Professional Documents

Culture Documents

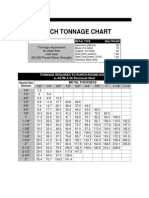

Measurements/ Specifications: Tons of Pressure Required

Measurements/ Specifications: Tons of Pressure Required

Uploaded by

smartcad60Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Measurements/ Specifications: Tons of Pressure Required

Measurements/ Specifications: Tons of Pressure Required

Uploaded by

smartcad60Copyright:

Available Formats

MEASUREMENTS/

seleCTing A punCH

The following information is provided as a convenient

general reference guide for metal punching operations.

S P E C I F I C AT I O N S

Tons of Pressure

Hole size vs. mATeRiAl THiCkness

required

Punching holes in metal is the fast, economical way to

get precise hole size, smoothness and minimum burr.

Compressive strength of the punch steel determines that

the thickness of the metal being punched must not exceed the diameter of the punch. This relationship varies

with the type of material. For example: the minimum hole

diameter will be 1/4" in 1/4" mild steel, 1/4" in 3/16"

stainless steel, and 1/4" in 5/16" aluminum.

deTeRmining TonnAges

foR Round Holes

mAximum RATed CApACiTy

To determine tonnages for hot rolled mild steel (typically

used in bar size angle iron, channels, tees and zees) with

a 50,000 PSI shear strength, read directly from chart #1.

Example: To punch a 3/8" diameter hole thru 3/8" thick

mild steel, chart #1 shows 11.1 tons are required.

For ASTM A-36 steel (typically used for structural size

wide flange, H and I beams, tees and zees) with a 60,000

PSI shear strength, read direct from chart #2. Example: To

punch a 1/4" round hole in 1/4" thick A-36 steel, chart

#2 shows 5.9 tons of force is needed.

All punching tools have their maximum capacity for safe,

dependable operation over a long life span. The hydraulic

punches listed in this catalog have a rated capacity

based on their design strength. Before selecting a tool,

use the following charts to determine the specific tonnage required to punch the size and shape holes through

the type and gauge metal considered.

CHART #1

Tons of pRessuRe RequiRed To punCH mild sTeel

Round Hole Diameter

1

/8"

.4

.5

.6

.7

1.0

1.2

1.3

/16"

.5

.7

.9

1.1

1.5

1.8

2.0

2.8

/4"

.7

.9

.6

1.2

1.5

2.1

2.4

2.6

3.7

4.9

/16"

.9

1.2

1.5

1.8

2.6

2.9

3.3

4.6

6.1

7.8

/8"

1.1

1.4

1.8

2.2

3.1

3.5

4.0

5.5

7.4

9.2

11.1

/16"

1.2

1.6

2.1

2.6

3.6

4.1

4.6

6.4

8.6

10.7

12.8

/2"

1.4

1.9

2.3

2.9

4.1

4.7

5.3

7.4

9.8

12.3

14.8

19.7

/16"

1.6

2.1

2.6

3.3

4.6

5.1

5.9

8.3

11.1

13.9

16.5

22.0

/8"

1.8

2.4

2.9

3.7

5.1

5.9

6.6

9.2

12.3

15.4

18.5

24.6

11

/16"

1.9

2.6

3.2

4.0

5.7

6.2

7.3

10.1

13.5

17.0

20.2

26.9

/4"

2.1

2.8

3.5

4.4

6.2

7.1

7.9

11.0

14.7

18.5

22.1

29.5

13

/16"

2.3

3.1

3.8

4.8

6.7

7.6

8.6

12.0

16.0

20.0

23.8

31.8

12

11

10

3/ "

16

1/ "

4

5/ "

16

3/ "

8

1/ "

