Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

39 viewsKatiework 2014

Katiework 2014

Uploaded by

api-242944654Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Aerodynamics For Engineers 6th Edition - John Bertin, Russell CummingsDocument49 pagesAerodynamics For Engineers 6th Edition - John Bertin, Russell CummingsAfshar Arabi33% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Munirah Ghazali Invited Speaker Presentation 2nd International Conference Transformation of Basic Education in Facing Industrial Era ICEET Sept 2021Document19 pagesMunirah Ghazali Invited Speaker Presentation 2nd International Conference Transformation of Basic Education in Facing Industrial Era ICEET Sept 2021Arespi JunindraNo ratings yet

- IMS dELHI Info 2023 FinalDocument62 pagesIMS dELHI Info 2023 Finalsandeep mohanNo ratings yet

- INTE 010 Murphy, Todd (Eds.) - 'A Man Very Well Studyed' - New Contexts For Thomas Browne 2008 PDFDocument334 pagesINTE 010 Murphy, Todd (Eds.) - 'A Man Very Well Studyed' - New Contexts For Thomas Browne 2008 PDFL'uomo della RinascitáNo ratings yet

- EMCEE Script UrataDocument2 pagesEMCEE Script UrataAlleli Faith LeyritanaNo ratings yet

- L Trình Basic 4.5 - 5.0 - 5.0 - 5.5Document3 pagesL Trình Basic 4.5 - 5.0 - 5.0 - 5.5CORA EnglishNo ratings yet

- CV Sophie La English Dec 2017Document1 pageCV Sophie La English Dec 2017Anonymous j96ksZpP08No ratings yet

- The Comparative e Cacy of Two Approaches To Teaching Sixth Graders Opinion Essay WritingDocument28 pagesThe Comparative e Cacy of Two Approaches To Teaching Sixth Graders Opinion Essay WritingFlorencia FerreroNo ratings yet

- Convocation 2017 ProceedingsDocument36 pagesConvocation 2017 ProceedingswebiisNo ratings yet

- Depedquezon Sdo Per 04 058 005 2Document1 pageDepedquezon Sdo Per 04 058 005 2Nichole Anne Pagayon YapNo ratings yet

- Lexi TFolio CV 2Document2 pagesLexi TFolio CV 2Alexandra LeomoNo ratings yet

- Assistive Technology Devices For AutismDocument11 pagesAssistive Technology Devices For AutismAutism Parenting100% (1)

- Opening and Closing Ranks For Courses - Iit Jee-2011Document14 pagesOpening and Closing Ranks For Courses - Iit Jee-2011combatpsNo ratings yet

- Year 5 Independent Writing AcitivitiesDocument49 pagesYear 5 Independent Writing AcitivitiesRuby Fatima100% (4)

- Click Here For Time Table of Fiitjee Tower, Sec-62, NoidaDocument7 pagesClick Here For Time Table of Fiitjee Tower, Sec-62, NoidaAnsh agarwalNo ratings yet

- Applied Optimal Control: Optimization, Estimation, and ControlDocument3 pagesApplied Optimal Control: Optimization, Estimation, and ControlisraelNo ratings yet

- Module 4 Beginning Concept Book Lesson PlanDocument2 pagesModule 4 Beginning Concept Book Lesson Planapi-548313160No ratings yet

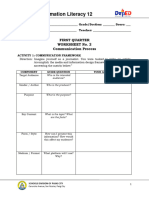

- TVL Mil12 q1 Dw2Document3 pagesTVL Mil12 q1 Dw2Joanna May PacificarNo ratings yet

- Singapore English Cover-Op2.pdf 2010/9/2 11:20:47 PMDocument323 pagesSingapore English Cover-Op2.pdf 2010/9/2 11:20:47 PMbobtaguba100% (1)

- Structural Mechanics 2 - M.Grzywiński PDFDocument5 pagesStructural Mechanics 2 - M.Grzywiński PDFWojtek GoszczyńskiNo ratings yet

- Flyer Thss 2012 FinalDocument2 pagesFlyer Thss 2012 Finalapi-67201372No ratings yet

- 2014 Cambodia Trade Integration Strategy 2014-2018 (ENG) PDFDocument512 pages2014 Cambodia Trade Integration Strategy 2014-2018 (ENG) PDFHeng Narith100% (3)

- A Manual For Implementation: Workload Indicators of Staffing Need (WISN)Document131 pagesA Manual For Implementation: Workload Indicators of Staffing Need (WISN)Ikhsan AkbarNo ratings yet

- Ama Education SystemDocument1 pageAma Education SystemBheya Samantha MontieroNo ratings yet

- Primary Huh Curriculum Conversations With Subject Leaders in Primary Schools Mary Myatt All ChapterDocument67 pagesPrimary Huh Curriculum Conversations With Subject Leaders in Primary Schools Mary Myatt All Chapterjeanette.rasmussen227100% (6)

- CSC Job Portal: Mgo Rizal, Laguna - Region IvDocument1 pageCSC Job Portal: Mgo Rizal, Laguna - Region IvCastiel del RosarioNo ratings yet

- Subject: Ed 201 (Sociological-Philosophical Foundations of Education)Document3 pagesSubject: Ed 201 (Sociological-Philosophical Foundations of Education)Rahila DeeNo ratings yet

- English A1 Assessment Criteria EEDocument4 pagesEnglish A1 Assessment Criteria EEgc doomNo ratings yet

- LeadershipDocument67 pagesLeadershipSita ChhetriNo ratings yet

- List of ScholsDocument25 pagesList of Scholspaisa321No ratings yet

Katiework 2014

Katiework 2014

Uploaded by

api-2429446540 ratings0% found this document useful (0 votes)

39 views38 pagesOriginal Title

katiework2014

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

39 views38 pagesKatiework 2014

Katiework 2014

Uploaded by

api-242944654Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 38

PPG Today Coverage: Created for employee IntranetDaily

Imagination Untamed unleashed at gala Edit

Michael McGarry (left), executive vice president, with "action painter" George Williams at the

Pittsburgh Zoo and PPG Aquarium Gala.

