Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

16 viewsAssociation For Preservation Technology International (APT)

Association For Preservation Technology International (APT)

Uploaded by

Sanjeev SharmaThis document provides an overview of water turbines, including their key components and functions. It describes how water flows from a race or penstock into the turbine, passing through it to impart energy and power machinery before exiting. Different types of turbines are discussed, such as scroll case, tub, and pressure case designs. Methods for controlling water flow and turbine speed are also summarized, including gates, governors, and draft tubes. The primer aims to familiarize readers with basic mechanical concepts relating to water turbines and observed practices.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- (Get Now) SOAP For Family Medicine by Daniel Maldonado: Â Š PDF Â Š KINDLE Â ŠDocument12 pages(Get Now) SOAP For Family Medicine by Daniel Maldonado: Â Š PDF Â Š KINDLE Â ŠMauricio Solano DiazNo ratings yet

- Warren Truss Bridge ReportDocument12 pagesWarren Truss Bridge ReportRaaj Chatterjee50% (2)

- SWE Training Manual PDFDocument371 pagesSWE Training Manual PDFALBERTO OLIVEROS100% (1)

- Pig Launcher and ReceiverDocument7 pagesPig Launcher and ReceiverGerman Felipe Torres100% (4)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- The Layout of Fluid Mechanics and Hydraulic Machinery LabDocument4 pagesThe Layout of Fluid Mechanics and Hydraulic Machinery LabAhmad RazaNo ratings yet

- Sample Road Design ReportDocument77 pagesSample Road Design ReportKwaku frimpongNo ratings yet

- L10 Hydraulic Turbines PDFDocument23 pagesL10 Hydraulic Turbines PDFDhavanLalNo ratings yet

- Wartsila SP A Id Waterjet B 2Document6 pagesWartsila SP A Id Waterjet B 2Junaid YNo ratings yet

- Hydraulic TurbineDocument19 pagesHydraulic TurbineJohn Mark James GaloNo ratings yet

- Home Built Hydraulic Ram PumpsDocument84 pagesHome Built Hydraulic Ram PumpsZwq92yNo ratings yet

- Inventions in Turbine Technology: Water Wheels and NoriasDocument8 pagesInventions in Turbine Technology: Water Wheels and Noriasßhardwaj NitishNo ratings yet

- PPE Expriment No-01Document9 pagesPPE Expriment No-01Aasawari Mahagaonkar100% (1)

- The Elements of Hydroelectric Power Plant Are As FollowsDocument8 pagesThe Elements of Hydroelectric Power Plant Are As FollowsDanial DanialNo ratings yet

- Hydraulic Ram-2017 - PDF RoomDocument7 pagesHydraulic Ram-2017 - PDF RoomR Nandhan 3BNo ratings yet

- Back To Basics: Part 1 - Components of A Steam LocomotiveDocument28 pagesBack To Basics: Part 1 - Components of A Steam LocomotivekabuldasNo ratings yet

- Petroleum Eng 1Document23 pagesPetroleum Eng 1Shah Fahad AlamNo ratings yet

- The Drilling Rig ComponentsDocument30 pagesThe Drilling Rig ComponentsKhaled El AssaadNo ratings yet

- A Review of Oscillating Water ColumnsDocument12 pagesA Review of Oscillating Water ColumnsCristobal Michelangelo FernaandesNo ratings yet

- DesignPriciples Concept Selection PDFDocument42 pagesDesignPriciples Concept Selection PDFBona_VentureNo ratings yet

- Functions of A Production PlatformDocument10 pagesFunctions of A Production Platformajwad_hashim5100% (1)

- Turbines SynopsisDocument4 pagesTurbines SynopsisNeeraj TripathiNo ratings yet

- Turbine: Types of TurbinesDocument6 pagesTurbine: Types of TurbinesKunal JadhavNo ratings yet

- Drilling Rig ComponentsDocument18 pagesDrilling Rig ComponentsIsmail A. IsmailNo ratings yet

- Advanced Technology - Archimedean Screw Summary 2015 10 19Document4 pagesAdvanced Technology - Archimedean Screw Summary 2015 10 19api-288292935No ratings yet

- Lecture No 7Document4 pagesLecture No 7Musa KhanNo ratings yet

- Water Turbine: From Wikipedia, The Free EncyclopediaDocument16 pagesWater Turbine: From Wikipedia, The Free Encyclopediakaushiksumit100% (1)

- Hydro-Electric Power PlantDocument46 pagesHydro-Electric Power Plantk rajendraNo ratings yet

- SpillwayDocument5 pagesSpillwaymaheshNo ratings yet

- Agitation and MixingDocument12 pagesAgitation and MixingSiri Nal100% (1)

- Gates For Flow ControlDocument41 pagesGates For Flow ControlkyogesswaranNo ratings yet

- Tugboat OperationsDocument15 pagesTugboat Operationsreurri0% (1)

- 8Document7 pages8Gigi SimaNo ratings yet

- Design Concept For A More Efficient Steam-Water SeparatorDocument7 pagesDesign Concept For A More Efficient Steam-Water SeparatorArini RizalNo ratings yet

- Hydro Electric Power Plant: V P H H Y HDocument10 pagesHydro Electric Power Plant: V P H H Y Harkan1976No ratings yet

- Equipo de PerforacionDocument21 pagesEquipo de PerforacionJoanna Guio0% (1)

- Rig Components PDFDocument19 pagesRig Components PDFBalant AxNo ratings yet

- Low Pressure SewersDocument23 pagesLow Pressure SewersUlil A JaNo ratings yet

- Hydro-Electric Power PlantDocument46 pagesHydro-Electric Power PlantAdrian Ray Ayam100% (1)

- The Water Tunnel As A Tool in Hydraulic Research PDFDocument24 pagesThe Water Tunnel As A Tool in Hydraulic Research PDFAbdul Wahab TariqNo ratings yet

- Rig Components 101Document90 pagesRig Components 101irrosel4650100% (1)

- Water Turbine - Wikipedia, ..Document9 pagesWater Turbine - Wikipedia, ..manbkkNo ratings yet

- Types of Turbines: Turbine ClassificationsDocument6 pagesTypes of Turbines: Turbine ClassificationsalbertNo ratings yet

- Rotary Positive Displacement PumpsDocument16 pagesRotary Positive Displacement Pumpsalexmuchmure2158No ratings yet

- Livestock Watering: Using Stream Energy To Pump Livestock WaterDocument4 pagesLivestock Watering: Using Stream Energy To Pump Livestock WaterraffaNo ratings yet

- Pumpjack: Above Ground Down-Hole Water Well Pumpjacks See Also References External LinksDocument5 pagesPumpjack: Above Ground Down-Hole Water Well Pumpjacks See Also References External LinksBenjamin KonjicijaNo ratings yet

- Drilling Engineering 1Document51 pagesDrilling Engineering 1Adnan AhmadNo ratings yet

- 11.2 Chapter 2 FinalDocument19 pages11.2 Chapter 2 FinalPhoo PhooNo ratings yet

- Chapter 3 Mine PumpsDocument29 pagesChapter 3 Mine PumpsOolasyar KhattakNo ratings yet

