Professional Documents

Culture Documents

Diseño Plantas

Diseño Plantas

Uploaded by

DianaVázquezCopyright:

Available Formats

You might also like

- CBC - Agricultural Crops Production NC IIIDocument110 pagesCBC - Agricultural Crops Production NC IIIaccorlandscaping84% (25)

- SIP Report On Equity ResearchDocument56 pagesSIP Report On Equity ResearchAkshay Gour57% (7)

- Seminar Questions For The Boeing 7E7 CaseDocument2 pagesSeminar Questions For The Boeing 7E7 CaseLucasNo ratings yet

- Timing Versus Sizing Skill in The Investment Process: Email AlertsDocument9 pagesTiming Versus Sizing Skill in The Investment Process: Email AlertsAndres100% (1)

- Environmental Management PlanDocument31 pagesEnvironmental Management PlanAssif Yousuf100% (4)

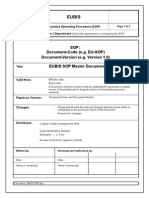

- EUBIS SOP-Master Version 1 0Document4 pagesEUBIS SOP-Master Version 1 0iman8869No ratings yet

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesFrom EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesRating: 5 out of 5 stars5/5 (1)

- Sanjay Saraf SFM Volume 2 Portfolio ManagementDocument131 pagesSanjay Saraf SFM Volume 2 Portfolio ManagementShubham AgrawalNo ratings yet

- F Den 323 Food Plant DesignDocument133 pagesF Den 323 Food Plant DesignDaniel PaulNo ratings yet

- ArupDocument4 pagesArupSubhakanta NayakNo ratings yet

- Process Design Sample Q Lecture 1Document4 pagesProcess Design Sample Q Lecture 1umarzamirNo ratings yet

- Revised Curriculum: SY 2006 Subject Syllabus: Course Title: Course Code: Course Credit: Course DescriptionDocument4 pagesRevised Curriculum: SY 2006 Subject Syllabus: Course Title: Course Code: Course Credit: Course DescriptionjinkoloyNo ratings yet

- CV Instrumentation EngineerDocument4 pagesCV Instrumentation EngineerisukuruNo ratings yet

- SAP Process Industries (PP-PI)Document4 pagesSAP Process Industries (PP-PI)Fernando AF100% (1)

- Kamran - Shaikh - KS259151 - 19 (1) 1Document9 pagesKamran - Shaikh - KS259151 - 19 (1) 1akeey4uNo ratings yet

- Design Project 5Document3 pagesDesign Project 5pelayo240No ratings yet

- Resume For Joel JacobsonDocument2 pagesResume For Joel Jacobsonapi-194873613No ratings yet

- Technical Report FormatDocument11 pagesTechnical Report FormatArvinthran Raja KumaranNo ratings yet

- M E (Water Resource Engg)Document35 pagesM E (Water Resource Engg)Chandrashekhar KulkarniNo ratings yet

- CBLM in Horticulre NC II Uc I ToolsDocument27 pagesCBLM in Horticulre NC II Uc I Toolsvincelda100% (13)

- It Capstone Project Proposed ContentsDocument24 pagesIt Capstone Project Proposed ContentsjhelLaurencianoNo ratings yet

- Rashid - Resume 1Document3 pagesRashid - Resume 1rashidsabiraliNo ratings yet

- Rakesh. A: Professional SynopsisDocument5 pagesRakesh. A: Professional SynopsisRakesh Nair ANo ratings yet

- Ip0234 Operations Research Ii Prerequisites (If Any) : ObjectivesDocument47 pagesIp0234 Operations Research Ii Prerequisites (If Any) : ObjectivesDeepika Selvaraju SNo ratings yet

- Implementation of An EMS in A Hotel: Environmental Management SystemsDocument45 pagesImplementation of An EMS in A Hotel: Environmental Management SystemsVinay WadhwaniNo ratings yet

- Wetlands ManualDocument164 pagesWetlands Manualkhangminh970No ratings yet

- Project Pfofile For Setting Up of Bio-Fertilizer Production UnitDocument3 pagesProject Pfofile For Setting Up of Bio-Fertilizer Production UnitsuryasanNo ratings yet

- Summer Training Report Madhumita 12049Document60 pagesSummer Training Report Madhumita 12049anon_149741654No ratings yet

- FSEP HACCP Template ManualDocument64 pagesFSEP HACCP Template ManualFloreidNo ratings yet

- 3 ImplementationMethodologyDocument9 pages3 ImplementationMethodologysreekumarNo ratings yet

- Diagnostic Form ADocument12 pagesDiagnostic Form AYmon TuallaNo ratings yet

- Water System PQDocument46 pagesWater System PQasit_mNo ratings yet

- SAP Plant Maintenance Module OverviewDocument71 pagesSAP Plant Maintenance Module OverviewStephanie Ratliff100% (2)

- Supply Chain Manager ResumeDocument3 pagesSupply Chain Manager ResumeRaheelJairajpuriNo ratings yet

- Yetaseb Learning ModuleDocument12 pagesYetaseb Learning ModuleYetaseb SeyoumNo ratings yet

- Instrumentation and Control Servicing NC IV TESDADocument95 pagesInstrumentation and Control Servicing NC IV TESDAOscar MirandaNo ratings yet

- 6439-Faisal CV Aug 2011Document4 pages6439-Faisal CV Aug 2011Shaikh Muhammad UsamaNo ratings yet

- General Sample ResumeDocument6 pagesGeneral Sample Resumesathish2829No ratings yet

- Process Engineer Gurgaon Rangeesh ResumeDocument5 pagesProcess Engineer Gurgaon Rangeesh ResumerangeeshNo ratings yet

- Third Yr Booklet - Civil 040511Document28 pagesThird Yr Booklet - Civil 040511Akash AwareNo ratings yet

- Surface Production System - SylabusDocument4 pagesSurface Production System - SylabusinovasigroupNo ratings yet

- Course File EGDocument87 pagesCourse File EGPoyyamozhi Nadesan Ranjith0% (1)

- CBC-RAC Servicing (Domestic) NC IIDocument99 pagesCBC-RAC Servicing (Domestic) NC IIBinalonan Pangasinan100% (2)

- Project Quality Plan Rev 2Document69 pagesProject Quality Plan Rev 2natrix029No ratings yet

- CBLM in Horticulre NC II Uc 2 VegetablesDocument17 pagesCBLM in Horticulre NC II Uc 2 Vegetablesvincelda67% (6)

- Guidelines For Report Writing G78/G84/R75 Project Work ReportDocument14 pagesGuidelines For Report Writing G78/G84/R75 Project Work ReportSyed Ahmed KabeerNo ratings yet

- Factory Inspection (Kosong)Document21 pagesFactory Inspection (Kosong)Hanis JoeNo ratings yet

- Venkatesh ABAPDocument5 pagesVenkatesh ABAPPawan SinghNo ratings yet

- Seemonraja: 12 Years Petrochemical PlantsDocument6 pagesSeemonraja: 12 Years Petrochemical PlantsSiva KumarNo ratings yet

- FormDocument9 pagesFormani9228No ratings yet

- Abhijeet ResumeDocument7 pagesAbhijeet Resumesunildubey02No ratings yet

- Chapter 4Document9 pagesChapter 4Kaushal ChhadvaNo ratings yet

- Lesson 3Document17 pagesLesson 3Czyrra Lyn Dimapush FetalverNo ratings yet

- Ae Board Recalled Questions Part 1 in Farm Machinery and Allied SubjectspdfDocument5 pagesAe Board Recalled Questions Part 1 in Farm Machinery and Allied Subjectspdffrancis rueloNo ratings yet

- Ernest Allen's CVDocument6 pagesErnest Allen's CVernestrallenNo ratings yet

- EMAIL: Gopikrishna (Tkrcet) ANUSHA (Tkrcet) : E-Wastage: Challenges and OpportunitiesDocument9 pagesEMAIL: Gopikrishna (Tkrcet) ANUSHA (Tkrcet) : E-Wastage: Challenges and Opportunitiesyuviraj0810No ratings yet

- PLM150 EngineeringChangeAndConfigurationManagementDocument226 pagesPLM150 EngineeringChangeAndConfigurationManagementFriends4us100% (1)

- Control Plan WIDocument2 pagesControl Plan WIJetesh DevgunNo ratings yet

- Objective: Muhammad Bilal Aslam Electrical Engineer Abu Dhabi, UaeDocument4 pagesObjective: Muhammad Bilal Aslam Electrical Engineer Abu Dhabi, Uaeمھمد بلال اسلم عبدالعزیزNo ratings yet

- Career Objective Education: To Pursue A Career Opportunity With A Leading OrganizationDocument2 pagesCareer Objective Education: To Pursue A Career Opportunity With A Leading OrganizationDeepa NyatiNo ratings yet

- Tugas B.Ing IIDocument1 pageTugas B.Ing IIWulyo H SugihartoNo ratings yet

- Av HK Sop 002 House KeepingDocument6 pagesAv HK Sop 002 House KeepingjfejfeNo ratings yet

- New Appoaches in the Process Industries: The Manufacturing Plant of the FutureFrom EverandNew Appoaches in the Process Industries: The Manufacturing Plant of the FutureNo ratings yet

- Financial Management-Kings 2012Document2 pagesFinancial Management-Kings 2012Suman KCNo ratings yet

- V.balamurugan and M.manoharanDocument10 pagesV.balamurugan and M.manoharanAmritansh ChoubeyNo ratings yet

- Chapter 26 - Capital BudgetingDocument60 pagesChapter 26 - Capital Budgetingmbarecruit75% (4)

- EntrepreneurshipDocument4 pagesEntrepreneurshipSukriti MandalNo ratings yet

- PDF Review Materials On Capital Budgeting DLDocument7 pagesPDF Review Materials On Capital Budgeting DLRose Ann Juleth LicayanNo ratings yet

