Professional Documents

Culture Documents

Mechanisms of Electrospinning

Mechanisms of Electrospinning

Uploaded by

Eub EuCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- NDT 30P Penetrant Testing 090217 - Notes For Electronic DistributionDocument105 pagesNDT 30P Penetrant Testing 090217 - Notes For Electronic DistributionUlvi Ismayilov100% (6)

- ME 501: Statistical Thermodynamics Lecture 18: Population Distributions For Diatomic MoleculesDocument18 pagesME 501: Statistical Thermodynamics Lecture 18: Population Distributions For Diatomic MoleculesEub EuNo ratings yet

- Plastics Consultancy Network - Corona1Document4 pagesPlastics Consultancy Network - Corona1Eub EuNo ratings yet

- 1999 Reneker Fong Chun Beaded Nanofibers Formed During ElectrospinningDocument8 pages1999 Reneker Fong Chun Beaded Nanofibers Formed During ElectrospinningEub EuNo ratings yet

- AstaInfrared SpectrosDocument14 pagesAstaInfrared SpectrosEub EuNo ratings yet

- Electronic SpectrosDocument82 pagesElectronic SpectrosEub EuNo ratings yet

- Electrospinning Doc-32 PDFDocument10 pagesElectrospinning Doc-32 PDFEub EuNo ratings yet

- Ferroelectrics: To Cite This Article: Qian Zhang & Peter A. Lewin (1995) : PVDF Polymers: Imaging Transducers andDocument24 pagesFerroelectrics: To Cite This Article: Qian Zhang & Peter A. Lewin (1995) : PVDF Polymers: Imaging Transducers andEub EuNo ratings yet

- Procedures For Hair AnalysisDocument7 pagesProcedures For Hair AnalysisEub EuNo ratings yet

- Forensics of Hair AnalysisDocument29 pagesForensics of Hair AnalysisEub EuNo ratings yet

- 2011 - UV-Vis Iron (III) - Salicylate Complex PDFDocument11 pages2011 - UV-Vis Iron (III) - Salicylate Complex PDFEub Eu33% (3)

- CV Ashta GhoshDocument3 pagesCV Ashta GhoshwoodlyincNo ratings yet

- Rhodopsin Dyes For Polyamide by RDNDocument96 pagesRhodopsin Dyes For Polyamide by RDNSaidul KarimNo ratings yet

- VICTREX CT 100 Polymer - Technical Data SheetDocument2 pagesVICTREX CT 100 Polymer - Technical Data SheetHari KiranNo ratings yet

- 10KG Cylinder Assembly DrawingDocument1 page10KG Cylinder Assembly Drawingpaul akhanobaNo ratings yet

- Carbonate RocksDocument21 pagesCarbonate Rockskanishk singalNo ratings yet

- Hazardous Materials Table 172 - 101tbDocument211 pagesHazardous Materials Table 172 - 101tbZeero AndoneNo ratings yet

- Dissertation Arthur ReadingDocument148 pagesDissertation Arthur ReadingAsad MughalNo ratings yet

- ASTM 1510 03 Iodine Adsorption NumberDocument7 pagesASTM 1510 03 Iodine Adsorption NumberMaria BradaNo ratings yet

- Metformin HCL BPDocument4 pagesMetformin HCL BPLia Arifiani100% (1)

- "MHD Power Generator": Bachelor of Technology IN Mechanical EngineeringDocument17 pages"MHD Power Generator": Bachelor of Technology IN Mechanical Engineeringyeswanth seguNo ratings yet

- Alfa Laval Brazed Heat ExchangersDocument20 pagesAlfa Laval Brazed Heat ExchangersCelso FernandesNo ratings yet

- VAM Recommended Storage Running Compound Tables - Rev May 2014Document1 pageVAM Recommended Storage Running Compound Tables - Rev May 2014saptagunungNo ratings yet

- General Information Theory - LindabDocument27 pagesGeneral Information Theory - LindabaudithanNo ratings yet

