Professional Documents

Culture Documents

AN296110 Current Sensing For Renewable Energy

AN296110 Current Sensing For Renewable Energy

Uploaded by

Phạm Văn TưởngOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AN296110 Current Sensing For Renewable Energy

AN296110 Current Sensing For Renewable Energy

Uploaded by

Phạm Văn TưởngCopyright:

Available Formats

296110-AN

Product Information

Current sensing for renewable energy

In grid-tied photovoltaic systems, designers must focus on minimizing

cost per watt to deliver the best possible return on investment

With increasing concerns about the global demand for

energy and the overall expansion of environmental aware-

ness, designers for power electronics applications are under

constant pressure to improve efficiency. The advent of the

Smart Grid, Plug-in Hybrid Electric Vehicles (PHEV), and

full Battery Electric Vehicles (BEV), as well as grid-tied

photovoltaic (PV) and other grid-tied renewable energy

systems, requires development of high-efficiency power

inverters. Usually, higher efficiency is associated with

higher application cost and reduced performance.

True advances in technology enable improved efficiency

while maintaining or improving upon cost and performance.

For example, as the cost of microprocessors continues to

drop, more advanced control algorithms can be cheaply

embedded in applications where simplistic, inefficient, and

poorly performing analog control was previously the norm.

With this trend continuing, the limiting factor for perfor-

mance and cost is shifting to the numerous sensors required

for advanced control algorithms.

For current sensors used in grid-tied photovoltaic systems,

design is ever focused on minimizing the cost per watt in

an effort to deliver the best possible return on investment in

solar energy (figure 1).

PV systems

For a grid-tied photovoltaic system, the conversion of

energy from solar panels is usually done in two stages. First,

a DC / DC converter is used both to convert the voltage from

the panel or array to something close to the grid voltage, as

well as to maximize the power extracted from the panels.

Then, an inverter is used to convert from DC to AC and

By Alex Latham, Systems Engineer, and

Shaun Milano, Strategic Marketing Manager

Allegro MicroSystems, LLC

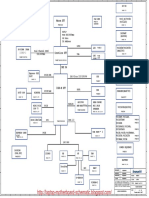

Figure 1. Current sensors are needed throughout grid-tied systems for control of the converters and inverters, optimization of

power extraction from solar panels, and fault detection for safety.

Loads

Residential

Commercial

Utility

Power Grid

Control

Panel

Photovoltaic

Single Panel

or Array

Microcontroller

DC-to-DC

and MPPT

Control

Inverter

Control

DC-to-DC

Converter

High

Efficiency

DC-to-AC

Converter

Supply Side

I

PV

I

S

V

S

V

PV

I

Short_Circuit

Load Side

Current

Sensor

1

Current

Sensor

2

Current

Sensor

3

Current

Sensor

4

Current

Sensor

5

Current

Sensor

6

Scaling Scaling

Gating

Signals

Gating

Signals

Power

Meter

Scaling

296110-AN

2

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

sync it up with the grid. There is no standard or widely agreed

upon topology for any of these stages or systems as a whole, as

each conversion system is usually designed in their entirety by

one manufacturer; each stage is designed and optimized to work

most efficiently with the other stages in an attempt to yield the

highest overall efficiency. Regardless of the system design, cur-

rent sensors play an important role in the control of the different

stages of conversion, directly impacting the efficiency and effec-

tiveness of the system.

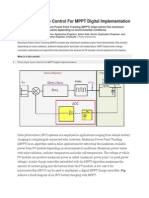

Conversion and MPPT

In any photovoltaic conversion system, maximum power point

tracking (MPPT) is an important aspect, enabling maximum

energy extraction from an array. The efficiency of MPPT algo-

rithms is greatly impacted by the sensors used for feedback. The

basis of MPPT is that at any given time the I-V curve of each

solar panel indicates the optimum operating point, or maximum

power point (MPP, see figure 2). However, it is also evident that

the I-V curve and, subsequently, the MPP will change with both

irradiance and temperature. It is the MPPT algorithms job to

constantly search for the MPP.

There are many different MPPT algorithms; however, most oper-

ate by measuring power either at the input or output of the

DC/DC converter stage and changing the operating point of

the converter to move along the I-V curve to find the MPP. These

algorithms all essentially perform some form of gradient ascent,

estimating the slope of the current-(or voltage)-versus-power

curve and using that to determine how to change the operating

point. If the slope is positive, the operating point is increased; if

negative, the operate point is decreased.

