Professional Documents

Culture Documents

Application of High Power Thyristors in HVDC and FACTS Systems

Application of High Power Thyristors in HVDC and FACTS Systems

Uploaded by

Nusrat Mary Chowdhury0 ratings0% found this document useful (0 votes)

57 views8 pagesThis document discusses the application of high power thyristors in HVDC and FACTS systems. It provides an overview of thyristor technology and its development over time, allowing for higher voltage ratings and current capabilities. Thyristors are assembled into valves by connecting many thyristors in series, with additional components like snubber capacitors and resistors, to achieve the high voltages required for HVDC transmission systems. The document outlines the key components and design of modern thyristor valves, noting a trend toward larger 6-inch thyristors to enable transmission systems with currents over 4,500 amps.

Original Description:

valve_final.

Original Title

080731 Paper262 Cepsi08 Valve Final

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses the application of high power thyristors in HVDC and FACTS systems. It provides an overview of thyristor technology and its development over time, allowing for higher voltage ratings and current capabilities. Thyristors are assembled into valves by connecting many thyristors in series, with additional components like snubber capacitors and resistors, to achieve the high voltages required for HVDC transmission systems. The document outlines the key components and design of modern thyristor valves, noting a trend toward larger 6-inch thyristors to enable transmission systems with currents over 4,500 amps.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

57 views8 pagesApplication of High Power Thyristors in HVDC and FACTS Systems

Application of High Power Thyristors in HVDC and FACTS Systems

Uploaded by

Nusrat Mary ChowdhuryThis document discusses the application of high power thyristors in HVDC and FACTS systems. It provides an overview of thyristor technology and its development over time, allowing for higher voltage ratings and current capabilities. Thyristors are assembled into valves by connecting many thyristors in series, with additional components like snubber capacitors and resistors, to achieve the high voltages required for HVDC transmission systems. The document outlines the key components and design of modern thyristor valves, noting a trend toward larger 6-inch thyristors to enable transmission systems with currents over 4,500 amps.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 8

Application of High Power Thyristors

in HVDC and FACTS Systems

Hartmut Huang

#1

, Markus Uder

#2

Siemens AG, Fryerslebenstr. 1, 91056 Erlangen, Germany

1

hartmut.huang@siemens.com

2

markus.uder@siemens.com

Reiner Barthelmess

#3

, Joerg Dorn

#4

Infineon Bipolar GmbH & Co. KG, Max-Planck-Str. 5, 59581 Warstein, Germany

3

reiner.barthelmess@infineon-bip.com

4

joerg.dorn@infineon-bip.com

Abstract Both HVDC and FACTS systems use power electronic converters for the power conversion and power

quality control. High power thyristors have been serving as the key component in HVDC and FACTS converters for

several decades now and are still being further developed for higher power rating nowadays. This paper describes the

thyristor technology and its development in application in HVDC and FACTS. The fundamental features and

characteristics of high power thyristors is discussed with particular reference to its application in high voltage and

high current area. Many thyristors connected in series together with specially designed auxiliary mechanical and

electronic systems build so called thyristor valves, which form the HVDC and FACTS converters. An overview of

thyristor valve design is provided. Furthermore, the latest development in the thyristor and thyristor valve technology

and its application in the ultra high voltage DC application (800 kV) is introduced. A summary of technical key

parameters and design features of 6 thyristor valves are provided including the valve design date for the first

UHVDC application.

I. INTRODUCTION

There is an increasing demand for high efficiency and high

quality of power transmission world wide. In this context the

modern High Voltage DC Transmission (HVDC) and Flexible

AC Transmission Systems (FACTS) gains more importance

and utilization in todays power transmission system. Both

HVDC and FACTS systems use power electronic converters

for the power conversion and power quality control. Therefore

the performance and quality of converter systems depend

much on the key component- high power thyristors. Since its

introduction in the HVDC application late sixties of last

century, thyristor technology has continuously further

developed to higher power rating over last decades (Fig.1).

The first thyristors used had a silicon wafer with a diameter of

33mm. They had a peak blocking voltage of 1600V and

supported a direct current of up to 1000 A. For higher current

ratings, thyristors were connected directly in parallel. Over the

last thirty years, the device ratings were permanently

increased. Today silicon wafers of 6 inch diameter can be

manufactured; the peak blocking voltage per device is 8000V

and a d.c. current of 4500A can be handled without parallel

connection.

The increase of thyristors power rating goes hand in hand

with increased demand for larger HVDC power transmission

schemes. Particularly the need to maximize the utilization of

land and space for transmission lines requires higher

transmission voltage, which reduced the transmission losses as

well. During last decades most bulk HVDC transmission

schemes worldwide have been built with 500 kV as rated dc

voltage. Recently years there are several large HVDC

transmission schemes under planning in China, India and

Brazil, which have a transmission distances between 1000 km

and 2000 km. Ultra high dc voltage (UHVDC) in the range

800 kV is the preferred dc voltage level for these applications.

