Professional Documents

Culture Documents

Global Tolerances

Global Tolerances

Uploaded by

Simbu Arasan100%(1)100% found this document useful (1 vote)

154 views24 pagesglobal tol

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentglobal tol

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

154 views24 pagesGlobal Tolerances

Global Tolerances

Uploaded by

Simbu Arasanglobal tol

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 24

ISO/CD 19902

ISO 2001 All rights reserved 245

21.4.4 Manufactured Pipe

The dimensional tolerances for pipe manufactured to a specification shall be in accordance with the applicable

specification, e.g. ANSI/API 5L, ASTM 106, BS 7191, or prEN 10225. For pipe diameters 600 mm (24") or greater,

the straightness and roundness of manufactured pipe shall be in accordance with API Specification 2B

21.4.5 Beams

Deck beams shall be erected with the top flanges level, or to the specified slope within allowable mill tolerances.

Deck beams shall be erected with the webs plumb. Distortion of deck beams from welding shall be corrected or

otherwise compensated so that the tolerances of this paragraph are met.

Cap beams shall be erected with the top flanges level. Disparity in beam depth due to mill tolerances in depth shall

be compensated by shimming between the cap beam and column. Cap beams shall be erected with the webs

plumb. Distortion of cap beams from welding shall be corrected or otherwise compensated so that the tolerances of

this paragraph are met.

21.4.6 Cruciform Joints

Where plates carrying in-plane loading are arranged to form a cruciform, the misalignment shall not exceed 50 % t

where t = thickness of the thinnest non-continuous member to 10 mm whichever is smaller.

Joint misalignment in fabricated tubulars and rectangular beams shall be in accordance with fit up dimensions

applicable to the qualified welding procedures and Figure 21.4-23.

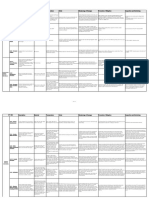

Table 21.4-1 Global Tolerances

Component / Item Tolerance

mm (inches)

See

Figure

DECK AND JACKET TOLERANCES

Ja-Da Horizontal distance centre-to-centre between adjacent legs at

top of jacket and bottom of deck legs (stab in nodes)

10 ( 3/8") 21.4-1

Jb-Db Horizontal distance centre-to-centre between legs other than

top elevation

20 (3/4") 21.4-1

Jc-Dc Difference of horizontal diagonal distances between legs 10 (3/8") (stab in)

20 (3/4")

21.4-1

Jc-Dc Elevation of plan 13 (1/2) 21.4-2

Jd -Dd Vertical level of braces in a horizontal plane 13 (1/2) 21.4-2

Je-De Vertical distance between elevations 13 (1/2) 21.4-2

Jf-Df Deviation from theoretical conductor guide centre line axis (line

from top to bottom elevation) and each conductor guide along

that axis

10 (3/8") at top;

10 (3/8"<40)';

13 (1/2>40')

21.4-3

Jg-Dg Alignment of legs (applies to structures with more than 4 legs) 10 (3/8") 21.4-4

Jh-Dh Location of cans with different wall thickness;

joint cans

50 (2");

25(1")

21.4-5

Ji-Di Straightness of tubulars and beams 3 x (Total m/3), not to

exceed 10 mm in 12

meters

ISO/CD 19902

246 ISO 2001 All rights reserved

Component / Item Tolerance

mm (inches)

See

Figure

(1/8" x (Total ft/10), not to

exceed 3/8" in 40 feet

Jk-Dk Straightness of jacket legs between horizontal bracing plans 10 (3/8") 21.4-2

Jk-Dk Location of different wall thickness for braces 50 (2") 21.4-6

Jl-Dl Alignment of brace end chord, or structural member work

points

13 (1/2) 21.4-7

Jm-Dm Elevation at top of legs as compared to theoretical 13 (1/2)

Jn Global pile guide centre line location at each elevation (applies

to pile guide sleeves)

