Professional Documents

Culture Documents

Α-Allenic Esters From Α-Phosphoranylidene Esters And Acid Chlorides

Α-Allenic Esters From Α-Phosphoranylidene Esters And Acid Chlorides

Uploaded by

Jarrett Robinson0 ratings0% found this document useful (0 votes)

29 views5 pagesA-ALLENIC ESTERS FROM a-PHOSPHORANYLIDENE ESTERS AND ACID CHLORIDES: ETHYL 2,3-PENTADIENOATE. A 1-L, three-necked, round-bottomed flask is equipped with a nitrogen inlet. The yellow solution is vigorously stirred at 25degC.

Original Description:

Original Title

CV7P0232

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA-ALLENIC ESTERS FROM a-PHOSPHORANYLIDENE ESTERS AND ACID CHLORIDES: ETHYL 2,3-PENTADIENOATE. A 1-L, three-necked, round-bottomed flask is equipped with a nitrogen inlet. The yellow solution is vigorously stirred at 25degC.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

29 views5 pagesΑ-Allenic Esters From Α-Phosphoranylidene Esters And Acid Chlorides

Α-Allenic Esters From Α-Phosphoranylidene Esters And Acid Chlorides

Uploaded by

Jarrett RobinsonA-ALLENIC ESTERS FROM a-PHOSPHORANYLIDENE ESTERS AND ACID CHLORIDES: ETHYL 2,3-PENTADIENOATE. A 1-L, three-necked, round-bottomed flask is equipped with a nitrogen inlet. The yellow solution is vigorously stirred at 25degC.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

Organic Syntheses, Coll. Vol. 7, p.232 (1990); Vol. 62, p.202 (1984).

-ALLENIC ESTERS FROM -PHOSPHORANYLIDENE ESTERS

AND ACID CHLORIDES: ETHYL 2,3-PENTADIENOATE

[2,3-Pentadienoic acid, ethyl ester]

Submitted by Robert W. Lang

1

and Hans-Jrgen Hansen

2

.

Checked by William F. Burgoyne and Robert M. Coates.

1. Procedure

A 1-L, three-necked, round-bottomed flask is equipped with a nitrogen inlet, a 250-mL, pressure-

equalizing dropping funnel fitted with a gas outlet, and a Teflon-coated magnetic stirring bar. The flask

is charged with 300 mL of dichloromethane (Note 1) and 34.8 g (0.10 mol) of ethyl

(triphenylphosphoranylidene)acetate (Note 2) and flushed with nitrogen. The yellow solution is stirred

at 25C as a solution of 10.1 g (0.10 mol) of triethylamine (Note 3) in 100 mL of dichloromethane is

added dropwise over 5 min. After 10 min, 9.25 g (0.10 mol) of propionyl chloride (Note 4) in 100 mL

of dichloromethane is added dropwise to the vigorously stirred solution over 15 min (Note 5). Stirring is

continued for an additional 0.5 hr (Note 6), after which the clear, yellow-tinted mixture is evaporated on

a rotary evaporator at reduced pressure using a water bath maintained at 25C (Note 7). A 500-mL

portion of pentane (Note 8) is added to the semisolid residue, and the slurry is allowed to stand for 2 hr

while it is shaken periodically to facilitate solidification and to complete the extraction of the product.

The precipitate is removed by filtration through a coarse, sintered-glass Bchner funnel, and the filter

cake is washed with a 50-mL portion of pentane. The filtrates are combined and concentrated at reduced

pressure to approximately one-fourth of the original volume using a water bath maintained at 25C. The

mixture is filtered again to remove triphenylphosphine oxide, and the remaining solvent is then

evaporated. Rapid distillation of the residual liquid in a short-path distillation apparatus under reduced

pressure (Note 9) affords a small forerun amounting to 0.5 mL or less and 7.88.1 g (6264%) of ethyl

2,3-pentadienoate, bp 5759C (1214 mm) (Note 10) and (Note 11).

2. Notes

1. Dichloromethane was purified by percolation through Woelm activity grade 1 basic alumina and

stored under nitrogen.

2. Ethyl (triphenylphosphoranylidene)acetate is available from Fluka AG and Tridom Chemical Inc.

under the name (ethoxycarbonylmethylene)triphenylphosphorane and from Aldrich Chemical Company,

Inc. under the name (carbethoxymethylene)triphenylphosphorane. The reagent may be prepared from

triphenylphosphine and ethyl bromoacetate by the following procedure.

