Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

30 viewsTreatment of Dairy Waste Water Using UASB Reactor and Generation of Energy

Treatment of Dairy Waste Water Using UASB Reactor and Generation of Energy

Uploaded by

vk100This document summarizes a study on treating dairy wastewater using an Upflow Anaerobic Sludge Blanket (UASB) reactor. Some key points:

1) Dairy wastewater is characterized and an UASB reactor is used to treat it. UASB reactors have advantages over other anaerobic processes.

2) The UASB process results in methane gas production which can be captured and used as an energy source, making the treatment process more economical.

3) The degree of organic matter removal correlates with methane production - continual downward trends in gas production indicate process failure.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Press MUd To Bio GasDocument5 pagesPress MUd To Bio GasAyush AgrawalNo ratings yet

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationFrom EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationNo ratings yet

- Refining HistoryDocument26 pagesRefining HistoryS M AseemNo ratings yet

- Internal Circulation Reactor Pushing The LimitsDocument9 pagesInternal Circulation Reactor Pushing The LimitsAbhishek TripathiNo ratings yet

- Minimization of Excess Sludge Production For Biological Wastewater TreatmentDocument15 pagesMinimization of Excess Sludge Production For Biological Wastewater Treatmentashoori79No ratings yet

- ReviewPaperonindustrialwastewatertreatmentprocesses PDFDocument19 pagesReviewPaperonindustrialwastewatertreatmentprocesses PDFPrathamesh KanganeNo ratings yet

- Anarebic PondsDocument5 pagesAnarebic Pondsunitechwater6517100% (2)

- Use of The Upflow Sludge Blanket (USB) ReactorDocument36 pagesUse of The Upflow Sludge Blanket (USB) ReactorinscNo ratings yet

- Anaerobic Treatments ProcessDocument6 pagesAnaerobic Treatments Processashe zinabNo ratings yet

- Application of Uasbr in Treatment of Dairy Waste Water: 1, PG Student, 2, Assistant ProfessorDocument9 pagesApplication of Uasbr in Treatment of Dairy Waste Water: 1, PG Student, 2, Assistant Professorvk100No ratings yet

- International Refereed Journal of Engineering and Science (IRJES)Document8 pagesInternational Refereed Journal of Engineering and Science (IRJES)www.irjes.comNo ratings yet

- Anaerobic Digestion in CanadaDocument44 pagesAnaerobic Digestion in Canadascience4uNo ratings yet

- Anaerobic MBR Potentials VisuDocument10 pagesAnaerobic MBR Potentials VisuAhmad HashimNo ratings yet

- Anaerobic Waste Stabilization Ponds A Low-Cost ConDocument6 pagesAnaerobic Waste Stabilization Ponds A Low-Cost ConrajeshNo ratings yet

- Chapter-1: 1.1 GeneralDocument33 pagesChapter-1: 1.1 GeneralAbhinay SinghNo ratings yet

- The Treatment of Baker - S Yeast Wastewater by An Up Flow Anaerobic Sludge Blanket (UASB) Reactor (#409483) - 448477Document6 pagesThe Treatment of Baker - S Yeast Wastewater by An Up Flow Anaerobic Sludge Blanket (UASB) Reactor (#409483) - 448477AlexandraGuajánNo ratings yet

- Powar (2013) Review On Applications of UASB Technology For Wastewater TreatmentDocument9 pagesPowar (2013) Review On Applications of UASB Technology For Wastewater TreatmentchemNo ratings yet

- Hossain 2019 Energy Efficient COD by Passively Aerated GAODocument11 pagesHossain 2019 Energy Efficient COD by Passively Aerated GAOFelipe galarceNo ratings yet

- IJE_Volume 36_Issue 3_Pages 490-496Document7 pagesIJE_Volume 36_Issue 3_Pages 490-496Muhammad TurmuziNo ratings yet

- PASSEGGI - 2012 - Modified UASB Reactor For Dairy Industry Wastewater Performance Indicators and Comparison With The Traditional AppDocument5 pagesPASSEGGI - 2012 - Modified UASB Reactor For Dairy Industry Wastewater Performance Indicators and Comparison With The Traditional AppThobiasNo ratings yet