10 (3/8") at top;

10 (3/8")<40';

13 (1/2)>40'

21.4-8

Jp-Dp Node and tube stiffener locations Node cones = 3 mm;

Launch legs = 3 mm;

Nodes = 5 mm;

Other loc. = 10 mm

21.4-14

Jo-Do Ring stiffener cross-section Jo

1

< 0,025h

Jo

2

< 0,015b

Jo

3

< 0,010h

21.4-15

Jq-Dq Out-of-straightness for longitudinal or diaphragm stiffeners in

tubulars

0,15 % L or 3 mm

whichever is larger

21.4-16

Jr-Dr Position of Appurtenances (Caisson Guides, J-Tubes, Riser

Clamps

10 at top

25 elsewhere

21.4-26

Jacket - Nodal Construction

Js Length of joint cans for nodal construction -5 +10 (cans) 21.4-11

Jt Length of stubs for nodal construction -5 +50 (stubs) 21.4-11

Ju Out of straightness tolerance for legs between nodes 10 mm 21.4-12

Ju Out of straightness tolerance for bracing between nodes L/1000 Global

L/1200 Local

21.4-12

Jv Node stub location Dn< 3 500 mm, Jm = 5

mm

J = 10 minutes

Dn > 3 500, Jm = 10 mm

J = 10 minutes

21.4-13

Jw Global Positioning Tolerance for Tubular Nodes Radius of Sphere of error

= 15

21.4-24

DECK

Dn Position of all beam centre lines 13 (1/2) V;

20 (3/4") H

21.4-9

ISO/CD 19902

ISO 2001 All rights reserved 247

Component / Item Tolerance

mm (inches)

See

Figure

Do Horizontal distance between skid beams 10 (3/8")

Dp Straightness of cap beams (See "DL" For Work points) 6 (1/4") V;

10 (3/8") H

Dq Elevation difference of work points on bottom of deck legs to

each other for deck to pile connections.

13 (1/2)

Dr Elevation difference of work points on bottom of deck legs to

each other for deck to jacket connections

6 (1/4")

Ds Vertical alignment of girders 13 (1/2)

Dt Tolerance on stab in points for deck to jacket connections

without deck legs

3 (1/8") 21.4-25

Du Plate girder cross section depth = 0,12 t, 5 max

flange width = 3

Due=0,015b, 5 max

Duf=0,0125b, 10 max

Dup=3

Duw=0,008h, 10 max

21.4-17

Dv Plate and box girder out-of-straightness, camber and sweep sweep = +0,001L, +15

max

camber = -0

21.4-18

Dw Plate girder stiffener a, p, and s = 5 21.4-19

Dx Box girder Diagonal = 0,005 g, 7

max;

Twist = 0,008h, 10 max

w=0,008h, 10 max

21.4-20

Dy Node lengths on girders -0 +10 21.4-21

Dz Stiffened plate panels, entire panel, lateral sagging or hogging between girders =

0,015L, 20 max;

between stiffeners =

0,01L

1

, 10 max

21.4-22

Dz Stiffened plate panels, stiffeners a and p = 5

s = 0,015L

1

, 5 max

21.4-22

Fencing and Handrails

Stanchions

12 (1/2) in any 3m (10

ft)

5 (1/4) from vertical

PILES

Pa Straightness in 10 feet;

Straightness in 40 feet

3 (1/8");

10 (3/8")

-

Pb Straightness greater than 40 feet 3 x (Total m/3) -

ISO/CD 19902

248 ISO 2001 All rights reserved

Component / Item Tolerance

mm (inches)

See

Figure

(1/8" x (Total ft/10)

or L/960

MISCELLANEOUS

Ma Landing and stair elevations 50 (2")

Mb Vertical distance between stair treads in one flight 3 (1/8")

Mc Levelness of stair treads 3 (1/8")

Md Horizontal locations of stairs and landings 50 (2")

Me Location of anodes 300 (12")

10 Radially

Mf Levelness of deck floor plate and grating 6 (1/4") in 3000 (10 ft)

Mg High/low of deck floor plate 3 (1/8")

Mh Valleys in deck floor plate 12 max (1/2")

Mi Separation between adjoining longitudinal welds for tubular 90 minimum

Mj Minimum Stagger between joint can longitudinal welds (only to

avoid brace member interference.)