- Stainless Steel Wire Mesh and Wire ClothDocument3 pagesStainless Steel Wire Mesh and Wire ClothStela LjevarNo ratings yet

- Quice Review Center 4 Exam August 19,2019 G. Tolentino ST., Sampaloc Manila Org Chem, Fluid Flow, ICDocument1 pageQuice Review Center 4 Exam August 19,2019 G. Tolentino ST., Sampaloc Manila Org Chem, Fluid Flow, ICquice reviewNo ratings yet

- Make The Grade As and A2 Chemistry Chemistry Revision Guide Edexcel As A2 Modular Nelson Advanced ScienceDocument147 pagesMake The Grade As and A2 Chemistry Chemistry Revision Guide Edexcel As A2 Modular Nelson Advanced Scienceareyouthere92100% (3)

- 2004 GPAT PaperDocument15 pages2004 GPAT PaperRajat GoelNo ratings yet

- KSSM F1 C6Document74 pagesKSSM F1 C6Tanisa SaminNo ratings yet

- Mud ViscosityDocument5 pagesMud Viscosityhindn162No ratings yet

- Mole RatioDocument12 pagesMole Ratiomaysanati2007No ratings yet

- Organometallic Chemistry: An Overview of Structures and ReactionsDocument28 pagesOrganometallic Chemistry: An Overview of Structures and ReactionsPadyala SriramNo ratings yet

- List of ReferencesDocument17 pagesList of ReferencesYash SankrityayanNo ratings yet

- UOP ButamerDocument2 pagesUOP Butamerphaniraj_c100% (1)

- Take Test: SW 3BDocument4 pagesTake Test: SW 3BJoseph ZamoraNo ratings yet

- Msds PDFDocument5 pagesMsds PDFputri azizahNo ratings yet

- Cambridge IGCSE: Combined Science 0653/12Document16 pagesCambridge IGCSE: Combined Science 0653/12Yvonne Poh “Yvonne Poh”No ratings yet

- KCCSILICONE Formulation PersonalCare Eng 230703Document10 pagesKCCSILICONE Formulation PersonalCare Eng 230703suwannaNo ratings yet

- Kelompok 8 - Irsan Bagas Maulana HarahapDocument20 pagesKelompok 8 - Irsan Bagas Maulana HarahapGale HawthorneNo ratings yet

- Atlas of OrthoticsDocument69 pagesAtlas of Orthoticsdjjang75No ratings yet

Mechanisms of Electrospinning

Mechanisms of Electrospinning

Uploaded by

Eub EuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanisms of Electrospinning

Mechanisms of Electrospinning

Uploaded by

Eub EuCopyright:

Available Formats

Proc.

ESA Annual Meeting on Electrostatics 2011 1

A Theoretical Understanding of the Physi-

cal Mechanisms of Electrospinning

Chitral J . Angammana and Shesha H. J ayaram

High Voltage Engineering Lab (http://www.power.uwaterloo.ca/HVEL/)

Department of Electrical and Computer Engineering, University of Waterloo

200 University Ave., Waterloo, ON, N2L 3G1, Canada

phone: (1) 519-888-4567

e-mail: cjangamm@uwaterloo.ca, jayaram@uwaterloo.ca

Abstract More recently, electrospinning models have been developed so that the electro-

spinning process could be approximately analyzed based on the parameters that govern the

process. However, parametric analysis and accounting complex electrode geometries in the

simulation are extremely difficult since the non-linearity nature in the problem. Therefore,

the aim of the present work is to develop an existing electrospinning model for viscoelastic

liquids in COMSOL Multiphysics for further analysis using the multi-physics analyzing ca-

pabilities in the software.

