Professional Documents

Culture Documents

BS - EN - 1371-1 - 1997 - DP Test

BS - EN - 1371-1 - 1997 - DP Test

Uploaded by

Harish JanardhananOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BS - EN - 1371-1 - 1997 - DP Test

BS - EN - 1371-1 - 1997 - DP Test

Uploaded by

Harish JanardhananCopyright:

Available Formats

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BRITISH STANDARD

BS EN

1371-1 : 1997

The European Standard EN 1371-1 : 1997 has the status of a

British Standard

ICS 77.040.20; 77.140.80; 77.150.99

NO COPYING WITHOUT BSI PERMISSION EXCEPT AS PERMITTED BY COPYRIGHT LAW

Founding

Liquid penetrant

inspection

Part 1. Sand, gravity die and low pressure

die castings

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

This British Standard, having

been prepared under the

direction of the Engineering

Sector Board, was published

under the authority of the

Standards Board and comes into

effect on 15 November 1997

BSI 1997

ISBN 0 580 28601 0

BS EN 1371-1 : 1997

Amendments issued since publication

Amd. No. Date Text affected

National foreword

This British Standard is the English language version of EN 1371-1 : 1997. It

supersedes BS 4080 : Part 2 : 1989 which is withdrawn.

The UK participation in its preparation was entrusted to Technical Committee

ISE/NFE/9, Foundry Technology, which has the responsibility to:

aid enquirers to understand the text;

present to the responsible international/European committee any enquiries

on the interpretation, or proposals for change, and keep the UK interests

informed;

monitor related international and European developments and promulgate

them in the UK.

A list of organizations represented on this committee can be obtained on request to

its secretary.

Cross-references

The British Standards which implement international or European publications

referred to in this document may be found in the BSI Standards Catalogue under the

section entitled `International Standards Correspondence Index', or by using the

`Find' facility of the BSI Standards Electronic Catalogue.

Compliance with a British Standard does not of itself confer immunity

from legal obligations.

Summary of pages

This document comprises a front cover, an inside front cover, the EN title page,

pages 2 to 26, an inside back cover and a back cover.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

CEN

European Committee for Standardization

Comite Europe en de Normalisation

Europa isches Komitee fu r Normung

Central Secretariat: rue de Stassart 36, B-1050 Brussels

1997 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national

Members.

Ref. No. EN 1371-1 : 1997 E

EUROPEAN STANDARD

EN 1371-1

NORME EUROPE

ENNE

EUROPA

ISCHE NORM

June 1997

ICS 77.140.80; 77.150.99

Descriptors: Foundry engineering, castings, steels, cast iron, surface condition, inspection, nondestructive tests, liquid penetrant tests,

surface defects, acceptability

English version

Founding Liquid penetrant inspection Part 1: Sand, gravity die

and low pressure die castings

Fonderie Contro le par ressuage Partie 1:

Pieces moulees au sable, en coquille, par gravite et

basse pression

Gieereiwesen Eindringpru fung Teil 1: Sand- ,

Schwerkraftkokillen- und

Niederdruckkokillengustu cke

This European Standard was approved by CEN on 1997-06-02. CEN members are

bound to comply with the CEN/CENELEC Internal Regulations which stipulate the

conditions for giving this European Standard the status of a national standard

without any alteration.

Up-to-date lists and bibliographical references concerning such national standards

may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German).

A version in any other language made by translation under the responsibility of a

CEN member into its own language and notified to the Central Secretariat has the

same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Czech

Republic, Denmark, Finland, France, Germany, Greece, Iceland, Ireland, Italy,

Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and

United Kingdom.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 2

EN 1371-1 : 1997

BSI 1997

Foreword

This European Standard has been prepared by

Technical Committee CEN/TC 190, Foundry technology,

the secretariat of which is held by DIN.

This European Standard shall be given the status of a

national standard, either by publication of an identical

text or by endorsement, at the latest by

December 1997, and conflicting national standards shall

be withdrawn at the latest by December 1997.

Within its programme of work, Technical Committee

CEN/TC 190 requested CEN/TC 190/WG 4.20, Surface

inspection, to prepare the following standard:

EN 1371-1 Founding Liquid penetrant

inspection Part 1: Sand, gravity die

and low pressure die castings

This is one of two European Standards for liquid

penetrant inspection. The other standard is:

prEN 1371-2 Founding Liquid penetrant

inspection Part 2: Investment castings

According to the CEN/CENELEC Internal Regulations,

the national standards organizations of the following

countries are bound to implement this European

Standard: Austria, Belgium, Czech Republic, Denmark,

Finland, France, Germany, Greece, Iceland, Ireland,

Italy, Luxembourg, Netherlands, Norway, Portugal,

Spain, Sweden, Switzerland and the United Kingdom.

