Professional Documents

Culture Documents

Sec Viii d2 Art D-3

Sec Viii d2 Art D-3

Uploaded by

Yuber Rodriguez HOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sec Viii d2 Art D-3

Sec Viii d2 Art D-3

Uploaded by

Yuber Rodriguez HCopyright:

Available Formats

ARTICLE D-3

SHELLS OF REVOLUTION UNDER

EXTERNAL PRESSURE

1

AD-300 SCOPE

The rules given in this Article for determining the

thicknesses of vessels under external pressure are appli-

cable to spherical, conical, and cylindrical shells with

or without stiffening rings, to formed heads, and to

tubular products (see AF-130.2). Charts for use in

determining the thicknesses of these components are

given in Subpart 3 of Section II, Part D.

AD-300.1 Nomenclature. The symbols used in this

Article are dened as follows:

Apfactor determined from Fig. G in Subpart 3 of

Section II, Part D and used to enter the applica-

ble material chart in Subpart 3 of Section II,

Part D. For the case of cylinders having D

o

/t

values less than 10, see AD-310.2. Also, factor

determined from the applicable chart in Subpart

3 of Section II, Part D for the material used in

a stiffening ring, corresponding to the factor B

(see below) and the design metal temperature

for the shell under consideration.

A

eL

peffective area of reinforcement at large end in-

tersection due to excessive metal thickness, sq

in. (mm

2

)

A

es

peffective area of reinforcement at small end in-

tersection due to excessive metal thickness, sq

in. (mm

2

)

A

rL

prequired area of reinforcement at large end of

cone, sq in. (mm

2

)

A

rs

prequired area of reinforcement at small end of

cone, sq in. (mm

2

)

A

s

pcross-sectional area of the stiffening ring, sq in.

(mm

2

)

A

T

pequivalent area of cylinder, cone, and stiffening

ring, sq in. (mm

2

), where

1

For formed heads under pressure on the convex side, this may be

either internal or external pressure, depending on the orientation of

the head on the shell.

88

A

TL

p

L

L

t

2

+

L

c

t

r

2

+ A

s

for large end

A

TS

p

L

sm

t

2

+

L

c

t

r

2

+ A

s

for small end

Bpfactor determined from the applicable chart in

Subpart 3 of Section II, Part D for the material

used in a shell or stiffening ring at the design

metal temperature

D

L

poutside diameter of large end of conical section

under consideration, in. (mm)

D

o

poutside diameter of cylindrical shell, in. (mm)

(In conical shell calculations, the value of D

s

or D

L

should be used in calculations in place

of D

o

, depending on whether the small end D

s

or large end D

L

, is being examined.)

D

o

/2h

o

pratio of the major to the minor axis of ellipsoidal

heads, which equals the outside diameter of the

head skirt divided by twice the outside height

of the head (see Table AD-350.2)

D

s

poutside diameter of small end of conical section

under consideration, in. (mm)

Epmodulus of elasticity of the material at design

temperature, psi (kPa). For external pressure

and axial design in accordance with this Section,

the modulus of elasticity to be used shall be

taken from the applicable materials chart in

Subpart 3 of Section II, Part D.

2

(Interpolation

may be made between lines for intermediate

temperatures.)

E

c

pmodulus of elasticity of cone material, psi (kPa)

E

r

pmodulus of elasticity of stiffening ring material,

psi (kPa)

2

Note that the modulus of elasticity values listed in Subpart 3 of

Section II, Part D for specic material groups may differ from those

values listed in Table TM-1 of Section II, Part D and need only

be applied for external pressure and axial compression design.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

AD-300.1 PART AD DESIGN REQUIREMENTS AD-300.1

E

s

pmodulus of elasticity of shell material, psi (kPa)

f

1

paxial load at large end due to wind, dead load,

etc., excluding pressure, lb/in. (kN/m)

f

2

paxial load at small end due to wind, dead load,

etc., excluding pressure, lb/in. (kN/m)

h

o

pone-half of the length of the outside minor axis

of the ellipsoidal head, or the outside height of

the ellipsoidal head measured from the tangent

line (head-bend line), in. (mm)

Ipavailable moment of inertia of combined ring

shellcone cross section about its neutral axis

parallel to the axis of the shell, in.

4

(mm

4

). The

width of shell which is taken as contributing to

the moment of inertia of the combined section

shall not be greater than 1.10D

o

t

s

and shall be

taken as lying one-half on each side of the

centroid of the ring. Portions of the shell plate

shall not be considered as contributing area to

more than one stiffening ring.

CAUTIONARY NOTE: Stiffening rings may be subject to lateral

buckling. This should be considered in addition to the requirements

for I

s

and I.

I

s

prequired moment of inertia of the combined

ringshellcone cross section about its neutral

axis parallel to the axis of the shell, in.

4

(mm

4

)

If the stiffeners should be so located that the maximum

permissible effective shell sections overlap on either

or both sides of a stiffener, the effective shell section

for that stiffener shall be shortened by one-half of each

overlap.

kp1 when additional area of reinforcement is not

required

py/S

r

E

r

when a stiffening ring is required, but k

not less than 1.0

K

o

pa factor depending on the ellipsoidal head pro-

portions D

o

/2h

o

(see Table AD-350.2)

Lptotal length of a tube between tubesheets, or the

design length of a vessel section, taken as the

largest of the following:

(a) the distance between head tangent lines

plus one-third of the depth of each head if there

are no stiffening rings (excluding conical heads

and sections);

(b) the distance between cone-to-cylinder

junctions for vessels with conical heads if there

are no stiffening rings;

(c) the greatest center-to-center distance be-

tween any two adjacent stiffening rings;

(d) the distance from the center of the rst

stiffening ring to the head tangent line plus one-

third of the depth of the head (excluding conical

89

heads and sections), all measured parallel to the

axis of the vessel, in. (mm); or

(e) the distance from the rst stiffening ring

in the cylinder to the cone-to-cylinder junction.

L

c

plength of cone between stiffening rings mea-

sured along surface of cone, in. For cones with-

out intermediate stiffeners,

L

c

p

L

x

2

+ (R

L

R

s

)

2

L

e

pequivalent length of conical section, in. (mm)

p(L

x

/ 2)(1 + D

s

/ D

L

)

L

L

pdesign length of a vessel section, in. (mm), taken

as the largest of the following:

(a) the center-to-center distance between the

cone-to-large-shell junction and an adjacent

stiffening ring on the large shell;

(b) the distance between the cone-to-large-

shell junction and one-third the depth of head

on the other end of the large shell if no other

stiffening rings are used.

