Professional Documents

Culture Documents

Fuel Transport Tank Truck

Fuel Transport Tank Truck

Uploaded by

suhailpmOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel Transport Tank Truck

Fuel Transport Tank Truck

Uploaded by

suhailpmCopyright:

Available Formats

Environmental Standard Operating Procedure

Originating Office:

MCAS Miramar

Environmental

Management

Department

Revision: Original Prepared By:

Environmental

Management

Department

Approved By:

William Moog

File Name: FTU-ESOP Effective Date: 22 May 2007 Document Owner: EMD

Title: Fuel Transport - Tank Truck

1.0 PURPOSE

The purpose of this Standard Operating Procedure (SOP) is to provide environmental guidelines for

performing fuel transports from vehicle fuel tankers into fuel storage tanks and dispensing facilities

such as aboveground storage tank(s) (ASTs) and/or underground storage tank(s) (USTs).

2.0 APPLICATION

This guidance applies to those individuals who work with or manage the transport of fuel from vehicle fuel

tankers into fuel storage and dispensing facilities such as ASTs and USTs onboard Marine Corps Air Station

(MCAS) Miramar.

3.0 REFERENCES

40 CFR 112.7(E) (Code of Federal Regulations)

CCR Title 23 Chapter 16

Underground Storage Tank Management Plan (USTMP)

Air Quality Management Plan (AQMP)

Spill Prevention Control & Countermeasure (SPCC)

Storm water Discharge Management Plan (SWDMP)

4.0 PROCEDURE

4.1 Discussion:

Spills and leaks associated with improper fuel transports from vehicle fuel tankers can be potentially detrimental

to human health and the environment and cause adverse regulatory action. Although the operator is responsible

for the actual operation of the vehicle fuel tanker itself, it the responsibility of the fuel dispensing facility

operator/manager to ensure that the fuel transport is performed according to standard operating procedures.

4.2 Operational Controls:

Each Unit/Section at the MCAS Miramar with ASTs and/or USTs will monitor the actual transport of fuel from the

fuel tanker truck into the storage container and provide guidance as it pertains to site specifics before, during,

and after filling operations.

The following procedures apply:

1. Ensure that MSDSs (Material Safety Data Sheets) are current and available for each product the fuel

tank truck may be carrying and where storage or transports are performed.

2. Ensure PPE (personal protective equipment) is available for spill clean-up.

3. Post No Smoking signs around ASTs and USTs.

4. Ensure that spill kits and fire extinguishers are available in case of an emergency.

5. Follow all Permit to Operate (PTOs) conditions for all Aboveground Storage Tank(s) as applicable.

6. Follow all Permit to Operate (PTOs) conditions for all Underground Storage Tank(s) as applicable.

7. Maintain turnover folder information for this Standard Operating Procedure.

4.3 Documentation and Record Keeping:

The following records must be maintained:

1. MSDSs for product stored in ASTs and USTs.

2. Hazard Communication and ASTs and USTs Logbook training records.

3. Vehicle Fuel Tank Operators will maintain their documents.

4.4 Training:

All affected personnel must be trained in this Standard Operating Procedure and the following:

1. Hazard Communication training.

2. ASTs & USTs Logbook training.

3. Vehicle Fuel Tank Operators will perform and provide their own training per their units SOPs.

4.5 Emergency Preparedness and Response Procedures:

Call 9-1-1.

4.6 Inspection and Corrective Action:

The Environmental Compliance Coordinator (ECC) shall designate personnel to perform inspections. The ECC

shall ensure deficiencies noted during the inspections are corrected immediately. Actions taken to correct each

deficiency shall be recorded on the inspection sheet.

Fuel Transport- Tank Truck Inspection Checklist

Date: Time:

Installation: Work Center:

Inspectors Name: Signature:

Inspection Items Yes No Comments

1. Are MSDSs readily available and current?

(29 CFR 1910)

2. Are all requirements per AST PTO being followed?

3. Are all requirements per UST PTO being followed?

4. Have No Smoking signs been posted around the

AST?