One of the most common algorithms is called perturb and

observe. Here, the power from the solar panel or array is mea-

sured, the operating point is changed, and the power is measured

again. If the power goes up, the operating point is moved in the

same direction; if the power goes down, the operating point is

moved in the opposite direction. This results in tracking of the

MPP, though it also results in steady-state oscillation around the

MPP. To minimize the steady-state oscillation the size of the steps

can be reduced. However, the update rate must be increased to

maintain the tracking speed.

Ultimately, the limiting factor in tracking efficiency will be the

noise in the power measurement. This is because reducing the

step size into the noise level of the power measurement will

confuse the algorithm and lead to oscillation around the MPP. All

hill-climbing algorithms, which includes perturb and observe,

as well as incremental conductance, or ripple correlation control,

to name a few, will be fundamentally limited by the noise in the

power measurement sensors.

Figure 2. The graph above shows how I-V curves change with both irradiance and temperature. Subsequently,

the maximum power point (MPP) will change, and the tracking algorithms must determine the new MPP.

Voltage (V)

High Temperature

MPP and peak power

Low Temperature

MPP and peak power

0

V

P

0 0

C

u

r

r

e

n

t

(

A

)

P

o

w

e

r

(

W

)

High Solar Irradiance

Moderate Solar Irradiance

Low Solar

Irradiance

296110-AN

3

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

For most MPPT applications, the bandwidth needed in a current

sensor is in the hundreds of hertz, meaning one will typically

filter or average the output of the sensor to decrease the noise

and improve tracking efficiency. However, sensors are necessary

if using ripple-correlation control, which uses the inherent input

ripple of the DC / DC converter to measure the slope of the volt-

age vs. power curve.

The inverter stage

In a photovoltaic system, the DC/ DC converter stage is typically

followed by an inverter stage, which ties the output of the system

to the grid (see figure 1). This signal must be compliant with the

utility systems requirements, including proper synchronization to

the grid and low total harmonic distortion (THD). Current sensors

are needed in the systems control loops to ensure proper connec-

tion to the grid. The sensors must not only accurately measure

both AC and DC currents, they must have high dynamic perfor-

mance: very fast response times are needed to react quickly to

any change in the grid, shutting off or disconnecting the system

in the case of a short circuit (that is, ground fault) or loss of the

grid connection (anti-islanding). The high output bandwidth is

also needed to measure high-frequency AC currents and harmon-

ics at different points in the system.

For inverters without a transformer or with a high-frequency

transformer, sensors must exhibit low offset drift with tempera-

ture (high accuracy) so as to control the DC component in the AC

current fed to the grid. Regulations differ from country to country

for this electrical DC current limit, but generally it is small: on

the order of tens to hundreds of milliamperes.

In a typical inverter configuration, there are a number of locations

where a current sensor might be used (see figure 3). While one

could use an expensive, high-precision current sensor, it is also

possible to achieve high accuracy by using one or more economi-

cal current sensor ICs in conjunction with the microprocessor

already necessary for the system. The on-board intelligence can

be used to calibrate out offset error. For example, there will be

periods of time where sensors 2 and 3 will have no current flow-

ing through them. One can sample the output of the sensor ICs

during those periods and use a moving average filter to generate

an internal zero amperage output reference for that sensor IC,

dramatically decreasing the offset drift, limited only by the noise

and size of the averaging filter.

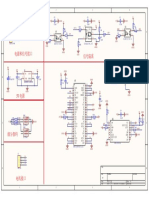

Figure 3. Multiple current sensors are seen in this diagram of a typical inverter configuration. For simplicity, filter components are not shown;

however, they will usually be placed on either side of the transformer (if one is used at all), with designers often using the leakage inductance

of the transformer as part of the filter.

Current

Sensor

2

Current

Sensor

3

Current

Sensor

1

Current

Sensor

4

Current

Sensor

5

296110-AN

4

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

Based on an article originally published in Electronic Products, Hearst Business Communications, Inc., October 2013, pp. 40-43. Used with permis-

sion. For portions not copyrighted by original publisher, Copyright 2013, Allegro MicroSystems, LLC

The information contained in this document does not constitute any representation, warranty, assurance, guaranty, or inducement by Allegro to the

customer with respect to the subject matter of this document. The information being provided does not guarantee that a process based on this infor-

mation will be reliable, or that Allegro has explored all of the possible failure modes. It is the customers responsibility to do sufficient qualification

testing of the final product to insure that it is reliable and meets all design requirements.

