Professional Documents

Culture Documents

Atlas Copco Exploration Product Catalogue

Atlas Copco Exploration Product Catalogue

Uploaded by

amir_hayfaCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Bico MotorsDocument132 pagesBico Motorsamir_hayfa67% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Well Trajectory DesignDocument95 pagesWell Trajectory Designamir_hayfa100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Drill Bit Classifier 2014Document34 pagesDrill Bit Classifier 2014CAIYZ6301No ratings yet

- Ca612pd - Au-20100301.103037 - Dynapac Padfoot RollerDocument1 pageCa612pd - Au-20100301.103037 - Dynapac Padfoot Rolleramir_hayfaNo ratings yet

- Halco Dominator SeriesDocument10 pagesHalco Dominator Seriesamir_hayfaNo ratings yet

- Jetting-Assemblies - SlimdrillDocument4 pagesJetting-Assemblies - Slimdrillamir_hayfaNo ratings yet

- Sou400-Handbook-30012013Document18 pagesSou400-Handbook-30012013amir_hayfaNo ratings yet

- Var-3704 - Performanceupdates-Me - Brochure-V1.0sm - ROP DATA PDFDocument12 pagesVar-3704 - Performanceupdates-Me - Brochure-V1.0sm - ROP DATA PDFamir_hayfaNo ratings yet

- Expandable Drill Bit Provides Significant Advantages: 30 September/October 2003Document4 pagesExpandable Drill Bit Provides Significant Advantages: 30 September/October 2003amir_hayfaNo ratings yet

- PDC - Vortex - Xceed - Kuwait - Cs - ROP DATA PDFDocument2 pagesPDC - Vortex - Xceed - Kuwait - Cs - ROP DATA PDFamir_hayfaNo ratings yet

- QLD Gas Pipeline Specs - Jemena PDFDocument1 pageQLD Gas Pipeline Specs - Jemena PDFamir_hayfaNo ratings yet

- Drilling Fluid Considerations in HDD - GOOD PDFDocument11 pagesDrilling Fluid Considerations in HDD - GOOD PDFamir_hayfaNo ratings yet

- Fusible PVC SpecificationsDocument17 pagesFusible PVC Specificationsamir_hayfaNo ratings yet

- Guidelines For Kinetic Input and Calibration of Petroleum System Models PDFDocument61 pagesGuidelines For Kinetic Input and Calibration of Petroleum System Models PDFc_b_umashankarNo ratings yet

- Metodologia de La InvestigacionDocument40 pagesMetodologia de La InvestigacionparpejoNo ratings yet

- Plate Tectonics and Continental DriftDocument95 pagesPlate Tectonics and Continental DriftRudic DomencoNo ratings yet

- Year 9 ScienceDocument7 pagesYear 9 ScienceAmarpreet KaurNo ratings yet

- Chalcobamba P00142 PFS Independent Peer Review June 2018 Final Report Rev 0 CompiledDocument82 pagesChalcobamba P00142 PFS Independent Peer Review June 2018 Final Report Rev 0 CompiledVíctor Rojas Pasten100% (1)

- Density of Construction MaterialsDocument4 pagesDensity of Construction Materialshncc ghazniNo ratings yet

- Top-Up T3 GI 04 - 13 - Notes Excavation - DrillingDocument9 pagesTop-Up T3 GI 04 - 13 - Notes Excavation - Drilling廿田一No ratings yet

- Mud Architecture - Construction Details and Techniques: Laurie BakerDocument16 pagesMud Architecture - Construction Details and Techniques: Laurie BakerSeban AugustineNo ratings yet

- Method Statement FOR Earthwork: ProjectDocument6 pagesMethod Statement FOR Earthwork: ProjectKelvin Lau Hin HuatNo ratings yet

- Phreatic Line AssignmentDocument7 pagesPhreatic Line AssignmentAnonymous EIjnKecu0JNo ratings yet

- Samudra-Manthan Story of Hindu Mythology in Present PerspectiveDocument49 pagesSamudra-Manthan Story of Hindu Mythology in Present PerspectiveVR Patil100% (2)

- Q Papers AimeDocument60 pagesQ Papers AimeAmandeep SinghNo ratings yet

- A Study of The Tectonic Elements of The Western Continent Margin of India - Yatheesh Vadakkehath - 2007Document243 pagesA Study of The Tectonic Elements of The Western Continent Margin of India - Yatheesh Vadakkehath - 2007Girawa Kanda100% (1)

- 6 Ispas 1 PDFDocument11 pages6 Ispas 1 PDFAdina CimpoesuNo ratings yet

- DLL in Science 10 (Week 7)Document5 pagesDLL in Science 10 (Week 7)Lhester D. AntolinNo ratings yet

- Professional Indonesian Time Sheet: Pt. Sangati Soerya Sejahtera Pt. Amman Mineral Nusa TenggaraDocument11 pagesProfessional Indonesian Time Sheet: Pt. Sangati Soerya Sejahtera Pt. Amman Mineral Nusa TenggaraIrdan Syafa'atNo ratings yet

- The BiosphereDocument15 pagesThe BiosphereSer RamirNo ratings yet

- Seismic Protection of Plumbing SystemDocument16 pagesSeismic Protection of Plumbing System185412No ratings yet

- Block Model Knowledge For Mining Engineers An Introduction 1Document33 pagesBlock Model Knowledge For Mining Engineers An Introduction 1arluis100% (3)

- Effect of Adding Scoria As Cement Replacement On Durability-Related PropertiesDocument14 pagesEffect of Adding Scoria As Cement Replacement On Durability-Related PropertiesGerardo JimenezNo ratings yet

- DEEP BLUE Edition BLAZING RED Edition: RRI - RED - RULEBOOK - ENG - HG - v02 - 20202205 - LUMA - Indd 1Document12 pagesDEEP BLUE Edition BLAZING RED Edition: RRI - RED - RULEBOOK - ENG - HG - v02 - 20202205 - LUMA - Indd 1Andy StraussNo ratings yet

- CHAPTER 1 BrittlenessDocument7 pagesCHAPTER 1 BrittlenessJin morarengNo ratings yet

- How Do The Different Soil Horizons Develop?Document2 pagesHow Do The Different Soil Horizons Develop?leilagreeyyyNo ratings yet

- Rock Mass Rating System (After Bieniawski 1989)Document6 pagesRock Mass Rating System (After Bieniawski 1989)Sumit SagarNo ratings yet

- Geology Rocks and Minerals HonorDocument65 pagesGeology Rocks and Minerals HonorGabrido Daquiado Jan LloydNo ratings yet

- Advances in Geological and Geotechnical Engineering Research - Vol.5, Iss.2 April 2023Document83 pagesAdvances in Geological and Geotechnical Engineering Research - Vol.5, Iss.2 April 2023Bilingual PublishingNo ratings yet

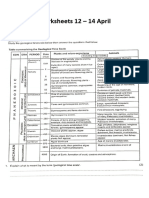

- Worksheets 12 - 14 AprilDocument8 pagesWorksheets 12 - 14 AprilmackersoapNo ratings yet

- K#02 Konsep-Konsep Dasar EkohidrologiDocument54 pagesK#02 Konsep-Konsep Dasar EkohidrologiAkhmadTsanyNo ratings yet

- Volcanoes and Plate Tectonics : What's The Connection?Document37 pagesVolcanoes and Plate Tectonics : What's The Connection?ED EduardNo ratings yet

- Sea Ice: Fast Ice Versus Drift (Or Pack) IceDocument9 pagesSea Ice: Fast Ice Versus Drift (Or Pack) IceIngbor99No ratings yet

Atlas Copco Exploration Product Catalogue

Atlas Copco Exploration Product Catalogue

Uploaded by

amir_hayfaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Atlas Copco Exploration Product Catalogue

Atlas Copco Exploration Product Catalogue

Uploaded by

amir_hayfaCopyright:

Available Formats

Atlas Copco Exploration Products

Product catalogue

In-The-Hole tools

2

In-The-Hole tools product catalogue

Atlas Copco Geotechnical Drilling and

Exploration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1. In-the-hole tools product catalogue . . . . . . 5

How to use this catalogue . . . . . . . . . . . . . 5

2. Efcient core recovery . . . . . . . . . . . . . . . . . 6

Core in the box . . . . . . . . . . . . . . . . . . . . . . 6

3. General application selection criteria. . . . . 8

Core barrels. . . . . . . . . . . . . . . . . . . . . . . . . 8

Tubular products. . . . . . . . . . . . . . . . . . . . . 9

4. General technical information. . . . . . . . . . 10

Dimensions at a glance . . . . . . . . . . . . . . 10

5. Surface double tube wireline core barrel. 11

5.1 Spare parts list BO/BTO . . . . . . . . . . . 12

5.2 Spare parts list NO/NTO. . . . . . . . . . . 16

5.3 Spare parts list HO/HTO. . . . . . . . . . . 20

5.4 Spare parts list PO/PTO . . . . . . . . . . . 24

5.5 Spare parts kits . . . . . . . . . . . . . . . . . . 28

6. Surface triple tube wireline core barrels . 29

6.1 Spare parts list NO3/NTO3. . . . . . . . . 30

6.2 Spare parts list HO3/HTO3. . . . . . . . . 34

6.3 Spare parts list PO3/PTO3 . . . . . . . . . 38

6.4 Spare parts kits . . . . . . . . . . . . . . . . . . 42

7. Surface thin wall double tube wireline

core barrels . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1 Spare parts list AOTW . . . . . . . . . . . . 44

7.2 Spare parts list BOTW . . . . . . . . . . . . 48

7.3 Spare parts list NO2/NTO2. . . . . . . . . 52

7.4 Spare parts kits . . . . . . . . . . . . . . . . . 56

8. Underground double tube wireline

core barrels . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.1 Spare parts list BO-U/BTO-U . . . . . . . 58

