Professional Documents

Culture Documents

Air Classifier Article

Air Classifier Article

Uploaded by

Peyman KhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Classifier Article

Air Classifier Article

Uploaded by

Peyman KhCopyright:

Available Formats

I

M

I

4 '

as

m

6

33

i

Although there are a

great many devices that

use air to separate parti-

cles by size, they are all

based on a few general

principles. Here is a run-

down on the way that

they operate, together

with a description of the

principal types of classi-

fiers available.

AIR

CLASSIFIERS

Ivan V Klumpar and Fred N. Currier, Sturtevant, Inc.

Terry A. Ring, Massachusetts Institute of Technology

tfi lassification is the separation of a particulate material into a coarse

g and a fine fraction; the separation is usually by size, but may also be

by other particle properties such as density. Depending on the

equipment used

, classification might also be affected by particle

shape, electric, magnetic and surface properties, and other factors.

For example, density is insignificant when using screens or sieves

,

but is a

major factor in air classifiers where fluid-drag forces are involved

,

as will be

discussed later.

Classification should be distinguished from solid-fluid separation

, although

the two operations overlap and the terms are often used interchangeably. For

example, cyclones are considered separation equipment even though a super-

fine fraction is entrained in the outlet gas and might be recovered in another

separation step - as in a bag filter downstream.

(Although cyclones are very efficient particle-fluid separators in a medium

size-range, they have a low classification efficiency. This efficiency will be

defined later.)

This article is limited to air classifiers that are also called

, traditionally but

less appropriately

, air separators. In such equipment, classification in the

medium to submicrometer particle range -1,000 - 0.1 jam - is effected in a

stream of gas, using a combination of any of the following forces: gravity,

drag, centrifugal and collision. Classification can be done in any gas, but air is

used in the overwhelming majority of cases. However, other gases are advanta-

geous under special conditions, e.g., nitrogen or flue gases if the solid material

is highly explosive.

Other classifier devices, such as grates and screens that operate in the large

to medium particle-size range (500 mm down to 0.1 mm),

will not be considered

in this article.

Early classifiers

Classification equipment evolved from two sources

,

the simple expansion

chamber and the Mumford and Moodie Separator. In the former, coarser

particles drop out of an air stream as its velocity is decreased upon expanding

to a larger space. Baffles,

vanes or other directional and impact devices were

later incorporated in the expansion chamber to change the air direction and

provide collision surfaces to knock out coarser particles.

The Mumford-Moodie Separator

,

patented in 1885, is similar to the Sturte-

vant Whirlwind (Fig. 9). Solids are fed into a rising air stream, using a rotating

distributor plate that imparts a centrifugal force. Coarser particles drop into an

inner cone; the fines are swept upward by the action of an internal fan

,

separated from air between vanes in the expansion section of the outer cone,

and collected at its bottom. The air is recirculated up toward the distributor.

Unlike the Mumford-Moodie machine

, the Whirlwind enhances separation by

an additional rejection device (called either selector blades or a secondary-,

auxiliary- or counter-fan) that knocks out most of the remaining coarse

particles. Thus, the Whirlwind incorporates almost all the features used (in

modified form) in the later air classifiers.

Based on a paper presented at the May 1984 meeting of the Belgian Engineering Stic. in Brussels.

CHEMICAL ENGINEERING/MARCH 3,1986 77

i

nGinRin6FnTUR

Modern equipment types

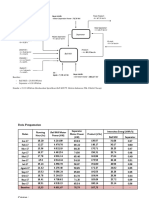

Equipment classification

Air classifiers can be conveniently grouped by the following

criteria (see the table on the opposite page):

. Forces that act on the particles. These are gravity, the

drag force of air, the centrifugal force exerted either by an

air vortex or a mechanical part such as a rotating distributor

plate, and collision force, effective when a particle hits a solid

surface. Collision force becomes an important classification

factor in machines equipped with a rejection device that is

part of the rotor. The rejector preferentially knocks out

coarser particles entrained by the air. The presence of a rotor

is indicated by a positive entry in Column 2 of the table . The

table specifically lists only centrifugal forces (Columns 3, 4);

the other forces are always present. However, some forces

may be insignificant in certain cases. Examples are collision

force in expansion chambers, (Item 1) and gravity in classi-

fiers having a horizontal rotor axis (Item 19).

. Relative velocity and direction of the air and the particles

controlled by the solid feed system, air vector and position of

the rotor if present (Columns 5, 6 and 2, respectively). If

particles enter the classifier with the air, the coarser ones

will separate as the drag force is overcome by gravity and

possibly centrifugal and collision forces). But, if the solids

are fed separately, fines will be swept away by the air, since

the drag force prevails (if the feed is properly distributed).

. Directional devices

, such as vanes, cones, or zigzag

plates, that change flow patterns of the air or particle-air

mixture and provide collision surfaces (Column 7).

Location of the fan and the fines-collection device (Col-

umns 8,9). Although these do not directly affect the separa-

tion process, they are important control and design factors.

For example, the inside collection of fines in the expansion

section of the Whirlwind (Fig. 9) is less efficient than the

Exhaust --

L

Makeup air

Air in

Feed

Inside fan

Classifier

Coarse

Fines

plus air

Air

out

Fines \ /

collector V /

Fines

Figure 1 - Classifier System with outside

fines collector (Sturtevant Superfine Air Separator)

outside fines separation in the cyclone dust-collector that is

part of the external air-recycle loop (Figs. 1,2). Independent

airflow control is difficult if the fan is mounted on the same

shaft as the feeder plate and selection blades

,

as in the

Whirlwind. Separate shafts (possibly concentric

, Fig. 12) can

overcome the problem, but an outside fan (Figs. 2,11) simpli-

fies design and allows precise control of the air flowrate.

Individual equipment types will be briefly discussed below

with reference to Figs. 1 through 19. Published drawings of

some classifiers are difficult to read because of the complex

internal design, but Figs. 1-19 are conceptual sketches that

emphasize important features rather than showing engi-

neering details. Principal parts, such as distributors, shafts,

and the flat surfaces of vanes and blades

,

are drawn in

contours, whereas minor items

, such as spokes, walls and

partitions, are indicated by single lines only. Furthermore,

some parts are left out to show the passage available for air

or particles

, e.g. spokes, fan details, hub walls and other

rotor elements on the left side of symmetrical sections. Air

flow inside the equipment is indicated by heavy arrows.

Classifiers without a rotor

In expansion chambers, coarser particles drop out as the

linear air velocity decreases (when the air-solid mixture.

expands from a duct into a wider space). In the grit separator

and zigzag classifier (Figs. 3

,4), separation is enhanced by

tortuous passages and collision surfaces placed across the

particle trajectories. The grit separator is designed for sepa-

rating small amounts of fines from the bulk of coarse

material. Linear air velocity is controlled by moving the

buoy, or "definer cone" up or down. In the rotary drum

classifier (Fig. 5), the rotational movement stirs the solid

mass to facilitate disengagement of coarse particles from

Intake

air

Exhaust air

I

I

I

Fan

T

i

i

i

i

I

Makeup air

Feed

Outlet air

Fines

plus air

Classifier

Cyclone

Coarse Fines

Figure 2 - Classifier system with outside fan and fines collector -

broken lines indicate optional air-recycle subsystem (Sturtevant SD)

v

78 CHEMICAL ENGINEERING/MARCH 3, 1986

Table - Air classifiers: devices for separating particulate material into a coarse and a fine fraction, using a gaseous entraining medium

Rotor

axis

No. (if any)

1 2

Plane of

centrifugal force

generated by

Inside or

Station- outsidea

Solid Principal arydi-

Fines

col-

feed air rectional

Air Feeder system direction device Fan lector

3 4 5 6 7 8 9

Example of

classifier

(separator)

10

Maximum

capacity b Maximum Fig.

t/h energy No. Ref.