- Draft Proposal (01-02-20107)Document14 pagesDraft Proposal (01-02-20107)Ahsan MurtazaNo ratings yet

- Water Turbine His To RZDocument6 pagesWater Turbine His To RZJosef LoLNo ratings yet

- Hydro Power PlantsDocument7 pagesHydro Power PlantsKyambadde Francisco100% (1)

- Mechanics of MachinesDocument13 pagesMechanics of MachinesJeff HardyNo ratings yet

- Types and Parts of Hydraulic JackDocument17 pagesTypes and Parts of Hydraulic JackDenialNo ratings yet

- AgitationDocument8 pagesAgitationroxetteNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Windmills and Waterwheels Explained: What They Do and How They WorkFrom EverandWindmills and Waterwheels Explained: What They Do and How They WorkNo ratings yet

- List of FilesDocument4 pagesList of FilesSanjeev SharmaNo ratings yet

- Attendance Position of Mba Students Up To 31St March 2016 Hptu Business School, Rggec Campus, Nagrota Bagwan Kangra 176047 (H.P.)Document6 pagesAttendance Position of Mba Students Up To 31St March 2016 Hptu Business School, Rggec Campus, Nagrota Bagwan Kangra 176047 (H.P.)Sanjeev SharmaNo ratings yet

- Institute of Pesticide Formulation Technology (IPFT) : Sector-20, Udyog Vihar, Gurgaon - 122 016 (Haryana)Document4 pagesInstitute of Pesticide Formulation Technology (IPFT) : Sector-20, Udyog Vihar, Gurgaon - 122 016 (Haryana)Sanjeev SharmaNo ratings yet

- Corporate GovernanceDocument469 pagesCorporate GovernanceSanjeev Sharma100% (2)

- December 2011, CA-CPT Question Paper (Based On Memory) : No.1 For CA/CWA & MEC/CECDocument16 pagesDecember 2011, CA-CPT Question Paper (Based On Memory) : No.1 For CA/CWA & MEC/CECSanjeev SharmaNo ratings yet

- How To Use The E-ResourcesDocument10 pagesHow To Use The E-ResourcesSanjeev SharmaNo ratings yet

- Curriculum Viate VishalDocument2 pagesCurriculum Viate VishalSanjeev SharmaNo ratings yet

- How To Use Ladybird Readers PDFDocument18 pagesHow To Use Ladybird Readers PDFJonas SilvaNo ratings yet

- Proto Catalog 108 2016 - Low ResDocument996 pagesProto Catalog 108 2016 - Low ResMasterrNo ratings yet

- Chapter 2 Empiricism and PositivismDocument15 pagesChapter 2 Empiricism and PositivismJames RayNo ratings yet

- Delta Ia-Plc DVP-PLC PM en 20140804Document749 pagesDelta Ia-Plc DVP-PLC PM en 20140804Ali PadaryamNo ratings yet

- B.Lib SyllabusDocument17 pagesB.Lib SyllabussantoshguptaaNo ratings yet

- AutoBiography of A RiverDocument4 pagesAutoBiography of A Riversukhamoy2571% (21)

- Soft StarterDocument7 pagesSoft Starterdvmreddy1232007No ratings yet

- Elfredo - Dr@yahoo - Co.id: Keywords: Factors, Delays, Study, Course, EssayDocument9 pagesElfredo - Dr@yahoo - Co.id: Keywords: Factors, Delays, Study, Course, Essayekka fauzanNo ratings yet

- KL202232 PSRPT 2022-05-18 18.01.51Document19 pagesKL202232 PSRPT 2022-05-18 18.01.51Thuy AnhNo ratings yet

- Deleuze Guattariandthe Indian DiagramDocument19 pagesDeleuze Guattariandthe Indian DiagramManu KhannaNo ratings yet

- Training Regulations: Motorcycle/ Small Engine Servicing NC IiDocument102 pagesTraining Regulations: Motorcycle/ Small Engine Servicing NC IiAmit Chopra AmitNo ratings yet

- S TR Ohl Surv (Rev.0 2010)Document6 pagesS TR Ohl Surv (Rev.0 2010)bogdanNo ratings yet

- QB GrammarDocument13 pagesQB GrammarMuhammed Ali AktaşNo ratings yet

- مطوية انجليزية 1Document2 pagesمطوية انجليزية 1Chaker HamdiNo ratings yet

- 4.3 - B - 7 - Procedure For OHS Management ProgrammeDocument3 pages4.3 - B - 7 - Procedure For OHS Management ProgrammeSASIKUMAR SNo ratings yet

- Design of Basic ComputerDocument29 pagesDesign of Basic ComputerM DEEPANANo ratings yet

- Sizing of The Buffer Tank in Chilled Water Distribution A C Systems - PUBLISHED VERSIONDocument31 pagesSizing of The Buffer Tank in Chilled Water Distribution A C Systems - PUBLISHED VERSIONHai PhanNo ratings yet

- Step2 - Oscar Parra - Grupo 8Document15 pagesStep2 - Oscar Parra - Grupo 8Andres RuizNo ratings yet

- MTC 17022021063931Document1 pageMTC 17022021063931Ahmed LepdaNo ratings yet

- Canal SystemsDocument69 pagesCanal SystemsAnter TsatseNo ratings yet

- Rapid Roll GameDocument23 pagesRapid Roll GameRithika RithiNo ratings yet

- ESOL Nexus Teaching MathematicsDocument38 pagesESOL Nexus Teaching MathematicsArnold HoNo ratings yet

- Ats22 User Manual en Bbv51330 02Document85 pagesAts22 User Manual en Bbv51330 02Catalin PelinNo ratings yet

- Rivera December Staar Eoc TA Testing PPDocument55 pagesRivera December Staar Eoc TA Testing PPOlga RenteriaNo ratings yet

- Microeconomics Question Set 4 (20231107) AnswerkeyDocument9 pagesMicroeconomics Question Set 4 (20231107) AnswerkeyMegumi TsuchiyaNo ratings yet

- PVC Cable Color Code ChartDocument1 pagePVC Cable Color Code ChartMiabNo ratings yet

- Long Quiz Prelim DiassDocument2 pagesLong Quiz Prelim DiassBel Patrice TisuelaNo ratings yet

Association For Preservation Technology International (APT)

Association For Preservation Technology International (APT)

Uploaded by

Sanjeev Sharma0 ratings0% found this document useful (0 votes)

16 views21 pagesThis document provides an overview of water turbines, including their key components and functions. It describes how water flows from a race or penstock into the turbine, passing through it to impart energy and power machinery before exiting. Different types of turbines are discussed, such as scroll case, tub, and pressure case designs. Methods for controlling water flow and turbine speed are also summarized, including gates, governors, and draft tubes. The primer aims to familiarize readers with basic mechanical concepts relating to water turbines and observed practices.