- BIOLOGICAL TREATMENT AND COMPOSTING NewDocument9 pagesBIOLOGICAL TREATMENT AND COMPOSTING NewKiruthika KiruthiNo ratings yet

- Bioresource Technology: Byung-Gon Ryu, Jungmin Kim, Jong-In Han, Ji-Won YangDocument9 pagesBioresource Technology: Byung-Gon Ryu, Jungmin Kim, Jong-In Han, Ji-Won YangThirumalaivasanNo ratings yet

- Pilot Scale Study of Horizontal Anaerobic Digester For Biogas Production Using Food WasteDocument4 pagesPilot Scale Study of Horizontal Anaerobic Digester For Biogas Production Using Food WasteAl AkilNo ratings yet

- A Review On Palm Oil Mill Biogas Plant Wastewater Treatment Using Coagulation-OzonationDocument7 pagesA Review On Palm Oil Mill Biogas Plant Wastewater Treatment Using Coagulation-OzonationMaizan Sofia Binti Mohd MaarofNo ratings yet

- Ijisrt20may964 PDFDocument6 pagesIjisrt20may964 PDFUna Isma100% (23)

- Parametric Study of Brewery Wastewater Effluent Treatment Using Chlorella Vulgaris MicroalgaeDocument8 pagesParametric Study of Brewery Wastewater Effluent Treatment Using Chlorella Vulgaris MicroalgaeAA0809No ratings yet

- Performances of An Activated Sludge Proc20160202 15516 14586m1 With Cover Page 1.2Document9 pagesPerformances of An Activated Sludge Proc20160202 15516 14586m1 With Cover Page 1.2Abdul rahmanNo ratings yet

- Energies 16 00571 v2Document18 pagesEnergies 16 00571 v2loliNo ratings yet

- Aerobic and Anaerobic ProcessDocument20 pagesAerobic and Anaerobic ProcessNayan GanjiNo ratings yet

- Heat New Chemical with New Starch Research ProgressDocument13 pagesHeat New Chemical with New Starch Research ProgressEudkrenutNo ratings yet

- Starch Research ProgressDocument15 pagesStarch Research ProgressEudkrenutNo ratings yet

- Water: Influence of Pre-Hydrolysis On Sewage Treatment in An Up-Flow Anaerobic Sludge BLANKET (UASB) Reactor: A ReviewDocument27 pagesWater: Influence of Pre-Hydrolysis On Sewage Treatment in An Up-Flow Anaerobic Sludge BLANKET (UASB) Reactor: A ReviewrajeshNo ratings yet

- Aip Conference Proceedings Aip Publishing LLC International Conference of Chemical and Material Engineering Iccme 2015-g1.4938380Document9 pagesAip Conference Proceedings Aip Publishing LLC International Conference of Chemical and Material Engineering Iccme 2015-g1.4938380Marcin ChęcińskiNo ratings yet

- Master Thesis: Moving Biofiles in Sequential Discharge Reactor (SBR)Document88 pagesMaster Thesis: Moving Biofiles in Sequential Discharge Reactor (SBR)DianerNo ratings yet

- Anaerobic Digestion Use in Wastewater Treatment - Sustainable DevelopmentsDocument7 pagesAnaerobic Digestion Use in Wastewater Treatment - Sustainable DevelopmentsUmutNo ratings yet

- Biogas From Organic Waste - A Case Study: SciencedirectDocument8 pagesBiogas From Organic Waste - A Case Study: Sciencedirectd3 tekim2018No ratings yet

- Challenges in UASB Reactor System Design: A Review: September 2015Document9 pagesChallenges in UASB Reactor System Design: A Review: September 2015song1088No ratings yet

- 5 ReportDocument20 pages5 ReportPRATEEK KUMAR DASNo ratings yet

- Critical Stage in Starch WastewaterDocument10 pagesCritical Stage in Starch WastewaterEudkrenutNo ratings yet