Contents

Page

Foreword 2

Introduction 3

1 Scope 3

2 Normative references 3

3 Conditions for liquid penetrant inspection 3

4 Method of inspection 3

4.1 Operating mode 3

4.2 Qualification of the operators 3

4.3 Surface preparation 3

4.4 Conditions of inspection 4

5 Acceptance criteria 4

5.1 Indications of discontinuities 4

5.2 Definition of liquid penetrant inspection

indications 4

5.3 Severity levels 4

6 Classification of the indications and

interpretation of results 5

7 Ordering 5

8 Retesting 5

9 Post-examination cleaning procedures 5

10 Inspection documentation 5

Tables

1 Nature of discontinuities and types of

corresponding liquid penetrant inspection

indications 6

2 Severity levels for liquid penetrant

inspection Non-linear indications isolated

(SP) or clustered (CP) 6

3 Severity levels for liquid penetrant

inspection Linear (LP) and aligned (AP)

indications 7

4 Recommended surface finish for liquid

penetrant inspection 8

Annexes

A (informative) Bibliography 9

B (informative) Reference figures Non-linear

isolated indications designated SP 9

C (informative) Reference figures Non-linear

indications designated SP and CP 14

D (informative) Reference figures Linear and

aligned indications designated LP and AP 17

E (informative) Model of a liquid penetrant

inspection document 24

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 3

EN 1371-1 : 1997

BSI 1997

Introduction

This European Standard complements the general

principles of liquid penetrant inspection given in

EN 571 for the additional requirements of the foundry

industry.

Liquid penetrant inspection, as well as any other non

destructive examination method, is part of a general or

specific assessment of the quality of a casting to be

agreed between the manufacturer and the purchaser at

the time of acceptance of the order.

Penetrant testing examination of castings is

standardized in two parts:

EN 1371-1: Sand, gravity die and low pressure die

castings

prEN 1371-2: Investment castings

1 Scope

This European Standard applies to the liquid penetrant

testing of all castings (except copper-tin and/or

copper-tin-lead alloy castings, where copper is the

major constituent) produced in conventional sand

moulds by gravity and low-pressure die casting,

whatever their grade and the casting procedure used to

produce them.

This standard does not apply to investment and

pressure die castings.

2 Normative references

This standard incorporates, by dated or undated

reference, provisions from other publications. These

normative references are cited at the appropriate

places in the text and the publications are listed

hereafter. For dated references, subsequent

amendments to or revisions of any of these

publications apply to this standard only when

incorporated in it by amendment or revision. For

undated references, the latest edition of the publication

referred to applies.

EN 473 Qualification and certification of NDT

personnel General principles

EN 571-1 Non-destructive testing Penetrant

testing Part 1: General principles

EN 1370 Founding Surface roughness

inspection by visualtactile comparators

prEN 1371-2 Founding Liquid penetrant

inspection Part 2: Investment castings

prEN 1956 Non-destructive testing Penetrant

testing and magnetic particle testing

Viewing conditions

NOTE. Informative reference to documents used in the

preparation of this standard, and cited at the appropriate places in

the text, are listed in a bibliography, see annex A.

3 Conditions for liquid penetrant

inspection

The manufacturing stage(s) when liquid penetrant

inspection is to be performed shall be clearly defined

by agreement between the manufacturer and the

purchaser.

Inspection shall be carried out only on those areas of

the castings and on the percentage of castings agreed.

Inspection requirements shall be clearly stated in the

call for tender, in the request for prices and, more

particularly, in the order sent to the manufacturer and

accepted by him, so that the manufacturer can assess

the costs of manfacturing to satisfy the required

severity level and the costs of additional inspections

and operations, and the manufacturing risks involved.

For each agreed area of the casting to be inspected,

the following shall be indicated:

type of discontinuity;

severity level.

Sensitivity can differ depending on the method of

liquid penetrant inspection selected. Therefore the

severity levels required shall be selected as a function

of the liquid penetrants used and the method agreed

between the manufacturer and the purchaser.

The type of discontinuity and the severity level can

vary depending on the area of the casting inspected

(see tables 1 to 3).

4 Method of inspection

4.1 Operating mode

Inspection shall be carried out as described in

EN 571-1. The characteristics of the penetrant materials

shall be checked in accordance with specifications to

be agreed between the manufacturer and the

purchaser.

4.2 Qualification of the operators

Inspection shall be performed by personnel qualified in

accordance with EN 473 or by a certification scheme

which is considered to be equivalent. The qualification

level of the personnel shall be agreed between the

manufacturer and the purchaser at the time of

acceptance of the order.

4.3 Surface preparation

The surface to be inspected shall be clean and free

from oil, grease, moulding and coating residues or any

other contaminant which could interfere with the

correct implementation and interpretation of the

penetrant inspection test results.

The surface finish of the casting in the area to be

tested shall have sufficient brightness and contrast of

colour and adequate shape to determine the required

severity level. Unless otherwise specified at the time of

ordering, the surface finish shall be selected from

table 4.

