Professional Documents

Culture Documents

Fans in Power Stations

Fans in Power Stations

Uploaded by

AkashKishoreOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fans in Power Stations

Fans in Power Stations

Uploaded by

AkashKishoreCopyright:

Available Formats

Fans in Power Stations

Power Plant Schematic

Need of Fans

Combustion Air Boiler

Flue Gases

Air needed for combustion

Flue are needed to be evacuated

Losses due to flow need to be overcome

Fan Operation

Fans cause pressure increase by:

Centrifual force created by rotation of t!e

column of air trapped between two blades

"inetic enery is supplied to t!e air t!rou!

t!e impeller

#otal pressure $ velocity !ead % static

pressure

Selection Considerations

&uantity of air to be moved per unit time

'stimated system resistance and

e(pected variations

Amount of noise permitted

Space available for fan

'conomic implications

S)S#'* +'S,S#ANC'

-!en a as is forced t!rou! a duct

system. a loss in pressure occurs/ #!is

loss in pressure is called system

resistance/

System resistance is composed of two

components:

Friction losses and

0ynamic losses/

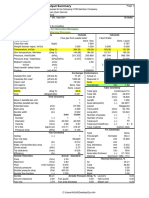

0raft Losses

#otal losses

Furnace. S1 2 +1 Losses

p

'conomi3er Losses

0ucts 2 dampers losses

Percent Boiler +atin

Fan Classification

0esinated as dynamic pumps

Centrifual

Furt!er classification by entry and e(it of fluid4as t!rou!

impeller

Aerodynamic classifications:

A(ial flow

+adial flow : referred to as 5centrifual fan5

Cross flow

*i(ed flow

Components of Centrifual Fan

Centrifual Fan Operation

Fans cause a pressure increase t!rou! two met!ods

6 Centrifual force is created by t!e rotation of t!e column of air

trapped between two blades/

6 "inetic enery is supplied to t!e air t!rou! t!e impeller

6 #otal pressure $ velocity !ead % static pressure

Blades are airfoil6type. bac7ward6curved. forwardcurved. or radial

8strai!t9

6 Airfoil6types are comple( and e(pensive but very efficient:

#!ey are used for lare systems w!ere t!e cost is ;ustified/

Applications where the fans will handle clean air or clean gas, the highly

efficient backward inclined airfoils are the preferred design. In an

application where the fan is subject to erosion due to heavy dust

loading, a straight radial type fan provides erosion resistance, but at the

expense of efficiency.

Bac7ward6Curved Fan Blades

1ave a self6limitin power c!aracteristic.

so if si3ed correctly t!e motor won<t

over!eat or burn out even if conditions

c!ane/

1i! efficiency and stable operation

ma7e t!is blade type popular/

C!oose t!e operatin point to be ;ust to

t!e ri!t of t!e pea7 pressure flow rate to

ac!ieve bot! !i! efficiency and a stable

flow rate/

#!is type of fan operates stably because

t!e pressure difference provided by t!e

fan drops if t!e flow rate oes up/ ,f t!e

opposite were true. increased an

increased flow rate would cause increase

fan power. w!ic! is unstable/

Section of a entrifugal !an

+adial Blades

Similar performance to a

bac7ward6curved e(cept t!at it<s

easier to over!eat because as flow

rate oes up. so does power/

'asier to maintain. so it<s used in

dirty situations 8easy to clean

strai!t blades. and t!ey don<t

collect as muc!9

Blades are stroner t!an ot!er

types/

=sed primarily in industrial systems

in a corrosive or erosive

environment. suc! as material

!andlin of airborne particulate or

w!ere !i! static pressure is

re>uired/

Forward6Curved Blades

1ave problems wit! instability

because a specified pressure

rise can fit t!ree different flow

rates/

Burnout can also be a

problem because fan power

increases wit! flow rate/

&uieter t!an ot!er fans: used

for most furnace blowers

=sually limited to clean

service applications

A(ial Flow Fans

Common types: propeller.

