Professional Documents

Culture Documents

Chronological Weekly Details

Chronological Weekly Details

Uploaded by

AnchalGuptaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chronological Weekly Details

Chronological Weekly Details

Uploaded by

AnchalGuptaCopyright:

Available Formats

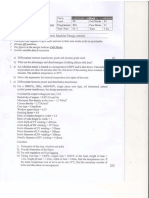

CHRONOLOGICAL WEEKLY

DETAILS:

STANDARD ROOM :

1. ELECTRONIC HEIGHT GAUGE:

CAPABILITIES : Height measurement

RANGE : 800 mm

LEAST COUNT : 0.001mm

2. FORM TESTER :

CAPABILITIES : Measurement of

roundness,squareness,surface finish.

RANGE : Measuring Height -500mm

Turn table diameter-400mm

3. MECHANICAL COMPARATOR :

CAPABILITIES :Length measurement

RANGE : Height 0-400mm

Scale - +_ 0.015mm

LEAST COUNT 0.0005mm

4. DIAL GAUGE CALIBRATOR :

RANGE : 0-0.2mm

LEAST COUNT -0.1mm

MECHANICAL SECTION :

VARIOUS MACHINES :

1. SCHAUBLIN 125:

It has been originated in Switzerland.Cost of it is Rs

33 lacs.

It operates on two axes( X,Z

axes).x=130mm,z=560mm.

It has a spindle speed of 3000 rpm.

2. ULTRA WIRE CUT :

It was installed in 2005 in HAL . Its cos is around 40

lacs.

It operates on three axes.(X,Y,Z).

X=400mm

Y=300mm

Z=250mm

It has a capability of profile cutting with minimum

filter.

3. CNC TWIN MILL :

It was originated in Germany.It operates on four axes

(X,Y,X,C)

It has a capability of contour turning,milling.

4. DMG DECKEL MAHO:

It has been originated in germany.It operates on four axes

(X,Y,Z,B ).It has a set of 40 tools.It has a spindle speed of

8000rpm.It has a table size of 400*500mm

5. TAJ MAC :

It has been installed in 2006 in HAL. It operates on four

asex. It has a spindle speed of 12000 rpm. It has a set of

102 tools. It has a worker area of 800*630mm

6. EMCO TURN 500 :

It has been orginated in Australia. It costs Rs 77.56 lacs.It

has two axes.

Its turret has 12 stations.It has a capability of precision

turning of medium component.

HR SECTION :

THREE TYPES OF COMPANIES :

1.Govt .

2.Public.

3.Private.

VARIOUS LAWS :

1.Minimum wage act.

2.Payment of wages act.

DIRECT ACTION TAKEN BY EMPLOYEE :

1.Strike.

2.Boycott.

3.Tool down and bend down .

4.Token Demand .

5.Relay hunger.

FACILITIES GIVEN TO EMPLOYEES :

1.Statuitory Facilities .

2.Czech Facilities.

3.Safety Facilities .

HYDRAULIC AND MECHANICAL

SYSTEM OF AIRCRAFT :

AIRCRAFT MECHANICAL SYSTEM:

1.Hydraulic system.

2.Aircraft flight control.

3.Take off/landing aids.

4.Ejection seat.

APPLICATION OF HYDRAULIC SYSTEM :

1.Steering system

2.Wheel brake system.

3.Thrust reversal of engines.

4.Weapons systems.

5.Flight control system.

ADVANTAGES OF HYDRAULIC SYSTEM :

1.Power to weight ratio is high.

2.system if efficient.

3.It can handle heavy loads.

DISADVANTAGES OF HYDRAULIC SYSTEM :

1.Fire hazardous.

2.Oil leak.

HYDRAULIC FLUID USED IN AIRCRAFT :

1.Mineral oil.

2.Sysnthetic hydrocarbons.

3.Halocarbons.

FUEL SYSTEM OF AIRCRAFT :

TYPES OF FUEL SYSTEM :

1Gravity feed system.

2.Pressure feed system.

ENGINE FUEL SYSTEM :

1.Air intake.

2.Swirl.

3.Compressor.

4.Combustion chamber.

TYPES OF GAS TURBINE ENGINES :

1.Turbojet.

2.Turbofan.

3.Turboprop.

4.Afterburning turbojet.

FUEL SYSTEM COMPONENTS :

1.Pumps.

2.Tanks.

3.Lines.

4.Valves.

5.Fuel-flow meters.

6.Filters and Strainers.