- 26-11 ProjDocument57 pages26-11 ProjSharath ChandraNo ratings yet

- Starch WastewaterDocument6 pagesStarch WastewaterEudkrenutNo ratings yet

- Use of Biomethane As A Sustainable FuelDocument35 pagesUse of Biomethane As A Sustainable FuelVedant KarnatakNo ratings yet

- Biogas Production From Municipal Sewage Sludge Using Ultrasound Speeding Digestion ProcessDocument10 pagesBiogas Production From Municipal Sewage Sludge Using Ultrasound Speeding Digestion ProcessInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Zhang Et Al. (2021) - UASBDocument9 pagesZhang Et Al. (2021) - UASBĐào Ngọc Bảo TrânNo ratings yet

- Biogas Production From Sawdust Waste, Cow Dung and Water Hyacinth-Effect of Sawdust ConcentrationDocument3 pagesBiogas Production From Sawdust Waste, Cow Dung and Water Hyacinth-Effect of Sawdust ConcentrationInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Recent Applications of Coagulation, Flocculation and Ballast Flocculation in Treatment of Wastewater-A ReviewDocument5 pagesRecent Applications of Coagulation, Flocculation and Ballast Flocculation in Treatment of Wastewater-A ReviewIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- 1 Treatment Process: 1.1 ThickeningDocument10 pages1 Treatment Process: 1.1 ThickeningAnang ARNo ratings yet

- Activated Sludge ProcessDocument48 pagesActivated Sludge Processrozma khanNo ratings yet

- 1 PDFDocument7 pages1 PDFsong1088No ratings yet

- Removal of CO From Biogas Plant Using Chemical Absorption ColumnDocument7 pagesRemoval of CO From Biogas Plant Using Chemical Absorption ColumnanirudhNo ratings yet

- Chapter OneDocument46 pagesChapter OneibukunadedayoNo ratings yet

- Sharda University: Bio Gas PlantsDocument19 pagesSharda University: Bio Gas PlantsEdrisNo ratings yet

- Biogas Fro Chicken WasteDocument8 pagesBiogas Fro Chicken WasteSekarNTutyNo ratings yet

- Oxidation PondDocument10 pagesOxidation PondCoc LoverNo ratings yet

- Optimization of Anaerobic Mechanism Using Response Surface Methodology (RSM) To Treat Pulp and Paper Industry Wastewater: A ReviewDocument9 pagesOptimization of Anaerobic Mechanism Using Response Surface Methodology (RSM) To Treat Pulp and Paper Industry Wastewater: A ReviewEditor IJTSRDNo ratings yet

- Granulation Strategies Applied To Industrial Wastewater TreatmentDocument11 pagesGranulation Strategies Applied To Industrial Wastewater TreatmentLixin YangNo ratings yet

- D M W T U L S S B R (SBR) : Airy Ilking Astewater Reatment Sing A AB Cale Equencing Atch EactorDocument10 pagesD M W T U L S S B R (SBR) : Airy Ilking Astewater Reatment Sing A AB Cale Equencing Atch EactorMinh Hằng TrầnNo ratings yet

- Applying Internal Circulation Anaerobic Reactor FoDocument8 pagesApplying Internal Circulation Anaerobic Reactor FoAlvaro HueteNo ratings yet

- Use of CowDung As A Source of Bio Culturing For ETPDocument7 pagesUse of CowDung As A Source of Bio Culturing For ETPRG SegaranNo ratings yet

- Biological Sludge Minimization and Biomaterials/Bioenergy Recovery TechnologiesFrom EverandBiological Sludge Minimization and Biomaterials/Bioenergy Recovery TechnologiesEtienne PaulNo ratings yet

- Climate Change and Cotton Production in Modern Farming SystemsFrom EverandClimate Change and Cotton Production in Modern Farming SystemsNo ratings yet

- Follow The Schedule As Per Given Guideline Without Fail. Prof. V.R. Kasar Subject Teacher/GuideDocument2 pagesFollow The Schedule As Per Given Guideline Without Fail. Prof. V.R. Kasar Subject Teacher/Guidevk100No ratings yet