L

s

pone-half of the distance from the centerline of

the stiffening ring to the next line of support

on one side, plus one-half of the centerline dis-

tance to the next line of support on the other side

of the stiffening ring, both measured parallel to

the axis of the component, in. (mm). A line of

support is:

(a) a stiffening ring that meets the require-

ments of this paragraph;

(b) a circumferential line on a head at one-

third the depth of the head from the head tan-

gent line;

(c) a circumferential connection to a jacket

for a jacketed section of a cylindrical shell; or

(d) a cone-to-cylinder junction.

L

sm

pdesign length of a vessel section, in. (mm), taken

as the largest of the following:

(a) the center-to-center distance between the

cone-to-small-shell junction and an adjacent

stiffening ring on the small shell;

(b) the distance between the cone-to-small-

shell junction and one-third the depth of head

on the other end of the small shell if no other

stiffening rings are used.

L

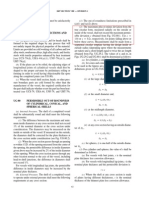

x

paxial length of cone, per Fig. AD-300.1, in.

(mm)

Ppexternal design pressure, psi (kPa)

P

a

pmaximum allowable external working pressure,

psi (kPa) (gage or absolute, as required)

Q

L

palgebraical sum of PR

L

/2 and f

1

, lb/in. (kN/m)

Q

s

palgebraical sum of PR

s

/2 and f

2

, lb/in. (kN/m)

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Fig. AD-300.1 2001 SECTION VIII DIVISION 2

FIG. AD-300.1 LENGTH L

x

OF SOME TYPICAL CONICAL SECTIONS FOR EXTERNAL PRESSURE

90

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

AD-300.1 PART AD DESIGN REQUIREMENTS AD-310.2

R

L

poutside radius of large cylinder, in. (mm)

R

o

pfor spherical shell, the outside radius, in. (mm)

pfor hemispherical head, the outside radius, in.

(mm)

pfor ellipsoidal head, the equivalent outside

spherical radius taken as K

o

D

o

, in. (mm)

pfor torispherical head, the outside radius of the

crown portion of the head, in. (mm)

R

s

poutside radius of small cylinder, in. (mm)

Spthe lesser of 1.5S

m

at design metal temperature

from the tables in Subpart 1 of Section II, Part

D, or 0.9 times the tabulated yield strength at

design metal temperature from the tables in

Subpart 1 of Section II, Part D, ksi (kPa)

S

c

pallowable stress intensity of cone, psi (kPa)

S

r

pallowable stress intensity of stiffening ring ma-

terial, psi (kPa)

S

s

pallowable stress intensity of shell, psi (kPa)

tpminimum required thickness of cylindrical shell

or tube, of spherical shell, or of formed head,

in. (mm)

t

c

pnominal thickness of cone at cone-to-cylinder

junction, in. (mm)

t

e

peffective thickness of conical section, in. (mm)

pt

r

cos

t

r

pminimum required thickness of cone at cone-

to-cylinder junction, in. (mm)

t

s

pnominal thickness used, of a cylindrical shell

or tube (for pipe, the tolerance requirements of

AF-105.2 shall apply), in. (mm)

ypcone-to-cylinder factor

pS

s

E

s

for stiffening ring on shell

pS

c

E

c

for stiffening ring on cone

pone-half the included (apex) angle of the cone

at the centerline of the head

pvalue to indicate need for reinforcement at cone-

to-cylinder intersection having a half apex angle

60 deg. When , no reinforcement is

required at the junction (see Table AD-360.3).

AD-310 CYLINDRICAL SHELLS AND

TUBES

The minimum required thickness of a cylindrical

shell or tube under external pressure, either seamless

or with longitudinal butt joints, shall be determined by

the following procedure.

AD-310.1 Cylinders Having D

o

/ t Values 10

Step 1. Assume a value for t and determine the

ratios L/ D

o

and D

o

/t.

Step 2. Enter Fig. G in Subpart 3 of Section II, Part

D at the value of L/D

o

determined in Step 1. For

91

values of L/D

o

greater than 50, enter the chart at a

value of L/D

o

of 50. For values of L/D

o

less than

0.05, enter the chart at a value of L/D

o

p 0.05.

Step 3. Move horizontally to the line for the value

of D

o

/t determined in Step 1. Interpolation may be

made for intermediate values of D

o

/t. From this intersec-

tion move vertically downwards and read the value of

factor A.

Step 4. Using the value of A calculated in Step 3,

enter the applicable material chart in Subpart 3 of

Section II, Part D for the material /temperature under

consideration. Move vertically to an intersection with

the material-temperature line for the design temperature

(see AD-121.2). Interpolation may be made between

lines for intermediate temperatures. In cases where the

value at A falls to the right of the end of the material-

temperature line, assume an intersection with the hori-

zontal projection of the upper end of the material-

temperature line. For values at A falling to the left of

the material line, see Step 7.

Step 5. From the intersection obtained in Step 4,

move horizontally to the right and read the value of

factor B.

Step 6. Using this value of B, calculate the value

of the maximum allowable external working pressure

P

a

using the following formula:

P

a

p

4B

3(D

o

/ t)

Step 7. For values of A falling to the left of the

applicable material-temperature line, the value of P

a

can be calculated using the following formula:

P

a

p

2AE

3(D

o

/ t)

Step 8. Compare P

a

with P. If P

a

is smaller than

P, select a larger value for t and repeat the design

procedure until a value for P

a

is obtained that is equal

to or greater than P. An example illustrating the use

of this procedure is given in G-112.

AD-310.2 Cylinders Having D

o

/ t Values < 10

Step 1. Using the same procedure as given in AD-

310.1, obtain the value of B. For values of D

o

/t less

than four, the value of factor A can be calculated using

the following formula:

A p

1.1

(D

o

/ t)

2

For values of A greater than 0.10, use a value of 0.10.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

AD-310.2 2001 SECTION VIII DIVISION 2 AD-331

Step 2. Using the value of B obtained in Step 1,

calculate a value P

a1

using the following formula:

P

a1

p

2.167

(D

o

/ t)

0.0833

B

Step 3. Calculate a value P

a2

using the following

formula:

P

a2

p

2S

D

o

/ t

1

1

D

o

/ t

where S is the lesser of 1.5S

m

at design metal tempera-

ture from the applicable table in Subpart 1 of Section

II, Part D, or 0.9 times the tabulated yield strength of

the material at design metal temperature from the

applicable table in Subpart 1 of Section II, Part D.

