Professional Documents

Culture Documents

March 27, 1934. G - J - Ranque 1,952,281: Filed Dec. 6, 1932' 3 Sheets-Sheet 1

March 27, 1934. G - J - Ranque 1,952,281: Filed Dec. 6, 1932' 3 Sheets-Sheet 1

Uploaded by

mrock_1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

March 27, 1934. G - J - Ranque 1,952,281: Filed Dec. 6, 1932' 3 Sheets-Sheet 1

March 27, 1934. G - J - Ranque 1,952,281: Filed Dec. 6, 1932' 3 Sheets-Sheet 1

Uploaded by

mrock_1Copyright:

Available Formats

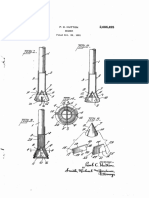

March 2 7 , 1 9 3 4 .

G _ J _ RANQUE 1 , 9 5 2 , 2 8 1

METHOD AND APPARATUS FOR OBTAINING FROI A FLUID UNDER PRESSURE

TWO CURRBNTS OF FLUIDS AT DIFFERENT TEIPBRATURES

Filed Dec. 6 , 1 9 3 2 ' 3 Sheets-Sheet 1

1 , 9 5 2 , 2 8 1

3 She' etsq Sheet 2

i 1 I? , I

March 2 7 , 1 9 3 4 . a. J . RANQUE

METHOD AND APPARATUS FOR OBTAINING FROM A FLUID UNDER PRESSURE

TWO CURRENTS OF FLUIDS AT DIFFERENT TEMPERATURES

Filed Dec. 6 , 1 9 3 2 .

Mai-ch 2 7 , 1 9 3 4 . " G J RAN-QUE 1 , 9 5 2 , 2 8 1

um' non AND' APPARATUS FOR on' mme men A FLUID UNDER PRESSURE '

' > We cuansng' s' OF FLUIDS AT DIFFERENT TEMPERATURES

' Filed Dec. 6 . 1 9 3 2 3 Sheets-Sheet 3

fig. 1 3 6

5

Ol

2 0

3 0

3 5

4 0

4 5

5 0

5 5

Patented Mar. 2 7 , 1 9 3 4

' UNITED STATES

1 , 9 5 2 , 2 8 1

PATENT OFFICE

1 , 9 5 2 , 2 8 1

METHOD AND APPARATUS FOR OBTAINING

FROM A FLUID UNDER PRESSURE TWO

CURRENTS OF FLUIDS \AT DIFFERENT

TEMPERATURES

G eorges J osep h Ranq ue, Montlucon, France, as

slgnor to La G iration Des . Fluides. Societe a

Resp onsab ilite Limitee, Montlucon, France, a

comp any of France

Ap p lication Decemb er 6 , 1 9 3 2 , Serial No. 6 4 6 , 0 2 0

In France Decemb er 1 2 . 1 9 3 1 I,

1 5 Claims.

The ob ject of my invention is a method for

automatically ob taining, from a comp ressib le

? uid (gas or vap our) under p ressure, a current

of hot ? uid and a current of cold ? uid,

that transformation of the initial ? uid

into two currents of different temp eratures

taking p lace without the help of any movab le

mechanical organ, merely through the work of

the molecules of ? uid up on one another.

The method according to my invention con

sists essentially in dividing the ? uid under p res

sure, which is admitted tangentially into a ves

sel having the shap e of a b ody of revolution,

into two coaxial sheets of ? uid moving with a

gyratory motion and reacting up on each other

so as to p roduce, under the action of centrifugal .

force, the comp ression of the outer sheet b y the

inner sheet which exp ands, this comp ression ab

sorb ing a certain amount of work, which is evi

denced b y a rise in the temp erature of the com

p ressed sheet at the exp ense of the other sheet,

which is thus cooled.

In a p ractical mode of carrying out this meth

od, the ? uid under p ressure is introduced tan

gentially into a vessel having the shap e of a

b ody of revolution p rovided with axial ori? ces

disp osed on either side of the ? uid inlet. Said

? uid is suitab ly guided so as to give it a helical

motion toward one of said ori? ces, the cross

section of which is suitab ly restricted so as to

p roduce a b ackward motion of a p ortion of the

? uid toward the op p osite ori? ce. This p roduces

two sheets of ? uids having op p osite axial mo

tions, the inner sheet exp anding and comp ress

ing the outersheet, thus sup p lying heat thereto.

A current of hot ? uid is thus received through

the ori? ce of restricted cross section, while a

current of cold ? uid is received through the op

p osite ori? ce. '

Another ob ject of my invention is to p rovide

an ap p aratus for carrying out the method ab ove

referred to. According to my invention, this

ap p aratus comp rises a chamb er having the shap e

of a b ody of revolution the middle p art of which

is p rovided with one or more tangential inlet

tub es for the ? uid under p ressure. Axial ori? ces

are p rovided at either end of said chamb er, one

of said ori? ces, toward which the liq uid, or ? uid

is directed through a suitab le guiding with a

gyratory motion, having a cross section smaller

than that of the sheet of ? uid, so that a p ortion

of the latter is driven b ack toward the op p osite

ori? ce in such manner that it is caused to ? ow

over the sheet of ? uid that is ap p lied against the

wall of the chamb er in q uestion.