- Focus Series Part 2Document0 pagesFocus Series Part 2diademny09No ratings yet

- NZ Tax IndividualDocument60 pagesNZ Tax IndividualSusana SembranoNo ratings yet

- Financial Performance Analysis of Commercial Private Banks in BangladeshDocument78 pagesFinancial Performance Analysis of Commercial Private Banks in Bangladeshmd.jewel ranaNo ratings yet

- Market at Much Less Than Book Value. The Weighted Average Stock Price in Relation To Book Value ForDocument10 pagesMarket at Much Less Than Book Value. The Weighted Average Stock Price in Relation To Book Value ForT Anil KumarNo ratings yet

- Problem.1. "If We Can Get That New Robot To Combine With Our Other Automated Equipment, We Wil Have Manager For Diller ProductsDocument6 pagesProblem.1. "If We Can Get That New Robot To Combine With Our Other Automated Equipment, We Wil Have Manager For Diller ProductsMd. Shahriar Kabir RishatNo ratings yet

- Quiz 3Document5 pagesQuiz 3shivi2504No ratings yet

- Foundations of Financial Management Canadian 1St Edition Block Test Bank Full Chapter PDFDocument65 pagesFoundations of Financial Management Canadian 1St Edition Block Test Bank Full Chapter PDFweickumralphie100% (10)

- FA3 CabreraDocument139 pagesFA3 CabreraLaurenz Simon ManaliliNo ratings yet

- Nigerian Gas Transmission Tariff Framework StudyDocument19 pagesNigerian Gas Transmission Tariff Framework StudyDaniel DamboNo ratings yet

- Finance Best BL Agro ReportDocument61 pagesFinance Best BL Agro ReportShobhit GoswamiNo ratings yet

- Financial Management (NOTES) Aug 2023Document289 pagesFinancial Management (NOTES) Aug 2023jhanvitiwari460No ratings yet

- PM T1Document4 pagesPM T1SiewChenSohNo ratings yet

- Part A: Multiple Choice Questions (20 Marks)Document18 pagesPart A: Multiple Choice Questions (20 Marks)Anonymous f5ZhkfZmk9100% (1)

- Equity ReportDocument34 pagesEquity ReportSagarNo ratings yet

- Uni Do Com Far Tomato Study CaseDocument30 pagesUni Do Com Far Tomato Study CaseSaeed Soroush MoghaddamNo ratings yet

- The Value of LearningDocument17 pagesThe Value of LearningFridRachmanNo ratings yet

- Cost of Capital Brigham Answer KeyDocument16 pagesCost of Capital Brigham Answer KeyRommel Lubon75% (4)

- Ch-4 Risk and Return-LatestDocument168 pagesCh-4 Risk and Return-Latestshakilhm0% (2)

- MGT411 Midterm MCQ PDFDocument31 pagesMGT411 Midterm MCQ PDFJessica Chambers100% (2)

- Piramal Enterprises Limited Annual Report 2017 18 1 1Document20 pagesPiramal Enterprises Limited Annual Report 2017 18 1 1lokeshNo ratings yet

- Measuring Risk-Adjusted Performance: Michel Crouhy and Stuart M. TurnbullDocument31 pagesMeasuring Risk-Adjusted Performance: Michel Crouhy and Stuart M. Turnbullabhishek210585No ratings yet

Diseño Plantas

Diseño Plantas

Uploaded by

DianaVázquezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diseño Plantas

Diseño Plantas

Uploaded by

DianaVázquezCopyright:

Available Formats

ACHARYA N.G.

RANGA AGRICULTURAL UNIVERSITY

B.Tech (Food Technology)

Course No. FDEN-323

Course Title: FOOD PLANT DESIGN AND LAYOUT

Credits:

3 (2 + 1)

Prepare !"

Er. #. SREENIVASULA REDDY

Assistant Professor (Food Engineering)

College of Food Science and Technology

Chinnarangapura! Puli"endula # $%&'()

*S+ (,A-APA) -istrict! Andhra Pradesh

DEPART$ENT OF FOOD ENGINEERING

% Course No : FDEN - 323

. Title : F%% P&a'( De)*+' a' La"%,(

' Credit hours : 3 (2+1)

/ 0eneral 123ecti"e : To ipart 4no5ledge on plant layout and design of

food industries

$ Specific 123ecti"es :

a) Theory : By the end of the course! the students 5ill ac6uire

4no5ledge on theoretical aspects to 2e considered

for site selection! layout selection and design

considerations for a food plant

2) Practical By the end of the course! the students 5ill de"elop

s4ills and ac6uaint in pro3ect preparations!

estiations and cost estiates of different

e6uipent and utilities of "arious food industries

A) T-e%r" Le.(,re O,(&*'e)

% 7ntroduction : Plant design concepts 8 situations gi"ing rise to plant design

pro2les 8 differences in design of food processing and non8food processing

plants

. 0eneral design considerations! Food Processing 9nit 1perations! Pre"ention

of Containation! Sanitation! -eterioration! Seasonal Production

' Flo5 Chart for Plant -esign! 7dentification Stage! :oo4ing for a need! Finding

a product! Preliinary Screening of ideas

/ Coparati"e rating of product ideas: Present ;ar4et! ;ar4et 0ro5th

potential! Costs! +is4s

$ Pre Selection < Pre feasi2ility stage! Analysis Stage: ;ar4et Analysis!

Situational analysis related to ar4et

& Technical analysis! Financial Analysis! Sensiti"ity and ris4 analysis! Feasi2ility

cost estiates

= Brea4 E"en Analysis: 7ntroduction! Brea48E"en Chart! Fi>ed Costs! ?aria2le

costs! Brea4 e"en point calculation

@ Plant location :7ntroduction! :ocation -ecision Process! Factors in"ol"ed in

the plant location decision!

( Territory selection and Site< counity selection

%

)

Su23ecti"e! Aualitati"e and Sei8Auantitati"e Techni6ues! E6ual Beights

;ethod! ?aria2le Beights ;ethod! Beight8cu8+ating ;ethod! Another

5eight8cu8rating ethod

%

%

Coposite ;easure ethod! :ocational Brea48E"en analysis

%

.

Food Plant 9tilities: Process Bater! Stea! Electricity! Plant Effluents

% Plant SiCe and Factors

2

'

%

/

The enterprise and its En"ironent! The total re"enue function! the total cost

function

%

$

Brea48e"en and shutdo5n points! Production! econoics of ass production!

Production anageent decision

%

&

Plant layout : 7portance! Flo5 Patterns

%

=

Basic Types of plant layouts! Product or line layout! Process or functional

layout! Cellular or group layout! and Fi>ed position layout! Plant :ayout

factors! :ayout design Procedure

%

@

0eneral guide lines for plant layout! Typical clearances! areas and

allo5ances! Plant layout! :ayout of e6uipent! Space deterination

%

(

Sy2ols used for food plant design and layout: 7ntroduction! "al"es! line

sy2ols! fluid handling! heat transfer! ;ass transfer

.

)

Sy2ols used for food plant design and layout: Storage "essels! con"eyors

and feeders! separators! i>ing and counition and process control and

instruentation sy2ols.

.

%

E>perientation in pilot layout : SiCe and structure of the pilot plant! iniu

and a>iu siCe! types and applications

.

.

Engineering Econoy : 7ntroduction! Ters: Tie "alue of oney! inflation!

7nterest! 7nterest rate! copound interest! rate of return! payent! receipt !

cash flo5! present "alue! E6ui"alence! sun4 costs! opportunity costs! Asset!

:ife of an asset! depreciation! 2oo4 "alue of an asset! sal"age "alue!

retireent! replaceent! defender and challenger.

.

'

;ethods of econoic e"aluation of engineering alternati"es

%. 9ndiscounted cash flo5 ethods 8pay 2ac4 period ethod

.. -iscounted cash flo5 ethods

a) Net present "alue ethod

2) E6ui"alent annual ethod

c) +ate of return ethod

'.Cost8 2enefit analysis! Social costs! social 2enefits

.

/

Process scheduling

.

$

:inear Prograing: 7ntroduction! Salient features of :inear prograing

(Terinology)

.

&

Forulation of linear prograing odel! Ad"antages! liitations and

applications of linear prograing! solution of linear prograing pro2les.

.

=

Aueuing theory : 7ntroduction! Eleents of 6ueuing syste! %) 7nput source!

.) Aueue

. Aueuing theory: Characteristics of 5aiting lines! ser"ice discipline! Ser"ice

3

@ echanis! syste out put! custoer 2eha"ior.

.

(

;aterials of construction of Food E6uipent : Characteristics of suita2le

construction aterial : Stainless steel! Aluinu! Nic4el and ;onel! Plastic

;aterials

'

)

7lluination and "entilation

'

%

Cleaning D sanitiCation

'

.

;aintenance of Food Plant Building : Safety Color Code! +oof 7nspection!

Care of Concrete floors

#) Pra.(*.a& C&a)) O,(&*'e)

% Preparation of pro3ect report

. Preparation of feasi2ility report

' :ayout of Food storage 5ares and godo5ns

/ :ayout and design of cold storage

$ :ayout of preprocessing house

& :ayout of ;il4 and ;il4 product plants

= -esign and layout of lo5 shelf life product plant

@ -esign and layout of fruits processing plants

( -esign and layout of "egeta2le processing plants

%

)

:ayout of ulti product and coposite food plants

%

%

E"aluation of gi"en layout

%

.

Baste treatent and anageent of food plant

%

'

-esign and layout of odern rice ill

%

/

-esign and layout of ango pulp canning industry

%

$

-esign and layout of spices anufacturing unit

%

&

-esign and layout of Ba4ery and related product plant

Re/ere'.e)

% ; ;oor! ;ac ;illan! Plant :ayout D -esign. :aes! Ne5 *or4.

. E.S. Eall D *.S. +osen! ;il4 Plant :ayout. FA1 Pu2lication! +oe.