5. Use only approved gasoline?

6. Have any abnormal conditions been found during

weekly inspections and their corrective actions been

recorded in the logbook?

7. Has equipment been found free of the following

defects?

a. Loose, missing, or disconnected nozzle

components, including but not limited to

boots, face seals, face cones, check valve

wires, diaphragm covers and latching devices;

b. Defective shutoff mechanisms;

c. Loose, missing, or disconnected vapor fuel

hoses and associated components including

but not limited to flow restrictors, swivels and

anti-recirculation valves;

d. Crimped, cut, severed, or otherwise damaged

vapor or fuel hoses;

e. Missing, turned off, or otherwise not

operating assist type vapor recovery systems,

or any components of such systems;

f. Improper or non-"CARB certified" equipment

or components;

g. Inoperative, severely malfunctioning or

missing vacuum producing device;

h. Inoperative, loose, missing or disconnected

pressure/vacuum relief valves, vapor check

valve or dry breaks.

8. Is a spill kit nearby?

(29 CFR 1910)

9. Is a fire extinguisher kept near potentially flammable

material?

(29CFR 1910)

10. Is PPE kept near potential health hazard areas?

(29CFR 1910)

11. Are training and inspection records maintained and

available for inspection?

(MCO P5090.2A 9104.1(k)(5)- inspection only)

ADDITIONAL COMMENTS:

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

CORRECTIVE ACTION TAKEN:

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Environmental Compliance Coordinator

Name: ___________________________

Signature: ________________________

Date: ___________________________

You might also like

- Iso 17020 - 2012 Sample Quality ManualDocument47 pagesIso 17020 - 2012 Sample Quality Manualsuhailpm77% (13)

- Business Plan For Teaching and Learning CenterDocument35 pagesBusiness Plan For Teaching and Learning CentersuhailpmNo ratings yet

- Opito Approved Standard Competence Assessor Training StandardDocument25 pagesOpito Approved Standard Competence Assessor Training StandardAfandi Mohamad Zaini100% (1)

- Kuwait Epa Act 210 - Year 2001Document306 pagesKuwait Epa Act 210 - Year 2001Francesca PorcelliNo ratings yet

- Sffeco Msds - SFD Ar-Afff 3x3% - c6Document3 pagesSffeco Msds - SFD Ar-Afff 3x3% - c6Mohammed SbeitanNo ratings yet

- Fire and Safety Management PlanDocument12 pagesFire and Safety Management PlansuhailpmNo ratings yet

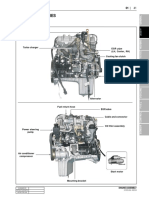

- K 737 Jul06 Engine Dxi 11 PDFDocument73 pagesK 737 Jul06 Engine Dxi 11 PDFStirb Adrian67% (3)

- Sagar Kumar Seminar Report PDFDocument20 pagesSagar Kumar Seminar Report PDFPRASHANTA BAL100% (1)

- Ocr 41847 PP 09 Jun L Gce 2812 01Document12 pagesOcr 41847 PP 09 Jun L Gce 2812 01Philip_830No ratings yet

- Ibmatsudresser: KDC 614 Series Engine Specification Manual SeriesDocument70 pagesIbmatsudresser: KDC 614 Series Engine Specification Manual SeriesCarlos Romero100% (3)

- Astm D-97Document5 pagesAstm D-97Sandrita Guardo EstepaNo ratings yet

- Abbrasive Blasting ProceduresDocument4 pagesAbbrasive Blasting Proceduresdanielpospited100% (1)

- Module One Plan and Prepare: Riiwhs205DDocument47 pagesModule One Plan and Prepare: Riiwhs205DIr ComplicatedNo ratings yet

- Voyage Log AbstractDocument3 pagesVoyage Log Abstractbarış KalkanNo ratings yet

- 704 Area Vehicle Entry ProcedureDocument11 pages704 Area Vehicle Entry ProcedureObominuru Egwonor FestusNo ratings yet

- PSB-221 Worker Hit by A Reversing VehicleDocument1 pagePSB-221 Worker Hit by A Reversing Vehiclejayand_netNo ratings yet

