Professional Documents

Culture Documents

Finite Element Simulation of Ball-On-Tennis Racket Impacts Using Abaqus/Cae

Finite Element Simulation of Ball-On-Tennis Racket Impacts Using Abaqus/Cae

Uploaded by

AJER JOURNALOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Finite Element Simulation of Ball-On-Tennis Racket Impacts Using Abaqus/Cae

Finite Element Simulation of Ball-On-Tennis Racket Impacts Using Abaqus/Cae

Uploaded by

AJER JOURNALCopyright:

Available Formats

American Journal of Engineering Research (AJER) 2014

w w w . a j e r . o r g

Page 151

American Journal of Engineering Research (AJER)

e-ISSN : 2320-0847 p-ISSN : 2320-0936

Volume-03, Issue-05, pp-151-155

www.ajer.org

Research Paper Open Access

Finite Element Simulation of Ball-On-Tennis Racket Impacts

Using ABAQUS/CAE

Dawit Bogale

1

, Sewnet Alemu

2

1&2

(School of Mechanical and Industrial Engineering, Bahir Dar University, Ethiopia)

Abstract: - The submitted paper describes development of tennis ball -racket models with ABAQUS/CAE

software that accurately simulate ball-on-tennis racket impacts. The racket model can be implemented in

ABAQUS Explicit analysis software in order to study the mechanical properties of the racket, especially the

impact, string bed of the racket and transverse to frame. These models are being used to investigate the

individual and combined effects of many different design variables and to develop insights for improving the

design of tennis rackets. The finite element code ABAQUS Explicit was mainly employed in the study of

sensitivity on the simulations to step time, material properties, mesh characteristics, and (COF) coefficient

of friction. The output of this simulation shows displacement (Elastic properties) which in turn is the mechanical

behavior of the tennis ball and string bed is appropriate and agrees with the objectives in the literature review.

Keywords: - ABAQUS/CAE software, COF, impact, mechanical behavior, Tennis ball racket

I. INTRODUCTION

In the real world there are physical scenarios related to impact problems which needs engineering

solution using numerical methods. Tennis ball racket is among a few scenarios which needs reengineering.

Here this paper investigates how we can design efficient and tennis racket with comfortable condition this can

be done through ABAQUS code by considering the elastic properties of the ball and the string bed and the

coefficient of friction between the ball and the racket, for desired solution here the mesh characteristics is

considered.

Detailed structural models of the tennis ball racket are required to gain more insight into the impact

dynamics of racket balls. This study introduced the development of a detailed FE model for the structural

analysis of racket balls. The models were calibrated against literature data obtained from research developed for

this purpose, including drop tests and high speed impact tests. Modern predictive models show that

improvements in tennis rackets which primarily focus on reduced mass and increased structural stiffness

allow a player to serve 17.5 percent faster using modern equipment compared to what was available in 1870

[1]. Tennis racket has been significantly changed, despite the plays rules are substantially the same, because

new materials and technologies have been widely used in the equipment manufacturing during the last two

decades? This freedom creates some troubles to the designers, which now must precisely define the project

objectives and identify the key mechanical parameters to be tuned for achieving such objectives [3].Researchers

scanned a racket with a laser to produce a surface model that reflected the geometry of a real racket. They used a

linear elastic material model for the rackets frame, which was meshed with 27,410 shell elements. The racket

model included an interwoven string bed that had a linear elastic material model. The string bed was no rigid,

and the individual strings had the capability to move where they intercept other strings [2].