Original Description:

CORPORATE GOVERNANCE REPORT OF COMPANY

Original Title

1493582

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an overview of water turbines, including their key components and functions. It describes how water flows from a race or penstock into the turbine, passing through it to impart energy and power machinery before exiting. Different types of turbines are discussed, such as scroll case, tub, and pressure case designs. Methods for controlling water flow and turbine speed are also summarized, including gates, governors, and draft tubes. The primer aims to familiarize readers with basic mechanical concepts relating to water turbines and observed practices.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

16 views21 pagesAssociation For Preservation Technology International (APT)

Association For Preservation Technology International (APT)

Uploaded by

Sanjeev SharmaThis document provides an overview of water turbines, including their key components and functions. It describes how water flows from a race or penstock into the turbine, passing through it to impart energy and power machinery before exiting. Different types of turbines are discussed, such as scroll case, tub, and pressure case designs. Methods for controlling water flow and turbine speed are also summarized, including gates, governors, and draft tubes. The primer aims to familiarize readers with basic mechanical concepts relating to water turbines and observed practices.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 21

A Primer on Water Turbines

Author(s): Robert A. Howard

Source: Bulletin of the Association for Preservation Technology, Vol. 8, No. 4 (1976), pp. 44-63

Published by: Association for Preservation Technology International (APT)

Stable URL: http://www.jstor.org/stable/1493582 .

Accessed: 17/07/2014 03:49

Your use of the JSTOR archive indicates your acceptance of the Terms & Conditions of Use, available at .

http://www.jstor.org/page/info/about/policies/terms.jsp

.

JSTOR is a not-for-profit service that helps scholars, researchers, and students discover, use, and build upon a wide range of

content in a trusted digital archive. We use information technology and tools to increase productivity and facilitate new forms

of scholarship. For more information about JSTOR, please contact support@jstor.org.

.

Association for Preservation Technology International (APT) is collaborating with JSTOR to digitize, preserve

and extend access to Bulletin of the Association for Preservation Technology.

http://www.jstor.org

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

A PRIMER ON WATER TURBINES

by

Robert A. Howard*

This article is intended to familiarize the reader with some mechanical

concepts

relative to the water turbine. It is written in

generalized

terms

based on the writer's research and

experience,

and reflects observed

practice

in the Middle Atlantic

region

of the United States.

Man's

application

of

technology

should in no

way

be considered

perfectly

rational. Most turbine installations,

for

example,

are somewhat modified

over

time, either for sound mechanical or economic reasons

and/or

because of

some

quirk

on the

part

of the local

operator.

In the 19th

century

the term waterwheel was

applied

to both what we

call waterwheels and what we define as water turbines. To

compound

the

confusion,

both wheels and turbines are found oriented

horizontally

and

vertically.

In order to differentiate between wheels and

turbines, anything

with buckets or blades each in a

single plane

is a

waterwheel,

and

anything

with curved vanes is a water turbine.

Let us

begin

with

Figure

1 and trace the water flow and define

parts

of

the

hydraulic system using

a turbine.

In most

systems

the water enters the race

(sometimes

called the head-

race)

above or at the dam. This race or canal maintains the water level

nearly

at the dam level. The number of water turbines served

by

a race can

vary

from one to

many. Generally,

if several turbines are

serviced,

the

race will narrow

slightly

after it

passes

the inlet for each. It is not

economical to move more earth than needed when

building

a race; however, the

race has to be

sufficiently

wide in

every place

to maintain the

velocity

of

the water

flowing through.

Should the water flow too

fast,

a

scouring

action will occur and the walls of the race will erode

away.

Most races

with which the writer is familiar are

masonry

walled

being

stone lined.

Earthen trenches have also been observed. Often there will be control

gates

and trash racks at the inlet of the race

and,

occasionally,

some sort of

fixed or

floating

barrier will be

provided

to

stop large floating logs.

To

get

water from the race to a

turbine,

a

flume

or

penstock

is

employed. Occasionally

a

penstock

will

begin

at the dam and no race will

be

present.

Flumes

may

be

open

or

enclosed, while a

penstock

is

invariably

a

watertight pipe

constructed of

iron, steel,

or wood. At the inlet end of

*Mr. Howard is

Engineering

Curator at The

Hagley Museum,

Greenville

(Wilmington),

Delaware.

A^F

Vol. VIII No. 4 1976 Page 45

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

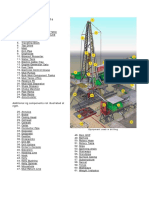

D RIVE

DETAILS

TAI L-

RACE

TYPICAL

SCHEME OF TURBINE

AR RANGEMENT

Figure

1

Ar

Vol. VIII No. 4 1976 Page

44

,4f

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

v"_s..b r -I*98~ir~L~~

.4' Xe ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~~I

Figure

2 Scroll case turbine at The

Hagley

Museum.

Courtesy

of The

Hagley

Museum

AD[ Vol. VIII No. 4 1976 Page

46

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

the flume or

penstock

there is

usually

a control

gate.

This allows

servicing

of the

waterway.

In the case of

gunpowder

mills this

gate

is used to control

the flow of water to the turbine so that the

operator

is some distance

away

from a mill in case of

explosion.

Most flumes and

penstocks

have a fine

grating

at the inlet

point,

also called a trash rack. This

prevents

debris

from

floating

into the turbine.

Control Gates: Control

gates

are found in

many arrangements.

The

principle

of a

gate

barrier

lifting

to

regulate

the flow is

nearly

universal.

The

types

of lift mechanisms observed

by

the author include a lever attached

to the

gate,

several

types

of rack and

gear mechanisms,

a threaded rod with

a

large

"nut" with handles,

and worm

gear

to threaded rod drives. A "chain

fall" attached to a

gateway

has also been observed in 20th

century

installa-

tions.

The water turbine can be one of

many settings.

The scroll case is an

early type

still

being

made. The case is

designed

to

impart

an

angular

momentum to the water. This

type

has its own

pressure

case which is bolted

directly

to the end of the flume or

penstock.

An

example

in

operating

condition can be found at Batsto Iron Works or in a static

setting

at The

Hagley

Museum

(Figure 2).

In the

open flume setting

the end of the flume has a hole in the bottom

which is

plugged by

the turbine

(like

the

plug

in the

sink).

In order for

the water to

escape

it

passes through

the

turbine, imparting

its

energy (see

Figure 3).

Tub Turbine: A wooden tub is fixed to the end penstock. This tub has

a hole in the bottom. The turbine rests between the penstock inlet and

this hole. In the

top

of the tub are sealed

joints (called packing glands)

through

which the turbine shaft is exited and

through

which a control rod

passes.

The

Hagley

Museum

operates

this

type

of turbine in the wheel mill

restoration

(Figure 4).

Other Pressure Cases: Instead of

using

a wooden tub,

or an iron scroll

case,

some sort of

pressure

case is

required

when the level of water

entering

the turbine exceeds the

height

of the container in which the turbine sits.

The

pressure

cases

may

be iron, concrete,

or fabricated steel. The

pictured

example (Figure 5)

is at The

Hagley

Museum and is at the bottom of a column

of water 24 feet

high.

Speed

Control on the Turbine: Most

processes operate

best when the

machinery

is

operating

at a

precalculated speed.