8.2 Spare parts list NO-U/NTO-U. . . . . . . 62

8.3 Spare parts list HO-U/HTO-U. . . . . . . 66

8.4 Spare parts kits . . . . . . . . . . . . . . . . . . 70

9. Underground thin wall double tube wireline

core barrels . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.1 Spare parts list AOTW-U . . . . . . . . . . 72

9.2 Spare parts list BOTW-U . . . . . . . . . . 76

9.3 Spare parts list NO2-U/NTO2-U. . . . . 80

9.4 Sparts kits . . . . . . . . . . . . . . . . . . . . . . 84

10. Drill rods and casing. . . . . . . . . . . . . . . . . 85

10.1 Wireline drill rods . . . . . . . . . . . . . . . 86

10.1.1 T Series Tuff rod . . . . . . . . . . 86

10.1.2 O-Series drill rod . . . . . . . . . . 87

10.1.3 TT Series Tuff rod - thin wall 88

10.1.4 OTW/GM Series rod - thin wall 89

10.2 Flush joint casing . . . . . . . . . . . . . . . 90

10.2.11 W-Series . . . . . . . . . . . . . . . . 90

11. Accessories . . . . . . . . . . . . . . . . . . . . . . . . 91

11.1 Water swivels . . . . . . . . . . . . . . . . . . 92

11.1.1 Water swivel 5000 T.C.. . . . . . 92

11.1.2 Drill rod to pin drill rod . . . . . 92

11.1.3 Water swivel 25000 T.C.. . . . . 93

11.1.4 Drill rod to pin to drill rod pin 93

11.1.5 Water swivel 18/0. . . . . . . . . . 94

11.1.6 Water swivel AWJ T.C.. . . . . . 95

11.2 Stufng box. . . . . . . . . . . . . . . . . . . . 96

11.2.1 Stufng box . . . . . . . . . . . . . . 96

11.2.2 Seal kit . . . . . . . . . . . . . . . . . . 96

11.2.3 Dimension kit . . . . . . . . . . . . . 96

11.3 Hoisting plugs . . . . . . . . . . . . . . . . . . 97

11.3.1 Hoisting plug AN . . . . . . . . . . 97

11.3.2 Drill rod to pin to drill rod pin . 97

11.3.3 Hoisting plug BNH. . . . . . . . . 98

11.3.4 Drill rod to pin to drill rod pin. . . 98

11.4 Substitutes . . . . . . . . . . . . . . . . . . . . 99

11.4.1 Drill rod box to drill rod pin. . . 99

11.4.2 Drill rod box to casing pin. . . 99

11.4.3 Other subs . . . . . . . . . . . . . . . 99

11.5 Recovery taps . . . . . . . . . . . . . . . . . 100

11.6 Handling tools. . . . . . . . . . . . . . . . . . 101

11.6.1 Rigid wrenches steel handles . 101

11.6.2 Full grip wrenches . . . . . . . . 101

12. Conversion factors . . . . . . . . . . . . . . . . . 102

3

Atlas Copco

Geotechnical Drilling and Exploration

Atlas Copco Geotechnical Drilling and Exploration, GDE, can offer the equipment needed for all

underground and surface exploration applications. This includes rigs and a full range of high tech

and high quality products, ITH equipment such as wireline, drill rods and conventional core bar-

rels as well as casing and diamond bits all designed to maximise our customers protability.

All our products are designed to help the user minimize down-time and maximize productivity.

Be assured we are ISO certied. However, if a problem should occur, we will quickly be at your

site thanks to the worldwide Atlas Copco organisation.

Just contact your local Atlas Copco representative.

4

5

1 - In-The-Hole tools product catalogue

To use this catalogue, choose tubular, core bar-

rel and accessories selections from respective sub

sections that will suit the application in question.

The Hole/Core diameter chart, see section 4.1, will

allow you to quickly reference what systems are

available in a given size and borehole orientation

to meet the objective.

Each section will start with basic technical data and

some helpful hints on proper product selection for

a given application. The last page of each section

will provide an at a glance summary of the spare

parts kits for the systems, and some of the available

options with explanations.

While the foreword contains general information

on diamond core drilling, product descriptions and

general technical data, detailed parts information

can be found in the respective application and

product sections.

For core barrels, frst determine the orientation of the

borehole. If the borehole will be drilled between

vertical down to 45 degrees from vertical down, (-90

to -45 degrees), choose one of the three surface

1.1 How to use this catalogue

style systems. For fatter or up holes, choose within

the two underground ranges of corebarrel systems.

For surface style selections, determine if the

application requires a double tube or triple tube

design. If a double tube design is preferred, then

choose if a standard wall or thin wall design is

favored. Likewise, for underground style selections,

determine if a standard wall or thin wall design is

favored.

Choosing a drill rod is based on the preferred

thread connection and the overall length that can

be handled effciently. Dont forget to consider

the limitations of the drill design and the envelope

within which the drill will be operating.

Finally, choose the accessories that you require

to complement the core barrel and drill rod

selections. Consider the threaded connections

required.

As a general rule, use these determining factors to

focus in on the correct sections to select products

for the given application.

Surface

core barrels

1. Determine direction of the core

drilling. If the borehole will be

drilled between vertical down

to 45 degrees from vertical down,

choose one of the three surface

style systems. For atter or up

holes, choose within the two

underground ranges of corebarrel

systems.

2. Determine requirements of the

application. For surface style selections,

determine if the application requires

a double tube or triple tube design. If a

double tube design is preferred choose

if a standard wall or thin wall design is

favored. Likewise, for underground

style selections, determine if a standard

wall or thin wall design is favored.

3. Determine threads, rods and accessories.

Choosing a drill rod is based on the

preferred thread connection and the

overall length that can be handled

efciently. Dont forget to consider the

limitations of the drill design and the

envelope within which the drill will be

operating. Choose the accessories that

you require to complement the core

barrel and drill rod selections.

Underground

core barrels

Double tube design Standard wall

Thin wall

For larger core

sample

Triple tube design

For better core recov-

ery in broken ground

Thin wall

For larger core

sample

Standard wall

Thread connection

Overall length to be handled

Accessories needed

6

2 - Efcient core recovery

is the core cutting tool. As the drill bit penetrates

through the material, it creates a core in its wake,

entering the core barrel until its recipient tube is

full, or the cores entry is impeded, at which time

the sample recipient tube is removed, emptied of

its core, replaced and drilling can resume.

Core sampling will consist of the borehole starting

point or collar, the target and the path in

between. Boreholes ranging from 48146 mm

diameter, and depths of 33000 m share the

following:

The diamond core drill

The fushing circuit

The drill rod string

The core barrel

The diamond tools

As a general rule; the larger the core diameter

the better the core recovery.

2.1 Core in the box

The end users of exploration core drilling products

are generally in the business of, providing

representative and quality core samples to their

customers.

Recovered core samples are used to extract vital

information where chips or other data gathering

techniques do not provide the level of confdence

required to make decisions.

The quality of recovered core samples is of greatest

importance, and is infuenced by the personnel,

capital and support equipment, diamond products,

tools and accessories used in given ground conditions.

In The Hole tools, (ITH), represents only a small

component of total project cost, but its selection

and use have great signifcance.

Understanding the end user then, his goals and in

particular his application, infuences how effcient

coring and commercial solutions are developed

and implemented.

Core drilling basics

Core can be generally defned as a volumetric

cylinder of material, created by the advancement

of a rotating hollow centered diamond drill bit

through a given in-situ formation and subsequently

removed.

Core recovery is a quantifable measurement

defned as the total linear amount of physical core

sample extracted over the total linear advancement

in a given borehole, expressed as a percentage.

Recovery is often measured against a section of

advance, typically in the target zone and/or for the

entire borehole.

Length of core

Length of advance

Mechanically speaking, the core being created is

encapsulated within and extracted by a retrievable

sampling device, called a core barrel.

It is connected to a consumable coring drill bit,

typically made with synthetic diamonds, which

CR (%) = x 100

7

2 - Efcient core recovery

Diamond drills come in many shapes and sizes.

The drill, properly anchored at the borehole collar,

primarily needs to transmit rotation, thrust and

pullback forces.

Fluid is primarily required to cool and fush the

cuttings from in front of the advancing diamond

core bit and evacuating them from the borehole.

The fushing medium can be clear water or

include needed additives, "muds", used to condition

borehole integrity and complete the circuit.

The fuid fushing circuit can vary signifcantly,

but typically consists of one or more pumps, the

fuid media itself, the drill rod string, the available

borehole annular area and the peripheral accessories

for controlling delivery, treatment and handling.

Connected to the diamond drill, a straight rod

string combined with smooth rotation and borehole

conditioning will turn vibration free in the hole

while transmitting the feed pressure to the cutting

tool.

The core barrel is most critical to effcient core

recovery.

The core barrel is sandwiched in between the drill

rods and the diamond bit. Whether conventional

or wireline, the design will typically be confgured

as a double tube system consisting of an outer

tube and inner tube. While the outer tube rotates

with the drill rod, the inner tube is meant to remain

stationary during advancement.

As a general rule; the smoother the transmission

of rotational force, the better the core recovery.

As a general rule; with deteriorating ground con-

ditions, focus on the fushing circuit to improve

core recovery.

As a general rule; proper care and handling of

rods and a vibration free rotation, are your keys

to improved core recovery.

Triple tube systems using a split inner tube are

common in broken or friable ground where the

fushing mediums pathway can wash away some

of the sample before it makes its way into the inner

tube with consequential effect on measurable re-

covery. Triple tube systems use core lifter cases and

diamond bits designed to direct the drilling fuid

through the bit blank instead of through the bit

throat preventing sample washing.