12 11 13 14

1 None None None Air Various None Out Out Expansion chambers Plant - - 1

2 None None None Air Vert. Buoy0 Out Out Sturtevant Grit 500 130 m3/s 3 2

3 None None None Chute Vert Zigzag Out Out Alpine Zigzag 100 NA 4 3

plates

4 None None None Belt Horiz. None Out Out Iowa Mfg. Rotary Drum 50 16 m3/s 5 4

5 None Vert. None Air Vert. Incl. Out Out General Electric Buell Plant 460 m3/t 6 5

6 None Vert. None Air Vert lnclc Out Out Hukki Centrifugal Plant NA 7 6

7 None Horiz. None Air Horiz. Portsc Out Out Hardinge Double Cono Plant NA 8 7

8 None Horiz. None Air Honz. Vert pipe Out In Cyclones Plant 24 m3/s - 8

9 Vert. None Horiz. Rotor Vert. None In In Sturtevant Whirlwind 2,700 600 kW 9 9

10 Vert. None Horiz Rotor Vert None In Out Sturtevant Superfine 5 75 kW 10 9

11 Vert. None Horiz. Rotor Vert None Out Out Humboldt Wedag 1,500 1,000 kW 11 10

Cyclone. Air

12 Vert.6 None Horiz. Plate6 Vert. None lne In Polysius Turbo . Plant NA 12 11

13 Vert. Horiz. None Air Vert. None Out Out Donaldson Majac 6- NA 13 12

14 Vert Honz. None Air Horiz. Vert, vanes Out Out Onoda O'SEPA 1,400 800 kW 14 13

15 Vert Horiz. None Chute Horiz. None In Out Donaldson Acucut 0.01 6 kW 15 14

.16 Vert. Honz. Horiz. Rotor Horiz. None In In Alpine Microplex MPV 13 \ 30 kW 16 3

17 Vert. Honz. . Horiz. Rotor Horiz. Vert, vanes Out Out Bauer Centri-Sonic 10 56 kW 17 15

18 Vert. Horiz. Horiz. Rotor Horiz. Cones'

"

Out Out Sturtevant SD 1,400 500 kW 18 16

19 Horiz.S Vert. None Chute Vert. None In Out Alpine Microplox MP 1.6 19 kW 19 3

Notes: Vert. = vertical; Horiz. = horizontal; Incl. = inclined; NA = not available;

a. Classifier systems with outside fan and fines collector are shown in Fig. 2; those with inside fan and outside fines collector are shown in Fig. 1.

b. If precise capacity is not known, or dependent on specific model, "Plant" denotes up to approximately 100 tons/h.

c. Adjustable

d. Because of low classification efficiency, cyclones are not considered to be classifiers.

c. Fan is independent of rotor with feeder and selector blades. . v

f. Alternatively horizontal vanes or none.

g. Gravity not used in classification:

t

Fines plus air

-

Buoy

Coarse I

f

t %' 1 Feed plus air

Figure 3 - Diagram of the Sturtevant grit separator

Fines plus air

Screens

Coarse

Feed

>

Air

J

Figure 4 - Alpine Zigzag cassifier employs tortuous passages

CHEMICAL ENGINEERING/MARCH 3,1986 79

"

.VV

nGinRinGFnTUR

fine ones that are then entrained by the air and dropped out

upon expansion in the fines collector.

The gravitational-inertial and centrifugal classifiers (Pigs.

6

,7) use the centrifugal force generated by the rotational

flow of air that is directed by wall curvatures and vanes. The

Hukki machine has adjustable vanes and a horizontal air-

outlet virtually perpendicular to the plane of rotation. In the

double cone classifier (Fig. 8), air develops a rotational flow

as it passes through adjustable peripheral ports in the upper

part of the inner cone. Unlike the grit separator

'

s buoy, this

Air

Fines collector

Rotating drum

Ar

Feed

Belt feeder

Coarse

Fines

Figure 5 - Iowa Manufacturing Co.'s rotary drum classifier

Fines plus air

Vanes-

Secondary air

r %

t

\

ft

i Coarse

Feed plus air

Figure 6 - General Electric Buell gravitational-inertial classifier

device's buoy serves as an air lock for the coarse material

,

that flows down after being separated in the inner cone.

Updraft and sidedraft classifiers

The classifiers of Figs. 10-12 are modifications of the Whirl-

wind (Fig. 9). We call them updraft machines because the

principal air direction in the critical separation zone is verti-

cally Upward, The central part of the rotor is a hollow hub

suspended on a vertical shaft. (Only selected elements of the

hub are indicated in the figures.) Two plates, an upper and a

Plan view

t

Fines

Section

/

Feed plus air

V N

Adjustable vanes

Coarse

Figure 7 - Hukki centrifugail classifier uses rotating airflow

t

Fines plus air

Port

Buoy-

Coarse

ray

ID

0

t

-Coarse material

passage

Feed plus air

Figure 8 - Hardinge double cone classifier also uses rotating airflow

80 CHEMICAL ENGINEERING/MARCH a, 1986

lower, are mounted on the hub; the upper plate provides

support for the selector blades. The Whirlwind and Super-

fine air separators have a fan mounted on the upper part of

the hub; the Turbo Separator has a separate fan shaft. The

cyclone air separator has an outside fan (see Fig. 2).

The material, fed via a top or side chute, passes along the

shaft and through ports in the hub wall to the lower distribit

tor plate, which spreads the feed into the ascending air. The

coarse particles either drop directly or are rejected by the

selector blades into the inner cone; fines are carried over to

Feed

Selector blade

/Fan blade

Port V--:

Shaft

Damper

-

Hub wall

Ar

Coarse

Fines

Distributor

Expansion

section

Return air vane

Figure 9 - Sturtevant Whirlwind air separator

Feed

,

Shaft

Selector-

blade

Port -

Distributor"

.

Fan blade

Fines plus

air outlet

(to cyclone)

~~

Hub wall

v

Coarse

Air (from

cyclone)

Figure 10 - Sturtevant Superfine separator-a modified Whirlwind Figure 12 - Polysius Turbo separator has separate fan shaft

the vessel's top. The upper plate redistributes any rejected

particles toward the shaft. In the Whirlwind and Turbo

classifiers, fines are then swept down the annular space

along the wall of the external cone, and are collected at the

bottom. Air, separated from the fines in. the expansion

section and between the vanes, is returned to the rotor. In

the Superfine (Fig. 1) and cyclone (Fig. 2) classifiers

,

fines

are separated in outside collectors. The Majac Air Classifier

(Fig. 13) operates on the same principle as the cyclone

classifier (Fig, 11) except that feed is introduced in a stream

-Shaft

Selector blade-

Fines plus air

(to cyclone)

Feed

1

i- \

- Hub wall

Port

_

Distributor

| Coarse

Air

(from fan)

Vane'

Figure 11- Humboldt Wedag cyclone air classifier

Outer shaft

Selector v

r Inner shaft

- Fan blade

Feed

Hub wall

-Distributor

bade

Port

Vane

Coarse -<-

Fines

1

Expansioir'

section

CHEMICAL ENGINEERING/MARCH 3,1986 81

nGinRinGfenTUR

-Shaft

Blade-,

3

Fines plus air

Rotating plates

Feed plus air

/

/ Secondary air

Coarse

Figure 13 - Donaldson Majac air classifier is similar to cyclone type

Shaft

Fines plus air

Blade

Annular space

Volute'

Tertiary air

sSpoke a

ir inlet

Blade

Section

Plate

Coarse

Plan view

o

y

t

-Vane

Feed plus

Feed plus air

-

Volute

Secondary air

Vane

-

--/- Radial air flow

Tangential air flow

Note: Spokes not shown

Figure 14 - Onoda O'SEPA air separator uses an external collector

Feed

-Shaft

Distributor

Fines collector- Coarse

\

Fines

Spiral fan

Figure 15 - Alpine Microplex MPV spiral air classifier

Section

Feed

Coarse

t

Fines plus air

/Blade

0

=

t

Shaft

Plan view

Coarse

Feed

\

Blade

Radial air flow

Figure 16 - Donaldson Acucut laboratory classifier

82 CHEMICAL ENGINEERING/MARCH 3

,

1986

of air. The secondary air and the rotating plates have func-

tions similar to the Whirlwind's return air and upper plate.

Classifiers that have a horizontal air-stream acting on the

particles are conceptually different from the previous ma-

chines. (Plant-size machines with a rejector will be called

side-draft equipment in this article.) In the O

'

SEPA, Centri-

Sonic and SD classifiers (Figs. 14,17,18), all or most of the air

is blown (by an outside fan) tangentially through a volute

that provides an even radial distribution. Particles carried by

the air (in the O'SEPA) or thrown horizontally into the air

stream by a distributor (in the other two machines) are

classified in a narrow separation zone in front of the rotor.

Coarse particles drop through the annulair space between

the rotor and volute into one or more collection cones, either

directly or after being rejected by the blades or pins of the

rotor. Fines are swept inside the rotor and pass to external

collectors either through a top discharge (O

'

SEPA), bottom

air-swept volute (Centri-Sonic), or streamlined by horizontal

vanes or inclined deflector cones (SD). The cones have the

additional advantage of preventing particles from leaving

the narrow separation zone before the radial air stream can

act on them. The O

'

SEPA and Centri-Sonic horizontal rotor

plates are claimed also to have a streamlining effect.