For

example,

the stone on

a

grist

mill revolves at a

speed slightly

in excess of one hundred revolu-

tions

per minute, while the wheels in a

gunpowder

mill revolve around the

spindle

at ten revolutions

per

minute.

Hence,

maintenance

operating speed

is

critical,

and if a new machine is turned on in a mill, as the bolter in

a

grist mill, then all the

previously operating machinery

will slow down.

The turbine then has to be

readjusted

so that the flow of water is increased

and the desired

speed

is re-established.

Usually

this is done

by

a

gate

arrangement

on the turbine

(Figure 6).

There is a

type

of turbine -- the

ADr

Vol. VIII No. 4 1976 Page 47

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

Open Flume

FIGURE 3

Vol. VIII No. 4 1976

Page

48

A^r

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

Figure

4 Tub

setting

for a turbine at The

Hagley

Museum.

Courtesy

of The

Hagley

Museum

ATr

Vol. VIII No. 4 1976

Page

49

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

Kaplan type

--

in which the blades of the runner are

adjustable.

These are

found both with and without

gates.

The

Kaplan

turbines were invented in the

20th

century

and are not common in historical situations.

Governors: Some water turbines have feedback devices called governors

(see Figure 7).

These machines

regulate

the

speed

of the turbine

(as

much

as the

governors

or steam

engines regulate

the

speed

of the

engines) by

controlling

the flow of the water into the turbine.

They automatically

adjust

the

previously-discussed speed

control. The

topic

"Governors" is

treated in detail in Feedback Mechanisms in the Collections

of

the National

Museum

of History

and

Technology, by

Otto

Mayer.

It is rare to find a

governor

in a small

installation,

but in

hydroelectric plants

and

large

installations

governors

are

invariably present.

Draft Tube: The draft tube is a section of

pipe

below the turbine

designed

as a suction device. These

vary

in

length

from nonexistent to

almost the total fall of the

site,

but not more than 20 feet. In some set-

tings

the turbine is set

just

below the level of the race and the tube is

several feet

long. Generally,

installations with the draft tube are a bit

more efficient than the ones without. There is a trade-off. When one

gains

by

draft

tubes, one in some measure loses

by

an effect called cavitation.

This is a more

rapid

erosion of the vanes of the turbine caused

by

the

bombardment of bubbles.

Many 19th-century

installations avoided cavitation

by placing

the turbine two feet below the level of the tailrace

(see

Figure 8).

Tailrace: The

spent

water flows out of the turbine and into the tail-

race.

Generally,

where the tailrace intersects the

river,

there is a small

deflection dam built into the river to allow the

discharge

to flow

smoothly,

and in some

cases,

to

gain

extra

power by taking advantage

of the

continuing

fall of the river

(refer

to

Figure 1).

Turbines in General: Water turbines have several marked

advantages

over

conventional waterwheels and a few drawbacks. Turbines are not as

badly

affected

by

ice as waterwheels. However,

a

phenomenon

called "anchor ice"

can raise

problems.

Not

every

installation which has

freezing

conditions

has this

problem.

Since turbines sit under

water, most

ice,

wooden debris

and

floating

debris is not as much of a

problem.

Turbines

generally require

less maintenance than waterwheels,

are easier to

install,

and are much

easier to service.

Turbines

by

no means

approach perfection.

For

example,

a turbine will

run

very efficiently

in

only

a small

range

of the

possible

flows

(see

Figure 9).

The late

Kaplan

turbines were built with

adjustable

vanes to

allow

higher efficiency

at several flows.

Many

small

mills,

in areas where

water was scarce, converted back to waterwheels, since waterwheels are

consistent in their

efficiency throughout

their

operating range. Single-

function mills where the

power requirement

was

consistent,

as cotton mills,

merchant

grist

mills and machine

works,

were best served

by

the water

turbine as were other mills where the amount of water available

proved

not

to be a

problem.

Hence,

in some cases inefficient utilization of the

energy

was more desirable than the maintenance of other

power

sources.

A^r

Vol.

VIII

No.

4 1976

Page

50

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

tl~ :::!

'Y:;; ::: :~:,x~;::iiii~:~

i,I

iw 1,' ...J*!.-.

X J j . :x?.*

^

:S

-

A --

:i

"

-

?'

;;

''e:"

^ss Jl

J.. :

I , % ..:... ...::..

: ***? .. .: I ( .*

Figure

5 Steel

pressure

case

being

set at The

Hagley

Museum

hydroelectric

plant

reconstruction. Water enters from

pipe

at

right

and

discharges

through opening

in bottom. Brackets at

top support

the

generator.

Courtesy

of The

Hagley

Museum

A)r Vol. VIII No. 4 1976 Page

51

I

or

f-

l^x

le I iL

eI 9 sILo '.: iBw' 1t

..

i

:

i: . Z

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

drive shaft

v

gate

controll

,

, I

run n

,

gates

thrust

bearing

draft

tube

CUTAWAY TURBIN

FIGURE 6

A^Zr

Vol. VIII No. 4 1976

Page

52

E

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

As the 20th

century dawned, ancillary

semi-diesel

engines

became

popular

and the

problem

of water turbine

efficiency

in small

multipurpose

mills was

less

important. Large

mills had been

using

steam

power

to

supplement

water-

power

as common

practice

since the second

quarter

of the 19th

century.

As an

aside, the U. S. census indicates that steam passed water in

popularity

as a

power

source in the decade between 1860 and 1870.

Historically,

the earliest turbines in the U. S. of which we are aware

were installed in the

early 1840's,

and their

popularity

increased as the

century passed. Many

installations went from waterwheel to water turbine.

For those

studying

such a

building

this

presents

several

problems.

First,

the mill drive train will show

signs

of

change.

Waterwheels turn

usually

around six revolutions

per

minute. The median

speed

for small turbines is

two hundred revolutions

per

minute. Hence,

when

looking

at the mill,

the

transmission

system

and

gearing

has to be

compatible

with the

power

source.

Historians

studying

turbines will encounter the terms inward and outward

discharge.

The

early

turbines

discharged

the used water around the circum-

ference of the runner while most later turbines

discharged through

the bottom.

The illustration in

Figure

6 is an inward

discharge.

Turbines were

cheaper

and easier to install than waterwheels. In fact,

it was common

practice

to install more than one turbine in small installa-

tions which served more than one function. For

example,

at the Black Rock

Mill in

Maryland

one turbine

powered

the

gristmill

while a second one

powered

a sawmill. The writer does not believe these

multiple

turbines were all a

manifestation of the

efficiency/water problem,

but more

just

a

simpler way

to

gear up

the

machinery. [In

the same Middle Atlantic

region,

all observed

waterwheel installations for

multipurpose

small mills had a

power

takeoff

from the

gristmill machinery

in whatever else was done

(as sawmill, etc.)]

The use of

multiple

wheels in small mills was not observed.

Having briefly

discussed the salient

parts

of a turbine

operation,

the

remainder of this article is devoted to restoration advice.

If one has an installation that was

initially wheel-powered

and subse-

quently

converted to

turbine-powered,

there has to be a decision as to which

mode the restoration will follow. Waterwheels are

by

far more

spectacular,

and also more trouble. Wheel installation and

operating

costs are also

higher.