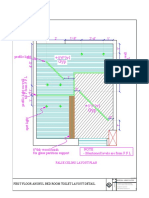

Fig.1 shows the tennis ball with racket

American Journal of Engineering Research (AJER) 2014

w w w . a j e r . o r g

Page 152

II. LITERATURE REVIEW

The tennis racket design had many improvements in last few years. The racket heads have grown

larger, on frames that have become lighter. The racket frame and strings are of great importance for the player

performance. The racket model can be implemented in Ansys analysis software in order to study the mechanical

properties of the racket, especially the impact, vibration between tennis ball, string bed of the racket and

transverse to frame. Tennis racket has been significantly changed, despite the plays rules are substantially the

same, because new materials and technologies have been widely used in the equipment manufacturing during

the last two decades? This freedom creates some troubles to the designers, which now must precisely define the

project objectives and identify the key mechanical parameters to be tuned for achieving such objectives . The

finite element method (FEM), which analyses the elastic behavior of rackets under static conditions, providing

chances for remarkably differentiation of rackets performances (Glitsch,1980). Also, considering both the racket

and ball (Hatze, 2002), acquire the information on the time dependent three-dimensional positions and

orientations of racket and ball. The model of the racket with different damp has calculated by finite element

method and testified the reliability using instrument (Buechler, 1999). But a great deal of racket model research

in free handle condition and the string hadnt been taken as important as racket. Today's tennis racquets are a

showcase of high tech materials and engineering . This knowledge can be used by a tennis player to choose the

best racket for him and to improve the tennis techniques. Understanding these design aspects is also important to

anyone with an interest in modern technology [2].Matthew Vokoun described in his work the design aspects of

Tennis Rackets the two main design aspects of tennis rackets, which are classified in external and internal

design aspects. The external design aspects consist in: strings, head size, and beam size. The internal design

aspects are material type, weight, and balance [1]. The strings characteristics such as elongation, tension, and

pattern density are of great importance in stroke production. The head size provides the desired power: a larger

head provides more power (longer head) or a better control (wider head). The beam size (racket's cross section)

influences the racket's stiffness and power. Ball impact behavior can be described in terms of coefficient of

restitution (energy dissipated in an impact) and stiffness (force and deformation of a ball during impact).

Official regulatory standards tend not to stipulate the material or construction for use in the ball, instead

specifying the required range of COR and stiffness characteristics. The International Tennis Federation

have reported that of the 272 brands submitted in 2006, 5.5% had failed. Similar figures have been

reported from 2005 (240 submitted: 7% failed). The most common failures have been from rebound and

deformation testing, with size and mass tests having the highest pass rates [2].

University researchers used ANSYS LS-DYNA explicit dynamics software to simulate tennis racket

ball impacts. The software simulates short-duration events with severe loadings and large deformations, thus

helping researchers to understand what happens during crashes, explosions and metal forming operations. LS-

DYNA is available within the ANSYS Workbench environment, which provides extensive CAD interfaces,

automatic meshing, integration with other simulation tools and design optimization The research team evaluated

the COF at 0.0, 0.2, 0.4, 0.5, 0.6, 0.7, 0.8 and 1. The simulation projected the tennis ball onto an initially

stationary, freely suspended racket. Engineers compared simulation results to the International Tennis

Federations custom racket impact machine, designed to simulate non spinning impacts between a tennis ball

and a racket at a range of velocities and locations on the long axis of the string bed. [3].A modelisation done by

seydel [4] of the trajectory of the tt-ball in air was finished 1990.the rebound of the ball on the table was

modelled by Durey [5]1987. Here we summarize our actual physical research done in Cachan (Paris) in the

laboratory of Alain Durey concerning the impact of the tt-ball on the racket. [6] Researchers used simulation to

investigate the effects of changing the COF between the strings and the balls. The results showed that with

low rebound angles (relative to racket face normal), the COF did not have a major impact on the balls

rebound characteristics. Examination of simulation results showed that the ball was effectively rolling off the

string bed, so coefficient of friction made little difference. The COF has a larger impact if the ball is sliding

or overspinning on the racket at the end of the impact.

III. METHODOLOGY

3.1. Finite Element Modeling

The tennis ball-racket impact scenario is modeled and simulated using ABAQUS/CAE. Before modeling the

part the frame and the strings are made in the sketcher which when assembled gives the racket.