3

A 1-L, two-necked, round-bottomed flask fitted with a dropping funnel and a mechanical stirrer is

charged with 131.0 g (0.5 mol) of triphenylphosphine (Fluka AG, purum) and 250 mL of benzene

(Merck, pro analysi). The solution is stirred vigorously while 83.5 g (0.5 mol) of ethyl bromoacetate

(Fluka AG, practical-grade) is added dropwise at a rate that maintains the reaction mixture at, or slightly

above, room temperature. After a total of 2 hr the reaction is complete and the colorless phosphonium

salt is filtered. The salt is washed with 300 mL of cold benzene and 200 mL of pentane and then

dissolved in 3 L of water at room temperature. Some further organic impurities are removed by

extraction with ether, after which 2 drops of 2% alcoholic phenolphthalein are added. The aqueous

solution is stirred vigorously and cooled in an ice bath as 2 M aqueous sodium hydroxide is added

slowly until the pink endpoint is reached (pH 810). The crystalline phosphorane is collected by

filtration, washed thoroughly with cold water, and dried, first with a rotary evaporator under reduced

pressure at 60C and then overnight in a drying oven at 180 mm and 70C. The white to cream-colored

crop of ethyl (triphenylphosphoranylidene)acetate, mp 124126C, weighs 150156 g (8690%) and

DOI:10.15227/orgsyn.062.0202

may be used for the preparation of -allenic esters without further purification.

3. Triethylamine was supplied by Fluka AG and Aldrich Chemical Company, Inc.

4. Propionyl chloride was purchased from Fluka AG and Aldrich Chemical Company, Inc. and was

freshly distilled at 7880C (760 mm) prior to use.

5. The checkers maintained the temperature of the reaction mixture at ca. 25C by cooling with a water

bath during the addition of propionyl chloride.

6. The progress of the reaction may be followed by analytical thin-layer chromatography on alumina.

The submitters used polygram precoated plastic sheets (Alox N/UV

254

) purchased from Macherey-

Nagel, Inc. The plates were developed with 1 : 1 hexane : ether and stained with basic permanganate.

The retardation factor of the product is 0.56.

7. For the isolation of relatively volatile -allenic esters such as ethyl 2,3-pentadienoate, the submitters

recommend that the rotary evaporation be carried out with cooling in an ice bath. When this precaution

was taken, the submitters obtained 8.59.5 g (6775%) of product after distillation.

8. The checkers dried the pentane over sodium wire prior to use.

9. The checkers stirred the distilling liquid rapidly with a magnetic stirrer and maintained a bath

temperature of 7585C throughout the distillation.

10. Ethyl 2,3-pentadienoate has the following spectral properties: IR (thin film) cm

1

: 1965, 1720, 1410,

1250, 1025, 865, 790;

1

H NMR (CCl

4

) : 1.26 (t, 3 H, J = 7, OCH

2

CH

3

), 1.78 (m, 3 H, CH

3

), 4.11 (q, 2

H, J = 7, OCH

2

CH

3

), 5.285.68 (m, 2 H, at C-2 and C-4).

11. On 0.01-mol scale the yield of ethyl 2,3-pentadienoate is 0.790.93 g (6474%). The product was

purified by bulb-to-bulb distillation with a Kugelrohr apparatus at 1214 mm with an oven temperature

at 7585C.

3. Discussion

The acylation of Wittig reagents provides the most convenient means for the preparation of allenes

substituted with various electron-withdrawing substituents.

4

The preparation of -allenic esters has been

accomplished by the reaction of resonance-stabilized phosphoranes with isolable ketenes

5,6,7,8,9,10

and

ketene itself

11

and with acid chlorides in the presence of a second equivalent of the phosphorane.

6

The

disadvantages of the first method are the necessity of preparing the ketene and the fact that the highly

reactive monosubstituted ketenes evidently cannot be used. The second method fails when the -carbon

of the phosphorane is unsubstituted.