(Cl. 6 2 -1 7 0 )

Preferred emb odiments of my invention will

b e hereinafter describ ed with reference to the

accomp anying drawings, given merely b y way of

examp le, and in which: .

Figs. 1 to 5 inclusive are diagrammatical views

illustrating the p rincip le of my invention,

Fig. 2 b eing a sectional view on the line 2 -2

of Fig. 1 ;

Fig. 6 is a diagrammatical view of an emb odi

ment of my invention;

Fig. 6 a is a sectional view on the line Sir-6 a

of Fig. 6 ;

Fig. 7 is a detailed view showing in axial sec

tion a p ractical emb odiment of my invention;

Fig. 7 a is a p ersp ective view of the helicoidal

guide;

Fig. 8 is a corresp onding p lan view on a smaller

scale; ,

Fig. 9 is a diagrammatical elevational view of

another emb odiment. of my invention;

Fig. 1 0 is an end view corresp onding to Fig. 9 ;

Fig. 1 1 is a diagrammatical view of another

emb odiment of my invention;

Fig. 1 2 is an end view corresp onding to Fig. 1 1 ;

Figs. 1 3 and 1 4 are diagrammatical views of

two other emb odiments of my invention. - '

The p rincip le on which my invention is b ased

is illustrated b y diagrammatic Figures 1 to 5 .

Sup p osing, as shown in Figs. 1 and 2 , . . that a

tub e A B is p rovided in its middle p art with a

tangential inlet p ip e 1 through which a current

of a comp ressib le ? uid (gas or vap our) under

p ressure is sent into said tub e, said ? uid is given

in said tub e a certain linear velocity p arallel

with the axis of said tub e, said rectilinear move

ment b eing comb ined with a gyratory movement

ab out the axis of the tub e. The ? uid ? ows to

ward b oth ends of the tub e.

As the ? uid is moving away from the inlet

p ip e, its rectilinear velocity, which is p arallel

with the axis as y of the tub e, increases, and its

angular velocity decreases, so that the ? uid

sp reads along the wall of the tub e so as to form

a sheet 2 having sub stantially the shap e of a

b ody of revolution ab out axis a: 1 / (Fig. 3 ). In

said sheet the molecules are sub jected to a p res

sure which is the higher as they are at a greater

distance from the axis of the tub e, due to the

action of the centrifugal force. At the same

time, the, ? ow of the ? uid p roduces a sub stantial

fall of p ressure in the central zone of the tub e,

so that the outer air, which is at the atmosp heric .

p ressure, is drawn toward the central zone of

the tub e, thus forming two axial currents 2 a

(Fig. 4 ). When the outer air reaches said cen

6 0

6 5

7 0

7 5

8 0

8 5

9 0

9 5

1 0 0

1 0 5

1 1 0

1 0

1 0

2 0

2 5

3 0

8 5

4 0

4 5

5 0

6 5

6 0

0 5

7 0

2

tral zone, it is driven b ack toward the outside

b y the ? uid moving with a gyratory movement,

thus forming streams 3 . '

If an annular diap hragm 4 , the free central

op ening 4 a of which has a diameter eq ual to the

minimum diameter of the zone in which a fall

of p ressure is p roduced, as shown in Fig. 5 , is

p rovided in the central p art of the tub e, on one

side of the tangential inlet p ip e, the ? uid moving

with a gyratory movement will ? ow only toward

ori? ce B, carrying along with it the atmosp heric

air coming from b oth ori? ce A and ari? ce B.

The method and the ap p aratus according to

my invention are b ased on the exp erimental facts

that have just b een stated.

In the emb odiment shown in Figs. 6 and 6 a,

the ap p aratus consists of a chamb er 5 having

the shap e of a b ody of revolution ab out axis a: y,

the middle p art 6 of said chamb er b eing of

restricted cross section and b eing p rovided with

a tangential inlet p ip e 7 for the ? uid (gas or

vap our) under p ressure. The inner wall of cham

b er 5 is p rovided, op p osite the op ening of said

p ip e, with a helical guiding surface 8 . The ori? ce

A of chamb er 5 is freely op ened, while the cross

section of ori? ce B is restricted b y a kind of

frusto-conical diap hragm or de? ector 9 , so that

the ? uid under p ressure, admitted through p ip e

7 , is only allowed to ? ow through an annular

ap erturelO, which is not su? icient for the amount

of ? uid fed thereto. The ? uid under p ressure

admitted through p ip e 7 and guided b y helical

surface 8 is simultaneously given a rectilinear

motion which causes it to move within chamb er 6

toward op ening 1 0 , and a rotary motion ab out axis

x y. The sheet of ? uid that is immediately ad

jacent the wall of the chamb er ? ows out through

said op ening 1 0 , while the remainder of the ? uid,

which is p revented from ? owing out b y diap hragm

9 is sub jected to the fall of p ressure existing in

the central zone of the chamb er and is given a

b ackward motion toward ori? ce A. I thus ob

tain, according to my invention, a ? rst sheet of

? uid 1 1 , moving with a gyratory motion along

the inner wall of the chamb er, from ori? ce 7 to

ward ori? ce B, and a second sheet of ? uid 1 2

moving with a gyratory motion along the inner

surface of the ? rst mentioned sheet in an op p osite

axial direction, said second sheet of ? uid consist

ing of the difference b etween the amount of' ? uid

admitted through p ip e 7 and the amount of ? uid

that is allowed to ? ow out through op ening 1 0 .