The writer likes

working

with turbines more than wheels as the

technology

for

dealing successfully

with them and

obtaining

the correct

appearance

of

parts

are both

conveniently (almost)

current. If the decision

for turbine

power

is made,

the

following

comments

may prove

useful.

Archaeology:

The

archaeology

has two

purposes.

The first is to find

out how the installation was

assembled,

and the second is to

physically

remove

the debris in the

way

of reconstruction. The

job

is dirty, heavy

work and

can encounter undesirable inhabitants as

poisonous

snakes, spiders

and the

ever-present

rat. Gristmills have rodent

problems

--

especially operative

ones when

grinding.

With the

archaeology

there is a trade-off between

retrieval of

knowledge

and

allowing

reusable

parts

to remain undisturbed.

A'r

Vol. VIII No. 4 1976

Page

53

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

Figure

7 Governor of the Civil War

period

in

original

location at

The

Hagley

Museum.

Courtesy

of The

Hagley

Museum

A)r

Vol. VIII No. 4 1976

Page

54

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

Beware of

great

timbers set and the

surrounding

wall

being

erected around

them. If the timber has been

continually wet, it will

probably

be in

good

shape. Removing it,

on the other hand, could necessitate the

rebuilding

of

a whole foundation.

Archaeology

in wet

pits

does not have to be concerned

too much with the strata of fill.

Although

this is

heresy,

the

simple

truth

is that all material exclusive of the

original

installation is

scrap

that

dates in the last one hundred

years

or so. Since the

pit

will

undoubtedly

be wet and need

pumps

to

keep

water out, the strata will not be definable

as

every

shovelful of mud will be

immediately replaced by

more mud.

On occasion the

archaeology

will find the

original

turbine in the

pit.

The effort in

removing

was

usually greater

than the

scrap

value and it

survived because it was worthless. Turbines are

basically

cast iron. Heat

and

pounding

have the

tendency

to crack

castings.

Removal of turbines should

be done

carefully

unless one

only

wants to

scrap

it. Turbines are held in

place by

some form of bolts and brackets. These must

go

before the unit is

lifted. Bolts and brackets are either

wrought

iron or steel. Since

they

will be too corroded to work

conveniently,

the bolts will have to be sheared

(carefully). Getting

the turbine out after it is loose is no

problem

if one

is careful. Remember it will

weigh

from one-half ton to several

tons,

and

the

approximate weight

needs to be known before

choosing rigging.

Lift

straight up.

This

might

well mean that a frame will have to be made for the

job

to hold the chain fall.

Quite

often old turbines can be

rebuilt;

there-

fore it behooves the

project manager

to take

special

care in

extracting

an

old unit.

In historic

settings,

the lower one

goes

the better the conditions of

the

setting

because the lowest

parts

were

constantly wet,

and

barring changes

in river

levels, probably

remain wet. Since the

original

builders had the

propensity

of

setting

massive wooden beams and then

building

foundations

around

them,

the reuse of sound

original

members can result in a

great savings

in

money,

time and

aggravation.

The wheel mill at

Hagley

reuses all

original

1880-vintage

timber 3 feet below the water line.

To test such

surviving

wooden

beams,

a Swedish increment

boring

tool is

useful,

since wood often seems fine on the outside but in the

process

of

wetting

and

drying

the center had rotted out.

If the

original

iron is intact and

basically

sound

enough

for

reuse,

be

sure to check it

again

soon after

start-up.

Experience has shown that vibra-

tions from

running

will shake the

rusty

scale

loose, thereby reducing

the

dimensions and

producing "slop"

in the

system.

Since exact

alignment

of

parts

is essential to smooth

operation

and low maintenance costs,

the above

is

very important. Upon completion, servicing

becomes the new

problem

of

the restoration.

Determining

the condition of

masonry

work is

fairly simple

as rocks are

visually obvious,

and the mortar can be checked with a screwdriver. One can

pretty

much assume that

repointing

will be

necessary.

Cement installations

should be

inspected by

a civil

engineer.

A

Fr

Vol. VIII No. 4 1976

Page

55

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

t?+\,--

?r 1

cs

r

?,

r

C

1 fi 1

k

?e ~"

?ci?.L 'L

cl *' I 4

1 IC'

? ?

r I .C

E 1 ?e r

Figure

8 Draft tube which will be bolted to the

opening

in the bottom

of the

pressure

case shown in

Figure

5.

Discharge

end in the

foreground.

Courtesy

of The

Hagley

Museum

A)^r Vol. VIII No. 4 1976

Page

56

*~~~~~~~~~ . .

-.t .v -, " "%.

I

.

.

,

,

%

- -N -

.r

. -

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

80

WHEEL

o

70

- X 60

44

rM

50

XS HYPOTHETICAL EFFICIENCY COMPARISON

^

40 BETWEEN A WATERWHEEL AND TURBINE

40

30

1 5 3 7 FULL

2 8 4 8

Amount of Flow

FIGURE 9

A)r

Vol. VIII No. 4 1976 Page 57

r -- ?--

-- ... __

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

Selecting

a Turbine: If

replacement

of the

original

turbine is

necessary

there are several factors to consider. One needs to know the head

(nominally

the difference in elevation between the

top

of water in headrace and

top

of

water in the

tailrace),

the flow

(usable

cubic feet

per

second in

power

source),

and the

power requirement

of one's mill. Turbines come in

high-head

and low-head varieties. This means

that,

if the difference between the water

intake level and the tailrace is

great (say,

100

feet),

the turbine is a

high-head

turbine and has the curve of the vanes calculated to run

efficiently

with the

great pressure.

If the difference is minimal

(10

feet or

so),

the

turbine is a low-head turbine.

Supposedly

the turbines were

originally

supplied

to each installation calculated for its head. The basic

principle

to

know, however,

is

having

a turbine the same size as the

original,

for

the site will in no

way

assure efficient

operation

and the same

power output.

There are several variables to take into account.

REINSTALLATION -- SOME HINTS

Penstocks: If one has the

responsibility

of

setting

flume

(penstocks)

pipe,

note that "level"

pipe probably

will incline downward at least

1/4

inch

per

foot. This allows for

drainage during servicing.

The lower one

gets

below the level of the race,

the

higher

the internal

pipe operating

pressures.

This means that

pipe joints

need to be

carefully joined, sealed,

or caulked and filled. The

technology

of wooden

pipe,

bell and

spiked

cast

pipe,

and fabricated sheet metal

pipe

varies

considerably.

At this

writing

all forms of

pipe

are still available, although large-diameter

cast iron

pipe

is more difficult to obtain and

quite costly.

Setting

a Turbine: Modern industrial

specifications

for

"setting" (or

leveling)

a turbine are t.005 inches

per

foot. If this can be achieved,

do

it. One can

buy

a machinist's level (ours

is a

Starrett)

which will read to

that tolerance. The more

accurately

the installation is

initially

set

up,

the less the maintenance

problems

in the future. Old

buildings quite

often

settle and

problems

arise.