0

2

4

6

8

1970 1980 1990 2000 2010

Fig. 1: Development of voltage rating (blue line) in kV and current rating (red

line) in kA of power thyristors

While the first 800 kV HVDC project Yun-Guang has a power

rating of 5000 MW, other 800 kV HVDC projects has a

significant higher dc current. Xiangjiaba-Shanghai Project has

a power rating of 6400 MW (dc current =4 kA) and Jinping

UHVDC Project has the highest bipole rating of 7200 MW

with rated dc current of 4.5 kA. In order to provide an

optimized converter design to cover these high dc current and

voltage application, new thyristors with larger diameters have

been developed.

II. STATE OF ART OF MODERN THYRISTOR TECHNOLOGY

In 1960 the development of thyristors (also called SCRs =

silicon controlled rectifier) was started; since that time many

development steps followed in order to increase the power

capability of the devices and to improve the reliability.

Power thyristors are manufactured from highly pure

monocrystaline silicon. They are so called NPNP

semiconductors. This means that they consist of four layers

which are doped alternately with P and N (Fig. 2). The outer,

highly doped zones are the emitting zones; the weakly doped,

inner layers are the base zones. The control connection G is

located on the P base; J1-J3 designate the junctions between

individual zones. The off-state voltage in the reverse direction

is blocked at junction J1 between P-emitter and N-base. The

off-state voltage in the forward direction is blocked at junction

J2 between P-base and N-base.

Fig. 2: Schematic cross section illustration of a high power thyristor

Thyristors are fast but not ideal switches. Several of the

imperfections of the thyristor in comparison with the ideal

switch can be recognized in the static V/I-characteristic of the

thyristor. In the presence of off-state voltage, an off-state

current (several mA) flows both in the forward direction and

in the reverse direction.

Also a non-ideal static behaviour of the thyristor is the on-

state voltage during conduction. The entire voltage drop of an

HVDC thyristor is of the order of two to three volts. This

means that for typical currents several kA, considerable power

losses must be dissipated.

Thyristors in press pack housings are ideal for both,

efficient cooling of the device and stacking for series

connection.

Fig. 3: Schematic illustration of stresses on press pack power thyristor

Next to the static non-ideal behaviour, thyristors have also

dynamic restrictions:

Limited di/dt-capability after turning on, as well as the

reverse recovery behaviour including turn-off time has to be

considered in the design of the powers stack.

Fig. 4: High power thyristors made of 4, 5 and 6 silicon wafer

Fig. 5: Photgraph of a 6 inch thyristor

There is a trend towards higher transmission current

capability of long-distance HVDC systems. With this trend,

the requirements for higher current capabilities arise. On the

other hand, the blocking voltage of about 8kV per thyristor

was derived as an optimum of overall operational losses.

As a consequence, a 6 inch thyristor with a blocking

voltage of 8 kV (repetitive blocking voltage) was developed.

This thyristor is capable to be utilized for dc transmission with

currents up to 4500 A. Due to the joining of the silicon wafer

with a molybdenum carrier disc, the required surge current

capability could be reached with an excellent high safety

margin. These immense current capabilities make the thyristor

also interesting for other applications with high current

requirements and high blocking voltage needs.

III. HIGH POWER THYRISTOR VALVES

Since the first commercial use of high voltage thyristor

valves in HVDC-transmission systems in the early seventies,

there has been a constant enhancement of performance

concerning the thyristors blocking as well as current carrying

capability.

That improvement of the thyristor characteristics results in

a drastic decrease of components in a thyristor valve: to

transmit the same amount of power as in the beginning of the

thyristor-era in HVDC-technique, only about 5% of the

thyristors (and snubber circuits) are necessary today.

Thus the reliability of the valves was considerably

increased and the way was pathed to the advantageous design

of modern thyristor valves resulting in a clear structured and

compact valve setup comprising easy assembly, easy

accessibility and easy maintainability

Despite the high blocking capability of modern thyristors

still a series connection of thyristors is necessary to compose a

valve with the required high voltage withstand capability.

The number of thyristors that have to be connected in series

varies depending on the application- between e.g. 10

thyristors per valve rated 8kV in a typical SVC application

and up to 120 thyristors in a typical HVDC valve in an 800kV

converter.

A. Electrical valve components

Due to the fact that a thyristor is not an ideal switch and to

properly perform their function in the series connection under

all steady state and transient conditions, the thyristors need to

be complemented by auxiliary components: snubber

capacitors, snubber resistors, non linear reactors, d.c. grading

resistors, and grading capacitors.