tubea(ial. vanea(ial

#ubea(ial: impeller is inside a tube

to uide airflow and improve

performance

?anea(ial: li7e a tubea(ial e(cept

vanes eit!er up or downstream of

t!e impeller are used to reduce

swirl and improve performance

=sed to deliver lare flow rates but

small increase in pressure

'(amples include fans used for

ventilation wit!out ductwor7. mobile

room fans. and fans used to cool

computers

Axial"flow fan for induced"draft service

System Pressure 'ffects

Fan curves are typically iven in terms of total pressure vs/

volumetric flow rate

A typical fan runnin at a fi(ed speed can provide a reater

volumetric flow rate for systems wit! smaller total pressure drops 8if

we<re to t!e ri!t of t!e pea7 in t!e fan curve9/

#otal pressure loss$static pressure loss%dynamic pressure loss

,f e(it and inlet area of a duct are about t!e same. t!e dynamic

pressure loss 8or ain9 may be minimal/

Fan Curves

*anufacturer will provide a fan curve for eac! fan

#!e fan curves predict t!e pressure6flow rate

performance of eac! fan/

C!oose a fan t!at ives you t!e volumetric flow rate you

need for your system pressure drop/

C!oose a fan t!at !as its pea7 efficiency at or near your

operatin point/

Sometimes will provide data in a table rat!er t!an in a

rap!/

Centrifual Fan Performance Curve/

Fan Laws

Flow ? Speed Pressure ? (Speed)

2

Power ? (Speed)

3

Q N

SP N

1

2

kW N

1

3

Varying the RPM by 10% Varying the RPM by 10% Varying the RPM by 10%

decreases or increases air decreases or increases the decreases or increases the

delivery by 10%. static pressure by 19%. power requirement by

!%.

Where Q - flow, SP - Static Pressure, kW - Power and N - speed (RP!

Fan Laws

Law @ 6 relates to effect of c!anin si3e. speed. or density on

volume flow. pressure. and power level

Law A 6 relates to effect of c!anin si3e. pressure. or density on

volume flow rate. speed. and power

Law B 6 s!ows effect of c!anin si3e. volume flow. or density on

speed. pressure. and power

#!e laws only apply to aerodynamically similar fans at t!e same

point of ratin on t!e performance curve/

!an Applications in Power Plant

Sc!eme of Air and Gas Pat!

0rau!t System Pressure ?ariation

Pressure drop calculation in air 2 as pat! and its

comparison wit! desin value/

Assessment of ,0 and F0 fan power as a function of

furnace pressure/

Assessment of effective 7inetic rate coefficient as a

function of furnace pressure/

F0 0uct AP1

Fan

0uct Furnace Bac7

pass

0uct AP1 'S

P

,0

Fan

C!imney

t 0

u

c

t 0

u

c

Pressure ?ariation

Furnace Pressure At ?arious Points in Boiler

F0 Fan ,nlet

@

ACD F0 Fan Outlet

A

ADD Air!eater ,nlet

B

@CD Air!eater Outlet

E

@DD -indbo( Pressure

C

CD F Furnace

D G Super!eater Platen ,nlet

@ A B E C F G H I @D @@ @A @B @E +e!eater ,nlet

6CD H

I L#S1 ,nlet

6@DD

@D 'conomiser ,nlet

6@CD

Air!eater ,nlet

@@

6ADD '/P/ ,nlet

@A

6ACD ,/0/ Fan ,nlet

@B

6BDD ,/0/ Fan Outlet

@E

Points in #oiler

!

u

r

n

a

c

e

P

r

e

s

s

u

r

e

Induced Draft Fans

*ove t!e combustion flue as t!rou! t!e boiler. air !eater. and

precipitator or t!e ba!ouse. scrubber. and c!imney to t!e

atmosp!ere

typically consume appro(imately AJ of t!e ross electrical output/

,0 fans !ave t!e larest desin marins of any ma;or e>uipment in a

fossil6fueled power plant/ typically @CJ on flow. BDJ on !ead. and

@CKC on temperature/

Lare marins are intended to allow for t!e followin

=ncertainty in determinin system re>uirements

Allowance for wear

Operatin fle(ibility

Allowance for pluae and lea7ae

Air infiltration

Gas to be !andled by ,0 fan

#!eoretical air for combustion

'(cess air re>uired at burner

,nfiltration

Lea7ae air6to6as t!rou! t!e air !eater

Forced Draft & PA Fans

F0 fans provide combustion air for boilers

,n pulveri3ed coal6fired boilers. appro(imately one6t!ird

of t!e combustion air is PA t!at is used to transport t!e

pulveri3ed coal to t!e burners/

#!e PA fan application is similar to t!e F0 fan:

#!e F0 fans for a coal6fired plant consume

appro(imately D/GJ of t!e ross electrical output/

#!e desin marins on F0 fans are typically smaller t!an

t!e marins on ,0 fans but still larer t!an on ot!er ma;or

e>uipment/ *arins of @CJ on flow and BDJ on !ead at

t!e ma(imum e(pected ambient temperature are

common/

Ot!er Fans in #!e System

Ignitor Air !an: Provide combustion air to t!e

initors/ #a7e suction air from t!e atmosp!ere and

supplies air to t!e initor wind bo(/

Scanner Air !an: Supplies coolin air to flame

scanners/ Normally t!ere are two fans ta7in suction

from F0 Fan disc!are duct/

$ill Seal air fan: Seal air fans provide air for t!e

sealin of *ill bearin/ Suction is from cold Primary

air and pressure is boosted up to maintain t!e

differential pressure

!an ontrols

,nlet ?anes

,nlet vanes introduce a swirl to t!e flow enterin a fan/

#!e ma;or disadvantae of inlet vanes is poor efficiency at lower loads/

,nlet vanes are sub;ect to erosion if as! concentrations are !i!

,nlet 0ampers

,nlet dampers control air flow by introducin a

swirl in t!e flow and pressure drop/

,nlet dampers !ave a low initial cost. are simple.

and are not as prone to erosion as inlet vanes/

inlet vanes and can be located completely

outside t!e duct/

#!e biest disadvantae of inlet dampers is

t!eir low efficiency at low loads/

#wo6Speed *otors

#!e fan selection wit! two6speed motors is

t!e same as wit! inlet vane control or inlet

damper control/ #!e fans for two6speed

motors are often si3ed so t!at t!e fan can

operate on low speed at full load and at

normal operatin temperature/ #!e !i!

speed provides t!e desin marin/

Fluid 0rive

Fluid drive is a met!od of varyin t!e fan speed for flow control/

#!e fan selection is essentially t!e same as t!e inlet damper

alternative. e(cept t!at a fluid drive is located between t!e motor

and t!e fan to control t!e fan speed/

,nlet dampers are typically used in addition to t!e fluid drive to

increase t!e speed of response to avoid furnace pressure

e(cursions durin transients

#!e use of t!e dampers for control durin normal operation is typical

but can be eliminated in most installations/

=sin speed control wit! t!e dampers full open can result in a

sinificant power savins

1ydraulic Couplin

Bearings

Bot! centrifual and a(ial fans can use eit!er

ball or roller bearins: !owever. ball and roller

bearins are more common on a(ial fans/

Slidin contact bearins are more common on

centrifual fans/

Ball and roller bearins consist of four ma;or

components:

Outer race

,nner race

+ollin elements

Spacer for t!e rollin elements

Sleeve #earing omponents

Lubrication Systems

Static lubrication in w!ic! eac! bearin !as a fi(ed supply of oil in

t!eir sumps is very common/

#!is met!od is simple and very cost6effective: !owever. it relies on

operator viilance to detect low oil levels or poor oil >uality/

=se of temperature sensors to provide remote warnin to t!e control

room operators. in case of a !ot bearin. offers added protection for

t!is met!od/

A ear pump attac!ed to t!e input s!aft of t!e driver is a second

met!od used to provide lube oil to fan and motor bearins/

A t!ird met!od. t!e use of fluid drives to supply oil to t!e bearins.

is also used on some fans/

A fourt! met!od involves t!e use of a dedicated circulatin lube oil

system/

#1AN"S

'SO'

P*,

+evisFluid *ec!anics

CDCAA@

ion

D@ EI EI

You might also like

- Cast Nylon PDFDocument2 pagesCast Nylon PDFrohitdakngNo ratings yet

- Manual GA 55 VSD Atlas CompresorDocument114 pagesManual GA 55 VSD Atlas Compresormondaxa_mme50% (4)

- Centrifugal Damper CatDocument8 pagesCentrifugal Damper CatAdil Shahzad100% (2)