NOTE. It is recommended that the assessment of surface finish is

carried out using a visual cast-surface roughness comparator.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 4

EN 1371-1 : 1997

BSI 1997

1)

Shot blasting is not recommended prior to liquid penetrant testing.

Liquid penetrant inspection shall be performed on

castings in the as-delivered conditon. If sand blasting

or shot blasting

1)

is required, it shall be as light as

possible, in order to avoid sealing or closing up

possible discontinuities. If the risk of sealing or closing

up possible discontinuities is unacceptable, then

blasting shall be followed by chemical etching in order

to enable detection of discontinuities. The chemical

composition of the etching bath and other parameters

such as concentration, temperature, immersion time,

neutralizing and rinsing, if applicable, shall be

recorded.

4.4 Conditions of inspection

The inspection shall be carried out with the naked eye

or at a maximum magnification of 3 and viewing

conditions in conformity with prEN 1956.

5 Acceptance criteria

5.1 Indications of discontinuities

5.1.1 General

The indication of discontinuities can be non-linear

(isolated or clustered), aligned or linear. Although

liquid penetrant inspection cannot generally be used to

determine the size of detected discontinuities, it allows

discontinuities to be assessed by measurement of the

length L of the indication. In the following clauses:

L indicates length;

W indicates width;

t indicates section thickness;

P indicates liquid penetrant;

SP indicates non-linear isolated indication;

CP indicates non-linear clustered indication;

AP indicates aligned indication;

LP indicates linear indication.

5.1.2 Criteria

The various types of penetrant indication can

correspond to the discontinuities (A, B, C, etc.) shown

in table 1.

The physical discontinuities detailed in table 1 shall

give either a non-linear, linear or aligned liquid

penetrant inspection indication.

5.2 Definition of liquid penetrant inspection

indications

a) linear indication (LP). An indication with the

largest dimension three or more times its smallest

dimension (i.e. L $ 3W);

b) non-linear indication. An indication with the

largest dimension less than three times its smallest

dimension (i.e. L < 3W):

isolated (SP);

clustered (CP): area of multiple indications, the

distance between the indications cannot be

measured (they seem to form only one indication);

c) aligned indication (AP). Indications that are

either:

linear: the distance between two indications is

smaller than the length of the longest discontinuity

in the alignment; or

non-linear: the distance between two indications

is less than 2 mm and at least three indications are

noted.

5.3 Severity levels

5.3.1 General

Several severity levels are recognized in accordance

with tables 2 and 3. It is necessary to carry out the test

on a surface corresponding to a given degree of finish

(see table 4) depending on the severity level desired.

The liquid penetrant inspection for each type of

indication and its severity levels shall be specified at

the time of ordering, by the purchaser, depending on

the use of the castings. The manufacturer shall give his

agreement.

The penetrant indications to be taken into account

shall have dimensions in accordance with the severity

level.

The required severity level shall be selected

accordingly and specified in the order by agreement

between the manufacturer and the purchaser.

5.3.2 Criteria

The maximum permissible length for linear or aligned

indications varies with the section thickness t. Three

section thickness types are specified (see table 3):

type a: t #16 mm;

type b: 16 mm < t #50 mm;

type c: t > 50 mm.

Tables 2 and 3 show the largest dimensions of the

smallest indications to be considered in the severity

level concerned.

5.3.3 Tables

Table 2 corresponds to non-linear isolated or non-linear

clustered indications.

Examples of non-linear indications are shown in

annexes B and C. These have been established in

accordance with table 2; the reference figures are given

to and shall be interpreted against a scale of 1:1.

Table 3 corresponds to linear or aligned indications.

Tables 2 and 3 are independent (differing severity levels

may be selected from these tables).

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 5

EN 1371-1 : 1997

BSI 1997

2)

ISO format A6. If the casting dimensions in total are smaller than 105 mm 3 148 mm, then the indicating criteria should be in

proportion to the surface area and agreed between the manufacturer and the purchaser.

6 Classification of the indications and

interpretation of results

In order to classify an indication of discontinuity, a

frame measuring 105 mm 3148 mm

2)

should be placed

in the most unfavourable location. The observed

indications shall be in relation to the reference severity

levels as described in this standard and compared to

the equivalent or immediately better severity level.

Indications shall be considered to be equivalent when the

same number of non-linear spots and/or the same length

of linear indications of similar appearance are detected.

Maximumpermissible discontinuities may appear

simultaneously on the area of 105 mm3148 mm

2)

.

If, for any indication type, the observed severity level is

worse than that specified in the order, the casting shall

be considered to be in non-conformance with this

standard. It shall be considered as conforming with

this standard when the observed severity level is equal

to or better than that specified in the order.

For severity levels 1, 2, 3, 4 and 5, classification shall be

made by comparison with reference figures. For

severity levels 001, 01, 02 and 03, and in the event of

dispute in the interpretation of severity

levels 1, 2, 3, 4 and 5, reference shall be made to the

values in tables 2 and 3.