The diamond tools are the business end of the

string and the bit in particular is a metallurgical

marvel. The diamond bit ultimately cuts through

the material that makes its way into the core barrel.

Crown profle, fushing, and guage design

characteristics react differently with changes to

rotation, thrust and fushing parameters.

As a general rule; ensure that bearings and wear

parts are regularly serviced, and avoid deforma-

tions, damaging blows and mishandling to the

inner tube in order to improve core recovery.

As a general rule; choose the largest triple tube

system possible in bad ground to improve core

recovery.

As a general rule; choose bit designs that protect

ID run out and that minimize back pressure and

sample washing to improve core recovery.

8

3 - General application selection criteria

3.1 Core barrels

Applying advanced technology to todays core

drilling tools and processes is a science in itself.

And its one in which Atlas Copco engineers have

taken a leadership role. Conventional or wireline

drilling, Atlas Copco drill rods, core barrels,

accessories and casings are being constantly

upgraded to exceed the expectations of todays

diamond drilling contractors and mining companies

around the globe.

Surface core barrels

Atlas Copco offers a full range of surface application

core barrels. Available in standard double tube

designs with the option for easy conversion to

triple tube confgurations in broken ground.

Thin wall core barrels, used when ground conditions

and drill rig selection are appropriate, offer the end

user an opportunity to increase sample size within

a nominal bore hole size.

Underground core barrels

Pump in, or underground style double tube and

double tube thin wall wireline core barrels are

available for fatter and up hole applications where

gravity does not permit unassisted movement of

the inner wireline components. Designed with

Atlas Copco attention to quality and performance,

you can count on these products where you need

to push the inner tube and overshot assemblies

through the drill rod string using the circulating

fuid. In addition, underground style core barrels

include built in safety designs.

Conventional core barrels

Conventional core barrels produce a larger core

diameter compared to the equivalent wireline

nominal size. Their rugged construction and design

features ensure optimization of productivity in

applications where the use of a wireline system is

not practical or cost effective.

Conventional core barrels are typically used in

shorter boreholes.

9

3 - General application selection criteria

3.2 Tubular products

Atlas Copco drill rods and casings are of the

highest quality delivering top level performance

to your equipment and your drill site. Whether

you are using our specially designed wire line or

conventional drill rods, Atlas Copco will be sure to

give you superior productivity everytime.

Wireline drill rods

Wireline drill rods are manufactured from high

quality carbon steel seamless tubes, which contain

superior yield and ultimate strength. Drill rods come

with a variety of threads including Atlas Copco's

T thread for straight deep hole applications.

Conventional drill rods

Conventional drill rods are available in mid-weight

steel and/or aluminum providing you with

ergonomic fexibility which will improve your

handling capabilities under the most strenuous of

conditions. Rod threads for mineral exploration

applications are typically WJ type threads, and

are used with conventional style core barrels.

Accessories

In the improvement of drilling quality and work

environment, it is often small items that make the

difference. In this section, we offer products

chosen for their quality and technical superiority.

Water swivels

A water swivel connects the pressure hose from the

fush pump to the drill string. Water swivels should

be selected in accordance with the type of drill rig

being used and the circulating fuid demands of the

application. A 'bail' style water swivel should be

selected for drill rigs that use a main hoist, while

automated drill rigs can use a swivel without a bail

such as the 18/0 where static lifting capacities are

not involved.

Hoisting & lowering

Atlas Copco hoisting plugs are designed for use

with drills equiped with main hoists used for

raising or lowering the drill string.

Designed with safety in mind, and available with

a large choice of adapter subs, Atlas Copco hoisting

plugs cover your drilling requirements. A large choice

of subs makes it suitable for use with a variety of rod

dimensions.

Recovery equipment

Atlas Copco high quality, heat treated recovery

taps cover most sizes of drill rods, casing tubes,

core barrels, bits and reaming shells in metric or

DCDMA standard sizes.

10

4 - General technical information

This page provides a quick reference guide for you while you navigate through the catalogue making your prod-

uct application selections.

Below are two useful charts with data:

A summary of the relevant data when evaluating core sample size for corresponding core barrel systems be they

double tube, triple tube or thin wall double tube for O surface or O-U pump in congurations.

A summary of weights and dimensions of tubular products to help you choose complimentary rod and casing.

4.1 Dimensions at a glance

Length and dimensions

Size Metric system Imperial system

Diameter Length Diameter Length

1.5 m 3.0 m 5 ft 10 ft

Rods OD ID Kg OD ID lbs

AO /AT 44.5 34.9 6.8 13.9 1.75 1.38 15.70 31.40

AGM / ATT 44.5 36.8 5.9 11.8 1.75 1.45 13.0 26.0

BO / BT 55.6 46.0 8.9 17.9 2.19 1.81 20.1 40.2

BGM / BTT 56.5 48.8 7.6 15.3 2.23 1.92 16.8 33.8

NO / NMO / NT 69.9 60.3 11.4 22.9 2.75 2.38 25.7 51.4

HO / HMO / HT 88.9 77.8 17.1 34.2 3.50 3.06 38.0 76.70

PT 114.3 101.6 25.4 56.0 4.50 4.00 56.9 123.5

Casing

AW 57.1 48.4 8.3 16.9 2.25 1.91 18.40 37.40

BW 73.0 60.3 15.3 31.2 2.88 2.38 33.80 68.80

NW 88.9 76.2 19.1 38.8 3.50 3.00 42.10 85.60

HW / HWT 114.3 101.6 25.0 50.8 4.50 4.00 55.10 112.10

PW /PWT 139.7 125.5 34.9 69.7 5.50 4.94 76.70 153.30

Double tube surface and/or underground

Size (Surface-Underground) Metric system (mm) Imperial system (in)

Hole diameter Core diameter Hole diameter Core diameter

BO/BO-U 60.0 36.4 2.36 1.43

NO/NO-U 75.7 47.6 2.98 1.88

HO/HO-U 96.1 63.5 3.78 2.50

PO 122.7 85.0 4.83 3.34

Triple tube surface

Size (Surface-Underground) Metric system (mm) Imperial system (in)

Hole diameter Core diameter Hole diameter Core diameter

NO3 75.7 45.0 2.98 1.78

HO3 96.1 61.1 3.78 2.41

PO3 122.7 83.0 4.83 3.27

Double tube thin wall surface and/or underground

Size (Surface-Underground) Metric system (mm) Imperial system (in)

Hole diameter Core diameter Hole diameter Core diameter

AOTW / -U 48.0 30.3 1.89 1.19

BOTW / -U 60.0 42.0 2.36 1.65

NO2 75.7 50.7 2.98 2.0

11

5 - Surface double tube wireline core barrel

Double tube wireline core barrels are the predominant

core barrel confgurations used in mineral exploration.

As a general rule, double tube core barrels are used in

all but the most broken and friable ground conditions,

and are designed for ease of use with drilling additives

and loss control materials when required.

Surface systems are those where the overshots and

inner tubes descend through the drill string under their

own weight, and as such are normally used in borehole

orientations between -90 and -45 degrees.

When selecting a surface double tube wireline core

barrel and associated drill rod string, a 'bail' style water

swivel and hoist plug is commonly chosen for use with

surface style drill rigs using a main hoist to raise and

lower the drill string.

Ensure that the adapter subs chosen mate to the chosen

rod thread.

Information

12

Inner tube

Core barrel

head

Overshot

Hoist

plug

Drill rod

adapter

Stop

ring

Core

lifter

Core

case

Bit

Reaming shell

Stabilizer

Landing ring

Adapter

coupling

Locking

coupling

Drill rod

adapter

Drill rod

Water

swivel

Outer tube

Double tube surface and/or underground

Size (Surface-

Underground)

Metric system (mm) Imperial system (in)

Hole

diameter

Core

diameter

Hole

diameter

Core

diameter

BO/BO-U 60.0 36.4 2.36 1.43

NO/NO-U 75.7 47.6 2.98 1.88

HO/HO-U 96.1 63.5 3.78 2.50

PO 122.7 85.0 4.83 3.34

12

5.1 - Spare parts list BO/BTO

Item Description Qty Part number

Choose core barrel assembly and/or locking coupling part numbers to suit drill rod ORod TRod