When

settling occurs,

there are two solutions. One can tear out the

culprit

and rebuild

it,

or one can shim it. All accurate

settings

have some

shims. One

deliberately

builds the base a small fraction of an inch low and

then shims

up

to true. This method is

vastly superior

to

grinding

excesses

away.

A

settling problem

will

require

careful examination to determine the

best solution.

Generally

a turbine will have two sets of

bearings,

the thrust and

collar. The bottom set takes all the

weight

and is called the thrust

bearing (see Figure 6).

The shaft is held true

by

a series of

adjustable

blocks

forming

a collar

bearing.

These have

historically

been made of the

wood

lignum

vitae.

Lignum

vitae is dense, oily

and

requires

no lubrication

beyond

the water which flows

through

the turbine. Both the turbine case and

the shaft have to be installed

accurately.

Do not set the case on askew and

correct with the collar

bearings.

ADr

Vol. VIII No. 4 1976 Page 58

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

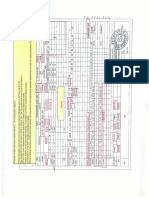

Figure

10 Generator floor under construction at the

Hydroelectric

Plant,

Hagley

Museum. This

project places

in service a

Smith-Kaplan

turbine

(seen

here

being

lowered into

pressure case)

and General Electric

generator (origi-

nally

made for the 1932 Winter

Olympic

Games in Lake

Placid)

on a site

origi-

nally developed

as a

hydroelectric plant

in the late 1890s. The

plant

is not

a restoration. It will

develop enough

electric

power

to

supply

the needs of

the Museum and will return in

savings

on the investment cost at a

high

rate.

There is a Visitor's Room with

explanatory panels

and a

viewing

area for see-

ing

the

generator

floor. The foundations and exterior of the

building

visu-

ally duplicate

the

original plant.

The

machinery

and switch

gear

meet modern

standards.

Waterpower

is still the cleanest and

cheapest practical

source of

energy

available.

Courtesy

of The

Hagley

Museum

Ar Vol. VIII No. 4 1976 Page 59

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

Figure

11

Hydroelectric plant

under construction. Generator

to

right partially

obscured

by

at the

Hagley

Museum.

in

center,

oil

pump

to

generator.

Generating

floor

left, governor

Courtesy

of The

Hagley

Museum

A

:

Vol. VIII

No. 4 1976

Page

60

I

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

If the turbine is set in a tub or

pressure case, the driveshaft and

control rod will

protrude

via a

stuffing

box

(see sketch).

These are not

bearings; they

are

accurately aligned

water seals.

Bearings, Couplings

and Shafts:

By

the time turbines came into common

usage,

the form of the

essentially

modern

bearing

had evolved. The

speeds

of a turbine are considered "low

speed" by

modern standards. The bronze or

babbit

bearings

are both correct

(for

mid-to-late 19th

century).

Roller and

ball

bearings

are more

usually

found on 20th

century

installations. While

modern roller

bearings

are found concealed in

restorations,

it is not

necessary,

and

perhaps

undesirable

mechanically.

Roller

bearings

will heat

up

if a roller breaks,

which can cause a

safety

hazard as in the case of a

gristmill

with dust in the air. Of course, the modern

bearings

are not

correct in older historical

settings.

As a

general

rule of

thumb, go

with

the

original technology.

The writer has had

experience

with

"improvements"

which cause

nothing

but

grief.

The

original,

fabricated to the best attain-

able

accuracy, usually gives

the best results.

Fortunately,

most turbines are

directly coupled

to iron shafts

geared

with all-iron or one iron-and-mortise

gear

on another iron shaft. In some

installations,

wooden shafts still remain to

power ancillary equipment,

but

this is

usually light

in terms of

power requirements.

Iron shafts and

gears

are

simpler

to work with than wood and

infinitely

more

pleasant

to maintain,

and use

easily

available stock

parts.

Start-up:

The initial

start-up period requires

close

supervision.

Gears

will "wear in" and will need

adjustment; pieces

will shake loose and need

realignment;

and

pieces

that are

inherently

weak will break. Schedule down-

time soon after

start-up

for

inspection.

After

running

the installation there

becomes a threefold maintenance

problem.

The first is lubrication,

done at

least

daily, usually by

the mill

operator. Also,

trash racks need

daily

inspection

and

cleaning

when

necessary,

which varies

seasonally. (At Hagley

we have

weekly inspections

of the

machinery by

the maintenace staff,

which

results in occasional minor

overhauls.)

These include

aligning gears,

bearings,

and

tightening stuffing

box seals.

Major

overhauls on turbines are

uncommon but

require major dismantling

and machine

shop

work. At

Hagley

trash racks are cleaned as needed

by

the

grounds

crew.

Corrosion Problems: Most water turbines are cast iron. If the turbine

is

kept wet,

the corrosion

problem

from

rusting

is

virtually

nonexistent.

Wetting

and

drying

will accelerate the rate of

rusting;

hence,

the

advantage

to the installations which rest below the tailrace. The cavitation

problem,

where

vapor

bubbles bombard the runner and

literally pop

off the metal, is

encountered with most draft tube turbines. The erosion

problem

is slow and,

since most restorations

operate

in terms of demonstration instead of

produc-

tion,

the erosion is a factor in

long-range planning (like replacing

tires on

an

automobile)

and not a deterrent in

doing

a restoration.

A^r

Vol. VIII No. 4 1976

Page

61

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

Maintenance Routine: Part of the

planning

for

every

restoration should

be maintenance. Machines need lubricants,

adjustment,

and

parts replaced.

All of this is a factor

usage.

Beware of dirt

getting

in

lubricants,

as it

will

effectively

convert

grease

to

grinding compound.

There is no

economy

in

reusing

the lubricant which works out of the

fittings.

The service

policy

at

Hagley

is to have the

operator

each

day

check lubricant levels,

and

replace

low levels where accessible. As

previously mentioned,

the service

department

makes routine checks (as does the curator who

put

the mill

together).

The

operator

should be able to detect

things going wrong by

the

change

in sound

of the

machinery

of vibrations. He should be trained to

report

the

problems

to the

proper persons

to make the

necessary repairs. During

all

servicing

except morning lubrication,

two men should be

present

for

safety.

Mills

were

designed

to increase man's

strength

and

consequently present

a hazard

to a lone man.

Conclusion: Turbines allow mechanical restorations to function

reliably

at a

very

low cost for

energy.

The

Hagley Museum,

for

example,

has

several,

one of which was

put

into service three

years ago

with

virtually

no

trouble. The institutional faith in this source of

power

is

being

demon-

strated

by

the erection of a

power plant

(on the site of an 1893

power house)

which will

provide electricity

for the entire

property.

Turbine

technology

is an

example

of a

technology

which was

perfected

to

a

high

level over a hundred

years ago,

and is a

technology being

utilized

today

with

only

a few

improvements. Hence,

when

considering

to

attempt

a

turbine-powered restoration,

one should be

encouraged

as the

problems

are

not that

great.