For the latest version of this document, visit our website:

www.allegromicro.com

For example, using a ACS710-6BB (see Current Sensor Solu-

tions at www.electronicproducts. com/Sensors_and_Transduc-

ers/Sensors/Current_sensing_for_renew able_energy-v2.aspx)

sampling at 20 kHz (with proper filtering to avoid anti-aliasing),

and averaging 2,000 samples (over many different durations of

zero current flowing through the sensor IC), can achieve a resolu-

tion of 1.5 mA to which the zero-current offset can be calibrated.

When this calibrated sensor IC is put in series with another sensor

IC, such as sensor 4, the relationship between the two can be

determined, calibrating sensor 4 will provide a very low offset

drift over temperature, allowing it to be used for sensing the DC

component of the current fed to the grid. Ultimately, there are a

number of similar techniques to calibrate current sensors dynami-

cally in inverter applications depending on the particular topol-

ogy and control scheme chosen that can lower overall system cost

and provide significant space savings.

You might also like

- Polycom Process-CalculationDocument42 pagesPolycom Process-Calculationdarkcorsair100% (5)

- Digital Power Suply ControlDocument30 pagesDigital Power Suply ControlPaul RomanNo ratings yet

- x300 SchematicsDocument99 pagesx300 SchematicsWondmagegn Abera DiresNo ratings yet

- C2 G 20 Max 3080000 Btu Output 10 To 1 TurndownDocument8 pagesC2 G 20 Max 3080000 Btu Output 10 To 1 TurndownBülent KabadayiNo ratings yet

- Full Control of A PWM DCAC Converter For AC Voltage RegulationDocument9 pagesFull Control of A PWM DCAC Converter For AC Voltage RegulationAndrés Felipe CelisNo ratings yet

- Digital Control of Switching Power ConvertersDocument6 pagesDigital Control of Switching Power ConvertersNISHANT VATSNo ratings yet

- Slis 140 ADocument33 pagesSlis 140 AAlvaro RoqueNo ratings yet

- Ac Meters Part 1Document22 pagesAc Meters Part 1Vam ArmodiaNo ratings yet

- Digital Power-Conversion For The Analog EngineerDocument12 pagesDigital Power-Conversion For The Analog EngineerfjwoemcuNo ratings yet

- Analog Devices CD ReferenceDocument8 pagesAnalog Devices CD ReferenceAcody Ie SyNo ratings yet

- Arduino Based Security SystemDocument35 pagesArduino Based Security SystemSaurabh Deshmukh100% (1)

- 3250 L532M DatasheetDocument2 pages3250 L532M DatasheetJavaid HosanyNo ratings yet

- Steady State Converter Analysis: Anjana S Ap, EeeDocument23 pagesSteady State Converter Analysis: Anjana S Ap, Eeemridul mpNo ratings yet

- Electrical Schematics - tm2002 - Service ADVISOR™ PDFDocument3 pagesElectrical Schematics - tm2002 - Service ADVISOR™ PDFdaniel5morales5castaNo ratings yet

- Develop Ineo-250 Error C2557Document2 pagesDevelop Ineo-250 Error C2557Tariq MajeedNo ratings yet

- PIC16 Sine-Wave InverterDocument2 pagesPIC16 Sine-Wave InverterNon DorelNo ratings yet

- RK Engineering Earth Leakage RelayDocument1 pageRK Engineering Earth Leakage RelaySEO BDMNo ratings yet

- Design and Micro Controller Implementation of A Three Phase SCR Power ConverterDocument8 pagesDesign and Micro Controller Implementation of A Three Phase SCR Power ConverterIsmael Ochoa JimenezNo ratings yet

- Intelligent Power Supply Design SolutionsDocument16 pagesIntelligent Power Supply Design SolutionsMeselao Meselao MeselaoNo ratings yet

- Zero CrossingDocument16 pagesZero CrossingAryan KapsNo ratings yet

- 1.2 Block Diagram With Explanation:: Chapter-1Document27 pages1.2 Block Diagram With Explanation:: Chapter-1SAMEULNo ratings yet