1-38 1.5 m / 5 ft Core barrel assembly 3760 0060 01 3760 0060 02

1-38 3.0 m / 10 ft Core barrel assembly 3760 0060 03 3760 0060 04

1-32 1.5 m / 5 ft Inner tube assembly 3760 0060 05

1-32 3.0 m / 10 ft Inner tube assembly 3760 0060 06

1-28 Head assembly 3760 0060 07

1 Spearhead 1 3760 0044 29

2 Spring pin 1 3760 0043 48

3 Compression spring 1 0384 5000 18

4 Detent 1 3760 0044 30

5 Spear head base 1 3760 0044 32

6 Latch retracting case 1 3760 0066 74

7 Spring pin 3/8 x 1 5/8 2 0108 1691 90

8 Latch spring 1 3760 0062 17

9 Latch 2 3760 0062 18

10 Latch support 1 3760 0062 19

11 Spring pin 3/8 x 1 1/4 2 0108 1691 39

12 Spring pin 1/4 x 1 1/4 2 0108 1691 34

13 Upper latch body 1 3760 0057 94

14 Landing shoulder 1 3760 0057 96

15 Lower latch body 1 3760 0057 95

16 Lock nut 1 0268 3112 00

17 Spindle 1 3760 0062 20

18 Shut-off valve 2 3760 0062 21

19 Valve adjusting washer 1 3760 0062 22

20 Thrust bearing 1 3760 0064 70

21 Spindle bearing 1 3760 0062 23

22 Hanger bearing 1 3760 0064 70

23 Compression spring 1 3760 0064 75

24 Lock nut 1 0292 1310 00

25 Inner tube cap assembly 1 3760 0062 24

26 Grease tting 1 0544 1100 07

27 Ball 1 0517 1428 00

28 Check valve body 1 3760 0072 20

29 1.5 m / 5 ft Inner tube 1 3760 0048 30

29 3.0 m / 10 ft Inner tube 1 3760 0048 29

30 Stop ring 1 3760 0062 25

31 Core lifter 1 3760 0062 26

32 Core lifter case 1 3760 0062 27

33 Locking coupling, tanged 1 3760 0060 12 3760 0060 13

34 Adapter coupling 1 3760 0060 14

35 Landing ring 1 3760 0062 28

36 1.5 m / 5 ft Outer tube 1 3760 0048 31

36 3.0 m / 10 ft Outer tube 1 3760 0048 32

37 Inner tube stabilizer 1 3760 0062 29

38 Thread protector (For shipping) / Handling purposes) 1 3760 0062 30

13

5.1 - Spare parts list BO/BTO

14

5.1.1 - Spare parts list overshot assembly BO/BTO

Item Description Qty Part number

1-19 Overshot assembly complete 1 3760 0048 44

1-6 Cable swivel assembly complete 1 3760 0063 75

1 Cable clamp 1 3760 0064 65

2 Wire line thimble 1 3760 0064 66

3 Eye bolt 1 3760 0072 15

4 Cable swivel collar 1 3760 0072 16

5 Bearing 1 3760 0064 67

6 Lock nut 1/2 1 0292 1408 00

7 Grease tting 1 0544 1100 07

8 Sinking bar body 1 3760 0063 76

9 Jar tube 1 3760 0063 77

10 Lock nut 7/16 1 5530 9645 00

11 Jar staff 1 3760 0063 78

12 Locking sleeve 1 3760 0063 72

13 Spring pin 7/32 x 1-1/4 2 0108 1691 83

14 Set screw 3/8 x 5/8 1 3760 0070 85

15 Spring pin 3/16 x 1 3/8 1 0108 1691 85

16 Overshot head 1 3760 0063 79

17 Lifting dog spring 1 3760 0063 73

18 Lifting dog 2 3760 0063 74

19 Pivot pin 1/2 x 1 1/2 1 3760 0063 80

15

5.1.1 - Spare parts list overshot assembly BO/BTO

16

5.2 - Spare parts list NO/NTO

Item Description Qty Part number

Choose core barrel assembly and/or locking coupling part numbers to suit drill rod ORod TRod

1-38 1.5 m / 5 ft Core barrel assembly 3760 0051 52 3760 0060 19

1-38 3.0 m / 10 ft Core barrel assembly 3760 0051 53 3760 0060 20

1-32 1.5 m / 5 ft Inner tube assembly 3760 0053 01

1-32 3.0 m / 10 ft Inner tube assembly 3760 0060 21

1-28 Head assembly 3760 0051 60

1 Spearhead 1 3760 0044 29

2 Spring pin 1 3760 0043 48

3 Compression spring 1 0384 5000 18

4 Detent 1 3760 0044 30

5 Spear head base 1 3760 0044 33

6 Latch retracting case 1 3760 0066 73

7 Spring pin 1/2 x 2 2 0108 1691 80

8 Latch spring 1 3760 0062 32

9 Latch 2 3760 0062 33

10 Latch support 1 3760 0062 34

11 Spring pin 1/2 x 1 1/2 1 0108 1691 43

12 Spring pin 1/4 x 1 1/2 1 0108 1691 35

13 Upper latch body 1 3760 0050 99

14 Landing shoulder 1 3760 0051 00

15 Lower latch body 1 3760 0050 98

16 Lock nut 1 1/8 1 0268 4138 24

17 Spindle 1 3760 0062 35

18 Shut-off valve 2 3760 0062 36

19 Valve adjusting washer 2 3760 0062 37

20 Thrust bearing 1 3760 0064 61

21 Spindle bearings 1 3760 0062 38

22 Hanger bearing 1 3760 0064 62

23 Compression spring 1 3760 0064 63

24 Lock nut 1 3760 0130 03

25 Inner tube cap assembly 1 3760 0062 39

26 Grease tting 1 0544 1100 07

27 Ball 7/8 1 0517 1100 25

28 Check valve body 1 3760 0072 21

29 1.5 m / 5 ft Inner tube 1 3760 0048 35

29 3.0 m / 10 ft Inner tube 1 3760 0062 40

30 Stop ring 1 3760 0062 40

31 Core lifter 1 3760 0062 41

32 Core lifter case 1 3760 0062 42

33 Locking coupling, tanged 1 3760 0060 26 3760 0060 27

34 Adapter coupling 1 3760 0060 28

35 Landing ring 1 3760 0062 43

36 1.5 m / 5 ft Outer tube 1 3760 0048 37

36 3.0 m / 10 ft Outer tube 1 3760 0048 39

37 Inner tube stabilizer 1 3760 0062 44

38 Thread protector (For shipping) / Handling purposes) 1 3760 0062 45

17

5.2 - Spare parts list NO/NTO

1

3

13

8

10

11

12

16

17

18

19

18

20

21

22

23

24

25

27

28

29

31

32

37

36

34

33

38

30

35

19

26

14

15

4

5

6

2

7

7

9

18

5.2.2 - Spare parts list overshot assembly NO/NTO

Item Description Qty Part number

1-19 Overshot assembly complete 1 3760 0048 46

1-6 Cable swivel assembly complete 1 3760 0063 75

1 Cable clamp 1 3760 0064 65

2 Wire line thimble 1 3760 0064 66

3 Eye bolt 1 3760 0072 15

4 Cable swivel collar 1 3760 0072 16

5 Bearing 1 3760 0064 67

6 Lock nut 1/2 1 0292 1408 00

7 Grease tting 1 0544 1100 07

8 Sinking bar body 1 3760 0063 84

9 Jar tube 1 3760 0063 85

10 Lock nut 1/2 1 0292 1308 00

11 Jar staff 1 3760 0063 86

12 Locking sleeve 1 3760 0063 81

13 Spring pin 1/4 x 1 1/2 2 0108 1691 35

14 Set screw 1 3760 0070 85

15 Spring pin 1/4 x 1 3/4 1 0108 1691 87

16 Overshot head 1 3760 0063 87

17 Lifting dog spring 1 3760 0063 73

18 Lifting dog 2 3760 0063 82

19 Pivot pin 1 3760 0063 83

19

5.2.2 - Spare parts list overshot assembly NO/NTO

1

2

3

4

5

6

7

8

9

12

13

15

14

19

10

11

17

18

16

20

5.3 - Spare parts list HO/HTO

Item Description Qty Part number

Choose core barrel assembly and/or locking coupling part numbers to suit drill rod ORod TRod

1-38 1.5 m / 5 ft Core barrel assembly 3760 0060 33 3760 0060 34

1-38 3.0 m / 10 ft Core barrel assembly 3760 0060 35 3760 0060 36

1-32 1.5 m / 5 ft Inner tube assembly 3760 0060 37

1-32 3.0 m / 10 ft Inner tube assembly 3760 0060 38

1-28 Head assembly 3760 0051 81

1 Spearhead 1 3760 0044 29

2 Spring pin 1 3760 0043 48

3 Compression spring 1 0384 5000 18

4 Detent 1 3760 0044 30

5 Spearhead base 1 3760 0044 34

6 Latch retracting case 1 3760 0066 75

7 Spring pin 1/2 x 2 3/4 2 0108 1691 46

8 Latch spring 1 3760 0062 47

9 Latch 2 3760 0062 48

10 Latch support 1 3760 0062 49

11 Spring pin 1/2 x 2 1 0108 1691 80

12 Spring pin 3/8 x 2 1 0108 1691 42

13 Upper latch body 1 3760 0051 49

14 Landing shoulder 1 3760 0051 50

15 Lower latch body 1 3760 0051 48

16 Lock nut 1 1/4 1 0268 3115 00

17 Spindle 1 3760 0062 50

18 Shut-off valve 2 3760 0062 51

19 Valve adjusting washer 2 3760 0062 52

20 Thrust bearing 1 3760 0064 71

21 Spindle bearing 1 3760 0062 53

22 Hanger bearing 1 3760 0064 61

23 Compression spring 1 3760 0077 65

24 Lock nut 1 0292 1313 00

25 Inner tube cap assembly 1 3760 0062 54

26 Grease tting 1 0544 1100 07

27 Ball 7/8 1 0517 1100 25

28 Check valve body 1 3760 0072 21

29 1.5 m / 5 ft Inner tube 1 3760 0060 48

29 3.0 m / 10 ft Inner tube 1 3760 0060 49

30 Stop ring 1 3760 0062 55

31 Core lifter 1 3760 0062 56

32 Core lifter case 1 3760 0062 57

33 Locking coupling, tanged 1 3760 0060 43 3760 0060 44

34 Adapter coupling 1 3760 0060 45

35 Landing ring 1 3760 0062 58

36 1.5 m / 5 ft Outer tube 1 3760 0060 46

36 3.0 m / 10 ft Outer tube 1 3760 0060 47

37 Inner tube stabilizer 1 3760 0062 59

38 Thread protector (For shipping) / Handling purposes) 1 3760 0062 60

21

5.3 - Spare parts list HO/HTO

1

3

13

8

10

11

12

16

17

18

19

18

20

21

22

23

24

25

27

28

29

31

32

37

36

34

33

38

30

35

19

26

9

14

15

4

5

2

7

7

6

22

5.3.1 - Spare parts list overshot assembly HO/HTO

Item Description Qty Part number

1-19 Overshot assembly complete 1 3760 0048 48

1-6 Cable swivel assembly complete 1 3760 0063 75

1 Cable clamp 1 3760 0064 65

2 Wire line thimble 1 3760 0064 66

3 Eye bolt 1 3760 0072 15

4 Cable swivel collar 1 3760 0072 16

5 Bearing 1 3760 0064 67

6 Lock nut 1 0292 1408 00

7 Grease tting 1 0544 1100 07

8 Sinking bar body 1 3760 0063 84

9 Jar tube 1 3760 0063 85

10 Lock nut 1/2 1 0292 1308 00

11 Jar staff 1 3760 0063 86

12 Locking sleeve 1 3760 0063 81

13 Spring pin 1/4 x 1 1/2 2 0108 1691 35

14 Set screw 1 3760 0070 85

15 Spring pin 1/4 x 1 3/4 1 0108 1691 87

16 Overshot head 1 3760 0063 87

17 Lifting dog spring 1 3760 0063 73

18 Lifting dog 2 3760 0063 82

19 Pivot pin 1 3760 0063 88

Head adapter sleeve 1 3760 0063 89

23

5.3.1 - Spare parts list overshot assembly HO/HTO

1

2

3

4

5

6

7

8

9

12

13

15

14

19

10

11

17

18

16

24

5.4 - Spare parts list PO/PTO

Item Description Qty Part number

Choose core barrel assembly and/or locking coupling part numbers to suit drill rod ORod TRod