' F.B. Farrall! -airy D Food Engineering. Fohn Billy D Sons! Ne5 *or4.

/ Food Plant -esign 2y Antonio :GpeC. 0GeC

$ Food plant engineering systes 2y Theunis C. +o22erts! C+C Press! Bashington

& Food plant econoics 2y Hacharias B. ;aroulis and 0eorge -. Sara"acos

pu2lished 2y Taylor and Francis 0roup! ::C

= Fundaentals of Production Systes Engineering! 0.S.Se4hon and A.S.Sachde"!

Pu2lished 2y -hanpat +ai and Copany Pri"ate :iited! -elhi (Chapter N1. %()

@ 1perations +esearch 2y ;anohar ;aha3an! Pu2lished 2y -hanpat +ai and

4

Copany Pri"ate :iited! -elhi

( Food Process -esign 2y Hacharias B. ;aroulis pu2lished 2y ;arcel -e44er! 7nc !

Ciarron +oad! ;onticello! Ne5 *or4 %.=)%! 9 S A

5

LECTURE NO. 1

INTRODUCTION0 PLANT DESIGN CONCEPTS - SITUATIONS GIVING RISE

TO PLANT DESIGN PRO#LE$S - DIFFERENCES IN DESIGN OF FOOD

PROCESSING AND NON-FOOD PROCESSING PLANTS

INTRODUCTION

Plant design refers to the o"erall design of a anufacturing enterprise <

facility. 7t o"es through se"eral stages 2efore it is copleted. The stages

in"ol"ed are : identification and selection of the product to 2e anufactured!

feasi2ility analysis and appraisal! design! econoic e"aluation! design report

preparation! procureent of aterials including plant and achinery construction!

installation and coissioning. The design should consider the (e.-'*.a& and

e.%'%1*. /a.(%r)! 2ar*%,) ,'*( %pera(*%') *'2%&2e3 e4*)(*'+ a' p%(e'(*a&

1ar5e( .%'*(*%') etc.

P&a'( e)*+' )pe.*/*e)0

(-e e6,*p1e'( to 2e used

per/%r1a'.e re6,*re1e'() for the e6uipent

*'(er.%''e.(*%') a' ra7 1a(er*a& /&%7) in ters of flo5 charts

and plant layouts

the p&a.e1e'( of e6uipent! storage spaces! shop facilities! office

spaces! deli"ery and shipping facilities! access 5ays! site plans and

ele"ation dra5ings

re6uired *')(r,1e'(a(*%' a' .%'(r%&)! and process onitoring

and control interconnections

utility and 7a)(e (rea(1e'( re6,*re1e'()! connections and

facilities

the rationale for site selection

the 2asis for )e&e.(*'+ a' )*8*'+ .r*(*.a& p*e.e) %/ e6,*p1e'(

5ays in 5hich the design 5as optiiCed and the engineering 2asis

for such optiiCation

They also often pro"ide econoic analyses of plant profita2ility in ters of

"arious product deand and price and aterial cost scenarios.

P&a'( De)*+' S*(,a(*%')

6

Plant design situations ay arise due to one or ore of the follo5ing:

design and erection of a copletely 'e7 p&a'(

design and erection of an a*(*%' (% (-e e4*)(*'+ p&a'(

the facility or plant operations and su2se6uent e>pansion restricted 2y a

p%%r )*(e3 (-ere!" 'e.e))*(a(*'+ (-e )e((*'+ ,p %/ (-e p&a'( a( a 'e7

)*(e

a*(*%' %/ )%1e 'e7 pr%,.( to the e>isting range

adoption of )%1e 'e7 pr%.e)) <replaceent of soe e>isting e6uipent

1%er'*8a(*%' 9 a,(%1a(*%' of the e>isting facility

e4pa')*%' of the plant capacity

re&%.a(*'+ the e>isting plant at a ne5 site 2ecause of ne5 econoic!

social! legal or political factors

D*//ere'.e) *' (-e De)*+' %/ F%% Pr%.e))*'+ a' N%'-F%% Pr%.e))*'+

P&a'()

;any of the eleents of plant design are the sae for food plants as they

are for other plants particularly those processing industrial cheicals. Eo5e"er!

there are any significant differences! 2asically in the areas of e6uipent

selection and siCing! and in 5or4ing space design. These differences ste fro

the 5ays in 5hich the processing of foods differ fro the processing of industrial

cheicals.

S,.- *//ere'.e) %..,r !e.a,)e %/ (-e /%&&%7*'+ .%')*era(*%')0

The storage life of foods is relati"ely liited and strongly affected 2y

teperature! pE! 5ater acti"ity! aturity! prior history! and initial icro2ial

containation le"els.

?ery high and "erifia2le le"els of product safety and sterility ha"e to 2e

pro"ided.

Foods are highly suscepti2le to icro2ial attac4 and insect and rodent

infestation.

Ferentations are used in producing "arious foods and 2io cheicals.

Successful processing re6uires the use of conditions! 5hich ensure the

doinance of desired strains of icroorganiss gro5th or acti"ity.

EnCye8catalyCed processes are used or occur in any cases. These! li4e

icro2ial gro5th and ferentation are "ery sensiti"e to teperature! pE! 5ater

acti"ity and other en"ironental conditions.

7

;any foods are still li"ing organiss or 2iocheically acti"e long after

har"est or slaughter.

7n soe cases foods (e.g. ripening cheeses) contain acti"e li"ing icro8

organiss! 5hich induce cheical transforations for long periods of tie.

Crop82ased food ra5 aterials ay only 2e a"aila2le in usa2le for on a

seasonal 2asis. Therefore! plant design ay in"ol"e the odeling of crop

a"aila2ility.

Food ra5 aterials are highly "aria2le and that "aria2ility is enhanced 2y

the ageing of ra5 aterial and uncontrolla2le "ariations in cliatic conditions.

The 2iological and cellular nature and structural cople>ity of foods causes

special heat8transfer! ass8transfer and coponent separation pro2les.

Foods are fre6uently solid. Eeat and ass8transfer pro2les in solids ha"e

to 2e created in 5ays that are different than those used for li6uid and gas

streas. The 4inetics of icro2e and enCye inacti"ation during therally

induced steriliCation and 2lanching and heat8transfer in the solids 2eing steriliCed

or 2lanched are strongly lin4ed.

Food processing generates 5astes 5ith high B1- loads.

Foods are often cheically cople> systes 5hose coponents tend to

react 5ith one another. Certain types of reactions! e.g. ;aillard reactions!

o>idati"e rancidification! hydrolytic rancidification and enCyatic 2ro5ning tend to

occur 5ith a high degree of fre6uency.

The engineering properties of foods and 2iological aterial are less 5ell

4no5n and ore "aria2le than those of pure cheicals and siple i>tures of

cheicals.

?aguely defined sensory attri2utes often ha"e to 2e preser"ed! generated

or odified. These re6uire sensory testing. +a5 aterial "ariation! inor

processing changes and trace containants leached fro processing e6uipent

and pac4ages can often cause significant changes in these attri2utes. Fre6uently!

5e do not ha"e echanistic 2ases for lin4ing these attri2utes to processing

conditions and e6uipent design. ;uch current food engineering and food

science research acti"ity at uni"ersities is designed to pro"ide such lin4ages.

7n the case of foods! prototype products ha"e to 2e consuer tested so as

to assure ar4et accepta2ility 2efore plants for large scale production are 2uilt.

8

;echanical 5or4ing is soeties used to induce desired te>tural changes.

E>aples include 4neading and sponge i>ing during the a4ing of 2read! the

calendaring of pastry dough! shearing during e>trusion te>turiCation.

Pac4aging in sall containers is often used or re6uiredI and strong8

pac4age8product interactions e>ist. Pac4aging often re6uires care to aintain

integrity of closure! reproduci2ility of fill eliination of air fro head spaces and

pre"ention of su2se6uent oisture and o>ygen transfer. Segregation often causes

pro2les in the pac4aging of po5dered foods. Aseptic pac4aging is starting to 2e

5idely used.

Food processing techni6ues and forulations are soeties constrained

2y standards of identity and good anufacturing practice regulations and codes.

Food processing is an art to a certain e>tent. Engineers and technologists

are fre6uently uncertain as to 5eather portions of that art are really 3ustified or

necessary. 7t is soeties difficult for the to translate the necessary portions of

that art into 6uantifia2le heat8transfer and cheical reaction processes on 5hich

rational designs can 2e 2ased.

9

LECTURE NO. 2

GENERAL DESIGN CONSIDERATIONS3 FOOD PROCESSING UNIT

OPERATIONS3 PREVENTION OF CONTA$INATION3 SANITATION3

DETERIORATION3 SEASONAL PRODUCTION

Ge'era& De)*+' C%')*era(*%')

Food plant designs ust pro"ide necessary le"els of sanitation! eans of

pre"enting product and aterial containation and eans of pre"enting or

liiting product! ra5 aterial! and interediate product deterioration due to

naturally occurring processes. 0reat care ust 2e e>ercised to achie"e high

le"els of product purity and preser"e product integrity. A 2rief description of soe

of the design considerations follo5s.

F%% pr%.e))*'+ ,'*( %pera(*%')

Food processing in"ol"es any con"entional unit operations 2ut it also

in"ol"es any 5hich differ greatly fro those usually encountered in the

production of industrial cheicals. These include: freeCing and tha5ing and other

teperature8induced phase transitions or phase transition analogs! freeCe drying!

freeCe concentration! curd and gel foration! de"elopent of structured gels!

cleaning and 5ashing (the operation 5hich occurs 5ith the greatest fre6uency in

food processing plants)! lea"ening! puffing! and foaing! slaughtering! carcass

disasse2ly! coponent e>cision! slicing and dicing! peeling and triing!

grading! cell disruption and aceration! pasteuriCation and steriliCation! 2lanching!