Section

Distributor

Plate--

I Feed

~ , .. Air

.

| y

Spoke ,Vane ,

V0|ute

5 d.

Blade-

Shaft

Ar

f recycle

Air inlet

Fines plus air outlet

Coarse

Plan view

f

Fines plus

air outlet

Air in et

\

Vane

\

Fines

volute

Blade-

.

Air

volute

-

Annular space

Radial air flow

Tangential air flow

Figure 17 - Bauer Centri-Sonic classifier is a side-draft type

Miscellaneous equipment

The remaining air classifiers have diverse designs. The

Acucut Laboratory Classifier (Fig. 16) feeds material

,

by

gravity, radially against a rejector into an air stream that has

a virtually horizontal direction in the separation zone. The air

is sucked in from the bottom, and entrained fines leave the

classifier through the top and pass to an outside collector;

coarse product is rejected tangentially. The fan is down-

stream from the collector.

The Microplex MPV Spiral Air Classifier (Fig. 15)

,

with its

inside fines collection

,

can be considered a modified Whirl-

wind-type, with a horizontal air flow in the separation zone.

It differs, of course

, in that the f an also acts as a rejector, the

distributor is above it, and the fine and coarse products

separate in the inside and outside cones

, respectively.

The Multiplex MP Spiral Air Classifier has a fan mounted

on a horizontal shaft (Fig. 19). Material is fed by gravity

between the fan and a vertical distributor plate. Air is

introduced into the same space from the bottom. Entrained

fines leave tangentially from the top. The coarse product is

rejected vertically and removed by a horizontal screw located

at the top of the machine, off the feed chute.

Section Feed

Single deflector

i

-eea

ws

Posts/Pins-

Partition--' -j

Shaft

/ Distributor plate Ajr

volute

4.

[-|-Multiple

deflectors

Annular space-j-

Chamber-

Note: Left side of drawing shows

volute without muttiple deflectors.

Airflow

Coarse

Plan view

Chamber s

Annular space

/f.

Deflectors

/

y

X

Fines plus air

Air inlet

Posts/Pins-

Radial air flow

Air

volute

-

Partition

/

7 Tangential

air flow

Airflow

Figure 18 - Sturtevant SD classifier-another side-draft type

CHEMICAL ENGINEERING/MARCH 3,1986 83

enGinRinG FRTUR

Particle dynamics

Bases for design

Classifier designers take advantage of a number of phenom-

ena: small particles fall more slowly in air than do large

particles; larger particles have a greater centrifugal force in

cyclonic flow than do small particles; smaller particles have

less inertia and can change their direction of flow easier than

can large particles; larger particles require a higher convey-

ing velocity; and larger particles have a higher probability of

collision with a rotating blade. A classifier is designed so that

there

,

is a mihimum of material interference among the

particles in the classification zone.

Forces

Forces acting on the individual particles are responsible for

directing large and small particles into their respective col-

lection chambers. The forces that act on particles during air

classification are: (a) gravity, (b) aerodynamic drag

,

(c) cen-

trifugal force, and (d) collision force. Each of the various

Fines plus air

t I

Feed

Blade--.

.

Spoke -

Shaft

: .!. /

'Screw

V V

j .--Distributor

Coarse

-Air inlet

Figure 19 - Alpine Microplex MP spiral air classifier

types of equipment uses one or more of these forces. The

interplay among these forces is complex and not very well

understood. Hence, no comprehensive mathematical model is

available to describe air classifiers.

The forces in action

All the forces listed above are used by the Sturtevant SD

Classifier (Fig. 18), so this device will be taken as an example

in the following discussion. Furthermore

,

in this machine

,

centrifugal forces are caused by both the rotor and the flow

of air through the volute, unlike the forces in updraft.

classifiers.

(The individual expressions for the forces will be valid for

other air classifiers. However, the directions of the force

vectors may be different and some of the forces may not be

necessary.)

The feed is introduced into the Sturtevant SD Classifier at

the center of a horizontal rotating feedplate. Friction with

Nomenclature

C Drag coefficient

E ~ Efficiency

M Cumulative mass percenl

R Recovery

iV#e Reynolds number

Nst Stokes number -

S Selectivity

V Angular velocity

W Mass flowrate

Y Yield

a Apparoni lAjiahs

d Diameter

/ Force

g Gravitational constant

m Mass

r Radius

s Sharpness index

u Slip velocity

v Velocity in general

Greek letters

ju. Viscosity

ir = 3.1416

p Density

2 Summation

Subscripts

C Centrifugal

D Drag

G Gravity

a Angular

c Coarse

/ Fine

i Force in general

k Capture

84 CHEMICAL ENGINEERING/MARCH 3,1986

*

the plate accelerates the particles radially. Once the particles

have an angular velocity, their centrifugal force accelerates

them and they bounce and roll to the outside edge of the

feedplate, where they fall off. The final velocity attained by

the falling particles will approach that of the angular veloci-

ty of the outside edge of the feed distributor plate. The

direction of this velocity vector is tangent to the circumfer-

ence of the distributor plate.

Once in the air, the particles encounter gravity, aerody-

namic drag and centrifugal force vectors,/ i, that change the

velocity vector, v, both in direction and in magnitude, accord-

ing to Newton's Second Law [27].

m dv/dt

(1)

where m is the mass of the particle (also pncPlb for a sphere

of diameter d and density p). The gravity force, f q, will be

directed downward in the classifier, as shown in Fig. 20, and

will be given by \17\.

fG = m(p-PAir)g (2)

where g is the gravitational constant.

Particle feed

Direction of rotation

H

A

1

fc

6>

:

\1

R

T

8

To coarse

particle -

cone

T Tangential air flo'

R Radial airflow '

To fine particle chamber

Figure 20 - Forces acting on a particle in a Sturtevant SD classifier

Air enters the classifier tangentially and then gradually

turns radially into the rotor. The net slip-velocity vector, u

.between this airflow and the velocity of

_

the particle will lead

to an aerodynamic drag-force vector,//) (given below) [18]

that will act in a direction opposite to the slip velocity vector,

as shown in Fig. 20.

fo = V4TTd2 X V2pAiru2 C

d

In the above expression, VivrcP is a characteristic area,

VzpAirU2 is a characteristic kinetic energy for the flow,

and

Cd is the drag coefficient. For spheres, the drag coefficient

is given as a function of Reynolds number (A e = upd/fj.)

[18], as shown in Fig. 21. At low Reynolds numbers (i.e. Njse

< 1.0), Stokes Law applies, reducing the drag force to the

simple formula [18]:

7d = (4)

Owing to the forces acting on the particles, there may be a

component of angular velocity, Va, in the particles' motion.

This

_

component will give rise to the centrifugal force vector,

[Wo-

_

fc=mVllr (5)

directed radially as shown in Fig. 20 from the radial position,

r

, of the particle.

The magnitude of all these forces is highly dependent

upon the diameter of the particle, either through its depen-

dence on the mass of the particle

, which is equivalent to

p7rcP/6, or through the drag coefficient and characteristic

area. As a result, the large particles will be affected most by

gravity and centrifugal forces and least by aerodynamic

drag, and so will end up in the coarse-particle chamber.

Intermediate-sized and fine particles will be affected most

by aerodynamic drag and affected least by gravity and

10*

103

Q

10z

.2

2

it

o

10

as

Q

1

Intermediate law

Stokes law

s a

0.1 L

10 102 103 10* 10-3 io-z 10-1 i 10= 106

Reynolds number, Afee

Figure 21 - Drag coefficient: spheres moving relative to a fluid [78]

03-

A. Direct interception

d

r

in

B. Inertial inpaction

Figure 22 - Streamlines and particle trajectories approaching a pin

CHEMICAL ENGINEERING/MARCH 3,1986 85

cnGin&nmGFCflTuite

1 iV"-"'.

1

102

10

Stokos' law

.2

o

u-d

Sphere

CO a

a J.

10-'

V

Ellipboid 1 0 75

(-

-

l

Ellipsoid 118

10-2

2X10-1 1

_L_ _l_ I _1_

10 102 103 10* 10s 106

Reynolds numt3er, NRe

Figure 23 - Capture efficiency by inertial

impaction on an isolated cyclinder (Taken from Ref. 22)

centrifugal forces, and will be directed into the rotor. Suffi-

ciently small particles will pass through the pins without

contact and out through the fine-particle chamber with the

bulk of the airflow. (Fine particles are separated from the

airflow by an external cyclone.) The intermediate-sized parti-

cles impact the pins and are redirected into the cOarse-

particle chamber.