- Material Handling Systehls For THE Fluidized-Bed Combustion Boiler Rivesville, J. Rranam Rosborough The MITRE CcrporationDocument20 pagesMaterial Handling Systehls For THE Fluidized-Bed Combustion Boiler Rivesville, J. Rranam Rosborough The MITRE CcrporationJordananandapNo ratings yet

- RCA en Fajas - 2 PDFDocument6 pagesRCA en Fajas - 2 PDFVíctor Fernández Narváez100% (1)

- Denseveyor Brochure1Document4 pagesDenseveyor Brochure1rumabiswas853100% (1)

- Vessel Conveyor SystemDocument4 pagesVessel Conveyor SystemleekiangyenNo ratings yet

- ENERGY STAR Guide Petroleum Refineries 20150330Document7 pagesENERGY STAR Guide Petroleum Refineries 20150330rameshkarthik810No ratings yet

- Freeze Protection: Heat TracingDocument4 pagesFreeze Protection: Heat TracingNaser JahangiriNo ratings yet

- Incropera - Dewitt Answers To Selected ExercisesDocument29 pagesIncropera - Dewitt Answers To Selected ExercisesMatthew Eyre100% (1)

- Comparison Between Rotary PD Pumps & Centrifugal PumpsDocument2 pagesComparison Between Rotary PD Pumps & Centrifugal Pumpsrafli septiwan100% (1)

- Dispersion Modeling BibliographyDocument1 pageDispersion Modeling BibliographyMilton BeychokNo ratings yet

- Air Preheater TypesDocument1 pageAir Preheater TypesMallinatha PNNo ratings yet

- Hot Oil SystemDocument2 pagesHot Oil SystemAbdulmalik HakimNo ratings yet

- Intro To Hydraulics PDFDocument28 pagesIntro To Hydraulics PDFsurjitvarmaNo ratings yet

- Dense & Dilute PhaseDocument2 pagesDense & Dilute PhaseBTENo ratings yet

- Emission Regulations Part - 2 PDFDocument24 pagesEmission Regulations Part - 2 PDFAkul SenapatiNo ratings yet

- Andrews' ExperimentsDocument3 pagesAndrews' ExperimentsRSLNo ratings yet

- Vibra Screw: Vibrating Feeders / Conveyors & ScreenersDocument5 pagesVibra Screw: Vibrating Feeders / Conveyors & ScreenersHoracio LancillottNo ratings yet

- En-13480 Allowable Stresses SH - Intergraph CADWorx & AnalysisDocument7 pagesEn-13480 Allowable Stresses SH - Intergraph CADWorx & AnalysisAnonymous Iev5ggSR100% (1)

- Donaldson, ToritGeneralBrochure PDFDocument16 pagesDonaldson, ToritGeneralBrochure PDFKuganesh SankaranNo ratings yet

- Hopper Design Principles - Chemical EngineeringDocument13 pagesHopper Design Principles - Chemical EngineeringElton ViannaNo ratings yet

- Crane Vs Eqvlnt Length Method For FittingsDocument177 pagesCrane Vs Eqvlnt Length Method For FittingsSamuel OnyewuenyiNo ratings yet

- Mesh BlanketsDocument13 pagesMesh Blanketsmodesty100% (1)

- Calculation of Flash Points and Flammability LimitDocument7 pagesCalculation of Flash Points and Flammability LimitMuhammad Taufiq FathaddinNo ratings yet

- Conveying Bends Article Paul SoltDocument8 pagesConveying Bends Article Paul SoltJoel Olson100% (1)

- Understanding Fan CurvesDocument4 pagesUnderstanding Fan CurvesGilberto RomanNo ratings yet

- Fluid Bed Dryer - FBDDocument4 pagesFluid Bed Dryer - FBDsagunswashNo ratings yet

- Thermodynamics An Engineering Approach 8Document1 pageThermodynamics An Engineering Approach 8Aracely PenaNo ratings yet

- Integrated Training Program / Phase B - Flare Protection Systems Page 1 of 33Document33 pagesIntegrated Training Program / Phase B - Flare Protection Systems Page 1 of 33metasoniko2014No ratings yet

