Professional Documents

Culture Documents

Quality Assurance-Food Safety Questionnaire: General Information: Date

Quality Assurance-Food Safety Questionnaire: General Information: Date

Uploaded by

FloreidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Assurance-Food Safety Questionnaire: General Information: Date

Quality Assurance-Food Safety Questionnaire: General Information: Date

Uploaded by

FloreidCopyright:

Available Formats

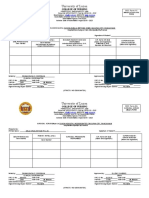

Quality Assurance- Food Safety Questionnaire

General Information:

Date: ___________________

Vendor# 2246352

Address:

_________________________________________________________

Vendor Name: __________________________

________________________________________________________

Main Contact: ___________________________

Phone: __________________________________________________________

Position: ________________________________

E-Mail:

__________________________________________________________

Indicate if you have certification for one of the followings:

SQF

BRC

ISO:

FSSC 22000

Other: __________________________________________

(Please provide copy of current Certificate)

Nature of Business: Primary Production

Food Manufacturing

Food Storage & Dist.

Other

(Please specify): __________________________________________________________________________________

Total number of staff at main site: Permanent (approx. #) __75__________

Temporary. (approx. #) ____30________

Social Responsibility

Yes/No or N/A

1

Does the company provide a safe, healthy work environment for all employees;

Y

comply with all laws that require the fair treatment of workers and prohibit the

use of forced, trafficked or child labor in connection with the production of any

merchandise?

2

Does the company employ a Non-Discriminatory Working Policy (race, color,

Y

religion, national origin, sex, age, disability) or other characteristics protected by

law?

3

Does the company have a Disciplinary Procedure in place? (Please provide a copy Y

of policy).

Comments:

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Processing Conditions, Procedures and Equipment

Yes/No or N/A

1

Do you have Inbound Inspections Procedures and Receiving Reports?

Is the Processing Line in straight flow to avoid Cross-Contamination points?

Is the Raw Material tracked from Receiving through Processing into Finished

Product?

Are Finished Products Temperature Requirements in place and is there an Action

Plan for Non-Conforming Product?

Do you have Food Allergens clearly identified and Control Procedures in place?

(peanuts, tree nuts, soy, milk, egg, wheat, fin fish and crustaceans)

Does your facility have a Physical Hazard Prevention Program (i.e., light bulbs

protected, peeling paint, rust, etc.)?

Does your facility have a method used to prevent Metal Contamination (i.e.,

metal detector equipment, in-line magnet traps, filters, etc. checking for ferrous,

non-ferrous, and stainless steel?)

4

5

6

7

January 6, 2013

Y

Y

Y

Y

Page 1

Are all Processing, Storage, Shipping and Receiving areas clean, in sanitary

Y

conditions and well organized?

Comments:

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Plant Quality Controls

Yes/No or N/A

Do you have Finished Product Specifications Manual and an Action Plan for NonConforming product?

Do you have a Traceability and Product Recall Program?

N

Y

Do you have a Pesticide Residual Analysis or a Pesticide Tracking Program?

Does your facility have a current Water Potability Certificate or Water Analysis

Certificate updated?

Is the temperature in all Processing, Storage, Shipping and Receiving areas

monitored and recorded?

Are Calibration/Certification of scales and temperature monitors recorded?

Does your facility have a current HACCP Program for the production process?

IN

PROCE

SS

Y&N

2

3

4

5

Y

Y

Does your facility have Laboratory Facilities or is there microbiological Tests

performed?

Comments: _________PRESENTLY IMPLEMENTING PROGRAM FOR HACCP______________________

Plant Cleaning and Sanitation

Yes/No or N/A

Does the facility have adequate written Good Manufacture Practices (GMPs)?

Are employees using proper attire for work? (i.e., gloves, hair restraint, apron, no

jewelry, etc.)

Are Master Sanitation Schedules and Pre-Operation Inspections Records

available?

Does the facility has an effective Pest/Rodent Control Program with the Control

Station Map in place and updated?

Are chemicals and Pest Control materials properly stored, locked and secured

with Material Safety Data Sheets (MSDS) binder available?

Are Hand Wash Stations properly stocked? (hot/cold potable water, soap, paper

towels, garbage containers and a hand wash sign posted)

Do you have a Plant Safety and Hygiene Program with ongoing employees

training?