I. INTRODUCTION

Electrospinning is a straightforward and inexpensive process that produces continuous

nanofibres from submicron diameters down to nanometre diameters. The process in-

volves an electrically charged jet of polymer solution or polymer melt consisting of

polymer molecules with a chain sufficiently long that they do not break up due to

Rayleigh instability. The basic principles for dealing with electrified fluids were pub-

lished in a series of papers by Taylor in the early 1960s [1, 2]. His ideas later became

known as the leaky dielectric model. With the advancement of nanotechnology and the

popularity of the electrospinning process, several other mathematical models were devel-

oped in order to describe the behaviour of the electrospun jet. More recently, electrospin-

ning models have been created so that the electrospinning process could be approxi-

mately analyzed based on the parameters that govern the process. As shown in Fig. 1, the

electrospinning process consists of three stages that correspond to the behaviour of the

electrospun jet: the formation of the Taylor cone, the ejection of the straight jet, and the

unstable whipping jet region.

The surface of the fluid droplet that is held at the spinneret by its own surface tension

becomes electrostatically charged with the application of high voltage. As shown in Fig.

1, the interactions of the electrical charges in the polymer solution with the external elec

Proc. ESA Annual Meeting on Electrostatics 2011 2

Fig. 1: Behaviour of the electrospun jet.

tric field result in the formation of the well-known Taylor cone [2]. In [1] and [3], a theo-

retical explanation has been given for the loss of stability and the formation of Taylor

cone from electrified fluid droplets. When the Taylor cone is subjected to a very strong

electric field with an appropriate field gradient at the tip of the cone, the droplet becomes

unstable, and a single fluid jet is drawn out from the apex of the Taylor cone, as shown in

Fig. 1. After traveling straight down for a specific position of its path, the ejected liquid

jet usually becomes unstable with respect to the jet propagation. In a study conducted by

Hohman et al., they developed a theoretical framework for understanding the physical

mechanisms of electrospinning and proposed a method of quantitatively predicting the

parameter regimes where the electrospinning occurs [4]. Feng et al. simplified the Hoh-

mans model by eliminating the ballooning instability of the electric field calculation.

The simplified model was tested by comparing its predictions with the experimental data

for a variety of boundary conditions and parameter values, such as the electric Peclet

number, the Froude number, the Reynolds number, and the Weber number. Non-

Newtonian rheology was also introduced into the theoretical model of electrospinning,

and the effects of extension thinning, extension thickening, and strain hardening of the

polymer solution were examined [5]. Reneker et al. and Yarin et al. contributed signifi-

cantly to the modeling of electrospinning by developing a discrete three-dimensional

model to describe the dynamics of electrospinning [6, 7].

The aim of the present work is to further analyze the electrospinning process based on

an existing electrospinning model for viscoelastic liquids using a finite element method

software named COMSOL Multiphysics.

II. MODEL DEVELOPMENT

Once the jet flows away from the Taylor cone in a nearly straight line, the travelling liq-

uid jet is subjected to a variety of forces, such as a Coulomb force, an electric force im-

posed by the external electric field, a viscoelastic force, a surface tension force, a gravita-

tional force, and an air drag force [6]. Therefore, the electrospun jet can be represented

by four steady-state equations as follows [4, 5]. The notations are provided in Table I.

Taylor cone

Straight jet

Whipping jet

Envelope cone

Proc. ESA Annual Meeting on Electrostatics 2011 3

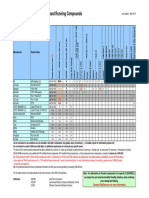

TABLE I : SYMBOLS EMPLOYED AND THEIR DEFINITIONS.

Symbol Definition Units

R J et radius m

Q Volume flow rate m

3

/s

E z component of the electric field V/m

v Velocity of the jet m/s

K Conductivity of the solution S/m

Surface charge density C/m

2

I J et current A

Fluid density Kg/m

3

zz

Viscous normal stress in the axial direction N/m

2

p Pressure N/ m

2

Surface tension of the solution N/m

e

t

t

Tangential stress exerted on the jet surface

due to the electric field

N/ m

2

e

n

t

Normal stress exerted on the jet surface due

to the electric field

N/ m

2

E

External electric field V/m

prr

Radial polymer normal stress N/ m

2

pzz

Axial polymer normal stress N/ m

2

Relaxation time s

p

Viscosity of the solution due to the polymer Pas

0

Viscosity of the solution at zero shear rate Pas

Mobility factor -

air

Dielectric constant of the ambient air -

Dielectric constant of the solution -

R

0

J et radius at the origin m

1. Conservation of mass

( )