Collision

For collision to occur, a particle must be aerodynamically

captured by the rotating pin. There are primarily three ways

for this to occur (Fig. 22): (a) direct interception, (b) inertial

deposition, and (c) electrostatic precipitation Electro-

static precipitation and other mechanisms of capture such as

diffusional deposition and thermal precipitation will not be

discussed in this section, as they affect only the smallest

particles that might remain stuck to the pins until being

knocked off by large colliding particles.

The efficiency of capture, is given by the ratio of the

cross-sectional area of the fluid stream from which all the

particles are removed to the cross-sectional area fprojeeted in

the flow direction of the pin.

Each capture mechanism has its specific capture-efficien-

cy relationship. For direct interception, the capture efficien-

cy [19] is given by:

Ek = (1 + d/dpiJ - (1 + d/dpin) -1

(6)

For other geometries, other capture-efficiency expressions

will apply. A discussion of flat plate geometry is given by

Rajhans [SO], and one for spheres is given by Ottavio and

GorenJM

For inertial collision, the capture efficiency is a function of

the Stokes number, as shown in Fig. 23 where the Stokes

number is given [Iff] by:

~

Nst = (VPinp(P)/(l8judpin) (7)

Where VH is the angular velocity of the pin. Other geome-

tries are discussed in Refs. 19-21. The total capture efficien-

cy for both mechanisms is simply the sum of the efficiency

from all the active mechanisms. For air classification using

86 CHEMICAL ENGINEERING/MARCH 3,1986

1.01- -

0.8 -

Uj

c 0

.

61-

.5

cd 0.4 -

0.2

0

0

i

T

_1_

i. I

1 2 3

Square root of Stokes' number, /VSf

4

Figure 24 - Drag coefficient for submerged bodies (From Ref. 24)

the cylindrical pins of the SD Classifier, the capture efficien-

cy is dependent on the angular velocity of the pins

,

the

number of pins on the circle

, the diameter of the pins, and the

diameter and density of the particles. As a result, both the

feed characteristics and the operating conditions will deter-

mine what intermediate sizes will impact the pins and be

directed back toward

/

the coarse-particle chamber. The force

that is imparted to a particle during contact with a pin will

determine its rebound velocity.

Once a particle is in free flight again, gravity, drag and

centrifugal forces must be accounted for to establish the

dynamics of the particle. With a sufficiently large collision

force, particles may fragment, resulting in the comminution

of the feed.

Nonsphericai particles

In the preceding sections, it has been convenient to define a

spherical shape equivalent in volume to irregularly shaped

particles. This is a typical simplification used throughout the

air classification industry, but it is fundamentally in error.

For irregularly shaped particles, the specific drag force will

not be parallel to the motion of the particle unless the particle

has a certain symmetry or a specific orientation. For most

real particles, the drag force will cause the particle to rotate

as well as to change translational velocity. Therefore, both

force and moment analyses must be performed for precise

accuracy.

Moment analysis adds a level of complication that is often

neglected. The drag on irregularly shaped particles is dis-

cussed in detail by Clift, Grace and Weber [33].

Basically, the irregularly shaped particle gives rise to a

different drag-coefficient-versus-Reynolds-number expres-

sion, as shown in Fig. 23 for simple geometries. For aspect

ratios less than 1, the drag coefficient is less than that of an

equivalent sphere, while for aspect ratios greater than 1, the.

drag coefficient is greater than that of an equivalent sphere.

Equations describing the gravity and centrifugal forces for

irregularly shaped particles will differ from an equivalent

sphere if the movement of the center of mass of the particles

is considered.

Measuring classifier performance

Size selectivity, recovery and yield

Size selectivity is the best meausre of classifier performance

under a given set of operating conditions. Size selectivity, S,

is defined as the ratio of the quantity of particles of size d

entering the coarse stream to the quantity of size d in the

feed. The equivalent mathematical expression is, on a mass

basis [25]:

'

S = WCM /{WCM + WfMj) (8)

where Wc is the mass flowrate of the coarse fraction; W/is

the mass flowrate of the fine fraction; Mg is the cumulative

percent mass of the coarse stream less than size d, and il is

the cumulative percent mass of the fine stream less than size

d. Selectivity of a typical air classifier is plotted as a function

of size in Fig. 25; selectivity monotonically increases from 0

to 1 as size increases (Curve b-b').

While size selectivity is a complete measure of classifier

35

30 -

25 -

20 -

15 h

10

5

0

35

30

25

5? 20

>

<: 15

~

r

A a = 0 s = 1.0 crS0=150jim

-

i (i ii

Coarse

Fines

Feed

j i i i

i i i n l

1

r

-

i ii I ii i I r i i ii i

C a = 0 s = 0.6 d5o = 122.5ju.m

Fines

Feed

Coarse

i i i i i i i I L_J

I I I I I I

10 -

5

0

i

1

-~

\

-

i

-

i i i i

I III H |

B a = 0.3 S 1.0 50 = 150: jim

10

Fines

Coarse

Feed

I : I l * ' <

100

D

, j

xm

-.1

' ' ' ' . l

1

1

1

1 I I I I | , 1 1 1 1-I I I I p

D a = 0.3 s = 0.6 d50 = 122.5ju.m

Fines

1

,

000 10

Coarse

i i i

< ' i i

100

D

, jLtm

Feed

-

i 'i ' '

1

,

000

Figure 25 - Size distributions for various types of air classifier performance

CHEMICAL ENGINEERING/MARCH 3,1986 87

nGinMnGFflTUft

performance, the user is often required to take a shortcut

method of expressing performance on a specific feed materi-

al. A practical measurement of overall classification perfor-

mance for a given application can be obtained by calculating

recovery and yield. Recovery is the relative amount of

material in the feed that is finer than size d that is recovered

in the product. Recovery, R, expressed as a fraction of the

feed can be calculated from the cumulative particle-size-

distribution data as follows:

When the fine stream is the product \25\.

Rd

i

f= WfMp{WfMf+ WCM$) (9)

and when the coarse stream is the product [#5]:

Rcj= WcMd c/(WfMj + Wc

Mi) (10)

The difference between the fine and coarse stream recov-

ery is sometimes called classifier efficiency.

Yield, on the other hand, is a measure of the product

obtained regardless of quality, and is calculated as a fraction

of the feed:

When the fine stream" is the product [ 5]:

F/= Wf/(Wf+ Wc) (11)

and when the coarse stream is the product [f5]:

Yc=Wc/(Wf+Wc) (12)

Classifier efficiency

The perfect classifier would send all particles in the feed

larger than a designated "cut size" to the coarse stream

,

and

all the particles smaller tha>n the designated cut size to the

fine stream. This assumes that size is the only characteristic

influencing particle trajectories. Other characteristics such

as

"

specific gravity and shape will also affect the forces

acting on the particles and influence their trajectories. For

this reason, size, shape and specific gravity will significantly

affect an air classifier

'

s performance.

Real classifiers suffer from two types of inefficiency. The

first type occurs because the trajectory taken by a specific

particle size varies from particle to particle. The probability

that a particle smaller than the cut size will end up in the

coarse stream is not 0. Instead, the probabihty increases

monotonically from 0 for particles much smaller than the cut

size to 1.0 for particles much larger, resulting in misplaced

material (see Fig. 25). The identity of the cut size is lost in

real classifiers. A substitute, d o, is used that is the size of

the particles whose probability of entering either stream is

50%.

A measure of the slope of the probability function at is

the Sharpness Index, s, which is the ratio of size of the

particles whose probability of entering the coarse stream is

25% to the size of the particles whose prbbability of entering

that stream is 75%.

s = d ldi*,

(13)

An ideal classifier would have a Sharpness Index of 1.0; real

classifiers have values less than this: Industrial classifiers

operating properly will have Sharpness Index values be-

tween 0.5 and 0.8. Actual Sharpness Index values will change

as a function of the properties of the feed and operating

conditions.

The other type of air classifier inefficiency is the Apparent

Bypass, a. If, because of mutual interference or other rea-

sons, some of the feed material bypasses the separation and

reports to either the fine or the coarse stream, then a certain

percentage of one of the product streams will have the same

particle size-distribution as the feed material. Both the Ap-

parent Bypass and the Sharpness Index dictate the perfor-

mance of air classifiers \25\.

Effects of Apparent Bypass and Sharpness Index

A comparison of the effects of Apparent Bypass and

Sharpness Index On the particle size distributions of the

coarse and fine streams is given in Figs. 25, A-D. In each

figure, the product is defined by a single control point (i.e.,

95% less than 150 jum) and is being produced from the same

feed (i.e., 50% less than 150 fxm). Fig. 25A shows the results

from an ideal classifier where the Apparent Bypass is 0 and

the Sharpness Index is 1.0. Fig. 25B shows the results from a

real classifier with an Apparent Bypass into the coarse

stream of 30% (a = 0.3, s = 1.0). Bypass into the coarse

stream is essentially the only type of bypass observed in air

classification equipment.