Do you conduct an Outbound Trailers Inspections? ( ensuring all trailers are

cleaned prior to loading and temperature of trailers recorded)

Are the outside facility grounds clean and well maintained? (i.e., parking lot

paved or dust control mechanisms, garbage bins sealed, etc.)

Are doors or entry ways kept closed at all times and/or with security guards?

3

4

5

6

7

8

9

10

January 6, 2013

Y

Y

Y

Y

Y

Y

Y

Y

Page 2

11

Does the facility have all visitors access strictly controlled? (i.e., sign-in,

temporarily visit badge, etc.)

Vendor Signature _________________________________

Comments:

__________________________________________________________________________________________________

__________________________________________________________________________________________________

January 6, 2013

Page 3

You might also like

- Biology Unit 2 For Cape ExaminationsDocument275 pagesBiology Unit 2 For Cape ExaminationsArmaggedon86% (14)

- COPD Case StudyDocument14 pagesCOPD Case StudyNita Gopinath100% (1)

- VACCP Template - Food Fraud VulnerabilityDocument2 pagesVACCP Template - Food Fraud VulnerabilityFloreid79% (29)

- Supplier Evaluation FormDocument4 pagesSupplier Evaluation FormGaganpreet100% (4)

- Every Patient Tells A Story by Lisa Sanders, M.D. - ExcerptDocument24 pagesEvery Patient Tells A Story by Lisa Sanders, M.D. - ExcerptCrown Publishing Group78% (18)

- Medical Coding Training - CPC (PDFDrive)Document214 pagesMedical Coding Training - CPC (PDFDrive)Esther Rani100% (9)

- Food Safety QuestionnaireDocument4 pagesFood Safety QuestionnaireSheredapple Orticio100% (2)

- Positive Release FormDocument2 pagesPositive Release FormFloreid100% (3)

- Layered Process Audit FormDocument3 pagesLayered Process Audit FormPawan Sehrawat100% (7)

- H.7 Supplier Approval QuestionnaireDocument4 pagesH.7 Supplier Approval QuestionnairePrabhu Prabhu100% (1)

- Packaging Approval ChecklistDocument2 pagesPackaging Approval ChecklistFloreid100% (2)

- Form QP 07-2 Supplier Evaluation Questionnaire - REV 0Document3 pagesForm QP 07-2 Supplier Evaluation Questionnaire - REV 0Charles Bill Eldredge100% (1)

- ANNEXURE XIX (GMP-Questionnaire For Packing Material Suppliers) MerckDocument17 pagesANNEXURE XIX (GMP-Questionnaire For Packing Material Suppliers) Merckyagnaashi9092No ratings yet

- As 9100 Rev D Internal Audit Checklist SampleDocument4 pagesAs 9100 Rev D Internal Audit Checklist SampleHoang TanNo ratings yet

- DMAIICDocument5 pagesDMAIICFloreidNo ratings yet

- BCP Participant Feedback Form - FINALDocument2 pagesBCP Participant Feedback Form - FINALFloreidNo ratings yet

- Factory Assessment Questionaire - BlankDocument6 pagesFactory Assessment Questionaire - BlankFloreidNo ratings yet

- Factors Affecting Pineapple Quality KPIs 2014Document116 pagesFactors Affecting Pineapple Quality KPIs 2014Floreid100% (1)

- Supplier'S Audit Checklist: Requirements Ratings Remarks 0 1 2 3 4Document3 pagesSupplier'S Audit Checklist: Requirements Ratings Remarks 0 1 2 3 4Rofelin SamarNo ratings yet

- WHOINSP-Inj Check ListDocument32 pagesWHOINSP-Inj Check ListmaikaNo ratings yet

- Supplier Evaluation FormDocument12 pagesSupplier Evaluation FormMoiz NaeemNo ratings yet

- R20.28FSMS SRI Registration Survey For ISO 22000 or FSSC 22000Document4 pagesR20.28FSMS SRI Registration Survey For ISO 22000 or FSSC 22000TATITO0306091012No ratings yet

- Template Investigation of Sterility Test FailureDocument4 pagesTemplate Investigation of Sterility Test FailureMina Maher MikhailNo ratings yet