2

/64

/8

9/

64

3/

16

1/

4

5/

16

3/

8

1/

2

1

1.2

1.4

1.9

2.1

2.4

3.3

4.4

2.5

2.8

3.2

4.4

5.9

7.4

8.8

3.1

3.5

4.0

5.5

7.4

9.2

11.0

3.7

4.2

4.8

6.6

8.6

11.0

13.3

4.3

4.9

5.6

7.7

10.3

12.9

15.5

4.9

5.7

6.4

8.8

11.8

14.7

17.7

23.6

5.6

6.4

7.2

9.9

13.2

16.5

19.9

26.5

6.2

7.1

7.9

11.0

14.7

18.4

22.1

29.4

6.8

7.8

8.7

12.1

16.2

20.2

24.3

32.4

7.4

8.5

9.5

13.2

17.7

22.0

26.5

35.3

13

/16"

8.0

9.2

10.3

14.3

19.1

24.0

28.7

38.3

POWERTEAM.COM

RESOURCES

Tons of pRessuRe

CHART #2 Tons of pRessuRe RequiRed To punCH AsTm-A36 sTRuCTuRAl sTeel

Material

Round Hole Diameter

1/ "

3/ "

1/ "

5/ "

3/ "

7/ "

1/ "

9/ "

5/ "

11/ "

3/ "

Thickness

8

16

4

16

8

16

2

16

8

16

4

Gauge Inches

Tons of pRessuRe

Material

Thickness

Gauge Inches

1/

20

32

3

18

/64

1/

16

16

5/

14

64

7/

12

64

1/

11

8

9/

10

64

3/ "

3/

16

16

1/

1/ "

4

4

5/

5/ "

16

16

3/ "

3/

8

8

1/ "

1/

2

2

227

You might also like

- Design of Penstock Pipe For A HydroelectDocument21 pagesDesign of Penstock Pipe For A Hydroelectjanardhana100% (1)

- Astm Bolt & NutsDocument24 pagesAstm Bolt & NutsDinesh Radhakrishnan100% (3)

- Astm A134Document4 pagesAstm A134Francisco HernandezNo ratings yet

- Pipe DesignDocument6 pagesPipe DesignmaneeshmsanjagiriNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Katalogas SuperBuild TechDocument38 pagesKatalogas SuperBuild Techsmartcad60No ratings yet

- Bentley AECOsim Building Designer V8i (SELECTseries 4) 08.11.09Document8 pagesBentley AECOsim Building Designer V8i (SELECTseries 4) 08.11.09smartcad60No ratings yet

- Shear Load CalculationDocument8 pagesShear Load Calculationvinny1978No ratings yet

- Beam Design As Per Is456Document2 pagesBeam Design As Per Is456mysteryNo ratings yet

- Design of RCC T Beams As Per IS 456-2000Document2 pagesDesign of RCC T Beams As Per IS 456-2000ankit kadamNo ratings yet

- Article - Structural BoltsDocument6 pagesArticle - Structural Boltsing_weroNo ratings yet

- ASTM BoltsDocument3 pagesASTM BoltsAnonymous IwqK1NlNo ratings yet

- Normal Grating Manual 531-09Document36 pagesNormal Grating Manual 531-09esaraviaNo ratings yet

- Ring Joint HandbookDocument7 pagesRing Joint HandbookchiliskyNo ratings yet

- Sigma FastenersDocument5 pagesSigma Fastenerskhafif01No ratings yet

- 8 - Wading-Lok Tube Stainless Steel IncDocument4 pages8 - Wading-Lok Tube Stainless Steel IncEvert Abraham Cortes OrozcoNo ratings yet

- MBG - 531-09 Metal Bar Grating ManualDocument36 pagesMBG - 531-09 Metal Bar Grating ManualCarlo Monsalve100% (1)

- Punchless Punching of Thin Sheet Metal by Ultrahigh Pressure Gas For Circular HoleDocument10 pagesPunchless Punching of Thin Sheet Metal by Ultrahigh Pressure Gas For Circular HoleManolo GipielaNo ratings yet

- Astm A449Document9 pagesAstm A449Fabricio Noronha100% (1)