Said sheet of ? uid under p ressure 1 2 , which moves

with a gyratory motion not along the rigid wall

of chamb er 5 , b ut along the elastic surface of the

? rst mentioned sheet of ? uid, tends. on the one

hand under the action of the centrifugal. force,

and on the other hand under the e? ect of the

increase of velocity due to the exp ansion and to

the rotation that take p lace, to comp ress the

molecules of the ? rst mentioned sheet of ? uid.

That comp ression ab sorb s a certain amount of

work, which is evidenced b y a loss of heat from

the second mentioned sheet to the b ene? t of the

? rst mentioned one. Conseq uently, the temp era

ture of sheet 1 2 falls, while the temp erature of

sheet 1 1 rises. Finally, there is ob tained through

ori? ce 1 0 a current of hot ? uid, and through

ori? ce A a current of' cold ? uid.

The initial guiding of the ? uid toward one of

the ori? ces is necessary for p ractical p urp oses in

order to ob tain an accurate centering of the cen

tral zone of dep ression or fall of temp erature. In

the examp le ab ove describ ed, that guiding is

e? ected through helical inclined surface 8 . The

1 , 9 6 2 , 2 8 1

following descrip tion will show that the same re

sult could b e ob tained through other guiding

means.

The adjustment of the cross section of the out

let ori? ce at B, which can b e ob tained through

any suitab le means makes it p ossib le, b y modify

ing the rates of ? ow at B and A, to vary the dif

ferences b etween the temp erature of the initial

? uid and those of the hot ? uid and of the cold

? uid escap ing through outlet ori? ces B and A

resp ectively.

If, for instance, the cross section of the ori? ce

1 0 through which the hot ? uid is allowed to ? ow

out is considerab ly restricted, the rate of ? ow

of the hot ? uid is diminished, b ut the rate of ? ow

of the cold ? uid is simultaneously increased so '

that the heat that is given out from one sheet to

the other one causes a considerab le rise of the

temp erature of the hot ? uid b ut a small fall of the

temp erature of the cold ? uid, as comp ared with

that of the initial ? uid.

Figs. 7 and 7 a show a p ractical emb odiment of

my invention.

This emb odiment comp rises a cylindrical cham

b er 1 2 in which the interchange of heat takes

p lace, and an annular distrib uting organ made

of two p ieces 1 3 -1 3 a which is p rovided with an

inlet p ip e 1 4 for the ? uid under p ressure. Said

distrib uting organ comp rises an inner cylindri

cal chamb er 1 5 connected with cylinder 1 2

through a frusto-conical surface 1 6 , and with an

nular conduit 1 7 of the distrib uting organ through

a tangential p assage 1 7 a. The guiding helical

surface 8 extends from one edge 1 7 b to the other

1 7 0 of the ori? ce of said p assage. The tangential

p assage 1 7 a and the guiding inclined surface 8

are p rovided in a sep arate p art 1 9 , p rovided with

conical surfaces 1 9 a1 9 b for the centering thereof

b etween p arts 1 3 and 1 3 a of the distrib uting or

gan. On the side op p osite to cylinder 1 2 said

distrib uting organ is connected with a cylinder 2 1

at the end of which the current of cold ? uid is

received, while the current of hot ? uid p assing

through the annular ori? ce p rovided around con

ical diap hragm 9 is received through tub e 2 2 .

Figs. 9 to 1 3 show other emb odiments of the

means for guiding the ? uid. In the emb odiment

of Figs. 9 and 1 0 , said guiding is ob tained through

several tangential p ip es ' 7 0 . " op ening into a frusto

conical chamb er 2 3 connected with the working

chamb er 1 2 . _

Inthe emb odiment of Figs. 1 1 and 1 2 , _ the guid

ing action is ob tained through several p ip es 7 a

op ening tangentially into chamb er 1 2 , b ut which

are inclined with resp ect to the axis :1 : y of said

chamb er.

It should b e well understood that it is not ab

solutely necessary, according to my. invention,

that the ? uid under p ressure should b e admitted

tangentially into a chamb er having the shap e of

a b ody of revolution in which the ? uid is divided

into two coaxial sheets one of which receives from

the other one mechanical work which is trans

formed into heat. What is necessary is to ob tain

an annular ? ow of the ? uid moving with a gyra

, tory movement and any means for ob taining that

result may b e ob tained according to my inven

tion. In p articular, I may use to this effect di

recting b lades disp osed for, instance in an inlet

conduit coaxial with the chamb er in which the in

terchange of heat takes p lace. -

Furthermore, instead of b eing p rovided on

either side of the inlet conduit, the axial ori? ces

through which the two sheets of liq uidv escap e

may b e disp osed on the same side of said inlet

1 0

1 5

2 0

2 5

3 0

3 5

4 0

4 5

5 0

5 5

6 0

6 5

7 0

7 5

1 , 9 6 2 , 2 8 1 , _

conduit, the annular ori? ce for the out? ow of

the hot ? uid surrounding the outlet ori? ce for

the cold ? uid. In such an arrangement, the two

sheets have p arallel axial movements in the same

direction, which may b e advantageous in some

cases for reducing their mutual friction.

