Professional Documents

Culture Documents

T3 Overview of Direct Displacement Based Design of Bridges

T3 Overview of Direct Displacement Based Design of Bridges

Uploaded by

Muntasir BillahCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- M. J. N. Priestley, F. Seible, G. M. Calvi-Seismic Design and Retrofit of Bridges-Wiley-Interscience (1996)Document705 pagesM. J. N. Priestley, F. Seible, G. M. Calvi-Seismic Design and Retrofit of Bridges-Wiley-Interscience (1996)Suman Kumar Yadav100% (12)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- OneSteel Composite Structures Design Booklet Db3.1Document62 pagesOneSteel Composite Structures Design Booklet Db3.1Brian Nasr100% (2)

- Biomass-A Massive Opportunity in Disguise: Biomass To Bio-Crude To Biofuel: Integrated Bio-Refineries in IndiaDocument14 pagesBiomass-A Massive Opportunity in Disguise: Biomass To Bio-Crude To Biofuel: Integrated Bio-Refineries in IndiarishikeshmandawadNo ratings yet

- Mil-Prf-85285e T2 PDFDocument3 pagesMil-Prf-85285e T2 PDFLuis Barrios ArandaNo ratings yet

- l3 MaterialsDocument32 pagesl3 MaterialsZaouiNo ratings yet

- Flatdeck Design ExamplesDocument8 pagesFlatdeck Design ExamplesMuntasir BillahNo ratings yet

- Fiber Beam-Columns Models With Flexure-Shear Interaction For Nonlinear Analysis of Reinforced Concrete StructuresDocument146 pagesFiber Beam-Columns Models With Flexure-Shear Interaction For Nonlinear Analysis of Reinforced Concrete StructuresMuntasir BillahNo ratings yet

- Loading Summary For A Slab On Girder Bridge According To The CAN/CSA-S6Document27 pagesLoading Summary For A Slab On Girder Bridge According To The CAN/CSA-S6Muntasir Billah100% (1)

- Effect of Bilateral Excitation On The Seismic Performance of Reinforced Concrete Bridge ColumnsDocument1 pageEffect of Bilateral Excitation On The Seismic Performance of Reinforced Concrete Bridge ColumnsMuntasir BillahNo ratings yet

- Pour Zey NaliDocument15 pagesPour Zey NaliMuntasir BillahNo ratings yet

- Basic Concepts of Fluid TransportDocument14 pagesBasic Concepts of Fluid TransportBernard BaluyotNo ratings yet

- Catalogue FX03 enDocument2 pagesCatalogue FX03 enonur_guzel6403100% (1)

- 01 Lubica Hallmann 2018 - Effect of Microstructure On The Mechanical Properties of Lithium DisilicateDocument16 pages01 Lubica Hallmann 2018 - Effect of Microstructure On The Mechanical Properties of Lithium DisilicatePatsawat YodhongNo ratings yet

- Addendum: Test Report 2006-2721: ResultsDocument2 pagesAddendum: Test Report 2006-2721: ResultsTimesLIVENo ratings yet

- Mro Products and Oem Adhesives Catalog 2021Document44 pagesMro Products and Oem Adhesives Catalog 2021piyush1124No ratings yet

- Ies/Ese Syllabus: Gate+Ies+Psu - Topper Notes: Click HereDocument5 pagesIes/Ese Syllabus: Gate+Ies+Psu - Topper Notes: Click Herepallavi guptaNo ratings yet

- Conbextra GP1 PDFDocument4 pagesConbextra GP1 PDFabhay_joshi2002No ratings yet

- FSM 120l Sustainability Inservice PresentationDocument3 pagesFSM 120l Sustainability Inservice Presentationapi-347153077No ratings yet

- Catalogo Brossard ParafusosDocument0 pagesCatalogo Brossard ParafusosMarco ViniciusNo ratings yet

- MCP 02 - 002 - 03Document24 pagesMCP 02 - 002 - 03Riski Dea100% (1)

- Stability & Determinacy of Trusses PDFDocument5 pagesStability & Determinacy of Trusses PDFuwj123No ratings yet

- Gas Sweetening TotalDocument62 pagesGas Sweetening TotalMehdi AlizadNo ratings yet