Step 4. The smaller of the values of P

a1

calculated

in Step 2 or P

a2

calculated in Step 3 shall be used

for the maximum allowable external working pressure

P

a

. Compare P

a

with P. If P

a

is smaller than P, select

a larger value for t and repeat the design procedure

until a value for P

a

is obtained that is equal to or

greater than P.

AD-320 SPHERICAL SHELLS

The minimum required thickness of a spherical shell

under external pressure, either seamless or of built-up

construction with butt joints, shall be determined by

the following procedure.

Step 1. Assume a value for t and calculate the value

of factor A using the following formula:

A p 0.125 / (R

o

/ t)

Step 2. Using the value of A calculated in Step 1,

enter the applicable material chart in Subpart 3 of

Section II, Part D for the material under consideration.

Move vertically to an intersection with the material-

temperature line for the design temperature (see AD-

121.2). Interpolation may be made between lines for

intermediate temperatures. In cases where the value at

A falls to the right of the end of the material-temperature

line, assume an intersection with the horizontal projec-

tion of the upper end of the material-temperature line.

For values at A falling to the left of the material-

temperature line, see Step 5.

Step 3. From the intersection obtained in Step 2,

move horizontally to the right and read the value of

factor B.

92

Step 4. Using the value of B obtained in Step 3,

calculate the value of the maximum allowable external

working pressure P

a

using the following formula:

P

a

p B/ (R

o

/ t)

Step 5. For values of A falling to the left of the

applicable material-temperature line, the value of P

a

can be calculated using the following formula:

P

a

p

0.0625E

(R

o

/ t)

2

Step 6. Compare P

a

obtained in Step 4 or 5 with

P. If P

a

is smaller than P, assume a larger value of

t and repeat the design procedure until a value for P

a

is obtained that is equal to or greater than P. An

example illustrating the use of this procedure is given

in G-113.

AD-330 STIFFENING RINGS FOR

CYLINDRICAL SHELLS

AD-331 Moment of Inertia for

Circumferential Stiffening Rings

The required moment of inertia of the combined

ringshell section is given by the following formula:

I

s

p

D

o

2

L

s

(t + A

s

/ L

s

)A

10.9

The moment of inertia for a stiffening ring shall be

determined by the following procedure.

Step 1. Assuming that the shell has been designed

and D

o

, L

s

, and t are known, select a member to be

used for the stiffening ring and determine its cross-

sectional area A

s

, and the value of I

s

dened in AD-

331. Then calculate B using the following formula:

B p

3

4

PD

o

t + A

s

/ L

s

Step 2. Enter the right-hand side of the applicable

material chart in Subpart 3 of Section II, Part D for

the material under consideration at the value of B

determined in Step 1. If different materials are used

for the shell and stiffening ring, then use the material

chart resulting in the larger value for factor A in Step

4 or 5 below.

Step 3. Move horizontally to the left to the material-

temperature line for the design metal temperature. For

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

AD-331 PART AD DESIGN REQUIREMENTS AD-340

values of B falling below the left end of the material-

temperature line, see Step 5.

Step 4. Move vertically to the bottom of the chart

and read the value of A.

Step 5. For values of B falling below the left end

of the material-temperature line for the design tempera-

ture, the value of A can be calculated using the following

formula:

A p 2B/ E

Step 6. If the required I

s

is greater than that computed

for the combined ringshell section I in Step 1, a new

section with a larger moment of inertia must be selected

and a new moment of inertia determined. If I

s

is smaller

than I computed for the section selected, then that

section should be satisfactory.

An example of the use of this procedure is given

in G-114.

AD-332 Arrangement of Stiffening Rings

Stiffening rings shall extend completely around the

vessel except as provided in (c)(1), (2), and (3) below.

(a) Any joints between the ends or sections of such

rings, as shown in Fig. AD-332.1 (A) and (B), and

any connection between adjacent portions of a stiffening

ring lying inside or outside the shell, as shown in (C),

shall be made so that the required moment of inertia

of the combined ringshell section is maintained. For

a strut section, as shown in Fig. AD-332.1 (D), the

required moment of inertia shall be supplied by the

strut alone.

(b) Stiffening rings placed on the inside of a vessel

may be arranged as shown in Fig. AD-332.1 (E) and

(F) provided that the required moment of inertia of

the ring in (E) or of the combined ringshell section

in (F) is maintained within the sections indicated. Where

the gap at (A) or (E) does not exceed eight times the

thickness of the shell plate, the combined moment of

inertia of the shell and stiffener may be used.

(c) Any gap in that portion of a stiffening ring

supporting the shell, as shown in Fig. AD-332.1 (D)

and (E), shall not exceed the length of arc given in Fig.

AF-130.3 unless additional reinforcement is provided as

shown in (C) or unless:

(1)

the length of unsupported shell arc does not

exceed 90 deg; and

(2)

the unsupported shell arcs in adjacent stiffening

rings are staggered 180 deg; and

(3)

the dimension L dened in AD-300.1 is taken

as the larger of the distance between alternate stiffening

93

rings or the distance from the head-bend line to the

second stiffening ring plus one-third of the head depth.

(d) When internal plane structures perpendicular to

the longitudinal axis of the cylinder, such as bubble

trays or bafe plates, are used in a vessel, they may

also be considered to act as stiffening rings provided

they are designed to function as such.

(e) Any internal stays or supports used shall bear

against the shell of the vessel through the medium of

a substantially continuous ring.

AD-333 Permissible Methods of Attaching

Stiffening Rings

Stiffening rings shall be attached to either the outside

or the inside of the vessel by continuous welding (see

Fig. AD-912.1). Where gaps occur in the stiffening

ring, the attachment weld shall conform to the details

in Fig. AD-912.1 sketch (e).

AD-340 CYLINDERS UNDER AXIAL

COMPRESSION

The maximum allowable compressive stress to be

used in the design of cylindrical shells and tubes

subjected to loadings that produce longitudinal compres-

sive stresses in the shell or tube shall be the smaller

of the following values:

(a) the maximum allowable stress intensity at design

metal temperature from the tables in Subpart 1 of

Section II, Part D;

(b) the value of the factor B determined from the

applicable chart in Subpart 3 of Section II, Part D,

using the following denitions for the symbols on the

charts:

R

o

poutside radius of cylindrical shell or tube, in.

(mm)

tpminimum required thickness of cylindrical shell

or tube, in. (mm)

The value of B shall be determined from the applicable

chart in Subpart 3 of Section II, Part D in the following

manner.