The Apparent Bypass does not affect the size distribution

of the fine stream. However, it does affect that of the coarse

stream; the ratio of the coarse stream mass to the fine

stream mass increases, and the recovery of 150-ju,m particles

decreases.

Fig. 25C shows the results from a real classifier having a

Sharpness Index of 0.6 (s = 0.6, a = 0.0). The cut size, d ,

must be lowered to achieve the desired control value of 95%

less than 150 jum. This trend is typical of classifier behavior.

The lower the Sharpness Index, the smaller the cut size

required to produce the desired single-point

'

control value.

Fig. 25D represents a typical industrial aif-classifier having

100

b a

'

c

CO

50

CO

c

b a

0

05 00

0%

Particle dia., D, (u.m

Figure 26 - Types of size selectivity curves

88 CHEMICAL ENGINEERING/MARCH 3,1986

both types of inefficiency (a = 0.3 and s = 0.6). The ratio of

the coarse stream mass to the fine stream mass is f urther

increased and the recovery value of the 150- ,m particles is

further decreased by the combination of both types of

inefficiency. '

The effects of bypass on size selectivity are shown in Fig.

26. Bypass reporting to the fine stream moves from Curve b

to Curve c. Bypass reporting to the coarse stream moves

from Curve b' to Curve c'. Grinding of the particles by an air

classifier will give rise to a size selectivity curve such as d.

Analysis of various types of industrial classifiers has led

to the observation that the Sharpness Index is essentially

constant for a classifier (with a fixed geometrical configura-

tion) over its normal operating range. Assuming that bypass

is minimal, only two things affect the size distribution of the

fine stream - the size distribution of the feed

,

and the cut

size. Hence, if the size distribution of the feed is constant

,

only the cut size ( 50) will affect the size distribution of the

fines. Bypass can be minimized by proper design and opera-

tion of the feedplate, and other design factors.

Design and operation

Applications

Air classifiers are used in many solids-processing plants,

such as those in the chemical, pharmaceutical, food, pigment,

coal, mineral, metal and cement industries. The equipment

can operate in an open or closed circuit with a grinding mill.

An example of an open circuit operation is coal dedusting.

Comminution of coal to small sizes is done in several dry

and/or wet stages. If a coal slurry is required (e.g., for

physical beneficiation, chemical cleaning, or slurry transpor-

tation), it is sometimes desirable to use dry grinding and

separate the fine fraction before slurrying the coal, to avoid

the expensive handling of sMdges that are left after coal has

been separated from the liquid. The separation of the fine

coal fraction, or dedusting, can be effectively done with a

classifier after the milling and before the slurrying step. The

fine fraction might be briquetted or discarded.

An example of an air classifier in closed circuit with a

grinding mill (see Fig. 27) is a cement plant [Sffj. The raw-mill

or finished discharge is fed to a classifier. The fine fraction is

Classifier feed

Classifier

Bucket

elevator

Mill

discharge

Fine product

Tails

Mill feed

Mill

Figure 27 - Classifier in closed circuit with mill

the intermediate or final product

,

while the coarse fraction

(or tails) is recirculated to the mill. The circulating load or

mass ratio of feed to tails is related to classifier recovery.

The higher the recovery, the lower the circulating load and

the smaller the equipment and power requirements of the

circuit.

Some air classifier types have been modified for cooling

,

heating or flash drying of the solids, using cold or hot air

[2?]. A typical cement-drying system using a modified Whirl-

wind is shown in Fig. 28. Hot air at 450

C is supplied by a

burner at a rate of approximately 140 m3/ton of feed having

up to 8% moisture. The air passes through the classifier and

is exhausted to a bag filter at 80C.

Equipment specification, cost and selection

Air classifier capacities range from 1-kg/h solids throughput

for small laboratory units.to 3,000 tons/h for large equip-

ment in cement manufacturing or coal preparation (see

Column 11 in the table). Column 12 of the table lists the

n

Moist

cool

air to

bag filter

Hot dry

air from

burner

Figure 28 - Drying in a Whirlwind air classifier

CHEMICAL ENGINEERING/MARCH 3,1986 89

nGinRinGFnTUR

maximum energy requirements of the individual equipment

examples. Equipment prices in 1984 dollars range from

$10,000 for the smallest laboratory models to $300,000 for the

largest standard classifiers, i.e. units having an internal fan

and fines collector. Systems with outside fans and cyclones

might cost twice as much or more. Any classifier or classifi-

cation system price can be scaled up or down using the

equation:

Cost/Reference cost =

(Throughput/Reference throughput)6 (14)

where the exponent e - 0.46 for standard classifiers (1 to 8

m dia.). Installation-material and labor costs vary widely

with geographic location and overall plant design. The large

standard classifiers (3 to 8 m dia.) require a five to six man

erection crew with total workhours rising from 0.061 to 0.084

per 1 m2 cross-sectional area as the size increases. During

regular operation, large automated classification systems

need very little attention by plant personnel. For a typical

entire closed circuit shown in Fig. 27 the allocation of 0.5

operator workhours/shift suffices.

For the selection of air classifiers, empirical relationships

have been developed by equipment manufacturers, particu-

larly for the cement industry. Fig. 29 shows the correlation

between recovery and fineness of product that can be used

for standard classifiers in conjunction with Eqs. (9) and (10).

Selection of the right size of this equipment type is facilitated

by Fig. 30, which shows the correlation of fines production

rate with classifier diameter, and with product quality ex-

80

i i ---i

70

60

8

2 50

DC

40

30 -

J

60 70 80 90

Fineness, Mf, %

100

Figure 29 - Fines recovery: % of given size (cumulative) that goes to

fine product, vs. fineness (% passing that size screen). See Eq. (9)

pressed as the percentage of the plus 74 and 90 ju,m fraction

[13]. Both Figs. 29 and 30 are valid for cement and similar

materials having a density of around 3 g/cm3 hut the data

might be roughly adjusted to other materials as well as to

diiferent equipment types, using concepts and equations

discussed in the Particle Dynamics section above. The nomo-

graph in Fig. 31 is an example of a density correction method

for the production rate on the Y-axis of the chart in Fig. 30.

Before using the chart, the required production rate is

multiplied by the factor read from the nomograph.

Performance

The classification process is primarily the result of the

balance of at least two of the four forces that may act oh the

particles-i.e., collision, drag and centrifugal forces, and

gravity. Collision is controlled by mechanical devices, partic-

ularly the rotor, the speed of which can be varied. Stationary

directional devices affect classification only indirectly, in

most cases by speeding up or slowing down the air and/ or by

turning it in the desired direction. The drag force is con-

trolled by the air vector

, i.e., the velocity and direction of the

air. This can be again varied. Centrifugal force is generated

either by the rotor or by rotating air. The air rotation can also

be conveniently expressed in terms of the air vector. Finally,

gravity is independent of the equipment and airflow. It can

be seen that the two most important variable parameters

that control classification are the air vector and rotor

characteristics.

To discuss performances of all commercial classifier types.

1

,

000

5

% Residue, 325 mesh

10 15 25 30

500

26

24

200 22

20

18

100

o

16 o

3 50

14 ra

3) a.

12

20 10

ID

N

O

8

10

6

5

4.5

3.

1.67

2

1 2. 3 4 6 8 10 20 30

% Residue, 200 mesh

Figure 30 - Whirlwind size selection: Size (ft. dia.) as a function of

fines production rate (t/h) and quality (% on 170 or 200 mesh screen)

90 CHEMICAL ENGINEERING/MARCH 3,1986

listed in the table, and how each is affected by equipment

design and operation control, is beyond the scope of this

article. The discussion will be limited to rotor-equipped large

industrial units. The reader will be able to apply the follow-

ing concepts to simpler equipment without a rotor and to the

smaller units. There are two basic categories of rejector-

equipped large industrial classifiers, the traditional updraft

machines with vertical airflow (Figs. 9-12) and the new side-

draft equipment with horizontal airflow (Figs. 14,15).

Classifier yield increases with linear air velocity in the

separation zone upstream from the rotor, and generally

decreases with increasing rejection that, in turn, is controlled

by raising the speed and active surface area of the rejector.

As this area is usually provided by a set of rejection elements

such as blades or pins, yield decreases with the increasing

size and number of rejection elements. The rejector preferen-

tially knocks out coarser particles. Accordingly, product

fineness or the ratio of fine to coarse particles in the fine

product increases with rotational speed and with the size and

number of rejection elements.

