding consumable manufacturers recommendation is available for the redrying parameters, those

recommendations shall supersede the above requirements.

(MTD 11)

Reprography Unit, BIS, New Delhi, India

You might also like

- Ed Soja ThirdspaceDocument193 pagesEd Soja Thirdspacepoemadelsol69% (13)

- 4 HorloverDocument418 pages4 HorloverCiel Phantomhive100% (2)

- K-12 School Presentation PDFDocument28 pagesK-12 School Presentation PDFDinabandhu PatraNo ratings yet

- A Guide To Classroom Observartion - Rob Walker & Clem Adelman PDFDocument159 pagesA Guide To Classroom Observartion - Rob Walker & Clem Adelman PDFKatia ManeroNo ratings yet

- Is 7226 1974Document14 pagesIs 7226 1974Santosh KumarNo ratings yet

- Is 2041 2009Document12 pagesIs 2041 2009Katie RamirezNo ratings yet

- Disclosure To Promote The Right To InformationDocument27 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- Is 10096-1-1 (1983)Document14 pagesIs 10096-1-1 (1983)slamienkaNo ratings yet

- Is 5986-2011Document14 pagesIs 5986-2011oneakshay100% (1)

- Is 2480-1Document20 pagesIs 2480-1TPM BMPNo ratings yet

- Disclosure To Promote The Right To Information: IS 11100 (1984) : Sweeping Brooms (CED 9: Timber and Timber Stores)Document14 pagesDisclosure To Promote The Right To Information: IS 11100 (1984) : Sweeping Brooms (CED 9: Timber and Timber Stores)arindam_chowdhu1926No ratings yet

- Is 15560 - 2005Document12 pagesIs 15560 - 2005kalpanaadhiNo ratings yet

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationRebecca FrancisNo ratings yet

- Is 6913 1973Document11 pagesIs 6913 1973diwakar1978No ratings yet

- Is 1897 2008Document12 pagesIs 1897 2008Santosh KumarNo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationSanje1024No ratings yet

- Emirates Steel: Pre QualificationDocument36 pagesEmirates Steel: Pre Qualificationnyuvraj2001No ratings yet

- Disclosure To Promote The Right To InformationDocument16 pagesDisclosure To Promote The Right To InformationCristian WalkerNo ratings yet

- Is 6755 1980Document7 pagesIs 6755 1980sarath6725No ratings yet

- Is 1079 (2009) - Hot Rolled Carbon Steel Sheet and StripDocument13 pagesIs 1079 (2009) - Hot Rolled Carbon Steel Sheet and StripJeetu GosaiNo ratings yet

- Is 3618 1966 PDFDocument19 pagesIs 3618 1966 PDFLakhwant Singh KhalsaNo ratings yet

- Is 10343 1999Document11 pagesIs 10343 1999Arjuna ReddyNo ratings yet

- Is 276 2000Document12 pagesIs 276 2000gotosudNo ratings yet

- 4853 1982Document20 pages4853 1982govimanoNo ratings yet

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- Disclosure To Promote The Right To InformationDocument21 pagesDisclosure To Promote The Right To InformationJaisree Balu PydiNo ratings yet

- Is 7666 1988Document9 pagesIs 7666 1988chepurthiNo ratings yet

- Disclosure To Promote The Right To InformationDocument22 pagesDisclosure To Promote The Right To Informationchitti409No ratings yet

- Copper PowderDocument4 pagesCopper Powderfsgitaly2011No ratings yet

- Is 513 StandardsDocument18 pagesIs 513 StandardsEr Abhijeet Kamble0% (1)

- Investment Casting CalculationsDocument7 pagesInvestment Casting CalculationsRawendrraw KuriNo ratings yet

- Is 3074 2005Document16 pagesIs 3074 2005Kuldeep SinghNo ratings yet

- Is 11802 (1986) - Method of Determination of Diffusible Hydrogen Content of Deposited Weld Metal From Covered Electrodes in Welding Mild and Low Alloy SteelsDocument19 pagesIs 11802 (1986) - Method of Determination of Diffusible Hydrogen Content of Deposited Weld Metal From Covered Electrodes in Welding Mild and Low Alloy SteelsBerk ÖzdirikNo ratings yet