1-40 1.5 m / 5 ft Core barrel assembly 3760 0048 70 3760 0048 72

1-40 3.0 m / 10 ft Core barrel assembly 3760 0048 71 3760 0048 73

1-34 1.5 m / 5 ft Inner tube assembly 3760 0048 74

1-34 3.0 m / 10 ft Inner tube assembly 3760 0048 75

1-30 Head assembly 3760 0048 76

1 Spearhead 1 3760 00 48 78

2 Spring pin 1 3760 0048 81

3 Compression spring 1 3760 0048 82

4 Detent 1 3760 0048 80

5 Spearhead base 1 3760 0048 79

6 Latch retracting case 1 3760 0062 61

7 Spring pin 3/4 x 3 3/4 2 3760 0077 51

8 Latch spring 1 3760 0062 63

9 Latch 2 3760 0062 64

10 Spring pin 1/2 x 2 2 0108 1691 80

11 Latch support 1 3760 0062 65

12 Spring pin 1/2 x 2 3/4 1 0108 1691 46

13 Upper latch body 1 3760 0062 62

14 Landing shoulder 1 3760 0062 78

15 Lock nut 1 3760 0077 49

16 Spindle assy 1 3760 0062 66

17 Valve adjusting washer 3 3760 0062 68

18 Shut-off valve 2 3760 0062 67

19 Bearing spacer 4 3760 0062 77

20 Thrust bearing 2 3760 0064 72

21 Spindle bearing 1 3760 0062 69

22 Thrust bearing spacer 1 3760 0062 81

23 Compression spring 1 3760 0077 66

24 Spring retaining washer 1 3760 0062 80

25 Lock nut 1 0292 1338 08

26 Inner tube assembly 1 3760 0062 70

27 Grease tting 1 0544 1100 07

28 Ball 1 1/8 1 0517 1100 27

29 O-ring 1 0663 9182 00

30 Check valve body 1 3760 0072 22

31 1.5 m / 5 ft Inner tube 1 3760 0060 64

31 3.0 m / 10 ft Inner tube 1 3760 0060 65

32 Stop ring 1 3760 0062 71

33 Core lifter 1 3760 0041 85

34 Core lifter case 1 3760 0062 73

35 Carbide locking coupling, tanged 1 3760 0060 59 3760 0060 60

36 Adapter coupling 1 3760 0060 61

37 Landing ring 1 3760 0062 74

38 1.5 m / 5 ft Outer tube 1 3760 0060 62

38 1.5 m / 5 ft Outer tube 1 3760 0060 63

39 Inner tube stabilizer 1 3760 0062 75

40 Thread protector (For shipping) 1 3760 0062 76

25

5.4 - Spare parts list PO/PTO

1

8

3

13

10

11

12

16

18

17

18

20

21

19

20

23

24

28

31

33

34

39

38

36

35

40

32

37

17

27

14

15

4

5

6

2

9

7

7

17

19

19

19

25

22

26

29

30

26

5.4.1 - Spare parts list overshot assembly PO/PTO

Item Description Qty Part number

1-20 Overshot assembly complete 1 3760 0060 54

1-7 Cable swivel assembly complete 1 3760 0063 98

1 Cable clamp 1 3760 0077 52

2 Wire line thimble 1 0373 0200 05

3 Eye bolt 1 3760 0072 17

4 Cable swivel collar 1 3760 0072 18

5 Bearing 1 3760 0064 70

6 Lock nut 1 0281 2238 13

7 Cotter pin 1 5530 8184 00

8 Grease tting 1 0544 1100 07

9 Sinking bar body 1 3760 0063 93

10 Jar tube 1 3760 0063 94

11 Lock nut 3/4 1 0292 1338 07

12 Jar staff 1 3760 0063 95

13 Locking sleeve 1 3760 0063 91

14 Spring pin 5/16 x 2 2 0108 1691 89

15 Set screw 1 3760 0070 85

16 Spring pin 1/4 x 3 1 0108 1691 88

17 Overshot head 1 3760 0063 96

18 Lifting dog spring 1 3760 0064 77

19 Lifting dog 2 3760 0063 92

20 Pivot pin 1 x 3 3/8 1 3760 0063 97

27

5.4.1 - Spare parts list overshot assembly PO/PTO

1

2

3

4

5

6

8

9

10

13

14

16

15

20

11

12

18

19

17

7

28

Spare parts kits core barrel

Parts included Qty. BO NO HO PO

Spearhead 1

n n n n

Compression spring 1

n n n n

Detent 1

n n n n

Spirol pin 2

n n n n

Spring pin 2

n n n n

Latch spring 4

n n n n

Latch 4

n n n n

Spring pin 4

n n n n

Spring pin 4

n n n n

Landing shoulder 1

n n n n

Lock nut 1

n n n n

Shut-off valve 4

n n n n

Upper bearing 2

n n n n

Lower bearing 2

n n n n

Spindle bearing 1

n n n n

Lock nut 1

n n n n

Stell ball 1

n n n n

Grease tting 2

n n n n

Stop ring (If required) 4

n n n n

Core lifter 20

n n n n

Core lifter case 4

n n n n

Landing ring 2

n n n n

Inner tube stabilizer 2

n n n n

BO NO HO PO

3760 0060 15 3760 0060 29 3760 0060 50 3760 0060 66

Spare parts kits overshots

BO NO HO PO

3760 0060 16 3760 0060 30 3760 0060 51 3760 0060 67

Parts included Qty. BO NO HO PO

Cable clamp 1

n n n n

Thimble 1

n n n n

Bearing 1

n n n n

Lock nut 1

n n n n

Grease tting 2

n n n n

Lock nut 1

n n n n

Spring pin 2

n n n n

Spring pin 2

n n n n

Dog spring 4

n n n n

Lifting dog 2

n n n n

Pivot pin 1

n n n n

5.5 - Spare parts kits

29

Triple tube wireline core barrels are the predominant

core barrel confgurations used in mineral exploration

where gound conditions are generaly categorized as

poor, are commonly friable and broken.

These designs permit ease of use with drilling addi-

tives and loss control materials as these are typically

required. The barrel uses an additional split inner tube

to encourage an undisturbed sample recovery while

corresponding diamond bit designs ensure minimum

contact of the circulating fuid with the core sample

maximizing core recovery.

Surface systems are those where the overshots and

inner tubes descend through the drill string under their

own weight, and as such are normally used in borehole

orientations between -90 to -45 degrees.

When selecting a surface triple tube wireline core

barrel and associated drill rod string, a 'bail' style water

swivel and hoist plug is commonly chosen for use with

surface style drill rigs using a main hoist to raise and

lower the drill string.

Ensure that the adapter subs chosen mate to the chosen

rod thread.

6 - Surface triple tube wireline core barrels

Application information

Inner tube

Core barrel

head

Overshot

Hoist

plug

Drill rod

adapter

Stop

ring

Core

lifter

Core

case

Bit

Reaming shell

Stabilizer

Landing ring

Adapter

coupling

Locking

coupling

Drill rod

adapter

Water

swivel

Drill rod

Piston

Split tube

Outer tube

Triple tube surface

Size (Surface-

Underground)

Metric system (mm) Imperial system (in)

Hole

diameter

Core

diameter

Hole

diameter

Core

diameter

NO3 75.7 45.0 2.98 1.78

HO3 96.1 63.5 3.78 2.41

PO3 122.7 83.1 4.83 3.27

30

6.1 - Spare parts list NO3/NTO3

Item Description Qty Part number

Choose core barrel assembly and/or locking coupling part numbers to suit drill rod ORod TRod