NOTE 1. Reference figures corresponding to non-linear, aligned

and clustered indications in accordance with tables 2 and 3 are

represented in annexes B, C and D for guidance only, drawn to a

scale of 1:1.

The requirements detailed in the order or in the

specifications shall be written in conformance to the

terminology used in this standard.

Examples of how the requirements shall be specified

are as follows:

non-linear indications level 2 (abbreviated as SP 2);

linear and aligned indications level 5 (abbreviated

as LP 5c and AP 5c).

NOTE 2. `c' in LP 5c means that the section thickness type t is

greater than 50 mm.

NOTE 3. Severity level references are arbitrary. They cannot be

considered in the same progression from one table to the other,

nor from one kind of indication to another.

NOTE 4. Provided that, on the casting surface, no tested area

contains discontinuities which exceed the agreed severity level,

there is no limit to the acceptability of discontinuities.

7 Ordering

The enquiry and/or order shall specify the following

points:

a) the area(s) of the casting(s) and percentage of

castings to be inspected (see clause 3);

b) the manufacturing stage or stages when the

inspection is to be carried out, as agreed between

the parties (see clause 3);

c) the type of discontinuity indications and the

severity level for each area of the casting(s) to be

inspected (see clause 3 and 5.2).

8 Retesting

Retesting shall be in accordance with EN 571-1.

9 Post-examination cleaning procedures

Post-examination cleaning procedures shall be in

accordance with EN 571-1.

10 Inspection documentation

Inspection documentation shall be in accordance with

EN 571-1. A model of a trilingual inspection document

is shown in annex E.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 6

EN 1371-1 : 1997

BSI 1997

Table 1. Nature of discontinuities and types of corresponding liquid penetrant inspection

indications

Nature of discontinuities Symbol Types of liquid penetrant inspection indications

non-linear linear aligned

isolated clustered

SP CP LP AP

Gas porosity A X X X

Sand and/or slag

inclusions (other than

alumina)

B X X X

Shrinkage defects due

to nitrogen

1)

C X X X X

Cracks D X X

Hot tears E X X

Inserts F X X X

Laps and cold shuts H X X

Presence of alumina

2)

J X X

Graphite flotation

1)

K No image, but `background' indications

1)

For cast iron only.

2)

For non-ferrous alloys only.

Table 2. Severity levels for liquid penetrant inspection Non-linear indications

1)

isolated (SP) or

clustered (CP)

Characteristic Severity levels

SP 01

2)

SP 02 SP 03 SP 1 SP 2 SP 3 SP 4 SP 5

CP 01

2)

CP 02 CP 03 CP 1 CP 2 CP 3

Inspection means Magnifying

glass or

eye

eye

Magnification for

observation of

penetrant indication

# 3 1

Diameter of smallest

indication to be

considered in mm

0,3 0,5 1 1,5 2 3 5 5

Maximum number of

non-linear indications

allowed

5 6 7 8 8 12 20 32

Maximum size of

discontinuity indication

A, B, C and F allowed

in mm

isolated indications

SP

1 1 1,5 3 6 9 14 21

clustered

indications CP (for

aluminium alloys

only, with a

maximum of 2 per

area)

3 4 6 10 16 25

1)

Such that L # 3W, where L is the length and W is the width of the indication.

2)

Severity level to be reserved for particular uses.

NOTE 1. Only values expressed in this table are valid. Reference figures are for information only (see annexes B and C).

NOTE 2. The sensitivity can differ depending on the method of penetrant inspection selected.

NOTE 3. The penetrant indications may grow over a period of time and this should be taken into account.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 7

EN 1371-1 : 1997

BSI 1997

Table 3. Severity levels for liquid penetrant inspection Linear (LP) and aligned (AP) indications

1)

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 8

EN 1371-1 : 1997

BSI 1997

Table 4. Recommended surface finish for

liquid penetrant inspection

Dimension of

smallest

indication

Visualtactile comparators

1)

mm

BNIF

2)

SCRATA

2)

0,3 2/0SI 1/0SI

1 S2 2 S2

1,5 1 S1 2 S1

3 S2 4 S2

A 1

H 1

2 2 S1 3 S1

4 S2 5 S2

A 2

H 2

$ 3 non specified

(rough surface)

A 3 A 4

H 3

1)

See EN 1370.

2)

See annex A.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 9

EN 1371-1 : 1997

BSI 1997

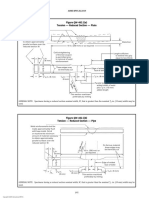

Figure B.1 Severity level SP 1

Annex A (informative)

Bibliography

In the preparation of this European Standard, use was

made of a number of documents for reference

purposes. These informative references are cited at the

appropriate places in the text and the publications are

listed hereafter.

ISO 4987 Steel castings Penetrant inspection

ISO 9916 Aluminium alloy and magnesium alloy

castings Liquid penetrant inspection

SCRATA comparators for the definition of surface

quality of steel castings, available from The Castings

Development Centre Ltd., 7 East Bank Road, Sheffield,

S2 3PT, United Kingdom.