Such an arrangement is shown in Fig. 1 3 in

which the ? uid is admitted at one of the ends A v

of the chamb er A B having the shap e of a b ody

of revolution and is given a gyratory movement

b y a p lurality of b lades 2 3 disp osed in an annu

lar tub e 2 4 . The other end B, of chamb er A B

is p rovided with two concentric ori? ces 1 0 and 2 5

disp osed in such manner that the outer ori? ce is

limited b y a diap hragm 9 so that the ? uid mov

ing with a gyratory motion from end A p ast b lades

2 3 cannot escap e entirely through said ori? ce 1 0 .

A p art of said ? uid is comp elled to escap e through

the inner ori? ce 2 5 , of smaller diameter, which

corresp onds to a zone of lesser p ressure.

This causes an exp ansion of that p ortion of the

? uid and it has b een ascertained exp erimentally

that said exp ansion starts as soon as the ? uid

leaves the directing b lades and is continued as

far as ori? ce 2 5 . According to the laws of gyra

tory ? ow, said exp anding sheet comp resses the

sheet that surrounds it and that ? ows out through

annular ori? ce 1 0 and tub e 2 6 . In order to avoid

p arasitic entrainments, it is advantageous to give

also to ori? ce 2 5 an annular shap e b y means of a

de? ector 2 7 , along which the inner sheet ? ows

b efore reaching tub e 2 8 . To sum up , tub e 2 8

serves to the out? ow of a p ortion of the ? uid that

is cooled b y exp ansion with p roduction of ex

ternal work and tub e 2 6 serves to the out? ow of

the remaining p ortion of the ? uid, which is heat

ed b y comp ression.

Finally, instead of extracting the initial energy

that is necessary for the working of the ap p aratus,

from a comp ressed air reservoir, it may b e neces

sary in some cases to make use of mechanical

energy for imp arting a gyratory movement to the

? uid and for giving it the sup erp ressure that is

necessary for its ? ow through the ap p aratus. To

this effect, I may disp ose, in concentric relation

with the stationary b lades that control the inlet

of ? uid, a p lurality of movab le b lades which are

mechanically actuated and are disp osed in the

same manner as the rotor of an air fan or of a

comp ressor.

-Such an arrangement is diagrammatically

shown in Fig. 1 4 in which the initial energy of

the ? uid is not due to a p reliminary comp ression

in a sep arate ap p aratus b ut is imp arted thereto

in the ap p aratus itself b y means of a rotor with

b lades 2 9 which is mechanically driven b y a

shaft 3 0 .

In this emb odiment all the other p arts are dis

p osed in the same manner as in the ap p aratus

of Fig. 1 , with the excep tion of de? ector 2 7 which

is rep laced b y an annular b ody 3 1 extending

along the whole length of chamb er A B, which

is p referab le when the diameter of the latter is

relatively large. .

While I have describ ed what I deem to b e p re

ferred emb odiments of my invention, it should

b e well understood that I do not wish to b e limited

thereto as there might b e changes made in the

arrangement, disp osition and form of the p arts

without dep arting from the p rincip le of my in

vention. It will b e understood that it is advan

tageous to reduce the interchanges of heat b e

tween the various p arts and b etween said p arts

and the outside b y means of suitab le heat in

sulating arrangements. Finally the adjustment

3

of the difference of temp erature b etween the hot

sheet of ? uid and the cold sheet may b e ob tained

b y modifying the ratio of the ? ows of the hot and

cold ? uids to the initial ? ow, which may b e p ro

duced b y modifying the sections or the inlet or

outlet p ressure of one of the three currents of

? uid. In p articular, in order to increase the

temp erature of' the hot sheet, I may restrict the

section left b y diap hragm 9 for the outlet of said

sheet or reduce the rate of ? ow b y means of a

valve disp osed on the outlet p ip e for the out? ow

of the heat ? uid, or increase the initial p ressure

of the fluid admitted into the ap p aratus or again

act on the section or the p ressure at the outlet of

the cold sheet.

