Professional Documents

Culture Documents

Distribution in Low-Voltage Installations: Chapter E

Distribution in Low-Voltage Installations: Chapter E

Uploaded by

Midhun VargheseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Distribution in Low-Voltage Installations: Chapter E

Distribution in Low-Voltage Installations: Chapter E

Uploaded by

Midhun VargheseCopyright:

Available Formats

Schneider Electric - Electrical installation guide 2005

E1

Chapter E

Distribution in low-voltage

installations

Contents

LV distribution schemes E2

1.1 Principles E2

1.2 Availability of electrical power E9

1.3 Quality of electrical power E10

1.4 Safety or emergency-services installations and standby E13

power supplies

Earthing schemes E17

2.1 Earthing connections E17

2.2 Definition of standardised earthing schemes E18

2.3 Characteristics of TT, TN and IT systems E21

2.4 Selection criteria for the TT, TN and IT systems E23

2.5 Choice of earthing method - implementation E25

2.6 Installation and measurements of earth electrodes E26

The installation system E30

3.1 Distribution boards E30

3.2 Cables and busways E33

External influences (IEC 60364-5-51) E38

4.1 Definition and reference standards E38

4.2 Classification E38

4.3 List of external influences E38

4.4 Protection provided for enclosed equipment: codes IP and IK E41

1

2

3

4

Schneider Electric - Electrical installation guide 2005

E2

E - Distribution in low-voltage installations

1 LV distribution schemes

1.1 Principles

Main LV distribution schemes

In a typical LV installation, distribution circuits originate at a main low-voltage

switchboard (MLVS) from which conductors supply loads via sub-distribution and/or

final distribution boards.

LV distribution levels

For medium to large sites, three distribution levels are generally used to supply

LV power to all loads:

c Distribution from the main low-voltage switchboard (MLVS)

At this level, power from one or more MV/LV transformers connected to the

MV network of the electrical utility is distributed to:

v Different areas of the site: shops in a factory, homogeneous production areas in

industrial premises, floors in office buildings, etc.

v Centralised high-power loads such as air compressors and water cooling units in

industrial processes or air conditioners and lifts in office buildings

c Sub-distribution used to distribute electricity within each area

c Final distribution, used to supply the various loads

Basic topologies (see Fig. E1 )

All distribution schemes are combinations of two basic topologies:

c Star topology: Radial (or centralised) distribution

c Bus topology: Distribution using busways (also referred to as busbar trunking systems)

Fig. E1 : The two basic topologies distribution schemes

Star Bus

Selecting a distribution scheme

The LV distribution scheme is selected according to a number of criteria including:

v Energy availability requirements

v Size of the site (area and total power to be distributed)

v Load layout (equipment and power density)

v Installation flexibility requirements

c Energy availability requirements

The creation of independent circuits to different parts of an installation makes it

possible to:

v Limit the consequences of a fault to the circuit concerned

v Simplify fault locating

v Carry out maintenance work or circuit extensions without interrupting the supply of

power to the whole installation.

In general, the following circuit groups are required:

v Lighting circuits (the circuits on which the majority of insulation faults occur)

v Socket-outlet circuits

v Heating, ventilation and air-conditioning circuits

v Power circuits for motor-driven fixed plant

v Power-supply circuits for auxiliary services (indication and control)

v Circuits for safety systems (emergency lighting, fire-protection systems and

uninterruptible power supplies (UPS) circuits for computer systems, etc.), the

installation of which is normally subject to strict regulations and codes of practice.

c Size of the site

v Small sites are supplied directly by the utilitys LV network and the size and power

requirements of the electrical installation do not justify a 3-level distribution system

(see Fig. E2 opposite page). Electrical distribution in small premises (stores, homes,

small offices, etc.) most often involves only one or two levels.

k

c

a

B

Schneider Electric - Electrical installation guide 2005

E3

E - Distribution in low-voltage installations

1 LV distribution schemes

M M M

Final distribution

Supply to loads

Repartition within

the different areas

(floor, factory shop,

etc.)

M M M M

Final distribution

Supply to loads

Repartition within

the different areas

(floor, factory shop,

etc.)

Electrical distribution

to the different areas

of the building

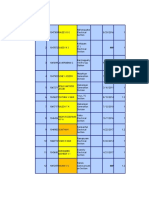

Fig. E2 : Small sites

v Medium-sized sites (e.g. factory, office building) are generally connected to the

utilitys MV network (see Fig. E3 ). One or more transformers and their MLVSs supply

the entire site.

v Large industrial or infrastructure sites (e.g. airports) are generally connected to the

utilitys HV network. An MV distribution system supplies MV/LV substations located

at different points on the site as illustrated in Figure E4 next page.