2a4ing! coo4ing (for purposes of tenderiCation or te>tural odification)! roasting

(for purposes of fla"our generation)! radiation steriliCation! echanical e>pression!

structure82ased coponent separation! filling and pac4aging! canning and

2ottling! coating and encapsulation! sausage and fle>i2le casing! stuffing!

controlled atosphere storage! fuigation and so4ing! churning! artificially

induced ripening! ferentation! pureeing! eulsification and hoogeniCation!

2iological 5aste treatent! and controlled feeding of confined anials! poultry and

fish.

Pre2e'(*%' %/ .%'(a1*'a(*%'

Pre"ention of containation 5ill in"ol"e the pro"ision or use of filtered air!

air loc4s! piping layouts that ensure coplete drainage and present cross8strea

containation (particularly containation of finished products 2y unsteriliCed or

10

unpasteuriCed ra5 aterial and cleaning solutions)! solid aterial and huan

traffic flo5 layouts that also pre"ent such containation! suita2ly high cur2s 5hen

pipes! con"eyors or e6uipent pass through floors and 5here gang5ays pass

o"er processing areas! 2actericides in cooling 5ater! culinary (i.e. containant8

free) stea 5hene"er direct contact 2et5een a product and stea is used!

iperea2le co"ers for insulation! dust co"ers o"er con"eyors and clear plastic

co"ers for electric lights! ethods for 5ashing 2ottles and containers! suita2le

2arriers against pest entry! 5indo5less construction! solid instead of hollo5 5alls!

or copletely tight enclosure of hollo5 spaces in 5alls! air circulation syste and

e>ternal roof and 5all insulation that pre"ent the foration of condensate 5hich

can drip into products or fa"or old gro5th! ultra8"iolet irradiation of tan4 head

spaces! electric light traps for flying insects! ipactors for 4illing insect eggs!

lar"ae! pupae and adults in grain! car2on dio>ide and nitrogen fuigation of dry

food storage 2ins! screening syste to reo"e insects and insect parts! agnetic

traps! iron screens for sie"ing e6uipent (so that screen fragents can 2e pic4ed

up 2y agnetic traps)! etal detectors for re3ecting pac4aged product that

contains un5anted etal! and ethods for storing and 4eeping trac4 of

segregated 2atches of ra5 aterials and finished goods until necessary 6uality

assurance tests ha"e 2een carried out.

Sa'*(a(*%'

Sanitation! 5hich helps pre"ent containation! should 2e facilitated 2y

pro"iding or using: iperea2le coated or tiled floors and 5alls! at least one floor

drain per e"ery /)

.

of 5et processing area! special traps for such drains!

pitched floors that ensure good drainage! polished "essels and e6uipent that do

not contain dead spaces and 5hich can 2e drained and autoatically cleaned in

place! sanitary piping! clean8in8place (C7P) systes! plate heat e>changers and

other types of e6uipent 5hich can 2e readily disasse2led for cleaning if

necessary! clearances for cleaning under and around e6uipent! grouting to

eliinate cre"ices at the 2ase of e6uipent support posts and 2uilding coluns!

tu2ular pedestals instead of support posts constructed fro 2eas! and ethods

for reo"ing solid particles 5hich fall off con"eyors. Air flo5 and huan traffic

flo5 patterns should 2e aintained to eliinate possi2ilities of containent

transfer fro dirty areas to clean ones. ?ery high le"els of sanitation ust 2e

pro"ided for foodstuffs that pro"ide good su2strates for the gro5th of icro8

organiss and 5hen processing teperatures and conditions fa"or such gro5th.

11

De(er*%ra(*%'

To iniiCe product and ra5 aterial deterioration! pro"isions should 2e

ade for: refrigerated and controlled en"ironent storage areas! space and

facilities for product inspection and for carrying out 6uality assurance tests! surge

"essels for processed aterial 2et5een different operations (particularly

operations 5hich are su23ect to 2rea4do5n)! e6uipent for pre8cooling aterial

stored in such "essels! eans of cooling! turning o"er or rapidly discharging the

contents of 2ins and silos 5hen e>cessi"e teperature rises! occur! and stand2y

refrigeration and utility arrangeents 5hich are ade6uate to pre"ent product and

ra5 aterial deterioration in case of po5er interruptions or unusual cliatic

conditions.

Sea)%'a& pr%,.(*%'

Food plants ha"e to 2e siCed to accoodate pea4 seasonal flo5s of

product 5ithout e>cessi"e delay! and in soe cases! ha"e to 2e highly fle>i2le so

as to handle different types of fruits and "egeta2les. ;odeling of crop and anial

gro5th processes can 2e of great help in scheduling production and ade6uately

siCing plants.

12

LECTURE NO. 3

FLO: CHART FOR PLANT DESIGN3 IDENTIFICATION STAGE3 LOO;ING

FOR A NEED3 FINDING A PRODUCT3 PRELI$INARY SCREENING OF IDEAS

Fig. Flo5 chart for plant design

FEASIBILITY STUDY

Technical

Coe!cial " #a!$e%

Econoic

Financial

Social

A&an'on

(o

Ye)" Fa*o!a&le

+!eliina!,

in*e)%en% 'eci)ion

E(-I(EE.I(- DESI-("+LA(T DESI-(

+lan% loca%ion

+lan% )i/e " Ca0aci%,

+!o'1c% 'e)i2n " )0eci3ica%ion

+!oce)) )elec%ion " 'e)i2n

E41i0en% )elec%ion " 'e)i2n

#a!$e% 'e)i2n " anal,)i)

E41i0en% " 0lan% la,o1%

+i0in2 an' in)%!1en%a%ion 'e)i2n " )elec%ion

U%ili%ie) an' )e!*ice)

+lan% &1il'in2 an' )1!!o1n'in2)

Co)% an' &ene3i% anal,)i)

+.56ECT IDEA

A&an'on

(o

Ye)

Final In*e)%en%

'eci)ion

+!o7ec% .e0o!%

+!oc1!een% o3 .a8 #a%e!ial an' E41i0en%

B1il'in2 Con)%!1c%ion

In)%alla%ion9 Coi))ionin2 an' )%a!% 10

Uni% in +!o'1c%ion " 50e!a%ion

13

Ca0i%al Ac41i)i%ion

#a!$e%in2

FEASI#ILITY STUDY

The 2asis for the success of the design of any food processing plant is a

coprehensi"e feasi2ility study and e"aluation. The feasi2ility study in"ol"es an

analysis and e"aluation of the design concept fro all the rele"ant angles. The

study pro"ides an iediate indication of the pro2a2le success of the enterprise

and also sho5s 5hat additional inforation is necessary to a4e a coplete

e"aluation. 7t gi"es an insight in to: re6uireents of huan! financial and aterial

resourcesI plant and achinery! technologyI and econoic gains or profita2ility of

the proposed "enture.

The feasi2ility analysis in"ol"es a certain nu2er of stages during 5hich

"arious eleents of the plant design are prepared and e>ained to arri"e at

appropriate decision. The feasi2ility study can! therefore! 2e seen as a series of

acti"ities culinating in the esta2lishent of a certain nu2er of study eleents

and docuents! 5hich perit decision a4ing. 7dentification stages! preliinary

selection stage! analysis stage and e"aluation and decision stage are the

iportant stages.

Ie'(*/*.a(*%' S(a+e

1nce a product idea occurs! the starting point of analysis is the

esta2lishent of the o23ecti"es to 2e attained. The o23ecti"e ay 2e to pro"e that

it is possi2le and desira2le to anufacture a certain product or group of products!

to add a piece of e6uipent to the e>isting plant or to utiliCe certain resources.

The ideas for ne5 products or di"ersification can 2e generated in an

inforal and spontaneous anner fro custoers! distri2utors! copetitors!

sales people! and others! or the entrepreneur can rely on a systeatic process of

idea generation.

T5o 4ey approaches for product identification and selection could 2e:

i) :oo4 for a need and then the product to satisfy that need! or

ii) Find a product idea and then deterine the e>tent of the need.

L%%5*'+ /%r a 'ee

?enture ideas can 2e stiulated 2y inforation 5hich indicates possi2le

need. This approach re6uires access to data and considera2le analysis. Eo5e"er!

if the percei"ed need is real! the product idea has a 2etter than a"erage chance of

leading to a successful "enture. The need ay 2e one no5 2eing ser"ed

inefficiently at high cost! or it ay 2e presently unser"ed. The second iplies that

14

a considera2le aount of creati"e design and de"elopent ay 2e re6uired to

arri"e at a product that appears to satisfy the need. The follo5ing is suggested for

identification of the need.

study e>isting industries for 2ac45ard and for5ard product integration to

indicate input and output needs

analyCe population trends and deographic data for their affect on the

ar4et

study de"elopent plans and consult de"elopent agencies for

de"elopent needs and "enture opportunities

e>aine econoic trends in relation to ne5 ar4et needs and

opportunities .

analyCe social changes

study the effects of ne5 legislations in relation to creation of ne5

opportunities

F*'*'+ a pr%,.(

Each of the preceding suggestions for idea generation centers on the

recognition of a need in order to arri"e at a product idea. The suggestions that

follo5 are product oriented. They are intended to stiulate product ideas 5hich

ay eet one or ore of the criteria pre"iously discussed. Their use should result

in a large nu2er of ideas 5hich can 2e su2se6uently e>ained 5ith regard to

need. The follo5ing list should 2e useful in conducting such an e>ercise.

in"estigate local aterials and other resources for their current utiliCation

pattern! utiliCation potential and con"erti2ility into ore "alue added

products

e>aine iport su2stitutions for indigenous production

study local s4ills for production and ar4eting of "alue added products

study iplications of ne5 technologies for ipro"eent of e>isting

products or to create < produce ne5 ones

study and analyCe pu2lished sources of ideas

Pre&*1*'ar" S.ree'*'+ %/ Iea)

By follo5ing the a2o"e approaches! it should 2e possi2le to de"elop a long

list of potential "enture opportunities. 12"iously! it 5ould not 2e realistic to

conduct a detailed feasi2ility analysis for each idea. Bhat is needed is a

15

preliinary screening to eliinate the any ideas that ha"e little or no hope for

success and to pro"ide! if possi2le! a ran48ordering of the reaining fe5. The

screening can 2e conducted as t5o8phase process. 7n the first phase "enture

ideas are eliinated on a go<no8go 2asis. A J*esJ response to any of the follo5ing

should eliinate the idea fro further consideration.