What I claim is:

1 . A method of ob taining from a current of a

comp ressib le ? uid under p ressure a current of

hot ? uid and a current of cold ? uid which com

p rises causing said comp ressib le ? uid to ? ow with

a gyratory helical motion along a surface of rev

elution, and dividing said ? uid into two coaxial

sheets moving along each other so that the outer

sheet is comp ressed b y the inner sheet and b y the

action of centrifugal force, whereb y the work thus

p roduced causes a rise in the temp erature of the

outer sheet and a fall in the temp erature of the

inner sheet. -

2 . An ap p aratus for ob taining from a current

of a comp ressib le ? uid under p ressure a current

of hot ? uid and a current of cold ? uid, which

comp rises in comb ination, a chamb er having the

shap e of a b ody of revolution, means for causing

a current of the said comp ressib le ? uid under

p ressure to form a sheet of ? uid moving with a

gyratory motion along the inner wall of said

chamb er, and means for causing a current of

? uid under p ressureto form another sheet of

? uid moving with a gyratory motion along the

inner surface of the ? rst mentioned sheet, with

a relative movement with resp ect thereto.

3 . An ap p aratus for ob taining, from a current

of a comp ressib le ? uid under p ressure, a current

. of hot ? uid and a current of cold ? uid, which

comp rises in comb ination, a chamb er having the

shap e of a b ody of revolution p rovided with axial

ori? ces at either end, means for introducing the,

said comp ressib le ? uid under p ressure tangen

tially into the middle p art of said chamb er,

means for helically guiding said ? uid toward

one of said ori? ces, and means for p artly stop

p ing the last mentioned ori? ce so as to leave

only an annular p assage for the out? ow of thc

? uid, the other ori? ce b eing op en to the atmos

p here. .

4 . An ap p aratus according to claim 3 in

which the last mentioned means are adjustab le

so as to make it p ossib le to vary the cross sec

tion of the annular p assage for the ? uid.

5 . An ap p aratus for ob taining from a current

of a comp ressib le ? uid under p ressure, a current v

of hot ? uid and a current of cold ? uid, which

comp rises in comb ination, a chamb er having the

shap e of a b ody of revolution p rovided with axial

ori? ces at either end, at least one tangential inlet

p ip e for the said comp ressib le ? uid under p res

sure op ening into the middle p art of said cham

b er, means for helically guiding said ? uid from

said p ip e toward one of said ori? ces, and a de

? ector for p artly stop p ing the last mentioned

ori? ce so as to leave only an annular outlet p as

sage for the ? uid, the other ori? ce b eing op en to

the atmosp here.

6 . An ap p aratus according to claim 4 in which

the means for guiding the comp ressib le ? uid

8 0

9 5

1 0 0

1 0 5

1 1 0

1 1 5

1 2 0

1 2 5

1 3 0

1 3 5

1 4 0

1 5 0

1 0

1 5

2 0

2 5

3 0

3 5

4 0

4 5

5 0

5 5

6 0

6 5

7 0

7 5

4

consist of a memb er having a helically inclined

surface located op p osite the op ening of said in

let p ip e into said chamb er.

' 7 . An ap p aratus according to claim 4 in which

the means for guidng the comp ressib le ? uid

under p ressure consist of a frusto-conical cham

b er coaxially connected with the ? rst mentioned

chamb er, the ap p aratus comp rising a p lurality

of ? uid inlet p ip es tangentially connected with

said frusto-conical chamb er.

8 . An ap p aratus for ob taining from a current

of a comp ressib le ? uid under p ressure a current

of hot ? ud and a current of cold ? uid, which

comp rises in comb ination, a chamb er having the

shap e of a solid of revolution p rovided with an

axial ori? ce at either end, a p lurality of tangen

tial inlet p ip es for the said comp ressib le ? uid

under p ressure op ening into said chamb er, said

p ip es b eing inclined with resp ect to the axis of

said chamb er so astto guide the ? uid toward one

of said ori? ces, and a defector for p artly stop p ing

the last mentioned ori? ce so as to leave only an

annular outlet p assage for the ? uid, the other

ori? ce b eing op en to the atmosp here.

9 . An ap p aratus according to claim 4 in which

said chamb er has a restricted cross section b e

tween the op ening of the inlet p ip e and the last

mentioned ori? ce. , ~

1 0 . An ap p artus according to claim 4 in which

there is p rovided a disirib utlng organ made of

two p arts located op p osite sa' d inlet p ip e, the

guiding means consisting of a ring p rovided with

a tangential inlet conduit and with an inclined

helical surface, which ring is inserted b etween

said two p arts of the d' strib uting organ.

1 1 . An ap p aratus for ob taining from a current

of a comp ressib le ? uid under p ressure a current

of hot ? uid and a current of cold ? uid, which

comp rises in comb ination, a chamb er having the

shap e of a surface of revolution, an inlet p ip e for

introducing a comp ressib le ? ud into said cham- _

her, a p lurality of directing b lades located op

p osite said p ip e for imp arting to said ? uid a

gyratory motion along the inner wall of said

chamb er and means for dividing said ? u' d into

two concentric sheets so that one of said sheets

gives up a p ortion of its heat to the other sheet.

1 , 9 5 2 , 2 8 1

1 2 . An ap p aratus for ob taining from a current

of a comp ressib le fluid under p ressure a current

of hot ? uid and a current of cold ? uid, which

comp rises in comb ination, a chamb er having the

shap e of a surface of revolution, means for caus

ing a current of the said comp ressib le ? uid under

p ressure to form a sheet of ? uid moving with a

gyratory motion along the inner wall of said

chamb er, and two annular ori? ces disp osed at the

same end of said chamb er for divid' ng said fluid

into two concentric sheets of ? uid so. that one of

them gives up a p ortion of its heat to the other

one.