Fig. E3 : Medium-sized sites

k

c

a

B

k

c

a

B

Schneider Electric - Electrical installation guide 2005

E4

E - Distribution in low-voltage installations

M M M M

Final distribution

Supply to loads

Repartition within

the different areas

(floor, factory shop,

etc.)

Electrical distribution

to the different areas

of the building

c Load layout on the site

Two types of loads, depending on their layout on the site, must be taken into

account:

v Concentrated loads, generally corresponding to building utilities used for the entire

site and requiring high power (e.g. centralised air conditioning units, lifts,

refrigeration units in supermarkets, air compressors in industrial applications)

v Distributed loads that can be dealt with in groups corresponding to a homogeneous

area (floor, factory shop, production line) and characterised by two parameters: power

density (in VA/m

2

) and equipment density (in number of devices per 10 or 100 m

2

)

(see Fig. E5 ).

Fig. E4 : Large industrial or infrastructure sites

Low power density High power density

< 100 VA/m

2

> 100 VA/ m

2

Low equipment density c Machine centres

c Roof-top air conditioners

in factories or supermarkets

High equipment density c Lighting c Machine shops, presses

c Office computing:

PC, ink-jet printers

c Manual work stations, e.g.

in the clothing industry

Fig. E5 : Example of concentrated and distributed loads

c Installation flexibility requirements

Installation flexibility is an increasingly important requirement, in particular for

commercial and industrial premises. This need concerns mainly distributed loads

and is present at every distribution level:

v Main low-voltage switchboard level: Flexibility in design, allowing electrical power

to be distributed to the different areas of the site without detailed knowledge of the

needs at sub-distribtuion level.

Typical example: Risers in office buildings are used to distributed electricity to all the

floors. They are sized according to the average power requirements of the entire

site, making it possible to subsequently meet the very non-uniform power

requirements of each floor even though they are not known precisely during the

design phase.

v Sub-distribution level: Flexibility for installation and operation

v Final distribution level: Flexibility for utilisation

1 LV distribution schemes

k

c

a

B

k

c

a

B

Schneider Electric - Electrical installation guide 2005

E5

E - Distribution in low-voltage installations

1 LV distribution schemes

c Location of the substation and the main LV switchboard

The starting point for the design of an electrical installation, and the physical location

of sub-distribution and final distribution boards, is a drawing of the building(s) concerned

with the location of the loads together with their power requirements. The MV/LV

substation, replacement sources and the main LV distribution board, should, for both

technical and economic reasons, be placed as near to the electrical centre of the load

area as possible. On a large industrial site, a number of MV/LV substations and MLVSs

can be located in the same manner, i.e. based on the electrical centre of the load area.

However, many other factors must be considered, and in particular, the agreement

of the utility concerning the location of the MV/LV substation, and its related civil

engineering works.

Busways, also referred to as busbar trunking systems, can be used to ensure a high

degree of flexibility for future extension or modifications in the electrical distribution

system. To make sure that the enhanced flexibility for future modifications is not

detrimental to ease of operation, it may be necessary to install protective devices as

close to the loads as possible.

Examples of distribution schemes

c Radial branched distribution

This scheme of distribution is the most widely used and generally follows

arrangements similar to those illustrated below.

v Advantages

- One circuit only is de-energised (by fuses or MCCBs) in the event of a fault

- Faults are easily located

- Maintenance or extensions to the circuit can be carried out with the rest of the

installation in service. Conductor sizes can be tapered to suit the decreasing current

levels towards the final sub-circuits

v Disadvantages

- A fault occurring on one of the conductors from the main LV switchboard will cut off

supply to all circuits of related downstream sub-distribution and final distribution boards.

v Conventional wiring (see Fig. E6 )

Conventional wiring is suitable for buildings intended for specific use, where the

electrical distribution system is relatively stable, such as homes, hotels, agricultural

activities, schools, etc.

Specific advantages: Virtually unrestricted passage for ducts, cable trays, conduits,

trunking, etc.