- Autoclave PDFDocument8 pagesAutoclave PDFDïëgöNïïckYtzNo ratings yet

- Steam or Thermal OilDocument3 pagesSteam or Thermal OilCharith Liyanage100% (1)

- Boleo Process FlowDocument1 pageBoleo Process Flowcarlos hurtadoNo ratings yet

- Transfer Points - Dust Control at Transfer PointsDocument8 pagesTransfer Points - Dust Control at Transfer PointsPaijo TejoNo ratings yet

- DensePhase MS.1033.1017-BrochureDocument4 pagesDensePhase MS.1033.1017-BrochurednielprasetyoNo ratings yet

- Text Dense PhaseDocument4 pagesText Dense PhaseZakir Hossain BiplobNo ratings yet

- Recommended Steam Piping Velocities 2Document1 pageRecommended Steam Piping Velocities 2Hassan AbdulAzim FadilNo ratings yet

- Thermal Stratification CFDDocument15 pagesThermal Stratification CFDms280674No ratings yet

- Pneumatic Conveying Systems..Document61 pagesPneumatic Conveying Systems..efka808No ratings yet

- 015 - Zubin Kumana PSV Deficiency PDFDocument9 pages015 - Zubin Kumana PSV Deficiency PDFgharonk MukharrorNo ratings yet

- A Quick Look at Pneumatic Convey Systems Basics-NOL-TECDocument3 pagesA Quick Look at Pneumatic Convey Systems Basics-NOL-TECStacy WilsonNo ratings yet

- Insertable Dust Collectors NR.01B2 WEB PDFDocument3 pagesInsertable Dust Collectors NR.01B2 WEB PDFEdy SuprayitnoNo ratings yet

- Designing Atmospheric Crude Distillation For Bitumen Service PDFDocument6 pagesDesigning Atmospheric Crude Distillation For Bitumen Service PDFfawmer61No ratings yet

- University of Mindanao Matina, Davao City: Pneumatic Conveying CHE 439: Intro To Particle TechnologyDocument10 pagesUniversity of Mindanao Matina, Davao City: Pneumatic Conveying CHE 439: Intro To Particle TechnologyQuenneBelocura100% (1)

- Study of The Pressure Drop of Dense Phase Gas-Solid Flow Through NozzleDocument5 pagesStudy of The Pressure Drop of Dense Phase Gas-Solid Flow Through NozzleMuhammad Adnan LaghariNo ratings yet

- Calculation Economizer - PL ProjectDocument12 pagesCalculation Economizer - PL ProjectXuan Man NguyenNo ratings yet

- Liquid Ring Vacuum Pumps, Compressors and Systems: Conventional and Hermetic DesignFrom EverandLiquid Ring Vacuum Pumps, Compressors and Systems: Conventional and Hermetic DesignNo ratings yet

- Municipal Solid Waste to Energy Conversion Processes: Economic, Technical, and Renewable ComparisonsFrom EverandMunicipal Solid Waste to Energy Conversion Processes: Economic, Technical, and Renewable ComparisonsNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Plant Engineering and Design The Ultimate Step-By-Step GuideFrom EverandPlant Engineering and Design The Ultimate Step-By-Step GuideNo ratings yet

- Engineering Encyclopedia: Saudi Aramco Desktop StandardsDocument12 pagesEngineering Encyclopedia: Saudi Aramco Desktop StandardsFA Ay100% (1)

- Fans in Thermal Power PlantsDocument3 pagesFans in Thermal Power PlantsMuhammad Nadeem RazaNo ratings yet

- Understanding Lobe Blowers Roots BlowersDocument9 pagesUnderstanding Lobe Blowers Roots Blowersmishraengg100% (2)

- Overview On FansDocument54 pagesOverview On Fansniteshnerist100% (1)

- 4CHE3 Parts Catalog PDFDocument75 pages4CHE3 Parts Catalog PDFokta bedjo100% (1)

- Mercedes Benz Sprnter Code DescriptionDocument73 pagesMercedes Benz Sprnter Code Descriptionbamwine100% (2)

- Daikin Mks D 1Document80 pagesDaikin Mks D 1pRAMOD g pATOLENo ratings yet

- MT - Sales Brochure V4Document5 pagesMT - Sales Brochure V4cubarro1234No ratings yet