1-43 1.5 m / 5 ft Core barrel assembly 3760 0060 70 3760 0060 71

1-43 3.0 m / 10 ft Core barrel assembly 3760 0060 72 3760 0060 73

1-37 1.5 m / 5 ft Inner tube assembly 3760 0060 74

1-37 3.0 m / 10 ft Inner tube assembly 3760 0060 75

1-28 Head assembly 3760 0051 60

1 Spearhead 1 3760 0044 29

2 Spring pin 1 3760 0043 48

3 Compression spring 1 0384 5000 18

4 Detent 1 3760 0044 30

5 Spearhead base 1 3760 0044 33

6 Latch retracting case 1 3760 0066 73

7 Spring pin 1/2 x 2 2 0108 1691 80

8 Latch spring 1 3760 0062 32

9 Latch 2 3760 0062 33

10 Latch support 1 3760 0062 34

11 Spring pin 1/2 x 1 1/2 1 0108 1691 43

12 Spring pin 1/4 x 1 1/2 1 0108 1691 35

13 Upper latch body 1 3760 0050 99

14 Landing shoulder 1 3760 0051 00

15 Lower latch body 1 3760 0050 98

16 Lock nut 1 0268 4138 24

17 Spindle 1 3760 0062 35

18 Shut-off valve 2 3760 0062 36

19 Valve adjusting washer 2 3760 0062 37

20 Thrust bearing 1 3760 0064 61

21 Spindle bearing 1 3760 0062 38

22 Hanger bearing 1 3760 0064 62

23 Compression spring 1 3760 0064 63

24 Lock nut 3/4 1 0292 1338 07

25 Inner tube cap assembly 1 3760 0062 39

26 Grease tting 1 0544 1100 07

27 Ball 7/8 1 0517 1100 25

28 Check valve body 1 3760 0072 21

29 Adapter 1 3760 0062 93

30 Piston plug 1 3760 0062 83

31 O-ring 1 0663 9196 00

32 Piston 1 3760 0062 94

33 1.5 m / 5 ft Split tube 1 3760 0060 76

33 3.0 m / 10 ft Split tube 1 3760 0082 94

34 1.5 m / 5 ft Inner tube 1 3760 0048 35

34 3.0 m / 10 ft Inner tube 1 3760 0048 36

35 Stop ring 1 3760 0062 85

36 Core lifter 1 3760 0062 86

37 Core lifter case 1 3760 0062 87

38 Locking coupling, tanged 1 3760 0060 26 3760 0060 27

39 Adapter coupling 1 3760 0060 28

40 Landing ring 1 3760 0062 43

41 1.5 m / 5 ft Outer tube 1 3760 0048 37

41 3.0 m / 10 ft Outer tube 1 3760 0048 39

31

6.1 - Spare parts list NO3/NTO3

1

3

13

8

10

11

12

16

17

18

19

18

20

21

22

23

24

25

27

28

29

36

37

42

41

39

38

43

35

40

19

26

9

14

15

4

5

2

30

31

32

33

34

7

7

6

Item Description Qty Part number

Choose core barrel assembly and/or locking coupling part numbers to suit drill rod ORod TRod

42 Inner tube stabilizer 1 3760 0062 44

43 Thread protector (For shipping) / Handling purposes) 1 3760 0062 45

32

6.1.1 - Spare parts list overshot assembly NO3/NTO3

Item Description Qty Part number

1-19 Overshot assembly complete 1 3760 0048 46

1-6 Cable swivel assembly complete 1 3760 0063 75

1 Cable clamp 1 3760 0064 65

2 Wire line thimble 1 3760 0064 66

3 Eye bolt 1 3760 0072 15

4 Cable swivel collar 1 3760 0072 16

5 Bearing 1 3760 0064 67

6 Lock nut 1 0292 1408 00

7 Grease tting 1 0544 1100 07

8 Sinking bar body 1 3760 0063 84

9 Jar tube 1 3760 0063 85

10 Lock nut 1 0292 1308 00

11 Jar staff 1 3760 0063 86

12 Locking sleeve 1 3760 0063 81

13 Spring pin 1/4 x 1 1/2 2 0108 1691 35

14 Set screw 1 3760 0070 85

15 Spring pin 1/4 x 1 3/4 1 0108 1691 87

16 Overshot head 1 3760 0063 87

17 Lifting dog spring 1 3760 0063 73

18 Lifting dog 2 3760 0063 82

19 Pivot pin 1 3760 0063 83

33

6.1.1 - Spare parts list overshot assembly NO3/NTO3

1

2

3

4

5

6

7

8

9

12

13

15

14

19

10

11

17

18

16

34

6.2 - Spare parts list HO3/HTO3

Item Description Qty Part number

Choose core barrel assembly and/or locking coupling part numbers to suit drill rod ORod TRod

1-43 1.5 m / 5 ft Core barrel assembly 3760 0060 79 3760 0060 80

1-43 3.0 m / 10 ft Core barrel assembly 3760 0060 81 3760 0060 82

1-37 1.5 m / 5 ft Inner tube assembly 3760 0060 83

1-37 3.0 m / 10 ft Inner tube assembly 3760 0060 84

1-28 Head assembly 3760 0051 81

1 Spearhead 1 3760 0044 29

2 Spring pin 1 3760 0043 48

3 Compression spring 1 0384 5000 18

4 Detent 1 3760 0044 30

5 Spearhead base 1 3760 0044 34

6 Latch retracting case 1 3760 0066 75

7 Spring pin 1/2 x 2 3/4 2 0108 1691 46

8 Latch spring 1 3760 0062 47

9 Latch 2 3760 0062 48

10 Latch support 1 3760 0062 49

11 Spring pin 1/2 x 2 1 0108 1691 80

12 Spring pin 1/2 x 2 1 0108 1691 42

13 Upper latch body 1 3760 0051 49

14 Landing shoulder 1 3760 0051 50

15 Lower latch body 1 3760 0051 48

16 Lock nut 1 0268 3115 00

17 Spindle 1 3760 0062 50

18 Shut-off valve 2 3760 0062 51

19 Valve adjusting washer 2 3760 0062 52

20 Thrust bearing 1 3760 0064 71

21 Spindle bearing 1 3760 0062 53

22 Hanger bearing 1 3760 0064 61

23 Compression spring 1 3760 0077 65

24 Lock nut 1 0292 1313 00

25 Inner tube cap assembly 1 3760 0062 54

26 Grease tting 1 0544 1100 07

27 Ball 7/8 1 0517 1100 25

28 Check valve body 1 3760 0072 21

29 Adapter 1 3760 0062 95

30 Piston plug 1 3760 0062 83

31 O-ring 1 0663 2100 93

32 Piston 1 3760 0062 96

33 1.5 m / 5 ft Split tube 1 3760 0056 41

33 3.0 m / 10 ft Split tube 1 3760 0056 40

34 1.5 m / 5 ft Inner tube 1 3760 0060 48

34 3.0 m / 10 ft Inner tube 1 3760 0060 49

35 Stop ring 1 3760 0062 88

36 Core lifter 1 3760 0062 89

37 Core lifter case 1 3760 0062 90

38 Locking coupling, tanged 1 3760 0060 43 3760 0060 44

39 Adapter coupling 1 3760 0060 45

40 Landing ring 1 3760 0062 58

41 1.5 m / 5 ft Outer tube 1 3760 0060 46

41 3.0 m / 10 ft Outer tube 1 3760 0060 47

35

6.2 - Spare parts list HO3/HTO3

1

3

13

8

10

11

12

16

17

18

19

18

20

21

22

23

24

25

27

28

29

36

37

42

41

39

38

43

35

40

19

26

9

14

15

4

5

2

30

31

32

33

34

7

7

6

Item Description Qty Part number

Choose core barrel assembly and/or locking coupling part numbers to suit drill rod ORod TRod

42 Inner tube stabilizer 1 3760 0062 59

43 Thread protector (For shipping) / Handling purposes) 1 3760 0062 60

36

6.2.2 - Spare parts list overshot assembly HO3/HTO3

Item Description Qty Part number

1-19 Overshot assembly complete 1 3760 0048 48

1-6 Cable swivel assembly complete 1 3760 0063 75

1 Cable clamp 1 3760 0064 65

2 Wire rope thimble 1 3760 0064 66

3 Eye bolt 1 3760 0072 15

4 Cable swivel collar 1 3760 0072 16

5 Bearing 1 3760 0064 67

6 Lock nut 1/2 1 0292 1408 00

7 Grease tting 1 0544 1100 07

8 Sinking bar body 1 3760 0063 84

9 Jar tube 1 3760 0063 85

10 Lock nut 1/2 1 0292 1308 00

11 Jar staff 1 3760 0063 86

12 Locking sleeve 1/4 x 1 1/2 1 3760 0063 81

13 Spring pin 2 0108 1691 35

14 Set screw 1 3760 0070 85

15 Spring pin 1/4 x 1 3/4 1 0108 1691 87

16 Overshot head 1 3760 0063 87

17 Lifting dog spring 1 3760 0063 73

18 Lifting dog 2 3760 0063 82

19 Pivot pin 1/2 x 2 9/16 1 3760 0063 88

Adapter sleeve (Not shown) 1 3760 0063 89

37

6.2.2 - Spare parts list overshot assembly HO3/HTO3

1

2

3

4

5

6

7

8

9

12

13

15

14

19

10

11

17

18

16

38

Item Description Qty Part number

Choose core barrel assembly and/or locking coupling part numbers to suit drill rod ORod TRod