Fig. E6 : Radial branched distribution by conventional wiring at 3 levels

MLVS

(main LV switchboard)

Sub-distribution board

(workshop A)

Process

M M

Power

final distribution

board

Lighting & heating

final distribution

board

k

c

a

B

Schneider Electric - Electrical installation guide 2005

E6

E - Distribution in low-voltage installations

Fig. E7 : Radial branched distribution using busways at sub-distribution level

v Busways for sub-distribution (see Fig. E7 )

Busways are an excellent solution for industrial and commercial sector installations

that will be subject to future changes.

Specific advantages: Flexible and easy installation in large non-partitioned areas

Fig. E8 : Radial branched distribution using busways for final distribution to lighting and socket-outlets

MLVS

(main LV switchboard)

To lighting & heating

final distribution board

M M M

Busway

Second busway

Process

v Busways for final distribution (see Fig. E8 )

For offices, laboratories and all modular premises subject to frequent rearrangements.

Specific advantages: A flexible, attractive and easily installed solution for final distribution

in locations where partitioning may change according to consumers requirements.

MLVS

(main LV switchboard)

Sub-distribution

board (office C)

B A C

To heating final

distribution board

Lighting

busway

Socket-outlet

busway

1 LV distribution schemes

k

c

a

B

k

c

a

B

Schneider Electric - Electrical installation guide 2005

E7

E - Distribution in low-voltage installations

1 LV distribution schemes

c Simple (unbranched) radial distribution

This scheme (see Fig. E9 ) is used for the centralised control, management,

maintenance and monitoring of an installation or process dedicated to a particular

application.

v Advantages

- A fault (other than at busbar level) will interrupt one circuit only

v Disadvantages

- Surplus of copper due to the number and length of circuits

- High ratings of protective devices (proximity of source, dependent on short-circuit

current at the point considered)

Fig. E9 : Simple radial distribution

MLVS

(main LV switchboard)

M M M

Process

M

c Mixed distribution from MLVSs and high-power busways

Principle

A high-power busway connected to the MLVS can be used to supply feeders at other

locations throughout the site. These feeders supply sub-distribution boards and/or

sub-distribution busways. For high power requirements, the transformers and

MLVSs can also be located throughout the site. In this case, busways are used to

interconnect the different MLVSs.

Here are a few examples (see Fig. E10 below and Fig. E11 next page).

v Single MLVS

Fig. E10 : Example with a single MLVS

Feeders supplied

by MLVS

Feeders supplied

by busway

k

c

a

B

k

c

a

B

Schneider Electric - Electrical installation guide 2005

E8

E - Distribution in low-voltage installations

v Advantages

- Greater design flexibility, independence of main LV switchboard level design and

installation with respect to the sub-distribution level, higher energy availability for the

site

- Parallel sources ensure the availability of electrical power in the event of failure of

one of them. They also make it possible to take into account non-uniformity in the

distribution of load power requirements over the site.

Changing neutral systems

In large LV installations, two voltage levels are normally used:

c 380 V, 400 V or 415 V (or exceptionally 480 V), mainly for motors (process

applications)

c 220 V, 230 V or 240 V (or exceptionally 277 V) for lighting and socket-outlet circuits

When the neutral is not distributed, LV/LV transformers will be installed wherever a

neutral is required. These transformers provide galvanic isolation of the circuits,

making it possible to change the neutral system and improve the main isolation

characteristics (see Fig. E12 ).

Fig. E11 : Example with 2 substations

Feeders supplied

by MLVS

Feeders supplied

by MLVS

Feeders supplied

by busway

v MV/LV transformers and MLVSs located throughout the site

Fig. E12 : Use of a single-phase or three-phase transformer to change from an IT to a TT system

IT system

400 V / 230 V

transformer

TT system for

lighting circuits

Residual current

device

PE protective

earthing conductor

1 LV distribution schemes

k

c

a

B

k

c

a

B

You might also like

- Electrical System For High Rise BuildingDocument47 pagesElectrical System For High Rise Buildingdeskaug1100% (3)

- Basics of Medium-Voltage Wiring For PV Power Plant AC Collection SystemsDocument15 pagesBasics of Medium-Voltage Wiring For PV Power Plant AC Collection Systemsdanisweet100% (1)

- Electrical System For High Rise BuildingDocument47 pagesElectrical System For High Rise BuildingMohammad Belal Hossain87% (30)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Garmin Connect OAuth SpecificationDocument8 pagesGarmin Connect OAuth SpecificationDANIEL MARQUEZNo ratings yet