- Sop (RTP)Document9 pagesSop (RTP)WahyuPurboSuasanaNo ratings yet

- Product Data Sheet: Miniature Circuit Breaker - iC60N - 1 Pole + N - 4 A - C CurveDocument2 pagesProduct Data Sheet: Miniature Circuit Breaker - iC60N - 1 Pole + N - 4 A - C CurveNicolae ChirilaNo ratings yet

- Secondary Treatment of Wastewater - 15 PDFDocument171 pagesSecondary Treatment of Wastewater - 15 PDFIshan PalNo ratings yet

- MTO Philosophy & GuidelinesDocument18 pagesMTO Philosophy & GuidelinesManish SharmaNo ratings yet

- Sta-Rite Series DS2 Pump ManualDocument12 pagesSta-Rite Series DS2 Pump ManualbarnstoreNo ratings yet

- JSPL FLS Internal-IR-02 Mechanism SteelDocument4 pagesJSPL FLS Internal-IR-02 Mechanism SteelMohammad AdilNo ratings yet

- Dishwasher Installation InstructionsDocument52 pagesDishwasher Installation InstructionsFrancis Violet RaymondNo ratings yet

- Experiment 2Document5 pagesExperiment 2Vivek Surana40% (5)

- Effect of Soda Ash, Urea, Time and Temperature On Colour Strength of Cotton Reactive Dyes On SubstrateDocument10 pagesEffect of Soda Ash, Urea, Time and Temperature On Colour Strength of Cotton Reactive Dyes On Substrate3120262820301No ratings yet

- Rugged, Long Gauge Length Extensometers: 3542L For Long Gauge Lengths With Smaller Measuring RangesDocument2 pagesRugged, Long Gauge Length Extensometers: 3542L For Long Gauge Lengths With Smaller Measuring RangesWeb ConfigNo ratings yet

- Dissimilar Metal Welding CrackingDocument10 pagesDissimilar Metal Welding CrackingMohd SyafiqNo ratings yet

- Byk-014 TDS (En)Document2 pagesByk-014 TDS (En)nailur rohmanNo ratings yet

- Dcpe Exmo 2023-07-17Document32 pagesDcpe Exmo 2023-07-17Xy karNo ratings yet

- Kyocera Fs 6525mfp 6530mfp Parts ListDocument44 pagesKyocera Fs 6525mfp 6530mfp Parts Listmmcchuck_284436071No ratings yet

- Arteche DS Vru-36 enDocument2 pagesArteche DS Vru-36 enFacturas SempsaNo ratings yet

T3 Overview of Direct Displacement Based Design of Bridges

T3 Overview of Direct Displacement Based Design of Bridges

Uploaded by

Muntasir BillahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T3 Overview of Direct Displacement Based Design of Bridges

T3 Overview of Direct Displacement Based Design of Bridges

Uploaded by

Muntasir BillahCopyright:

Available Formats

NCSU

Overview of Direct

Displacement-Based Design of

Bridges

July 9, 2012

Mervyn J. Kowalsky

Professor of Structural Engineering

North Carolina State University

kowalsky@ncsu.edu

919 515 7261

NCSU

Outline

Brief History

DDBD Fundamentals

SDOF Example

MDOF Fundamentals

MDOF Example

Design verification

Sources for more information

Current and future areas of study

NCSU

Things to think about during the talk:

Philosophical differences: DDBD,

AASHTO LRFD (Force based), and

AAHSTO Guide Spec for Seismic Design

(Displacement-based).

Examples: How would they be handled

with current AASHTO methods?

End Result: Does DDBD Make a

difference? (Best to try it for yourself!)

NCSU

Brief History

1993 Myths and

Fallacies paper by

Priestley.

Continual development

from 1993 through 2007.

Culminated in 2007 book.

Chapter in 2013 Bridge

engineering handbook.

Continued refinement,

adaptations, and

verifications.

NCSU

For seismic design

You are the boss of the structure tell it what

to do! Tom Paulay

Strength is essential, but otherwise

unimportant. Hardy Cross

Analysis should be as simple as possible, but

no simpler. Albert Einstein

Always follow the principle of consistent

crudeness. Nigel Priestley

NCSU

Within the context of

Performance Based Design:

What should the structural strength be (i.e.

base shear force)?