Are the capital re6uireents e>cessi"eK

Are en"ironental effects contrary to 0o"ernent regulationsK

7s "enture idea inconsistent 5ith national policies! goals and restrictionsK

Bill effecti"e ar4eting need e>pensi"e sales and distri2ution systeK

Are there restrictions! onopolies! shortages! or other causes that a4e

any factor of production una"aila2le at reasona2le costK

16

LECTURE NO. 4

CO$PARATIVE RATING OF PRODUCT IDEAS0 PRESENT $AR;ET3

$AR;ET GRO:TH POTENTIAL3 COSTS3 RIS;S

C%1para(*2e Ra(*'+ %/ Pr%,.( Iea)

After eliination of unattracti"e "enture ideas! it is desira2le to choose the

2est of those reaining for further analysis. ?arious coparati"e schees ha"e

2een proposed for rating "enture ideas. 7n this section factors that should 2e

considered and soe possi2le ran4ing ethods are e>ained. For a product idea

to lead to a successful "enture! it ust eet the follo5ing four re6uireents:

%. An ade6uate present ar4et

.. ;ar4et gro5th potential

'. Copetiti"e costs of production and distri2ution

/. :o5 ris4 in factors related to deand! price! and costs

1. Pre)e'( $ar5e(0- The siCe of the presently a"aila2le ar4et ust pro"ide the

prospect of iediate sales "olue to support the operation. Sales estiates

should not 2e 2ased solely on an estiate of the nu2er of potential custoers

and their e>pected indi"idual capacity to consue. Soe factors that effect sales

are:

;ar4et siCe (nu2er of potential custoers)

ProductLs relation to need

Auality8price relationship copared to copetiti"e products

A"aila2ility of sales and distri2ution systes and sales efforts re6uired

E>port possi2ilities

2. $ar5e( Gr%7(- P%(e'(*a&0 There should 2e a prospect for rapid gro5th and

high return on in"ested capital. Soe indicators are:

Pro3ected increase in need and nu2er of potential custoers

7ncrease in custoer acceptance

Product ne5ness

Social! political and econoic trends (fa"ora2le for increasing

consuption)

3. C%)() (Copetiti"e costs of production and distri2ution)0 The costs of

production factors and distri2ution ust perit an accepta2le profit 5hen the

17

product is priced copetiti"ely. The coparati"e rating process should consider

factor li4ely to result in costs higher than those of copetiti"e producers should:

Costs of ra5 aterial inputs

:a2or costs

Selling and distri2ution costs

Efficiency of production processes

Patents and licenses

<. R*)5) 0 12"iously it is ipossi2le to loo4 into the future 5ith certainty! and the

5illingness to assue ris4 is the a3or characteristic that sets the entrepreneur

apart. Eo5e"er! unnecessary ris4 is foolhardy and! 5hile it ay 2e difficult or

ipossi2le to predict the future! one can e>aine! 5ith considera2le confidence!

the possi2le effect of unfa"ora2le future e"ents on each of "enture ideas. The

follo5ing factors should 2e considered.

;ar4et sta2ility in econoic cycles

Technological ris4s

7port copetition

SiCe and po5er of copetitors

Auality and relia2ility ris4s (unpro"en design)

7nitial in"estent cost

Predicta2ility of deand!

?ulnera2ility of inputs (supply and price)

:egislation and controls

Tie re6uired to sho5 profit

7n"entory re6uireents

For purposes of preliinary screening! these factors can 2e su23ecti"ely

e"aluated.

18

LECTURE NO. 5

PRE SELECTION 9 PRE FEASI#ILITY STAGE3 ANALYSIS STAGE0 $AR;ET

ANALYSIS3 SITUATIONAL ANALYSIS RELATED TO $AR;ET

Pre )e&e.(*%' 9 Pre /ea)*!*&*(" S(a+e

The preliinary screening ay ha"e se"eral ideas 5hich appear to 2e

5orthy of further study. Since a coplete feasi2ility study is tie consuing and

e>pensi"e! it ay 2e desira2le to perfor a pre feasi2ility analysis in order to

further screen the possi2le ideas. The purpose of a pre feasi2ility study is to

deterine.

Bhether the pro3ect sees to 3ustify detailed study

Bhat atters deser"e special attention in the detailed study (e.g. ar4et

analysis! technical feasi2ility! in"estent costs)

An estiate of cost for the detailed study

For any ideas the pre8feasi2ility analysis ay pro"ide ade6uate e"idence

of "enture profita2ility if certain segents are ore carefully "erified. Ephasis

depends on the nature of the product and the area of greatest dou2t. 7n ost

cases ar4et aspects and aterials recei"e priary ephasis. The pre8feasi2ility

study ay include soe or all of the follo5ing eleents.

1. Pr%,.( e).r*p(*%'. The productLs characteristics should 2e 2riefly descri2ed!

along 5ith possi2le su2stitutes 5hich e>ist in the ar4et place. Also! allied

products should 2e identified! 5hich can or should 2e anufactured 5ith the

product under study.

2 De).r*p(*%' %/ 1ar5e(. The present and pro3ected potential ar4et and the

copetiti"e nature of the ar4et should 2e delineated.

Bhere is the product no5 anufacturedK

Eo5 any plants e>ist and ho5 specialiCed are theyK

Bhat are the national production! iports! and e>portsK

Are there go"ernent contracts or incenti"esK

Bhat is the estiated product longe"ity or future consuptionK

Bhat is the price structureK

3. O,(&*'e %/ (e.-'%&%+*.a& 2ar*a'(). The technology choices that e>ist for the

anufacture of the product should 2e descri2ed 2riefly. Also! the 4ey plant

location factors should 2e identified.

19

<. A2a*&a!*&*(" %/ 1a*' pr%,.(*%' /a.(%r). Production factors such as ra5

aterials! 5ater! po5er! fuel and la2or s4ills should 2e e>ained to ensure

a"aila2ility.

=. C%)( e)(*1a(e). Estiates should 2e ade of the necessary in"estent costs

and costs of operation.

>. E)(*1a(e %/ pr%/*(. The data gathered should include estiates of profits of

firs anufacturing siilar products or! if the preliinary data are e>tensi"e! an

actual estiated profit for the pro3ect under study.

?. O(-er a(a. 7n certain cases! local attitudes to5ard industryI educational!

recreational and ci"ic dataI and a"aila2ility of local sites! ay 2e the ost

iportant in the e"aluation of the suita2ility of a proposed product! especially in

the case of the esta2lishent of a ne5 fir.

Thus pre feasi2ility study can 2e "ie5ed as a series of steps culinating in

a docuent 5hich perits deterination of 5hether or not a coplete detailed

feasi2ility study should 2e ade. 7t does not possess the depth the detailed study

is e>pected to ha"e! and the data usually are gathered in an inforal anner.

A'a&")*) S(a+e

At the analysis stage "arious alternati"es in ar4eting! technology and

capital a"aila2ility need to 2e studied. The analysis can 2e conducted at different

le"els of effort 5ith respect to tie! 2udget and personnel! depending on the

circustances. The coplete study is referred to as techno8econoic feasi2ility

study. 7n soe cases such a detailed study is not necessary. For e>aple! if the

product has an assured ar4et! in8depth ar4et analysis is not re6uired. 7n soe

cases! a partial study of the ar4et or of the technologies satisfies the data

re6uireents for decision a4ing. The detailed analysis should include the

follo5ing.

$ar5e( a'a&")*) 9 )(,"

;ar4et analysis can ser"e as a tool for screening "enture ideas and also as a

eans of e"aluating the feasi2ility of a "enture idea in ters of the ar4et. 7t

pro"ides:

understanding of the ar4et

inforation on feasi2ility of ar4eting the product

analytical approach to the decision a4ing

7n addition! it assists in analyCing the decisions already ta4en. $ar5e( a'a&")*)

a')7er) 6,e)(*%') a!%,(.

20

siCe of ar4et and share anticipated for the product in ters of "olue and

"alue

pattern of deand

ar4et structure

2uying ha2its and oti"es of 2uyers

past and future trends

price 5hich 5ill ensure acceptance in the ar4et

ost efficient distri2ution channels!

copanyLs strong points in ar4eting

;ar4et analysis in"ol"es systeatic collection! recording! analysis! and

interpretation of inforation on:

e>isting and potential ar4ets

ar4eting strategies and tactics

interaction 2et5een ar4et and product

ar4eting ethods

current or potential products

7n collecting the ar4et data! for 5hate"er siCe ar4et or type of product! it

is helpful to follo5 an orderly procedure.

The initial step is to put do5n in 5riting a preliinary stateent of

o23ecti"es in as uch detail as possi2le. A good procedure is to structure the

o23ecti"es in 6uestion for. Bhen setting o23ecti"es! al5ays 4eep in ind as to

ho5 the inforation 5ill 2e used 5hen it is o2tained. This helps in eliinating

o23ecti"es that 5ould not a4e a contri2ution to the ar4et analysis.

S*(,a(*%'a& a'a&")*) re&a(e (% $ar5e(

The situational analysis of the ar4et in"ol"es analyCing the productLs

relationship to its ar4et 2y using readily a"aila2le inforation. The inforation

re"ie5ed and each 6uestion as4ed 5ill gi"e the analyst a feel for the situation

surrounding the product. The state in"ol"es an inforal in"estigation 5hich

includes tal4ing to people in 5holesale ar4et! 2ro4ers! copetitors! custoers

and other indi"iduals in the industry. 7f this inforal in"estigation produces the

sufficient data to easure the ar4et ade6uately! the analysis need not proceed

further. Also! in soe instances! 5here tie is critical or 5here 2udget is a

pro2le! the data gathered during the inforal ar4et analysis ay 2e all that is

a"aila2le on 5hich to 2ase decisions.