APPENDIX

Known Firms

working

with Water Turbines

James Leffel & Co. (manufacture and

repair)

426 East Street

Springfield,

Ohio 45501

Barber

Hydraulic Turbine,

Ltd. (manufacture and

repair)

Box 340

Port Colburn,

Ontario

Canada L3K 5W1

Allis-Chalmers

Corp. (large plants)

Turbine Division

1126 S. 70th St.

Milwaukee, Wisconsin 53201

Hydro

International (civil contractor -- work with

1 Court

Drive, Apt.

C.

Empire

&

Niagara)

Wilmington,

Delaware 19805

A)r

Vol. VIII No. 4 1976

Page

62

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

Harry

J.

McKay

68 Tennessee Ave.

Port Colburn,

Ontario

Canada L3K 2R9

(erector only)

(repair

and

erecting) Empire

Company

General

Delivery

Woodland, Maine 04694

Niagara

Water Wheels

706 E. Main St.

Welland,

Ontario

Canada L3B 3Y4

Robert L. Johnson

Whistles in the Woods

Route 1, Box 265-A

Rossville, Georgia

30741

Campbell

Waterwheel

Company

420 South 42nd Street

Philadelphia, Pennsylvania

19104

(new/repair/design)

(will produce

odd

parts

such

as wooden

gears)

(general services)

A Fr

Vol. VIII No. 4 1976 Page 63

This content downloaded from 14.139.240.6 on Thu, 17 Jul 2014 03:49:14 AM

All use subject to JSTOR Terms and Conditions

You might also like

- (Get Now) SOAP For Family Medicine by Daniel Maldonado: Â Š PDF Â Š KINDLE Â ŠDocument12 pages(Get Now) SOAP For Family Medicine by Daniel Maldonado: Â Š PDF Â Š KINDLE Â ŠMauricio Solano DiazNo ratings yet

- Warren Truss Bridge ReportDocument12 pagesWarren Truss Bridge ReportRaaj Chatterjee50% (2)

- SWE Training Manual PDFDocument371 pagesSWE Training Manual PDFALBERTO OLIVEROS100% (1)

- Pig Launcher and ReceiverDocument7 pagesPig Launcher and ReceiverGerman Felipe Torres100% (4)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- The Layout of Fluid Mechanics and Hydraulic Machinery LabDocument4 pagesThe Layout of Fluid Mechanics and Hydraulic Machinery LabAhmad RazaNo ratings yet

- Sample Road Design ReportDocument77 pagesSample Road Design ReportKwaku frimpongNo ratings yet

- L10 Hydraulic Turbines PDFDocument23 pagesL10 Hydraulic Turbines PDFDhavanLalNo ratings yet

- Wartsila SP A Id Waterjet B 2Document6 pagesWartsila SP A Id Waterjet B 2Junaid YNo ratings yet

- Hydraulic TurbineDocument19 pagesHydraulic TurbineJohn Mark James GaloNo ratings yet

- Home Built Hydraulic Ram PumpsDocument84 pagesHome Built Hydraulic Ram PumpsZwq92yNo ratings yet

- Inventions in Turbine Technology: Water Wheels and NoriasDocument8 pagesInventions in Turbine Technology: Water Wheels and Noriasßhardwaj NitishNo ratings yet

- PPE Expriment No-01Document9 pagesPPE Expriment No-01Aasawari Mahagaonkar100% (1)

- The Elements of Hydroelectric Power Plant Are As FollowsDocument8 pagesThe Elements of Hydroelectric Power Plant Are As FollowsDanial DanialNo ratings yet

- Hydraulic Ram-2017 - PDF RoomDocument7 pagesHydraulic Ram-2017 - PDF RoomR Nandhan 3BNo ratings yet

- Back To Basics: Part 1 - Components of A Steam LocomotiveDocument28 pagesBack To Basics: Part 1 - Components of A Steam LocomotivekabuldasNo ratings yet

- Petroleum Eng 1Document23 pagesPetroleum Eng 1Shah Fahad AlamNo ratings yet

- The Drilling Rig ComponentsDocument30 pagesThe Drilling Rig ComponentsKhaled El AssaadNo ratings yet

- A Review of Oscillating Water ColumnsDocument12 pagesA Review of Oscillating Water ColumnsCristobal Michelangelo FernaandesNo ratings yet

- DesignPriciples Concept Selection PDFDocument42 pagesDesignPriciples Concept Selection PDFBona_VentureNo ratings yet

- Functions of A Production PlatformDocument10 pagesFunctions of A Production Platformajwad_hashim5100% (1)

- Turbines SynopsisDocument4 pagesTurbines SynopsisNeeraj TripathiNo ratings yet

- Turbine: Types of TurbinesDocument6 pagesTurbine: Types of TurbinesKunal JadhavNo ratings yet

- Drilling Rig ComponentsDocument18 pagesDrilling Rig ComponentsIsmail A. IsmailNo ratings yet

- Advanced Technology - Archimedean Screw Summary 2015 10 19Document4 pagesAdvanced Technology - Archimedean Screw Summary 2015 10 19api-288292935No ratings yet

- Lecture No 7Document4 pagesLecture No 7Musa KhanNo ratings yet

- Water Turbine: From Wikipedia, The Free EncyclopediaDocument16 pagesWater Turbine: From Wikipedia, The Free Encyclopediakaushiksumit100% (1)

- Hydro-Electric Power PlantDocument46 pagesHydro-Electric Power Plantk rajendraNo ratings yet

- SpillwayDocument5 pagesSpillwaymaheshNo ratings yet

- Agitation and MixingDocument12 pagesAgitation and MixingSiri Nal100% (1)

- Gates For Flow ControlDocument41 pagesGates For Flow ControlkyogesswaranNo ratings yet

- Tugboat OperationsDocument15 pagesTugboat Operationsreurri0% (1)

- 8Document7 pages8Gigi SimaNo ratings yet

- Design Concept For A More Efficient Steam-Water SeparatorDocument7 pagesDesign Concept For A More Efficient Steam-Water SeparatorArini RizalNo ratings yet

- Hydro Electric Power Plant: V P H H Y HDocument10 pagesHydro Electric Power Plant: V P H H Y Harkan1976No ratings yet

- Equipo de PerforacionDocument21 pagesEquipo de PerforacionJoanna Guio0% (1)

- Rig Components PDFDocument19 pagesRig Components PDFBalant AxNo ratings yet

- Low Pressure SewersDocument23 pagesLow Pressure SewersUlil A JaNo ratings yet

- Hydro-Electric Power PlantDocument46 pagesHydro-Electric Power PlantAdrian Ray Ayam100% (1)

- The Water Tunnel As A Tool in Hydraulic Research PDFDocument24 pagesThe Water Tunnel As A Tool in Hydraulic Research PDFAbdul Wahab TariqNo ratings yet

- Rig Components 101Document90 pagesRig Components 101irrosel4650100% (1)

- Water Turbine - Wikipedia, ..Document9 pagesWater Turbine - Wikipedia, ..manbkkNo ratings yet

- Types of Turbines: Turbine ClassificationsDocument6 pagesTypes of Turbines: Turbine ClassificationsalbertNo ratings yet