- Chemical Approval Form - Polintek Stop LeakDocument2 pagesChemical Approval Form - Polintek Stop LeakYosep SasadaNo ratings yet

- Chemical Approval Form - Polintek Lining & ProtectionDocument2 pagesChemical Approval Form - Polintek Lining & ProtectionYosep SasadaNo ratings yet

- Hygiene Check ListDocument15 pagesHygiene Check ListpatricioacurioNo ratings yet

- Farm Name - Doc 3.34 Supplier Approval QuestionnaireDocument3 pagesFarm Name - Doc 3.34 Supplier Approval QuestionnaireVeronica SebaldNo ratings yet

- QF-200-20-07 Ampco Supplier Profile QuestionnaireDocument5 pagesQF-200-20-07 Ampco Supplier Profile QuestionnaireDung Do ThanhNo ratings yet

- Chemical Approval Form - Polintek Lining & Protection Plus For MetalDocument2 pagesChemical Approval Form - Polintek Lining & Protection Plus For MetalYosep SasadaNo ratings yet

- Site Audit FormDocument16 pagesSite Audit FormNasir IbrahimNo ratings yet

- Hold and Release LogDocument2 pagesHold and Release LogPoulami DeNo ratings yet

- Production Department Business Plan: Company Quality-Control ProceduresDocument2 pagesProduction Department Business Plan: Company Quality-Control ProceduresJean PlajoNo ratings yet

- Pharmaceutical Wholesaler Checklist 2 0Document16 pagesPharmaceutical Wholesaler Checklist 2 0atulbs100% (2)

- Usda GapDocument28 pagesUsda Gaptstacct543No ratings yet

- Miflora M. Gatchalian-Food Safety Programs in Fish Processing From Farm To ForkDocument29 pagesMiflora M. Gatchalian-Food Safety Programs in Fish Processing From Farm To ForknataliatirtaNo ratings yet

- Borang Permohonan Skim HACCPDocument3 pagesBorang Permohonan Skim HACCPChan Chee LeongNo ratings yet

- Self Assessment Capability SurveyDocument3 pagesSelf Assessment Capability SurveyAnbuNo ratings yet

- Food Quality Check Sample Requisition FormDocument2 pagesFood Quality Check Sample Requisition Formbenz bernardNo ratings yet

- Amar Ishwar Sawalkar. Mob. +91-9137571749, 8432840109 EmailDocument3 pagesAmar Ishwar Sawalkar. Mob. +91-9137571749, 8432840109 EmailAMAR SAWALKAR KANCHANJYOTI HEALTH CARE PUNENo ratings yet

- 2015 HBV EQA Result FormDocument3 pages2015 HBV EQA Result FormTiny Coffee HouseNo ratings yet

- Procurement and Supply Stakeholders Mock ExamDocument15 pagesProcurement and Supply Stakeholders Mock ExamLattifah SerweNo ratings yet

- 1 AS 9100 D Over ISO 9001 Audit Checklist SampleDocument3 pages1 AS 9100 D Over ISO 9001 Audit Checklist SamplePANDIYAN100% (1)

- SITHCCC202 - SITHCCC302 - SITHCCC303 - Final Assessment Learner GuideDocument19 pagesSITHCCC202 - SITHCCC302 - SITHCCC303 - Final Assessment Learner Guidejsebastian7.saNo ratings yet

- Pre-Qualification Questionaire For A VendorDocument8 pagesPre-Qualification Questionaire For A VendorMuhammad Owais100% (1)

- GSP For Warehouse and StoreDocument69 pagesGSP For Warehouse and StoreJohn OoNo ratings yet

- Process Validation ProtocolDocument10 pagesProcess Validation ProtocolDivya SekarNo ratings yet

- Yum! GAP Checklistv2Document9 pagesYum! GAP Checklistv2shani31No ratings yet

- Business Plan Template (Technical Drawing) Shane CunninghamDocument10 pagesBusiness Plan Template (Technical Drawing) Shane Cunninghamshamarasharpe48No ratings yet

- Quality Assurance PPT 2035Document20 pagesQuality Assurance PPT 2035divensinglaNo ratings yet

- CIDESCO Model Consent Form For Eyelash TintingDocument1 pageCIDESCO Model Consent Form For Eyelash Tintingmatina papaspyrouNo ratings yet