(Click here for more photos.)

Approximately 30 PPG employees and volunteers attended the Pittsburgh Zoo and PPG Aquarium

Gala themed Imagination Untamed.

The biennial black tie fundraiser attracted nearly 1,000 people, including some of the regions most

influential leaders.

Entertainment for the evening included PPG-sponsored action painting by artist George Williams.

Using music as a backdrop and Manor Hall paint products by PPG, Williams painted large (three foot

by four foot) portraits over the course of three to five songs. In the show, Williams produced

paintings of a cheetah and the Pittsburgh skyline. To the glee and applause of the audience, he

presented the finished paintings to Michael McGarry, PPG executive vice president.

Williams performed in the PPG-sponsored PPG Paint Plaza, which featured PPG paint color chip

lanterns created by employee volunteers. PPG volunteers also distributed gala programs.

Other dcor included the Guinness Book of World Records largest paint swatch by PPG. PPGs

record-setting swatch is 19 feet tall.

The gala raised approximately $500,000 to help launch Wildlife Legacy, a major expansion thats

expected to complete the zoo landscape. The zoo plans to develop its final six acres to include new

outdoor exhibits and a solarium for some of the worlds rarest and most fragile species.

Lanterns made of PPG paint chips lit the "PPG Paint Plaza."

Lanterns made of PPG paint chips lit the "PPG Paint Plaza."

Lanterns made of PPG paint chips lit the "PPG Paint Plaza."

Sigma S2U Allure receives PPG 'Customer Sustainability

Solution' award

Edit

Rick Tepper, environment, health and safety director, EMEA, presents the PPG Customer

Sustainability Solution award to the Sigma S2U Allure team: From left to right: Rick Tepper,

Cees Brandjes, group leader, solvent based lacquers; Christelle Tuffery, technical product

manager; Martin Bloem, product specialist; Michael J ansen, product marketer; and Maarten

Buijs, manager, sustainability.

(Click here for an enlarged version of this photo.)

The Sigma S2U Allure primer and gloss lacquer system developed by the architectural coatings,

northern Europe business in PPGs Europe, Middle East and Africa (EMEA) region -- has received a

PPG Customer Sustainability Solution award.

Driving sustainability with innovative technologies and services is essential to ensure the success

and lasting presence of our company for the benefit of our customers, suppliers, shareholders,

employees and our neighbors, said Rick Tepper, environment, health and safety director, EMEA.

Sigma S2U Allure provides our customers with quantifiable improvement in their environmental and

sustainability metrics.

The Sigma S2U Allure system has advanced through three developments to become an award-

winning product. The main challenge for research and development was to maintain drying

properties of the formulation while improving the application properties and durability, according to

Cees Brandjes, group leader, solvent based lacquers. Sigma S2U Allure underwent an extensive

screening of resin combinations until the team developed the new Dual Guard System resin that has

a lifespan of 10 years.

After the introduction of the improvements, the product was tested by the Dutch Institute for Building

and Ecology, said Maarten Buijs, manager, sustainability, architectural coatings, northern Europe.

The institute awarded the Sigma S2U Allure system the DUBOkeur label, which places it in the most

sustainable product solution in its category.

Sigma Coatings has always been positioned as a premium professional brand, said Michael

Jansen, product marketer, Sigma Coatings. By introducing this super premium product, we can

attract a large part of the market while ensuring price is less of an issue.

PPG automotive refinish coatings unit, raw material purchasing

group host exhibition

OMNI PLUS Diamond Toners, part of the Omni refinish product line.

PPGs automotive refinish coatings business and corporate raw material purchasing group hosted a

raw materials exhibition in Strongsville, Ohio, to introduce employees across several business units

to a range of new suppliers providing pigments and additives to the U. S. coatings market.

The two-day event arranged by Frank Jemiola, PPG global technical manager, solvent-borne color

platform, and his team consisted of formal and informal presentations by the suppliers aligned with

PPGs overall production strategy of reducing formula costs while increasing material quality,

according to Jemiola.

We asked the suppliers to tell us what theyll be selling down the road to solve multiple issues the

industry anticipates, Jemiola said. They were enthusiastic and that made for an energetic and

productive conference.

This is the second raw material exhibition held. The first was arranged by raw material purchasing

and focused solely on pigments in 2012. This years conference focused on general coating

technologies. The suppliers concentrated on various industry challenges such as environmental,

product quality and others. Breakout sessions provided an opportunity for supplier representatives

and senior members of PPGs research and technical communities to exchange ideas.

According to Jemiola, pigments presented at the 2012 conference were evaluated, approved and

are now used in 12-15 codes across all target markets and technologies, which he hopes to replicate

this year.

Approximately 55 PPG employees representing PPGs architectural coatings, automotive original

equipment manufacturer, automotive refinish coatings, building and construction and industrial

coatings businesses, and the coatings innovation center in Allison Park, Pennsylvania, attended the

event. Eighteen vendors, 10 pigment suppliers and eight from the additives business, participated.

PPG STEM advertorial featured in 'Pittsburgh Magazine'

The PPG STEM advertorial in Pittsburgh Magazine.

(Click here for the enlarged advertorial.)

(Click here for the STEM coverpage.)

A PPG science, technology, engineering and mathematics (STEM) advertorial appears in the June

issue of Pittsburgh Magazine.

The advertorial discusses PPGs STEM philosophy and careers. The advertorial highlights the PPG

Foundations dedication to supporting programs that broaden access to education and strengthen

skills related to STEM. The advertorial also features Kristi Kauffman, senior research chemist, at

PPGs coatings innovation center in Allison Park, Pennsylvania.