C

K

C

B

R

B

L

VD

thyristor level

grading capacitor

R

DC

saturable

reactor

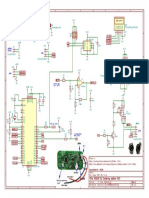

Figure 6: Main circuit components and their circuit arrangement in HVDC

thyristor valves; valve used as a dc switch

C

B

R

B

thyristor level

R

DC

Figure 7: Main circuit components and their circuit arrangement in SVC

thyristor valves; valve used as an ac switch

1) Snubber capacitors C

S

Snubber capacitors are required in parallel to each thyristor

to handle the voltage overshoot during turn off. In a modern

thyristor valve, they are single, SF6 filled units rated for the

full blocking capability of the thyristor.

2) Snubber resistors RS

To damp oscillations caused by the combination of snubber

capacitor and circuit inductance, a resistor is connected in

series to the capacitor. The resistor is subjected to the full

snubber capacitor current. Therefore, it has to be designed for

high losses.

To dissipate these losses the deionized water available in

the valve is used due to its good heat removal capability. The

resistive material is directly placed into the water (wire-in-

water technology). A resistor of this type can dissipate from

4.5 kW to 7 kW at moderate flow rate.

3) DC grading resistors RDC

When the valve is blocked and is subjected to d.c. voltage,

the voltage distribution along the series connection is

determined by the leakage current of the thyristors which is

subject to manufacturing tolerances. With an appropriate

valve cooling design (see below) part of the d.c. grading is

achieved by the water circuit. In addition, a self cooled

resistor of about 0.5M is connected in parallel to each

thyristor.

Due to huge dimensions of high voltages resp. ultra high

voltage HVDC thyristor valves additional components are

necessary to limit the impact of the large -converter inherent-

stray capacitances on the thyristors.

4) Valve reactors LVD

To limit the di/dt stress of the thyristors at turn on and the

dv/dt during transients in the off state, reactors are connected

in series with the thyristor string which have to meet

conflicting requirements: a high inductance at the beginning

of current flow but a low inductance as soon as the thyristor is

turned on safely, so as not increase the commutating reactance.

The valve reactors are therefore designed with a saturating

iron core.

Without further provisions, the valve reactor would form

an oscillating circuit of low damping with the stray

capacitances of the converter. This can result in a high

oscillating discharge current that extinguishes the turn on

current in the thyristor. The reactor is therefore provided with

a damping resistor that is coupled via a secondary winding

and thus is not effective when the reactor core has saturated.

5) Grading capacitors CK

The various components in the valve, being at different

electrical potentials and at different distances with respect to

ground and to other components, represent a complex network

of stray capacitances. For steep voltage transients, an uneven

voltage distribution between thyristor levels would result. To

control this unbalance, grading capacitors of a few nF are

connected in shunt to the series connection of thyristor levels

and valve reactors. They are not required (and only little

stressed) at low frequency phenomena but linearize the

voltage distribution for high frequency (steep) wave shapes.

They are filled with SF6 gas to achieve a high voltage

withstand without the use of oil as a dielectric.

B. Thyristor Gating and monitoring

Because of the high voltage environment of the thyristors,

it is absolutely necessary to electrically separate the triggering

and monitoring unit at ground potential (referred to as valve

base electronics VBE) from the thyristor at high voltage

potential. Therefore, the trigger command for the thyristor is

transmitted as a light pulse via a fibre optic cable irrespectible

of the thyristor type used: electrically triggered thyristors

(ETT) or direct light triggered thyristors (LTT).

Figure 8: gating and monitoring of light triggered thyristors (LTT) and

electrical triggered thyristors (ETT).

Associated to each thyristor a printed circuit board

monitors the state of the thyristor and generates check back

signals also transmitted via fibre optical cables to the VBE.

The check back signals of all thyristor levels are processed

in the VBE and communicated to the converter control unit.

The main task of that valve monitoring system is to check the

availability of the thyristor valve resp. the converter.

To enhance the reliability of the thyristor valves redundant

thyristor levels are incorporated in the series string of levels.

Due to the fact that even a defective press pack thyristor is

able to handle the full load current, the valve could remain in

operation without restriction as long as the number of

defective levels in one valve does not exceed the number of

redundant levels.

C. Valve cooling

In HVDC thyristor valves, more than 95% of the heat

losses are produced in the thyristors, snubber resistors, and

valve reactors, requiring forced cooling. Due to its good

thermal capability water is used as cooling medium in

thyristor valves. To serve as an effective insulating medium,

and to limit electrolytic currents, the conductivity of the water

is maintained at or below about 0.2S/cm at maximum water

inlet temperature. Also, the cross-section of all piping is kept

as small as possible to provide for a high effective resistance.

By choosing a proper geometry of the physical layout (fig.

11) and by placing electrodes at strategic locations, the water

pipes connecting to the thyristor heat sinks can be made to

have the same electrical potential throughout avoiding

electrolytic currents between the water cooled components of

a thyristor stack.

water in

water out

grading electrode

Figure 9: piping configuration for the cooling circuit of a thyristor stack.