- TB67S109 V1.0Document1 pageTB67S109 V1.0冯江泰100% (1)

- Pid20a Pid20c Pid30a Pid30c Pid20c Pid30c Pid30a Pid20a: MCBSTM32F200/F400Document15 pagesPid20a Pid20c Pid30a Pid30c Pid20c Pid30c Pid30a Pid20a: MCBSTM32F200/F400hbaocrNo ratings yet

- LECTURE 27 (Ch. 11) Ac Voltage Controllers: ECE 452 Power ElectronicsDocument15 pagesLECTURE 27 (Ch. 11) Ac Voltage Controllers: ECE 452 Power ElectronicsSumukha KumarNo ratings yet

- SUBBU DAC Power Supply V3 SchematicsDocument1 pageSUBBU DAC Power Supply V3 Schematicscristi289100% (1)

- Variablepowersupply MICRO-PROJECT ORGDocument21 pagesVariablepowersupply MICRO-PROJECT ORGAbhishek HatagaleNo ratings yet

- Dds70mhz 120db AttDocument9 pagesDds70mhz 120db AttIan McNairNo ratings yet

- Automatic Car Parking System: A Mini Project Report Submitted byDocument24 pagesAutomatic Car Parking System: A Mini Project Report Submitted bythasarathanr1993_939No ratings yet

- Brojac BalaDocument1 pageBrojac Balamladen100% (1)

- Intelligent Street Light Control While Obstacle PassingDocument32 pagesIntelligent Street Light Control While Obstacle Passingprashanthi_komatireddyNo ratings yet

- Precision Rectifier CircuitsDocument13 pagesPrecision Rectifier CircuitsWaqas PervaizNo ratings yet

- 0-12v Variable Power SupplyDocument19 pages0-12v Variable Power Supplygirigtr2010100% (1)

- Mach Dieu Khien Toc Do Dong Co: OUT CV THR DSCHGDocument3 pagesMach Dieu Khien Toc Do Dong Co: OUT CV THR DSCHGthuhaui100% (1)

- Fire Bird Software ManualDocument62 pagesFire Bird Software ManualEyantra_resourcesNo ratings yet

- Design and Implementation of Space Vector PWM Inverter Based On A Low Cost MicrocontrollerDocument12 pagesDesign and Implementation of Space Vector PWM Inverter Based On A Low Cost MicrocontrollerHaider NeamaNo ratings yet

- Railway GateDocument46 pagesRailway GateRocky SinghNo ratings yet

- Power Electronic (Pe) SystemDocument63 pagesPower Electronic (Pe) SystemFarid DafaNo ratings yet

- Schematic KIT PIC V3 MinhHaGroupDocument2 pagesSchematic KIT PIC V3 MinhHaGroupTrần MạnhNo ratings yet

- Chapter 5 - DC - Ac Converter (Part A)Document29 pagesChapter 5 - DC - Ac Converter (Part A)andersonNo ratings yet

- Logic Analyzer 4Document1 pageLogic Analyzer 4Rick BazzaNo ratings yet

- Assembly Manual K2639Document32 pagesAssembly Manual K2639Asse NavNo ratings yet

- MTP 610 P 210 Manual Book LeonicsDocument2 pagesMTP 610 P 210 Manual Book LeonicsRido ManikNo ratings yet

- 1,3Ghz Frequency Counter 1,3Ghz Frequency Counter 1,3Ghz Frequency Counter 1,3Ghz Frequency CounterDocument1 page1,3Ghz Frequency Counter 1,3Ghz Frequency Counter 1,3Ghz Frequency Counter 1,3Ghz Frequency Counteredosvirac100% (1)

- A Novel Single Phase Cascaded H-Bridge Inverter With Reduced Power Electronics SwitchesDocument8 pagesA Novel Single Phase Cascaded H-Bridge Inverter With Reduced Power Electronics SwitchesHemanth KumarNo ratings yet

- Raptor Ser Ies High Perfor Mance Mo Tor DrivesDocument7 pagesRaptor Ser Ies High Perfor Mance Mo Tor DrivesJohn-Michael 'J' BillsNo ratings yet

- EE 435 SCR Notes3Document32 pagesEE 435 SCR Notes3Dado GaudiNo ratings yet

- DFR0063 v1.2 SchematicDocument1 pageDFR0063 v1.2 SchematicVasi ValiNo ratings yet