- MinEx Traffic Management WebDocument24 pagesMinEx Traffic Management WebSuriya Prakash.mNo ratings yet

- Procedure For JHADocument9 pagesProcedure For JHAkenoly123No ratings yet

- Health and Safety Policy OrientationDocument3 pagesHealth and Safety Policy OrientationKarn SandhuNo ratings yet

- Safety and Accident Loss Statistics: Prof. Shishir SinhaDocument43 pagesSafety and Accident Loss Statistics: Prof. Shishir SinhaganeshNo ratings yet

- Chlorine Hazard AwarenessDocument83 pagesChlorine Hazard AwarenessNesgedioNo ratings yet

- Guide To Safe Handling of Compressed Gases Publ 03Document25 pagesGuide To Safe Handling of Compressed Gases Publ 03devneekiNo ratings yet

- Guidelines On Personal Protective Equipment (PPE) : Ppe To Be Used Page No 4-11Document51 pagesGuidelines On Personal Protective Equipment (PPE) : Ppe To Be Used Page No 4-11upt vadodaraNo ratings yet

- Control of Hazardous EnergyDocument67 pagesControl of Hazardous Energymalik jahan100% (1)

- FAS08-080 Powered Industrial Vehicle and Pedestrian Safety Revised 20080327Document6 pagesFAS08-080 Powered Industrial Vehicle and Pedestrian Safety Revised 20080327Ann BeckNo ratings yet

- Safety Manual: Mitsubishi Electric Industrial RobotDocument36 pagesSafety Manual: Mitsubishi Electric Industrial Robotemil100% (1)

- Machine Guarding PowerPointDocument54 pagesMachine Guarding PowerPointMohammad Ashpak100% (1)

- HSE MS Bridging Ducument Between UCD and SinopecDocument12 pagesHSE MS Bridging Ducument Between UCD and SinopecbilouNo ratings yet

- FMEA BoilerDocument2 pagesFMEA BoilerKevin FloresNo ratings yet

- QHSE Improvement Plan 2018 FINAL VERSIONDocument1 pageQHSE Improvement Plan 2018 FINAL VERSIONJennifer WangNo ratings yet

- HSE Recognition & Disciplinary Guideline-SC PDFDocument5 pagesHSE Recognition & Disciplinary Guideline-SC PDFone driveNo ratings yet

- h2s Instructor 1Document96 pagesh2s Instructor 1SafetymanmarkNo ratings yet

- Finlay Training Services Ad24a98430Document1 pageFinlay Training Services Ad24a98430Christian MakandeNo ratings yet

- PPE2Document48 pagesPPE2akmeezNo ratings yet

- Guidance Material OM BVLOS Drone Operations Over Sparsely Populated Areas - v1Document10 pagesGuidance Material OM BVLOS Drone Operations Over Sparsely Populated Areas - v1prasenjitdey786No ratings yet

- Material Safety Data Sheet: Section 1: Product IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1: Product Identificationcvolkan1No ratings yet

- Confined Space Training OutlineDocument28 pagesConfined Space Training OutlineCarrigan BillNo ratings yet

- Heavy Equipment Inspection Checklists - MRBDocument5 pagesHeavy Equipment Inspection Checklists - MRBMyla AguadoNo ratings yet

- Safety Moment For CoP June 2006Document14 pagesSafety Moment For CoP June 2006Gagan SidhuNo ratings yet

- RA-0021 Eastern Perumai at Fujairah Port (Drydock Area) BLASTING & PAINTINGDocument6 pagesRA-0021 Eastern Perumai at Fujairah Port (Drydock Area) BLASTING & PAINTINGJustine Christian DimaculanganNo ratings yet

- Procedure For Vehicle and Mobile Equipment OperationDocument18 pagesProcedure For Vehicle and Mobile Equipment OperationAtiq MoghulNo ratings yet

- HydroplaningDocument11 pagesHydroplaningCharles BaldozNo ratings yet

- Forklift Daily Checklist ElectricDocument2 pagesForklift Daily Checklist Electricmikel derrickNo ratings yet