0

2

=

dz

v R d

(1)

2. Conservation of charge

( ) 0 2

2

= + KE R v R

dz

d

(2)

3. Conservation of momentum

( )

( ) ( )

+ + + =

dz

dR

t t R

dz

dR

R

R

P R

dz

d

g R

dz

v R d

e

n

e

t zz

2 2

2 2

2 2

(3)

Proc. ESA Annual Meeting on Electrostatics 2011 4

4. Coulombs integral for the tangential electric field inside the jet

( ) ( )

=

E

dz

R d

dz

E R d

E

air

1

2

1

ln

2

2

2

(4)

In addition, Equations (5) and (6) are considered here to represent the non-uniform uni-

axial extension of viscoelastic polymer solutions [8].

( ) ' ' '

2

v v v

p prr

p

prr prr prr

= + + +

(5)

( ) ' 2 ' '

2

v v v

p pzz

p

pzz pzz pzz

= + +

(6)

The Equations (1) to (6) can be transformed into dimensionless form using the dimen-

sionless parameters and groups that are shown in Table II and Table III.

TABLE II: CHARACTERISTICS PARAMETERS EMPLOYED AND THEIR DEFINITIONS.

Parameters definition

Length R

0

Velocity

2

0

0

R

Q

v

=

Electric field

K R

I

E

2

0

0

=

Surface charge den-

sity

0 0

E

air

=

Viscous stress

0

0 0

0

R

v

=

Inserting these dimensionless parameters and groups into the equations (1) to (6) gives

the following dimensionless equations.

1

2

= v R (7)

1

2

= + PeRv ER (8)

( )

+ + + + +

+ =

R

E

dz

dE

E

dz

d

E

dz

dR

WeR R

T

dz

dv

R

dz

d

R

r

Fr dz

dv

v

p

P n

2 1 '

Re

1

Re

1 3 1

2 2

2

2

(9)

( ) ( )

=

E

dz

R d

dz

ER d

E

2

2

2

2

ln

(10)

Proc. ESA Annual Meeting on Electrostatics 2011 5

( ) ' ' '

2

v r

r

De

v v De

prr prr prr prr

= + + +

(11)

( ) ' 2 ' '

2

v r

r

De

v v De

pzz pzz pzz pzz

= + +

(12)

TABLE III: DIMENSIONLESS GROUPS EMPLOYED AND THEIR DEFINITIONS.

Group definition Group definition

Froude number

0

2

0

gR

v

Fr =

Aspect ratio

0

R

L

=

Reynolds num-

ber

0

0 0

Re

R v

=

Peclet number

0

0

2

KR

v

Pe

air

=

Weber number

0

2

0

R v

We =

Electrostatic

force parameter

2

0

2

0

v

E

E

air

p

=

Deborah num-

ber

0

0

R

v

De

=

Ratio of dielec-

tric constant

1 =

air

Viscosity ratio

0

p

r =

Tensile force

( )

prr pzz P

R T =

2

As shown in Fig. 2, the boundary conditions are applied at z = 0 and z = . Equa-

tions (13), (14), (15), and (16) represent the boundary conditions at z = 0. Similarly,

Equations (17) and (18) give the boundary conditions at z = .

( ) 1 0 = R (13)

( )

0

0 E E = (14)

dz

dR

R

r

prr 3

1

2 ) 0 (

=

(15)

prr pzz

2 ) 0 ( = (16)

E L E = ) ( (17)

0

) (

4 ) ( = +

dz

L dR

z L R

(18)

Proc. ESA Annual Meeting on Electrostatics 2011 6

Fig. 2: Illustration of boundary conditions.