- Torque CalculatorDocument4 pagesTorque CalculatorNityananda Permadi TjokrodimurtiNo ratings yet

- Torque Setting Formula - GeorgeDocument4 pagesTorque Setting Formula - Georgegeorge_hemNo ratings yet

- Swagelok Tubing DataDocument8 pagesSwagelok Tubing DataSyahirul Alim100% (1)

- Procedures For Drill String Design Engineering EssayDocument16 pagesProcedures For Drill String Design Engineering EssayGerardy Cantuta AruniNo ratings yet

- Hottappingrequirement1 160722152313Document94 pagesHottappingrequirement1 160722152313ansherina2No ratings yet

- Hottappingrequirement1 160722152313 PDFDocument94 pagesHottappingrequirement1 160722152313 PDFadel100% (1)

- A134-96 (2012) Standard Specification For Pipe, Steel, Electric-Fusion (Arc) - Welded (Sizes NPS 16 and Over) PDFDocument4 pagesA134-96 (2012) Standard Specification For Pipe, Steel, Electric-Fusion (Arc) - Welded (Sizes NPS 16 and Over) PDFJosé Israel HGNo ratings yet

- Connection - Bolt 2022Document80 pagesConnection - Bolt 2022LUGHANO NGAJILONo ratings yet

- Mechanical Design of Shell and TubeDocument21 pagesMechanical Design of Shell and TubeMahesh ewRRpuqQrcNo ratings yet

- Astm A134 A134m 18Document3 pagesAstm A134 A134m 18leedg7120No ratings yet

- F 1018 - 87a R99 - RJEWMTG - PDFDocument12 pagesF 1018 - 87a R99 - RJEWMTG - PDFRománBarciaVazquezNo ratings yet

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDocument12 pagesSpecifying Bolt Length For High-Strength Bolts: Manual of Steel Constructionpreds1717No ratings yet

- FastenersDocument46 pagesFastenerser_lalitgargNo ratings yet

- Schedule 40 PipeDocument2 pagesSchedule 40 Piperasnowmah2012No ratings yet

- 3.1 Metal ReinforcementDocument26 pages3.1 Metal ReinforcementAbestano JadeNo ratings yet

- A 394Document6 pagesA 394sontakkesd100% (2)

- Maryland Metrics - Metric ASTM Structural FastenersDocument5 pagesMaryland Metrics - Metric ASTM Structural Fastenerslimulsa78No ratings yet

- 6.design of Connections in Steel Building ConstructionDocument50 pages6.design of Connections in Steel Building ConstructionNovember RainNo ratings yet

- Steel Pipes and FittingsDocument14 pagesSteel Pipes and FittingsMohammed ShallabyNo ratings yet

- Astm Material Summary For BoltsDocument2 pagesAstm Material Summary For BoltsAkshay PoddarNo ratings yet

- RTJ FlangesDocument3 pagesRTJ FlangesMoynomanNo ratings yet

- Steel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringDocument19 pagesSteel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringAshba13No ratings yet

- Stainless Steel Pipe and Fittings SpecificationDocument10 pagesStainless Steel Pipe and Fittings SpecificationCassy AbulenciaNo ratings yet

- PTSC MC-Piping Design Training-Basic Piping-LATESTDocument31 pagesPTSC MC-Piping Design Training-Basic Piping-LATESTNguyen Anh Tung50% (2)

- Catalogo Tecnico Stud WeldingDocument68 pagesCatalogo Tecnico Stud Weldingalexfc81No ratings yet

- CapScrewA325 A490Document2 pagesCapScrewA325 A490sergiosilvahNo ratings yet

- 34-Article Text-161-1-10-20220605Document18 pages34-Article Text-161-1-10-20220605S A KaleNo ratings yet