PPGs advertorial is one in a series launched by the Carnegie Science Center encouraging parents

to consider Getting Kids Fired Up About STEM. The series suggests kids need to focus on how

cool science can beand how this coolness can lead to a career. PPGs commitment to providing

STEM opportunities intends to develop a pool of best-in-class STEM talent that can contributeto

business and technology, according to the advertorial.

Pittsburgh Magazine has a circulation of more than 400,000, including more than 80,000 business

owners and 55,000 decision-makers.

Ten Hagen presents at chemical manufacturing summit

Peter Ten Hagen

Peter Ten Hagen, global director, automotive refinish coatings, supply chain and operations,

presented at the recent American Chemical Manufacturing Summit.

Ten Hagens presentation, Improving Supply Chain Operations through Effective Inventory Planning

and Optimization, spotlighted the process for reaching optimal inventory levels in diverse, complex

supply chains; managing complexity across all levels of the supply chain; and driving supply chain

improvements across a decentralized, global organization.

At PPG, we improve supply chain through focus and alignment, said Ten Hagen. It is important to

know where you currently are, have a vision of where you need to be and a strategy to get there.

The American Chemical Manufacturing Summit, conducted in Pittsburgh, brought together industry

leaders to discuss manufacturing footprint strategy, supply chain optimization, and health, safety,

and environment topics.

PPG continues pursuit of chemical reform legislation

Gabe Pellathy (right), PPG's managing director of government affairs, with Senator David

Vitter (left), met to discuss chemical reform.

(Click here for more photos.)

Gabe Pellathy, PPG's managing director of government affairs, met with Congressman John

Shimkus and Cal Dooley, president and chief executive officer of the American Chemistry Council, in

Washington D.C., to discuss chemical reform. Pellathy joined Dooley at the hearing on the

modernization of the Toxic Substances Control Act (TSCA) hosted by the House Energy and

Commerce Committees Subcommittee on Environment and the Economy.

The hearing was led by Subcommittee Chairman Shimkus and focused on increasing public

confidence in the chemicals used across the U.S. economy and streamlining commerce among

states. Shimkus unveiled a draft of the Chemicals in Commerce Act that reforms TSCA to ensure a

transparent, workable and risk-based process for chemical review and regulation. The subcommittee

will review a revised draft of the legislation.

Prior to the event, Pellathy discussed the importance of a consistent chemical standard for PPGs

business units with members of Congress. The meeting also served as a follow-up to recent

discussions with Senator David Vitter to voice PPGs support for regulatory uniformity that would

simplify compliance and promote investment for businesses operating in multiple U.S. states.

Chemical reform is a key regulatory issue that impacts all of PPGs business units and nation-wide

manufacturing.

Governor visits Dover facility for product launch

Neal Nicastro, manager of PPG's Dover coatings plant (left), and Delaware Governor J ack

Markell proudly display a can from the Ralph Lauren architectural coatings line.

Delaware Governor Jack Markell recently visited PPGs Dover, Delaware, coatings manufacturing

plant for the launch the new Ralph Lauren line of architectural coatings produced at the facility.

Neal Nicastro, Dover plant manager, provided Markell with information about the facilitys history,

manufacturing processes, and the architectural coatings products manufactured there.

Governor Markell understands the importance of manufacturing in our economy, Nicastro said. He

has always been a strong supporter of PPG and it was great to have him help kick off the

introduction of our Ralph Lauren product line.

Markell said he was impressed by the plant and that he is looking forward to seeing the new Ralph

Lauren products on the shelves throughout the state.

Markells tour was part of the plants ongoing Delaware outreach, which has already included both

U.S. Senators Thomas Carper and Chris Coons in 2014.

PPG Foundation awards U.S. college scholarships

Bryan Iams (standing/left), vice president, corporate and government affairs, and Sue Sloan

(standing/right), executive director, PPG Industries Foundation, with the Pittsburgh-area

employee-child National Merit Scholarship winners.

The PPG Industries Foundation announced its sponsorship of 54 new four-year undergraduate

college scholarships in the United States this year.

The scholarships include 17 Plant Community scholarships (for students living in communities near

PPG facilities), two National Achievement scholarships (for African-American students), 32

Special Scholarships for PPG employees children, and three Merit Scholarships for PPG

employees children. Scholarship winners are selected by National Merit Scholarship Corp. based on

test scores and additional criteria, and they receive awards of $1,500 annually for four years of

undergraduate study.

"Through the National Merit Scholarship Programs, the PPG Industries Foundation has been helping

academic dreams come true for five decades," said Sue Sloan, executive director of the foundation.

"It's quite an honor to know we're making a difference to so many young minds and future leaders."

The foundation recognized the Pittsburgh-area employee-child winners at a recent luncheon at the

Pittsburgh Zoo and PPG Aquarium. Bryan Iams, vice president, corporate and government affairs,

delivered remarks before presenting the scholarship to the recipients.

My overall advice is to maximize the moment, Iams said. Your recognition today proves that you

know how to do that, but youll have many more moments and opportunities in the future to

maximize.

Iams offered seven points of advice as the scholarship recipients prepare for college:

1. Commit to work hard. Youre doing that today, but youll be tested in your college experience

and professional career. Its those who work the hardest that usually have the most success.

2. Get involved. Youll have much course work in college, but there will be lots of other activities

and opportunities to stretch yourself. Find activities and clubs that are new to you; that offer different

people and friends. Really push yourself to get into your college experience.

3. Build a network. Take every opportunity to meet people. Find people who are in the field you

intend to pursue. Arrange to sit down over breakfast or coffee, ask them how they got where they

are today and ask for their advice. Come prepared for the discussion and take a lot of notes.

4. Learn from others. Look at your friends and peer network members who are really focused and

moving forward. Watch their behavior, their personal style, how they prepare and approach their

work. Emulate and incorporate the best in others. You can learn from people at all levels.