Step 1. Using the selected values of t and R

o

, calculate

the value of factor A using the following formula:

A p 0.125 / (R

o

/ t)

Step 2. Using the value of A calculated in Step 1,

enter the applicable material chart in Subpart 3 of

Section II, Part D for the material under consideration.

Move vertically to an intersection with the material-

temperature line for the design temperature (see AD-

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Fig. AD-332.1 2001 SECTION VIII DIVISION 2

FIG. AD-332.1 VARIOUS ARRANGEMENTS OF STIFFENING RINGS FOR

CYLINDRICAL VESSELS SUBJECTED TO EXTERNAL PRESSURE

94

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

AD-340 PART AD DESIGN REQUIREMENTS AD-360.1

121.2). Interpolation may be made between lines for

intermediate temperatures. In cases where the value at

A falls to the right of the end of the material-temperature

line, assume an intersection with the horizontal projec-

tion of the upper end of the material-temperature line.

For values at A falling to the left of the material-

temperature line, see Step 4.

Step 3. From the intersection obtained in Step 2,

move horizontally to the right and read the value of

factor B. This is the maximum allowable compressive

stress for the values of t and R used in Step 1.

Step 4. For values of A falling to the left of the

applicable material temperature line, the value of B

can be obtained using the following formula:

B p AE/ 2

Step 5. Compare the value of B determined in Step

3 or 4 with the computed longitudinal compressive

stress in the cylindrical shell or tube using the selected

values of t and R

o

. If the value of B is smaller than

the computed compressive stress, a greater value of t

must be selected and the design procedure repeated

until a value of B is obtained which is greater than

the compressive stress computed for the loading on

the cylindrical shell or tube.

AD-350 FORMED HEADS

The minimum required thickness at the thinnest

point after forming of hemispherical, ellipsoidal, or

torispherical heads under pressure on the convex side

3

(minus heads) shall be determined by the appropriate

rules or formulas in the following subparagraphs.

AD-350.1 Hemispherical Heads. The minimum re-

quired thickness of a hemispherical head having pressure

on the convex side shall be determined in the same

manner as given in AD-320 for determining the mini-

mum required thickness for a spherical shell.

AD-350.2 Ellipsoidal Heads. The minimum required

thickness of an ellipsoidal head having pressure on the

convex side, either seamless or of built-up construction

with butt joints, shall not be less than that determined

by the same design procedure as is used for spherical

shells in AD-320, except that the value of R

o

for

3

Pressure on the convex side may be caused by either internal

pressure or external pressure, depending upon the orientation of the

head as it is attached to the shell.

95

TABLE AD-350.2

VALUES OF SPHERICAL RADIUS FACTOR K

o

FOR

ELLIPSOIDAL HEAD WITH PRESSURE ON

CONVEX SIDE

Interpolation Permitted for Intermediate Values

D

o

/2h

o

. . . 3.0 2.8 2.6 2.4 2.2

K

o

. . . 1.36 1.27 1.18 1.08 0.99

D

o

/2h

o

2.0 1.8 1.6 1.4 1.2 1.0

K

o

0.90 0.81 0.73 0.65 0.57 0.50

ellipsoidal heads shall be the equivalent outside spherical

radius taken as K

o

D

o

in the corroded condition.

AD-350.3 Torispherical Heads. The minimum re-

quired thickness of a torispherical head having pressure

on the convex side, either seamless or of built-up

construction with butt joints, shall not be less than that

determined by the same design procedure as is used

for spherical shells in AD-320, except that the value

of R

o

for torispherical heads shall be the outside radius

of the crown portion of the head in the corroded

condition.

AD-360 CONICAL SHELLS AND HEADS

The required thickness of a conical head or section

under pressure on the convex side, either seamless

or of built-up construction with butt joints, shall be

determined in accordance with AD-360.1 or AD-360.2.

Stiffening rings shall be in accordance with AD-360.3.

AD-360.1 Cone Angle 60 deg

(a) Cones Having D

L

/t

e

Values 10

Step 1. Assume a value for t

e

and determine the

ratios L

e

/D

L

and D

L

/t

e

.

Step 2. Enter Fig. G in Subpart 3 of Section II, Part

D at a value of L/D

o

equivalent to the value of L

e

/D

L

determined in Step 1. For values of L

e

/D

L

greater than

50, enter the chart at a value of L

e

/D

L

p 50.

Step 3. Move horizontally to the line for the value

of D

o

/t equivalent to the value of D

L

/t

e

determined

in Step 1. Interpolation may be made for intermediate

values of D

L

/t

e

. From this point of intersection move

vertically downwards to determine the value of factor A.

Step 4. Using the value of A calculated in Step 3,

enter the applicable material chart in Subpart 3 of

Section II, Part D for the material under consideration.

Move vertically to an intersection with the material-

temperature line for the design temperature (see AD-

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

AD-360.1 2001 SECTION VIII DIVISION 2 AD-360.3

121.2). Interpolation may be made between lines for

intermediate temperatures.

In cases where the value of A falls to the right of

the end of the material-temperature line, assume an

intersection with the horizontal projection of the upper

end of the material-temperature line. For values of A

falling to the left of the material-temperature line, see

Step 7.

Step 5. From the intersection obtained in Step 4,

move horizontally to the right and read the value of

factor B.

Step 6. Using this value of B, calculate the value

of the maximum allowable external working pressure

P

a

using the following formula:

P

a

p

4B

3(D

L

/ t

e

)

Step 7. For values of A falling to the left of the

applicable material-temperature line, the value of P

a

can be calculated using the following formula:

P

a

p

2AE

3(D

L

/ t

e

)

Step 8. Compare the calculated value of P

a

obtained

in Step 6 or 7 with P. If P

a

is smaller than P, select

a larger value for t and repeat the design procedure

until a value of P

a

is obtained that is equal to or

greater than P.

Step 9. Provide adequate reinforcement of the cone-

to-cylinder juncture according to AD-360.3.

(b) Cones Having D

L

/ t

e

Values < 10

Step 1. Using the same procedure as given in (a)

above, obtain the value of B. For values of D

L

/t

e

less

than 4, the value of factor A can be calculated using

the following formula:

A p

1.1

(D

L

/ t

e

)

2

For values of A greater than 0.10, use a value of 0.10.