- Magnecraft RelaysDocument210 pagesMagnecraft RelaysMohamed ElsayedNo ratings yet

- Circuit Diagrams For Logic Analyzer & Counters LabsDocument4 pagesCircuit Diagrams For Logic Analyzer & Counters LabsNazmus SakibNo ratings yet

- CPU921-922 6ES5998-0UL22 (E) OCRDocument548 pagesCPU921-922 6ES5998-0UL22 (E) OCRnasir_khan_24No ratings yet

- Experiment No 1 AM TransmitterDocument6 pagesExperiment No 1 AM TransmitterashfaqiNo ratings yet

- Smart Relay: Ordering InformationDocument5 pagesSmart Relay: Ordering InformationbhagyeshNo ratings yet

- Smart HomeDocument5 pagesSmart HomeThùy Đào100% (1)

- Adaptive Prediction Model Accuracy in The Control of Residential Energy ResourcesDocument6 pagesAdaptive Prediction Model Accuracy in The Control of Residential Energy ResourcesMario SammyNo ratings yet

- Nguyenly PDFDocument1 pageNguyenly PDFThanh Nguyễn Văn100% (1)

- Power Supply ReviewDocument4 pagesPower Supply Reviewramesh ranjitNo ratings yet

- Dkg-109 Automatic Mains Failure UnitDocument46 pagesDkg-109 Automatic Mains Failure UnitmohsenNo ratings yet

- A Low Cost High Efficiency Inverter For Photovoltaic ApplicationsDocument6 pagesA Low Cost High Efficiency Inverter For Photovoltaic ApplicationsbpchimeraNo ratings yet

- Switchgear Application Issues For Mission Critical Power Systems, Part OneDocument12 pagesSwitchgear Application Issues For Mission Critical Power Systems, Part OneMithra Sathish KumarNo ratings yet

- Design and Analysis of A Practical Three-Phase Grid-Connected Photovoltaic InverterDocument5 pagesDesign and Analysis of A Practical Three-Phase Grid-Connected Photovoltaic InverterAhmed RefaatNo ratings yet

- Voltage Control in Power System Using Expert System Based On SCADA SystemDocument5 pagesVoltage Control in Power System Using Expert System Based On SCADA SystemFABIANCHO2210100% (1)

- Ethernet IP Texas InstrumentsDocument6 pagesEthernet IP Texas InstrumentsFranzKafkaNo ratings yet

- Uninterruptible Power Supply Multiloop Control Employing Digital Predictive Voltage and Current RegulatorsDocument9 pagesUninterruptible Power Supply Multiloop Control Employing Digital Predictive Voltage and Current RegulatorsPhạm Văn TưởngNo ratings yet

- Uhc AwatersDocument60 pagesUhc Awaterskammu9713No ratings yet

- All About HarmonicsDocument240 pagesAll About HarmonicsKhushal KharadeNo ratings yet

- Direct Duty Cycle Control For MPPT Digital ImplementationDocument5 pagesDirect Duty Cycle Control For MPPT Digital ImplementationPhạm Văn TưởngNo ratings yet

- Pulse-Width Modulation For Electronic Power ConversionDocument18 pagesPulse-Width Modulation For Electronic Power ConversionPhạm Văn TưởngNo ratings yet

- Phan Tich 1 Bai Task 2 by Ngoc BachDocument4 pagesPhan Tich 1 Bai Task 2 by Ngoc BachPhạm Văn Tưởng100% (1)

- (Matsui) Sensorless PM Brushless DC Motor DrivesDocument9 pages(Matsui) Sensorless PM Brushless DC Motor DrivesPhạm Văn TưởngNo ratings yet

- 1 - Review of Position-Sensorless Operation of Brushless Permanent-Magnet MachinesDocument11 pages1 - Review of Position-Sensorless Operation of Brushless Permanent-Magnet MachinesPhạm Văn TưởngNo ratings yet

- Analysis and Simulation of The High-Speed Torque Performance of BrushleDocument10 pagesAnalysis and Simulation of The High-Speed Torque Performance of BrushlePhạm Văn TưởngNo ratings yet

- Implementing Field Oriented Control of A Brushless DC MotorDocument10 pagesImplementing Field Oriented Control of A Brushless DC MotorPhạm Văn TưởngNo ratings yet