- Tieu Chuan IECDocument410 pagesTieu Chuan IECAlexander GuzmánNo ratings yet

- Electrical System For High Rise Building PDFDocument47 pagesElectrical System For High Rise Building PDFShanaia Bual100% (2)

- Chapter 3 InstalletionDocument38 pagesChapter 3 InstalletionTesfahun LukasNo ratings yet

- HandOut CH3Document33 pagesHandOut CH3gteklay100% (6)

- Electrical InstallationDocument28 pagesElectrical Installationyonas abebeNo ratings yet

- Electrical Installation Design: Terminology and DefinitionsDocument27 pagesElectrical Installation Design: Terminology and DefinitionsMirkena kebede100% (1)

- HandOut CH3Document33 pagesHandOut CH3Ělîâȟ Gṫȓ Gûângûl67% (3)

- Instrumentation Electrical ElectronisDocument22 pagesInstrumentation Electrical Electronisyonas abebeNo ratings yet

- Chapter Three: Design of Installation SystemsDocument15 pagesChapter Three: Design of Installation SystemsNama DesalewNo ratings yet

- General Rules of Electrical Installation Design: Chapter ADocument20 pagesGeneral Rules of Electrical Installation Design: Chapter AMuhammad Mahfud Rosyidi100% (1)

- EIG A Electrical DesignDocument20 pagesEIG A Electrical DesignMahmoud FakhereddinNo ratings yet

- General Rules of Electrical Installation Design: Chapter ADocument20 pagesGeneral Rules of Electrical Installation Design: Chapter Agenial72No ratings yet

- Design and Installation of EHV - EHV and EHV - HV SubstationsDocument22 pagesDesign and Installation of EHV - EHV and EHV - HV SubstationsBalmNo ratings yet

- Electrical High Rise BuildingDocument11 pagesElectrical High Rise BuildingAstha Goyal100% (1)

- AR222S Week 1-5 BDocument83 pagesAR222S Week 1-5 BJOHANAH MICAH MARCOSNo ratings yet

- Electrical Cable GuideDocument19 pagesElectrical Cable GuideatramanathanNo ratings yet

- Ex29007-Pdf BDDocument155 pagesEx29007-Pdf BDsereptNo ratings yet

- Installation Chapter 3Document102 pagesInstallation Chapter 3tazeb100% (4)

- ELEC9713 Lecture Notes 2IN1Document268 pagesELEC9713 Lecture Notes 2IN1smart jamesNo ratings yet

- CT169 HV Industrial Networks DesignDocument24 pagesCT169 HV Industrial Networks DesignlcatelaniNo ratings yet

- Install CH 3Document66 pagesInstall CH 3Wudu YitagesuNo ratings yet

- He HeheDocument47 pagesHe HeheWinwinwin DeldeldeldelNo ratings yet

- BLDG Ser Elect BSCDocument12 pagesBLDG Ser Elect BSCDon MustyNo ratings yet

- Definitions of Design CriteriaDocument34 pagesDefinitions of Design CriteriaJeremy HensleyNo ratings yet

- Week 1 Presentation NotesDocument35 pagesWeek 1 Presentation Notesyuki03190897No ratings yet

- Distribution Inside Large Buildings: Department of Electrical Engineering - Dr. Hussain Al-MashatDocument56 pagesDistribution Inside Large Buildings: Department of Electrical Engineering - Dr. Hussain Al-MashatbarkaNo ratings yet

- Electrical Installation Design ProcedureDocument58 pagesElectrical Installation Design ProcedureAhmad KalbounahNo ratings yet

- Ssali Sub StationDocument8 pagesSsali Sub StationBUKENYA BEEE-2026No ratings yet

- Design Consideration of Electrical InstallationDocument29 pagesDesign Consideration of Electrical InstallationBhavarth Vaidya100% (4)

- Control Systems Guide For Inteface Between Control Systems and ElectricalDocument4 pagesControl Systems Guide For Inteface Between Control Systems and Electricalaugur886No ratings yet

- Electrical Design CriteriaDocument26 pagesElectrical Design Criteriafarooq929No ratings yet

- Highly Efficient Single-Phase Transformerless Inverters For Grid-Connected Photovoltaic SystemsDocument11 pagesHighly Efficient Single-Phase Transformerless Inverters For Grid-Connected Photovoltaic SystemsKarim EfthuNo ratings yet

- Elsevier - A Technical Evaluation Framework For The Connection of DG To The Distribution NetworkDocument11 pagesElsevier - A Technical Evaluation Framework For The Connection of DG To The Distribution Networkstarmd3No ratings yet