21

Seldo do the data o2tained during the situational analysis ans5er all the

necessary 6uestions. The inforal analysis pro"ides the 2asis for re"ision of the

o23ecti"es and fre6uently indicates the ost fruitful ethods 2y 5hich ar4et can

2e studied. This also helps in preparing a coprehensi"e prograe of ar4et

study. Such a prograe should include a description of the tas4s and ethods

2y 5hich each type of inforation is to 2e gathered. 7t should include not only the

tie schedule for each tas4! 2ut also an estiate of costs li4ely to 2e incurred.

Basic steps in"ol"ed in a ar4et study for a ne5 enterprise are outlined

2elo5:

-efine o23ecti"es of the study and specify inforation re6uired

Bor4out details of the study as under:

8identify sources of inforation (2oth secondary and priary)

8tie and cost in"ol"eent

8ethodology and action plan

Select saples and decide contacts and "isits

Prepare the 6uestionnaire as the sur"ey instruent and field test the sae

Conduct the sur"ey and analyCe inforation

Prepare the report 5ith findings and interpretations

The analysis should generally contain:

A 2rief description of the ar4et including the ar4et area! ethods of

transportation e>isting rates of transportation! channels of distri2ution! and

general trade practices

Analysis of past and present deand including deterination of 6uantity

and "alue of consuption! as 5ell as identification of the a3or consuers

of the product

Analysis of past and present supply 2ro4en do5n as to source! inforation

on copetiti"e position of the product such as selling prices! 6uality! and

ar4eting practices of the copetitors

Estiate of future deand of the product

Estiate of the pro3ectMs share of the ar4et considering all a2o"e factors

22

LECTURE NO. 6

TECHNICAL ANALYSIS3 FINANCIAL ANALYSIS3 SENSITIVITY AND RIS;

ANALYSIS3 FEASI#ILITY COST ESTI$ATES

Te.-'*.a& a'a&")*)0

The technical analysis ust esta2lish 5hether or not the identified "enture

is technically feasi2le and! if so! a4e tentati"e choices aong technical

alternati"es and pro"ide cost estiates in respect of:

(i ) fi>ed in"estent!

(ii) anufacturing costs and e>penses! and

(iii) start8up costs and e>penses.

7n order to pro"ide cost estiates! tentati"e choices ust 2e ade aong

technical alternati"es such as:

(i) le"el of product < anufacturing technology!

(ii) ra5 aterial inputs!

(iii) e6uipent!

(i") ethods!

(") organiCation! and

("i) facilities location and design.

T-e a'a&")*) )-%,& *'.%rp%ra(e0

-escription of the product! including specifications relating to its physical!

echanical! and cheical properties as 5ell as the uses of the product

-escription of the selected anufacturing process sho5ing detailed flo5

charts as 5ell as presentations of alternati"e processes considered and

3ustification for adopting the one selected

-eterination of plant siCe and production schedule! 5hich includes the

e>pected "olue for a gi"en tie period! considering start8up and technical

factors

Selection of achinery and e6uipent! including specifications! e6uipent

to 2e purchased and origin! 6uotations fro suppliers! deli"ery dates! ters

of payent! and coparati"e analysis of alternati"es in ters of costs!

relia2ility! perforance and spare parts a"aila2ility .

7dentification of plantLs location and assessent of its desira2ility in ters

of its distance fro ra5 aterial sources and ar4ets. For a ne5 pro3ect

23

this part ay include a coparati"e study of different sites! indicating the

ad"antages and disad"antages of each.

-esign of a plant layout and estiation of the costs of erection of the

proposed types of 2uildings and land ipro"eents

Study of a"aila2ility of ra5 aterials and utilities! including a description of

physical and cheical properties! 6uantities! needed! current and

prospecti"e costs! ters of payent! source of supply and their location

and continuity of supply

Estiate of la2or re6uireents including a 2rea4do5n of the direct and

indirect la2or super"ision re6uired for the anufacture of product

-eterination of the type and 6uantity of 5aste to 2e disposed of!

description of the 5aste disposal ethod! its costs and necessary

clearance fro the authorities

Estiation of the production cost for the product

The eliination of inappropriate technology alternati"es for producing the

identified product can 2e done on the 2asis of side effects. The factors 5hich ay

2e considered as side effects include:

contri2ution to eployent

re6uireents for scarce s4ills

energy re6uireents

capital re6uireents

need for iported e6uipent

support of indigenous industry

ultiplier effect of the "enture operation

en"ironental effects.

safety and health haCards!

7nforation concerning anufacturing processes and e6uipent! 5hich

ay facilitate the selection and decision a4ing! ay 2e o2tained fro: (i)

e>isting anufacturers of the product! (ii) trade pu2lications! (iii) trade

associations and organiCations! and (i") e6uipent anufacturers.

F*'a'.*a& a'a&")*)

The financial analysis ephasiCes on the preparation of financial

stateent! so that the "enture idea can 2e e"aluated in ters of coercial

profita2ility and the agnitude of financing re6uired. 7t re6uires the asse2ly of

24

the ar4et and the technical cost estiates into "arious profora stateents. 7f

ore inforation on 5hich to 2ase an in"estent decision is needed! a sensiti"ity

analysis or! possi2ly! a ris4 analysis can 2e conducted. The depth of analysis

5ould depend! to a certain e>tent! on the "enture idea and the o"erall o23ecti"es

of the feasi2ility analysis.

The financial analysis should include:

For e>isting copanies8audited financial stateents! such as 2alance

sheets! incoe stateents and cash flo5 stateents

For ne5 copanies8stateents of total pro3ect costs! initial capital

re6uireents and cash flo5s relati"e to the pro3ect tie ta2le

For all pro3ects8financial pro3ections for future tie periods! including

incoe stateents! cash flo5s and 2alance sheets

Supporting schedules for financial pro3ections! stating assuptions used as

to collection period of sales! in"entory le"els! payent period of purchases

and e>penses! eleents of product costs! selling! adinistrati"e and

financial e>penses

financial analysis sho5ing return on in"estent! return on e6uity! 2rea48

e"en "olue and price analysis

Sensiti"ity analysis to identify ites that ha"e a large ipact on profita2ility

or possi2ility of ris4 analysis

The analyst ay o2tain profita2ility easures for the "enture 2eing studied

in se"eral 5ays. Coon non8tie "alue approaches to easure profita2ility are

the pay 2ac4 period and financial stateent (accounting) rates of return. These

rates of return are 2ased on soe net incoe figure di"ided 2y soe in"estent

2ase. Fre6uently used profita2ility easure of this type are: net incoe to assets!

first8year earnings to initial in"estent! a"erage net incoe to initial in"estent!

and a"erage net incoe to a"erage in"estent.

Profita2ility easures! 5hich consider the tie "alue of oney! that is!

discounted cash flo5 ethods! are net present "alue (NP?)! internal rate of return

(7++)! and the discounted 2enefit < cost ratio. Bhen profita2ility easures other

than financial stateent rates of return are used as the in"estent decision

criteria! the analyst needs estiates of the follo5ing:

the net in"estent! 5hich is gross capital less any capital reco"ered fro

the sale or trade of e>isting assetsI

25

the operating cash flo5s! 5hich are the after8ta> cash flo5s resulting fro

the in"estentI

the econoic life of the "enture! defined as the tie period during 5hich

2enefits can 2e o2tained fro the "entureI and

the appropriate discount rate.

Bith the rele"ant cash flo5s coputed for the "enture! the ne>t step is to

decide 5hich in"estent decision criterion to use for the acceptance or re3ection

of "entures as 5ell as their ran4ing. Theoretically! the net present "alue criterion is

the 2est easure of profita2ility of the in"estent decision criteria used to

e"aluate ne5 "enture ideas! the internal rate of return appears as the techni6ue to

2e of prie iportance. The pay2ac4 period is used priarily as a suppleentary

techni6ue.

Se')*(*2*(" a' r*)5 a'a&")*)

+ecogniCing that the "enture profita2ility forecast hinges on future

de"elopents 5hose occurrence can not 2e predicted 5ith certainty! the decision8

a4er ay 5ant to pro2e further. The analyst ay 5ant to deterine the ipact

of changes in "aria2les such as product price! ra5 aterial costs! and operating

costs on the o"erall results. Sensiti"ity analysis and ris4 analysis are the

techni6ues that allo5 the analyst to deal 5ith such pro2les.

The purpose of sensiti"ity analysis is to identify the "aria2les that ost

affect the outcoe of a "enture. Sensiti"ity analysis is useful for deterining

conse6uences of a stated percentage change in a "aria2le such as product price.

7t in"ol"es specifying the possi2le range for the "aria2le! such as price! and

calculating the effect of changes in this "aria2le to profita2ility. Bith such a

calculation! the analyst can deterine the relati"e iportance of each of the

"aria2les to profita2ility. Eo5e"er! only ris4 analysis can pro"ide any indication of

the li4elihood that such e"ents (change in product price) 5ill actually occur.

+is4 analysis ta4es into account the recogniCed fact that "aria2les! such as

product price! depend on future e"ents 5hose occurrence can not 2e predicted

5ith certainty. Eence! in"estent decision situations can 2e characteriCed 5ith

respect to certainty! ris4 and uncertainty. Since certainty seldo e>ists for future

returns on in"estent! only ris4 and uncertainty are of interest. 9ncertainty is

used to refer to an e"ent! such as technological 2rea4through resulting in

o2solescence! that is e>pected to ta4e place although the pro2a2ility

26

of its occurrence cannot 2e forecasted during the "entureLs lifetie. +is4 refers to

a situation in 5hich a pro2a2ility distri2ution of future returns can not 2e

esta2lished for the "enture. The ris4iness of the "enture can 2e defined as the

"aria2ility or dispersion of its future returns. 7n practice! there are usually se"eral

"aria2les and the aggregate ris4 of the "enture can not 2e deterined easily

2ecause it is coposed of nuerous ris4s. The purpose of ris4 analysis is to

isolate the ris4s and to pro"ide a eans 2y 5hich "arious "enture outcoes can

2e reduced to a forat fro 5hich a decision can 2e ade. A ore detailed

co"erage can 2e found under profita2ility analysis.