Step 2. Using the value of B obtained in Step 1,

calculate a value P

a1

using the following formula:

P

a1

p

2.167

(D

L

/ t

e

)

0.0833

B

Step 3. Calculate a value P

a2

using the following

formula:

96

P

a2

p

2S

D

L

/ t

e

1

1

D

L

/ t

e

where

Spthe lesser of two times the maximum allowable

stress value at design metal temperature, from

the applicable table in Subpart 1 of Section II,

Part D, or 0.9 times the yield strength of the

material at design temperature, psi (kPa)

Step 4. The smaller of the values of P

a1

calculated

in Step 2 or P

a2

calculated in Step 3 shall be used

for the maximum allowable external working pressure

P

a

. Compare P

a

with P. If P

a

is smaller than P, select

a larger value for t and repeat the design procedure

until a value for P

a

is obtained that is equal to or

greater than P.

Step 5. Provide adequate reinforcement of the cone-

to-cylinder juncture according to AD-360.3.

AD-360.2 Cone Angle > 60 deg. When of the

cone is greater than 60 deg, the thickness of the cone

shall be the same as the required thickness for a at

head under external pressure, the diameter of which

equals the largest diameter of the cone, or shall be

designed by special analysis in accordance with AD-

360.3(e).

AD-360.3 Rules for Reinforcement of Cone-to-

Cylinder Junction Under External Pressure

(a) The formulas of (b) and (c) below provide for

the design of reinforcement, if needed, at the cone-to-

cylinder junctions for reducer sections and conical heads

where all the elements have a common axis and the

half apex angle 60 deg. Subparagraph (e) below

provides for special analysis in the design of cone-to-

cylinder intersections with or without reinforcing rings,

including those where is > 60 deg.

In the design of reinforcement for a cone-to-cylinder

juncture, the requirements of AD-551 for reinforcement

material strength for nozzles are applicable to reinforce-

ment for a cone-to-cylinder juncture.

(b) Reinforcement shall be provided at the junction

of the cone with the large cylinder for conical heads

and reducers without knuckles when the value of

obtained from Table AD-360.3 using the appropriate

ratio P/S

s

is less than . Interpolation may be made

in the Table.

The cross-sectional area of the reinforcement ring

shall be at least equal to that indicated by the following

formula:

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

AD-360.3 PART AD DESIGN REQUIREMENTS AD-360.3

TABLE AD-360.3

VALUES OF FOR JUNCTIONS AT THE LARGE

CYLINDER FOR 60 deg

P/S

s

0 0.002 0.005 0.010 0.02

, deg 0 5 7 10 15

P/S

s

0.04 0.08 0.10 0.125 0.15

, deg 21 29 33 37 40

P/S

s

0.20 0.25 0.30 0.35 Note (1)

, deg 47 52 57 60

NOTE:

(1) p 60 deg for greater values of P/S

s

.

A

rL

p

kQ

L

D

L

tan

2S

s

1

1

4

PD

L

2Q

L

2Q

L

(1)

When the thickness of both the reducer and cylinder

exceeds that required by the applicable design formulas,

the minimum excess thickness may be considered to

contribute to the required stiffening ring in accordance

with the following formula:

A

eL

p (t

s

t)

D

L

t

s

2

+ (t

c

t

r

)

D

L

t

c

2 cos

(2)

Any additional area of stiffening which is required

shall be situated within a distance of D

L

t

s

/2 from

the junction of the reducer and the cylinder. The centroid

of the added area shall be within a distance of 0.5

D

L

t

s

/2 from the junction.

The stiffening ring at the cone-to-cylinder junction

shall also be considered as a stiffening ring.

The moment of inertia for a stiffening ring at the large

end shall be determined by the following procedure.

Step 1. Assuming that the shell has been designed

and D

L

, L

L

, and t are known, select a member to be

used for the stiffening ring and determine cross-sectional

area A

TL

. Then calculate factor B using the following

formula:

B p

3

4

F

L

D

L

A

TL

where

F

L

p PM + f

1

tan

M p

D

L

tan

4

+

L

L

2

+

D

L

2

D

s

2

6D

L

tan

**

** For some of the terms of the equations, it may be necessary to

convert millimeters to meters to obtain a rational result in SI units.

97

Step 2. Enter the right-hand side of the applicable

material chart in Subpart 3 of Section II, Part D for

the material under consideration at the value of B

determined by Step 1. If different materials are used

for the shell and stiffening ring, use the material chart

resulting in the larger value of A in Step 4 below.

Step 3. Move horizontally to the left to the material-

temperature line for the design metal temperature. For

values of B falling below the left end of the material-

temperature line, see Step 5 below.

Step 4. Move vertically to the bottom of the chart

and read the value of A.

Step 5. For values of B falling below the left end

of the appropriate material-temperature curve, the value

of A can be calculated using the formula A p 2B/E

r

.

For values of B falling above the appropriate material-

temperature line, the design shall be adjusted by either

changing the conguration, or changing the stiffener

ring size or location, such that B is reduced to a value

below or at the appropriate material-temperature curve.

For values of B having multiple values of A, such as

when B falls on a horizontal portion of the curve, the

smallest value of A shall be used.

Step 6. Compute the value of the required moment

of inertia from the formula for I

s

. For the combined

ringshellcone section:

I

s

p

AD

L

2

A

TL

10.9

Step 7. Determine the available moment of inertia

I of the combined ringshellcone section.

Step 8. Evaluate the equation

I I

s

If the equation is not satised, a new section with

a larger moment of inertia must be selected, and the

calculation shall be done again until the equation is met.

The requirements of AD-332 and AD-333 are to be

met in attaching stiffening rings to the shell.

(c) The stiffening ring shall be provided at the

junction of the conical shell of a reducer without a

are and the small cylinder. The cross-sectional area

of the stiffening ring shall be at least equal to that

indicated by the following formula:

A

rs

p

kQ

s

D

s

tan

2S

s

(3)

When the thickness of either the reducer or cylinder

exceeds that required by the applicable design formula,

the thickness may be considered to contribute to the

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

AD-360.3 2001 SECTION VIII DIVISION 2 AD-360.4

required reinforcement ring in accordance with the

following formula:

A

es

p

D

s

t

c

2 cos

(t

c

t

r

) +

D

s

t

s

2

(t

s

t) (4)

Any additional area of stiffener which is required

shall be situated within a distance D

s

t

s

/ 2 from the

junction, and the centroid of the added area shall be

within a distance 0.5D

s

t

s

/ 2 from the junction.

The stiffening ring at the cone-to-cylinder junction

shall also be considered as a stiffening ring.

The moment of inertia for a stiffening ring at the small

end shall be determined by the following procedure.