- Earthing SchematicDocument36 pagesEarthing SchematicjavadNo ratings yet

- Lecture 02 - Introduction ContinueDocument7 pagesLecture 02 - Introduction Continuesethdesilva.clNo ratings yet

- Electrical WiringDocument11 pagesElectrical WiringRasydan AliNo ratings yet

- Substation ReportDocument39 pagesSubstation ReportPraveen Kumar Choudhary100% (2)

- IPD and Illu - 10Document10 pagesIPD and Illu - 10Milan AcharyaNo ratings yet

- Design, Installation and Maintenance of The Electrical Systems of A BuildingDocument18 pagesDesign, Installation and Maintenance of The Electrical Systems of A Buildingbuddhika MadusankaNo ratings yet

- Day 11 To 13Document8 pagesDay 11 To 13mahmoud fawzyNo ratings yet

- Diary Report SirDocument14 pagesDiary Report SirNeeraj PurohitNo ratings yet

- أساسيات المحطات الكهربائية الحديثة - الجزء 1Document21 pagesأساسيات المحطات الكهربائية الحديثة - الجزء 1abdulkawi alasharyNo ratings yet

- Mid EXAMD DepBSC - Elect Tech - CourseEPDUName Mhammad Suliman Reg SU-18-01-146-029Document6 pagesMid EXAMD DepBSC - Elect Tech - CourseEPDUName Mhammad Suliman Reg SU-18-01-146-029sardar aliNo ratings yet

- Ep 2Document9 pagesEp 2MuhdAliBhuttaNo ratings yet

- Schneider EMC-EMI GuideDocument26 pagesSchneider EMC-EMI Guideeurasoglu100% (1)

- Generalities On Electricity GridsDocument10 pagesGeneralities On Electricity Grids4gen_5No ratings yet

- Fundamental Concepts in Substation DesignDocument26 pagesFundamental Concepts in Substation DesignLivia Alburguetti100% (1)

- Multiple Earthed NeutralDocument6 pagesMultiple Earthed Neutralrajpre1213No ratings yet

- MEN System of EarthningDocument6 pagesMEN System of EarthningstarykltNo ratings yet

- High VoltageDocument56 pagesHigh VoltageMarcos Casanova LopezNo ratings yet

- Chapter2 3Document23 pagesChapter2 3alemaklil21No ratings yet

- High Rise Building SlidesDocument21 pagesHigh Rise Building SlidesLatif Ismail ShaikhNo ratings yet

- Distribution of Electrical Power: Lecture Notes of Distribution of Electrical Power CourseFrom EverandDistribution of Electrical Power: Lecture Notes of Distribution of Electrical Power CourseNo ratings yet

- Control SystemDocument31 pagesControl SystemMidhun VargheseNo ratings yet

- Frequency Response Analysis (FRA) in Power Transformers: An Approach To Locate Inter-Disk SC FaultDocument2 pagesFrequency Response Analysis (FRA) in Power Transformers: An Approach To Locate Inter-Disk SC FaultMidhun VargheseNo ratings yet

- Chavara Public School: Hannah Mary Thomas Sanil Thomas 9400883232 3468015320181330Document1 pageChavara Public School: Hannah Mary Thomas Sanil Thomas 9400883232 3468015320181330Midhun VargheseNo ratings yet

- Measurments CR ExtDocument122 pagesMeasurments CR ExtMidhun VargheseNo ratings yet

- SL No Feeder Name Current Transformer Manufacture Year Serial Number Tand DeltaDocument10 pagesSL No Feeder Name Current Transformer Manufacture Year Serial Number Tand DeltaMidhun VargheseNo ratings yet

- Motor Insurance Proposal Form - Two Wheeler: Details of VehicleDocument2 pagesMotor Insurance Proposal Form - Two Wheeler: Details of VehicleMidhun VargheseNo ratings yet

- Kerala State Electricity Board Limited: Regional Power Training InstituteDocument18 pagesKerala State Electricity Board Limited: Regional Power Training InstituteMidhun VargheseNo ratings yet

- TransferDocument152 pagesTransferMidhun VargheseNo ratings yet

- Presentation For Statutory Training Transmission On: Deputy Chief EngineerDocument1 pagePresentation For Statutory Training Transmission On: Deputy Chief EngineerMidhun VargheseNo ratings yet