5. Get experience. Engage in internships and work studies as soon as possible. Getting

experience within an organization can pay great dividends. In addition to providing great experience

and career preparation, it will also help to shape your life studies.

6. Stay on track. Once you decide on a field of study, stay committed, focused and on track. Its

much more difficult and challenging if you get off course and take a job outside that field. People

who move on and off career tracks run into difficulty against job candidates who consistently

progress on their chosen career track.

7. Enjoy the experience. College is a once-in-a-lifetime experience. Have a great attitude, meet as

many people as you can, and soak it all in. Get involved as much as you can and really enjoy the

experience.

After the scholarship presentation event, the students participated in behind-the-scenes tours of the

lion and tiger exhibits.

For a list of 2014 scholarship winners and more information about PPG Industries Foundations

scholarship programs please visit the PPG Foundation intranet.

PPG hosts Ohio plant tours, promotes bipartisanship

PPG color specialists explain how automotive OEM products are tested and selected to

Congresswoman Kaptur (right).

(Click here for more photos.)

PPG recently hosted three plant tours for the offices of U.S. Representative Marcy Kaptur, U.S.

Representative Pat Tiberi and U.S. Senator Rob Portman. The tours, which took place at PPGs

Cleveland and Delaware, Ohio, facilities, were part of an ongoing effort to educate legislators about

PPGs business, products and priorities.

Congresswoman Kaptur visited PPG's automotive original equipment manufacturer (OEM) coatings

plant in Cleveland, PPGs largest OEM plant globally. Keith Schneider, plant manager, and Keith

Johnston, technical director for the United States and Canada, led a comprehensive presentation

about the manufacturing, testing and ongoing investment at the facility. This presentation included a

discussion of PPGs science and technology capabilities. Afterward, Kaptur and her staff toured the

Cleveland site, and met employees who design and manufacture OEM products. She also met with

Brian Pollock, operations director for the Americas, John Kovaleski, manager of quality assurance,

and Melinda Rutledge, production superintendent.

Congressman Tiberi visited the Delaware site, PPGs North American hub for automotive refinish

coatings. Carl Johnson, plant manager and director of manufacturing for PPG automotive refinish

coatings, led a presentation followed by a plant tour of all three Delaware operations: solvent,

waterborne and resins. Throughout the tour, the congressman expressed his admiration of PPGs

highly-technical work in his district, the site's "international footprint," and its affiliation with PPG's

automotive refinish coatings and research facility in Milan, Italy. Tiberi is a member of the House

Ways and Means Committee and is an important voice on tax issues.

Senator Portmans district representative, Stephen White, also toured the Delaware facility. White,

who represents the Ohio district that includes the Delaware facility, engaged with plant leaders and

mentioned Portmans ongoing interest in PPGs presence in Ohio. Portman is a strong proponent of

developing energy-efficient technology, which is an important issue for PPG.

Springdale cell improved quality, reduced costs

(l-r) Tom Hodder, J oe Mark, and Mark Funkhouser with the Springdale CP Cell.

The cationic paste (CP) cell at the Springdale, Pa., coatings plant has supported PPGs global

leadership position in the electro-coat business for the last several decades. Beginning in 2000, the

cell was rebuilt in a more automated manner, to improve functionality. The manufacture of cationic

pastes for heavy-duty equipment and appliance applications is just a small part of the plants

investment in process automation and lean process improvement, according to Bill Cramer,

Springdale plant manager.

The installation of the CP cell improved process quality and reduced manufacturing costs Cramer

said. In 1999, producing 2,000 gallons of cationic black or white paint would have required several

smaller steps of 500 gallon batches, Cramer said. Process time was four to five days, the first run

capable (FRC) rate was 65.8 percent and the second run capable (SRC) rate was 86.2 percent.

Annual production rate was approximately 520,000 gallons of paint.

The process began to improve in 2000 when two new systems were installed at Springdale for large-

batch cationic production. Two 2,000 gallon mixers were installed with two 200 liter mills. The

installation of this machinery reduced the cycle time for a 2,000-gallon batch of paint to 24 hours with

a FRC rate of 81.4 percent and a SRC rate of 94.9 percent. Annual production increased to 900,000

gallons.

Springdale also introduced a lean manufacturing initiative in 2000. The plant used the CP Cell as a

model for increasing the productivity of a cell using lean manufacturing automation and formula

optimization. From 2000-2013, lean initiatives and improvement efforts continually optimized the

process, largely because of the teamwork between many engineers, particularly Tom Hodder,

engineer manager, and Mark Funkhouser, manufacturing and coating technologist.

Today, the CP Cell cycle time has been reduced to 12 hours. The FRC rate is approximately 99.51

percent and the SRC rate reached 100 percent in 2013. These results have encouraged plant

officials to continue their pursuit of process improvement and lean manufacturing. Springdale is

currently executing a multi-year process automation plan to extend success to other manufacturing

areas, Cramer said.

PPG Foundation supports Tickets for Kids Charities

PPG Foundation Executive Director Sue Sloan (second from left) and screening committee

member Michelle Welch (far right), PPG business director for TESLINsubstrate, attended a

TFK event along with TFK Board Chairman and President Bruce B. Weiner and TFK Executive

Director Rosemary Mendel.

The PPG Industries Foundation has donated $6,000 to TICKETS FOR KIDS Charities (TFK), a

Pittsburgh-based nonprofit organization that distributes tickets to arts, cultural, educational, family

entertainment and sporting events through social-service agencies nationwide to at-risk children and

low-income families. The grant will help increase TFK offerings in West Coast communities where

PPGs aerospace business has operations.