- CE ESE Objective Volume-1 (2017)Document12 pagesCE ESE Objective Volume-1 (2017)vk100No ratings yet

- Sr. No. Item/Particulars Material Required Qty Actual QtyDocument11 pagesSr. No. Item/Particulars Material Required Qty Actual Qtyvk100No ratings yet

- Civil Event Details-Shodh2018Document4 pagesCivil Event Details-Shodh2018vk100No ratings yet

- External Optical Level (2-Peg Test) SurveyDocument7 pagesExternal Optical Level (2-Peg Test) Surveyvk100No ratings yet

- Laboratory Manual For The Microbiological Analyses of Public Drinking Water 2001Document74 pagesLaboratory Manual For The Microbiological Analyses of Public Drinking Water 2001vk100No ratings yet

- Capr I En6273Document45 pagesCapr I En6273vk100No ratings yet

- Auto Cad ListDocument6 pagesAuto Cad Listvk100No ratings yet

- ATM Networks: © N. Ganesan, PH.DDocument19 pagesATM Networks: © N. Ganesan, PH.Dvk100No ratings yet

- Chinease Postman ProblemDocument9 pagesChinease Postman Problemvk100No ratings yet

- Basic Concepts and Definitions of Graph TheoryDocument39 pagesBasic Concepts and Definitions of Graph Theoryvk100No ratings yet

- Basic Graph Theory Definitions and NotationDocument2 pagesBasic Graph Theory Definitions and Notationvk100No ratings yet

- Origin of Graph TheoryDocument5 pagesOrigin of Graph Theoryvk100No ratings yet

- Capr I En6273Document45 pagesCapr I En6273vk100No ratings yet

- Basis of SafetyDocument2 pagesBasis of SafetyTen Dye MungwadziNo ratings yet

- Dam Design and Completion ReportDocument8 pagesDam Design and Completion ReportPasi C4SieleNo ratings yet

- Experiment 2: Water Analysis Colour Measurement On Suspended Solid DeterminationDocument4 pagesExperiment 2: Water Analysis Colour Measurement On Suspended Solid DeterminationSyafiq Shaffiai0% (1)

- Unit 4Document37 pagesUnit 4achuilmajokaNo ratings yet

- EDTA MsdsDocument5 pagesEDTA MsdsĐại Việt Quốc XãNo ratings yet

- Calculator Programmable ThermostatDocument5 pagesCalculator Programmable Thermostataravoof84No ratings yet

- School Dampalit ES Grade Level Five Teacher Joanne S. Velarde Learning Areas Science Teaching Dates and Time Day Quarter FirstDocument7 pagesSchool Dampalit ES Grade Level Five Teacher Joanne S. Velarde Learning Areas Science Teaching Dates and Time Day Quarter FirstAnatasuki100% (1)

- ALPHA MOTORS LTD Integrating Life Cycle EnviroDocument9 pagesALPHA MOTORS LTD Integrating Life Cycle EnviroSharif ShaikNo ratings yet

- Solid Waste Technology PDFDocument37 pagesSolid Waste Technology PDFJohn Feil JimenezNo ratings yet

- Aspect Impact Register - DAICECDocument59 pagesAspect Impact Register - DAICECmaxscribdNo ratings yet

- aBHISHEK SEMINAR ON CIGRATTE BUTTS BRICKSDocument16 pagesaBHISHEK SEMINAR ON CIGRATTE BUTTS BRICKSAvinash Noubade100% (1)

- Elec & I&C Cable Construction Progress (As of 21 June, 2018)Document7 pagesElec & I&C Cable Construction Progress (As of 21 June, 2018)Kharisma Pangeran LanangNo ratings yet

- MSDS Vanadium PentoxideDocument5 pagesMSDS Vanadium PentoxideRezer AxelNo ratings yet

- Air Pollution in NepalDocument2 pagesAir Pollution in NepalEducational HubNo ratings yet