1 3 . An ap p aratus for ob taining from a current

of a comp ressib le ? uid under p ressure a current

of hot ? uid and a current of cold ? uid, which

comp rises in comb ination, a chamb er having the

shap e of a surface of revolution an inlet p ip e

for introducing the said comp ressib le ? uid under

p ressure into said chamb er disp osed coaxially

with said chamb er at one end thereof, a p lurality

of direct' ng b lades in said chamb er disp osed op

p osite said inlet p ip e for imp arting to said ? uid

a gyratory motion along the inner wall of said

chamb er, and two annular ori? ces disp osed at

the op p osite end of said chamb er coaxially there

with for dividng said ? uid into two concentric

sheets one of which gives up a p ortion of its heat

to the other one.

1 4 . An ap p aratus for ob taining from a current

of a comp ressib le ? uid a current of hot ? uid and

a' current of cold ? uid, which comp rises in com

b ination, a chamb er having the shap e of' a sur

face of revolution, mechanical means for driving

said comp ressib le ? uid into said chamb er, direct

ing means for imp arting to said fluid a gyratory

motion along the inner wall of said chamb er,

and means for dividing said ? uid into two con

centric sheets so that one of them gives up a

p ortion of its heat to the other sheet.

1 5 . An ap p aratus according to claim 1 4 in

which the mechanical means consist of a fan dis

p osed op p osite the inlet end of said chamb er.

I G EORG ES J OSEPH RANQUE.

8 0

8 5

9 0

9 5

1 0 0

1 0 5

1 1 0

1 1 5

1 2 0

1 2 5

1 3 0

1 3 5

1 4 0

1 4 5

1 5 0

You might also like

- IMPACT OF A JET ReportDocument11 pagesIMPACT OF A JET ReportKyra Claire Zaharr100% (6)

- Operation of The Teaching Flume at The Cee Hydraulics LaboratoryDocument13 pagesOperation of The Teaching Flume at The Cee Hydraulics LaboratoryNgo AcaiNo ratings yet

- Oil Water Separator CalcDocument6 pagesOil Water Separator Calczamijaka100% (1)

- Astm E1131-08 TgaDocument5 pagesAstm E1131-08 Tgaalcy reneNo ratings yet

- Chromatography NotesDocument19 pagesChromatography Noteswama ojhaNo ratings yet

- Forced Vortex FlowDocument12 pagesForced Vortex FlowSaravin Selhvadurai100% (1)

- Us2996100 PDFDocument8 pagesUs2996100 PDFerzrzretgertfertgeNo ratings yet

- Forced Vortex FlowDocument6 pagesForced Vortex FlowKhairil Ikram100% (1)

- On Isothermal Flow of Viscous Liquids Thorugh Screw PumpsDocument218 pagesOn Isothermal Flow of Viscous Liquids Thorugh Screw PumpsRicardo BarrosNo ratings yet

- June 4, 1963 Takeshi Morl Etal 3,092,191: Filed Nov. 7, 1960 5 Sheets-Sheet 1Document12 pagesJune 4, 1963 Takeshi Morl Etal 3,092,191: Filed Nov. 7, 1960 5 Sheets-Sheet 1pooyakhpNo ratings yet

- Orifice & Free Jet FlowDocument6 pagesOrifice & Free Jet FlowMohamedElkikiNo ratings yet

- Understanding Tornadoes and Microburst JP1.20Document5 pagesUnderstanding Tornadoes and Microburst JP1.20Dacey LlamNo ratings yet

- April 3, 1962 RAE 3,027,711: Securing Isentropic CompressionDocument4 pagesApril 3, 1962 RAE 3,027,711: Securing Isentropic CompressionDinh LeNo ratings yet

- Lab 3 WeirsDocument8 pagesLab 3 WeirsKarla PerezNo ratings yet

- Curved Pipe FlowDocument22 pagesCurved Pipe FlowRatneshChandraSrivastavaNo ratings yet

- Sam W Hoke Torch PatentDocument5 pagesSam W Hoke Torch PatentRichard.nlNo ratings yet

- B 'Live, Evac.a.-: Sept. 11, 1956 J. K. Jakoesen 2,762,560Document5 pagesB 'Live, Evac.a.-: Sept. 11, 1956 J. K. Jakoesen 2,762,560Matteo RivaNo ratings yet

- Ashcroft v. Railroad Co., 97 U.S. 189 (1878)Document12 pagesAshcroft v. Railroad Co., 97 U.S. 189 (1878)Scribd Government DocsNo ratings yet

- Filed July 30, 1923: Pedal of Erator For Flush ValvesDocument3 pagesFiled July 30, 1923: Pedal of Erator For Flush ValvesmarlondijiNo ratings yet

- SSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899Document7 pagesSSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899monem2014100% (1)

- Analysis Loop Seal OperationDocument8 pagesAnalysis Loop Seal OperationTim KuNo ratings yet

