Professional Documents

Culture Documents

Testex System Press o Film Ld2070 m44

Testex System Press o Film Ld2070 m44

Uploaded by

musaismail88630 ratings0% found this document useful (0 votes)

56 views2 pages1. Replica tape is used to measure the surface profile of blasted surfaces. Different grades of replica tape can measure surface roughness from 0.4 to 5.0 mils.

2. The tape comes with adhesive-backed plastic film squares and a burnishing tool. To take a measurement, the film is applied to the surface and rubbed with the tool to replicate the profile.

3. The replicated film is then placed between the anvils of a surface profile gauge and the peak-to-valley height in mils is read off the gauge after subtracting the thickness of the substrate. This provides the average roughness of the blasted surface.

Original Description:

hgkjghkhk

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. Replica tape is used to measure the surface profile of blasted surfaces. Different grades of replica tape can measure surface roughness from 0.4 to 5.0 mils.

2. The tape comes with adhesive-backed plastic film squares and a burnishing tool. To take a measurement, the film is applied to the surface and rubbed with the tool to replicate the profile.

3. The replicated film is then placed between the anvils of a surface profile gauge and the peak-to-valley height in mils is read off the gauge after subtracting the thickness of the substrate. This provides the average roughness of the blasted surface.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

56 views2 pagesTestex System Press o Film Ld2070 m44

Testex System Press o Film Ld2070 m44

Uploaded by

musaismail88631. Replica tape is used to measure the surface profile of blasted surfaces. Different grades of replica tape can measure surface roughness from 0.4 to 5.0 mils.

2. The tape comes with adhesive-backed plastic film squares and a burnishing tool. To take a measurement, the film is applied to the surface and rubbed with the tool to replicate the profile.

3. The replicated film is then placed between the anvils of a surface profile gauge and the peak-to-valley height in mils is read off the gauge after subtracting the thickness of the substrate. This provides the average roughness of the blasted surface.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

1 |

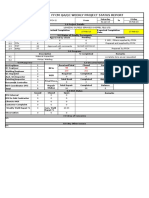

TESTEX REPLICA TAPE PRESS-O-FILM

LD2065, LD2066, LD2067, LD2070, LD2071

1 PRODUCT DESCRIPTION

Replica tape for measuring blasted surface profiles. By placing the Tqc replica tape on

the surface and rubbing over it, the Rt (total roughness) or peak-to-valley height of

the profile can be taken and then measured with a film thickness meter.

1.1 specifications

Testex-tape X-COARSE - 1.5 to 4.5 mils / 40 to 115m

Testex-tape COARSE - 0.8 to 2.0 mils / 20 to 50m

Testex-tape MEDIUM - 0.4 mils/10m not to be used with a film thickness meter

Testex-tape MINUS - 0.5 to 1.0 mils / 12 to 25 m

Testex-tape X-COURSE PLUS - 4.6 to 5.0 mils / 116 to 127 m

2 STANDARDS

ASTM D4417 03

3 WHATS IN THE BOX?

Testex tape roll (50 stickers)

Burnishing tool

4 PERFORM A MEASUREMENT

1. Locate a representative site for measurement.

2. Turn the gauge on (ON/OFF -5-).

3. Choose the appropriate parameter (mm/inch -1-).

4. Zero (-6-)the gauge

5. Pull a single piece of adhesive-backed printed paper free of the release paper. The

Press-O-Film is the 0.4 inch (1 cm) square white plastic film at the centre of the

adhesive-backed paper. A circle of paper should remain on the release paper.

6. Apply film to surface to be measured. The adhesive-backed paper will hold it firmly in

place.

7. Rub burnishing tool over the round cut-out portion of replica tape, using moderate to firm pressure. Use

the smoothest surface on the rubbing tool. A firm pressure is desirable, with either circular, or x- and y-

direction, rubbing motions. Compress all parts of the film but be careful not to slide the film with respect to

the surface by bumping the edges of the circular paper cut-out. When surface is

replicated the replica tape will become darker. Make sure that the entire

circular area has uniformly darkened.