- Lecture No. 4 Fate and Transport of ContaminantsDocument12 pagesLecture No. 4 Fate and Transport of ContaminantsJorn DoeNo ratings yet

- 2 Summary Report of Planning and Management - Rspo NPP PT - Agro Muara RupitDocument16 pages2 Summary Report of Planning and Management - Rspo NPP PT - Agro Muara RupitDede AhdiyatNo ratings yet

- Design and Analysis of Muffler To Reduce The Back PressureDocument5 pagesDesign and Analysis of Muffler To Reduce The Back PressureijsretNo ratings yet

- Human Influences On EcosystemsDocument10 pagesHuman Influences On Ecosystemsnurul sakeenaNo ratings yet

- Experimental Study On Concrete With Partial Replacement of Cement With Fly Ash & Coarse Aggregate by Ceramic TilesDocument7 pagesExperimental Study On Concrete With Partial Replacement of Cement With Fly Ash & Coarse Aggregate by Ceramic TilesIJSTENo ratings yet

- Final Project ReportDocument24 pagesFinal Project Reportapi-436879593No ratings yet

- 9th Grade Lesson Plan-1-1Document121 pages9th Grade Lesson Plan-1-1Aigerim MurzamdamovaNo ratings yet

- Iaea Tecdoc 1472 PDFDocument584 pagesIaea Tecdoc 1472 PDFRussell ClarkNo ratings yet

- BrandixDocument15 pagesBrandixshreay12345100% (1)

- API SN 5w 30 MsdsDocument5 pagesAPI SN 5w 30 MsdsahmetNo ratings yet

- Dolomite and Kaliwa Dam DefenseDocument8 pagesDolomite and Kaliwa Dam DefenseEa YangNo ratings yet

- Slide Presentation by Lesley Allen Kabigting For The Role of Economics in Environmental ManagementDocument35 pagesSlide Presentation by Lesley Allen Kabigting For The Role of Economics in Environmental ManagementLee K.No ratings yet

- River MorphologyDocument20 pagesRiver Morphologyale hopeju2009100% (1)

- Case Study On Environmental PollutionDocument34 pagesCase Study On Environmental PollutionDr Dheeraj Mehrotra63% (8)

- Responsibility For Preserving The Environment Ultimately Belongs To Each Individual & Not To GovernmentDocument1 pageResponsibility For Preserving The Environment Ultimately Belongs To Each Individual & Not To GovernmentHammad HassanNo ratings yet

Treatment of Dairy Waste Water Using UASB Reactor and Generation of Energy

Treatment of Dairy Waste Water Using UASB Reactor and Generation of Energy

Uploaded by

vk1000 ratings0% found this document useful (0 votes)

30 views5 pagesThis document summarizes a study on treating dairy wastewater using an Upflow Anaerobic Sludge Blanket (UASB) reactor. Some key points:

1) Dairy wastewater is characterized and an UASB reactor is used to treat it. UASB reactors have advantages over other anaerobic processes.

2) The UASB process results in methane gas production which can be captured and used as an energy source, making the treatment process more economical.

3) The degree of organic matter removal correlates with methane production - continual downward trends in gas production indicate process failure.

Original Description:

ccxz

Original Title

Dairy

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes a study on treating dairy wastewater using an Upflow Anaerobic Sludge Blanket (UASB) reactor. Some key points:

1) Dairy wastewater is characterized and an UASB reactor is used to treat it. UASB reactors have advantages over other anaerobic processes.

2) The UASB process results in methane gas production which can be captured and used as an energy source, making the treatment process more economical.

3) The degree of organic matter removal correlates with methane production - continual downward trends in gas production indicate process failure.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

30 views5 pagesTreatment of Dairy Waste Water Using UASB Reactor and Generation of Energy

Treatment of Dairy Waste Water Using UASB Reactor and Generation of Energy

Uploaded by

vk100This document summarizes a study on treating dairy wastewater using an Upflow Anaerobic Sludge Blanket (UASB) reactor. Some key points:

1) Dairy wastewater is characterized and an UASB reactor is used to treat it. UASB reactors have advantages over other anaerobic processes.