12

TABLE I

PREPARATION OF -ALLENIC ESTERS BY THE WITTIG REACTION

13

R

1

R

2

R

3

R

4

Solvent Procedure

a

Yield (%)

CH

3

H H H

CH

2

Cl

2

A

40

C

2

H

5

H

(CH

3

)

3

C

H

CH

3

CN

B

55

CH

3

H

C

6

H

5

H

CH

3

CN

B

23

The present procedure affords a general method for preparing -allenic esters (Table I) that avoids

the limitations of the previous methods.

12

Thus, -allenic esters unsubstituted at C-2 are now available

in generally satisfactory yields. Ethyl 2,3-pentadienoate, the title compound, had not been prepared prior

to the development of this procedure by the submitters. The mild conditions (i.e., room temperature for

relatively short times), avoid the base-catalyzed isomerization of the conjugated allenes to acetylenes.

14

The corresponding phosphonium salts may also be used directly in the reaction provided two

equivalents of triethylamine are employed, obviating the lengthy process for drying the phosphorane.

15

Dichloromethane and acetonitrile have been used as solvents for the reaction.

12

The -allenic esters are

usually obtained in analytically pure form after bulb-to-bulb distillation. They may also be purified by

column chromatography on alumina with 9 : 1 hexane : ether as eluant.

14

The submitters have shown that these reactions proceed by dehydrochlorination of the acid chloride

to the ketene, which is then trapped by reaction with the phosphorane. The resulting betaine decomposes

to the allenic ester via an oxaphosphetane. In contrast, the reaction of acid chlorides with 2 equiv of

phosphoranes involves initial acylation of the phosphorane followed by proton elimination from the

phosphonium salt.

5

This preparation is referenced from:

Org. Syn. Coll. Vol. 9, 436

References and Notes

1. Zentrale Forschungslaboratorien, CIBA-Geigy AG, Postfach CH-4002, Basel, Switzerland;

2. Zentrale Forschungseinheiten, F. Hoffmann-La Roche & Co. AG, Postfach, CH-4002 Basel,

C

2

H

5

CH

3

H H

CH

2

Cl

2

A

59

C

2

H

5

CH

3

CH

3

H

CH

2

Cl

2

A

74

C

2

H

5

CH

3

CH

3

CH

3

CH

2

Cl

2

B

39

CH

3

CH

3

(CH

3

)

3

C

H

CH

3

CN

B

66

C

2

H

5

CH

3

C

6

H

5

H

CH

2

Cl

2

A

70

a

The reaction times varied from 10 min to 18 hr. Procedure: Athe corresponding phosphonium s

was used with the addition of 2 mol of triethylamine; Bthe corresponding phosphorane was use

with the addition of 1 mol of triethylamine.

Switzerland. Work done at the Institute of Organic Chemistry, University of Fribourg, CH-1700

Fribourg, Prolles, and supported by the Swiss National Science Foundation.

3. Isler, O.; Gutmann, H.; Montavon, M.; Regg, R.; Ryser, G.; Zeller, P. Helv. Chim. Acta 1957,

40, 12421249.

4. Traylor, D. R. "The Chemistry of Allenes," Chem. Rev. 1967, 67, 317359; Sandler, S. R.; Karo,

W. "Organic Functional Group Preparations"; Academic Press: New York, 1971; Vol. 2, pp. 1

40; Murray, M. "Allene bzw. Kumulene" in "Methoden der Organischen Chemie" (Houben-

Weyl), 4th ed., Mller, E., Ed.; Thieme: Stuttgart, 1977; Vol. 5/2a, pp. 9631076; "The

Chemistry of Allenes," Landor, S. R., Ed.; Academic Press: London, 1982; Vols. 13; Schuster,

H. F.; Coppola, G. M.; "Allenes in Organic Synthesis," J. Wiley & Sons, New York, 1984.

5. Wittig, G.; Haag, A. Chem. Ber. 1963, 96, 15351543.

6. Bestmann, H.-J.; Hartung, H. Chem. Ber. 1966, 99, 11981207.

7. Aksnes, G.; Fryen, P. Acta Chem. Scand. 1968, 22, 23472352.

8. Andrews, S. D.; Day, A. C.; Inwood, R. N. J. Chem. Soc. (C) 1969, 24432449.

9. Orlov, V. Y.; Lebedev, S. A.; Ponomarev, S. V.; Lutsenko, I. F. J. Gen. Chem. U.S.S.R. (Engl.

transl.) 1975, 45, 696.