8. Remove replica and place it (by gently pressuring the lever -4-)

centered between anvils(-2-, -3-). Place the anvil, by gently

pressuring the lever (-4-), on the Press-O-Film. Subtract 2 mills

or 0,05 mm or 50 m) from the gage reading (the thickness of

the incompressible substrate). The resulting number is the

average peak-to-valley height of the blasted surface (Rave).

4 4

1 1

5 5

7 7

6 6

2 2

3 3

2 |

9. Confirm that reading is well within the tape's recommended range. Tape is most accurate in mid-range

region. If the measured profile is near the upper or lower end of the tape's range, confirm your reading with

a grade more appropriate to the observed profile. By slightly shifting the replica tape (with anvils released)

you can make verification measurements.

5 DISCLAIMER

The right of technical modifications is reserved.

The information given in this manual is not intended to be exhaustive and any person using the product for any

purpose other than that specifically recommended in this manual without first obtaining written confirmation

from us as to the suitability of the product for the intended purpose does so at his own risk. Whilst we

endeavour to ensure that all advice we give about the product (whether in this manual or otherwise) is correct

we have no control over either the quality or condition of the product or the many factors affecting the use and

application of the product. Therefore, unless we specifically agree in writing to do so, we do not accept any

liability whatsoever or howsoever arising for the performance of the product or for any loss or damage (other

than death or personal injury resulting from our negligence) arising out of the use of the product. The

information contained in this manual is liable to modification from time to time in the light of experience and

our policy of continuous product development.

You might also like

- AS 1100 Part 301 Architectural DrawingDocument24 pagesAS 1100 Part 301 Architectural DrawingHao Much100% (4)

- Astm F726 - 12Document6 pagesAstm F726 - 12Charlyn Abella CamachoNo ratings yet

- Ann Rea - Discovery JournalDocument47 pagesAnn Rea - Discovery JournalKarolis KauneckasNo ratings yet

- Certificado de Brida CiegaDocument1 pageCertificado de Brida Ciegabenedicto soto mestanzaNo ratings yet

- Cylinders Shall Be Produced As Per IS 7285 and Approved by Chief Controller of ExplosiveDocument1 pageCylinders Shall Be Produced As Per IS 7285 and Approved by Chief Controller of ExplosiveAlanka Prasad100% (1)

- 77 20 01 PDFDocument4 pages77 20 01 PDFAnonymous 298xlo3uUNo ratings yet

- Data Sheet: Elcometer 124 Thickness GaugeDocument3 pagesData Sheet: Elcometer 124 Thickness GaugeMohamed NouzerNo ratings yet

- Thickness of Paper and Paperboard: Standard Test Method ForDocument3 pagesThickness of Paper and Paperboard: Standard Test Method ForfrostestNo ratings yet

- Testex Tape Product Data Sheet 122Document2 pagesTestex Tape Product Data Sheet 122Bash MatNo ratings yet

- Certificado Calidad-Codo SCH40Document1 pageCertificado Calidad-Codo SCH40ALENo ratings yet

- C Tape Datasheet PDFDocument2 pagesC Tape Datasheet PDFIftikhar Ahmed KhalidNo ratings yet

- Single Chamber Blast Machines ABSC-24524: Owner'S ManualDocument7 pagesSingle Chamber Blast Machines ABSC-24524: Owner'S ManualBiggie Tafadzwa GanyoNo ratings yet

- Fr20-016.007-1-Bridas de 10-SlipDocument1 pageFr20-016.007-1-Bridas de 10-SlipEduardo Dudlei Jimenez CarbajalNo ratings yet

- ABSC 2452 Blast MachineDocument8 pagesABSC 2452 Blast MachineMehman NasibovNo ratings yet

- Tensile Test ReportDocument1 pageTensile Test ReportGHULAM NABINo ratings yet

- Certificate of Conformity 2016 PDFDocument2 pagesCertificate of Conformity 2016 PDFRaul AviñaNo ratings yet