2) The UASB process results in methane gas production which can be captured and used as an energy source, making the treatment process more economical.

3) The degree of organic matter removal correlates with methane production - continual downward trends in gas production indicate process failure.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

PRATIBHA: INTERNATIONAL JOURNAL OF SCIENCE, SPIRITUALITY,

BUSINESS AND TECHNOLOGY (IJSSBT), Vol. 2, No.1, November 2013

ISSN (Print) 22777261

52

Treatment of Dairy waste water using UASB Reactor and

generation of energy

1

. Prof.P.A.Shirule

2*

Mr.Nana M.Mulik

3

Prof V P Sangore

1

(Ass Professor Dept. of Civil Engg. SSBTs COET Jalgaon.)

2

(Student M.E IInd year civil Environmental Engg.SSBTs COE Jalgaon.)

3

(Assistant Professor Dept .of Chemical Engg. SSBTsCOET Jalgaon.)

*

(Email-nanamulik78@gmail.com) (Contact-9766002273)

ABSTRACT

In recent years we have been moving towards

more and more industrial development. As a

result we are facing many environmental

pollution problems. The waste water emanating

from this highly processed industrial processes

which are putrescible in nature. Hence

treatment of such waste water is essential before

disposal of river, stream etc.

The quality of wastewater decides the line of

treatment. The study undertaken involved the

characterization of wastewater and the dairy

waste is selected for this purpose. The model

study gives the approximate idea about the

usability and function of the treatment of the

waste water of industry by UASB method.

UASB being the anaerobic treatment many

other processes also exists but with comparison

to UASB it has certain advantages which are

also made here. Thus trying to bring out the

best and foremost means to use the UASB

against others.

The anaerobic treatment results in formation of

methane (CH

4

) which can be used as an energy

source. Therefore anaerobic process followed

by aerobic process has proved to be economical

in waste treatment.

The degree of removal of organic matter is in

direct proportion to the amount of methane

produced. If gas production trend is downward

continually the digestion process is failing.

Gas produced after degradation of organic

matter contains about nearly 75-80% CH

4

by

volume, 15 to 25% CO

2

& small of N

2

, H

2

other

gases. Since methane gas has high calorific

value. This gas is collected & can be used as an

alternative source of energy. Thus, this process

becomes economical and effective for high BOD

wastes.

1. INTRODUCTION

India is one of the fast developing countries with

growing number of industries. The situation is

similar to that prevailing in most of the developing

countries, which have not been able to develop

adequate civic infrastructure even when their

number of citizens and industries have increased

rapidly. As a result many of cities have grown into

overcrowded and ill-equipped settlements with a

highly polluted environment prone to frequent

epidemics and hardships. Dairy industry has

become one of the major food processing

industries of the world in current century after the

inversion of milk preservation techniques and

pasteurization and powderisation technique.

In India near about in 273 dairy industries

processing and supplying 18.33 million liters milk

soled per day through arranged sales. But in whole

process large amount of waste water generates,

thats why it is necessary to treat that water by

using sustainable method like UASB reactor (i.e.

Upflow Anaerobic Sludge Blanket reactor).

The Upflow Anaerobic Sludge Blanket (UASB)

process is one of the recent developments in field

of anaerobic treatment. In this process the use of

primary treatment and the filter bed is completely

eliminated. The UASB process is seen as one of

the most cost effective & efficient anaerobic

treatment. The anaerobic treatment results in

formation of methane (CH4) which can be used as

an energy source. Therefore anaerobic process

followed by aerobic process has proved to be

economical in waste treatment.

2. LITERATURE REVIEW

In any dairy plant, the quantity and

characteristics of effluent is depending upon the

extent of production activities, pasteurization of

several milk products. The anaerobic digesters are

used in the first phase of treatment, which is

followed by high rate aerobic treatment.