American Journal of Engineering Research (AJER) 2014

w w w . a j e r . o r g

Page 153

TABLE 1 shows the material properties assigned for each models

The the racket and the tennis ball is assembeled in its initial position and the meshing are done for both

the ball and the racket. the mesh control for the ball with element shape Quadrilateral dominated with free

technique.but some research and experience shows that triangular mesh comes with better solution than others

but the analysis time will increase. The element type is explicit and geometric order is linear with family of shell

S4R: A 4-node doubly curved thin or thick shell, reduced integration, hourglass control, finite membrane

strains.

IV. RESULT AND DISCUSSION

The result from the numerical method that is finite element method which simulated the real tennis ball

racket scenario shows that the time step and the mesh characteristics as well as the COF shows that all this

factors will affect the final solution and more importantly this result shows ABAQUS/CAE is the powerful

finite elements analysis tool for solving this kind of real world problems . In the figures 4 below the shows the

displacement of the ball and the racket strings. And in figure 5 the velocity of the Ball at six different step time.

Fig4. shows the displacement of the ball and string bed Fig5. shows the velocity of the ball

Materials Properties Denstiy (kg/m^3) Young's Modulus (pa) Poissons Ratio

Frame Elastic 0.001 10000000000 0

String Elastic 0.000107 1000000 0

Ball Hyper elastic 0.0001 Polynomial Coefficients

C10 C01 D1

100 25 0.0001

American Journal of Engineering Research (AJER) 2014

w w w . a j e r . o r g

Page 154

As it is observed from the above impact simulation the displacement of the ball will increase and because of the

ball have important mechanical behavior (Elastic properties) it will rebound after the impact on the string bed

and it will recover its round shape. Also the velocity was high initially but as time goes it will decrease.

Fig6. Shows the max in plane Logarithmic strain at step time=1.0500E-02

The logarithmic strain shows the deformation of the ball as the time increases. From the above figures

the maximum in plane principal LE will occur at step time of 1.0500E-02.Let us know see the reaction of the

string bed towards the impact of the ball. To see this displacement U is considered. And since the string bed is

designed for elastic materials as shown in the figure below it doesnt fail plastically.

Fig7. Shows the deformation of the string bed on displacement contours at different time step

The following figures are the result drawn from ABAQUS Visualization module as it is observed bel ow the

outcome show significant mechanical behavior of the string bed in figure (a). Here the displacement increases

American Journal of Engineering Research (AJER) 2014

w w w . a j e r . o r g

Page 155

dramatically and suddenly regain it original shape. As expected the acceleration as well as the velocity will

decrease and increase after rebound from the racket.

(a) (b)

c)

Fig8. Shows (a) String bed displacement, (b) Acceleration of the Ball, (c) Velocity of the Ball

V. CONCLUSION

This paper investigates the effect of mesh characteristics, Coefficient of friction (COF), material

properties, and step time on the tennis racket impact scenario. The finite element code ABAQUS Explicit was

mainly employed in the study of sensitivity of the simulations to step time, material properties, mesh

characteristics, and (COF) coefficient of friction. The output of this simulation shows displacement (Elastic

properties) which in turn is the mechanical behavior of the tennis ball and string bed is appropriate and agrees

with the objectives in the literature review. Here as the step time decrease the solution become more accurate

and the material properties show significant result on the racket so it opens new design innovation for this sport

regardless of the rules and there by improve the performance of the players. Finally it is worth nothing without

mentioning ABAQUS code is powerful tool for such kind of problems.

REFERENCES

[1] P.K.Chidambaram, R. Ramakrishanan, Synthesis, Testing Of Nylon 6,6/Multi-Wall Carbon Nanotube

And Modeling , Analysis Of Tennis Racket, International Journal Of Engineering Science And

Technology (Ijest),2013

[2] ITF Technical Centre [Homepage On The Internet]. International Tennis Federation. Accessed 12 April

2008. Available From: www.Itftennis.Com/Technical

[3] Tom Allen, Sports Engineering Researcher, Centre For Sports Engineering Research, Ansys. Inc,

Sheffield Hallam University, Sheffield, U.K ,2012.