Step 1. Assuming that the shell has been designed

and D

s

, L

sm

, and t are known, select a member to be

used for the stiffening ring and determine cross-sectional

area A

TS

. Then calculate factor B using the following

formula:

B p

3

4

F

s

D

s

A

TS

where

F

s

p pN + F

2

tan

N p

D

s

tan

4

+

L

sm

2

+

D

L

2

D

s

2

12D

s

tan

Step 2. Enter the right-hand side of the applicable

material chart in Subpart 3 of Section II, Part D for

the material under consideration at the value of B

determined by Step 1. If different materials are used

for the shell and stiffening ring, use the material chart

resulting in the larger value of A in Step 4 below.

Step 3. Move horizontally to the left to the material-

temperature line for the design metal temperature. For

values of B falling below the left end of the material-

temperature line, see Step 5 below.

Step 4. Move vertically to the bottom of the chart

and read the value of A.

Step 5. For values of B falling below the left end

of the appropriate material-temperature curve, the value

of A can be calculated using the formula A p 2B/E

r

.

For values of B falling above the appropriate material-

temperature line, the design shall be adjusted by either

changing the conguration, or changing the stiffener

ring size or location, such that B is reduced to a value

below or at the appropriate material-temperature curve.

For values of B having multiple values of A, such as

98

when B falls on a horizontal portion of the curve, the

smallest value of A shall be used.

Step 6. Compute the value of the required moment

of inertia from the formula for I

s

. For the combined

ringshellcone section:

I

s

p

AD

s

2

A

TS

10.9

Step 7. Determine the available moment of inertia

I of the combined ringshellcone section.

Step 8. Evaluate the equation:

I I

s

If the equation is not satised, a new section with

a larger moment of inertia must be selected, and the

calculation shall be done again until the equation is met.

The requirements of AD-332 and AD-333 are to be

met in attaching stiffening rings to the shell.

(d) The reinforcement of reducers not described in

AD-210, such as those made up of two or more conical

frustums having different slopes, may be designed in

accordance with (e) below.

(e) For conical sections with the half apex angle

greater than 60 deg, and as an alternative to the rules

provided in (b) and (c) above, the design may be based

on special analysis such as numerical methods or the

beam-on-elastic-foundation analysis of Timoshenko,

Hetenyi, or Watts and Lang. The stresses at the junction

shall meet all of the allowable stress limits of this

Division. The effect of shell and cone buckling on the

required area and moment of inertia at the joint shall

also be considered in the analysis. The theoretical

buckling pressure of the junction shall be at least 3.3

times the allowable external design pressure of the

junction.

AD-360.4 Toriconical Heads and Shell Sections.

The required thickness of a toriconical head having

pressure on the convex side, either seamless or of built-

up construction with butt joints within the head, shall

not be less than that determined from AD-360.1 or

AD-360.2, with the exception that L

e

shall be determined

as follows.

(a) For sketch (c) in Fig. AD-300.1,

L

e

p r

1

sin

1

+

L

2

D

L

+ D

s

D

Ls

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

AD-360.4 PART AD DESIGN REQUIREMENTS AD-370

(b) For sketch (d) in Fig. AD-300.1,

L

e

p r

2

D

ss

D

L

sin

2

+

L

2

D

L

+ D

s

D

L

(c) For sketch (e) in Fig. AD-300.1,

L

e

p r

1

sin

1

+ r

2

D

ss

D

Ls

sin

2

+

L

2

(D

L

+ D

s

)

D

Ls

NOTE: Nomenclature is as dened in Fig. AD-300.1.

AD-360.5 Eccentric Cones. The thickness of an

eccentric cone shall be taken as the greater of the two

thicknesses obtained using both the smallest and largest

in the calculations.

AD-370 OPENINGS IN SHELLS AND

HEADS

Openings in shells and heads convex to pressure

shall comply with the requirements of AD-520.

99

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

You might also like

- BS 2779-1986 Ó ÖÆ ÇÃÜ Â ÜÂÝÎÆ (BSP)Document20 pagesBS 2779-1986 Ó ÖÆ ÇÃÜ Â ÜÂÝÎÆ (BSP)Vaibhav ShuklaNo ratings yet

- BS 7570-2000 - Validation of Arc Welding EquipmentDocument18 pagesBS 7570-2000 - Validation of Arc Welding EquipmentDarryl007100% (1)

- Terminal CheatsheetDocument2 pagesTerminal CheatsheetVictor CarreraNo ratings yet

- ABS 2014 Steel Vessel Rules - Propellers, SVR - Part - 4 - E-Feb14Document14 pagesABS 2014 Steel Vessel Rules - Propellers, SVR - Part - 4 - E-Feb14cupidkhhNo ratings yet

- Aa 036322 001Document1 pageAa 036322 001petronashscribdidNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- ZTE LTE FDD X2 Self-Configuration Feature GuideDocument50 pagesZTE LTE FDD X2 Self-Configuration Feature GuideengrSadiqueNo ratings yet

- Pages From Asme Viii Div 1-2007Document2 pagesPages From Asme Viii Div 1-2007kaustubh_dec17No ratings yet

- F0503HDocument12 pagesF0503HSopon SrirattanapiboonNo ratings yet

- Stress Analysis of Steam Generator Shell Nozzle Junction For Sodium Cooled Fast Breeder ReactorDocument9 pagesStress Analysis of Steam Generator Shell Nozzle Junction For Sodium Cooled Fast Breeder ReactorVinh Do Thanh100% (1)

- Pewaja Steel SectionDocument80 pagesPewaja Steel SectionWok YohNo ratings yet

- Shear Area of Reinforced Circular Concrete MembersDocument7 pagesShear Area of Reinforced Circular Concrete MemberstrabajosicNo ratings yet

- SPREADSHEETS SERIES No. 0009S - 2Document4 pagesSPREADSHEETS SERIES No. 0009S - 2Emma DNo ratings yet

- Design Methodology of Pressure Vessel NozzleDocument5 pagesDesign Methodology of Pressure Vessel NozzleLiu YangtzeNo ratings yet

- Forum Question - Warping ConstantDocument6 pagesForum Question - Warping ConstantBolarinwaNo ratings yet

- PipelineDocument3 pagesPipelineKrystle FlowersNo ratings yet

- Sif B31 3Document10 pagesSif B31 3Sergio SmithNo ratings yet

- Riveted Joints ASME IDocument7 pagesRiveted Joints ASME ICastoriadisNo ratings yet

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocument7 pagesDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodebiniamNo ratings yet

- Pressure Vessel Training ModuleDocument40 pagesPressure Vessel Training ModuleIdil Fitri100% (1)

- Shear Load CalculationDocument8 pagesShear Load Calculationvinny1978No ratings yet