PPGs donation illustrates its dedication to supporting educational experiences for children in its

communities, and it enables us to increase support for children in western U.S. markets, said

Rosemary Mendel, executive director, Tickets for Kids Charities. TFK is dedicated to enriching the

lives of children by giving them access they may not otherwise have to events and activities that can

provide them with inspiration and ideas.

TFK currently administers community outreach and ticket exchange programs for sports teams,

Cirque du Soleil, Ringling Bros. and Barnum & Bailey Circus, and hundreds of other cultural and

entertainment entities across the country. The organization distributes tickets through more than

2,800 social-service agency partners nationwide to thousands of children and their families each

year. Since its inception in 1994, TFK has served more than 1.6 million individuals.

As a company dedicated to innovation, PPG strongly supports programs that help enrich childrens

lives by offering them unique experiences that stimulate creative thought and encourage critical

thinking, said Sue Sloan, executive director, PPG Industries Foundation. PPG is pleased to help

Tickets for Kids Charities include children from our aerospace-facility communities in a variety of

events that expose them to new activities, accomplishments, culture and ideas.

For more information, visit the foundation's intranet site.

About Tickets for Kids Charities

Founded in 1994, TICKETS FOR KIDS Charities (TFK) is a Pittsburgh-based nonprofit

organization committed to enriching the lives of low-income children and their families through

inclusion in a variety of events and activities. By creating access to a world of ideas,

accomplishment, creativity and culture, TFK strives to provide experiences that will be a source of

both enjoyment and inspiration. For more information, visit www.ticketsforkids.org.

(Teslin is a registered trademark of PPG Industries Ohio, Inc.)

S&T intranet site launched

PPG has launched a new Science and Technology (S&T) intranet site that provides a range of

resources including strategy, metrics and a site regarding career building.

The launch of the site for the S&T employees around the world will provide information about PPGs

innovation, S&T technical strategy, career development, and other related content.

This website will provide PPGs global technical community an opportunity to understand and

execute our strategy to drive business-aligned innovation, said Chuck Kahle, chief technology

officer and vice president of coatings research and development. The website which features a

career development segment is designed for use PPGs entire 3,000-member S&T function and

offers a range of information and tools for personal and business success.

The site will provide enhanced employee development tools to insure that our technical employees

have the resources and direction to build their careers at PPG, said John Coyne, global human

resources director, S&T. It will increase our ability to reach across the regions to promote

collaboration and sharing of S&T information and best practices.

Human resources, information technology, and library services contributed to the development of the

site.

For more information, visit the global portal and career builder site.

PPG government affairs connects with Canada

Gabe Pellathy (right) with Daniel Rondeau, PPG logistics manager, Montreal.

PPGs government affairs (GA) team recently toured PPGs Montreal, Canada, architectural coatings

distribution center and participated in various architectural coatings business meetings.

Gabe Pellathy, managing director, government affairs, met with PPG leaders and employees to

discuss the companys businesses in Canada. He also met with government officials during the 41st

Quebec general election and learned more about the impact of the election from key PPG

managers.

Pellathy also visited the Montreal distribution center to see operations and product lines first-hand,

including the SICO brand of paints that has been successful in Canada for more than 75 years.

In related news, PPGs government affairs team has also been participating in activities related to

the new Canadian consulate in Pittsburgh. The proximity of the consulate to PPGs global

headquarters presents PPG a unique opportunity to develop relations with Canada and support

PPGs business units operating locally, Pellathy said.

PPG supports Lexington-area programs

PPG Lexington Maintenance Engineer Dalewyn Spinks joins a student he mentors through

Communities In Schools of Lexington / Davidson County, N.C., which was supported recently

by a PPG Industries Foundation grant.

The PPG Industries Foundation has donated more than $27,000 to five Davidson County

organizations for educational and human-services programs. The grants were made on behalf of

PPG's fiber glass manufacturing facility in Lexington, N.C., and each donation represents the

companys commitment to supporting local organizations that provide needed resources in the

community.

The recent grants helped:

Davidson County Community College offer STEM Camp, a summer camp for rising 4th-8th graders

to develop their science, technology, engineering and math skills;

Fairgrove Family Resource Center provide support to a variety of local programs;

Pastor's Pantry continue targeting senior hunger;

United Way of Davidson County continue to provide support to various community activities;

Communities In Schools of Lexington/Davidson County, N.C., support efforts to keep kids in

school, off drugs and alcohol, and out of trouble.

Each of these organizations does great work offering opportunities and support in the Lexington

community, and we hope this funding will help them continue and expand their valued efforts, said

Jeff Smith, manufacturing manager at PPG Lexington. PPG is pleased to support organizations that

directly impact its communities and improve the lives of our youth and other residents.

For more information, visit www.ppgfoundation.com.

PPG presents 2013 Sustainability Awards

Springdale industrial coatings plant manager Bill Cramer displays a 2013 Sustainability

Award.

PPG recently presented Sustainability Awards to 67 teams for outstanding dedication to

sustainability and innovation during 2013.

The sustainability awards were presented in four categories: Safety, Health and Wellness;

Environmental Impact; Community Engagement; and Customer Sustainability Solutions.

The Safety, Health and Wellness award recognizes the dedication of employees within a site or

business to reducing safety and health risks and to improving their health and wellness.

Recipients of the Environmental Impact award demonstrated excellent environmental performance

and energy management. The Community Engagement award commends employee volunteer

teams which had the greatest impact on enhancing the education, health/human services or culture

of their respective communities. Teams receiving the Customer Sustainability Solution award are

recognized for product and service solutions that provide PPG customers with quantifiable

environmental impact improvements in customer sustainability metrics.

Recipients of multiple awards were:

For a full list of recipients, click here.

Horton speaks with Tianjin officials, foreign business leaders

PPGs Cathy Yan (left) and Mike Horton discussed the company and Tianjins mutual

interests with Tianjins vice mayor, Ren Xuefeng (right), prior to Hortons speech at the

Tianjin foreign-invested enterprises and government communication meeting.