Fea)*!*&*(" .%)( E)(*1a(e)

A lot of guess 5or4 goes into feasi2ility cost estiate. Attepts are al5ays

ade to collect and update historical figures 5ith additions for escalation < inflation

and local factors! 2ased on statistics and guess 5or4. 7n such a situation 5hat is

e>pected is a rule of thu2 or an order of agnitude estiate. The order of

agnitude estiate is deri"ed fro the cost reports of copleted "entures.

Pro2a2ility of this estiates accuracy is generally 2et5een N.$! and /) percent.

Preliinary control estiate is often used in the feasi2ility report.

This is prepared! generally! after the copletion of the process design and

a3or e6uipent listing. Accuracy of this estiate ay "ary 2et5een N %$ and .$

percent. Endea"our is usually ade to achie"e a N.) percent accuracy in the

feasi2ility report estiates. For a rule of thu2! the follo5ing are the percentages

of the "enture cost factors:

8Pro3ect de"elopent and detailed pro3ect report (-P+) preparation 8 . O

8Engineering and design 8 %' O

8Brought out aterials and e6uipent8$$ O

8Fa2rication and construction8 ') O

-epending on the type of "enture! sector and cople>ity! these can "ary on either

side.

27

LECTURE NO. 7

#REA; EVEN ANALYSIS0 INTRODUCTION3 #REA;-EVEN CHART3 FI@ED

COSTS3 VARIA#LE COSTS3 #REA; EVEN POINT CALCULATION

Break-Even Analysis

I'(r%,.(*%'

Brea48e"en analysis is a techni6ue 5idely used 2y production anageent

and anageent accountants. 7t is 2ased on categoriCing production costs

2et5een those 5hich are J"aria2leJ (costs that change 5hen the production output

changes) and those that are Jfi>edJ (costs not directly related to the "olue of

production).

Total "aria2le and fi>ed costs are copared 5ith sales re"enue in order to

deterine the &e2e& %/ )a&e) 2%&,1e3 )a&e) 2a&,e %r pr%,.(*%' a( 7-*.- (-e

!,)*'e)) 1a5e) 'e*(-er a pr%/*( '%r a &%)) ((-e A!rea5-e2e' p%*'(A).

BA 2rea4e"en analysis *) ,)e (% e(er1*'e -%7 1,.- )a&e) 2%&,1e "%,r

!,)*'e)) 'ee) (% )(ar( 1a5*'+ a pr%/*(.C

T-e #rea5-E2e' C-ar(

7n its siplest for! the 2rea48e"en chart is a graphical representation of

costs at "arious le"els of acti"ity sho5n on the sae chart as the "ariation of

incoe (or sales! re"enue) 5ith the sae "ariation in acti"ity. The point at 5hich

neither profit nor loss is ade is 4no5n as the J2rea48e"en pointJ and is

represented on the chart 2elo5 2y the intersection of the t5o lines:

28

7n the diagra a2o"e! the line OA represents the "ariation of incoe at

"arying le"els of production acti"ity (JoutputJ). O# represents the total fi>ed costs

in the 2usiness. As output increases! "aria2le costs are incurred! eaning that

(%(a& .%)() (/*4e + 2ar*a!&e) also increase. At lo5 le"els of output! Costs are

greater than 7ncoe. At the p%*'( %/ *'(er)e.(*%'3 P! costs are e4a.(&" e6,a& (%

*'.%1e! and hence neither profit nor loss is ade.

F*4e C%)()

Fi>ed costs are those 2usiness costs that are '%( *re.(&" re&a(e to the

le"el of production or output. 7n other 5ords! e"en if the 2usiness has a Cero

output or high output! the le"el of fi>ed costs 5ill reain 2roadly the sae. 7n the

long ter fi>ed costs can alter 8 perhaps as a result of in"estent in production

capacity (e.g. adding a ne5 factory unit) or through the gro5th in o"erheads

re6uired to support a larger! ore cople> 2usiness.

Examples of fixed costs:

8 +ent and rates

8 -epreciation

8 +esearch and de"elopent

8 ;ar4eting costs (non8 re"enue related)

8 Adinistration costs

Var*a!&e C%)()

?aria2le costs are those costs 5hich "ary directly 5ith the le"el of output.

They represent payent output8related inputs such as ra5 aterials! direct

la2our! fuel and re"enue8related costs such as coission.

#rea5 E2e' P%*'( Ca&.,&a(*%'

Calculation of BEP can 2e done using the follo5ing forula :

: ; VCUP SUP

TFC

BEP

=

5here !

BEP P 2rea48e"en point (9nits of production)

TFC P total fi>ed costs

29

?C9P P "aria2le costs per unit of production

S9P P Selling price per unit of production

For e>aple! suppose that fi>ed costs for producing %))!))) 5idgets 5ere

Q')!))) a year. ?aria2le costs are Q...) aterials! Q/.)) la2our! and Q).@)

o"erhead! for a total of Q=.)). 7f selling price 5as chosen as Q%..)) for each

5idget! then: Brea4 e"en point 5ill 2e Q')!))) di"ided 2y (Q%..)) 8 =.))) e6uals

&))) units.This is the nu2er of 5idgets that ha"e to 2e sold at a selling price of

Q%..)) 2efore 2usiness 5ill start to a4e a profit.

A2a'(a+e) %/ #rea5 E2e' A'a&")*)

7t e>plains the relationship 2et5een cost! production "olue and returns.

The a3or 2enefit to using 2rea48e"en analysis is that it indicates the lo5est

aount of 2usiness acti"ity necessary to pre"ent losses.

L*1*(a(*%') %/ #rea5-e2e' -A'a&")*)

7t is 2est suited to the analysis of one product at a tie

30

LECTURE NO. 8

PLANT LOCATION0 INTRODUCTION3 LOCATION DECISION PROCESS3

FACTORS INVOLVED IN THE PLANT LOCATION DECISION

I'(r%,.(*%'

Plant location decisions are strategic! long ter and non8repetiti"e in

nature. Bithout sound and careful location planning in the 2eginning itself! the

ne5 plant ay pose continuous operating disad"antages. :ocation decisions are

affected 2y any factors! 2oth internal and e>ternal to the organiCationMs

operations.

7nternal factors include the technology used! the capacity! the financial

position! and the 5or4 force re6uired.

E>ternal factors include the econoic! political and social conditions in the

"arious localities.

;ost of the fi>ed and soe of the "aria2le costs are deterined 2y the

location decision. The efficiency! effecti"eness! producti"ity and profita2ility of the

plant are also affected 2y the location decision. :ocation decisions are 2ased on a

host of factors! soe su23ecti"e! 6ualitati"e and intangi2le 5hile soe others are

o23ecti"e! 6uantitati"e and tangi2le.

:-e' D%e) a L%.a(*%' De.*)*%' Ar*)eD

The ipetus to e2ar4 upon a plant location study can 2e attri2uted to

reasons as gi"en 2elo5:

7t ay arise 5hen a ne5 plant is to 2e esta2lished.

7n soe cases! the plant operations and su2se6uent e>pansion are

restricted 2y a poor site! there2y necessitating the setting up of the facility

at a ne5 site.

The gro5ing "olue of 2usiness a4es it ad"isa2le to esta2lish additional

facilities in ne5 territories.

-ecentraliCation and dispersal of industries reflected in the industrial policy

resolution so as to achie"e an o"erall de"elopent 5ould necessitate a

location decision at a acro le"el.

7t could happen that the original ad"antages of the plant ha"e 2een

out5eighed due to ne5 de"elopents.

Ne5 econoic! social! legal or political factors could suggest a change of

location of the e>isting plant.

31

Soe or all the a2o"e factors could force a fir or an organiCation to

6uestion 5hether the location of its plant should 2e changed or not.

Bhene"er the plant location decision arises! it deser"es careful attention

2ecause of the long8ter conse6uences. Any ista4e in selection of a proper

location could pro"e to 2e costly. Poor location could 2e a constant source of

higher cost! higher in"estent! difficult ar4eting and transportation! dissatisfied

and frustrated eployees and consuers! fre6uent interruptions of production!

a2noral 5astage! delays and su2standard 6uality! denied ad"antages of

geographical specialiCation and so on. 1nce a plant is set up at a location! it is

"ery difficult to shift later to a 2etter location 2ecause of nuerous econoic!

political and sociological reasons.

Ra7 $a(er*a&

1n the 2asis of a"aila2ility! the ra5 aterials can 2e categoriCed into:

(a) u2i6uitous8to denote those a"aila2le alost e"ery5here and

(2) localiCed aterials! ha"ing specific locations! 5hich are further di"ided

into pure aterial 5hich contri2utes nearly the total 5eight of it to the finished

products! and gross aterial! 5hich contri2utes only a sall fraction of total

5eight to the finished products. 7t is o2"ious that u2i6uitous hardly influence the

decision of location. A aterial inde> has 2een proposed! 5hich e6uals the 5eight

of localiCed aterial used in the finished product di"ided 2y the 5eight of the

finished product.

0!o'1c% 3ini)he' %he o3 <ei2h%

0!o'1c% 3ini)he' in %he 1)e' a%e!ial local o3 <ei2h%

;#I: In'e= #a%e!ial =

7f the aterial inde> is greater than unity! location should 2e nearer to the

source of ra5 aterial and if it is less than unity! then a location nearer to ar4et

is ad"ised.