[4] Seydel R., Spielbestimmende Faktoren Beim Tischtennissport. Messung Und Simulation Von

Ballflugkurven, Berichte Und Materialien Des Bundesinstitutes Fur Sportwissenschaft; Koln 199

[5] Durey, A.; Vers Des Activites Didactique De Mise Au Point Des Modeles: Rajectoires, Frappes,

Rebounds De Balles En Rotation, These Detat Paris 7, 1987.

[6] Haake, S.; Allen, T.; Choppin, S.; Good will., S. The Evolution Of The Tennis Racket And Its Effect

On Serve Speed. Tennis Science And Technology 3, 2007, Vol. 1, Pp 257271.

You might also like

- Unit Tests. Poziom Podstawowy: KluczDocument9 pagesUnit Tests. Poziom Podstawowy: KluczIza WłochNo ratings yet

- MS50295 - 01E Maintenance ScheduleDocument68 pagesMS50295 - 01E Maintenance Schedulevictor baccaNo ratings yet

- Pin Vs Fixed Joints in TrussDocument4 pagesPin Vs Fixed Joints in TrussgazzafletchNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Interactive Fantasy 3 - Web (14262881)Document164 pagesInteractive Fantasy 3 - Web (14262881)Chance Jason Kallisti100% (1)

- Dynamic Simulation of Tennis Racket and String Gu Yao-Dong, Li Jian-She Faculty of Physical Education, Ningbo University, Ningbo, Zhejiang, ChinaDocument4 pagesDynamic Simulation of Tennis Racket and String Gu Yao-Dong, Li Jian-She Faculty of Physical Education, Ningbo University, Ningbo, Zhejiang, Chinacarmen4621No ratings yet

- Using Experimental Modal Analysis To Validate A Finite Element Model of A Tennis Racket - ScienceDirectDocument6 pagesUsing Experimental Modal Analysis To Validate A Finite Element Model of A Tennis Racket - ScienceDirectDanny SrtyNo ratings yet

- Optimum Redesign of Axial Fan Blade AttachmentDocument15 pagesOptimum Redesign of Axial Fan Blade AttachmentNarayanaNo ratings yet

- Static, Dynamic and Fatigue Behavior of Newly Designed Stem Shapes For Hip Prosthesis Using Finite Element AnalysisDocument7 pagesStatic, Dynamic and Fatigue Behavior of Newly Designed Stem Shapes For Hip Prosthesis Using Finite Element AnalysisnishantsinghbmeNo ratings yet

- Tennis Kinematics Transient Analysis A Ball Spin Racket Collision DescriptionDocument53 pagesTennis Kinematics Transient Analysis A Ball Spin Racket Collision DescriptionIoan-Alexandru CodarceaNo ratings yet

- A Mechanical Study On Tennis Racquets To Investigate Design Factors That Contribute To Reduced Stress and Improved Vibrational DampeningDocument6 pagesA Mechanical Study On Tennis Racquets To Investigate Design Factors That Contribute To Reduced Stress and Improved Vibrational Dampeningkevin mcNo ratings yet

- Effect of Range of Motion (ROM) For Pedicle-Screw Fixation On Lumbar Spine With Rigid and Semi-Rigid Rod Materials: A Finite Element StudyDocument9 pagesEffect of Range of Motion (ROM) For Pedicle-Screw Fixation On Lumbar Spine With Rigid and Semi-Rigid Rod Materials: A Finite Element Studyneerajkumarer9680No ratings yet

- Comparison of Stress Distribution Patterns Within Quadrangle, Hexagonal and Octagonal Impact Socket Drive Designs of A Torque Wrench Using Finite Element AnalysisDocument3 pagesComparison of Stress Distribution Patterns Within Quadrangle, Hexagonal and Octagonal Impact Socket Drive Designs of A Torque Wrench Using Finite Element AnalysisIJSTENo ratings yet

- Optimization of Space Frame Design: February 2008Document9 pagesOptimization of Space Frame Design: February 2008Ahmed mohammedNo ratings yet

- High Torque Nozzle MK66Document12 pagesHigh Torque Nozzle MK66Sergio SacristanNo ratings yet