- Rotary Positive Displacement PumpsDocument16 pagesRotary Positive Displacement Pumpsalexmuchmure2158No ratings yet

- Livestock Watering: Using Stream Energy To Pump Livestock WaterDocument4 pagesLivestock Watering: Using Stream Energy To Pump Livestock WaterraffaNo ratings yet

- Pumpjack: Above Ground Down-Hole Water Well Pumpjacks See Also References External LinksDocument5 pagesPumpjack: Above Ground Down-Hole Water Well Pumpjacks See Also References External LinksBenjamin KonjicijaNo ratings yet

- Drilling Engineering 1Document51 pagesDrilling Engineering 1Adnan AhmadNo ratings yet

- 11.2 Chapter 2 FinalDocument19 pages11.2 Chapter 2 FinalPhoo PhooNo ratings yet

- Chapter 3 Mine PumpsDocument29 pagesChapter 3 Mine PumpsOolasyar KhattakNo ratings yet

- Draft Proposal (01-02-20107)Document14 pagesDraft Proposal (01-02-20107)Ahsan MurtazaNo ratings yet

- Water Turbine His To RZDocument6 pagesWater Turbine His To RZJosef LoLNo ratings yet

- Hydro Power PlantsDocument7 pagesHydro Power PlantsKyambadde Francisco100% (1)

- Mechanics of MachinesDocument13 pagesMechanics of MachinesJeff HardyNo ratings yet

- Types and Parts of Hydraulic JackDocument17 pagesTypes and Parts of Hydraulic JackDenialNo ratings yet

- AgitationDocument8 pagesAgitationroxetteNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Windmills and Waterwheels Explained: What They Do and How They WorkFrom EverandWindmills and Waterwheels Explained: What They Do and How They WorkNo ratings yet

- List of FilesDocument4 pagesList of FilesSanjeev SharmaNo ratings yet

- Attendance Position of Mba Students Up To 31St March 2016 Hptu Business School, Rggec Campus, Nagrota Bagwan Kangra 176047 (H.P.)Document6 pagesAttendance Position of Mba Students Up To 31St March 2016 Hptu Business School, Rggec Campus, Nagrota Bagwan Kangra 176047 (H.P.)Sanjeev SharmaNo ratings yet

- Institute of Pesticide Formulation Technology (IPFT) : Sector-20, Udyog Vihar, Gurgaon - 122 016 (Haryana)Document4 pagesInstitute of Pesticide Formulation Technology (IPFT) : Sector-20, Udyog Vihar, Gurgaon - 122 016 (Haryana)Sanjeev SharmaNo ratings yet

- Corporate GovernanceDocument469 pagesCorporate GovernanceSanjeev Sharma100% (2)

- December 2011, CA-CPT Question Paper (Based On Memory) : No.1 For CA/CWA & MEC/CECDocument16 pagesDecember 2011, CA-CPT Question Paper (Based On Memory) : No.1 For CA/CWA & MEC/CECSanjeev SharmaNo ratings yet

- How To Use The E-ResourcesDocument10 pagesHow To Use The E-ResourcesSanjeev SharmaNo ratings yet

- Curriculum Viate VishalDocument2 pagesCurriculum Viate VishalSanjeev SharmaNo ratings yet

- How To Use Ladybird Readers PDFDocument18 pagesHow To Use Ladybird Readers PDFJonas SilvaNo ratings yet

- Proto Catalog 108 2016 - Low ResDocument996 pagesProto Catalog 108 2016 - Low ResMasterrNo ratings yet

- Chapter 2 Empiricism and PositivismDocument15 pagesChapter 2 Empiricism and PositivismJames RayNo ratings yet

- Delta Ia-Plc DVP-PLC PM en 20140804Document749 pagesDelta Ia-Plc DVP-PLC PM en 20140804Ali PadaryamNo ratings yet

- B.Lib SyllabusDocument17 pagesB.Lib SyllabussantoshguptaaNo ratings yet

- AutoBiography of A RiverDocument4 pagesAutoBiography of A Riversukhamoy2571% (21)

- Soft StarterDocument7 pagesSoft Starterdvmreddy1232007No ratings yet

- Elfredo - Dr@yahoo - Co.id: Keywords: Factors, Delays, Study, Course, EssayDocument9 pagesElfredo - Dr@yahoo - Co.id: Keywords: Factors, Delays, Study, Course, Essayekka fauzanNo ratings yet

- KL202232 PSRPT 2022-05-18 18.01.51Document19 pagesKL202232 PSRPT 2022-05-18 18.01.51Thuy AnhNo ratings yet

- Deleuze Guattariandthe Indian DiagramDocument19 pagesDeleuze Guattariandthe Indian DiagramManu KhannaNo ratings yet

- Training Regulations: Motorcycle/ Small Engine Servicing NC IiDocument102 pagesTraining Regulations: Motorcycle/ Small Engine Servicing NC IiAmit Chopra AmitNo ratings yet

- S TR Ohl Surv (Rev.0 2010)Document6 pagesS TR Ohl Surv (Rev.0 2010)bogdanNo ratings yet

- QB GrammarDocument13 pagesQB GrammarMuhammed Ali AktaşNo ratings yet

- مطوية انجليزية 1Document2 pagesمطوية انجليزية 1Chaker HamdiNo ratings yet

- 4.3 - B - 7 - Procedure For OHS Management ProgrammeDocument3 pages4.3 - B - 7 - Procedure For OHS Management ProgrammeSASIKUMAR SNo ratings yet

- Design of Basic ComputerDocument29 pagesDesign of Basic ComputerM DEEPANANo ratings yet

- Sizing of The Buffer Tank in Chilled Water Distribution A C Systems - PUBLISHED VERSIONDocument31 pagesSizing of The Buffer Tank in Chilled Water Distribution A C Systems - PUBLISHED VERSIONHai PhanNo ratings yet

- Step2 - Oscar Parra - Grupo 8Document15 pagesStep2 - Oscar Parra - Grupo 8Andres RuizNo ratings yet

- MTC 17022021063931Document1 pageMTC 17022021063931Ahmed LepdaNo ratings yet

- Canal SystemsDocument69 pagesCanal SystemsAnter TsatseNo ratings yet

- Rapid Roll GameDocument23 pagesRapid Roll GameRithika RithiNo ratings yet

- ESOL Nexus Teaching MathematicsDocument38 pagesESOL Nexus Teaching MathematicsArnold HoNo ratings yet

- Ats22 User Manual en Bbv51330 02Document85 pagesAts22 User Manual en Bbv51330 02Catalin PelinNo ratings yet

- Rivera December Staar Eoc TA Testing PPDocument55 pagesRivera December Staar Eoc TA Testing PPOlga RenteriaNo ratings yet

- Microeconomics Question Set 4 (20231107) AnswerkeyDocument9 pagesMicroeconomics Question Set 4 (20231107) AnswerkeyMegumi TsuchiyaNo ratings yet

- PVC Cable Color Code ChartDocument1 pagePVC Cable Color Code ChartMiabNo ratings yet

- Long Quiz Prelim DiassDocument2 pagesLong Quiz Prelim DiassBel Patrice TisuelaNo ratings yet