Performance of a classifier can be controlled by selecting

or designing the machine for a particular application, setting

certain equipment parameters in ad-

vance before startup, and varying oth-

ers during operation, either manually

or as part of an automatic control sys-

tem in response to changes in process

parameters such as feed available or

products desired. The required perfor-

mance is virtually attained by carefully

balancing rejection and air velocity. x

There obviously are limits to the height of the separation

zone, dictated by equipment cost and, for an updraft classi-

fier, by requirements for the power to pump the air through

longer passages. In the sidedraft machines, the increase in

volute height to match the rejector height causes problems

for the even vertical air-distribution that are best solved by

horizontal vanes or conical deflectors (Fig. 18).

Fines bypassing is most serious in updraft classifiers

having an internal fan and a fines collector. It is caused by

the inefficient separation of air from particles in the expan-

sion section (Fig. 9). The particles slide down the outer cone

while the air is returned to the separation zone. The more

particles stay entrained the higher the buildup of fines in the

return air and the more fines eventually end up in the coarse

product. This type of bypassing has been successfully re-

solved by the introduction of outside fans (Fig. 2) at the price

of higher capital and power costs.

A less-serious bypassing occurs in the side-draft classi-

fiers as some of the particles are thrown outside the separa-

tion zone and deposit at the bottom of the volute at the

vertical outside wall where the tangential air velocity is

relatively small. While coarser particles settle down prefer-

Equipment design

Classification efficiency is negatively-

affected by two factors [28]: entrap-

ment of fine particles by coarse ones,

and fines bypassing. The former can be

overcome by spreading the descending

curtain of particles evenly across a wid-

er area and providing a longer resi-

dence time in the separation zone.

The shape of the curtain can be con-

trolled by the rotational speed and form

of the distributor, as well as by the

aerodynamic design of the surrounding

space. For example, in an SD Classifier

version without the multiple deflector

cones shown in Fig. 18, the even density

of the curtain is controlled by a single

deflector plate positioned at an opti-

mum angle and distance from the dis-

tributor, see Fig. 32. In the Centri-Sonic

Classifier (Fig. 17), the width of the

curtain is affected by the air recycle.

Residence , time can be increased by

raising the height of the separation

zone and, in the case of side-draft sepa-

rators, by enhancing the spiral motion

of the particles around the rejector as

discussed in the previous paragraph.

190

180

170

60

150

140

CO

130

120

-110

10

0.8 0.4 0.6 0.8 0.6 0.4

Correction factor Correction factor

80

70

60

50

40

Example: For llOlb/ft3,

the correction factor is 0.8

Figure 31 -Correction-factor nomograph. Multiplier for production rate (use with Fig. 30)

CHEMICAL ENGINEERING/MARCH 3,1986 91

nGmftinGFmUR

4r

entially, they trap finer particles among them, and the entire

deposit gradually slides down to the coarse product, contami-

nating it with fine particles.

This bypassing can be prevented by installing a set of

inclined overlapping deflectors in the form of stacked con-

centric truncated cones that direct the particles back to the

separation zone (Fig. 18).

Operation control

In the classical Whirlwind (Fig. 9), the number of rejector

blades can be contrplled independently of the air velocity

whereas their rotational speed cannot, because the fan is

also a part of the rotor. This has since been corrected in two

ways. Either the rejector is mounted on a separate shaft

(Fig. 12), or the air is pumped by an outside fan (Fig. 2).

Increasing the size or number of rejector elements is limited

to shut-dowti periods but, because of only a slight change in

the interaction between air and rejector,

this does not affect

power consumption whereas the increase in rejector speed

requires more power.

In addition to varying the rotational speed of the fan,

whether it is mounted on the rotor or outside the classifier

,

the air velocity can be also changed by reducing or expand-

ing the air passage. In the updraft classifiers

,

the cross-

sectional area of the passage is controlled by horizontal

sliding dampers between the selector and fan blades (Fig. 9).

In sidedraft machines

, this is accomplished by vertical vanes

(Fig. 14) that also help to turn the air radially, or by a single

long vertical spiral partition that seals off the outer half of

the volute (Fig. 18).

This optional partition is unique in that it reduces only the

tangential-air-velocity component without affecting the radi-

al component as long as the volumetric flowrate is main-

tained. In this way, the trajectories of the particles descend-

ing through the separation zone around the rejector are bent

into a more spiral pattern, resulting in longer residence time

and better separation. However

, if the air velocity increase is

too high, the volute might act as a cyclone, pulling even some

of the fine particles down toward the annular space and thus

contaminating the coarse product.

Acknowledgment

The authors would like to acknowledge the help of William

English, president of Sturtevant

, Inc., who supported the

state-of-the-art study of air classification technology.

Roy Hughson, Editor

References

1. "C

omminution and Energy Consumption," National Materials Advisory

Board, NMAP-364, PB 81-225708, National Technical Information Ser-

vice, Springfield, Va., May 1981, pp. 12&-150.

2. "Gri

t Separator," Data Sheet D-1347, Sturtevant, Inc., Boston, Mass.,

Dec. 1980.

3. "P

roduction and Laboratory Equipment,

"

Catalog No. 018, 11/73-LP-

10M, Alpine American Corp., Natick, Mass., 1973.

4. "M

odel 8020 RDC Rotary Drum Classifier,

Form 15231," Iowa Manufac-

turing Corp., Cedar Rapids, Iowa, 1979.

5. "GE Classifiers,

"

attachment to "International Environmental Ser-

vices,

"

Bulletin S258R1/1282/7-5M, General Electric Co., Lebanon

, Pa.,

1977.

6. Rogers. R. S. C, "Coal Materials Handling: Classifier Evaluation," Quar-

terly Progress Report, DOE/MC/14266-73, Kennedy-Van Saun Co., Dan-

ville, Pa, 1973. .

7. "H

ardinge Mills For Dry Grinding,

"

Bulletin 17-C, Hardinge Co, York,

Pa, 1956.

8. Cheremisinoff, P. N, and Young, R. A, "Air Pollution Control and

Design Handbook," Part 2, M. Dekker, New York, 1980, pp. 246-315.

9. "Ai

r Separators,

"

Bulletin AS-B-083, Sturtevant, Inc., Boston

,

Mass,

1983.

10. "Cyclone Air Classifier," Bulletin 3-440e, KHD Industrieanlagen Hum

boldt Wedag, Cologne, Germany, 1976.

11. "TURBOPOL Turbo Separator," Bulletin 1269E (2.5981FM), Polysius,

AG, Beckum, Germany.

12. "Majac Jet Pulverizers and Air Classifiers,

"

Bulletin 2000-1, Donaldson

Co, Majac Div, Minneapolis, Minn, 1973.

13. Misakava, T, Furukawa, T, and Onuma, E, "Air Classifier" U.S. Patent

4

,

296

,864, Onoda Cement Co, Tokyo, Japan, Oct. 27,1981.

14. "Acucut Laboratory Classifier," Bulletin 9810-4, Donaldson Co, Majac

Div, Minneapolis, Minn, undated.

15. "Centri-Sonic Classifier," Bulletin G-8D, CE Bauer

, Springfield, Ohio,

1971.

16. Saverse, R. R, and Jones, H.T, "Particle Classifier

,

"

U.S. Patent

4

,

551,241, Nov: 5,1985.

17. Housner, G. W, and Hudson, D. E, "Applied Mechanics and Dynamics,"

2nd ed. Van Nostrand Reinhold, New York

, 1959, p. 2.

18. Bird, R. B, Stewart, W. E, and Lightfoot, E. N, "Transport Phenome-

na,

"

John Wiley & Sons, New York, 1960, p. 192.

19. Licht, W, "Removal of Particulate Matter from Gaseous Wastes-

Filtration," American Petroleum Institute

,

1961.

20. Rajhans, G. S, "Inertial and Gravitational Collectors," Air Sampling

Instruments, 6th ed, 1983, Lioy, P. J. and Lioy, M. J. Y, editors, p. Q-t.

21. Ottavio, T. D, and Goren, S. L, Aerosol Sci. Technol

, Vol. 2, pp. 91-108

(1983).

22. Wong, J. B, Ranz, W. E, and Johnstone, H. F, ./. Avpl Phys., Vol. 27,

pp. 161 -169 (1956).

23.

24.

Clift, R, Grace

, J. R, and Weber, M. E, "Bubbles, Drops and Particles,

"

Academic Press, New York

, 1978, p. 69.