Mike Horton, PPG president, Asia Pacific, spoke at the Tianjin foreign-invested enterprises and

government communication meeting on behalf of foreign companies operating in Tianjin, China. The

meeting was hosted by the Tianjin Association of Enterprises with Foreign Investment (TAEFI).

We are making ongoing investments in Tianjin because of the citys unique geographical

advantages, friendly investment environment and full-fledged support of industry, said Horton. We

are confident that Tianjins strategy of industry-led economic development will continue fueling the

tremendous growth weve experienced here.

Horton discussed PPGs plans to leverage its technological strengths to provide the Chinese market

with additional innovative green products and top-quality services. He highlighted the companys

intention to continue serving the community and focusing on bettering the quality of life and work for

all employees.

Cathy Yan, general manager of PPG corporate and government affairs, Asia Pacific, joined Horton

and 200 others at the event. Attendees included Tianjins vice mayor, Ren Xuefeng, as well as other

Tianjin officials and foreign business leaders. Horton met with Xuefeng before the event to exchange

views about PPG and Tianjins development.

PPG donates $18,000 for Chester-area programs

PPG Chester Manufacturing Manager Al Reid (far left) meets students participating in the

Clemson University and Chester County 4-H Science on the Move program at one of the

groups events. Click here for more photos.

The PPG Industries Foundation donated nearly $18,000 to seven Chester County organizations for

educational and human-services programs. Each grant was made on behalf of PPGs fiber glass

manufacturing facility in Chester, S.C., and represents PPG Industries commitment to supporting

local organizations that provide needed resources in the community.

The recent grants helped:

Clemson University and Chester County 4-H offer the Science on the Move program that brings

mobile science and technology education to different communities;

Communities in Schools of Chester County, Inc., continue to support efforts that keep kids in

school, off drugs and alcohol, and out of trouble;

Chester County Public Education Foundation provide funding for Chester County School District

student activities and scholarships;

Junior Achievement of Central Carolinas provide economic education to local students;

United Way of Chester County continue to support various community activities;

York Technical College Foundation offer summer externships for local teachers through the

Catawba Regional Education Center; and

Saluda Trail Middle School fund a student robotics team.

Each of these organizations does great work offering opportunities and support in the Chester

County community, and we hope this funding will help them continue and expand their valued

efforts, said Al Reid, manufacturing manager at PPG Chester. PPG is pleased to support

organizations that directly impact its communities and improve the lives of our youth and other

residents.

For more information, visit www.ppgfoundation.com.

Southeast chapter of WLC conducts kick-off meeting

Almost 60 employees attended the kick-off meeting for the Southeast chapter of the Women's

Leadership Council.

About 60 employees representing three strategic business units attended the kick-off meeting of the

Southeast chapter of PPGs Womens Leadership Council (WLC) at the aerospace facility in

Huntsville, Ala.

The event featured a review of the WLC vision and mission, a presentation of the chapters 2014

goals, a tour of the Huntsville facility and a personality test and evaluation. The day also included a

question and answer session featuring Ann Wommack, senior account manager, aerospace;

Michelle Welch, WLC chairperson and business director, teslin substrate products; Patty Kimm,

export compliance coordinator, aerospace; and Janet Castens, business analyst, aerospace.

Our goal is to offer programs and activities that will support the WLCs mission to attract, retain and

develop woman leaders, said Trish Warren, chairperson of the WLC Southeast chapter and control

store manager, architectural coatings. We are excited that our first major event brought together so

many women to get the conversation and work started.

Key activities for 2014 include developing toolkits for onboarding and mentoring programs, providing

new exempt female employees with pertinent PPG information, creating teams for the Susan G.

Komen Race for the Cure and identifying locations to execute the Girl Scouts STEM (science,

technology, engineering and math) badge program.

The chapter represents PPG businesses in Alabama, Arkansas, Florida, Georgia, Louisiana,

Mississippi, North Carolina, South Carolina and Tennessee.

Tianjin plant hits 100,000-ton annual production milestone

PPGs Tianjin coatings production facility celebrates achieving a 100,000-ton annual

production volume for the first time in 2013.

PPGs Tianjin, China, coatings plant the companys largest coatings complex in the world

celebrated reaching a new production record of 100,000 tons of coatings.

This is a major milestone, said John Richter, vice president of operations, coatings, Asia Pacific.

Tianjin has been a wonderful success story. Im certain that through the joint efforts of Tianjins

employees, the plant will continue setting records.

During the ceremony, plant manager Shan Qi and seven veteran employees pressed the filling

switch to achieve the 100,000-ton milestone. Shan also introduced the plants new semi-automatic

filling machine, conveyor system and automatic palletizer.

Employees participating in the event represented the following areas of the plant: Zhang Huidong, E-

Coat Cell; Shao Yonglai, IC CE/IF Cell; Wang Lipeng, IC Wood Cell; Hu Jie, IC HDE Cell; Xu Bin,

Auto Solvent Borne Cell; Sun Hao, Auto Waterborne Cell; and Sun Chunxiang, Warehouse.

The Tianjin facility, which began production in 1995, manufactures both automotive original

equpiment manufacturer (OEM) and industrial coatings. It is PPGs largest coatings production

facility in the Asia Pacific region and globally.

Read the current edition of PPG Global for more Asia Pacific news.

PMC business launches new light-duty products website

Front page of new high performance coatings website

PPGs protective and marine coatings (PMC) business recently launched a new website dedicated

to PPGs high performance coatings light-duty protective products.

The website incorporates PPGs new branding standards and focuses on PMCs vision to be the

worlds most customer-preferred supplier of protective and marine coatings.

Advantages of the website include a simplified page layout and easy navigation. Current and

prospective customers can search for product by brand name, gain insight on coating chemistry and

locate the nearest store. A key feature of the website is easy access to material safety data sheets

and product/technical data sheets on each product page.