BNIF 359 Recommandation technique du Bureau de

Normalisation des Industries de la Fonderie.

Caracterisation d'etats de surface des pieces

moulees Utilisation des echantillons types

de 110 3160 mm, available from Editions Techniques

des Industries de la Fonderie, 44 avenue de la Division

Leclerc, 92310 Se vres, France.

Annex B (informative)

Reference figures Non-linear isolated

indications designated SP

Valid for all cast alloys, except cast aluminium and

magnesium alloys.

NOTE. All reference figures shown in this annex are for guidance

only and are drawn, and shall be used, at a scale of 1:1.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 10

EN 1371-1 : 1997

BSI 1997

Figure B.2 Severity level SP 2

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 11

EN 1371-1 : 1997

BSI 1997

Figure B.3 Severity level SP 3

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 12

EN 1371-1 : 1997

BSI 1997

Figure B.4 Severity level SP 4

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 13

EN 1371-1 : 1997

BSI 1997

Figure B.5 Severity level SP 5

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 14

EN 1371-1 : 1997

BSI 1997

Figure C.1 Severity level SP 1 CP 1

Annex C (informative)

Reference figures Non-linear

indications designated SP and CP

Valid only for aluminium and magnesium cast alloys.

NOTE. All reference figures shown in this annex are for guidance

only and are drawn, and shall be used, at a scale of 1:1.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 15

EN 1371-1 : 1997

BSI 1997

Figure C.2 Severity level SP 2 CP 2

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 16

EN 1371-1 : 1997

BSI 1997

Figure C.3 Severity level SP 3 CP 3

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 17

EN 1371-1 : 1997

BSI 1997

Figure D.1 Severity level LP 1a AP 1a

Annex D (informative)

Reference figures Linear and aligned

indications designated LP and AP

Valid for all cast alloys.

NOTE. All reference figures shown in this annex are for guidance

only and are drawn, and shall be used, at a scale of 1:1.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 18

EN 1371-1 : 1997

BSI 1997

Figure D.2 Severity level 1b AP 1b [LP 2a

*)

AP 2a

*)

]

*)

Approximately comparable at these severity levels.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 19

EN 1371-1 : 1997

BSI 1997

Figure D.3 Severity level LP 1c AP 1c [LP 2b

*)

AP 2b

*)

or LP 3a

*)

AP 3a

*)

]

*)

Approximately comparable at these severity levels.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 20

EN 1371-1 : 1997

BSI 1997

Figure D.4 Severity level LP 2c AP 2c [LP 3b

*)

AP 3b

*)

or LP 4a

*)

AP 4a

*)

]

*)

Approximately comparable at these severity levels.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 21

EN 1371-1 : 1997

BSI 1997

Figure D.5 Severity level LP 3c AP 3c [LP 4b

*)

AP 4b

*)

or LP 5a

*)

AP 5a

*)

]

*)

Approximately comparable at these severity levels.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 22

EN 1371-1 : 1997

BSI 1997

Figure D.6 Severity level LP 4c AP 4c [LP 5b

*)

AP 5b

*)

]

*)

Approximately comparable at these severity levels.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 23

EN 1371-1 : 1997

BSI 1997

Figure D.7 Severity level LP 5c AP 5c

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 24

EN 1371-1 : 1997

BSI 1997

Annex E (informative)

Model of a liquid penetrant inspection document

Company Liquid-penetrant inspection document No.

n

o

Socie te Document de contro le Nr.

Firma Pru fbescheinigung zur Eindringpru fung Sheet

Page

Blatt

According to

Conforme a

Entsprechend

Customer Order No.

Client Commande n

o

Kunde Bestell-Nr.

Specification Material Heat No.

Spe cification Nuance Coule e n

o

Vorschrift Werkstoff Schmelze Nr.

Identification Quantity Casting designation Lot No. Drawing No.

Marquage Quantite De signation des

pie ces

n

o

du lot Plan n

o

Kennzeichnung Menge Gustu ckbezeichnung Los Nr. Zeichnung Nr.

Area examined zone contro le e - Pru fbereich

100 %

testing scheme plan de contro le Pru fplan

cavity root fonds affouillements Ausmuldung fu r Schweiung

Stage stade Zustand

after heat treatment apre s traitement thermique - nach Wa rmebehandlung

before stress relieving avant de tensionnement vor Spannungsarmglu hen

Dye-penetrant pe ne trant Eindringmittel.......................................................................................................................

Trademark marque Handelsmarke................................................................................................................................

Excess penetrant remover produit de lavage Spu lmittel ...........................................................................................

Trademark marque Handelsmarke................................................................................................................................

Developer re ve lateur Entwickler ..................................................................................................................................

Trademark marque Handelsmarke................................................................................................................................