- M010-MSI-HSE-00-PLN-02007 - Rev5 Heat Stress & Summer Working Plan PDFDocument66 pagesM010-MSI-HSE-00-PLN-02007 - Rev5 Heat Stress & Summer Working Plan PDFEldhose VargheseNo ratings yet

- Bridging Document For Iso 9001 14001 Ohsas 18001Document10 pagesBridging Document For Iso 9001 14001 Ohsas 18001Hadi NugrohoNo ratings yet

- Standart Anzi Eyewash PDFDocument12 pagesStandart Anzi Eyewash PDFDwiki Yanuar Ramadhan100% (1)

- Fatigue Risk Management ChartDocument1 pageFatigue Risk Management ChartMurali DharNo ratings yet

- 3.IM 09 B Executive Inspection Tour FormDocument7 pages3.IM 09 B Executive Inspection Tour FormchepurthiNo ratings yet

- Machine GuardingDocument54 pagesMachine GuardingAbderrahmane LarbiNo ratings yet

- Risk AssesmentDocument2 pagesRisk Assesmentsabu1995No ratings yet

- Msds of Argon GasDocument6 pagesMsds of Argon GasQilah KamarudinNo ratings yet

- HSE Training 1Document28 pagesHSE Training 1michaelkazindaNo ratings yet

- PRO-HSE 001 HSE Objective and Management System Rev.0ADocument6 pagesPRO-HSE 001 HSE Objective and Management System Rev.0ADesfrial DialNo ratings yet

- 03-06-Pro Hse 013 SH-FCP r01 Lifting SignedDocument31 pages03-06-Pro Hse 013 SH-FCP r01 Lifting SignedLokmane YellouNo ratings yet

- Cutting & Welding Job JSADocument1 pageCutting & Welding Job JSADeepak PatelNo ratings yet

- 1.10 Short Service Employee PolicyDocument7 pages1.10 Short Service Employee PolicyMashur Al JunaibiNo ratings yet

- Workplan:: Heavy Equipment Hazards and ControlsDocument3 pagesWorkplan:: Heavy Equipment Hazards and ControlsRenauld WilsonNo ratings yet

- BP Driving Safety ProcedureDocument11 pagesBP Driving Safety ProcedureKama EfendiyevaNo ratings yet

- Npe Project Ikpt Hsse Programs 2018: NO. Programmed & CoursesDocument1 pageNpe Project Ikpt Hsse Programs 2018: NO. Programmed & CoursesilhamNo ratings yet

- Welding, Cutting and BrazingDocument66 pagesWelding, Cutting and BrazingSohail AnjumNo ratings yet

- 002 - Hydro TestDocument8 pages002 - Hydro TestMohammed AdnanNo ratings yet

- Incident Reporting Recording and InvestigationDocument13 pagesIncident Reporting Recording and InvestigationSamuelFarfanNo ratings yet

- MSU Standard Operating Procedures Vehicle and Equipment Fueling Introduction and PurposeDocument2 pagesMSU Standard Operating Procedures Vehicle and Equipment Fueling Introduction and Purposesarge18100% (1)

- Barricade ProcedureDocument4 pagesBarricade ProcedureSravan PulsarboyNo ratings yet

- Fuel Transfer Tank TruckDocument5 pagesFuel Transfer Tank TruckSangeeth.KpNo ratings yet

- Jet Engine Test CellDocument8 pagesJet Engine Test Cellkordamirimohammad4No ratings yet

- Checklist For Planned Maintenance Focused Inspection CampaignDocument4 pagesChecklist For Planned Maintenance Focused Inspection Campaignnaing kyawNo ratings yet

- ESOP 11 Fuel Storage AST Ver2 100212Document21 pagesESOP 11 Fuel Storage AST Ver2 100212Cepi Sindang KamulanNo ratings yet

- BS 1290 Wire Rope Sling and Slings Legs For General Lifi E97 PDFDocument16 pagesBS 1290 Wire Rope Sling and Slings Legs For General Lifi E97 PDFNazmi O. Abu JoudahNo ratings yet

- GTGC-RID-IMS-PRC-06 Context of The Organisation PDFDocument7 pagesGTGC-RID-IMS-PRC-06 Context of The Organisation PDFsuhailpmNo ratings yet