Donna Christofel, manager, light-duty brands, protective and marine coatings; Jamie Cowden,

marketing communications manager, protective and marine coatings; Brian Turi, manager,

commercial products and services, architectural coatings; and Mark Wanczak, digital marketing lead,

IT, architectural coatings, collaborated to develop the new website.

Click here to visit www.ppghighperformancecoatings.com.

PPG programs fund typhoon relief

Example of the destruction caused in the Philippines by Typhoon Yolanda.

PPG programs contributed more than $11,000 toward relief efforts in the Philippines after Typhoon

Yolanda last November. U.S. employees donated $4,760 to the American Red Cross, which PPG

matched through its Matching Gifts program to provide a total donation of $9,520. The Matching

Gifts program provides an incentive for personal giving by PPG employees by matching their

contributions to eligible institutions in the United States.

These donations funded the American Red Crosss efforts to purchase and distribute emergency

relief items such as food, shelter supplies, hygiene kits and mosquito nets, and to provide cash

grants that help typhoon survivors address storm-related needs.

PPG employees in the Asia Pacific region donated $890 to the Give2Asia Typhoon Yolanda

recovery fund. PPG matched the amount, providing a total donation of $1,780.

Give2Asias primary investment will focus on rebuilding Guiuan, the first municipality to be hit by

Yolanda. Typhoon Yolanda affected 50,000 residents and damaged approximately 12,000 homes in

the municipality, which is the third-poorest in the Philippines.

To help this vulnerable area transition to long-term recovery, Give2Asia developed a plan that

includes re-starting livelihoods and providing supplies for fishermen, coconut farmers and small

retailers; promoting disaster preparedness in the rebuilding of infrastructure as protection against

future storms; and using micro-finance loans to combat price inflation and restore access to staple

foods through small retailers.

For more information about PPGs matching gifts program and other disaster relief efforts, please

visit www.ppgfoundation.com.

CHROMATIC system launched in Paris

PPG's architectural coatings business in France recently launched the CHROMATIC system.

More than 500 people recently joined the leadership of PPGs architectural coatings business in

France to celebrate the launch of CHROMATIC comprehensive and interactive color system. The

system has the potential to change the way design professionals and other customers choose and

use color for commercial and residential use.

The CHROMATIC system and its palette of 1,170 of unique tones is supported by a range of

marketing materials for specialized wholesalers and distributors. This includes the Cube built-in

video capability; Color Box format fans (color samples) and the launch of chromaticstore.com, which

offers an array of online professional services. Through chromaticstore.com, visitors can order color

samples or made-to-measure samples, color charts, or color studies with calibrated printing. The

users can also access a photo simulator, color-formulation hotline and other tools to help

differentiate themselves and market their respective services more effectively. The site was

developed in partnership with PPG information technology specialists in the United States who

helped create PPGs highly interactive Voice of Color website.

The CHROMATIC system offers customers the experience and know-how of all of our brands, said

Loic Derrien, general manager, architectural coatings (AC), Europe, Middle East and Africa (EMEA),

Southern Europe. Based on the strength of our brands, the CHROMATIC system has the potential

to become the color reference for professionals."

The CHROMATIC system launch, conducted in Paris, featured JonOne, a highly-regarded American

street artist. He engaged guests with a live performance and created a vibrant piece of art inspired

by the CHROMATIC palette. PPG AC France donated the artwork to Paint A Smile, an organization

which uses paint and color to help make hospitals more welcoming and cheerful for patients.

EMEA announces new Wellness Leadership Team

Luis Herrero, J ean-Marie Greindl, Brenda Fisk, Rene Bos, Carina Gomes, J aclyn Thorold,

Mark Chapman and Luis Aragon (l-r) are part of a new team that will lead wellness efforts

across EMEA.

(Click here for enlarged photo.)

As part of its ongoing efforts to strengthen the health and well-being of its employees and their

families, Europe, Middle East and Africa (EMEA) has established a new Wellness Leadership Team

(WLT) that will develop and guide wellness programs across EMEA sites.

The team met in late January at PPGs EMEA headquarters in Rolle, Switzerland, to launch their

efforts. In the coming months, they will work to raise the awareness of health and wellness programs

among all EMEA employees. The main focus will be the four PPG Wellness Absolutes, including

exercise, stress management, nutrition and health screenings. The group will also higlight PPGs 10

Keys of Healthy Living, available at wellness.ppg.com. Finally, the team will develop Key

Performance Indicators to help measure the effectiveness of wellness programming among

employees and their families.

Members of the WLT include Luis Herrero, Mark Chapman, Jaclyn Thorold, Rene Bos, Brenda Fisk,

Richard Tepper, Carina Gomes and Luis Aragon. A sub-committee comprised of Herrero, Aragon,

Patrice Combedimanche, Petra Bauerova, James Beech, Paolo Benvenuto, Elisabetta Cascone and

Lus Herrero will work closely with the WLT to develop wellness programs for colleagues who work

outside company facilities, such as Field and TSSR people, Deco stores, among others.

Prominent Paints wins 'Most Innovative Award'

Michael Valsecchi, Mark Swartz, Jessica Baldeo, Niels Bormans, Sipho Motloung, Jackie

Putter and Pierre Taag (l-r) were part of the team that represented PPG Prominent Paints at

the 2014 MassBuild Confex.

(Click here for more photos.)

PPGs Prominent Paints, a leading manufacturer of architectural coatings in South Africa, received

the Most Innovative Product award in the paint category at the influential 2014 MassBuild Confex

conducted recently in Sun City, South Africa.

The award recognizes the efforts of the Prominent Paints team regarding the research, development

and launch of Evolve, a new paint product that is perhaps one of the most environmentally-friendly

paints on the market. Evolve is completely lead-free, contains zero solvents, is 70 percent organic

and has no volatile organic compounds.