The above mathematical model is formulated using the partial differential equation

(PDE) module in the software named COMSOL Multiphysics. In addition, the results of

a parametric study investigating the effects of the solution conductivity and the magni-

tude of the external electric field on fibre diameter are presented in the following section.

III. RESULTS

A solution is obtained through the model using the desired material parameters

of

3

10 5 . 2 Re

= , 1 . 0 = We , 1 . 0 = Fr , 1 . 0 = Pe , 1 =

p

E , 40 = , 5 = , and

10 = De . The results match quite well with the previous works that have been published

in [5, 8]. As shown in Fig. 3 (a), the rate of thinning of R is maximum at z = 0, and then

it relaxes smoothly with the growth of the jet. On the other hand, E shoots up to a peak

value and then relaxes over the progression of the jet. The electric field E is mainly in-

duced by the axial gradients of surface charges

( )

dz

R d

[5]. For the parameters con-

sidered, it can be estimated as

( )

( ) Pe

dz

dR

R

dz

R d

/ 2

. Therefore, Equation (10)

becomes

( ) ( ) Pe

dz

R d

dz

dE

/ ln

2

2 2

, which is a large positive number, hence E ini-

tially shoots up [5]. Physically, the amount of charges that can be conducted reduces with

decreasing jet radius. However, to maintain the same jet current, the convection has to

carry more surface charges. Therefore, the density of surface charge gradually increases

in the region that has been considered in the simulation (<5). As the jet gets thinner and

Proc. ESA Annual Meeting on Electrostatics 2011 7

0.4

0.6

0.8

1.0

0 1 2 3 4 5

R

Pe =0.1

Pe =0.01

Pe=0.005

(a)

0.5

0.7

0.9

1.1

1.3

1.5

0 1 2 3 4 5

E

Pe =0.1

Pe =0.01

Pe =0.005

(b)

0

20

40

60

80

100

0 1 2 3 4 5

Pe =0.1

Pe =0.01

Pe =0.005

(c)

Fig. 3: Solutions for (a) R; (b) E; and (c) for varying values of Pe.

Proc. ESA Annual Meeting on Electrostatics 2011 8

(a)

(b)

(c)

Fig. 4: Solutions for (a) R; (b) E; and (c) for varying values of E

.

0.4

0.6

0.8

1.0

1.2

0 1 2 3 4 5

R

E =0.73

E =0.9

E =0.5

0.0

0.5

1.0

1.5

2.0

0 1 2 3 4 5

E

E =0.73

E =0.9

E =0.5

0.0

1.0

2.0

3.0

4.0

5.0

6.0

0 1 2 3 4 5

E =0.73

E =0.9

E =0.5

Proc. ESA Annual Meeting on Electrostatics 2011 9

faster, electric conduction gradually transfers to convection [5]. The initial oscillation

that is observed in appears due to the chosen value of (0). This has been discussed in

[5] in more detail. Fig. 3 (a), (b), and (c) show the variation of dimensionless radius of

the jet (R), the total electric field (E), and the surface charge density () for different Pe

values which is directly proportional to the conductivity K of the solution. As shown in

Figures 3 (a) and (c), increasing Pe decreases the stretching of the jet as a result of

weaker electrostatic pulling force with the decrease of the surface charge density at the

fluid surface.

As shown in Fig. 4 (a) and (b), the external electric field E

is insensitive to the thin-

ning of the electrospun jet. The reason is the decrease of electrostatic pulling force in

consequence of the reduction of surface charge density (as shown in Fig. 4 (c)), if the

current I is held at a constant value. However, in reality, the increase of the strength of

the electric field also increases the jet current I, relatively linearly [4, 5]. Therefore, as

reported in [5], E

p

is a better parameter to reflect the variation of electric field than E

.

IV. CONCLUSIONS

An electrospinning model was formulated with the help of a finite element method soft-

ware using an existing viscoelastic electrospinning model. The model was validated

comparing the results that have been published by previous researchers. The model can

be used for the advanced analysis such as complex electrode geometries using the multi-

physics capabilities in COMSOL multyphysics.