1-45 1.5 m / 5 ft core barrel assembly 3760 0049 65 3760 0049 69

1-45 3.0 m / 10 ft core barrel assembly 3760 0049 67 3760 0049 71

1-39 1.5 m / 5 ft Inner tube assembly 3760 0049 64

1-39 3.0 m / 10 ft Inner tube assembly 3760 0049 66

1-30 Head assembly 3760 0048 76

1 Spearhead 1 3760 0048 78

2 Spring pin 1 3760 0048 81

3 Compression spring 1 3760 0048 82

4 Detent 1 3760 0048 80

5 Spearhead base 1 3760 0048 79

6 Latch retracting case 1 3760 0062 61

7 Spring pin 3/4 x 3 3/4 2 3760 0077 51

8 Latch spring 1 3760 0062 63

9 Latch 2 3760 0062 64

10 Spring pin 1/2 x 2 2 0108 1691 80

11 Latch support 1 3760 0062 65

12 Spring pin 1/2 x 2 3/4 1 0108 1691 46

13 Upper latch body 1 3760 0062 62

14 Landing shoulder 1 3760 0062 78

15 Lock nut 1/2 1 3760 0077 49

16 Spindle assembly 1 3760 0062 66

17 Valve adjusting washer 3 3760 0062 68

18 Shut-off valve 2 3760 0062 67

19 Bearing spacer 4 3760 0062 77

20 Thrust bearing 2 3760 0064 72

21 Spindle bearing 1 3760 0062 69

22 Thrust bearing spacer 1 3760 0062 81

23 Compression spring 1 3760 0077 66

24 Spring retaining washer 1 3760 0062 80

25 Lock nut 1 0292 1338 08

26 Inner tube cap assembly 1 3760 0062 70

27 Grease tting 1 0544 1100 07

28 Ball 1 0517 1100 27

29 O-ring 1 0663 9182 00

30 Check valve body 1 3760 0072 22

31 Adapter 1 3760 0062 82

32 Piston plug 1 3760 0062 83

33 O-ring 1 0663 9216 00

34 Piston 1 3760 0062 84

35 1.5 m / 5 ft Split tube 1 3760 0056 29

35 3.0 m / 10 ft Split tube 1 3760 0082 93

36 1.5 m / 5 t Inner tube 1 3760 0060 64

36 3.0 m / 10 ft Inner tube 1 3760 0060 065

37 Stop ring 1 3760 0062 91

38 Core lifter 1 3760 0062 92

39 Core lifter case 1 3760 0062 73

40 Carbice locking coupling ,tanged 1 3760 0060 59 3760 0060 60

6.3 - Spare parts list PO3/PTO3

39

6.3 - Spare parts list PO3/PTO3

1

3

13

10

11

12

16

18

17

18

20

21

19

20

23

24

28

44

43

41

40

45

42

17

27

14

15

4

5

6

2

9

7

7

17

19

19

19

25

22

26

29

30

31

38

39

37

32

33

34

35

36

8

Item Description Qty Part number

Choose core barrel assembly and/or locking coupling part numbers to suit drill rod ORod TRod

41 Adapter coupling 1 3760 0060 61

42 Landing ring 1 3760 0062 74

43 1.5 m / 5 ft Outer tube 1 3760 0060 62

43 3.0 m / 10 ft Outer tube 1 3760 0060 63

44 Inner tube stabilizer 1 3760 0062 75

45 Thread protector (For shipping) / Handling purposes) 1 3760 0062 76

40

6.3.1 - Spare parts list overshot assembly PO3/PTO3

Item Description Qty Part number

1-20 Overshot assembly complete 1 3760 0060 54

1-7 Cable swivel assembly complete 1 3760 0063 98

1 Cable clamp 1 3760 0077 52

2 Wire line thimble 1 0373 0200 05

3 Eye bolt 1 3760 0072 17

4 Cable swivel collar 1 3760 0072 18

5 Bearing 1 3760 0064 70

6 Lock nut 1 0281 2238 13

7 Cotter pin 1 5530 8184 00

8 Grease tting 1 0544 1100 07

9 Sinking bar body 1 3760 0063 93

10 Jar tube 1 3760 0063 94

11 Lock nut 3/4 1 0292 1338 07

12 Jar staff 1 3760 0063 95

13 Locking sleeve 1 3760 0063 91

14 Spring pin 5/16 x 2 2 0108 1691 89

15 Set screw 1 3760 0070 85

16 Spring pin 1/4 x 3 1 0108 1691 88

17 Overshot head 1 3760 0063 96

18 Lifting dog spring 1 3760 0064 77

19 Lifting dog 2 3760 0063 92

20 Pivot pin 1 x 3 3/8 1 3760 0063 97

41

6.3.1 - Spare parts list overshot assembly PO3/PTO3

1

2

3

4

5

6

8

9

10

13

14

16

15

20

11

12

18

19

17

7

42

Spare parts kits core barrel

Parts included Qty. NO3 / NTO3 HO3 / HTO3 PO3 / PTO3

Spearhead 1

n n n

Compression spring 1

n n n

Detent 1

n n n

Spirol pin 2

n n n

Spring pin 2

n n n

Latch spring 4

n n n

Latch 4

n n n

Spring spring 4

n n n

Spring pin 4

n n n

Landing shoulder 1

n n n

Lock nut 1

n n n

Shut-off valve 4

n n n

Upper bearing 2

n n n

Lower bearing 2

n n n

Spindle bearing 1

n n n

Lock nut 1

n n n

Stell ball 1

n n n

Grease tting 2

n n n

Stop ring (If required) 4

n n n

Core lifter 20

n n n

Core lifter case 4

n n n

Landing ring 2

n n n

Inner tube stabilizer 2

n n n

NO3 / NTO3 HO3 / HTO3 PO3 / PTO3

3760 0060 78 3760 0060 85 3760 0060 86

Spare parts kits overshots

NO3 / NTO3 HO3 / HTO3 PO3 / PTO3

3760 0060 30 3760 0060 51 3760 0060 67

Parts included Qty. NO3 / NTO3 HO3 / HTO3 PO3 / PTO3

Cable clamp 1

n n n

Thimble 1

n n n

Bearing 1

n n n

Lock nut 1

n n n

Grease tting 2

n n n

Lock nut 1

n n n

Spring pin 2

n n n

Spring pin 2

n n n

Dog spring 4

n n n

Lifting dog 2

n n n

Pivot pin 1

n n n

6.4 - Spare parts kits

43

Double tube thin wall wire line core barrels are used in

select mineral exploration applications.

Using thinner walled cross sections for rods, tubes and

diamond bit kerfs creates a larger core sample within

nominal 'A' and 'B' bore holes. Their design allows

for ease of use with less dense drilling additives when

required, and are typically chosen for more competent

ground conditions and for use with high speed drills

having lower pull down forces.

By changing a handfull of components only, the NO2"

confgurations provide a marginally larger core sample,

all the while using traditional N wireline drill rod

Surface systems are those where the overshots and

inner tubes descend through the drill string under their

own weight, and as such are normally used in borehole

orientations between reintations between -90 to -45

degrees.

When selecting a surface thin wall double tube wireline

core barrel and associated drill rod string, a 'bail' style

water swivel and hoist plug is commonly chosen for

use with surface style drill rigs using a main hoist to

raise and lower the drill string.

Ensure that the adapter subs chosen mate to the chosen

rod thread.

7 - Surface thin wall double tube wireline core barrels

Application information

12

Inner rod

Core barrel

head

Overshot

Hoist

plug

Drill rod

adapter

Core

lifter

Core

case

Bit

Reaming shell

Stabilizer

Landing ring

Adapter

coupling

Locking

coupling

Drill rod

adapter

Drill rod

Water

swivel

Outer rod

Double tube thin wall surface and/or underground

Size (Surface-

Underground)

Metric system (mm) Imperial system (in)

Hole

diameter

Core

diameter

Hole

diameter

Core

diameter

AOTW / -U 48.0 30.3 1.89 1.19

BOTW / -U 60.0 42.0 2.36 1.65

NO2 75.7 50.7 2.98 2.0

44

7.1 - Spare parts list AOTW

Item Description Qty Part number

Choose core barrel assembly and/or locking coupling part numbers to suit drill rod AGMRod ATTRod