On the other hand, due to the conductivity of the water, the

piping of the cooling circuit in a thyristor valve functions as a

resistive network. By appropriate layout of the pipe work such

as the parallel circuit in fig.9 this effect is used to advantage to

provide resistive voltage grading of the thyristor levels and

valve sections, assuming part of the duty of the d.c. grading

resistors.

D. Valve mechanical design

To easily adapt the thyristor valves to the HVDC or

FACTS application and to standardize the valve design a

strictly modular design is used to compose a customized

thyristor valve resulting in a cost optimized design.

The thyristor modules (Figs. 10, 11) are self-supporting

units with a frame of aluminium profiles, which mechanically

supports all components within the modules.

In HVDC thyristor modules the frame also serves as a

corona shield; its electrical potential is that of the centre cross

beam so that the module is divided into two symmetrical areas.

Each area accommodates a complete valve section, consisting

of thyristor stack, snubber circuits, valve reactors, monitoring

boards, grading capacitor, water circuit and the routing of the

optical fibres.

Figure 10: modular unit used in SVC applications

Figure 11: modular unit used in HVDC applications

The arrangement of the thyristors and heat sinks in the

stack and their associated equipment is a straightforward

image of the electric circuit diagram. A uniform voltage

grading and ease of testing are advantages of this design.

The mechanical arrangement of a valve depends on the

application and the number of series connected thyristor levels.

A typical valve design used in a Static VAR Compensator

consists of three modular units -each one associated to a phase

in a three-phase system- arranged on top of each other thus

forming a three-phase ac switch.

The tower stands on the valve hall floor. The fibre optical

cables and the cooling water tubes are supplied from the

bottom side of the tower

Figure12: 3phase SVC thyristor valve tower

The mechanical design of an HVDC converter is based on

an arrangement of multiple valve towers for one twelve pulse

group. In a typical 500kV converter each valve twin-tower

comprises four valves, each valve is made up of three thyristor

modules. These twelve modules are arranged in six tiers

within the suspended twin structure of the tower. The high

voltage end is at the bottom and includes separate corona

shields (fig. 14 ).

quadruple valve

twelve pulse group

Figure 13: single line diagram of one 500kV HVDC pole

Figure 14: 500kV HVDC pole consisting of 3 twin towers each

containing one quadruple valve

The modules are suspended from the valve hall roof. This

design is very flexible and reduces seismic forces acting on

the modules.

Water circuit connections and optical fiber routing to the

valve tower is done at its top (ground potential).

IV. LATEST DEVELOPMENT OF POWER THYRISTOR

A. Technology of 6 Thyristors

In power transmission and distribution applications, such

as HVDC systems of FACTS, highest reliability of the

thyristors is required. On the other hand economic

considerations ask for high power thyristors with high

continuous current, surge current capability and optimized

blocking voltage capability. The maximum diameter of the

silicon wafer of an HVDC thyristor is currently six inch. The

thickness of a wafer with a blocking capability of 8000 Volts

is about 1.5 millimetre.

Stable manufacturing processes and outstanding

technologies are the key for an economic production of high

power thyristors. Different measures, processes and

technologies have been introduced in these mature power

semiconductors achieving an unrivalled performance and

reliability.

High purity diffusion processes, i.e. a low amount of

undesired atoms within the silicon wafer are the basis for the

production of high power thyristors, resulting in sufficient

high charge carrier lifetimes and homogeneous charge carrier

distributions on the wafer.

The optimization of the trade-off between on-state voltage

on the one hand and reverse recovery charge and turn-off time

on the other hand is achieved by electron irradiation,

dependent on the application specific requirements.

In many applications a high-efficient thermal coupling of a

thermal capacity to the silicon wafer is desired in order to

achieve a high surge current capability on the one hand and

reasonable and manageable clamping forces for the thyristor

on the other hand. A technology which is called low-

temperature sintering allows joining of a molybdenum carrier

disc to the silicon wafer even in case of large diameters like

six inch wafers. The sintering process is performed at a

process temperature of about 220C. This results in a good

thermal coupling between the molybdenum disc and the whole

diameter of the silicon wafer. Thus also the edge of the

thyristor has an effective cooling, which is important for high

voltage devices utilized with high junction temperatures and

high blocking requirements. Therefore an excellent high

temperature high voltage blocking stability and high surge

current capability with reasonable clamping forces are

achieved by applying this technique.

A stable passivation of the bevelled edge region of the

silicon device is necessary to realise a long-term stability for

device life time requirements up to forty years. Semi-

insulating amorphous hydrogenated carbon layers are the key

to achieve high reliable blocking stability of the device.