- Section 2 PDFDocument5 pagesSection 2 PDFimanNo ratings yet

- Astm A381Document7 pagesAstm A381hadeNo ratings yet

- High-Strength Bolts For Structural Steel Joints (Metric)Document5 pagesHigh-Strength Bolts For Structural Steel Joints (Metric)carlokandiNo ratings yet

- Astm 139Document6 pagesAstm 139Kenny WongNo ratings yet

- Ruukki Hot Rolled Steels Processing of Material Flanging Raex and Optim QCDocument9 pagesRuukki Hot Rolled Steels Processing of Material Flanging Raex and Optim QCM R PatraputraNo ratings yet

- Testing and Analysis of Steel-Concrete-Steel Sandwich BeamsDocument23 pagesTesting and Analysis of Steel-Concrete-Steel Sandwich Beamsgy279571025No ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- Advance SteelDocument1 pageAdvance Steelsmartcad600% (4)

- PP PW Pertec PimDocument20 pagesPP PW Pertec Pimsmartcad60No ratings yet

- Cvev051 - Structures I: NotesDocument1 pageCvev051 - Structures I: Notessmartcad60No ratings yet

- Cold Formed Steel Construction Connectors Catalog - Download PDFsDocument3 pagesCold Formed Steel Construction Connectors Catalog - Download PDFssmartcad60No ratings yet

- Cantilever Storage Racks - Steel King Inc PDFDocument3 pagesCantilever Storage Racks - Steel King Inc PDFsmartcad60No ratings yet

- FCAW or Flux Cored Arc W..Document5 pagesFCAW or Flux Cored Arc W..smartcad60No ratings yet

- Big Steel Rack - Sheet M PDFDocument2 pagesBig Steel Rack - Sheet M PDFsmartcad60No ratings yet

- Import Revit Into SAP2000 - SAP2000 - CSIDocument1 pageImport Revit Into SAP2000 - SAP2000 - CSIsmartcad60No ratings yet

- 009 SandvikDocument2 pages009 Sandviksmartcad60No ratings yet

- Slitter Knives (Top/Bottom Slitter Knives) 裁切專用刀具-分條圓刀 (上/下圓刀)Document3 pagesSlitter Knives (Top/Bottom Slitter Knives) 裁切專用刀具-分條圓刀 (上/下圓刀)smartcad60No ratings yet

- WWW - Saintl.biz PDF About Financial Info Flexi8.1HelpDocument2 pagesWWW - Saintl.biz PDF About Financial Info Flexi8.1Helpsmartcad60No ratings yet

- Metric Round Honed Tubing SpecificationsDocument1 pageMetric Round Honed Tubing Specificationssmartcad60No ratings yet

- Steel Data ChartDocument2 pagesSteel Data Chartsmartcad60No ratings yet

- Hook Crack in Electric Resistance Welded Line Pipe SteelDocument9 pagesHook Crack in Electric Resistance Welded Line Pipe Steelsmartcad60No ratings yet

- Punch Tonnage Chart: Tonnage Required To Punch Round Holes in ASTM A-36 Structural SteelDocument1 pagePunch Tonnage Chart: Tonnage Required To Punch Round Holes in ASTM A-36 Structural Steelsmartcad60No ratings yet

- Nichtmetrische Einheiten eDocument2 pagesNichtmetrische Einheiten esmartcad60No ratings yet

- Determining Your Optimal Storage Density: A Case ForDocument2 pagesDetermining Your Optimal Storage Density: A Case Forsmartcad60No ratings yet

- B Ooms: M Odel F B F Ork L If T B Ooms - TelescopicDocument5 pagesB Ooms: M Odel F B F Ork L If T B Ooms - Telescopicsmartcad60No ratings yet

- Determination of Velocity Seal AreaDocument4 pagesDetermination of Velocity Seal AreaNajem A. SakorNo ratings yet

- Autoclave Aerated ConcreteDocument3 pagesAutoclave Aerated ConcreteFireSwarmNo ratings yet