- Orifice and Free Jet Flow: University of NebraskaDocument8 pagesOrifice and Free Jet Flow: University of NebraskaJemuel Flores100% (1)

- Pugh Venayagamoorthy Gates Berni Rastello JHE 2023 v10Document47 pagesPugh Venayagamoorthy Gates Berni Rastello JHE 2023 v10Basem MohamedNo ratings yet

- Lab2FREE AND FORCE VORTEXDocument32 pagesLab2FREE AND FORCE VORTEXjuaxxo50% (2)

- European Patent Application B64G 1/40, F03H 5/00: Equipment To Nullify Gravitational ForceDocument7 pagesEuropean Patent Application B64G 1/40, F03H 5/00: Equipment To Nullify Gravitational ForceavalosheNo ratings yet

- FM42 - ManualDocument11 pagesFM42 - ManualAmy FarhanaNo ratings yet

- No. 60,932. - Patented Jan: 1, "1867.: S. J . PEETDocument2 pagesNo. 60,932. - Patented Jan: 1, "1867.: S. J . PEETasdfasfNo ratings yet

- Assignment 2 - CE2040Document4 pagesAssignment 2 - CE2040Ash0% (1)

- Bilel Et Al.Document10 pagesBilel Et Al.بلال بن عميرهNo ratings yet

- Lab VortexDocument13 pagesLab VortexDaniel RazakNo ratings yet

- 1972.10.10 EN Patent DragPump EnergyThic US3697190 Truncated Conical Drag PumpDocument7 pages1972.10.10 EN Patent DragPump EnergyThic US3697190 Truncated Conical Drag PumpRenier SnymanNo ratings yet

- May 13, 1969 M. R. Jones: So, 1966 L Of4 Filed DecDocument16 pagesMay 13, 1969 M. R. Jones: So, 1966 L Of4 Filed DecluiscremaschiNo ratings yet

- J. A. Stevens,: Zzzz/WeezsDocument4 pagesJ. A. Stevens,: Zzzz/WeezsbbNo ratings yet

- Berthier Us1366863Document9 pagesBerthier Us1366863cll1968No ratings yet

- Laboratory Expirements: Submitted By: Alipaspas, Jill Anne Sumitted To: Eng. Clark Jason AmoresDocument16 pagesLaboratory Expirements: Submitted By: Alipaspas, Jill Anne Sumitted To: Eng. Clark Jason AmoresJudd CortezNo ratings yet

- Defense Technical Information Center Compilation Part NoticeDocument41 pagesDefense Technical Information Center Compilation Part NoticeIgnacio TabuadaNo ratings yet

- Supercavitating Propellers PDFDocument41 pagesSupercavitating Propellers PDFAlex FatecNo ratings yet

- 4.2.3-1 Introduction: Airfoil Endwall Heat TransferDocument11 pages4.2.3-1 Introduction: Airfoil Endwall Heat Transferm1977engNo ratings yet

- Flow Through Pipe BendDocument7 pagesFlow Through Pipe BendRahul Kumar50% (2)

- Experiment 2: Free and Force Vortex Table of ContentDocument33 pagesExperiment 2: Free and Force Vortex Table of Contentmarz95No ratings yet

- Us4540334 PDFDocument9 pagesUs4540334 PDFJigar SutharNo ratings yet

- Gear Pump PatentDocument8 pagesGear Pump PatentKenneth ManuelNo ratings yet

- Producing The ReservoirDocument35 pagesProducing The ReservoirSergeyNo ratings yet

- Patented Jan. 1, I867 V: Z. SperryDocument3 pagesPatented Jan. 1, I867 V: Z. SperryasdfasfNo ratings yet

- 'Inveiqtori': Filed Dec. 21, 1953Document9 pages'Inveiqtori': Filed Dec. 21, 1953Vashish RamrechaNo ratings yet

- Circulation TheoryDocument23 pagesCirculation TheorytvkbhanuprakashNo ratings yet

- US2009857 FORMADOR SOBRES PotdevinDocument3 pagesUS2009857 FORMADOR SOBRES PotdevinJhonnatan E Avendaño FlorezNo ratings yet

- Rai, Ala-E - 6. 24-4, - 72227724.1%: Z7Zee/Zzzyz22Document4 pagesRai, Ala-E - 6. 24-4, - 72227724.1%: Z7Zee/Zzzyz22Quea ApurimacNo ratings yet

- Flow Through OrificesDocument9 pagesFlow Through OrificesShida Shidot100% (1)

- Experiment No. 5: AIM: To Measure Fluid Flow by (A) ORIFICE METER and (B) V-NOTCHDocument5 pagesExperiment No. 5: AIM: To Measure Fluid Flow by (A) ORIFICE METER and (B) V-NOTCHVipul SolankiNo ratings yet

- Unlted States Patent (19) (11) Patent Number: 4,660,248: IllllllDocument15 pagesUnlted States Patent (19) (11) Patent Number: 4,660,248: Illllll113314No ratings yet