300 (12") 21.4-10

Mk Minimum clearance between chord longitudinal welds and

brace stub longitudinal welds

30 off centre line of Cord

Longitudinal

21.4-10

Ml Minimum clearance between chord girth welds and longitudinal

welds of brace stub ends

150 (6") 21.4-10

Mm Minimum clearance between tubular girth welds 915 (3 ft) of 1 OD

Mn Joint mismatch tolerance, rectangular, all thickness (except

skid beams)

12 % t, but not >5 mm 21.4-23

Mn Joint mismatch tolerance, circular and long seams double sided welds:

10 % t not >6 mm

Single sided welds: 10 % t

not >3 mm

21.4-23

ISO/CD 19902

ISO 2001 All rights reserved 249

Figure 21.4-1

Figure 21.4-2

ISO/CD 19902

250 ISO 2001 All rights reserved

Figure 21.4-3

Figure 21.4-4

ISO/CD 19902

ISO 2001 All rights reserved 251

Figure 21.4-5

Figure 21.4-6

ISO/CD 19902

252 ISO 2001 All rights reserved

Figure 21.4-7

Figure 21.4-8

ISO/CD 19902

ISO 2001 All rights reserved 253

Figure 21.4-9

ISO/CD 19902

254 ISO 2001 All rights reserved

Figure 21.4-10

ISO/CD 19902

ISO 2001 All rights reserved 255

Figure 21.4-11

ISO/CD 19902

256 ISO 2001 All rights reserved

Figure 21.4-12

ISO/CD 19902

ISO 2001 All rights reserved 257

Figure 21.4-13

ISO/CD 19902

258 ISO 2001 All rights reserved

Figure 21.4-14

ISO/CD 19902

ISO 2001 All rights reserved 259

Figure 21.4-15

Figure 21.4-16

ISO/CD 19902

260 ISO 2001 All rights reserved

Figure 21.4-17

ISO/CD 19902

ISO 2001 All rights reserved 261

Figure 21.4-18

ISO/CD 19902

262 ISO 2001 All rights reserved

Figure 21.4-19

Figure 21.4-20

ISO/CD 19902

ISO 2001 All rights reserved 263

Figure 21.4-21

ISO/CD 19902

264 ISO 2001 All rights reserved

Figure 21.4-22

ISO/CD 19902

ISO 2001 All rights reserved 265

Figure 21.4-23

Figure 21.4-24

ISO/CD 19902

266 ISO 2001 All rights reserved

Figure 21.4-25

Figure 21.4-26

ISO/CD 19902

ISO 2001 All rights reserved 537

A.21 Fabrication

No guidance is offered.

ISO/CD 19902

538 ISO 2001 All rights reserved

You might also like

- Minimum Orifice Plate Thickness To Avoid Plastic Deformation (Buckling)Document10 pagesMinimum Orifice Plate Thickness To Avoid Plastic Deformation (Buckling)Hadi VeyseNo ratings yet

- Catalogo Tração CarraroDocument9 pagesCatalogo Tração Carrarotrader troladorNo ratings yet

- Aisin AW TF-80SCDocument1 pageAisin AW TF-80SCJesus Alejandro Miranda Palacios100% (1)

- JFD 100Document1 pageJFD 100ecsuperalNo ratings yet

- MS HoneycombDocument3 pagesMS Honeycombmoytabura96No ratings yet

- MST of Installation of BiogasDocument29 pagesMST of Installation of BiogasJayakrishnan RadhakrishnanNo ratings yet