- Daily Inspection Report CISEDocument1 pageDaily Inspection Report CISEArsalan MahmoodNo ratings yet

- Gap Inc. 2015 - 16 CSR ReportDocument108 pagesGap Inc. 2015 - 16 CSR Reportyasin husenNo ratings yet

- P2 - Bba Entrepreneurship Project Log Book Top Sheet 2019-2020Document10 pagesP2 - Bba Entrepreneurship Project Log Book Top Sheet 2019-2020elvee.hrNo ratings yet

- 10 Examination Paper - ISO 9001 2015 QMS LATC - v3.2cDocument17 pages10 Examination Paper - ISO 9001 2015 QMS LATC - v3.2cbprajhr3226No ratings yet

- Quality Manual Template1Document27 pagesQuality Manual Template1Lenana KoikaiNo ratings yet

- 67 Dutch Presentation FSSC 22000Document28 pages67 Dutch Presentation FSSC 22000widyaNo ratings yet

- Audit Test ShalgaltDocument12 pagesAudit Test ShalgaltBgl TseNo ratings yet

- Total Quality Management: SubagyoDocument70 pagesTotal Quality Management: SubagyoAdri Muhaimin AfifNo ratings yet

- Practicum Form Mid Year Summer 2021Document22 pagesPracticum Form Mid Year Summer 2021Jayson GamoNo ratings yet

- CIS WSH sp02 77890 7Document18 pagesCIS WSH sp02 77890 7Gli OxalNo ratings yet

- Employee Evaluation Form - RRKDocument3 pagesEmployee Evaluation Form - RRKShannin MaeNo ratings yet

- 9IQA Case Studies 1 Rev 4Document4 pages9IQA Case Studies 1 Rev 4Raajha MunibathiranNo ratings yet

- User Manual 502591900: Getinge 46-SeriesDocument24 pagesUser Manual 502591900: Getinge 46-SeriesVagner Barbosa NovaisNo ratings yet

- Checklist Auditoria SQF 2010Document21 pagesChecklist Auditoria SQF 2010cramirez48No ratings yet

- AS-9100-Rev-D Internal-Audit-Checklist SampleDocument4 pagesAS-9100-Rev-D Internal-Audit-Checklist Samplesaifulramli69No ratings yet

- RubricsDocument1 pageRubricsARIEL ANGELIONo ratings yet

- ANNEX C On Site Monitoring FormDocument3 pagesANNEX C On Site Monitoring FormJohnRayFloresArquisolaNo ratings yet

- Role and Responsibility of Pharmaceutical Industry Plant PersonnelFrom EverandRole and Responsibility of Pharmaceutical Industry Plant PersonnelNo ratings yet

- Sterling Test Prep OAT Organic Chemistry Practice Questions: High Yield OAT Organic Chemistry QuestionsFrom EverandSterling Test Prep OAT Organic Chemistry Practice Questions: High Yield OAT Organic Chemistry QuestionsNo ratings yet

- Egg Safety: Consumer AdvisoryDocument2 pagesEgg Safety: Consumer AdvisoryFloreidNo ratings yet

- BCP Exercise Planner Instructions - FINAL - v6 - APR 25Document11 pagesBCP Exercise Planner Instructions - FINAL - v6 - APR 25FloreidNo ratings yet

- AnnuallyDocument70 pagesAnnuallyFloreidNo ratings yet

- Eating OutDocument1 pageEating OutFloreidNo ratings yet

- Caricom LabellingDocument15 pagesCaricom LabellingFloreidNo ratings yet

- Blind Taste Test ReportDocument63 pagesBlind Taste Test ReportFloreid50% (2)

- Whitepaper - Automated Audit ManagementDocument6 pagesWhitepaper - Automated Audit ManagementFloreidNo ratings yet

- Pineapple Sub SectionsDocument1 pagePineapple Sub SectionsFloreidNo ratings yet

- PostHarvest Technology - Topic 1 IntroductionDocument1 pagePostHarvest Technology - Topic 1 IntroductionFloreidNo ratings yet

- Batter Type # Brand Flavour Size Standard Viscosity by ASTM MethodDocument1 pageBatter Type # Brand Flavour Size Standard Viscosity by ASTM MethodFloreidNo ratings yet