Eisner, E, Proceedings 3rd International Congress on Applied Mechan-

ics

, 1930, p. 32.

25. "Particle Size Classifiers-A Guide to Performance Evaluation

,

"

AIChE

Equipment Testing Procedure,

1980.

26. Duda, W. H, "Cement Data Book," Macdonald & Evans

, London, 1977, p.

227 - 248.

27. Currier

, F. N, "Air Separators," Mill and Grinding Course,

Portland

Cement Assn, Skokie, 111, held annually, last time Nov. 1985..

28. Austin, L. G, and Luckie, P. T, "An Empirical Model for Air Separator

Data," Pennsylvania State University, University Park, Pa, paper Ob-

tained from author, 1983.

The authors

P

'

2

m

i

I. V. Klumpar F. Currier T. A Ring

Ivan V. Klumpar is director of development at Sturtevant, Inc., 103 Clayton

St, Boston, MA 02122. Tel. (617) 825-6500. (Sturtevant is a manufacturer of

size reduction, classification and mixing equipment.) He has worked in the

areas of fjrocess design, capital and operating cost estimation, economic

analysis, pilot-plant operation, plant startup, and computer applications in the'

fields of chemicals

, fuels and metals technology. He holds a Ph.D. in chemical

engineering from the Prague Institute of Technology, is a member of AIChE,

the American Institute of Cost Engineers, and is a registered professional

engineer in Massachusetts.

Fred Currier is chief engineer of Sturtevant, Inc., where he worked for 11

years in layout and design, then as a sales engineer and since 1965 as head of

the engineering department. He is a graduate of Northeastern University

School of Engineering, and spent two years taking graduate courses, at night,

in structural engineering from Massachusetts Institute of Technology.

Terry A. Ring is Associate Professor of Materials Engineering in the Dept.

of Materials Science and Engineering, Massachusetts Institute of Technology,

Cambridge, MA 02139. His research interests are in engineering processes

that involve particles, with a specialization in fine-particle processing. He

holds three degrees in chemical engineering: a B.S. from Clarkson College, an

M.S. from the University of California at Berkeley and a Ph.D. from Cam-

bridge University. He also holds an M.S. in physical chemistry from Clarkson

College.

92 CHEMICAL ENGINEERING/MARCH 3,1986

You might also like

- Voortman Steel Machinery - Voortman VSB ShotblastDocument4 pagesVoortman Steel Machinery - Voortman VSB ShotblastPeyman KhNo ratings yet

- Christian Pfeiffer Maschinenfabrik GMBHDocument5 pagesChristian Pfeiffer Maschinenfabrik GMBHPeyman KhNo ratings yet

- Lecture Notes in Advanced THermodynamics Part 1Document20 pagesLecture Notes in Advanced THermodynamics Part 1alawi747594No ratings yet

- Lyapunov-Based Controller For The Inverted Pendulum Cart SystemDocument6 pagesLyapunov-Based Controller For The Inverted Pendulum Cart Systemle duc huynhNo ratings yet

- F3 Seperators and ClassifiersDocument52 pagesF3 Seperators and ClassifiersadityaksrivastavaNo ratings yet

- Bulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropDocument2 pagesBulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropSivaram KrishnamoorthyNo ratings yet

- Cement Chapter 5Document18 pagesCement Chapter 5shani5573No ratings yet

- Better Grinding Systems: Figure 1: DeglomeratorDocument5 pagesBetter Grinding Systems: Figure 1: DeglomeratorGerman Gabriel Anaya VegaNo ratings yet

- Ball Mill Empty Height Measurment For Calculation of % Volume Filling Cement Mill NO-1Document13 pagesBall Mill Empty Height Measurment For Calculation of % Volume Filling Cement Mill NO-1imam janiNo ratings yet

- Precommissioning Checks in Pyro - Kiln Feed AreaDocument1 pagePrecommissioning Checks in Pyro - Kiln Feed AreaVijay BhanNo ratings yet

- 2006 Slag Grinding With MPS Vertical Roller MillsDocument4 pages2006 Slag Grinding With MPS Vertical Roller Millslijosh_rexy1983No ratings yet

- Presentation For Holcim: Presented By: Thomas Leppak Head of Customer Support Customer Service Thomas - Leppak@loesche - deDocument33 pagesPresentation For Holcim: Presented By: Thomas Leppak Head of Customer Support Customer Service Thomas - Leppak@loesche - deYoussef Khali100% (1)

- Separators in The Cement IndustryDocument5 pagesSeparators in The Cement Industryzane truesdaleNo ratings yet

- V P P P: Alid Ractice Roduction RocessDocument3 pagesV P P P: Alid Ractice Roduction RocessMin MCLNo ratings yet

- Mill Performance Analysis and ComparisonDocument22 pagesMill Performance Analysis and ComparisonHerwin Navarrete100% (1)

- Ball Mill GrindingDocument6 pagesBall Mill GrindingShyanu Udeshika WijerathnaNo ratings yet

- V SK VSK: Focus On EfficiencyDocument8 pagesV SK VSK: Focus On EfficiencyGerman Gabriel Anaya VegaNo ratings yet

- KHD Pyroclon EnglDocument4 pagesKHD Pyroclon Englkresimir.mikoc9765100% (1)

- Transformations E.12Document36 pagesTransformations E.12Dilnesa EjiguNo ratings yet

- Air SeperatorDocument35 pagesAir SeperatorhasanNo ratings yet

- Ball MillDocument10 pagesBall MillLuthfanNo ratings yet

- Dokumen - Tips - Atox Raw Mill 55844e0e63329Document13 pagesDokumen - Tips - Atox Raw Mill 55844e0e63329pipit agusNo ratings yet

- Mill Performance CalculationsDocument9 pagesMill Performance Calculationssafwat hassanNo ratings yet

- 1.0 General Plant Information: Existing Cement Mill Process Data SheetDocument6 pages1.0 General Plant Information: Existing Cement Mill Process Data SheetBùi Hắc HảiNo ratings yet

- Tromp CurveDocument3 pagesTromp CurveShakil AhmadNo ratings yet

- FivesFCB Brochure Horomill GBDocument6 pagesFivesFCB Brochure Horomill GBpeymanNo ratings yet

- GGBFS Opeartion ManualDocument41 pagesGGBFS Opeartion ManualPushpendra Kumar KushwahaNo ratings yet

- Third Generation Separators - Part 1Document2 pagesThird Generation Separators - Part 11qwerNo ratings yet

- VRM Fan ..Document2 pagesVRM Fan ..harikrushnaNo ratings yet

- Fls Pfister Autogap FaqDocument5 pagesFls Pfister Autogap FaqPhong Ky ThuatNo ratings yet

- enDocument22 pagesenAnonymous iI88LtNo ratings yet

- Cement Mill: History Materials Ground Temperature Control Ball MillsDocument5 pagesCement Mill: History Materials Ground Temperature Control Ball MillsAli HadiNo ratings yet

- Raw Meal BeneficiationDocument41 pagesRaw Meal Beneficiationdina safiri100% (1)

- Ball MillDocument2 pagesBall Millpadma26327No ratings yet

- Raw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Document6 pagesRaw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Bùi Hắc HảiNo ratings yet

- Vertical Roller MillDocument7 pagesVertical Roller MillJoko DewotoNo ratings yet

- Factors Influencing The Grinding EfficiencyDocument27 pagesFactors Influencing The Grinding Efficiencygrameshkreddy2013No ratings yet

- Chap. 4.1Document11 pagesChap. 4.1Azizah UlfaNo ratings yet

- 3 Cooleftrr - PpsDocument19 pages3 Cooleftrr - PpsAli HüthütNo ratings yet

- Cement Process Engineering Vade-Mecum: 4. MillingDocument21 pagesCement Process Engineering Vade-Mecum: 4. Millinganwar saeedNo ratings yet

- RABH-sugest by SatputeDocument1 pageRABH-sugest by Satputegvrr1954No ratings yet

- KHD SEPARATORS April 2012 PDFDocument4 pagesKHD SEPARATORS April 2012 PDFGilberto PérezNo ratings yet

- Diagnostic Study For Cement Mill OptimizationDocument9 pagesDiagnostic Study For Cement Mill OptimizationHilmy MuhammadNo ratings yet

- Tube Mill OptimisationDocument7 pagesTube Mill OptimisationJoko DewotoNo ratings yet

- Ball Mill Inspection - Chap 2Document5 pagesBall Mill Inspection - Chap 2Min MCLNo ratings yet

- MHR21924 CMC Chapter CCDocument48 pagesMHR21924 CMC Chapter CCDede KaladriNo ratings yet