How should the strength be distributed?

How can design be elevated by analysis?

What should the strength of capacity

protected actions be?

NCSU

DDBD Fundamentals

Displacement Response Spectrum (DRS)

based.

DRS can be easily obtained from code ARS

or site specific.

Utilizes equivalent linearization (inelastic

spectra also possible)

Effective stiffness.

Equivalent viscous damping

NCSU

Fundamentals

NCSU

Basic Method (SDOF)

Select target displacement, D

d

Strain, Drift, or Ductility

Calculate yield displacement, D

y

Fundamental member property

Calculate equivalent viscous damping, z

Relationships between damping and

ductility available and easily obtained

Calculate effective period, T

eff

From Response spectra

Calculate effective stiffness, K

eff

K

eff

= 4p

2

m/T

eff

2

Calculate design base shear force, V

b

V

b

= K

eff

D

d

NCSU

How Are Damping Equations Obtained?

Area based hysterestic damping from above is corrected (NLTHA)

and then combined with viscous damping (i.e. 5% tangent stiffness)

to obtain expressions for equivalent viscous damping for a given

hysteretic shape, i.e. RC Column or steel beam, etc.

NCSU

Example Single bent bridge

H=10m

d=2m

f

y

=470MPa

E

s

=200GPa

W=5000kN

q

d

=0.035

m

d

=4

Target Displacement:

Drift: D

d

=(0.035)(10m) = 0.350 m

Ductility: D

d

=m

d

D

y

D

y

=f

y

H

2

/3

f

y

=2.25e

y

/D=0.00264 1/m

D

y

= 0.088 m

D

d

= 4(0.088) = 0.353 m

875

mm

4 sec.

z=5%

NCSU

Example Single bent bridge

Equivalent Viscous Damping (These expressions all assume 5% tangent

stiffness proportional viscous damping and hysteretic damping):

NCSU

Example Single bent bridge

D

c

5%

= 875 mm

T

c

= 4

z=5%

Obtaining Effective Period:

D

d

= 350 mm

D

c

15.5%

= 553 mm

z=15.5%

T

eff

= 2.53 Period (sec)

Disp (mm)

NOTE: D

c

X%

= D

c

5%

R

x

2 + z

R

x

=

7

NCSU

Example Single bent bridge

Obtaining Effective Stiffness:

Obtaining Design Base Shear:

NCSU

Simplified Base Shear Equation for DDBD

a = 0.5 for regular conditions

a = 0.25 for velocity pulse conditions

NOTE: Damping expressed as ratio in the above equation (not %).

NOTE: Equation assumes a linear DRS to the corner point.

NCSU

Transverse design displacement profiles

Dual seismic load paths

Effective system properties

displacement, damping, mass

Degree of fixity at column top

Impact of abutment support conditions

Iterative, in some cases.

Complexities for Multi-Span Bridges

NCSU

Transverse Displaced Shapes

D

D

D

D

D

(a) Symm., Free abuts. (b) Asymm., Free abuts. (c) Symm., free abuts.

Rigid SS translation Rigid SS translation+rotation Flexible SS

D

D

3

D

4

D

5

D

D

D

D

D

D

D

D

D

3

D

3

D

3

D

3

D

4

D

4

D

4

D

4

D

5

D

5

D

5

D

5

(d) Symm,. Restrained abuts. (e) Internal movement joint (f) Free abuts., M.joint

Flexible SS Rigid SS, Restrained abuts. Flexible SS

D

NCSU

Obtaining Displaced Shape

D

i

s

p

l

a

c

e

m

e

n

t

Position along bridge

Note: Stars are limit state displacements based on strain, ductility, or drift

NCSU

System Displacement and Effective Mass

From work balance between MDOF and SDOF systems:

From force equilibrium between MDOF and SDOF systems:

NCSU

Pier Damping:

System Damping:

Damping Components

System damping obtained by weighting component damping

according to work done by each component

NCSU

Force is distributed in proportion to mass and pier top displacement.

Base Shear Distribution

NCSU

Higher mode effects?