- Iso 9001 2015Document4 pagesIso 9001 2015FloreidNo ratings yet

- Instruments - Puerto RicoDocument1 pageInstruments - Puerto RicoFloreidNo ratings yet

- NIST Handbook 133, Fourth Edition: Checking The Net Contents of Packaged GoodsDocument71 pagesNIST Handbook 133, Fourth Edition: Checking The Net Contents of Packaged Goodsakhilesh120No ratings yet

- Republic of The Philippines vs. Drugmakers G.R. No. 190837 March 5, 2014Document10 pagesRepublic of The Philippines vs. Drugmakers G.R. No. 190837 March 5, 2014herbs22225847No ratings yet

- Massage Therapy PDFDocument1 pageMassage Therapy PDFVirgilio BernardinoNo ratings yet

- Message CEAP 2023Document2 pagesMessage CEAP 2023Given GiftNo ratings yet

- Taenia SagitaDocument3 pagesTaenia SagitaNur LiyanaNo ratings yet

- Flavouring and SavouringDocument4 pagesFlavouring and SavouringVaishaly MA Psych sem1No ratings yet

- DS-1 Q&aDocument3 pagesDS-1 Q&aGotcha148100% (2)

- Harmony XB4 - XB4BD53Document5 pagesHarmony XB4 - XB4BD53vNo ratings yet

- Adalimumab: General InformationDocument6 pagesAdalimumab: General InformationAhmed Ben MohamedNo ratings yet

- A Perspective in Accelerated Orthodontics With Aligner Treatment 2017 Seminars in OrthodonticsDocument7 pagesA Perspective in Accelerated Orthodontics With Aligner Treatment 2017 Seminars in Orthodonticsdruzair007No ratings yet

- Sở Gd&Đt Quảng NamDocument4 pagesSở Gd&Đt Quảng NamSapinette Le Phương HòaNo ratings yet

- Datasheets For LuminairesDocument5 pagesDatasheets For Luminairesronniee287No ratings yet

- Soal SMSTR Genap Bahasa InggrisDocument7 pagesSoal SMSTR Genap Bahasa InggrisEric WilkersonNo ratings yet

- Print Ko BukasDocument3 pagesPrint Ko BukasKatrina CaveNo ratings yet

- HRST Housekeeping Module April 6Document9 pagesHRST Housekeeping Module April 6Mary Jane OcampoNo ratings yet

- Acid Value and Amine Value of Fatty Quaternary Ammonium ChloridesDocument3 pagesAcid Value and Amine Value of Fatty Quaternary Ammonium ChloridesShaker Qaidi100% (1)

- Demand Side Policies CanadaDocument3 pagesDemand Side Policies CanadaIva ChadikovskaNo ratings yet

- ALUMINIUMTECHNOLOGIES Week1 PDFDocument141 pagesALUMINIUMTECHNOLOGIES Week1 PDFNasional GotongroyongNo ratings yet

- Standard Operating ProcedureDocument11 pagesStandard Operating ProcedureproteoglycanNo ratings yet

- Designing A World Class Health Care System - NAAJ April 2003Document23 pagesDesigning A World Class Health Care System - NAAJ April 2003Fatma Risda HidayantiNo ratings yet

- 10P 2L8M D5 V3 Product SpecificationsDocument6 pages10P 2L8M D5 V3 Product SpecificationsAnkur PrasadNo ratings yet

- 4we10 .. Serie 5XDocument24 pages4we10 .. Serie 5XDanilo BrunelloNo ratings yet

- Anesthetics and Analgesics SheepDocument1 pageAnesthetics and Analgesics Sheepari putraNo ratings yet

- Thursday 200L Physiology Practical Groups 2021Document3 pagesThursday 200L Physiology Practical Groups 2021Ezih SharahNo ratings yet

- Modicon TM3 - TM3DI16Document8 pagesModicon TM3 - TM3DI16Abdan SyakuraNo ratings yet

- SOP02: Standard Operating Procedure For Staff Training & RecordsDocument12 pagesSOP02: Standard Operating Procedure For Staff Training & Recordsnihal mujawarNo ratings yet

- Collective Nouns Worksheet Answers: A Brood of ChicksDocument2 pagesCollective Nouns Worksheet Answers: A Brood of ChicksGirish NagNo ratings yet