(continued)

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 25

EN 1371-1 : 1997

BSI 1997

Model (continued)

Testing conditions conditions d'examen Pru fbedingungen

Surface condition e tat de surface Oberfla chenzustand

shot blasted grenaille gestrahlt

ground meule geschliffen

machined usine mechanisch bearbeitet

Casting temperature tempe rature de la pie ce moule e Gustu cktemperatur

5 C up to/jusqu'a /bis 14 C

15 C up to/jusqu'a /bis 35 C

36 C up to/jisqu'a /bis 55 C

............................................. C

Pre-cleaning nettoyage pre alable Vorreinigung

yes oui ja

no non nein

Penetrant application application du pe ne trant Auftragen des Pru fmittels

brush pinceau Pinsel

spray pulve risation Spru hen

dip immersion Tauchen

Penetration time temps d'impre gnation Eindringdauer ..................... min

Penetration removal elimination du pe ne trant Entfernen des Eindringmittels

cleaning with water lavage a l'eau Abspu len mit Wasser

solvent solvant Lo semittel

Drying time dure e de se chage Trocknungsdauer ................................min

Drying temperature tempe rature de se chage Trocknungstemperatur......................C

Developer application application du re ve lateur Anwendung des Entwicklers

brush pinceau Pinsel

spray pulve risation Spru hen

wet humide na

dry sec trocken

Developing time temps de re ve lation Entwicklungsdauer .......................... min

Illumination e clairage Beleuchtung

natural naturel Tageslicht

artificial artificiel ku nstlich

ultraviolet ultraviolet ultraviolett

Testing results re sultats de l'examen Pru fergebnisse

According to conforme a entsprechend

.................................................................................................................................................................................................

.................................................................................................................................................................................................

Accepted accepte abgenommen

yes oui ja

no non nein

Non-conformance note fiche d'anomalie Beanstandung

.................................................................................................................................................................................................

.................................................................................................................................................................................................

(continued)

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

Page 26

EN 1371-1 : 1997

BSI 1997

Model (continued)

Continuation sheet annexe Fortsetzungsblatt

yes oui ja

no non nein

Inspection authority organisme de contro le Abnahmegesellschaft

................................................................................................................................................................................................

Quality assurance section service assurance qualite Abteilung Qualita tssicherung

................................................................................................................................................................................................

Date date Datum

................................................................................................................................................................................................

Signature of inspector/operator signature de l'inspecteur/contro leur Unterschrift des Leiters der

Pru fstelle/Pru fers

................................................................................................................................................................................................

If applicable, tick the relevant box.

Suivant le cas, cocher le case correspondante.

Falls zutreffend, Entsprechendes ankreuzen.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

blank

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

BSI

389 Chiswick High Road

London

W4 4AL

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BSI British Standards Institution

BSI is the independent national body responsible for preparing British Standards. It

presents the UK view on standards in Europe and at the international level. It is

incorporated by Royal Charter.

Revisions

British Standards are updated by amendment or revision. Users of British Standards

should make sure that they possess the latest amendments or editions.

It is the constant aim of BSI to improve the quality of our products and services. We

would be grateful if anyone finding an inaccuracy or ambiguity while using this

British Standard would inform the Secretary of the technical committee responsible,

the identity of which can be found on the inside front cover. Tel: 020 8996 9000.

Fax: 020 8996 7400.

BSI offers members an individual updating service called PLUS which ensures that

subscribers automatically receive the latest editions of standards.

Buying standards

Orders for all BSI, international and foreign standards publications should be

addressed to Customer Services. Tel: 020 8996 9001. Fax: 020 8996 7001.

In response to orders for international standards, it is BSI policy to supply the BSI

implementation of those that have been published as British Standards, unless

otherwise requested.

Information on standards

BSI provides a wide range of information on national, European and international

standards through its Library and its Technical Help to Exporters Service. Various

BSI electronic information services are also available which give details on all its

products and services. Contact the Information Centre. Tel: 020 8996 7111.

Fax: 020 8996 7048.

Subscribing members of BSI are kept up to date with standards developments and

receive substantial discounts on the purchase price of standards. For details of

these and other benefits contact Membership Administration. Tel: 020 8996 7002.

Fax: 020 8996 7001.

Copyright

Copyright subsists in all BSI publications. BSI also holds the copyright, in the UK, of

the publications of the international standardization bodies. Except as permitted

under the Copyright, Designs and Patents Act 1988 no extract may be reproduced,

stored in a retrieval system or transmitted in any form or by any means electronic,

photocopying, recording or otherwise without prior written permission from BSI.

This does not preclude the free use, in the course of implementing the standard, of

necessary details such as symbols, and size, type or grade designations. If these

details are to be used for any other purpose than implementation then the prior

written permission of BSI must be obtained.

If permission is granted, the terms may include royalty payments or a licensing

agreement. Details and advice can be obtained from the Copyright Manager.

Tel: 020 8996 7070.