- Springback Prediction in Sheet Metal Forming, Based On Finite Element Analysis and Artificial Neural Network ApproachDocument14 pagesSpringback Prediction in Sheet Metal Forming, Based On Finite Element Analysis and Artificial Neural Network ApproachMagesh BNo ratings yet

- HZ Tennis IssuuDocument16 pagesHZ Tennis IssuuM. Y. HassanNo ratings yet

- Castelleted BeamsDocument15 pagesCastelleted Beamsbasavasdmcet0% (1)

- Finite Element Analysis and Lightweight Optimization Design of Rocket Motor Tube Using A Thin-Walled CylinderDocument7 pagesFinite Element Analysis and Lightweight Optimization Design of Rocket Motor Tube Using A Thin-Walled CylinderGogyNo ratings yet

- Harmonic Analysis of Flex Seal of Rocket NozzleDocument14 pagesHarmonic Analysis of Flex Seal of Rocket NozzlemadhumamayyaNo ratings yet

- PagoluSreenivasaRao HariSankarVanka 48 PDFDocument8 pagesPagoluSreenivasaRao HariSankarVanka 48 PDFRavinder ReddyNo ratings yet

- SwatiNirmala2019 - Article - Analyze The Failure of A Suspension System Ball JointDocument5 pagesSwatiNirmala2019 - Article - Analyze The Failure of A Suspension System Ball JointNikki SinghNo ratings yet

- 2 Design and Optimisation of Disc Brake RotorDocument12 pages2 Design and Optimisation of Disc Brake Rotorankush belkarNo ratings yet

- Bijlaard Part 1 8Document17 pagesBijlaard Part 1 8Jie RongNo ratings yet

- Design and Analysis of Motorcycle Disk BrakeDocument5 pagesDesign and Analysis of Motorcycle Disk BrakeVIVA-TECH IJRINo ratings yet

- Vibrator TableDocument8 pagesVibrator TableyaredNo ratings yet

- Cotter Joint CoferenceDocument5 pagesCotter Joint CoferenceMuhammad AliNo ratings yet

- Development and Characteristics of Lightweight Sandwich Panel For Table Tennis TableDocument6 pagesDevelopment and Characteristics of Lightweight Sandwich Panel For Table Tennis TableAnjaneya PrasadNo ratings yet

- Analysis of Friction Disc of Single Plate Clutch by Using Ansys A ReviewDocument14 pagesAnalysis of Friction Disc of Single Plate Clutch by Using Ansys A ReviewIJRASETPublicationsNo ratings yet

- Estimating The Stress Distribution Within MERO Joint Using (FEM-ANN)Document10 pagesEstimating The Stress Distribution Within MERO Joint Using (FEM-ANN)yousefrezek95No ratings yet

- Rotordynamic Design Optimization of A Steam Turbine Rotor Bearing SystemDocument72 pagesRotordynamic Design Optimization of A Steam Turbine Rotor Bearing SystemTarkan KaragozNo ratings yet

- Design of A Novel Carbon-Fiber Ankle-Foot Prosthetic Using Finite Element ModelingDocument16 pagesDesign of A Novel Carbon-Fiber Ankle-Foot Prosthetic Using Finite Element ModelingThomson JohnyNo ratings yet

- Peeters 2018Document24 pagesPeeters 2018studentmgmNo ratings yet

- The Design and Analysis of Gas Turbine BladeDocument3 pagesThe Design and Analysis of Gas Turbine Bladeaerobrother100% (4)

- Ijret - Constructive Concepts For Reducing Wear Caused by The Friction Torque of Hip ImplantsDocument7 pagesIjret - Constructive Concepts For Reducing Wear Caused by The Friction Torque of Hip ImplantsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Budak tmt07Document29 pagesBudak tmt07abdollahzadehNo ratings yet

- Ydgb 2 U 1586735204Document15 pagesYdgb 2 U 1586735204sun rise1No ratings yet

- Cold Roll Forming Process Design Based On The Induction of Analytical Knowledge by Considering Material and Geometry EffectsDocument9 pagesCold Roll Forming Process Design Based On The Induction of Analytical Knowledge by Considering Material and Geometry Effectsassetio8185No ratings yet