REFERENCES

[1] G. Taylor, Disintegration of Water Drops in an Electric Field, Proceedings of the Royal Society of Lon-

don, Series A, Mathematical and Physical Sciences, vol. 280, No. 1382, pp. 383-397, J ul. 1964.

[2] G. Taylor, Electrically Driven J ets, Proceedings of the Royal Society of London, Series A, Mathematical

and Physical Sciences, vol. 313, No. 1515, pp. 453-475, Dec. 1969.

[3] J . Zeleny, Physical review, Phy. Rev., vol. III, No. 2, pp. 69-91, Feb. 1914.

[4] M.M. Hohman, M. Shin, G. Rutledge, and M.P. Brenner, Electrospinning and electrically forced jets. I.

Stability theory, Physics of Fluids, vol. 13, No. 8, pp. 2201-2220, Aug. 2001.

[5] J .J . Feng, The stretching of an electrified non-Newtonian jet: A model for electrospinning, Physics of

Fluids, vol. 14, No. 11, pp. 3912-3926, Nov. 2002.

[6] D.H. Reneker, A.L. Yarin, H. Fong, and S. Koombhongse, Bending instability of electrically charged

liquid jets of polymer solutions in electrospinning, J. Appl. Phys., vol. 87, 45314547, 2000.

[7] A.L. Yarin, S. Koombhongse, and D.H. Renekera, Bending instability in electrospinning of nanofibers,

Journal of Applied Phy., vol. 89, No. 5, pp. 3018-3026, Mar. 2001.

[8] P.C. Roozemond, Report No. MT07.12, A model for electrospinning viscoelastic fluids, Department of

mechanical engineering, Eindhoven University of Technology, Netherlands, 2007.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- NDT 30P Penetrant Testing 090217 - Notes For Electronic DistributionDocument105 pagesNDT 30P Penetrant Testing 090217 - Notes For Electronic DistributionUlvi Ismayilov100% (6)

- ME 501: Statistical Thermodynamics Lecture 18: Population Distributions For Diatomic MoleculesDocument18 pagesME 501: Statistical Thermodynamics Lecture 18: Population Distributions For Diatomic MoleculesEub EuNo ratings yet

- Plastics Consultancy Network - Corona1Document4 pagesPlastics Consultancy Network - Corona1Eub EuNo ratings yet

- 1999 Reneker Fong Chun Beaded Nanofibers Formed During ElectrospinningDocument8 pages1999 Reneker Fong Chun Beaded Nanofibers Formed During ElectrospinningEub EuNo ratings yet

- AstaInfrared SpectrosDocument14 pagesAstaInfrared SpectrosEub EuNo ratings yet

- Electronic SpectrosDocument82 pagesElectronic SpectrosEub EuNo ratings yet

- Electrospinning Doc-32 PDFDocument10 pagesElectrospinning Doc-32 PDFEub EuNo ratings yet

- Ferroelectrics: To Cite This Article: Qian Zhang & Peter A. Lewin (1995) : PVDF Polymers: Imaging Transducers andDocument24 pagesFerroelectrics: To Cite This Article: Qian Zhang & Peter A. Lewin (1995) : PVDF Polymers: Imaging Transducers andEub EuNo ratings yet

- Procedures For Hair AnalysisDocument7 pagesProcedures For Hair AnalysisEub EuNo ratings yet

- Forensics of Hair AnalysisDocument29 pagesForensics of Hair AnalysisEub EuNo ratings yet

- 2011 - UV-Vis Iron (III) - Salicylate Complex PDFDocument11 pages2011 - UV-Vis Iron (III) - Salicylate Complex PDFEub Eu33% (3)

- CV Ashta GhoshDocument3 pagesCV Ashta GhoshwoodlyincNo ratings yet

- Rhodopsin Dyes For Polyamide by RDNDocument96 pagesRhodopsin Dyes For Polyamide by RDNSaidul KarimNo ratings yet