L

i

c

e

n

s

e

d

C

o

p

y

:

I

n

s

t

i

t

u

t

e

O

f

T

e

c

h

n

o

l

o

g

y

T

a

l

l

a

g

h

t

,

I

n

s

t

i

t

u

t

e

o

f

T

e

c

h

n

o

l

o

g

y

,

M

o

n

D

e

c

2

5

1

0

:

4

7

:

5

5

G

M

T

+

0

0

:

0

0

2

0

0

6

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

You might also like

- BS en 13480-5-2017Document38 pagesBS en 13480-5-2017Rjeb mohamed100% (10)

- I-Roast II ManualDocument16 pagesI-Roast II Manualcwp194483% (6)

- Perkins 2300 2306c-E14Document156 pagesPerkins 2300 2306c-E14Chakroune71% (7)

- BS en 00612-2005 (2006)Document18 pagesBS en 00612-2005 (2006)Binh Hung OngNo ratings yet

- BS en 1371-2-2015Document24 pagesBS en 1371-2-2015김석천No ratings yet

- BS en 13923-2005 PDFDocument44 pagesBS en 13923-2005 PDFBravo Rd50% (4)

- BS en 447-2007 Grout For Prestressing Tendons - Basic RequirementsDocument16 pagesBS en 447-2007 Grout For Prestressing Tendons - Basic Requirementsgpred75% (4)

- EN 1371-1 Liquid Penetrant Inspection PDFDocument25 pagesEN 1371-1 Liquid Penetrant Inspection PDFrazimujtaba3251No ratings yet

- En 13018Document10 pagesEn 13018Hüseyin HızlıNo ratings yet

- En 13480-1-2002Document18 pagesEn 13480-1-2002Michel MunozNo ratings yet

- BS en 12644-2 Cranes Information For Use and Testing - MarkinDocument10 pagesBS en 12644-2 Cranes Information For Use and Testing - MarkinMohamed Farouk50% (2)

- En 1320-Fracture TestDocument17 pagesEn 1320-Fracture TestMadley RockNo ratings yet

- 09-08-2018 7th Sem B.Tech For Batch 2015-16Document363 pages09-08-2018 7th Sem B.Tech For Batch 2015-16felujiluNo ratings yet

- BS en 12350-4-2000-Degree of CompactabilityDocument8 pagesBS en 12350-4-2000-Degree of CompactabilityOana CristinaNo ratings yet

- BS en 1716Document11 pagesBS en 1716OmerfAtaNo ratings yet

- En 1317 Part 3 Road RestraintDocument23 pagesEn 1317 Part 3 Road RestraintDam NariusNo ratings yet

- 1289 UnlockedDocument8 pages1289 UnlockedAidan ShortNo ratings yet

- BS en 12062Document16 pagesBS en 12062Einsteinw275% (4)

- PrEN 12271-10 - Factory Production ControlDocument17 pagesPrEN 12271-10 - Factory Production ControlPedjaNo ratings yet

- En 10228-2 1998Document6 pagesEn 10228-2 19989823458877No ratings yet

- BS en 1561Document21 pagesBS en 1561OmerfAta100% (2)

- BS en 1711-2000Document24 pagesBS en 1711-2000FelipeVelasquezZapataNo ratings yet

- En 1714Document27 pagesEn 1714madhunikhilNo ratings yet

- BS en 10250-3-2000Document17 pagesBS en 10250-3-2000Mansi BalduwaNo ratings yet

- BS en Iso 17652-1-03Document10 pagesBS en Iso 17652-1-03gaso99No ratings yet

- European Standard Norme Européenne Europäische NormDocument18 pagesEuropean Standard Norme Européenne Europäische NormAtef Hamdi100% (1)

- BS en 445-1997Document17 pagesBS en 445-1997wahyuniarsih50% (2)

- BS EN295-7 1991 (Part 7) PDFDocument19 pagesBS EN295-7 1991 (Part 7) PDFFuadChiwa100% (2)

- En 10228-3 1998Document15 pagesEn 10228-3 19989823458877No ratings yet

- BS 3900 Cross Cut Test PDFDocument18 pagesBS 3900 Cross Cut Test PDFHassan Feki100% (2)

- Bsen25817 PDFDocument18 pagesBsen25817 PDFdzat_sudrazat0% (1)

- BS en 14692-2017 - TC - (2020-08-27 - 08-40-55 Am) PDFDocument28 pagesBS en 14692-2017 - TC - (2020-08-27 - 08-40-55 Am) PDF梁山伯No ratings yet

- BS en 1714-98 - Ultrasonic Examination of Weld JointDocument26 pagesBS en 1714-98 - Ultrasonic Examination of Weld Jointsortancil100% (4)

- BS 00030-1-1-1998 (2006)Document10 pagesBS 00030-1-1-1998 (2006)Balaji NaikNo ratings yet

- En 1418-1998Document12 pagesEn 1418-1998apostolidis83No ratings yet

- PD CR 12952-17-2002Document24 pagesPD CR 12952-17-2002navaronefraNo ratings yet