- Douglas Chero Catalogue Valve 6-2003Document89 pagesDouglas Chero Catalogue Valve 6-2003Yurizki LhzNo ratings yet

- Ringo - Control ValvesDocument36 pagesRingo - Control ValvesPatricio Acuña100% (1)

- Cone Penetration of Lubricating Grease: Standard Test Methods ForDocument14 pagesCone Penetration of Lubricating Grease: Standard Test Methods ForROHITNo ratings yet

- Certificado de Calidad Brida WN SCH-80 2.5Document1 pageCertificado de Calidad Brida WN SCH-80 2.5Jackelin MayraNo ratings yet

- Astm D 6079Document8 pagesAstm D 6079Jesús GarcíaNo ratings yet

- Mag General Business: Mill Test CertificateDocument1 pageMag General Business: Mill Test CertificateRaul SebastiamNo ratings yet

- Certificado de Calidad Brida Anillo GhasDocument1 pageCertificado de Calidad Brida Anillo GhasJKarlos Barrientos ÑufloNo ratings yet

- Dean RA Pump ManualsDocument23 pagesDean RA Pump ManualscoltonNo ratings yet

- API 6A RadiographyDocument4 pagesAPI 6A RadiographyminakshissawantNo ratings yet

- D6185-11 Standard Practice For Evaluating Compatibility of Binary Mixtures of Lubricating GreasesDocument9 pagesD6185-11 Standard Practice For Evaluating Compatibility of Binary Mixtures of Lubricating GreasesSalvatore LombardoNo ratings yet

- Plano Camal MunicipalDocument1 pagePlano Camal MunicipalJulio MoralesNo ratings yet

- Aerial Survey: PhotogrammetryDocument87 pagesAerial Survey: PhotogrammetryNoordeen ItimuNo ratings yet

- Split Tee Hot Tap Fitting Spec SheetDocument8 pagesSplit Tee Hot Tap Fitting Spec SheetJesus Alberto Carrasco OrtizNo ratings yet

- Test Certificate: (, Phone: 26751763 MillDocument1 pageTest Certificate: (, Phone: 26751763 MillQc QatarNo ratings yet

- Airvac Portable Vacuum Recovery SystemDocument8 pagesAirvac Portable Vacuum Recovery SystemEngTamerNo ratings yet

- Weflo Valve Co., LTD.: Material Test CertificateDocument1 pageWeflo Valve Co., LTD.: Material Test CertificateCarlosEduardoMorenoManceraNo ratings yet

- WI-08 - Work Instruction For Use of UTM 18.03.2021Document1 pageWI-08 - Work Instruction For Use of UTM 18.03.2021Saurav KumarNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- MP 2530Document5 pagesMP 2530Jose OcañaNo ratings yet

- Item 13. Codo SCH-80 A234 - 783Document1 pageItem 13. Codo SCH-80 A234 - 783ELMER CHILON MINCHANNo ratings yet

- Deliver High Performance: Advanced MaterialsDocument6 pagesDeliver High Performance: Advanced Materialsmkamat007No ratings yet

- AJ401Document36 pagesAJ401Richar Manuel Simanca FontalvoNo ratings yet

- Abnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Document1 pageAbnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Mohamed RaafatNo ratings yet

- Quality Certificated 123Document1 pageQuality Certificated 123Zaid Raslan Ayoub100% (1)

- 2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14Document8 pages2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14JORGE BAENA100% (1)

- Certificado Brida 3Document1 pageCertificado Brida 3juan aguilarNo ratings yet

- Hempel Product Data SheetDocument6 pagesHempel Product Data SheetHendri Arief SetyawanNo ratings yet

- Annex BDocument14 pagesAnnex BPercy Junior Berrios Muñoz100% (1)

- PMS-V32-Ball Valves - FlangedDocument2 pagesPMS-V32-Ball Valves - FlangedMB Azharudeen100% (1)

- Data Sheet For Split TeeDocument3 pagesData Sheet For Split Teepablo100% (1)

- VP 30 Product Data 11 15Document2 pagesVP 30 Product Data 11 15marcos crisosto100% (1)