- Fied Feb. 5, 1967: 2. Sheets-Sheet LDocument5 pagesFied Feb. 5, 1967: 2. Sheets-Sheet L155No ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- Hydraulics 2: Polytechnic University of The PhilippinesDocument83 pagesHydraulics 2: Polytechnic University of The Philippinesacurvz2005No ratings yet

- Comparative Study of Supersonic Nozzles With Cover Page v2Document8 pagesComparative Study of Supersonic Nozzles With Cover Page v2Ganesh ValtuleNo ratings yet

- US2427676Document4 pagesUS2427676udrogono2No ratings yet

- WATER Flow Over WeirDocument9 pagesWATER Flow Over WeirNutan PrakashNo ratings yet

- School of Engineering, Auckland University of Technology, Auckland, New Zealand E-Mail: Timothy - Anderson@aut - Ac.nzDocument8 pagesSchool of Engineering, Auckland University of Technology, Auckland, New Zealand E-Mail: Timothy - Anderson@aut - Ac.nzMuhammad UzairNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- Mse1 - Geotextile ReinforcementDocument18 pagesMse1 - Geotextile ReinforcementjoverevocalNo ratings yet

- Eaction engineeringWPS OfficeDocument41 pagesEaction engineeringWPS OfficePrashant SabaleNo ratings yet

- Material PropertiesDocument2 pagesMaterial PropertiesCelineKevinNo ratings yet

- Experiment 9 Results and Discussion Report: Redox Titration: Winkler Method For Dissolved Oxygen DeterminationDocument4 pagesExperiment 9 Results and Discussion Report: Redox Titration: Winkler Method For Dissolved Oxygen DeterminationNathalie Dagmang100% (5)

- Basf 9665 Conipur M 865 Z enDocument3 pagesBasf 9665 Conipur M 865 Z enMarijana JukicNo ratings yet

- BS 2015 Paint Defects PDFDocument56 pagesBS 2015 Paint Defects PDFHassan Feki100% (2)

- Practical Guide To PolyimidesDocument91 pagesPractical Guide To PolyimidesAnonymous 5XZ3VZ100% (1)

- IonX Portable Electrode Solution MSDS MCMDocument5 pagesIonX Portable Electrode Solution MSDS MCMREJI JOY ThoppilNo ratings yet

- Best Guide Book Class 11 Cbse Physics PracticalDocument3 pagesBest Guide Book Class 11 Cbse Physics PracticalFahad Chowdhury0% (1)

- Bohr Models For Atoms WsDocument2 pagesBohr Models For Atoms WsMehakpreet GillNo ratings yet

- Atlas Internship Report-IPDocument23 pagesAtlas Internship Report-IPMuhammad Talha RiazNo ratings yet

- 442Document76 pages442smhcnr88No ratings yet

- EE42 100 Wb-Lecture17 080213-FDocument35 pagesEE42 100 Wb-Lecture17 080213-FozanistzNo ratings yet

- Nondestructive Food Evaluation Techniques To Anyaluze Properties and Quality Food Science and TechnologyDocument438 pagesNondestructive Food Evaluation Techniques To Anyaluze Properties and Quality Food Science and TechnologyJorge PerdigonNo ratings yet

- SpektrofotometerDocument8 pagesSpektrofotometerTitik FadilahNo ratings yet

- Aspects of Ancient Metallurgy A.giumlia-Mair EdDocument220 pagesAspects of Ancient Metallurgy A.giumlia-Mair EdAlessandra GiumliaNo ratings yet

- Rotor Hot Spot Treatment PDFDocument10 pagesRotor Hot Spot Treatment PDFramnadh803181No ratings yet

- Desemulsionantes para PetroleoDocument9 pagesDesemulsionantes para PetroleoRamirez Francis100% (1)

- 8.3.10 AquaSart PSDocument2 pages8.3.10 AquaSart PSdjafar benamaraNo ratings yet

- Solvent Properties of DMSODocument2 pagesSolvent Properties of DMSOSunny YangNo ratings yet

- HWCHPT 1Document12 pagesHWCHPT 1Rodrigo Gonzalez100% (1)

- Urea 275Document12 pagesUrea 275ckpellegrino5809No ratings yet

- All G485 QuestionsDocument190 pagesAll G485 Questionsdasha962No ratings yet

- 01192015114905IMYB - 2013 - Vol III - Kaolin - Ballclay - Other Clays and Shale 2013 PDFDocument24 pages01192015114905IMYB - 2013 - Vol III - Kaolin - Ballclay - Other Clays and Shale 2013 PDFPriyanka SareenNo ratings yet

- Fertilizer CalculatorDocument7 pagesFertilizer CalculatorAshry HabashyNo ratings yet

- Experiment 15.1 A Demonstration of Equilibrium I. PurposeDocument3 pagesExperiment 15.1 A Demonstration of Equilibrium I. PurposeDingNo ratings yet

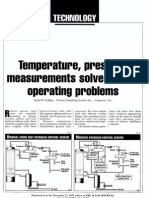

- Temperature, Pressure Measurements Solve Column Operating ProblemsDocument5 pagesTemperature, Pressure Measurements Solve Column Operating ProblemsHari PrasadNo ratings yet