- Installation Procedure For TowerDocument4 pagesInstallation Procedure For TowerRachel FloresNo ratings yet

- Abschn 14Document3 pagesAbschn 14Vikas NaikNo ratings yet

- Erection Tank MethodDocument1 pageErection Tank MethodAndre YosiNo ratings yet

- Sampling Frequency of Concrete CubeDocument2 pagesSampling Frequency of Concrete CubeRAJESH KUMAR SRIVASTAVA100% (1)

- SOW Fabrikasi C-335-01 - 19.116.1Document1 pageSOW Fabrikasi C-335-01 - 19.116.1AlfanNo ratings yet

- PRE-QUALIFICATION - Pavers - Aalco GroupDocument75 pagesPRE-QUALIFICATION - Pavers - Aalco GroupJason RazatlabNo ratings yet

- 09 Job Procedure For Fire ProofingDocument4 pages09 Job Procedure For Fire ProofingAlvin Smith100% (2)

- Monthly ReportDocument22 pagesMonthly ReportzulkifliharahapNo ratings yet

- End Plate Thickness CalculationDocument5 pagesEnd Plate Thickness CalculationP s JagatheesanNo ratings yet

- Cleaning Balls PDFDocument8 pagesCleaning Balls PDFAlexandruNicolaNo ratings yet

- RUX Ball ValveDocument1 pageRUX Ball Valvejustine lopez100% (1)

- Test Pack Table of ContentsDocument1 pageTest Pack Table of ContentsRavindra S. JivaniNo ratings yet

- Electrode Consumption On Pipe WeldingDocument2 pagesElectrode Consumption On Pipe Weldinganjangandak2932100% (1)

- KP-00+++-CY712-G0047-Rev 0-COMMISSIONING AND TEST PROCEDURE FOR MOTOR OPERATED VALVES MOV PDFDocument14 pagesKP-00+++-CY712-G0047-Rev 0-COMMISSIONING AND TEST PROCEDURE FOR MOTOR OPERATED VALVES MOV PDFrebinshwNo ratings yet

- Weld Cleaning MethodsDocument7 pagesWeld Cleaning MethodsTrần Thùy LinhNo ratings yet

- General Method Statement R1.Document21 pagesGeneral Method Statement R1.Ganjar Dreadlocks NugrahaNo ratings yet

- مواصفات التكييفDocument54 pagesمواصفات التكييفoth369No ratings yet

- Jacobs: Equipment Inspection Code: ADocument2 pagesJacobs: Equipment Inspection Code: ASigit BintanNo ratings yet

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDocument1 page4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFabdullah amanullah0% (1)

- ASME CheckDocument14 pagesASME Checkfuransu777No ratings yet

- Larsen & Toubro Limited: Inspection and Test Plan For TankDocument4 pagesLarsen & Toubro Limited: Inspection and Test Plan For TankABDELKADER BENABDALLAHNo ratings yet

- GS P&D Archsd 2012Document127 pagesGS P&D Archsd 2012Andy Lee100% (1)

- Dimension ReportDocument4 pagesDimension ReportKarthikeyan ShanmugavelNo ratings yet

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -No ratings yet

- Method Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Document9 pagesMethod Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Delil OzanNo ratings yet

- RFI Chipping & PaddingDocument80 pagesRFI Chipping & Paddingcrys suryo prayogoNo ratings yet

- Single V WeldDocument4 pagesSingle V WeldkoyahassanNo ratings yet

- Piling Procedure - IoclDocument8 pagesPiling Procedure - IocltpgggkNo ratings yet

- Wall Thickness Calculations - Using B31.4 Code: T P D S FDocument1 pageWall Thickness Calculations - Using B31.4 Code: T P D S FRamalingam PrabhakaranNo ratings yet

- NT2-L3-M-000!21!00022 MS For Oil Flushing of The Fuel Oil Piping SystemDocument15 pagesNT2-L3-M-000!21!00022 MS For Oil Flushing of The Fuel Oil Piping SystemHuynh Thanh TamNo ratings yet