- Manual CalidadDocument23 pagesManual CalidadGabriel GaraventaNo ratings yet

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- SES Amercoat Dimetcote 9Document4 pagesSES Amercoat Dimetcote 9kamalkashNo ratings yet

- Amercoat 370Document3 pagesAmercoat 370Victor Hugo Bustos Beltran100% (1)

- Plastico Asme IxDocument13 pagesPlastico Asme IxAnonymous t0r2yT4No ratings yet

- Penetrante CantescoDocument1 pagePenetrante CantescoAries MarteNo ratings yet

- Malmedi 50HZ 14-09-04Document538 pagesMalmedi 50HZ 14-09-04rhusseinpos4765No ratings yet

- Certificado 3.1 y Calibracion Termopares - TecamDocument11 pagesCertificado 3.1 y Calibracion Termopares - TecamigorNo ratings yet

- Swagelok Magnehelic Gauge InstructionsDocument4 pagesSwagelok Magnehelic Gauge InstructionsAnonymous vF4wgBTdSbNo ratings yet

- Certificado Reduccion SW de Acero X 3000.6000 Lbs. A-105 - Bushing1.5x1 y Reduccion 2.5x 1.5Document1 pageCertificado Reduccion SW de Acero X 3000.6000 Lbs. A-105 - Bushing1.5x1 y Reduccion 2.5x 1.5ENERGIA ATLANTANo ratings yet

- NDT & QCDocument20 pagesNDT & QCEswara Rao Boddu100% (1)

- Cylindrical Bend Test 100mm Incl Mandrel Set Sp1820 m44 1Document2 pagesCylindrical Bend Test 100mm Incl Mandrel Set Sp1820 m44 1oktaviani fajar handiniNo ratings yet

- How to Apply StarkTape Kinesiology Tape. Best Kinesiology Taping TechniquesFrom EverandHow to Apply StarkTape Kinesiology Tape. Best Kinesiology Taping TechniquesRating: 5 out of 5 stars5/5 (1)

- Flow charts of pharmaceutical quality control tests for different dosage formsFrom EverandFlow charts of pharmaceutical quality control tests for different dosage formsNo ratings yet

- Flow Chart For Handling Incoming DocumentsDocument1 pageFlow Chart For Handling Incoming Documentsmusaismail8863100% (1)

- 02 MechanicalDocument44 pages02 Mechanicalmusaismail8863No ratings yet

- FFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)Document1 pageFFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)musaismail8863100% (1)

- Material Specification Sheet Saarstahl - C40E (Ck40)Document2 pagesMaterial Specification Sheet Saarstahl - C40E (Ck40)musaismail8863No ratings yet

- Abs Guide Rules For Fpso ConversionDocument1 pageAbs Guide Rules For Fpso Conversionmusaismail8863No ratings yet

- MDR NDT Drawing Tembikai As of 08.11.2014Document1 pageMDR NDT Drawing Tembikai As of 08.11.2014musaismail8863100% (1)

- 232 50Document2 pages232 50musaismail8863No ratings yet

- Risks in Facility Build Quality and Project Handover: What Happened?Document3 pagesRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863No ratings yet

- Instruction Manual - Dial Thickness Gauge Kit How Replica Tape WorksDocument6 pagesInstruction Manual - Dial Thickness Gauge Kit How Replica Tape Worksmusaismail8863No ratings yet

- Apartment Harga SederhanaDocument3 pagesApartment Harga Sederhanamusaismail8863No ratings yet

- 16 - Metal and SpecialtyDocument12 pages16 - Metal and Specialtymusaismail8863No ratings yet

- STARS (SHE Tracking Analysis Reporting System) Plant ViewDocument18 pagesSTARS (SHE Tracking Analysis Reporting System) Plant ViewrajatNo ratings yet

- HelicoptersDocument11 pagesHelicoptersJordan MosesNo ratings yet

- MLOG GX CMXA75 v4 0 322985a0 UM-ENDocument311 pagesMLOG GX CMXA75 v4 0 322985a0 UM-ENjamiekuangNo ratings yet