L%.a(*%' De.*)*%' Pr%.e))

Ta2le gi"en 2elo5 lists possi2le foral steps in a plant location decision

process. The actual approach "aries 5ith the siCe and scope of operations.

The o23ecti"es are influenced 2y! o5ners! suppliers! eployees and

custoers of the organiCation influence the o23ecti"es. They ay ste fro

opportunities (or concerns) 5ith respect to any phase of the production syste

(i.e. inputs! processing! or outputs). The follo5ing sections descri2e the "aria2les!

criteria and odels rele"ant to the location decision process.

32

Ta!&e Steps in a facility location decision

% -efine the location o23ecti"es and associated "aria2les

. 7dentify the rele"ant decision criteria

R 6uantitati"e8econoic

R 6ualitati"e 8 less tangi2le

' +elate the o23ecti"es to the criteria in the for of a odel! or odels ( such

as 2rea48e"en! linear prograing! 6ualitati"e factor analysis)

/ 0enerate necessary data and use the odels to e"aluate the alternati"e

locations

$ Select the location that 2est satisfies the criteria

Fa.(%r) I'2%&2e I' (-e P&a'( L%.a(*%' De.*)*%'

:ocation studies are usually ade in t5o phases naely!

7. the general territory selection phase and

II> the e>act site < counity selection phase aongst those a"aila2le in the

general locale. The considerations "ary at the t5o le"els! though there is

su2stantial o"erlap as sho5n in the follo5ing Ta2le.

Ta!&e Fa.(%r) *'2%&2e *' (-e (7% )(a+e) %/ p&a'( &%.a(*%' )(,"

L%.a(*%' /a.(%r) Ge'era& (err*(%r"

)e&e.(*%'

Se&e.(*%' %/ )pe.*/*.

)*(e

;ar4et R

+a5 aterial R

Po5er R R

Transportation R R

Cliate and fuel R

Euan resource and

5ages

R R

+egulatory la5s and

ta>es

R R

Counity ser"ices R

Bater and 5aste R

Ecology and pollution R

Capital a"aila2ility R R

Site characteristics R

Security R R

A typical tea studying location possi2ilities for a large pro3ect ight

in"ol"e econoists! accountants! to5n planners! ar4eting e>perts! legal e>perts!

politicians! e>ecuti"es! industrial engineers! ecologists etc. 7t is indeed an

interdisciplinary tea that should 2e set up for underta4ing location studies.

33

LECTURE NO.

TERRITORY SELECTION AND SITE9 CO$$UNITY SELECTION

Terr*(%r" Se&e.(*%'

For the general territory < region < area! the follo5ing are soe of the

iportant factors that influence the selection decision.

1. $ar5e()0 There has to 2e soe custoer < ar4et for the product. The ar4et

gro5th potential and the location of copetitors are iportant factors that could

influence the location. :ocating a plant or facility nearer to the ar4et is preferred

if proptness of ser"ice is re6uired particularly if the product is suscepti2le to

spoilage. Also if the product is relati"ely ine>pensi"e and transportation costs add

su2stantially to the cost! a location close to the ar4et is desira2le.

2. Ra7 1a(er*a&) a' ),pp&*e): Soeties accessi2ility to "endors<suppliers of

ra5 aterials! e6uipent etc. ay 2e "ery iportant. The issue here is

proptness and regularity of deli"ery and in5ard freight cost iniiCation.

7f the ra5 aterial is 2ul4y or lo5 in cost! or if it is greatly reduced in 2ul4

"iC. transfored into "arious products and 2y8products or if it is perisha2le and

processing a4es it less so! then location near ra5 aterial source is iportant. 7f

ra5 aterials coe fro a "ariety of locations! the plant < facility ay 2e situated

so as to iniiCe total transportation costs. The costs "ary depending upon

specific routes! ode of transportation and specific product classifications

3. Tra')p%r(a(*%' /a.*&*(*e)0 Ade6uate transportation facilities are essential for

the econoic operation of production syste. For copanies that produce or 2uy

hea"y 2ul4y and lo5 "alue per ton coodities! 5ater transportation could 2e an

iportant factor in location plants.

<. $a'p%7er ),pp&"0 The a"aila2ility of s4illed anpo5er! the pre"ailing 5age

pattern! li"ing costs and the industrial relations situation influence the location.

=. I'/ra)(r,.(,re0 This factor refers to the a"aila2ility and relia2ility of po5er!

5ater! fuel and counication facilities in addition to transportation facilities.

>. Le+*)&a(*%' a' (a4a(*%': Factors such as financial and other incenti"es for

ne5 industries in 2ac45ard areas or no8industry8district centers! e>eption fro

certain state and local ta>es! octroi etc. are iportant.

S*(e 9 C%11,'*(" Se&e.(*%'

Ea"ing selected the general territory < region! one 5ould ha"e to go in for

site < counity selection. Soe factors rele"ant for this are:

34

1. C%11,'*(" /a.*&*(*e)0 These in"ol"e factors such as 6uality of life 5hich in

turn depends on a"aila2ility of facilities li4e education! places of 5orship! edical

ser"ices! police and fire stations! cultural! social and recreation opportunities!

housing! good streets and good counication and transportation facilities.

2. C%11,'*(" a((*(,e)0 These can 2e difficult to e"aluate. ;ost counities

usually 5elcoe setting up of a ne5 industry especially since it 5ould pro"ide

eployent opportunities to the local people directly or indirectly. Eo5e"er! in

case of polluting industries! they 5ould try their utost to locate the as far a5ay

as possi2le. Soeties 2ecause of pre"ailing la5 and order situation! copanies

ha"e 2een forced to relocate their units. The attitude of people as 5ell as the state

go"ernent has an ipact on location of polluting and haCardous industries.

3. :a)(e *)p%)a&0 The facilities re6uired for the disposal of process 5aste

including solid! li6uid and gaseous effluent need to 2e considered. The plant

should 2e positioned so that pre"ailing 5inds carry any fues a5ay fro

populated areas and that the 5aste ay 2e disposed off properly and at

reasona2le costs.

<. E.%&%+" a' p%&&,(*%'0 These days! there is a great deal of a5areness

to5ards aintenance of natural ecological 2alance. There are 6uite a fe5

agencies propagating the concepts to a4e the society at large ore conscious

of the dangers of certain a"aila2le actions.

=. S*(e )*8e0 The plot of land ust 2e large enough to hold the proposed plant and

par4ing and access facilities and pro"ide roo for future e>pansion.

>. T%p%+rap-"0 8The topography! soil structure and drainage ust 2e suita2le. 7f

considera2le land ipro"eent is re6uired! lo5 priced land ight turn out to 2e

e>pensi"e.

?. Tra')p%r(a(*%' /a.*&*(*e)0 The site should 2e accessi2le prefera2ly 2y road

and rail. The dependa2ility and character of the a"aila2le transport carriers!

fre6uency of ser"ice and freight and terinal facilities is also 5orth considering.

E. S,pp%r(*'+ *',)(r*e) a' )er2*.e)0 The a"aila2ility of supporting ser"ices

such as tool roos! plant ser"ices etc. need to 2e considered.

F. La' .%)()0 These are generally of lesser iportance! as they are non8

recurring and possi2ly a4e up a relati"ely sall proportion of the total cost of

locating a ne5 plant.

0enerally! the site 5ill 2e in a city! su2ur2 or country location. 7n general!

the location for large scale industries should 2e in rural areas! 5hich helps in

35

regional de"elopent also. 7t is seen that once a large industry is set up (or e"en

if a decision to this effect has 2een ta4en)! a lot of infrastructure de"elops around

it as a result of the location decision. As for the location of ediu scale

industries is concerned! these could 2e prefera2ly in the su2ur2an < sei8ur2an

areas 5here the ad"antages of ur2an and rural areas are a"aila2le. For the sall8

scale industries! the location could 2e ur2an areas 5here the infrastructural

facilities are already a"aila2le. Eo5e"er! in real life! the situation is soe5hat

parado>ical as people! 5ith oney and eans! are usually in the cities and 5ould

li4e to locate the units in the city itself.

Soe of the industrial needs and characteristics that tend to fa"our each of

this location are.

+e6uireents go"erning choice of a .*(" &%.a(*%' are:

A"aila2ility of ade6uate supply of la2our force

Eigh proportion of s4illed eployees

+apid pu2lic transportation and contact 5ith suppliers and

custoers

Sall plant site or ulti floor operation

Processes hea"ily dependent on city facilities and utilities

0ood counication facilities li4e telephone! tele>! post

offices

0ood 2an4ing and health care deli"ery systes

+e6uireents go"erning the choice of a ),!,r!a' &%.a(*%' are:

:arge plant site close to transportation or population centre

Free fro soe coon city 2uilding Coning (industrial

areas) and other restrictions

Freedo fro higher par4ing and other city ta>es etc.

:a2our force re6uired to reside close to the plant

Counity close to! 2ut not in large population centre

Plant e>pansion easier than in the city

+e6uireents go"erning the choice of a r,ra& &%.a(*%' are:

:arge plant site re6uired for either present deands or

e>pansion

-angerous production processes

:esser effort re6uired for anti8pollution easures

36

:arge "olue of relati"ely clean 5ater

:o5er property ta>es! a5ay fro 9r2an :and Ceiling Act

restrictions

Protection against possi2le sa2otage or for a secret process

Balanced gro5th and de"elopent of a de"eloping or

underde"eloped area

9ns4illed la2our force re6uired

:o5 5ages re6uired to eet copetition

37

LECTURE NO. 1!

SU#GECTIVE3 HUALITATIVE AND SE$I-HUANTITATIVE TECHNIHUES3

EHUAL :EIGHTS $ETHOD3 VARIA#LE :EIGHTS $ETHOD3 :EIGHT-CU$-

RATING $ETHOD3 ANOTHER :EIGHT-CU$-RATING $ETHOD