- CR 13445-7-2002-OtklDocument23 pagesCR 13445-7-2002-OtklVasko MandilNo ratings yet

- EN196-7 Taking & PreparingDocument20 pagesEN196-7 Taking & PreparingMaNda MumtahanaNo ratings yet

- SIST-EN-16502-2014 Acidité Baumann Du SolDocument9 pagesSIST-EN-16502-2014 Acidité Baumann Du SolGbale Pregnon ThierryNo ratings yet

- (2004) Eng.Document20 pages(2004) Eng.Zoran VlašićNo ratings yet

- Bs en 1435-1997Document36 pagesBs en 1435-1997Jimmy JohnNo ratings yet

- Din 1670Document10 pagesDin 1670GODREJ LAB THANENo ratings yet

- BS en 01395-1-2007Document12 pagesBS en 01395-1-2007sepehr heidariNo ratings yet

- BS - en - 22768-2-1993Document16 pagesBS - en - 22768-2-1993Nyamcz CristianNo ratings yet

- Hellenic Standard: Non Destructive Testing of Welds - Ultrasonic Testing of Welded JointsDocument16 pagesHellenic Standard: Non Destructive Testing of Welds - Ultrasonic Testing of Welded JointsAslanNo ratings yet

- BS en 480-1-2006+A1+2011 Admixtures For Concrete, Mortar and Grout - Test Methods - Part 1 - Reference Concrete and Reference Mortar For TestingDocument14 pagesBS en 480-1-2006+A1+2011 Admixtures For Concrete, Mortar and Grout - Test Methods - Part 1 - Reference Concrete and Reference Mortar For TestingIvan Filipović100% (2)

- European Standard Norme Européenne Europäische NormDocument14 pagesEuropean Standard Norme Européenne Europäische NormAtef HamdiNo ratings yet

- BS en 13523-9 2001 PDFDocument10 pagesBS en 13523-9 2001 PDFAnuradhaPatraNo ratings yet

- EN 13395-1-2002 - enDocument10 pagesEN 13395-1-2002 - enoptbestoreNo ratings yet

- Iso 1464Document20 pagesIso 1464Giri Wisnu Nugroho100% (1)

- BS en - 14532 2 2004 PDFDocument26 pagesBS en - 14532 2 2004 PDFPacoNo ratings yet

- Sist en 15421 2022Document10 pagesSist en 15421 2022Tissa Novida Aulia ZahraNo ratings yet

- Glass in Building Ð Coated Glass Ð: Part 1: Definitions and ClassificationDocument14 pagesGlass in Building Ð Coated Glass Ð: Part 1: Definitions and Classificationraybo1No ratings yet

- BS en Iso 13625-2002 - (2019-01-04 - 03-43-06 PM) PDFDocument36 pagesBS en Iso 13625-2002 - (2019-01-04 - 03-43-06 PM) PDFaloliveira7811No ratings yet

- Grout For Prestressing Tendons Ð Test Methods: British Standard Bs en 445: 1997Document16 pagesGrout For Prestressing Tendons Ð Test Methods: British Standard Bs en 445: 1997Vladimir SimeunovicNo ratings yet

- ДСТУ EN ISO 2400-2016 - Калибровочный блок V1Document11 pagesДСТУ EN ISO 2400-2016 - Калибровочный блок V1Игорь ВадешкинNo ratings yet

- Radiographic Testing of Welds BSEN 1435Document37 pagesRadiographic Testing of Welds BSEN 1435thanhhai66100% (2)

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- Guideline for EN 9100:2018: An Introduction to the European Aerospace and Defence StandardFrom EverandGuideline for EN 9100:2018: An Introduction to the European Aerospace and Defence StandardNo ratings yet

- Practical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsFrom EverandPractical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsNo ratings yet

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)From EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Rating: 4 out of 5 stars4/5 (2)

- Group 2 Test ADocument16 pagesGroup 2 Test AHarish JanardhananNo ratings yet

- Group No 02 Minimum Wages Act - FinalDocument18 pagesGroup No 02 Minimum Wages Act - FinalHarish JanardhananNo ratings yet

- Digital MarketingDocument12 pagesDigital MarketingHarish JanardhananNo ratings yet

- B2B Notes Section 4 - MergedDocument80 pagesB2B Notes Section 4 - MergedHarish JanardhananNo ratings yet

- Category Analysis Entry Level Luxury Cars India Jun 2017Document12 pagesCategory Analysis Entry Level Luxury Cars India Jun 2017Harish JanardhananNo ratings yet

- B2B FocusDocument32 pagesB2B FocusHarish JanardhananNo ratings yet

- DIN - EN - 1371-2-1998 - DP TestDocument13 pagesDIN - EN - 1371-2-1998 - DP TestHarish JanardhananNo ratings yet

- Contoh Company ProfileDocument7 pagesContoh Company Profilenoname spycodeNo ratings yet

- BokashiBall7Final PDFDocument2 pagesBokashiBall7Final PDFRoy GonzaNo ratings yet