- Quantum Tunneling and Spin 14Document14 pagesQuantum Tunneling and Spin 14plfratarNo ratings yet

- State-Of-Charge Estimation of Lithium-Ion Batteries Using Extended Kalman Filter and Unscented Kalman FilterDocument4 pagesState-Of-Charge Estimation of Lithium-Ion Batteries Using Extended Kalman Filter and Unscented Kalman FilterRick MaityNo ratings yet

- No Tears For TiersDocument4 pagesNo Tears For Tiersapi-143406529No ratings yet

- Sika Backing FillerDocument2 pagesSika Backing FillerErdenebileg SangidorjNo ratings yet

- Stevenson12e Preface PDFDocument31 pagesStevenson12e Preface PDFLukas OstjenNo ratings yet

- GN No 333 Public Procurement (Amendment) Regulations, 2016Document45 pagesGN No 333 Public Procurement (Amendment) Regulations, 2016imran hameerNo ratings yet

- Ibm - R61i Vga ShareDocument100 pagesIbm - R61i Vga Shareحسن علي نوفلNo ratings yet

- JM Mechanically Fastened and Adhered Details UltraGard TPO Roof Drain New Construction Detail Drawing B18270Document1 pageJM Mechanically Fastened and Adhered Details UltraGard TPO Roof Drain New Construction Detail Drawing B18270michael jan tubongbanuaNo ratings yet

- RS232Document29 pagesRS232Pravish Sainath100% (1)

- Agilent 6850 Gas Chromatograph Maintenance PDFDocument9 pagesAgilent 6850 Gas Chromatograph Maintenance PDFFrancesco MoriscoNo ratings yet

- 13 565Document4 pages13 565Nabeel SheikhNo ratings yet

- Key Performance IndicatorsDocument27 pagesKey Performance IndicatorsZiad NayyerNo ratings yet

- Module 3 - AmcmlDocument3 pagesModule 3 - AmcmlAmotsik GolezNo ratings yet

- Signals and System PDFDocument38 pagesSignals and System PDFdeepakNo ratings yet

- 211-Article Text-399-1-10-20180522 PDFDocument42 pages211-Article Text-399-1-10-20180522 PDFAlex KanathNo ratings yet

- Symbiosis PresentationDocument7 pagesSymbiosis Presentationmisterbrowner@yahoo.com100% (1)

- A CLFILE Is A ANSI Standard Generic Output File For ToolDocument2 pagesA CLFILE Is A ANSI Standard Generic Output File For ToolFadetwoNo ratings yet

- Historical Change and Ceramic Tradition: The Case of Macedonia - Zoi KotitsaDocument15 pagesHistorical Change and Ceramic Tradition: The Case of Macedonia - Zoi KotitsaSonjce Marceva100% (2)

- ReadyMade in IndiaDocument6 pagesReadyMade in IndiaHari KrishnaNo ratings yet

- Mechanical Engineering Undergraduate ResumeDocument2 pagesMechanical Engineering Undergraduate ResumeAndré ArayaNo ratings yet

- EDFD 211: Psychological Foundations in Education First Semester SY 2016-17 Course DescriptionDocument4 pagesEDFD 211: Psychological Foundations in Education First Semester SY 2016-17 Course DescriptionLeezl Campoamor OlegarioNo ratings yet

- Method Statement Ceiling RemovalDocument7 pagesMethod Statement Ceiling RemovalSimpol MathNo ratings yet

- MicroZed-3.3 Operators Manual SW v9.00Document64 pagesMicroZed-3.3 Operators Manual SW v9.00Emeka Pius Oramunwa100% (1)

- U5 - Ultrasonic InspectionDocument83 pagesU5 - Ultrasonic InspectionSuraj B SNo ratings yet

- Sailor Moon Episode 123 Sweet DreamsDocument4 pagesSailor Moon Episode 123 Sweet DreamssuveertamNo ratings yet

- 9286 Ds Opsycom PFPDocument2 pages9286 Ds Opsycom PFPamir11601No ratings yet