Due to the high density of states (DOS) of the semi-

insulating electroactive passivation layer, surface charges are

compensated effectivly by induction of mirror charges at the

interface of the semi-insulating layer to the reverse biased

silicon substrate. With an appropriate adjustment of the DOS-

distribution the induced charges at the interface of passivation

layer to the silicon effectively reduces the electrical field

strength at the surface of the blocking junction. On the other

hand this electroactive passivation layer shields the device

against surface charges and guarantees long-term stability of

the potential distribution at the semiconductors surface and

thus avoids a long-term drift of blocking characteristics of the

semiconductor.

The experience from the field applications shows, that the

failure rate of thyristors in HVDC and FACTS converters is

below 10 fit (1 fit = 1 failure per 10

9

hours). This shows that

devices manufactured by the above mentioned technology

have excelent long term stability and high reliability of

electrical and thermal properties.

B. Application of 6 Thyristors in UHVDC Project

The first application of 6 thyristors is the 6400 MW

UHVDC transmission scheme connecting hydropower station

Xianjiaba and the metropolitan area of Shanghai. Due to the

extra high voltage and power rating the converter is arranged

with two valve groups in series for each pole. Each valve

group is consisting of 6 double valve MVUs side by side

forming a 12-pulse group for the 1600 MW valve group and

3200 MW per pole.

The converter valve at sending station Fulong has

following design parameters:

Converter Station Fulong

Thyristor type 6 ETT

No. of thyristors per valve 60

No. of redundant thyristors 2

No. of thyristors per valve section 15

No. of reactors per valve 8

No. of reactors per valve section 2

No. of valve sections per valve 4

Tower arrangement single

MVU arrangement double valves

Insulation levels across single valve

(switching impulse/lightning impulse)

456/456 kV

Insulation level across MVU structure

(switching impulse/lightning impulse)

1600/1800 kV

Figure 15 : schematic diagram of an 800kV UHVDC pole made up of two

series connected 400kV twelve pulse bridges

The converter will be composed using 200kV twin valve

towers. Each valve will be equipped with 60 series connected

6 thyristors and 8 valve reactor units physically arranged in

two modular units per valve.

Thus one twin valve tower is made up of 4 modular units

suspended from the valve hall ceiling.

Figure 16: drawing of a twin valve tower related to a 600kV valve base

Figure 17 : drawing of a thyristor modular unit designed to contain 6-

thyristors and the associated equipment

n = 2 n = 15

n = 1

valve section

snubber circuit

valve reactor

grading capacitor

6"/8kV-ETT

Figure 18: Schematic diagram of a thyristor modular unit consisting of two

identical valve sections with 15 thyristor levels and 2 valve reactor units each.

One thyristor level consists of a 6/8kV press pack

thyristor, a single snubber resistor and capacitor as well as the

dc grading resistors and the thyristor monitoring boards. The

latter comprises the electronic logic for individual thyristor

monitoring as well as for the conversion of optical control

signals received via fiber optics from the valve base

electronics (VBE).

V. CONCLUSION

Modern power electronics gain increased importance for

the power transmission and distribution applications.

Particularly the power thyristors play a key role in the modern

HVDC and FACTS systems. During last decades the

technology of thyristors has been contentiously developing

both in performance and rating. The design of converter

valves shall fully utilize the capability of thyristors on one

side and meet various challenging requirements of

transmission systems on other side. Long time design and

manufacturing experience ensure the high quality of these

important products. Increased power rating, especially in

connection with ultra high transmission voltage of 800 kV,

requires new type of thyristors with larger diameter. Therefore

new thyristors based on 6 Si-wafer have been successfully

developed. Thyristor valves using this new type 6 thyristor

will be used for the 6400 MW UHDVC Project XiangJiaBa

Shanghai in China.

You might also like

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- KNUST Electrical and Electronic Engineering Course DescriptionsDocument45 pagesKNUST Electrical and Electronic Engineering Course DescriptionsRobert Owusu-MirekuNo ratings yet

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingRating: 4.5 out of 5 stars4.5/5 (2)

- Toshiba Satellite L300 - L305 INVENTEC PS10S 6050A2170401-MB-A03 SchematicDocument63 pagesToshiba Satellite L300 - L305 INVENTEC PS10S 6050A2170401-MB-A03 SchematicMohammed AbdullahNo ratings yet

- HVDC Converter TransformersDocument12 pagesHVDC Converter TransformersНемања Вукотић100% (1)

- Alphagage + Manual - v5Document80 pagesAlphagage + Manual - v5JC Schwartz100% (2)

- HVDC Transmission Technology For Sustainable Power Supply: J. Dorn H. Gambach, D. RetzmannDocument6 pagesHVDC Transmission Technology For Sustainable Power Supply: J. Dorn H. Gambach, D. RetzmannSiti SitiNo ratings yet

- Assignment#2: Applications of Thyristors in HVDCDocument5 pagesAssignment#2: Applications of Thyristors in HVDCRashid AltafNo ratings yet