10. Gompper, R.; Wolf, U. Liebigs Ann. Chem. 1979, 13881405, 14061425.

11. Hamlet, Z.; Barker, W. D. Synthesis 1970, 543544.

12. Bestmann, H.-J.; Arnason, B. Chem. Ber. 1962, 95, 15131527; Bestmann, H.-J. Angew. Chem.

1965, 77, 651666.

13. Lang, R. W.; Hansen, H.-J. Helv. Chim. Acta 1980, 63, 438455.

14. Cymerman Craig, J.; Moyle, M. J. Chem. Soc. 1963, 53565360; Busby, R. J. Quart. Rev. Chem.

Soc. 1970, 24, 585600.

15. Lang, R. W.; Hansen, H.-J. Helv. Chim. Acta 1979, 62, 10251039.

Appendix

Chemical Abstracts Nomenclature (Collective Index Number);

(Registry Number)

alumina

Benzene (71-43-2)

ether (60-29-7)

acetonitrile (75-05-8)

sodium hydroxide (1310-73-2)

nitrogen (7727-37-9)

sodium wire (13966-32-0)

Pentane (109-66-0)

dichloromethane (75-09-2)

phenolphthalein (77-09-8)

propionyl chloride (79-03-8)

Ethyl bromoacetate (105-36-2)

hexane (110-54-3)

triethylamine (121-44-8)

triphenylphosphine (603-35-0)

triphenylphosphine oxide (791-28-6)

betaine (107-43-7)

phosphorane (7723-14-0)

Ethyl 2,3-pentadienoate,

2,3-Pentadienoic acid, ethyl ester (74268-51-2)

ethyl (triphenylphosphoranylidene)acetate,

(ethoxycarbonylmethylene)triphenylphosphorane,

(carbethoxymethylene)triphenylphosphorane (1099-45-2)

oxaphosphetane

Copyright 1921-2005, Organic Syntheses, Inc. All Rights Reserved

You might also like

- Organic Syntheses Collective Volume 2Document813 pagesOrganic Syntheses Collective Volume 2caltexas88% (8)

- Synthesis of P2PDocument15 pagesSynthesis of P2PRiki Mandol84% (25)

- Organic Syntheses Collective Volume 3Document1,060 pagesOrganic Syntheses Collective Volume 3caltexas100% (5)

- Synthesis of 2-Acetylcyclohexanone Using Pyrrolidine-EnamineDocument3 pagesSynthesis of 2-Acetylcyclohexanone Using Pyrrolidine-Enaminerobet12No ratings yet

- HE ROL Users GuideDocument42 pagesHE ROL Users GuideMiguel RomanNo ratings yet

- Organic Chemistry Practical 3Document11 pagesOrganic Chemistry Practical 3Kah Jun100% (2)

- Organic Syntheses Collective Volume 6Document1,299 pagesOrganic Syntheses Collective Volume 6caltexas100% (2)

- Synthesis of 2-NitropropeneDocument3 pagesSynthesis of 2-NitropropeneVictor VikeneNo ratings yet

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- Epl KLRP&CPP Eis-SmDocument189 pagesEpl KLRP&CPP Eis-Smleedsutd100% (1)

- LRA067AT7 Air Cond Manual 2020211a2133enDocument12 pagesLRA067AT7 Air Cond Manual 2020211a2133enguidonero100% (1)

- Exp 2 Dry FractionationDocument15 pagesExp 2 Dry FractionationSyahrul EzanieNo ratings yet

- Air Oxidation of Primary Alcohols Catalyzed by Copper (I) /TEMPO. Preparation of 2-Amino-5-Bromo-BenzaldehydeDocument15 pagesAir Oxidation of Primary Alcohols Catalyzed by Copper (I) /TEMPO. Preparation of 2-Amino-5-Bromo-BenzaldehydeCarlos GonzalezNo ratings yet

- OS Coll. Vol. 2 P389-PhenylacetoneDocument5 pagesOS Coll. Vol. 2 P389-Phenylacetonesunil_vaman_joshi100% (2)

- Working With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsDocument5 pagesWorking With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsmghaffarzadehNo ratings yet

- Experiment # 8 Six-Step Synthesis Aniline To 1-Bromo-3cholor-5iodobenzeneDocument10 pagesExperiment # 8 Six-Step Synthesis Aniline To 1-Bromo-3cholor-5iodobenzeneColin CheNo ratings yet