- Tab 5 Coolant System TroubleshootingDocument18 pagesTab 5 Coolant System TroubleshootingagvassNo ratings yet

- Koolman Air-CooldedWater Chiller With Heat Pump OptionDocument16 pagesKoolman Air-CooldedWater Chiller With Heat Pump OptionLuis PinoNo ratings yet

- Proposal PresentationDocument58 pagesProposal Presentationmannu057No ratings yet

- 7 Gas Turbine Plant: G. Boxer, Applications of Engineering Thermodynamics © G. Boxer 1979Document2 pages7 Gas Turbine Plant: G. Boxer, Applications of Engineering Thermodynamics © G. Boxer 1979WestNo ratings yet

- Irrigation Water PumpsDocument13 pagesIrrigation Water Pumpshhghgh0% (1)

- Tech .Specification of Fabrication & Errection of Structural SteelDocument45 pagesTech .Specification of Fabrication & Errection of Structural SteelarunNo ratings yet

- Crompton Greaves Self PrimingDocument1 pageCrompton Greaves Self PrimingPankaj JaiswalNo ratings yet

- RC LEGO The Bull BuggyDocument64 pagesRC LEGO The Bull BuggyCesar GonzalezNo ratings yet

- Caterpillar Gas EngineDocument4 pagesCaterpillar Gas Enginecandra100% (2)

- Framo Oil and Gas Pumping Systems: Overview of SolutionsDocument44 pagesFramo Oil and Gas Pumping Systems: Overview of SolutionsBrian Lee BantuganNo ratings yet

- Sae Technical Paper Series: Edinilson Alves Costa and Márcio Gonçalves PintoDocument8 pagesSae Technical Paper Series: Edinilson Alves Costa and Márcio Gonçalves PintosmsnvhNo ratings yet

- 2023, Vinay Thakur, Experimental Evaluation On Behaviour of Geocell Geogrid Reinforced Sand Subjected Static and Cyclic LoadingDocument14 pages2023, Vinay Thakur, Experimental Evaluation On Behaviour of Geocell Geogrid Reinforced Sand Subjected Static and Cyclic Loadingkommanamanchi.vamsiNo ratings yet

- The Messenger: Principal's MessageDocument10 pagesThe Messenger: Principal's MessagerishiNo ratings yet

- F225F 13Document81 pagesF225F 13MarianoBonetFeoNo ratings yet

- DimplesDocument20 pagesDimplesrajuNo ratings yet

- Maa Narmada Testing & Research LaboratoriesDocument3 pagesMaa Narmada Testing & Research Laboratoriesankit hardahaNo ratings yet

- Problema Ligjet e NjutonitDocument9 pagesProblema Ligjet e NjutonitMentor KushoNo ratings yet

- 86 366 1 PB PDFDocument6 pages86 366 1 PB PDFMuhammad Cendekia AirlanggaNo ratings yet

- Chapter 4-6 11-14-Mud Rheology Circuling Systems PumpsDocument117 pagesChapter 4-6 11-14-Mud Rheology Circuling Systems Pumpsbakri OmanNo ratings yet

- 797B Differential System OperationDocument4 pages797B Differential System OperationneedNo ratings yet

- Middle East, 323F BA 10 - 1996-, GASOLINE-ENGINE 4-CYLINDER SUPPLEMENT, 1370 B EMISSION CONTROL SYSTEM (INLET SIDE) (GASOLINE) (1600CC) PDFDocument4 pagesMiddle East, 323F BA 10 - 1996-, GASOLINE-ENGINE 4-CYLINDER SUPPLEMENT, 1370 B EMISSION CONTROL SYSTEM (INLET SIDE) (GASOLINE) (1600CC) PDFalejo sotoNo ratings yet

- Fired Heater Tube Fretting. - Boiler and Pressure Vessel Engineering - Eng-TipsDocument2 pagesFired Heater Tube Fretting. - Boiler and Pressure Vessel Engineering - Eng-Tips최승원No ratings yet

- 06 System of Particles and Rotational MotionDocument3 pages06 System of Particles and Rotational MotionMUHAMMED ANAS KNo ratings yet

- Plug Valves RevA 2021Document3 pagesPlug Valves RevA 2021Cap1284No ratings yet