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDocument12 pagesSpecifying Bolt Length For High-Strength Bolts: Manual of Steel Constructionpreds1717No ratings yet

- Leakage Account For Radial Face Contact Seal in AiDocument7 pagesLeakage Account For Radial Face Contact Seal in AiMohamed ElgendyNo ratings yet

- Is 7906 1 1997Document37 pagesIs 7906 1 1997paragbholeNo ratings yet

- Stress Analysis of Piston Using Pressure Load and Thermal LoadDocument8 pagesStress Analysis of Piston Using Pressure Load and Thermal LoadInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis and Design of Members For TensionDocument91 pagesAnalysis and Design of Members For TensionAL DANIEL VIN FULVADORANo ratings yet

- Design Aids For Tension Members As Per Revised Is: 800-2007Document7 pagesDesign Aids For Tension Members As Per Revised Is: 800-2007dev_1989No ratings yet

- Tir A9 XX - d4 - 9 13 13 - CleanDocument102 pagesTir A9 XX - d4 - 9 13 13 - Cleany2kareinNo ratings yet

- Analysis and Design of Members For TensionDocument84 pagesAnalysis and Design of Members For TensionicpertacortaNo ratings yet

- Pressure Vessels AsmeDocument45 pagesPressure Vessels AsmeetayhailuNo ratings yet

- Cone Tolerance PDFDocument21 pagesCone Tolerance PDFsosu_sorin3904No ratings yet

- ChecklistDocument61 pagesChecklistjhunkujha11No ratings yet

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocument8 pagesDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeYakubu100% (1)

- Eccentric ConnecctionsDocument41 pagesEccentric ConnecctionsShyam Suryawanshi100% (1)

- Why InsulationDocument13 pagesWhy InsulationnguyenNo ratings yet

- DSS Overview PDFDocument13 pagesDSS Overview PDFtekula akhilNo ratings yet

- M 269-96 (2008) (Turnbuckles and Shackles)Document25 pagesM 269-96 (2008) (Turnbuckles and Shackles)tran_lamNo ratings yet

- Lecture Mechanical Design of Heat ExchangerDocument46 pagesLecture Mechanical Design of Heat ExchangerDawitNo ratings yet

- DIN-2605-2-95 StandartDocument9 pagesDIN-2605-2-95 StandartGürolNo ratings yet

- Cylinders, Compound Cylinders, Press & Shrink FitsDocument9 pagesCylinders, Compound Cylinders, Press & Shrink Fitstvsaagar100% (1)

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocument8 pagesDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeAndres Rodriguez HerreraNo ratings yet

- Steel Springs, Helical, Heat-Treated: Standard Specification ForDocument6 pagesSteel Springs, Helical, Heat-Treated: Standard Specification Forquiensabe0077No ratings yet

- Minimum Thickness of MetalDocument15 pagesMinimum Thickness of MetalswatiNo ratings yet

- Append - A 13-15Document3 pagesAppend - A 13-15Cristian GordilloNo ratings yet

- ABS 2014 High Speed Naval Craft - Propellers, HSNC - Part - 4 - E-Feb14Document13 pagesABS 2014 High Speed Naval Craft - Propellers, HSNC - Part - 4 - E-Feb14cupidkhhNo ratings yet

- MoldEng 2 ENG 0830Document35 pagesMoldEng 2 ENG 0830Titus RoshanNo ratings yet

- Sif B31 3Document24 pagesSif B31 3vuqar0979100% (1)

- G For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of TheDocument6 pagesG For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of Theክበር ተመስጌንNo ratings yet

- A. Design Considerations For A PistonDocument7 pagesA. Design Considerations For A PistonTechnos_IncNo ratings yet

- Is 4049 Part 1Document7 pagesIs 4049 Part 1Otavio123No ratings yet

- 5 Strength AnalysisDocument63 pages5 Strength Analysisdan20000No ratings yet

- Optimization Technique For The Geometry of Twin Screw Cryogenic ExtruderDocument5 pagesOptimization Technique For The Geometry of Twin Screw Cryogenic ExtruderIJSTENo ratings yet

- ResDocument3 pagesRes245120736081No ratings yet

- Dimensions: Dimension and Tolerance SymbolsDocument6 pagesDimensions: Dimension and Tolerance Symbolsjdsa123No ratings yet

- Two Pile GroupDocument12 pagesTwo Pile GroupJammy KingNo ratings yet

- Design and Fabrication of Metal Spinning ComponentsDocument6 pagesDesign and Fabrication of Metal Spinning ComponentsAnonymous VRspXsmNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Greg AlvaradoDocument36 pagesGreg AlvaradoYuber Rodriguez HNo ratings yet

- CFR 2011 Title29 Vol8 Sec1926 1432Document1 pageCFR 2011 Title29 Vol8 Sec1926 1432Yuber Rodriguez HNo ratings yet

- Occupational Safety and Health Admin., Labor 1926.1433Document4 pagesOccupational Safety and Health Admin., Labor 1926.1433Yuber Rodriguez HNo ratings yet

- TextDocument1 pageTextYuber Rodriguez HNo ratings yet

- 29 CFR Ch. XVII (7-1-11 Edition) 1926.1434: 1926.1434 Equipment ModificationsDocument5 pages29 CFR Ch. XVII (7-1-11 Edition) 1926.1434: 1926.1434 Equipment ModificationsYuber Rodriguez HNo ratings yet

- CFR 2011 Title29 Vol8 Sec1926 1437Document6 pagesCFR 2011 Title29 Vol8 Sec1926 1437Yuber Rodriguez HNo ratings yet

- CFR 2011 Title29 Vol8 Sec1926 1434Document1 pageCFR 2011 Title29 Vol8 Sec1926 1434Yuber Rodriguez HNo ratings yet

- CFR 2011 Title29 Vol8 Sec1926 1439Document1 pageCFR 2011 Title29 Vol8 Sec1926 1439Yuber Rodriguez HNo ratings yet

- 29 CFR Ch. XVII (7-1-11 Edition) 1926.1436: 1926.1436 DerricksDocument5 pages29 CFR Ch. XVII (7-1-11 Edition) 1926.1436: 1926.1436 DerricksYuber Rodriguez HNo ratings yet

- Occupational Safety and Health Admin., Labor 1926.1440: 1926.1438 Overhead & Gantry CranesDocument2 pagesOccupational Safety and Health Admin., Labor 1926.1440: 1926.1438 Overhead & Gantry CranesYuber Rodriguez HNo ratings yet