- Flexible AC: Power Electronics Transmission SystemDocument2 pagesFlexible AC: Power Electronics Transmission SystemAnonymous DAjfj9HIBmNo ratings yet

- Flexible AC: Power Electronics Transmission SystemDocument2 pagesFlexible AC: Power Electronics Transmission SystemheerapotterNo ratings yet

- Recent Trends in HVDC TransmissionDocument11 pagesRecent Trends in HVDC TransmissionAswini AshNo ratings yet

- HVDC - SiemensDocument48 pagesHVDC - SiemenslearningalotNo ratings yet

- HVDC Technology PDFDocument0 pagesHVDC Technology PDFAnonymous vcadX45TD7No ratings yet

- Advantages of HVDCDocument17 pagesAdvantages of HVDC1balamanianNo ratings yet

- Siemens! HVDC Proven TechnologyDocument48 pagesSiemens! HVDC Proven Technologycharlesc5746No ratings yet

- HVDC Proven TechnologyDocument48 pagesHVDC Proven TechnologyMano Paul100% (1)

- High-Voltage Direct CurrentDocument13 pagesHigh-Voltage Direct CurrentBrandon ReedNo ratings yet

- Technology and Development of 800 KV HVDC Applications: M. Haeusler H. Huang V. Ramaswami D. KumarDocument12 pagesTechnology and Development of 800 KV HVDC Applications: M. Haeusler H. Huang V. Ramaswami D. KumarRatheesh KumarNo ratings yet

- Project Report (Submit)Document32 pagesProject Report (Submit)aakashNo ratings yet

- Modern HVDC Thyristor ValvesDocument6 pagesModern HVDC Thyristor ValvesAnonymous OpLDOPNo ratings yet

- DocumentationDocument40 pagesDocumentationRajani Kancharla100% (1)

- HVDC and HVAC Line IonDocument9 pagesHVDC and HVAC Line IonChaitanya ShakyaNo ratings yet

- Converter Stations Design YG ZhangDocument5 pagesConverter Stations Design YG ZhangNunna BaskarNo ratings yet

- High Voltage Direct Current (HVDC) Transmission Systems Technology Review PaperDocument19 pagesHigh Voltage Direct Current (HVDC) Transmission Systems Technology Review PaperPremMehtaNo ratings yet

- HVDC TransmissionDocument78 pagesHVDC Transmissiondhay aliNo ratings yet

- HVDC TransmissionDocument80 pagesHVDC TransmissionKaran SinghaniaNo ratings yet

- High Voltage Direct Current Transmission Systems Technology Review PaperDocument19 pagesHigh Voltage Direct Current Transmission Systems Technology Review PaperDavid Jose Poma GuillenNo ratings yet

- HVDC 8Document124 pagesHVDC 8Bvijaya krishnaNo ratings yet

- HVDC Transmission PPT Part 1Document39 pagesHVDC Transmission PPT Part 1srinimeha@gmail.com100% (1)

- UHVDC Article AbbDocument5 pagesUHVDC Article AbbAbhideep DasguptaNo ratings yet

- Converter Station Design of The 800 KV UHVDC Project Yunnan-GuangdongDocument5 pagesConverter Station Design of The 800 KV UHVDC Project Yunnan-GuangdongdheerajNo ratings yet

- High Voltage Direct Current Transmission: A Training Report OnDocument43 pagesHigh Voltage Direct Current Transmission: A Training Report OnSaurabh AnandNo ratings yet

- HVDC TransmissionDocument80 pagesHVDC Transmissionsrinimeha@gmail.com75% (4)

- HVDC Systems in Smart GridsDocument17 pagesHVDC Systems in Smart GridsKiran SomayajiNo ratings yet

- 04 0800 HVDC Plenary RashwanDocument24 pages04 0800 HVDC Plenary RashwanDante FilhoNo ratings yet

- 12.2 HVDC Proven TechnologyDocument48 pages12.2 HVDC Proven TechnologyJean Baptiste nkongoloNo ratings yet

- Trends enDocument0 pagesTrends enmaxi_1987No ratings yet

- S17A - Kel.5 - Laporan Ujian Akhir SemesterDocument320 pagesS17A - Kel.5 - Laporan Ujian Akhir SemesterWahyu Anantyo AkbarNo ratings yet

- High Voltage Direct Current (HVDC) Transmission Systems Technology Review PaperDocument17 pagesHigh Voltage Direct Current (HVDC) Transmission Systems Technology Review PaperManu SinghNo ratings yet

- 5 HVDCDocument40 pages5 HVDCghulamqadir.pmpNo ratings yet

- HVDC TechnologyDocument48 pagesHVDC TechnologyIsrajuddinNo ratings yet

- Nueva Vida Rectificadores D PotenciaDocument10 pagesNueva Vida Rectificadores D PotenciaprimekronosNo ratings yet