- Thermocouple Documentation Temp-Pro IncDocument13 pagesThermocouple Documentation Temp-Pro IncCrls Armnd CNo ratings yet

- Is 1570 6 1996Document9 pagesIs 1570 6 1996Kiran KumarNo ratings yet

- Is 6392 1971Document62 pagesIs 6392 1971Chandra SekharNo ratings yet

- IS 460 Part 1Document19 pagesIS 460 Part 1Muhammed NoufalNo ratings yet

- Datasheet DMV 304 HCu 20081118Document4 pagesDatasheet DMV 304 HCu 20081118Anuj ShahiNo ratings yet

- Is 7291 1981 PDFDocument38 pagesIs 7291 1981 PDFAnubhav LakhmaniNo ratings yet

- Is 432 2 1982 PDFDocument14 pagesIs 432 2 1982 PDFAnil Daniel HansNo ratings yet

- Is 1852 1985Document31 pagesIs 1852 1985pavan_03No ratings yet

- Is.437.1979 SIZE ANALYSIS of Coal and Coke For MarketingDocument16 pagesIs.437.1979 SIZE ANALYSIS of Coal and Coke For Marketingak_thimiriNo ratings yet

- Is 3018 1977 Specification For Standard Silica Sand For Raw Material Testing in FoundriesDocument14 pagesIs 3018 1977 Specification For Standard Silica Sand For Raw Material Testing in FoundriespsewagNo ratings yet

- Rubber Research Institute Testing FeeDocument15 pagesRubber Research Institute Testing FeemoumonaNo ratings yet

- 1405Document19 pages1405Neeraj Agrawal100% (1)

- Is 12776 2002 PDFDocument12 pagesIs 12776 2002 PDFVenkataLakshmiKorrapatiNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To Informationsarath6725No ratings yet

- Is 9417 1989Document15 pagesIs 9417 1989Ganesh RajaNo ratings yet

- CH 22Document5 pagesCH 22ProfNDAcharyaNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Ceramics for Environmental SystemsFrom EverandCeramics for Environmental SystemsLianzhou WangNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- Ut Rule of ThumbDocument1 pageUt Rule of ThumbTonyo Ayshiyu100% (6)

- Int QDocument103 pagesInt QgovimanoNo ratings yet

- Cbse - Biz: Paper Prepared byDocument3 pagesCbse - Biz: Paper Prepared bygopi_dey8649No ratings yet

- API 620 Vs API 650Document5 pagesAPI 620 Vs API 650govimanoNo ratings yet

- Surface Preparation For Carbon SteelDocument2 pagesSurface Preparation For Carbon Steelgovimano100% (1)

- DeaeratorDocument3 pagesDeaeratorNury RinjaniNo ratings yet

- Pressure Vessel and Heat Exchanger BooksDocument1 pagePressure Vessel and Heat Exchanger BooksgovimanoNo ratings yet

- Boiler Water TreatmentDocument4 pagesBoiler Water TreatmentgovimanoNo ratings yet

- Guide To The Fundamentals of Helium Leak TestingDocument4 pagesGuide To The Fundamentals of Helium Leak TestinggovimanoNo ratings yet

- Fluid Static PressureDocument1 pageFluid Static PressuregovimanoNo ratings yet

- Is 1387 1993Document10 pagesIs 1387 1993anilkumar18No ratings yet

- Laminar & Turbulent FlowDocument1 pageLaminar & Turbulent FlowgovimanoNo ratings yet

- Chloride Attack On Stainless SteelDocument10 pagesChloride Attack On Stainless SteelgovimanoNo ratings yet

- Is 1757 1988 PDFDocument7 pagesIs 1757 1988 PDFkarthikkandaNo ratings yet

- Detergent Colour CodeDocument1 pageDetergent Colour CodegovimanoNo ratings yet

- Disclosure To Promote The Right To InformationDocument23 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- Disclosure To Promote The Right To InformationDocument10 pagesDisclosure To Promote The Right To InformationrajmarathiNo ratings yet