- Fit Up ReportDocument41 pagesFit Up ReportFendik NewbieNo ratings yet

- VJ3140-101-A-749 - 0 - 0010 - Construction Method For Waterproofing & Screeding - Approved (REZA)Document9 pagesVJ3140-101-A-749 - 0 - 0010 - Construction Method For Waterproofing & Screeding - Approved (REZA)MustofaNo ratings yet

- GR5HRM-CIVIL-ITP-ENGLISH VersionDocument66 pagesGR5HRM-CIVIL-ITP-ENGLISH VersionGaneshNo ratings yet

- Double Wall Tank Installation InstructionsDocument4 pagesDouble Wall Tank Installation InstructionsalokinstNo ratings yet

- Precision Storage Vessels PVT LTD: Pressure Test ReportDocument2 pagesPrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- BGR-PPD-208-EL-FQP-0553, REV0 - 28.01.2015 - Action 5Document4 pagesBGR-PPD-208-EL-FQP-0553, REV0 - 28.01.2015 - Action 5Santoshkumar GuptaNo ratings yet

- Tank Fabrication & ErectionDocument72 pagesTank Fabrication & ErectionPramod GrNo ratings yet

- Pipeline Lowering CalculationDocument5 pagesPipeline Lowering CalculationrabeemhNo ratings yet

- 039-Itp For Embedded Plate PDFDocument7 pages039-Itp For Embedded Plate PDFKöksal PatanNo ratings yet

- 1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Document1 page1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Eng hassan hussienNo ratings yet

- Guide - Foam Glass InsulationDocument25 pagesGuide - Foam Glass InsulationChristian DoriaNo ratings yet

- MS For Crane & Hoist Erection Rev.ADocument21 pagesMS For Crane & Hoist Erection Rev.AThành CôngNo ratings yet

- Mto TankDocument1 pageMto TankHarun Al-RasyidNo ratings yet

- NIOEC-SP-00-53 (0) : Layout and SpacingDocument15 pagesNIOEC-SP-00-53 (0) : Layout and SpacingAmirhossein DavoodiNo ratings yet

- NTT-COOLING TOWER - Structural Priced BOQ R3-09-03-2021Document18 pagesNTT-COOLING TOWER - Structural Priced BOQ R3-09-03-2021Corrosion Factory100% (1)

- Preliminary Welding Procedure Specification Pwps PDF FreeDocument1 pagePreliminary Welding Procedure Specification Pwps PDF FreeFirozNo ratings yet

- 3.1 Fabrication and Installation of PipingDocument45 pages3.1 Fabrication and Installation of PipingArie100% (1)

- Index Final Data BookDocument2 pagesIndex Final Data Booksajadsadeghi123100% (1)

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- Excavation Man Hour: Post Author:info - Projectestimate Post Published:november 10, 2019 Post category:MAN-HOURDocument5 pagesExcavation Man Hour: Post Author:info - Projectestimate Post Published:november 10, 2019 Post category:MAN-HOURAl Patrick Dela CalzadaNo ratings yet

- How To Write A Welding Procedure Specification (WPS)Document5 pagesHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- Foster Adhesive: Technical Data SheetDocument2 pagesFoster Adhesive: Technical Data SheetMounir BoutaghaneNo ratings yet

- 1 Balancing Valve Bronze GALA-smDocument1 page1 Balancing Valve Bronze GALA-smNon Etabas GadnatamNo ratings yet

- M2 CV ST D 002 (R0)Document13 pagesM2 CV ST D 002 (R0)ksshashidhar100% (1)

- Rcc95 Continuous Beams (Tables)Document8 pagesRcc95 Continuous Beams (Tables)Steve JsobNo ratings yet

- FCD VLENTB0200 Mark200TB AQ PDFDocument36 pagesFCD VLENTB0200 Mark200TB AQ PDFmetal_dung2No ratings yet