- Matlab Simulink of Three Phase Six-PulseDocument6 pagesMatlab Simulink of Three Phase Six-PulseMohammed SelmanNo ratings yet

- Capacitor SelectionDocument72 pagesCapacitor SelectionSatyendra Kumar100% (2)

- 229 HVDC NoteDocument58 pages229 HVDC NoteSubhashree RoutNo ratings yet

- E T ReactorsDocument16 pagesE T ReactorsFleancuCatalinNo ratings yet

- Driving Piezoelectric ActuatorsDocument5 pagesDriving Piezoelectric ActuatorsNavin KaranthNo ratings yet

- High Voltage Direct Current (HVDC) Transmission Systems Technology Review PaperDocument26 pagesHigh Voltage Direct Current (HVDC) Transmission Systems Technology Review PaperYamini ArunaNo ratings yet

- HVDC TransmissionDocument27 pagesHVDC TransmissionAlan ClarkeNo ratings yet

- HVDC PPTDocument34 pagesHVDC PPTBattinapati Shiva100% (1)

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesFrom EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Power Electronics and Energy Conversion Systems, Fundamentals and Hard-switching ConvertersFrom EverandPower Electronics and Energy Conversion Systems, Fundamentals and Hard-switching ConvertersNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- Highly Integrated Gate Drivers for Si and GaN Power TransistorsFrom EverandHighly Integrated Gate Drivers for Si and GaN Power TransistorsNo ratings yet

- High Voltage Direct Current Transmission: Converters, Systems and DC GridsFrom EverandHigh Voltage Direct Current Transmission: Converters, Systems and DC GridsNo ratings yet

- 8.1.2.7 Lab - Using The Windows Calculator With Network AddressesDocument7 pages8.1.2.7 Lab - Using The Windows Calculator With Network AddressesNusrat Mary ChowdhuryNo ratings yet

- 7.2.5.3 Packet Tracer - Configuring IPv6 Addressing Instructions PDFDocument3 pages7.2.5.3 Packet Tracer - Configuring IPv6 Addressing Instructions PDFiraqi4everNo ratings yet

- GatewayDocument80 pagesGatewayNusrat Mary ChowdhuryNo ratings yet

- 700-V Asymmetrical 4H-Sic Gate Turn-Off Thyristors (Gto'S)Document3 pages700-V Asymmetrical 4H-Sic Gate Turn-Off Thyristors (Gto'S)Nusrat Mary ChowdhuryNo ratings yet

- Byou DissertationDocument177 pagesByou DissertationNusrat Mary ChowdhuryNo ratings yet

- A New Current-Source Converter Using A Symmetric Gate-Commutated Thyristor (SGCT)Document8 pagesA New Current-Source Converter Using A Symmetric Gate-Commutated Thyristor (SGCT)Nusrat Mary ChowdhuryNo ratings yet

- IELTS in The US and Beyond: A Truly Global Experience: NAFSA Region XII 2012Document30 pagesIELTS in The US and Beyond: A Truly Global Experience: NAFSA Region XII 2012Nusrat Mary ChowdhuryNo ratings yet

- Name: Rafi Dar: Very Large Instruction WordDocument18 pagesName: Rafi Dar: Very Large Instruction WordNusrat Mary ChowdhuryNo ratings yet

- Ieltsreadingpreparationtips 121229130101 Phpapp02Document29 pagesIeltsreadingpreparationtips 121229130101 Phpapp02Nusrat Mary ChowdhuryNo ratings yet

- 7 - SCRDocument11 pages7 - SCRNusrat Mary ChowdhuryNo ratings yet

- The Ielts Exam - : ReadingDocument11 pagesThe Ielts Exam - : ReadingNusrat Mary ChowdhuryNo ratings yet

- WWW Study-India Co inDocument16 pagesWWW Study-India Co inNusrat Mary ChowdhuryNo ratings yet

- Success Starts With IELTS: British Council 2012Document33 pagesSuccess Starts With IELTS: British Council 2012Nusrat Mary ChowdhuryNo ratings yet

- Studies Abroad CounselorsDocument38 pagesStudies Abroad CounselorsNusrat Mary ChowdhuryNo ratings yet

- Computer Organization and Architecture: Instruction-Level Parallelism and Superscalar ProcessorsDocument43 pagesComputer Organization and Architecture: Instruction-Level Parallelism and Superscalar ProcessorsNusrat Mary ChowdhuryNo ratings yet

- Analysis of The Task Superscalar Architecture Hardware DesignDocument10 pagesAnalysis of The Task Superscalar Architecture Hardware DesignNusrat Mary ChowdhuryNo ratings yet

- Computer Organization and Architecture What Does Superscalar Mean?Document14 pagesComputer Organization and Architecture What Does Superscalar Mean?Nusrat Mary ChowdhuryNo ratings yet