- Design Comparison of Different ReinforceDocument8 pagesDesign Comparison of Different ReinforceALINo ratings yet

- 14 DesignDocument9 pages14 DesignRathinasamy SalethNo ratings yet

- Analysis of Disc Break by Using Fea and Ansys: R.Lakshmanaik, Dr. T. Dharma Raju, T. JayanandDocument7 pagesAnalysis of Disc Break by Using Fea and Ansys: R.Lakshmanaik, Dr. T. Dharma Raju, T. JayanandJyotsanaTrivediNo ratings yet

- 1 s2.0 S0263224120310940 MainDocument15 pages1 s2.0 S0263224120310940 Mainabcde.xyz1No ratings yet

- SpitzerPohletalEd2022 EndlessFibreReinforcedComposite Metal ImpellerDocument9 pagesSpitzerPohletalEd2022 EndlessFibreReinforcedComposite Metal ImpellerJoshua KarthikNo ratings yet

- Failure Analysis of A Coupled Shaft From A Shredder: Luis.g.reis@tecnico - Ulisboa.ptDocument12 pagesFailure Analysis of A Coupled Shaft From A Shredder: Luis.g.reis@tecnico - Ulisboa.ptMulugetaNo ratings yet

- 612121Document5 pages612121goliatrgsNo ratings yet

- Weight Optimization of Turbine BladesDocument19 pagesWeight Optimization of Turbine BladesLe Anh TuanNo ratings yet

- Optimization of Post Tensioned ConcreteDocument8 pagesOptimization of Post Tensioned ConcreteTùng HìNo ratings yet

- Modal AnalysisDocument4 pagesModal AnalysisJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Design Structural Analysisand Modal Analysisofa Wing Sectioninan UAVDocument10 pagesDesign Structural Analysisand Modal Analysisofa Wing Sectioninan UAV紀俞揚No ratings yet

- Figure 2.7: Possible Failure Modes Considered by The AISC Manual 15th Ed. (2017)Document5 pagesFigure 2.7: Possible Failure Modes Considered by The AISC Manual 15th Ed. (2017)mn4webNo ratings yet

- Manufacturing and Experimental Testing of Carbon Fiber Composite Helicopter BladeDocument10 pagesManufacturing and Experimental Testing of Carbon Fiber Composite Helicopter BladeIJRASETPublicationsNo ratings yet

- Modelling and Analysis of A Prosthetic Runner BladeDocument11 pagesModelling and Analysis of A Prosthetic Runner BladeIJRASETPublicationsNo ratings yet

- AI Check 2Document33 pagesAI Check 2ma.shaheNo ratings yet

- FEM-supported Simulation of Chip Formation and Ow in Gear Hobbing of Spur and Helical GearsDocument10 pagesFEM-supported Simulation of Chip Formation and Ow in Gear Hobbing of Spur and Helical GearsKylo RenNo ratings yet

- A Study On Analytical T-Stub Prying Models For Rhs Joints in TensionDocument10 pagesA Study On Analytical T-Stub Prying Models For Rhs Joints in TensionEJOUMALENo ratings yet

- 1 s2.0 S2214785316303856 Main - 3Document7 pages1 s2.0 S2214785316303856 Main - 3mesfin DemiseNo ratings yet

- 61562-Article Text-751375261078-1-10-20221220Document12 pages61562-Article Text-751375261078-1-10-20221220Prakash PrajapatiNo ratings yet

- Icndme 14224Document7 pagesIcndme 14224Abdelillah feghoulNo ratings yet

- Principles Tire DesignDocument22 pagesPrinciples Tire DesignsiritapeNo ratings yet

- Fluid-Structure Interaction of Cropped Delta Wing With Experimental ValidationDocument14 pagesFluid-Structure Interaction of Cropped Delta Wing With Experimental ValidationTJPRC PublicationsNo ratings yet

- Space Frame OptimisationDocument9 pagesSpace Frame OptimisationSreehari AshokNo ratings yet