- DN-1672-PO-029298 (SLA 4) - 04 NOS (With 28 Days Report)Document1 pageDN-1672-PO-029298 (SLA 4) - 04 NOS (With 28 Days Report)Simbu ArasanNo ratings yet

- PDO Bus TemplateDocument3 pagesPDO Bus TemplateSimbu ArasanNo ratings yet

- OPES2024 Brochure V7Document12 pagesOPES2024 Brochure V7Simbu ArasanNo ratings yet

- My Desk: Time Is GoldDocument22 pagesMy Desk: Time Is GoldSimbu ArasanNo ratings yet

- 001 - Standard Procedure For Hydrostatic Pressure Test of PipingDocument8 pages001 - Standard Procedure For Hydrostatic Pressure Test of PipingSimbu Arasan0% (1)

- TWI Welding Training 4Document36 pagesTWI Welding Training 4Simbu Arasan100% (1)

- 004 - Standard Procedure For Surface Preparation and PaintingDocument9 pages004 - Standard Procedure For Surface Preparation and PaintingSimbu ArasanNo ratings yet

- Mitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateDocument4 pagesMitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateSimbu ArasanNo ratings yet

- 003 - Standard Procedure For Coating and WrappingDocument6 pages003 - Standard Procedure For Coating and WrappingSimbu ArasanNo ratings yet

- TATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Document4 pagesTATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Simbu ArasanNo ratings yet

- BHEL Earthing SystemDocument8 pagesBHEL Earthing SystemSimbu ArasanNo ratings yet

- 571 SummaryDocument3 pages571 SummarySimbu Arasan100% (1)

- Electrode Backing RegisterDocument4 pagesElectrode Backing RegisterSimbu Arasan100% (1)

- UF NF Dispatch Master Data 04-11-15Document47 pagesUF NF Dispatch Master Data 04-11-15Simbu ArasanNo ratings yet

- DO's & Dont'sDocument5 pagesDO's & Dont'sSimbu ArasanNo ratings yet

- 006 CBCRDT Tata ProjectsDocument3 pages006 CBCRDT Tata ProjectsSimbu ArasanNo ratings yet

- Structural Tank Instructions 11967-ADocument22 pagesStructural Tank Instructions 11967-Aiftikhar_khalid_1No ratings yet

- SWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtyDocument2 pagesSWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtySimbu ArasanNo ratings yet

- Nano Membrane Status SheetDocument3 pagesNano Membrane Status SheetSimbu ArasanNo ratings yet

- WPPDC-QMD-001-Material Control and Werehousing ProcedureDocument5 pagesWPPDC-QMD-001-Material Control and Werehousing ProcedureSimbu ArasanNo ratings yet

- Standerd 1000LPH BOM-SS PipeDocument10 pagesStanderd 1000LPH BOM-SS PipeSimbu ArasanNo ratings yet

- TPL-US-QMD-002 - Surface Preparation and Painting ProcedureDocument4 pagesTPL-US-QMD-002 - Surface Preparation and Painting ProcedureSimbu ArasanNo ratings yet

- Uf 500 LPHDocument6 pagesUf 500 LPHSimbu ArasanNo ratings yet

- CR QapDocument2 pagesCR QapSimbu ArasanNo ratings yet

- Standard BOQ-UF 1000LPH-Single MembraneDocument9 pagesStandard BOQ-UF 1000LPH-Single MembraneSimbu ArasanNo ratings yet

- Design and Analysis of Multi-Phase Permanent Magnet BLDC Generator For Domestic Wind Turbine ApplicationsDocument4 pagesDesign and Analysis of Multi-Phase Permanent Magnet BLDC Generator For Domestic Wind Turbine ApplicationsLullaby summerNo ratings yet