- Direct 4Document652 pagesDirect 4suhailpmNo ratings yet

- Carl Stahl UAE CatalogDocument64 pagesCarl Stahl UAE CatalogsuhailpmNo ratings yet

- BV Inspection+GuideDocument16 pagesBV Inspection+GuidesuhailpmNo ratings yet

- Inspection International Requirements and Auditing Practices For ISO IEC 17020Document72 pagesInspection International Requirements and Auditing Practices For ISO IEC 17020bgonzalez198150% (2)

- Convince Me: That It's Worth ItDocument97 pagesConvince Me: That It's Worth ItsuhailpmNo ratings yet

- Fire & Emergency Evacuation ProceduresDocument6 pagesFire & Emergency Evacuation Proceduressuhailpm100% (1)

- Hazard IdentificationDocument4 pagesHazard IdentificationsuhailpmNo ratings yet

- Avensis Intake System PDFDocument19 pagesAvensis Intake System PDFMladen VidovićNo ratings yet

- PipesDocument4 pagesPipesCamille Joy CucioNo ratings yet

- The Fuel of The FutureDocument21 pagesThe Fuel of The FutureAkshay DeshpandeNo ratings yet

- Gas FluctuationDocument11 pagesGas FluctuationAjeay PamintuanNo ratings yet

- Complete List of Licensable ChemicalsDocument14 pagesComplete List of Licensable ChemicalsLukmannNo ratings yet

- 2012 Annual Report - English 2012 PDFDocument53 pages2012 Annual Report - English 2012 PDFvadivvelkavinNo ratings yet

- ArticleDocument2 pagesArticleShaik RehmanNo ratings yet

- ACTW (Problems)Document4 pagesACTW (Problems)Julrick Cubio EgbusNo ratings yet

- Topic 4 Mechanical Pulping Pulp SuspensionDocument14 pagesTopic 4 Mechanical Pulping Pulp SuspensionnotengofffNo ratings yet

- Summer Project Report On: Performance Management System in GailDocument119 pagesSummer Project Report On: Performance Management System in GailAnkush SharmaNo ratings yet

- Gruppo-Aturia General BrochureDocument20 pagesGruppo-Aturia General Brochuremn_amin100% (1)

- Astm D 976 - 06Document4 pagesAstm D 976 - 06Julian Felipe Noguera CruzNo ratings yet

- LFHDocument8 pagesLFHSarang JoshiNo ratings yet

- Py Gas StudyDocument3 pagesPy Gas StudySumitAggarwalNo ratings yet

- Wartsila O E RT Flex58T D MIM Part 2 of 2Document302 pagesWartsila O E RT Flex58T D MIM Part 2 of 2Uhrin Imre100% (1)

- Power Plant OperationDocument199 pagesPower Plant OperationVijay Bhargav Badam86% (7)

- Hyundai H100Document8 pagesHyundai H100Adelmárcio André0% (1)

- Wagon R Suzuki Motor 12ka-Calibracion ValvulasDocument2 pagesWagon R Suzuki Motor 12ka-Calibracion Valvulascpaolinod100% (1)

- 3-15-6 Pressure Vessels Austenitic SteelDocument24 pages3-15-6 Pressure Vessels Austenitic SteelJaime CastilloNo ratings yet

- Honeywell-T8000 - ScbaDocument4 pagesHoneywell-T8000 - ScbaEngr Amjad Ali Abbasi0% (2)

- Kyron 1 Engine 002 04 003Document18 pagesKyron 1 Engine 002 04 003Anderson BombistaNo ratings yet

- Petrof Refining TechnologiesDocument9 pagesPetrof Refining TechnologiesvaraduNo ratings yet

- Offshore Piping PresentationDocument135 pagesOffshore Piping PresentationAlfredo A Lopez100% (2)

- ProStar Product GuideDocument168 pagesProStar Product Guidechiliwilly0% (1)

- FG-FGS enDocument9 pagesFG-FGS enAnonymous DPkjxLvYmRNo ratings yet