- VICTREX CT 100 Polymer - Technical Data SheetDocument2 pagesVICTREX CT 100 Polymer - Technical Data SheetHari KiranNo ratings yet

- 10KG Cylinder Assembly DrawingDocument1 page10KG Cylinder Assembly Drawingpaul akhanobaNo ratings yet

- Carbonate RocksDocument21 pagesCarbonate Rockskanishk singalNo ratings yet

- Hazardous Materials Table 172 - 101tbDocument211 pagesHazardous Materials Table 172 - 101tbZeero AndoneNo ratings yet

- Dissertation Arthur ReadingDocument148 pagesDissertation Arthur ReadingAsad MughalNo ratings yet

- ASTM 1510 03 Iodine Adsorption NumberDocument7 pagesASTM 1510 03 Iodine Adsorption NumberMaria BradaNo ratings yet

- Metformin HCL BPDocument4 pagesMetformin HCL BPLia Arifiani100% (1)

- "MHD Power Generator": Bachelor of Technology IN Mechanical EngineeringDocument17 pages"MHD Power Generator": Bachelor of Technology IN Mechanical Engineeringyeswanth seguNo ratings yet

- Alfa Laval Brazed Heat ExchangersDocument20 pagesAlfa Laval Brazed Heat ExchangersCelso FernandesNo ratings yet

- VAM Recommended Storage Running Compound Tables - Rev May 2014Document1 pageVAM Recommended Storage Running Compound Tables - Rev May 2014saptagunungNo ratings yet

- General Information Theory - LindabDocument27 pagesGeneral Information Theory - LindabaudithanNo ratings yet

- Stainless Steel Wire Mesh and Wire ClothDocument3 pagesStainless Steel Wire Mesh and Wire ClothStela LjevarNo ratings yet

- Quice Review Center 4 Exam August 19,2019 G. Tolentino ST., Sampaloc Manila Org Chem, Fluid Flow, ICDocument1 pageQuice Review Center 4 Exam August 19,2019 G. Tolentino ST., Sampaloc Manila Org Chem, Fluid Flow, ICquice reviewNo ratings yet

- Make The Grade As and A2 Chemistry Chemistry Revision Guide Edexcel As A2 Modular Nelson Advanced ScienceDocument147 pagesMake The Grade As and A2 Chemistry Chemistry Revision Guide Edexcel As A2 Modular Nelson Advanced Scienceareyouthere92100% (3)

- 2004 GPAT PaperDocument15 pages2004 GPAT PaperRajat GoelNo ratings yet

- KSSM F1 C6Document74 pagesKSSM F1 C6Tanisa SaminNo ratings yet

- Mud ViscosityDocument5 pagesMud Viscosityhindn162No ratings yet

- Mole RatioDocument12 pagesMole Ratiomaysanati2007No ratings yet

- Organometallic Chemistry: An Overview of Structures and ReactionsDocument28 pagesOrganometallic Chemistry: An Overview of Structures and ReactionsPadyala SriramNo ratings yet

- List of ReferencesDocument17 pagesList of ReferencesYash SankrityayanNo ratings yet

- UOP ButamerDocument2 pagesUOP Butamerphaniraj_c100% (1)

- Take Test: SW 3BDocument4 pagesTake Test: SW 3BJoseph ZamoraNo ratings yet

- Msds PDFDocument5 pagesMsds PDFputri azizahNo ratings yet

- Cambridge IGCSE: Combined Science 0653/12Document16 pagesCambridge IGCSE: Combined Science 0653/12Yvonne Poh “Yvonne Poh”No ratings yet

- KCCSILICONE Formulation PersonalCare Eng 230703Document10 pagesKCCSILICONE Formulation PersonalCare Eng 230703suwannaNo ratings yet

- Kelompok 8 - Irsan Bagas Maulana HarahapDocument20 pagesKelompok 8 - Irsan Bagas Maulana HarahapGale HawthorneNo ratings yet

- Atlas of OrthoticsDocument69 pagesAtlas of Orthoticsdjjang75No ratings yet