- MDPE - Assignment 1Document1 pageMDPE - Assignment 1lata sinsinwarNo ratings yet

- SGGP Reference No: P0116-TAK-P01-0071-02Document20 pagesSGGP Reference No: P0116-TAK-P01-0071-02Jabel Oil Services Technical DPTNo ratings yet

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptiontamharNo ratings yet

- Modified - TECHNICAL - DIARY - FINAL 25.07Document61 pagesModified - TECHNICAL - DIARY - FINAL 25.07Sudhanshu Sekhar Sahoo100% (1)

- 2018 H2 Chemistry Paper 4 (Ans)Document8 pages2018 H2 Chemistry Paper 4 (Ans)Justin GohNo ratings yet

- Reverse Osmosis Process: Gepa Capsule ReportDocument13 pagesReverse Osmosis Process: Gepa Capsule ReportYogesh YogiNo ratings yet

- Folded Plate StructureDocument38 pagesFolded Plate StructurePatt Myaz100% (2)

- 1Document15 pages1dalton2004No ratings yet

- Stressline Lintel Technical June 2016 Final - Digi - DownloadDocument4 pagesStressline Lintel Technical June 2016 Final - Digi - DownloadKovacs Zsolt-IstvanNo ratings yet

- Bipolar Junction TransistorDocument17 pagesBipolar Junction TransistorRonald Andrei DaguioNo ratings yet

- TDS - Masterpren TPE-FDocument2 pagesTDS - Masterpren TPE-FAlexi ALfred H. TagoNo ratings yet

- Unit - VDocument38 pagesUnit - VSrikanth PalaniswamyNo ratings yet

- Book 1 - Gyproc PlastersDocument24 pagesBook 1 - Gyproc PlastersFariz AbdullaNo ratings yet

- Lecture 2 Forming NptelDocument12 pagesLecture 2 Forming Nptelaghosh704No ratings yet

- Ce340: Strength of Materials: Homework #05: Torsion (SOLUTIONS)Document7 pagesCe340: Strength of Materials: Homework #05: Torsion (SOLUTIONS)fred ruvalcabaNo ratings yet

- 2934-D (V1) (Zara Kids) (10.4.2023) P-81Document1 page2934-D (V1) (Zara Kids) (10.4.2023) P-81Rohan KabirNo ratings yet

- Mortar Mix - Coloured DatasheetDocument3 pagesMortar Mix - Coloured DatasheetHIMANSHU SRIVASTAVANo ratings yet

- PGE 361, HW 5, Ideal Answer, 1442Document6 pagesPGE 361, HW 5, Ideal Answer, 1442urmomNo ratings yet

- Lab Technique Review WorksheetDocument5 pagesLab Technique Review WorksheetBashir AhmadNo ratings yet

- Fs Item Master 06.08.21Document81 pagesFs Item Master 06.08.21Prem RathoreNo ratings yet

- Jis G3312 2012 JisfDocument27 pagesJis G3312 2012 JisfTUAN NGUYEN VANNo ratings yet

- SF10 and SF16Document22 pagesSF10 and SF16Shanil BussooaNo ratings yet

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Skirt & Anchor Bolt BROWNELL & YOUNG Process Equip. DesignDocument15 pagesSkirt & Anchor Bolt BROWNELL & YOUNG Process Equip. DesignImthiyaz HNo ratings yet

- U2-Electricity, Q&ADocument34 pagesU2-Electricity, Q&ALiang LuNo ratings yet

- 2015 Chem Rev. Metzger Unimolecular ElectronicsDocument60 pages2015 Chem Rev. Metzger Unimolecular ElectronicsChris SmithNo ratings yet

- Chapter 4 Environmental Risk Assessment and Emergency Response PlanDocument10 pagesChapter 4 Environmental Risk Assessment and Emergency Response Planangelo plumosNo ratings yet

- Crysytal Growth GelDocument18 pagesCrysytal Growth GelGnana SilviaNo ratings yet