In general, not a problem for most bridges

with regards to displaced shape.

Possible to use Effective modal analysis to

define displaced shape, but takes more effort.

Higher modes can be an issue for

superstructure bending and abutment

reactions use dynamic amplification

factors.

NCSU

Longitudinal Design: If the bridge is straight, this is generally

straightforward, and will often dominate design requirements.

Effective damping and design displacement are the main issues.

Transverse Design: More complex, but often doesnt govern.

Displacement shape may not be obvious at start. Design

displacement, damping, higher mode effects may need to be

considered.

DDBD OF MDOF BRI DGES

NCSU

Multi-span bridge longitudinal direction

1. In longitudinal direction, multi-span bridge is an SDOF system.

2. Shortest pier will govern target displacement.

3. Only complexity is that damping of each pier must be weighted.

4. For bridges restrained in the transverse direction but free

longitudinally, the governing direction is longitudinal.

NCSU

Force

Displ.

C

A

B

Design Choice: Equal moment capacity, piers.

Shears inversely proportional to height

Yield curvatures of piers are equal

Design Displacement based on shortest pier.

Ductility, and hence damping of piers are different.

abutments

NCSU

NCSU

NCSU

NCSU

12m

(39.4ft)

2.0m dia

(78.7in)

10MN 2250kips

Material props:

f

c

=30MPa: f

ce

=39MPa (5.7ksi)

f

y

=420MPa: f

ye

=462MPa (67ksi)

f

u

/f

y

=1.35

Long.bars: 40mm (1.575in) dia.

Trans.bars:20mm @100mm (4in)

Displacement for damage-control limit state for fixed top case

= 0.326m: based on strains (concrete governs at 0.0136 over

steel at 0.06).

Design Displacement for a Footing-Supported

Column under Long. Response (Central Pier)

NCSU

NCSU

NCSU

NCSU

Multi-span bridge transverse direction

Estimate portion of base shear to be carried by abutments due to

superstructure bending.

Define column and abutment target displacements.

Define displaced shape.

Scale shape to critical column or abutment displacement.

Express MDOF bridge as equivalent SDOF structure

system displacement

system mass

system damping

Calculate design base shear (use simplified equation)

Distribute base shear to each abutment and bent according to

displaced shape and mass of each bent/abutment.

Conduct secant stiffness analysis and compare response displaced

shape to target displaced shape.

Revise proportion of force carried by abutment, if needed

Iterate until convergence

NCSU

40m 50m 50m 40m

16m

12m

16m

B

C

A

D

E

(Not to scale)

Transverse Design (1): Ductile Piers, restrained abutments:

D

d

= 0.485m; x = 0.51; x = 0.085; V

Base

= 11.1MN

Transverse Design (2): Isolated piers and abutment:

D

d

= 0.5m; x = 0.0, x = 0.163; V

Base

= 5.6MN

Transverse Design Example

NCSU

Example 10.5, p507

NCSU

Da = De = 40mm

Db = Dd = 961mm

Dc = 596mm

Therefore, limit state displacements are:

Since displacements of pier b and d are estimated

as 70% of pier c, pier c is critical and profile is:

Da = De = 40mm; Db = Dd = 417mm; Dc = 596mm

NCSU

(Work balance) (Force equil.)

NCSU

NCSU

NCSU

NCSU

NCSU

Da = De = 40mm; Db = Dd = 417mm; Dc = 596mm (Target)

Da = De = 43mm; Db = Dd = 383mm; Dc = 572mm (actual)

NCSU

Da = De = 41mm; Db = Dd = 396mm; Dc = 593mm (rev. x)

NCSU

2

nd

iteration

NCSU

Sample Design and Analysis

Result for MDOF Bridge

NCSU

Other verification results

2, 4, 6 span bridges with 9 different

support conditions.

Each bridge designed with DDBD and

then analyzed with NLTH analysis.