- Johnston - Revisiting Methods For Design of Rock Socketed Piles (2020)Document13 pagesJohnston - Revisiting Methods For Design of Rock Socketed Piles (2020)Erik SkulstadNo ratings yet

- 10-ENGG 410 CHAPTER 8 - Part 1Document16 pages10-ENGG 410 CHAPTER 8 - Part 1Joana Rosette TordecillaNo ratings yet

- Ped Guidelines PDFDocument261 pagesPed Guidelines PDFariffabusemanNo ratings yet

- Physics Section CombinedDocument53 pagesPhysics Section CombinedTinashe Muzukwa100% (3)

- Symons Cone Crusher (CS Series Cone Crusher)Document3 pagesSymons Cone Crusher (CS Series Cone Crusher)19730000No ratings yet

- Sterilisation of Milk Dairy and Food EngineeringDocument11 pagesSterilisation of Milk Dairy and Food EngineeringFandi KurniawanNo ratings yet

- Écrouissage D'alliages D'aluminium: P O U R E N S A V O I R P L U SDocument2 pagesÉcrouissage D'alliages D'aluminium: P O U R E N S A V O I R P L U SdinoNo ratings yet

- Density MCQDocument4 pagesDensity MCQpawan singhNo ratings yet

- MECH3427 Design Project 2017Document8 pagesMECH3427 Design Project 2017Genesis Norbert AlconabaNo ratings yet

- Gas Power CyclesDocument19 pagesGas Power CyclesMa. Monica ConsulNo ratings yet

- Soil-Structure Interaction Analyses of Shallow-Founded Structures On A Potential-Liquefiable Soil Deposit PDFDocument9 pagesSoil-Structure Interaction Analyses of Shallow-Founded Structures On A Potential-Liquefiable Soil Deposit PDFAlly TNo ratings yet

- EibachDocument44 pagesEibachFranciscoNo ratings yet

- A240 Thru A247Document6 pagesA240 Thru A247alvarolsrNo ratings yet

- CMCO CM ET Product CatalogueDocument9 pagesCMCO CM ET Product CatalogueJoar Mitchel Grundy MaqueraNo ratings yet

- Rain and Ice Control System 2019Document1 pageRain and Ice Control System 2019JOSHUA NAZARIONo ratings yet

- NK150 2020Document83 pagesNK150 2020Nelson RodrigoNo ratings yet

- Conveyor Belt Manual PDFDocument74 pagesConveyor Belt Manual PDFawfahNo ratings yet

- CR Tools and Spare Parts 20.10Document82 pagesCR Tools and Spare Parts 20.10Oswaldo MongeNo ratings yet

- An Experimental Comparison of RC Beam-Column Joints IncorporatingSpliceDocument11 pagesAn Experimental Comparison of RC Beam-Column Joints IncorporatingSpliceAbhishek KumarNo ratings yet

- Control & Instrumentation 2Document0 pagesControl & Instrumentation 2SHIVAJI CHOUDHURY100% (3)

- Machine Tool-IDocument26 pagesMachine Tool-IAman ModanNo ratings yet

- Chapter 14: ThermodynamicsDocument15 pagesChapter 14: ThermodynamicsAzmira AhmadNo ratings yet

- DC Cooling Fan 120x120x25mm: Fax: 01371 875075 WWW - Dubilier.co - Uk Tel: 01371 875758Document1 pageDC Cooling Fan 120x120x25mm: Fax: 01371 875075 WWW - Dubilier.co - Uk Tel: 01371 875758Mariangel BaezNo ratings yet

- Lecture 1Document17 pagesLecture 1Okan BayarNo ratings yet

- SPPHYS2 Module 4th QRTR FinalDocument37 pagesSPPHYS2 Module 4th QRTR FinalJayson GamboaNo ratings yet

- Nielsen 1979Document5 pagesNielsen 1979CarlosNo ratings yet

- Muhammad Junaid - Research PaperDocument8 pagesMuhammad Junaid - Research PaperfefahimNo ratings yet