- 1.1.2the Direct Method GoodDocument6 pages1.1.2the Direct Method GoodKevin RodriguezNo ratings yet

- (Dry Type Transformer)Document23 pages(Dry Type Transformer)togirishsharmaNo ratings yet

- TimersDocument51 pagesTimersSaravanan T YNo ratings yet

- Supplementary Material: Illustration. The Following Series of Illustrations Are Based On The Figures ObtainedDocument3 pagesSupplementary Material: Illustration. The Following Series of Illustrations Are Based On The Figures ObtainedGabrielle Joshebed AbaricoNo ratings yet

- Memorandum of Understanding Download-FriendlyDocument4 pagesMemorandum of Understanding Download-FriendlyRaymy ConceptsNo ratings yet

- Evolution-of-Management-Theory 02 PDFDocument42 pagesEvolution-of-Management-Theory 02 PDFsafiqulislamNo ratings yet

- Đề MOS WORD 1Document2 pagesĐề MOS WORD 1Lan Anhh100% (1)

- Module 1, Graph Theory 1Document133 pagesModule 1, Graph Theory 1Ayush Kumar 20BTRIS004No ratings yet

- The Deodorant Market in India - FinalDocument6 pagesThe Deodorant Market in India - Finalabhisheklakh100% (4)

- Reading Assessment in English For KS 3 4Document23 pagesReading Assessment in English For KS 3 4JENIVIVE D. PARCASIO100% (1)

- Toilet False Ceiling PlanDocument1 pageToilet False Ceiling PlanPooja JabadeNo ratings yet

- FortiGate WAN Optimization Guide 4.0Document108 pagesFortiGate WAN Optimization Guide 4.0Paolo BoarettoNo ratings yet

- Critical Thinking 033-DownloadDocument3 pagesCritical Thinking 033-DownloadbeneqNo ratings yet

- Biotechnology - Principles and Processes - Mind Map - Lakshya NEET 2024Document7 pagesBiotechnology - Principles and Processes - Mind Map - Lakshya NEET 2024Test UserNo ratings yet

- Policy Guideliness For Community Radio in KenyaDocument36 pagesPolicy Guideliness For Community Radio in KenyaAmos Ochieng100% (1)

- DLL - Science 4 - Q1 - W9Document3 pagesDLL - Science 4 - Q1 - W9XXVKNo ratings yet

- f02 - Toolbox Talk Manual Rev. 02Document118 pagesf02 - Toolbox Talk Manual Rev. 02Venkadesh Periathambi100% (2)

- Summer Training Report On Shri Ram Piston and Rings LimitedDocument89 pagesSummer Training Report On Shri Ram Piston and Rings LimitedKevin Joy75% (4)

- Microsoft Age of Empires III Trial Readme File: September 2005Document4 pagesMicrosoft Age of Empires III Trial Readme File: September 2005Yoga RajNo ratings yet

- Lecture Week 2Document15 pagesLecture Week 2saneel kumarNo ratings yet

- PCE Nautilus en 20130318Document2 pagesPCE Nautilus en 20130318Iker BasqueAdventureNo ratings yet

- Tổng hợp đề thi HSK2Document5 pagesTổng hợp đề thi HSK2Tran My HanhNo ratings yet

- Heavyvinyl Issue1Document115 pagesHeavyvinyl Issue1Adam100% (2)

- CERTIFIED DIGITAL TRANSFORMATION PROFESSIONAL (CDTP) - CDTPFlyer2020Document6 pagesCERTIFIED DIGITAL TRANSFORMATION PROFESSIONAL (CDTP) - CDTPFlyer2020kien_le_14No ratings yet

- Φουρνος- convotherm - 4Document120 pagesΦουρνος- convotherm - 4Dimitris ThanasopoulosNo ratings yet

- Bletchley & District Allotment Association - Autumn News 2010Document3 pagesBletchley & District Allotment Association - Autumn News 2010ArchenfieldNo ratings yet

- Center Point LawsuitDocument52 pagesCenter Point LawsuitLarryDCurtisNo ratings yet