- CFR 2011 Title29 Vol8 Toc Id2Document1 pageCFR 2011 Title29 Vol8 Toc Id2Yuber Rodriguez HNo ratings yet

- CFR 2011 Title29 Vol8 SubtitleB ChapXVII Toc Id5Document3 pagesCFR 2011 Title29 Vol8 SubtitleB ChapXVII Toc Id5Yuber Rodriguez HNo ratings yet

- 29 CFR Ch. XVII (7-1-11 Edition) 1926.1500: 1926.1500 ScopeDocument7 pages29 CFR Ch. XVII (7-1-11 Edition) 1926.1500: 1926.1500 ScopeYuber Rodriguez HNo ratings yet

- CFR 2011 Title29 Vol8 Sec1926 12Document8 pagesCFR 2011 Title29 Vol8 Sec1926 12Yuber Rodriguez HNo ratings yet

- Occupational Safety and Health Admin., Labor 1926.6: WWW - Archives.gov/federal Code IbrDocument5 pagesOccupational Safety and Health Admin., Labor 1926.6: WWW - Archives.gov/federal Code IbrYuber Rodriguez HNo ratings yet

- CFR 2011 Title29 Vol8 Sec1926 13Document2 pagesCFR 2011 Title29 Vol8 Sec1926 13Yuber Rodriguez HNo ratings yet

- 29 CFR Ch. XVII (7-1-11 Edition) 1926.14Document1 page29 CFR Ch. XVII (7-1-11 Edition) 1926.14Yuber Rodriguez HNo ratings yet

- CFR 2011 Title29 Vol8 Sec1926 11Document1 pageCFR 2011 Title29 Vol8 Sec1926 11Yuber Rodriguez HNo ratings yet

- 29 CFR Ch. XVII (7-1-11 Edition) 1926.3: 1926.3 Inspections-Right of EntryDocument2 pages29 CFR Ch. XVII (7-1-11 Edition) 1926.3: 1926.3 Inspections-Right of EntryYuber Rodriguez HNo ratings yet

- Occupational Safety and Health Admin., Labor 1926.2: Subpart A-GeneralDocument2 pagesOccupational Safety and Health Admin., Labor 1926.2: Subpart A-GeneralYuber Rodriguez HNo ratings yet

- 29 CFR Ch. XVII (7-1-11 Edition) 1926.3: 1926.3 Inspections-Right of EntryDocument1 page29 CFR Ch. XVII (7-1-11 Edition) 1926.3: 1926.3 Inspections-Right of EntryYuber Rodriguez HNo ratings yet

- 29 CFR Ch. XVII (7-1-11 Edition) 1926.3: 1926.3 Inspections-Right of EntryDocument1 page29 CFR Ch. XVII (7-1-11 Edition) 1926.3: 1926.3 Inspections-Right of EntryYuber Rodriguez HNo ratings yet

- Caracteristicas de MotorgrDocument1 pageCaracteristicas de MotorgrYuber Rodriguez HNo ratings yet

- CIA Exam:: Updated. Aligned. FocusedDocument7 pagesCIA Exam:: Updated. Aligned. FocusedveveNo ratings yet

- ProfileDocument28 pagesProfileArunKumar GanesanNo ratings yet

- Digital Cable Locating SetDocument17 pagesDigital Cable Locating SetRavigupta19833100% (1)

- Types of Steel BarsDocument6 pagesTypes of Steel BarsvitamkupaNo ratings yet

- ABS Nondestructive Inspection of Hull WeldsDocument89 pagesABS Nondestructive Inspection of Hull Weldsbreeeeezzzzze100% (1)

- Bell Atlantic Supplement Common Channel Signaling (CCS) Network Interface SpecificationDocument83 pagesBell Atlantic Supplement Common Channel Signaling (CCS) Network Interface SpecificationGreg WilliamsNo ratings yet

- Specification HysterDocument5 pagesSpecification HysterFidusia100% (1)

- Chapter 6 Laplace TransformsDocument20 pagesChapter 6 Laplace TransformshanythekingNo ratings yet

- Tire Replacement ManualDocument55 pagesTire Replacement Manualpierrecmoeller1159No ratings yet

- ALL SFMS Ifsc Codes For BanksDocument7,468 pagesALL SFMS Ifsc Codes For Banksbargach.ithelpdeskNo ratings yet

- Leroy Somer Electrical MotorDocument132 pagesLeroy Somer Electrical Motorramabhpl100% (1)

- ABB 2340enDocument6 pagesABB 2340enThangco HutNo ratings yet

- MS-89 Method Statement Grid CeilingDocument36 pagesMS-89 Method Statement Grid CeilingRithesh ShettyNo ratings yet

- Concrete Pavement - Group 8Document8 pagesConcrete Pavement - Group 8Bryan YuNo ratings yet

- Crouse Hinds Exd JBDocument8 pagesCrouse Hinds Exd JBomh129No ratings yet

- 1132Document36 pages1132Hoàng Văn KiênNo ratings yet

- CP Backfill Tampers (US)Document1 pageCP Backfill Tampers (US)Sumit BhasinNo ratings yet

- Uh-1 - 10 C20Document134 pagesUh-1 - 10 C20Clifford McKeithan100% (1)

- Praktikum Ethical HackingDocument144 pagesPraktikum Ethical HackingKido KaindeNo ratings yet

- Transport and Main Roads Specifications MRTS62 Bridge SubstructureDocument9 pagesTransport and Main Roads Specifications MRTS62 Bridge SubstructureRAIMUNDO SUHERDINNo ratings yet

- PGBF Lecture Notes 2011-2012 SessionDocument38 pagesPGBF Lecture Notes 2011-2012 Sessionhariprem26No ratings yet

- Manual Rad ETX-1Document273 pagesManual Rad ETX-1Tavo's García67% (3)

- UL 746a PDFDocument57 pagesUL 746a PDFsabaris ksNo ratings yet

- Dell Systm Esuprt Tool v3.7 Concept Guide en UsDocument67 pagesDell Systm Esuprt Tool v3.7 Concept Guide en UsWolney DiasNo ratings yet

- Bs 84 1956Document20 pagesBs 84 1956sunny guptaNo ratings yet

- Amarok Body Builder Guidelines 2013 PDFDocument130 pagesAmarok Body Builder Guidelines 2013 PDFme45678No ratings yet

- Discrimination & Back-Up Protection: Page 1 of 9 The Guide - MEM Technical SupportDocument9 pagesDiscrimination & Back-Up Protection: Page 1 of 9 The Guide - MEM Technical SupportRukawa528No ratings yet