- Duoflex PDFDocument8 pagesDuoflex PDFTinTunNaingNo ratings yet

- VDZ Cement Manufacturing Course FlyerDocument4 pagesVDZ Cement Manufacturing Course FlyerfaheemqcNo ratings yet

- Mill Calculation: Plant: Date: Mill: VisaDocument2 pagesMill Calculation: Plant: Date: Mill: VisaThaigroup CementNo ratings yet

- BM TrompcurveDocument1 pageBM Trompcurveniladri.jagatyNo ratings yet

- Third Generation Separators - Part 2Document2 pagesThird Generation Separators - Part 21qwerNo ratings yet

- Ball Mill OperatingDocument14 pagesBall Mill OperatingCao Ngoc Anh100% (1)

- Cement Plant VIPDocument51 pagesCement Plant VIPengr kazamNo ratings yet

- 4 MPDocument33 pages4 MPSyed Shahzaib ShahNo ratings yet

- Raw Materials CalculationsDocument1 pageRaw Materials CalculationsTamer FathyNo ratings yet

- K - Constant For Cooler Fan FlowsDocument4 pagesK - Constant For Cooler Fan FlowsVijay Bhan100% (1)

- Air Classifier ArticleDocument16 pagesAir Classifier ArticleHemanth KumarNo ratings yet

- Air Classifier ArticleDocument16 pagesAir Classifier ArticleTsakalakis G. Konstantinos100% (2)

- Compressor and Hot Section Fouling in Gas Turbines - Causes and Effects by Meher-Homji (1987)Document9 pagesCompressor and Hot Section Fouling in Gas Turbines - Causes and Effects by Meher-Homji (1987)wolf_ns100% (1)

- Dust CollectorsDocument50 pagesDust Collectorsprakash bhadoria100% (1)

- Blower InformationDocument36 pagesBlower InformationshreemugNo ratings yet

- 4.0 Air Separators 4.1Document31 pages4.0 Air Separators 4.1Dilnesa Ejigu100% (1)

- Particle ClassifierDocument9 pagesParticle ClassifierDion Julio IskandarNo ratings yet

- Shotblasting Profiles Structures Pipes PlatesDocument2 pagesShotblasting Profiles Structures Pipes PlatesPeyman KhNo ratings yet

- Testing On Perlite and Vermiculite Samples From British Columbia by Lucie Morin and Jean-Marc Lamothe Canmet Mineral Processing Laboratory, OttawaDocument4 pagesTesting On Perlite and Vermiculite Samples From British Columbia by Lucie Morin and Jean-Marc Lamothe Canmet Mineral Processing Laboratory, OttawaPeyman KhNo ratings yet

- Napca Bulletin 1-65-94: Specification SymbolDocument1 pageNapca Bulletin 1-65-94: Specification SymbolPeyman KhNo ratings yet

- Materials and Equipment Standard: IPS-M-TP-290Document8 pagesMaterials and Equipment Standard: IPS-M-TP-290Peyman KhNo ratings yet

- Takraf EGT 4,0Document1 pageTakraf EGT 4,0Peyman KhNo ratings yet

- 2011 Minerals Yearbook: Vermiculite (Advance Release)Document6 pages2011 Minerals Yearbook: Vermiculite (Advance Release)Peyman KhNo ratings yet

- Vermiculite ExfoliationDocument4 pagesVermiculite ExfoliationPeyman KhNo ratings yet

- MUCHNA Typ 223Document1 pageMUCHNA Typ 223Peyman KhNo ratings yet

- Ammonium Nitrate: 1 FertilizerDocument5 pagesAmmonium Nitrate: 1 FertilizerPeyman KhNo ratings yet

- Truss Transfer ConveyorDocument2 pagesTruss Transfer ConveyorPeyman KhNo ratings yet

- Canbody WeldersDocument6 pagesCanbody WeldersPeyman KhNo ratings yet

- Pretreatment Method Result Reason For UseDocument1 pagePretreatment Method Result Reason For UsePeyman KhNo ratings yet

- 141 - 04-12 2b Engl Sulfur Pastilles PetrobrasDocument1 page141 - 04-12 2b Engl Sulfur Pastilles PetrobrasPeyman KhNo ratings yet

- Sweco Ecutec ULS ClassifierDocument3 pagesSweco Ecutec ULS ClassifierPeyman KhNo ratings yet

- ULS - Finest in ClassifyingDocument1 pageULS - Finest in ClassifyingPeyman KhNo ratings yet

- Viscosity Measurement - 2015Document22 pagesViscosity Measurement - 2015luckyNo ratings yet

- Manual de Herreria Una Guia Paso A Paso Lesur Luis Libro en Papel 9786071701251 Libreria El SotanoDocument3 pagesManual de Herreria Una Guia Paso A Paso Lesur Luis Libro en Papel 9786071701251 Libreria El Sotanodiego rotpeNo ratings yet

- Circular DPP-1 PaperDocument2 pagesCircular DPP-1 PaperᖰгіпcǝNo ratings yet

- eGr13TG PhysicsDocument54 pageseGr13TG Physicspragith kumarNo ratings yet

- 1 Thin Shells PDFDocument16 pages1 Thin Shells PDFMarcus Vinicius FaleiroNo ratings yet

- Microwave Lab ManualDocument52 pagesMicrowave Lab ManualDhanish VijayanNo ratings yet

- Phys 3 QPDocument18 pagesPhys 3 QPPhonxayNo ratings yet

- Centrifugal Force Calculation Description Result Unit 125: Graphical IllustrationDocument6 pagesCentrifugal Force Calculation Description Result Unit 125: Graphical IllustrationvenkateswaranNo ratings yet

- A Re-Examination of The Theory of Suspension BridgesDocument210 pagesA Re-Examination of The Theory of Suspension Bridgespiolenc@archivale.comNo ratings yet

- Rotational Dynamics and Rotational Inertia v2Document7 pagesRotational Dynamics and Rotational Inertia v2aDnan haiDerNo ratings yet

- Zalino On BifilarDocument4 pagesZalino On BifilarDilJalaayNo ratings yet

- Eploring The Mysteries of Quantum EntanglementDocument2 pagesEploring The Mysteries of Quantum Entanglementmanh huuNo ratings yet

- Boiling Film ExperimentDocument12 pagesBoiling Film ExperimentsquionkNo ratings yet

- Welcome: CHEM F111: General ChemistryDocument27 pagesWelcome: CHEM F111: General ChemistryRachit ShahNo ratings yet

- Practice Book PhysicsDocument91 pagesPractice Book PhysicsAndy HoNo ratings yet

- An Introduction To Chemical Engineering Kinetics and Reactor Design PDFDocument603 pagesAn Introduction To Chemical Engineering Kinetics and Reactor Design PDFAnonymous lDX3QhNo ratings yet

- Density of States of ZnoDocument21 pagesDensity of States of ZnoCocoroachd CocoNo ratings yet

- 7.3 Einstein's Photoelectric Theory (S)Document11 pages7.3 Einstein's Photoelectric Theory (S)NG WEI LONG MoeNo ratings yet

- Momentum Review 2004Document18 pagesMomentum Review 2004GajendraNo ratings yet

- First Law of Thermodynamics Conservation of Energy For A CM SystemDocument7 pagesFirst Law of Thermodynamics Conservation of Energy For A CM SystemLobo LoNo ratings yet

- Introduction To Chiral Perturbation TheoryDocument27 pagesIntroduction To Chiral Perturbation TheoryTialocNo ratings yet

- How To Calibrate Level Troll PDFDocument3 pagesHow To Calibrate Level Troll PDFJayJayNo ratings yet

- Chapter 3 Micromechanical Analysis of A Lamina: Volume Fractions, Weight Fractions, Density, and Void ContentDocument34 pagesChapter 3 Micromechanical Analysis of A Lamina: Volume Fractions, Weight Fractions, Density, and Void ContentSwetha Sharma100% (1)

- 9 Science NcertSolutions Chapter 10 ExercisesDocument12 pages9 Science NcertSolutions Chapter 10 Exercisestindutt life timeNo ratings yet

- Nanotechnology Optical Tweezers ReportDocument13 pagesNanotechnology Optical Tweezers ReportDaria RomanNo ratings yet

- Two Year Medical (Phase-01) Test Planner - AY-2023-2024 Version 4.0Document3 pagesTwo Year Medical (Phase-01) Test Planner - AY-2023-2024 Version 4.0divyanshu sharmaNo ratings yet

- Last Name, First CHE426:: F 33.54 GPMDocument5 pagesLast Name, First CHE426:: F 33.54 GPMGiancarlo HuertaNo ratings yet