- (R) - 3-Hydroxybutanoic Acid Methyl Ester Butanoic Acid, 3-Hydroxy-, (R) - Butanoic Acid, 3-Hydroxy-, Methyl Ester, (R)Document6 pages(R) - 3-Hydroxybutanoic Acid Methyl Ester Butanoic Acid, 3-Hydroxy-, (R) - Butanoic Acid, 3-Hydroxy-, Methyl Ester, (R)ArifSheriffNo ratings yet

- 16 6hexamethylbenzeneruthenium Complexes 1Document5 pages16 6hexamethylbenzeneruthenium Complexes 1Adrizz FrancoNo ratings yet

- Working With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsDocument6 pagesWorking With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsNik OthmanNo ratings yet

- Síntesis de 4,4-Diphenyl.... - V2Document4 pagesSíntesis de 4,4-Diphenyl.... - V2manuherreradariasNo ratings yet

- Synthesis 7 Hydroxy 4 Methyl CoumarinDocument4 pagesSynthesis 7 Hydroxy 4 Methyl CoumarinLam Khoa100% (1)

- STEP 1: Synthesis of N-Phenyl-1,2-Benzenediamine: Experimental ProdedureDocument2 pagesSTEP 1: Synthesis of N-Phenyl-1,2-Benzenediamine: Experimental ProdedureKonstantina MsNo ratings yet

- Alquilacion de Arenos Con AlcoholesDocument5 pagesAlquilacion de Arenos Con AlcoholesJosé Guadalupe García EstradaNo ratings yet

- CV9P0411Document6 pagesCV9P0411AvinashNo ratings yet

- 2hydroxy1,4 NaphthoquinoneDocument5 pages2hydroxy1,4 NaphthoquinoneZina ZinaNo ratings yet

- Preparation of n-Isopropylidene-n'-2-Nitrobenzenesulfonyl Hydrazine (IPNBSH) and Its Use in Palladium-Catalyzed Synthesis of Monoalkyl Diazenes. Synthesis of 9-AllylanthraceneDocument22 pagesPreparation of n-Isopropylidene-n'-2-Nitrobenzenesulfonyl Hydrazine (IPNBSH) and Its Use in Palladium-Catalyzed Synthesis of Monoalkyl Diazenes. Synthesis of 9-AllylanthraceneYami BaudelaireNo ratings yet

- Piperina 1Document10 pagesPiperina 1LisZvtsNo ratings yet

- Multistep Synthesis of 2-Chloro-4-BromoanilineDocument9 pagesMultistep Synthesis of 2-Chloro-4-Bromoanilinejcrider2100% (1)

- Anti-Markonikov Hydrobromination paper-SIDocument26 pagesAnti-Markonikov Hydrobromination paper-SIArvindMoreNo ratings yet

- Shi Epoxidation: Org. Process Res. Dev., 11 (1), 44 - 51, 2007Document9 pagesShi Epoxidation: Org. Process Res. Dev., 11 (1), 44 - 51, 2007kumbham5378No ratings yet

- MIL-101 CDC SupplDocument51 pagesMIL-101 CDC SupplAnkit MaharshiNo ratings yet

- Synthesis of Acetophenone DerivativesDocument6 pagesSynthesis of Acetophenone DerivativesAwad SaidNo ratings yet

- Damian L 1994Document6 pagesDamian L 1994yosyNo ratings yet

- A PhenylacetoacetonitrileDocument4 pagesA PhenylacetoacetonitrileNik OthmanNo ratings yet

- Esterifikasi Oleat-2 Etil HexanolDocument5 pagesEsterifikasi Oleat-2 Etil HexanolMardiyanti Dwi SaptariniNo ratings yet

- Working With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsDocument16 pagesWorking With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsIgennel Zeref Acnologia ErriugaNo ratings yet

- 9.2.27 AOAC Official Method 988.11 Mercury (Methyl) in Fish and ShellfishDocument2 pages9.2.27 AOAC Official Method 988.11 Mercury (Methyl) in Fish and ShellfishLêXuânThắngNo ratings yet

- Aldol Puzzle Lab ReportDocument11 pagesAldol Puzzle Lab Reportlaurabruce27100% (1)