NCSU

6 Span Bridge Results

X-Z X-Z X-Z

R-R PR-R R-PR

X: Longitudinal restraint

Z: Transverse restraint

NCSU

6 Span Bridge Results

X-Z X-Z X-Z

PR-PR U-R R-U

NCSU

6 Span Bridge Results

X-Z X-Z X-Z

U-U U-PR PR-U

NCSU

Sources for more information

NCSU (every fall on campus and by distance): CE 725 covers

displacement based design of structures. Currently developing a bridge

specific course as well (CE 725 will be a pre-req).

http://engineeringonline.ncsu.edu/index.html

Courses at the Rose School in Pavia Italy: Numerous courses on DDBD

(I teach the bridge course every three years, usually in May next 2013)

http://www.roseschool.it/

Seminars (Past: NC, DR, Ecuador, Vancouver, NZ, Italy).

NCSU

Sources for more information

Textbook.

Numerous papers.

Bridge engineering handbook, 2013, will

have a chapter on DDBD of Bridges.

Call or email me any time.

NCSU

Current and Future Areas of Study

DDBD of curved and irregular bridges (PhD

student Easa Khan), and arch bridges (with

Easa Khan and Dr. Tim Sullivan of Rose

School).

Impact of load history (and path) on limit state

definitions and the relationship between strain

and displacement.

Seismic behavior of reinforced concrete filled

pipes

NCSU

Research Methods

Analytical

Moment curvature analysis of sections

Fiber and FEM analysis of members

Experimental

Material tests

Large scale tests (30)

NCSU

Specimen Design

2ft Diameter

8ft Cantilever Length

Single Bending

16 #6 Longitudinal Bars

#3 or #4 Transverse at

Variable Spacing

Cover to Spiral

Quasi-Static Load Procedure

NCSU

Optotrak Certus HD

Position Sensor

NCSU

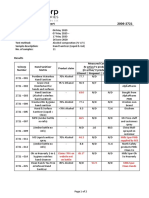

Experimental Tests

T

e

s

t

M

a

t

r

i

x

Specimens 1-12 Load History

Specimens 13-18

Transverse Steel

Load History

Specimens 19-24

Testing Aug - Dec

Axial Load

Aspect Ratio

Specimens 25-30

Longitudinal Steel

Axial Load

Currently 18 Tests Completed

NCSU

Quasi-Static Earthquake Loading Procedure

0 25 50 75 100 125 150

-1

-0.75

-0.5

-0.25

0

0.25

0.5

0.75

1

1.25

1.5

Time (sec)

A

c

c

e

l

e

r

a

t

i

o

n

(

g

)

-254 -154 -54 46 146 246

-356

-256

-156

-56

44

144

244

344

-80

-60

-40

-20

0

20

40

60

80

-10 -8 -6 -4 -2 0 2 4 6 8 10

Displacement (mm)

L

a

t

e

r

a

l

F

o

r

c

e

(

k

N

)

L

a

t

e

r

a

l

F

o

r

c

e

(

k

i

p

s

)

Displacement (in)

NCSU

Load History Characteristics

Test 9 Shown

Symmetric Three Cycle Set

Monotonic Test 1

El Centro 1940 Test 4 Tabas 1978 Tests 5 and 6

NCSU

Load History Characteristics

Japan 2011 Test 12

Kobe 1995 Test 11

Chichi 1999 Test 10

Chile 2010 Test 8

NCSU

I s Load History I mportant?

Load History as the Only Variable

NCSU

Load history and Buckling of Steel

Characteristic compression strain

capacity:

Impacted by boundary conditions, which

are effected by load history (i.e. large

compressive cycles which yield

transverse steel)

Tensile Strain Demand:

Impacted by number of reversals and

strain accumulation.

NCSU

Strain Profiles

0

200

400

600

800

1000

1200

0

5

10

15

20

25

30

35

40

45

-0.03 -0.02 -0.01 0 0.01 0.02 0.03 0.04 0.05

L

o

c

a

t

i

o

n

(

m

m

)

L

o

c

a

t

i

o

n

(

i

n

)