- TC Section Transgrid KozhikodeDocument1 pageTC Section Transgrid KozhikodeMidhun VargheseNo ratings yet

- InstructionDocument2 pagesInstructionMidhun VargheseNo ratings yet

- 5.acceptable Norms-Power Equipment Test Results-CBIPDocument18 pages5.acceptable Norms-Power Equipment Test Results-CBIPMidhun VargheseNo ratings yet

- 1st Lecture Notes - Wire & Wireless CommunicationDocument22 pages1st Lecture Notes - Wire & Wireless CommunicationJordan-James OlivoNo ratings yet

- Man FXM FKM MotorsDocument166 pagesMan FXM FKM MotorsPaun AlNo ratings yet

- Reaction PaperDocument12 pagesReaction PaperKeister EstradaNo ratings yet

- A Fast Malware Detection Algorithm Based On Objective-Oriented Association MiningDocument24 pagesA Fast Malware Detection Algorithm Based On Objective-Oriented Association MiningLove SharmaNo ratings yet

- Electric PC LS160 LS170 6 EUDocument62 pagesElectric PC LS160 LS170 6 EUsassine khouryNo ratings yet

- Digital Subscriber Line Access Multiplexer: DslamDocument14 pagesDigital Subscriber Line Access Multiplexer: DslamwasiullahNo ratings yet

- ELEPRA2 Practical Guide V32021Document37 pagesELEPRA2 Practical Guide V32021Tshepo MolotoNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument12 pagesCambridge International General Certificate of Secondary Educationahmed ramadanNo ratings yet

- Solar Powered Green House SchemeDocument2 pagesSolar Powered Green House Schemezainab444No ratings yet

- SKY03 Manual-V1.0Document10 pagesSKY03 Manual-V1.0Kittinan Mak-lonNo ratings yet

- CCNA Final Exam 4.0Document16 pagesCCNA Final Exam 4.0rasheeccnaNo ratings yet

- Maintenance & RepairDocument26 pagesMaintenance & RepairGrid Lock100% (1)

- Launchpad OverviewDocument29 pagesLaunchpad OverviewRonaldReyesNo ratings yet

- SAAB IRST, The System and Flight TrialsDocument15 pagesSAAB IRST, The System and Flight TrialsDhimas AfihandarinNo ratings yet

- Software Testing 1 CSE 3411 SWE 5411: Assignment #1 Replicate and Edit BugsDocument9 pagesSoftware Testing 1 CSE 3411 SWE 5411: Assignment #1 Replicate and Edit BugsPrakash KancharlaNo ratings yet

- Outline PhotographyDocument3 pagesOutline PhotographySara MartínNo ratings yet

- Atlas Copco ToolsDocument4 pagesAtlas Copco ToolsnotengofffNo ratings yet

- Constraint Random Verification With Python and CocotbDocument33 pagesConstraint Random Verification With Python and Cocotbspikie2800No ratings yet

- Research On Web BrowsersDocument60 pagesResearch On Web BrowserstravpreneurNo ratings yet

- Software Requirements Specification: Project Title: Self Adaptive Event Generation in MobilesDocument11 pagesSoftware Requirements Specification: Project Title: Self Adaptive Event Generation in Mobilesusmangani87No ratings yet

- Guitar Amplifier: Owner's Manual Manuel D'utilisation Bedienungsanleitung Manual de UsuarioDocument18 pagesGuitar Amplifier: Owner's Manual Manuel D'utilisation Bedienungsanleitung Manual de UsuarioGDNo ratings yet

- Multi Carrier Interworking Strategy For Hanoimacroandibc7thjuneDocument18 pagesMulti Carrier Interworking Strategy For Hanoimacroandibc7thjuneMohammad Khurram RazaNo ratings yet

- Grader - JOHN DEERE JD570 Depliant 01Document2 pagesGrader - JOHN DEERE JD570 Depliant 01Maurizio De LucaNo ratings yet

- Microsoft Word - BAE BL 008-02Document28 pagesMicrosoft Word - BAE BL 008-02Riccardo De RubeisNo ratings yet

- Ccss 3Document4 pagesCcss 3sunilbabukpNo ratings yet

- Theme ParkDocument2 pagesTheme ParkEder RonaldNo ratings yet

- Assignment 6Document2 pagesAssignment 6Musonda ChitupiNo ratings yet

- Auditing in A Computer Information SystemsDocument21 pagesAuditing in A Computer Information Systemsadrian ebora100% (1)