- FerroceneDocument16 pagesFerroceneshoeb321No ratings yet

- DypnonaDocument4 pagesDypnonaJBVdesarrollo 2019No ratings yet

- Monoterpene Biosynthesis in Agathosma Crenulata (Buchu) : Sabine Fuchs, Sabine Sewenig and Armin MosandlDocument13 pagesMonoterpene Biosynthesis in Agathosma Crenulata (Buchu) : Sabine Fuchs, Sabine Sewenig and Armin MosandlРусланNo ratings yet

- (2S) - ( ) - 3-Exo - (DIMETHYLAMINO) ISOBORNEOL ( (2S) - ( ) - DAIB)Document6 pages(2S) - ( ) - 3-Exo - (DIMETHYLAMINO) ISOBORNEOL ( (2S) - ( ) - DAIB)Alex CumbaNo ratings yet

- Synthesis 2,4,6 TriformylphloroglucinolDocument22 pagesSynthesis 2,4,6 Triformylphloroglucinolade saputra TanjungNo ratings yet

- 3 (5) AminopyrazoleDocument4 pages3 (5) AminopyrazoleSanjayShirodkarNo ratings yet

- The Uropygiols Identification of The Unsaponifiable Constituent of A Diester Wax From Chicken Preen GlandsDocument7 pagesThe Uropygiols Identification of The Unsaponifiable Constituent of A Diester Wax From Chicken Preen GlandsAgnieszka DaszczyńskaNo ratings yet

- (+) - (7as) - 7a-METHYL-2,3,7,7a-TETRAHYDRO-1 H-INDENE-1,5 - (6H-DIONEDocument7 pages(+) - (7as) - 7a-METHYL-2,3,7,7a-TETRAHYDRO-1 H-INDENE-1,5 - (6H-DIONEAlex CumbaNo ratings yet

- Supporting InformationDocument7 pagesSupporting InformationNGsalunkheNo ratings yet

- Santa Monica College Chem 22 Lab ManualDocument59 pagesSanta Monica College Chem 22 Lab ManualMide Ogundipe100% (1)

- Chem ExpDocument37 pagesChem Expken345007No ratings yet

- Inhibitors of Cerebroside MetabolismDocument12 pagesInhibitors of Cerebroside MetabolismMaarten van GinkelNo ratings yet

- Clove Oil Synthesis Organic ChemistryDocument8 pagesClove Oil Synthesis Organic ChemistrynewswagNo ratings yet

- Experiment 32Document14 pagesExperiment 32Morgan Elizabeth Lepley100% (6)

- Evans Auxiliary ProcedureDocument6 pagesEvans Auxiliary Procedureacmkim05No ratings yet

- Estimation Protocol Antinutrional Factors in Oilseeds: M.Narayanan 2019508202 GPB513Document23 pagesEstimation Protocol Antinutrional Factors in Oilseeds: M.Narayanan 2019508202 GPB513narayananNo ratings yet

- Study Diphenylamine Reaction Colorimetric Estimation of Deoxyribonucleic AcidDocument9 pagesStudy Diphenylamine Reaction Colorimetric Estimation of Deoxyribonucleic AcidJavier VariscoNo ratings yet

- O-Acylation of Ketone Enolates by Allyl 1H-Imidazole-1-Carboxylate Mediated With Boron Trifluoride EtherateDocument8 pagesO-Acylation of Ketone Enolates by Allyl 1H-Imidazole-1-Carboxylate Mediated With Boron Trifluoride EtheratedoubleffectNo ratings yet

- ( ) - (1S, 4R) - Camphanoyl ChlorideDocument5 pages( ) - (1S, 4R) - Camphanoyl ChlorideAlex CumbaNo ratings yet

- Takeyoshiminaga1978 PDFDocument9 pagesTakeyoshiminaga1978 PDFAracely FloresNo ratings yet

- Sintese de TosMIC - Van LeusenDocument5 pagesSintese de TosMIC - Van LeusentiagovillaNo ratings yet

- Ahmad Zakwan Bin Kassim - CHM557 - Exp4Document14 pagesAhmad Zakwan Bin Kassim - CHM557 - Exp4Ahmad ZakwanNo ratings yet

- To Whom Reprint Requests Should Be AddressedDocument11 pagesTo Whom Reprint Requests Should Be AddressedAracely FloresNo ratings yet