- The Ielts Exam - ListeningDocument9 pagesThe Ielts Exam - ListeningNusrat Mary ChowdhuryNo ratings yet

- Subb AraoDocument191 pagesSubb AraoNusrat Mary ChowdhuryNo ratings yet

- Subba ThesisDocument182 pagesSubba ThesisNusrat Mary ChowdhuryNo ratings yet

- Publications Requirements 1.4Document11 pagesPublications Requirements 1.4Nusrat Mary ChowdhuryNo ratings yet

- Multiple IssueDocument10 pagesMultiple IssueNusrat Mary ChowdhuryNo ratings yet

- Ice ManDocument2 pagesIce ManGuillermo ZapataNo ratings yet

- Hydraulic Steering & Accessories Pneumatic Controls Push-Pull Controls Disc BrakesDocument36 pagesHydraulic Steering & Accessories Pneumatic Controls Push-Pull Controls Disc BrakesBERANGER DAVESNE DJOMALIA SIEWENo ratings yet

- Akio Morita Failure To SuccessDocument2 pagesAkio Morita Failure To SuccessLesterNo ratings yet

- Case StudyDocument4 pagesCase Studyrubayet123No ratings yet

- Time - Independent Perturbation TheoryDocument9 pagesTime - Independent Perturbation Theory2832129No ratings yet

- Description: Ada V1.1 - DatasheetDocument6 pagesDescription: Ada V1.1 - DatasheetQuan Huy VuNo ratings yet

- Altivar 32 Variable Frequency Drive VFD - ATV32H075N4Document4 pagesAltivar 32 Variable Frequency Drive VFD - ATV32H075N4sandeep naikNo ratings yet

- Current Transformer, Potential Transformer, LTCT, Low Tension CT, Combined CTPT Unit, Metering Unit, Metering Cubicle, Resin Cast CT, Cast Resin CT, Cast Resin PT, RVT, Residual Voltatge TransformerDocument12 pagesCurrent Transformer, Potential Transformer, LTCT, Low Tension CT, Combined CTPT Unit, Metering Unit, Metering Cubicle, Resin Cast CT, Cast Resin CT, Cast Resin PT, RVT, Residual Voltatge TransformerSharafatNo ratings yet

- MOV Data SheetDocument2 pagesMOV Data SheetMathivanan AnbazhaganNo ratings yet

- At CommandsDocument2 pagesAt CommandsP K GautamNo ratings yet

- Battery State Sensor (BSS) : Automotive Products DivisionDocument2 pagesBattery State Sensor (BSS) : Automotive Products DivisionSREELAKSHMI C PNo ratings yet

- Graco Sweet Snuggle Swing InstructionsDocument3 pagesGraco Sweet Snuggle Swing InstructionsGabriela BichirNo ratings yet

- Asfjh PDFDocument22 pagesAsfjh PDFTzvetan DimitrovNo ratings yet

- Code Converters, Multiplexers, and DemultiplexersDocument34 pagesCode Converters, Multiplexers, and DemultiplexersjohnsamvlbNo ratings yet

- Electrostatics and Ohms LawDocument48 pagesElectrostatics and Ohms LawLourdes Marie MirasolNo ratings yet

- High Voltage MOSFETsDocument31 pagesHigh Voltage MOSFETsharendraNo ratings yet

- Lecture01 11Document33 pagesLecture01 11Niraj KhandekarNo ratings yet

- Project 8 Servo MotorsDocument4 pagesProject 8 Servo MotorsDarwin VargasNo ratings yet

- Snap-On ShopStream Connect FAQ'sDocument3 pagesSnap-On ShopStream Connect FAQ'sJose AGNo ratings yet

- Synplify Synthesis Faq PDFDocument19 pagesSynplify Synthesis Faq PDFmiulius13No ratings yet

- Probabilidad y Estadistica para Ingenieria y Ciencias - Devore 7thDocument16 pagesProbabilidad y Estadistica para Ingenieria y Ciencias - Devore 7thMoni Becerra WongNo ratings yet

- Item No. QTY Part No. Description VendorDocument11 pagesItem No. QTY Part No. Description Vendorcesar mierNo ratings yet

- Chapter 06 - WavesDocument9 pagesChapter 06 - WavesAl NazurisNo ratings yet

- Silicon On Insulator (Sol) TechnologyDocument17 pagesSilicon On Insulator (Sol) TechnologyCharan MsdNo ratings yet

- AccuSine+ Brochure and CatalogDocument22 pagesAccuSine+ Brochure and CatalogqaedmahmoodNo ratings yet

- Station STM32 T12 V3Document1 pageStation STM32 T12 V3triNo ratings yet

- 2013 CCTV CatalogDocument295 pages2013 CCTV CatalogEPCOMUSANo ratings yet