Strain

Ductility 1 +3

Ductility 1.5 +3

Ductility 2 +3

Ductility 3 +3

Ductility 4 +3

Ductility 6 +3

Ductility 8 +1

NCSU

Curvature Profiles

y = -37229x + 96

y = -2499.5x + 20

R = -0.018

y = -1978.9x + 21.575

R = 0.6693

y = -1547.3x + 25.102

R = 0.8831

y = -1429.2x + 28.909

R = 0.9692

y = -1113.4x + 32.04

R = 0.9857

y = -822.27x + 32.325

R = 0.9859

0 0.02 0.04 0.06 0.08 0.1 0.12

0

200

400

600

800

1000

1200

0

5

10

15

20

25

30

35

40

45

0 0.005 0.01 0.015 0.02 0.025 0.03 0.035 0.04

Curvature (1/m)

L

o

c

a

t

i

o

n

(

m

m

)

L

o

c

a

t

i

o

n

(

i

n

)

Curvature (1/ft)

Ductility 1 +3

Ductility 1.5 +3

Ductility 2 +3

Ductility 3 +3

Ductility 4 +3

Ductility 6 +3

Ductility 8 +1

NCSU

Plastic Hinge Method

y

L

c

L

sp

p

L

p

NCSU

Modified Plastic Hinge Method

y

L

c

L

sp

p

L

p

Elastic Flexure + Plastic Flexure + Strain Penetration + Shear

NCSU

0

1

2

3

4

5

6

7

8

9

10

0 20 40 60 80 100 120 140

D

i

s

p

l

a

c

e

m

e

n

t

(

i

n

)

Data Point Number

Original Plastic Hinge Method

Physical Test

Curvature Ductility Dependent Method

Comparison with Plastic Hinge Method

Input of

base

from Test Results

NCSU

L

M

M

M

M

1

M

2

M

1

M

2

(a) Multi-column Pier (b) Single Column, Single Bearing

(c) Single Column, Multiple Bearing (d) Single Column, Monolithic.

F F

F F

W

SS

fully fixed

at design

displace.

pinned

top moment

depends on

SS flexibility

top moment

indeterminate (2

modes)

Degree of Fixity at Pier Top

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- M. J. N. Priestley, F. Seible, G. M. Calvi-Seismic Design and Retrofit of Bridges-Wiley-Interscience (1996)Document705 pagesM. J. N. Priestley, F. Seible, G. M. Calvi-Seismic Design and Retrofit of Bridges-Wiley-Interscience (1996)Suman Kumar Yadav100% (12)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- OneSteel Composite Structures Design Booklet Db3.1Document62 pagesOneSteel Composite Structures Design Booklet Db3.1Brian Nasr100% (2)

- Biomass-A Massive Opportunity in Disguise: Biomass To Bio-Crude To Biofuel: Integrated Bio-Refineries in IndiaDocument14 pagesBiomass-A Massive Opportunity in Disguise: Biomass To Bio-Crude To Biofuel: Integrated Bio-Refineries in IndiarishikeshmandawadNo ratings yet

- Mil-Prf-85285e T2 PDFDocument3 pagesMil-Prf-85285e T2 PDFLuis Barrios ArandaNo ratings yet

- l3 MaterialsDocument32 pagesl3 MaterialsZaouiNo ratings yet

- Flatdeck Design ExamplesDocument8 pagesFlatdeck Design ExamplesMuntasir BillahNo ratings yet

- Fiber Beam-Columns Models With Flexure-Shear Interaction For Nonlinear Analysis of Reinforced Concrete StructuresDocument146 pagesFiber Beam-Columns Models With Flexure-Shear Interaction For Nonlinear Analysis of Reinforced Concrete StructuresMuntasir BillahNo ratings yet

- Loading Summary For A Slab On Girder Bridge According To The CAN/CSA-S6Document27 pagesLoading Summary For A Slab On Girder Bridge According To The CAN/CSA-S6Muntasir Billah100% (1)

- Effect of Bilateral Excitation On The Seismic Performance of Reinforced Concrete Bridge ColumnsDocument1 pageEffect of Bilateral Excitation On The Seismic Performance of Reinforced Concrete Bridge ColumnsMuntasir BillahNo ratings yet

- Pour Zey NaliDocument15 pagesPour Zey NaliMuntasir BillahNo ratings yet

- Basic Concepts of Fluid TransportDocument14 pagesBasic Concepts of Fluid TransportBernard BaluyotNo ratings yet

- Catalogue FX03 enDocument2 pagesCatalogue FX03 enonur_guzel6403100% (1)