- Com 97 8051Document5 pagesCom 97 8051bruna_0410No ratings yet

- Sustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeFrom EverandSustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeNo ratings yet

- Bio-Based SolventsFrom EverandBio-Based SolventsFrançois JérômeNo ratings yet

- Chem41 - Isolation of LipidsDocument2 pagesChem41 - Isolation of LipidsSebastian SmytheNo ratings yet

- PumpingDocument68 pagesPumpingbbmoksh100% (1)

- B.E-Chemical Engineer: Mayur VasavaDocument2 pagesB.E-Chemical Engineer: Mayur VasavamayurNo ratings yet

- Chem 219 Lab DocumentDocument5 pagesChem 219 Lab Documentheather jaramilloNo ratings yet

- I. THE Determination OF Calcium IN THE Presence OF Magnesium AND PhosphatesDocument14 pagesI. THE Determination OF Calcium IN THE Presence OF Magnesium AND PhosphatesPavli OsamaNo ratings yet

- Pb5522en MKDocument152 pagesPb5522en MKJezreel ZaragosaNo ratings yet

- General Chemistry 1: Properties of MatterDocument16 pagesGeneral Chemistry 1: Properties of MatterLovely Trixie D. DandalNo ratings yet

- UEMK1013 - Chemistry For Engineering - G03Document25 pagesUEMK1013 - Chemistry For Engineering - G03Allan ChongNo ratings yet

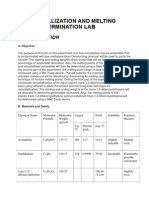

- Laboratory Report of Melting PointDocument5 pagesLaboratory Report of Melting PointHanna Anne88% (8)

- Chrompure Syringe FilterDocument5 pagesChrompure Syringe Filterthanyaporn.fNo ratings yet

- A Isolation of Caffeine From TeaDocument8 pagesA Isolation of Caffeine From TeaNisa Sabri67% (3)

- Displacement Guidelines: Best Practices ManualDocument44 pagesDisplacement Guidelines: Best Practices ManualMohamed Abozeima100% (1)

- Des Case Iso Cleanliness Guidelines For Hydraulic and Lube OilsDocument2 pagesDes Case Iso Cleanliness Guidelines For Hydraulic and Lube Oilsdawson creminNo ratings yet

- Confronting Crystallization IssuesDocument8 pagesConfronting Crystallization IssuesBramJanssen76No ratings yet

- Tristar & SPS Product Presentation General - by CSIDocument68 pagesTristar & SPS Product Presentation General - by CSILaksanarote FongonNo ratings yet

- Paras Filter Industries - CatalogDocument4 pagesParas Filter Industries - CatalogJitendra Kumar SinghNo ratings yet

- US4299809A - Process For The Manufacture of Calcium Chloride - Google PatentsDocument5 pagesUS4299809A - Process For The Manufacture of Calcium Chloride - Google PatentsThirumani SelvamNo ratings yet

- Gel Filtration ColumnDocument2 pagesGel Filtration ColumnkostrenarijekaNo ratings yet

- B ACC In-line-Filter DS-R6Document2 pagesB ACC In-line-Filter DS-R6li geneNo ratings yet

- Sample Gas Filter Agf - Va - 23Document2 pagesSample Gas Filter Agf - Va - 23Didik PrasetyaNo ratings yet

- Specification Sheet: Cold Soak Filtration Test (CSFT) of BiodieselDocument5 pagesSpecification Sheet: Cold Soak Filtration Test (CSFT) of BiodieselJorge EpbNo ratings yet

- ISO 16890 2019 12 16 FinalDocument2 pagesISO 16890 2019 12 16 FinalAlexis PradoNo ratings yet

- Learning Camp Science Lesson 21-30Document4 pagesLearning Camp Science Lesson 21-30Anna Liza GomezNo ratings yet

- Plomo 2Document14 pagesPlomo 2Octavio ContrerasNo ratings yet

- Evaluation - Chemical Pit - 0Document8 pagesEvaluation - Chemical Pit - 0Aiman AmirullahNo ratings yet

- Vlsi Verilog - Fir Filter Design Using VerilogDocument5 pagesVlsi Verilog - Fir Filter Design Using VerilogNanda KumarNo ratings yet