The recognition is likely to strengthen the already-productive relationship between Prominent Paints

and Wal-Mart. MassBuild is the core paint channel for Wal-Mart in South Africa.

We work well with Wal-Mart on the African continent, said Niels Bormans, managing director,

Prominent Paints, and regional business director, Southern & Eastern Africa. With the success of

MassBuild behind us, we look forward to continuing our relationship with them and other

distributors.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Aerodynamics For Engineers 6th Edition - John Bertin, Russell CummingsDocument49 pagesAerodynamics For Engineers 6th Edition - John Bertin, Russell CummingsAfshar Arabi33% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Munirah Ghazali Invited Speaker Presentation 2nd International Conference Transformation of Basic Education in Facing Industrial Era ICEET Sept 2021Document19 pagesMunirah Ghazali Invited Speaker Presentation 2nd International Conference Transformation of Basic Education in Facing Industrial Era ICEET Sept 2021Arespi JunindraNo ratings yet

- IMS dELHI Info 2023 FinalDocument62 pagesIMS dELHI Info 2023 Finalsandeep mohanNo ratings yet

- INTE 010 Murphy, Todd (Eds.) - 'A Man Very Well Studyed' - New Contexts For Thomas Browne 2008 PDFDocument334 pagesINTE 010 Murphy, Todd (Eds.) - 'A Man Very Well Studyed' - New Contexts For Thomas Browne 2008 PDFL'uomo della RinascitáNo ratings yet

- EMCEE Script UrataDocument2 pagesEMCEE Script UrataAlleli Faith LeyritanaNo ratings yet

- L Trình Basic 4.5 - 5.0 - 5.0 - 5.5Document3 pagesL Trình Basic 4.5 - 5.0 - 5.0 - 5.5CORA EnglishNo ratings yet

- CV Sophie La English Dec 2017Document1 pageCV Sophie La English Dec 2017Anonymous j96ksZpP08No ratings yet

- The Comparative e Cacy of Two Approaches To Teaching Sixth Graders Opinion Essay WritingDocument28 pagesThe Comparative e Cacy of Two Approaches To Teaching Sixth Graders Opinion Essay WritingFlorencia FerreroNo ratings yet

- Convocation 2017 ProceedingsDocument36 pagesConvocation 2017 ProceedingswebiisNo ratings yet

- Depedquezon Sdo Per 04 058 005 2Document1 pageDepedquezon Sdo Per 04 058 005 2Nichole Anne Pagayon YapNo ratings yet

- Lexi TFolio CV 2Document2 pagesLexi TFolio CV 2Alexandra LeomoNo ratings yet

- Assistive Technology Devices For AutismDocument11 pagesAssistive Technology Devices For AutismAutism Parenting100% (1)

- Opening and Closing Ranks For Courses - Iit Jee-2011Document14 pagesOpening and Closing Ranks For Courses - Iit Jee-2011combatpsNo ratings yet

- Year 5 Independent Writing AcitivitiesDocument49 pagesYear 5 Independent Writing AcitivitiesRuby Fatima100% (4)

- Click Here For Time Table of Fiitjee Tower, Sec-62, NoidaDocument7 pagesClick Here For Time Table of Fiitjee Tower, Sec-62, NoidaAnsh agarwalNo ratings yet

- Applied Optimal Control: Optimization, Estimation, and ControlDocument3 pagesApplied Optimal Control: Optimization, Estimation, and ControlisraelNo ratings yet

- Module 4 Beginning Concept Book Lesson PlanDocument2 pagesModule 4 Beginning Concept Book Lesson Planapi-548313160No ratings yet

- TVL Mil12 q1 Dw2Document3 pagesTVL Mil12 q1 Dw2Joanna May PacificarNo ratings yet

- Singapore English Cover-Op2.pdf 2010/9/2 11:20:47 PMDocument323 pagesSingapore English Cover-Op2.pdf 2010/9/2 11:20:47 PMbobtaguba100% (1)

- Structural Mechanics 2 - M.Grzywiński PDFDocument5 pagesStructural Mechanics 2 - M.Grzywiński PDFWojtek GoszczyńskiNo ratings yet

- Flyer Thss 2012 FinalDocument2 pagesFlyer Thss 2012 Finalapi-67201372No ratings yet

- 2014 Cambodia Trade Integration Strategy 2014-2018 (ENG) PDFDocument512 pages2014 Cambodia Trade Integration Strategy 2014-2018 (ENG) PDFHeng Narith100% (3)

- A Manual For Implementation: Workload Indicators of Staffing Need (WISN)Document131 pagesA Manual For Implementation: Workload Indicators of Staffing Need (WISN)Ikhsan AkbarNo ratings yet

- Ama Education SystemDocument1 pageAma Education SystemBheya Samantha MontieroNo ratings yet

- Primary Huh Curriculum Conversations With Subject Leaders in Primary Schools Mary Myatt All ChapterDocument67 pagesPrimary Huh Curriculum Conversations With Subject Leaders in Primary Schools Mary Myatt All Chapterjeanette.rasmussen227100% (6)

- CSC Job Portal: Mgo Rizal, Laguna - Region IvDocument1 pageCSC Job Portal: Mgo Rizal, Laguna - Region IvCastiel del RosarioNo ratings yet

- Subject: Ed 201 (Sociological-Philosophical Foundations of Education)Document3 pagesSubject: Ed 201 (Sociological-Philosophical Foundations of Education)Rahila DeeNo ratings yet

- English A1 Assessment Criteria EEDocument4 pagesEnglish A1 Assessment Criteria EEgc doomNo ratings yet

- LeadershipDocument67 pagesLeadershipSita ChhetriNo ratings yet

- List of ScholsDocument25 pagesList of Scholspaisa321No ratings yet