- Blaabjerg, F. Teodorescu, R. Liserre, M. Timbus, A.V. - Overview of Control and Grid Synchronization For DistributDocument12 pagesBlaabjerg, F. Teodorescu, R. Liserre, M. Timbus, A.V. - Overview of Control and Grid Synchronization For DistributPhạm Văn TưởngNo ratings yet

- A New Simulation Model of BLDC Motor With Real Back EMF WaveformDocument4 pagesA New Simulation Model of BLDC Motor With Real Back EMF WaveformPhạm Văn TưởngNo ratings yet

- Genesis 30uvDocument42 pagesGenesis 30uvCARLOSNo ratings yet

- Alpha BasicDocument190 pagesAlpha Basicmiguel_pinheiro_10No ratings yet

- OperationDocument7 pagesOperationEmmanuel NicholasNo ratings yet

- Skyblivion Architecture GuidelinesDocument11 pagesSkyblivion Architecture GuidelinesBrody EvensonNo ratings yet

- PM EquipmentDocument16 pagesPM Equipmentsiva prasadNo ratings yet

- BIAS Amp Product ChartDocument4 pagesBIAS Amp Product ChartMarco ZamoranoNo ratings yet

- Heat Load Estimation E20 Form SIDocument1 pageHeat Load Estimation E20 Form SIAslam AhamedNo ratings yet

- AEC Drying Brochure AEC2-115.1Document12 pagesAEC Drying Brochure AEC2-115.1serdigital0No ratings yet

- Hzt. Ammar e Yaser (R.a.)Document88 pagesHzt. Ammar e Yaser (R.a.)naqvi202No ratings yet

- Salesforce Workflow CheatsheetDocument4 pagesSalesforce Workflow Cheatsheetgowtham 099091No ratings yet

- All Document 'TYPES' & DescriptionsDocument5 pagesAll Document 'TYPES' & DescriptionsPhilipNo ratings yet

- Extension of MDRRMO OfficeDocument12 pagesExtension of MDRRMO OfficeJustin YuabNo ratings yet

- Installation & Maintenance ManualDocument80 pagesInstallation & Maintenance ManualWleed KhledNo ratings yet

- 5 Dairy Processing - Clarification and Cream SeparationDocument6 pages5 Dairy Processing - Clarification and Cream SeparationSPMUSER9ANo ratings yet

- CIV E 354 Geotechnical Engineering Ii: by Giovanni CascanteDocument11 pagesCIV E 354 Geotechnical Engineering Ii: by Giovanni CascanteVNo ratings yet

- Firmware Update by Telnet v11.2Document7 pagesFirmware Update by Telnet v11.2adiskylineNo ratings yet

- MID 185 - PSID 3 - FMI 8 Renault VolvoDocument3 pagesMID 185 - PSID 3 - FMI 8 Renault VolvolampardNo ratings yet

- BenzoinDocument7 pagesBenzoinLeah ThomasNo ratings yet

- IZenBridge PMI ACP Program PDFDocument4 pagesIZenBridge PMI ACP Program PDFadetolahNo ratings yet

- Raptor Techn RevCA 704010EN WebDocument194 pagesRaptor Techn RevCA 704010EN WebFranciscoNo ratings yet

- FCS-8005 User ManualDocument11 pagesFCS-8005 User ManualGustavo EitzenNo ratings yet

- The Cut Off List of Allotment in Round 03 For Programme B.Tech (CET Code-131) For Academic Session 2023-24Document42 pagesThe Cut Off List of Allotment in Round 03 For Programme B.Tech (CET Code-131) For Academic Session 2023-24addisarbaNo ratings yet

- PDF - SYLLABUS B2.new PDFDocument4 pagesPDF - SYLLABUS B2.new PDFSaniya khanNo ratings yet

- Chapter 9 (Cleaning and Fettling of Castings), 2003Document32 pagesChapter 9 (Cleaning and Fettling of Castings), 2003Desalegn DgaNo ratings yet

- PGN Case StudyDocument3 pagesPGN Case StudyFarizAgustyoNo ratings yet

- ScanSnap Ix500 TroubleshootDocument58 pagesScanSnap Ix500 TroubleshootrajinbacaNo ratings yet

- ADBA First 2 UnitsDocument1 pageADBA First 2 Unitsyash mNo ratings yet

- CollisionDocument7 pagesCollisionboltuNo ratings yet