1-34 1.5 m / 5 ft Core barrel assembly 3760 0042 10 3760 0060 87

1-34 3.0 m / 10 ft Core barrel assembly 3760 0042 11 3760 0060 88

1-28 1.5 m / 5 ft Inner tube assembly 3760 0042 48

1-28 3.0 m / 10 ft Inner tube assembly 3760 0042 49

1-24 Head assembly 3760 0042 14

1 Spearhead 1 3760 00 63 24

2 Latch retracting case 1 3760 0063 06

3 Spring pin 5/16 x 1 1/4 2 5530 8641 00

4 Latch spring 1 3760 0063 10

5 Latch 2 3760 0063 11

6 Latch support 1 3760 0063 12

7 Spring pin 5/16 x 3/4 1 0108 1691 37

8 Spring pin 1/4 x 3/4 1 0108 1691 86

9 Latch body 1 3760 0063 07

10 Landing shoulder 1 3760 0063 08

11 Retaining ring 1 3760 0063 09

12 Lock nut 1 3760 0077 50

13 Spindle 1 3760 0063 13

14 Shut-off valve 2 3760 0063 14

15 Valve adjusting washer 2 3760 0063 15

16 Ball thrust bearing 1 3760 0064 68

17 Spindle bearing 1 3760 0063 16

18 Hanger bearing 1 3760 0064 69

19 Compressing spring 1 3760 0064 73

20 Lock nut 1 0292 1308 00

21 Inner tube assembly 1 3760 0003 89

22 Grease tting 1 0544 1100 07

23 Ball 1/2 1 0517 1420 00

24 Check valve body 1 3760 0072 23

25 1.5 m / 5 ft Inner tube 1 3760 0060 03

25 3.0 m / 10 ft Inner tube 1 3760 0042 09

26 Stop ring 1 3760 0003 93

27 Core lifter 1 3760 0063 19

28 Core lifter case 1 3760 0003 92

29 Locking coupling, tanged 1 3760 0060 98 3760 0060 99

30 Adapter coupling 1 3760 0061 00

31 Landing ring 1 3760 0063 21

32 1.5 m / 5 ft Outer tube 1 3760 0061 01

32 3.0 m / 10 ft Outer tube 1 3760 0061 02

33 Inner tube stabilizer 1 3760 0063 22

34 Thread protector (For shipping/Handling purposes)) 1 3760 0063 23

45

1

3

3

2

9

4

5

6

7

8

12

10

11

13

14

15

14

15

16

17

18

19

20

21

23

24

22

25

27

28

33

32

31

30

29

34

26

7.1 - Spare parts list AOTW

46

Item Description Qty Part number

1-19 Overshot assembly complete 1 3760 0060 89

1-6 Cable swivel assembly complete 1 3760 0063 75

1 Cable clamp 1 3760 0064 65

2 Wire line thimble 1 3760 0064 66

3 Eye bolt 1 3760 0072 15

4 Cable swivel collar 1 3760 0072 16

5 Bearing 1 3760 0064 67

6 Lock nut 1 0292 1408 00

7 Grease tting 1 0544 1100 07

8 Sinking bar body 1 3760 0064 02

9 Jar tube 1 3760 0064 03

10 Lock nut 1 0292 1306 00

11 Jar staff 1 3760 0064 04

12 Spring pin 3/16 x 1 2 5530 7750 00

13 Jar head 1 3760 0064 05

14 Locking sleeve 1 3760 0063 99

15 Spring pin 1 5530 7750 00

16 Overshot head 1 3760 0064 06

17 Lifting dog spring 1 3760 0064 00

18 Lifting dog 2 3760 0064 01

19 Pivot pin 1 3760 0064 07

7.1.1 - Spare parts list overshot assembly AO/AOTW

47

1

2

3

4

5

6

7

8

9

10

11

14

12

12

13

15

17

18

19

16

7.1.1 - Spare parts list overshot assembly AO/AOTW

48

7.2 - Spare parts list BOTW

Item Description Qty Part number

Choose core barrel assembly and/or locking coupling part numbers to suit drill rod BGMRod BTTRod

1-37 1.5 m / 5 ft Core barrel assembly 3760 0061 09 3760 0061 10

1-37 3.0 m / 10 ft Core barrel assembly 3760 0061 11 3760 0061 12

1-31 1.5 m / 5 ft Inner tube assembly 3760 0061 13

1-31 3.0 m / 10 ft Inner tube assembly 3760 0061 14

1-28 Head assembly 3760 0061 15

1 Spearhead 1 3760 0044 29

2 Spring pin 1 3760 0043 48

3 Compression spring 1 0384 5000 18

4 Detent 1 3760 0044 30

5 Spearhead base 1 3760 0044 32

6 Latch retracting case 1 3760 0066 74

7 Spring pin 3/8 x 1 5/8 2 0108 1691 90

8 Latch spring 1 3760 0062 17

9 Latch 2 3760 0062 18

10 Latch support 1 3760 0062 19

11 Spring pin 3/8 x 1 1/4 2 0108 1691 39

12 Spring pin 1/4 x 1 1/4 2 0108 1691 34

13 Upper latch body 1 3760 0057 94

14 Landing shoulder 1 3760 0062 97

15 Lower latch body 1 3760 0122 33

16 Lock nut 1 0268 3112 00

17 Spindle 1 3760 0062 20

18 Shut-off valve 2 3760 0062 98

19 Valve adjusting washer 2 3760 0062 22

20 Thrust bearing 1 3760 0064 70

21 Spindle bearing 1 3760 0062 23

22 Hanger bearing 1 3760 0064 70

23 Compression spring 1 3760 0064 76

24 Lock nut 5/8 1 0292 1310 00

25 Inner tube assembly 1 3760 0062 99

26 Grease tting 1 0544 1100 07

27 Ball 1 0517 1428 00

28 Check valve body 1 3760 0077 63

29 1.5 m / 5 ft Inner tube 1 3760 0061 28

29 3.0 m / 10 ft Inner tube 1 3760 0061 29

30 Core lifter 1 3760 0063 01

31 Core lifter case 1 3760 0063 02

32 Locking coupling 1 3760 0061 24 3760 0030 17

33 Adapter coupling 1 3760 0061 25

34 Landing ring 1 3760 0063 03

35 1.5 m / 5 ft Outer tube 1 3760 0061 26

35 3.0 m / 10 ft Outer tube 1 3760 0061 27

36 Inner tube stabilizer 1 3760 0049 10

34 Thread protector (For shipping/Handling purposes)) 1 3760 0063 05

49

29

30

31

36

35

34

33

32

37

1

3

13

8

10

11

12

16

17

18

19

18

20

21

22

23

24

25

27

28

19

26

9

14

15

4

5

2

7

7

6

7.2 - Spare parts list BOTW

50

Item Description Qty Part number

1-19 Overshot assembly complete 1 3760 0048 44

1-6 Cable swivel assembly complete 1 3760 0063 75

1 Cable clamp 1 3760 0064 65

2 Wire line thimble 1 3760 0064 66

3 Eye bolt 1 3760 0072 15

4 Cable swivel collar 1 3760 0072 16

5 Bearing 1 3760 0064 67

6 Lock nut 1/2 1 0292 1408 00

7 Grease tting 1 0544 1100 07

8 Sinking bar body 1 3760 0063 76

9 Jar tube 1 3760 0063 77

10 Lock nut 1 5530 9645 00

11 Jar staff 1 3760 0063 78

12 Locking sleeve 1 3760 0063 72

13 Spring pin 7/32 x 1 1/4 2 0108 1691 85

14 Set screw 1 3760 0070 85

15 Spring pin 3/16 x 1 3/8 1 0108 1691 83

16 Overshot head 1 3760 0063 79

17 Lifting dog spring 1 3760 0063 73

18 Lifting dog 2 3760 0063 74

19 Pivot pin 1 3760 0063 80

7.2.1 - Spare parts list overshot assembly BO/BOTW

51

7.2.1 - Spare parts list overshot assembly BO/BOTW

52

7.3 - Spare parts list NO2/NTO2

Item Description Qty Part number

Choose core barrel assembly and/or locking coupling part numbers to suit drill rod ORod TRod

1-38 1.5 m / 5 ft Core barrel assembly 3760 0051 56 3760 0061 32

1-38 3.0 m / 10 ft Core barrel assembly 3760 0051 57 3760 0061 33

1-32 1.5 m / 5 ft Inner tube assembly 3760 0061 34

1-32 3.0 m / 10 ft Inner tube assembly 3760 0061 33

1-28 Head assembly 3760 0051 61

1 Spearhead 1 3760 0044 29

2 Spring pin 1 3760 0043 48

3 Compression spring 1 0384 5000 18

4 Detent 1 3760 0044 30

5 Spearhead base 1 3760 0044 33

6 Latch retracting case 1 3760 0066 73

7 Spring pin 1/2 x 2 2 0108 1691 80

8 Latch spring 1 3760 0062 32

9 Latch 2 3760 0062 33

10 Latch support 1 3760 0062 34

11 Spring pin 1/2 x 1 1/2 1 0108 1691 43

12 Spring pin 1/4 x 1 1/2 1 0108 1691 35

13 Upper latch body 1 3760 0050 99

14 Landing shoulder 1 3760 0052 41

15 Lower latch body 1 3760 0050 98

16 Lock nut 1 1/8 1 0268 4138 24

17 Spindle 1 3760 0062 35

18 Shut-off valve 2 3760 0062 36

19 Valve adjusting washer 2 3760 0062 37

20 Thrust bearing 1 3760 0064 61

21 Spindle bearing 1 3760 0062 38

22 Hanger bearing 1 3760 0064 62

23 Compression spring 1 3760 0064 63

24 Lock nut 3/4 1 0292 1338 07

25 Inner tube assembly 1 3760 0063 25

26 Grease tting 1 0544 1100 07

27 Ball 1 0517 1100 25

28 Check valve body 1 3760 0072 21

29 1.5 m / 5 ft Inner tube 1 3760 0061 36

29 3.0 m / 10 ft Inner tube 1 3760 0061 37

30 Stop ring 1 3760 0063 26

31 Core lifter 1 3760 0077 64

32 Core lifter case 1 3760 0063 28

33 Locking coupling, tanged 1 3760 0060 26 3760 0060 27

34 Adapter coupling 1 3760 0060 28

35 Landing ring 1 3760 0063 29

36 1.5 m / 5 ft Outer tube 1 3760 0048 37

36 3.0 m / 10 ft Outer tube 1 3760 0048 39

37 Inner tube stabilizer 1 3760 0083 17

38 Thread protector (For shipping/Handling purposes)) 1 3760 0062 45

53

16

1

3

13

8

10

11

12

17

18

19

18

20

21

22

23

24

25

27

28

29

31

32

37

36

34

33

38

30

35

19

26

9

14

15

4

5

2

7

7

6

7.3 - Spare parts list NO2/NTO2

54

Item Description Qty Part number

1-19 Overshot assembly complete 1 3760 0048 46

1-6 Cable swivel assembly complete 1 3760 0063 75

1 Cable clamp 1 3760 0064 65

2 Wire rope thimble 1 3760 0064 66

3 Eye bolt 1 3760 0072 15

4 Cable swivel collar 1 3760 0072 16

5 Bearing 1 3760 0064 67

6 Lock nut 1 0292 1408 00

7 Grease tting 1 0544 1100 07

8 Sinking bar body 1 3760 0063 84

9 Jar tube 1 3760 0063 85

10 Lock nut 1 0292 1308 00

11 Jar staff 1 3760 0063 86

12 Locking sleeve 1 3760 0063 81

13 Spring pin 2 0108 1691 35

14 Set screw 1 3760 0070 85

15 Spring pin 1 0108 1691 87

16 Overshot head 1 3760 0063 87

17 Lifting dog spring 1 3760 0063 73

18 Lifting dog 2 3760 0063 82

19 Pivot pin 1 3760 0063 83

7.3.1 - Spare parts list overshot assembly NO2/NTO2

55

1

2

3

4

5

6

7

8

9

12

13

15

14

19

10

11

17

18

16