- Disclosure To Promote The Right To InformationDocument14 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- 2643 2005Document14 pages2643 2005govimanoNo ratings yet

- Disclosure To Promote The Right To Information: IS 1751 (1984) : Fireclay Cupola Refrectories (MTD 15: Refractories)Document11 pagesDisclosure To Promote The Right To Information: IS 1751 (1984) : Fireclay Cupola Refrectories (MTD 15: Refractories)govimanoNo ratings yet

- Experiment No 16Document3 pagesExperiment No 16Usama MughalNo ratings yet

- Chapter 1 MergedDocument65 pagesChapter 1 MergedAdi SaputraNo ratings yet

- Bluedio R Manual PDFDocument2 pagesBluedio R Manual PDFAdalberto Orta Pozo0% (2)

- Artificial Neural Network Using PythonDocument3 pagesArtificial Neural Network Using PythonPoornima GhodkeNo ratings yet

- Refrigerant Suction Recovery UnitDocument4 pagesRefrigerant Suction Recovery UnitOmair FarooqNo ratings yet

- SAP SD Contract Creation User ManualDocument52 pagesSAP SD Contract Creation User ManualRayaseelan100% (1)

- NCERT G7 BOC Physics Ch-15-LightDocument6 pagesNCERT G7 BOC Physics Ch-15-LightTapan Kumar NayakNo ratings yet

- TM Family Lowres enDocument16 pagesTM Family Lowres enRui PratesNo ratings yet

- Quantel Optimis II Service Manual 51 60Document10 pagesQuantel Optimis II Service Manual 51 60Vladimir LevchenkoNo ratings yet

- Strategic Management - WalmartDocument7 pagesStrategic Management - WalmartKanika ShahNo ratings yet

- Quality Manual HETL FCS 17025 2017Document108 pagesQuality Manual HETL FCS 17025 2017Mohamed azarudeenNo ratings yet

- Charles LawDocument3 pagesCharles LawJohn Eliandrei Bañaga IINo ratings yet

- Good Things Come To Those Who Wait, But Only Those Things Left by Those Who Hustle' by Abraham LincolnDocument12 pagesGood Things Come To Those Who Wait, But Only Those Things Left by Those Who Hustle' by Abraham Lincolnsiva_mmNo ratings yet

- Environmental Audit Hand BookDocument70 pagesEnvironmental Audit Hand BookAnonymous ufxnMzUhKNo ratings yet

- Ôn DLKTDocument21 pagesÔn DLKTLinh DoanNo ratings yet

- EADS-Brochure VoltAir EnglishDocument6 pagesEADS-Brochure VoltAir EnglishHemesh AceNo ratings yet

- The Magic of Doing One Thing at A TimeDocument3 pagesThe Magic of Doing One Thing at A Timevenu4u498No ratings yet

- ShopeePay Payment Services Agreement - (Online Merchant) ESB LTE - (ESB Com) 23062022Document37 pagesShopeePay Payment Services Agreement - (Online Merchant) ESB LTE - (ESB Com) 23062022jessicaNo ratings yet

- Kromatografi TLCDocument24 pagesKromatografi TLCBloodySayeNo ratings yet

- Guidelines For Occlusion Strategy in Imp PDFDocument7 pagesGuidelines For Occlusion Strategy in Imp PDFpablogdv956No ratings yet

- Literary Analysis Final DraftDocument4 pagesLiterary Analysis Final Draftapi-645801422No ratings yet

- 17-619 Introduction To Real-Time Software and Systems: Carnegie MellonDocument7 pages17-619 Introduction To Real-Time Software and Systems: Carnegie Mellonbkit_n_haiNo ratings yet

- Evidence Based Dentistry - A Review: January 2014Document5 pagesEvidence Based Dentistry - A Review: January 2014Sitta Dea ViastiyaNo ratings yet

- PriyankaDocument2 pagesPriyankaPriyanka AmazonNo ratings yet

- Organizational Structure of PRDocument127 pagesOrganizational Structure of PRgopalmeb6368No ratings yet

- Multiple Intelligences InventoryDocument4 pagesMultiple Intelligences Inventorylape darwelNo ratings yet