7.Quantity indicator.

8.Warning components.

9.Fuel drainers.

10.Heaters.

TYPES OF PUMP :

1. Fuel pump system.

2. Booster pump.

3. Cross feed pump

4. Scavenge pump.

5. Vane type pump.

6. Centrifugal pump.

7. Ejector.

ELECTRICAL AND ELECTRONICS

SYSTEM OF AIRCRAFT :

TWO TYPES OF SUPPLIES :

1.DC-28V,Battery,DC Generator.

2.AC_115V,Alternaotr.

DIRECTION GYRO :

When ever we go any place by motor we have to need the

direction of our destination. Similarly in the air also we need

the direction that on which direction we go then we our

destination that need is accomplished by direction gryo. By

this instrument we set the angle of destination, match it with

zero and until it is at zero position this is like that will

confirmation about that we are gone at right path.

Air temperature gauge is a panel mounted instrument and

indicate the out side air temperature .The sensor position of

instrument produces o/p on the cockpit and sense the

outside air temperature

Coding particulars

NAME outside air temp gauge

CODE 1629.00.000

WEIGHT 150 Gms

SIZE 56 *155 mm

ACCURACY +-1.5 %

OPERATING TEMP -45to +75 cel

TEMPERATURE SWITCH :

Temp switch is used in ALH to close the electric circuit when

the temp in surrounding air reaches the predetermined

value

The unit also senses the oil temp of the transmission system

It works on vapor pressure action and consists of bulb

containing ethyl alcohol, due to sufficient change in temp the

organic liquid vaporizes and build up pressure with in the

closed chamber

This high vapor pressure compresses a bellow assembly

which in tern operates the snap action micro switch

Gear box oil temp senses temp with in the range 115+4to

115-4max and 110+4to 110-4 min

ALTERNATOR CONTROL AND PROTECTION UNIT:

Alternator control and protection unit regulates the

alternator o/p voltage with in specified limit under various

rated load and rated condition. This unit is having built in

protection against over / under voltage, over / under

frequency, overload feeder fault condition, the unit

disconnects the alternator from ac control system by

denergizing the line contractor and field.

The unit will be interfaced with the alternator having

characteristics

Type 3 phase star connection voltage 115/200

400hz

o/p power 5 kva

normal speed 12000 rpm

max speed for regulation 12600 rpm

min speed for regulation 11400 rpm

over speed 15000 rpm

frequency at 12000rpm 400 Hz

A/C ELCTRIC DISTRIBUTION BOX :

A/C distribution box is used in the advance light helicopter

(ALH).Excluding 2 alternator, 2 alternator control and

protection unit and static inverter primary a/c distribution

consists of the following boxes

1. A/C master box-3

2. A/C master box-4

3. 115v a/c emergency bus relay

4. 26v a/c emergency bus relay

A/c master box -3 consists of 3 phase main bus -1(115v), 1

phase emergency bus-1 and 2 (115v), I phase main bus-

1(26v) and 1 phase emergency bus-1(26v)

During normal operation (both alternator running),

complete system-1 is powered from alternator-1 .In case of

fault on alternator-1 all the bus of system-1 are connected to

alternator-2 with alternator-1 in failed condition. In the case

of a short circuit on a main bus-1 it goes disconnect from the

alternator-2.

In case of both alternator fail to supply the power of A/C

main buses, emergency buses of system-1are powered by

static inverter with a/c ground power in and selected in the

cockpit, external power control card validates in coming

ground power and automatically energies the external

power connecter to supply ground power to all buses of the

system 1and 2 through main bus -1 of the system-1 a/c

.Master box-4 is resistor in conduction and function to a/c

master box-3 as following.

This box does not include external power conductor and the

external power control card. However this has non essential

bus along with its connector. The non essential bus is

powered from the main bus-2 only when both alternators

are running or external power is on and selected .All power

o/p at different buses are protected with thermal circuit

breakers which are provided in each master box.