- 01 Lubica Hallmann 2018 - Effect of Microstructure On The Mechanical Properties of Lithium DisilicateDocument16 pages01 Lubica Hallmann 2018 - Effect of Microstructure On The Mechanical Properties of Lithium DisilicatePatsawat YodhongNo ratings yet

- Addendum: Test Report 2006-2721: ResultsDocument2 pagesAddendum: Test Report 2006-2721: ResultsTimesLIVENo ratings yet

- Mro Products and Oem Adhesives Catalog 2021Document44 pagesMro Products and Oem Adhesives Catalog 2021piyush1124No ratings yet

- Ies/Ese Syllabus: Gate+Ies+Psu - Topper Notes: Click HereDocument5 pagesIes/Ese Syllabus: Gate+Ies+Psu - Topper Notes: Click Herepallavi guptaNo ratings yet

- Conbextra GP1 PDFDocument4 pagesConbextra GP1 PDFabhay_joshi2002No ratings yet

- FSM 120l Sustainability Inservice PresentationDocument3 pagesFSM 120l Sustainability Inservice Presentationapi-347153077No ratings yet

- Catalogo Brossard ParafusosDocument0 pagesCatalogo Brossard ParafusosMarco ViniciusNo ratings yet

- MCP 02 - 002 - 03Document24 pagesMCP 02 - 002 - 03Riski Dea100% (1)

- Stability & Determinacy of Trusses PDFDocument5 pagesStability & Determinacy of Trusses PDFuwj123No ratings yet

- Gas Sweetening TotalDocument62 pagesGas Sweetening TotalMehdi AlizadNo ratings yet

- Sop (RTP)Document9 pagesSop (RTP)WahyuPurboSuasanaNo ratings yet

- Product Data Sheet: Miniature Circuit Breaker - iC60N - 1 Pole + N - 4 A - C CurveDocument2 pagesProduct Data Sheet: Miniature Circuit Breaker - iC60N - 1 Pole + N - 4 A - C CurveNicolae ChirilaNo ratings yet

- Secondary Treatment of Wastewater - 15 PDFDocument171 pagesSecondary Treatment of Wastewater - 15 PDFIshan PalNo ratings yet

- MTO Philosophy & GuidelinesDocument18 pagesMTO Philosophy & GuidelinesManish SharmaNo ratings yet

- Sta-Rite Series DS2 Pump ManualDocument12 pagesSta-Rite Series DS2 Pump ManualbarnstoreNo ratings yet

- JSPL FLS Internal-IR-02 Mechanism SteelDocument4 pagesJSPL FLS Internal-IR-02 Mechanism SteelMohammad AdilNo ratings yet

- Dishwasher Installation InstructionsDocument52 pagesDishwasher Installation InstructionsFrancis Violet RaymondNo ratings yet

- Experiment 2Document5 pagesExperiment 2Vivek Surana40% (5)

- Effect of Soda Ash, Urea, Time and Temperature On Colour Strength of Cotton Reactive Dyes On SubstrateDocument10 pagesEffect of Soda Ash, Urea, Time and Temperature On Colour Strength of Cotton Reactive Dyes On Substrate3120262820301No ratings yet

- Rugged, Long Gauge Length Extensometers: 3542L For Long Gauge Lengths With Smaller Measuring RangesDocument2 pagesRugged, Long Gauge Length Extensometers: 3542L For Long Gauge Lengths With Smaller Measuring RangesWeb ConfigNo ratings yet

- Dissimilar Metal Welding CrackingDocument10 pagesDissimilar Metal Welding CrackingMohd SyafiqNo ratings yet

- Byk-014 TDS (En)Document2 pagesByk-014 TDS (En)nailur rohmanNo ratings yet

- Dcpe Exmo 2023-07-17Document32 pagesDcpe Exmo 2023-07-17Xy karNo ratings yet

- Kyocera Fs 6525mfp 6530mfp Parts ListDocument44 pagesKyocera Fs 6525mfp 6530mfp Parts Listmmcchuck_284436071No ratings yet

- Arteche DS Vru-36 enDocument2 pagesArteche DS Vru-36 enFacturas SempsaNo ratings yet