Operational condition

Master power switch ON and bus tie in normal position

1. external power selected

2. alternator -1 selected

3. alternator -2 selected

4. both alternator are selected

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hal Dkb-2010 ManualDocument101 pagesHal Dkb-2010 Manualteconline-1No ratings yet

- Public Address System: Installation Instructions SlavamplifierDocument18 pagesPublic Address System: Installation Instructions SlavamplifierMarcelo Almeida100% (1)

- KWH Meter 2CMC485001L0201Document2 pagesKWH Meter 2CMC485001L0201Proc. RembangNo ratings yet

- How To Calculate Voltage Regulation of Distribution Line - EEPDocument8 pagesHow To Calculate Voltage Regulation of Distribution Line - EEPelectworldNo ratings yet

- Pages From P24019-30-99-63-1601 - 1afgDocument1 pagePages From P24019-30-99-63-1601 - 1afgRaeesNo ratings yet

- Eamm-A enDocument80 pagesEamm-A enIqtidar GulNo ratings yet

- Roll No 14 EE Experiment No. 10Document9 pagesRoll No 14 EE Experiment No. 10Asim AwanNo ratings yet

- SMA Specification (Upto3kw) PDFDocument2 pagesSMA Specification (Upto3kw) PDFduckman2009No ratings yet

- Wireless Charging of Mobile Phones Seminar ReportDocument23 pagesWireless Charging of Mobile Phones Seminar ReportDevesh Kumar Verma83% (6)

- AN/MPQ-T3: AAA Radar SimulatorDocument2 pagesAN/MPQ-T3: AAA Radar SimulatordanNo ratings yet

- Critical Book ReviewDocument13 pagesCritical Book ReviewSiti khadijahNo ratings yet

- Chapter 9Document25 pagesChapter 9mmkayaNo ratings yet

- GST I-9319 Intelligent Addressable Zone Interface Module DatasheetDocument2 pagesGST I-9319 Intelligent Addressable Zone Interface Module DatasheetFIRE SAFETY ENGINEERINGNo ratings yet

- D-CFL Balasto DimableDocument4 pagesD-CFL Balasto Dimabledlinares07No ratings yet

- Analysis of DC Offset in Fault Current Caused by MDocument6 pagesAnalysis of DC Offset in Fault Current Caused by MLast Greed7up1No ratings yet

- Der-628 18watt Usb PD Charger Using Innoswitch3-Cp and Cypress ControllerDocument60 pagesDer-628 18watt Usb PD Charger Using Innoswitch3-Cp and Cypress ControllerVan ToanNo ratings yet

- Michael FaradayDocument13 pagesMichael FaradayKyla MeiNo ratings yet

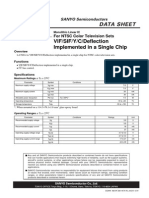

- VIF/SIF/Y/C/Deflection Implemented in A Single Chip: For NTSC Color Television SetsDocument35 pagesVIF/SIF/Y/C/Deflection Implemented in A Single Chip: For NTSC Color Television SetsLeonel MartinezNo ratings yet

- SP8K1Document4 pagesSP8K1aminotepNo ratings yet

- Revision - 1 - On ElectrochemistryDocument12 pagesRevision - 1 - On ElectrochemistryKiro RemonNo ratings yet

- Andrew Repeater Node-M and Node-C User-Manual-1271485Document62 pagesAndrew Repeater Node-M and Node-C User-Manual-1271485Viswanaath100% (1)

- Solar Energy Lecture Notes Modeling and Analysis of Photovoltaic and Electrochemical Solar Energy SystemsDocument137 pagesSolar Energy Lecture Notes Modeling and Analysis of Photovoltaic and Electrochemical Solar Energy SystemsBigyan BhattaraiNo ratings yet

- Chapter Test Answers Physics 12Document35 pagesChapter Test Answers Physics 12sawanyadav3010No ratings yet

- Hollow Prism Physics Investigatory Project Class 12 CBSEDocument12 pagesHollow Prism Physics Investigatory Project Class 12 CBSEkrishanubhasker10No ratings yet

- EE 280 Tutorial IDocument2 pagesEE 280 Tutorial IChinthaka WeerakkodyNo ratings yet

- Implementation of Solar Cap and Its Judicious UseDocument26 pagesImplementation of Solar Cap and Its Judicious UseShivam Jindal100% (1)

- Catalogue Raychem TerminationDocument8 pagesCatalogue Raychem TerminationVijvel Nithyan50% (4)

- 6 7 8 Biopotential AmplifiersDocument67 pages6 7 8 Biopotential Amplifiersahmed kakaNo ratings yet

- Electrical Machine DesignDocument6 pagesElectrical Machine DesignDeepak ThapaNo ratings yet

- Service Manual Trucks: Fault Codes, Adaptive Cruise Control MID 219 ACCDocument38 pagesService Manual Trucks: Fault Codes, Adaptive Cruise Control MID 219 ACCnaftaliNo ratings yet