Upflow Anaerobic Sludge Blanket reactors are

designed. UASB is a hybrid type of reactor,

involving both suspended and attached growth

PRATIBHA: INTERNATIONAL JOURNAL OF SCIENCE, SPIRITUALITY,

BUSINESS AND TECHNOLOGY (IJSSBT), Vol. 2, No.1, November 2013

ISSN (Print) 22777261

53

process. This study involves the treatment of dairy

industry wastewater by UASB reactor by varying

the retention times in days for a particular organic

loading rate . This has effectively removed BOD,

COD and other parameters because of the

combined suspended and attached growth

processes. [1]

Anaerobic wastewater treatment differs from

conventional aerobic treatment. The absence of

oxygen leads to controlled conversion of complex

organic pollutions, mainly to carbon dioxide and

methane.Anaerobic treatment has favourable

effects like removal of higher organic loading, low

sludge production, high pathogen removal, biogas

gas production and low energy

consumption.Application of anaerobic systems for

municipal sewage treatment is so far very limited.

The predominant reason given for is, that

municipal sewage are to weak (to low BOD or

COD) to maintain high biomass (in the form of

granules suspended solids or fixed film) content

in reactor.[2]

3. CHARACTERISTICS OF WASTE WATER

3.1 Physical characteristics :

a) Colour b) Odour c)

Temperature d) Solids:

3.2 Chemical characteristics:

a) Chloride b) Alkalinity c) Acidity

d) Hydrogen Concentration

e)Biochemical Oxygen Demand (BOD)

f) Chemical Oxygen Demand (COD)

3.3 COMPOSITION OF TYPICAL DAIRY

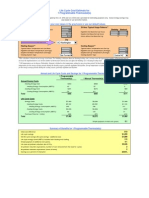

WASTEWATER:

Sr. No. Parameters Value

1 pH 7.2

2 Alkalinity 600

3 Total Dissolved Solids 1060 mg/lit

4 Suspended solids 760 mg/lit

5 BOD 1240 mg/lit

6 COD 2580 mg/lit

7 Total Nitrogen 84

8 Phosphorous 11.7

9 Oil and Greases 290

10 Chlorides 105

4. ANAEROBIC SUSPENDED GROWTH

TREATMENT PROCESSES

In the post ten years a number of different

anaerobic processes have been developed for the

treatment of sledges and high-strength organic

wastes. Some commonly use anaerobic suspended

growth treatment processes are given as follows:

A) Anaerobic digestion, B) Anaerobic

contact process, C) UASB blanket.

Up-flow anaerobic sludge-Blanket

process

In the up flow anaerobic sludge-blanket

(UASB) process, the wastewater flows upward

through a sludge blanket composed of biologically

formed granules or particles. Treatment produced

under anaerobic conditions (principally Methane

and carbon dioxide) cause internal circulation,

which helps in the formation and maintenance of

the biological granules. Some of the gas produced

within the sludge blanket becomes attached to the

biological granules. The free gas and the particles

with the attached gas rise to the top of the reactor.

4.1 Factors Affecting Anaerobic Digestion

A. Environmental factors:

1) PH & Alkalinity 2) Volatile acid concentration

3) Temperature 4) Nutrient Availability 5) Toxic

materials

B.Basic Factors:

1) Bacteria 2) Food 3) Contact 4) Time.

5. UASB PROCESS AND EXPERIMENTAL

SETUP

Brief History UASB:

The UASB process was developed by Dr. Gatze

Lettinga (and colleagues in the late 1970's at the

Wageningen University. Inspired by publications

of Dr. Perry McCarty, Lettinga's team was

experimenting with an anaerobic filter concept.

The anaerobic filter (AF) is a high rate anaerobic

reactor in which biomass is immobilized on an

inert porous support material. During experiments

with the AF, Lettinga had observed that in addition

to biomass attached on the support material, a large

proportion of the biomass developed into free

granular aggregates. The UASB concept

crystallized during a trip Gatze Lettinga made to

South Africa, where he observed at an anaerobic

plant treating wine vinasse, that sludge was

developing into compact granules. The reactor

design of the plant he was visiting was a

"clarigestor", which can be viewed as an ancestor

to the UASB. The upper part of the "clarigestor"

reactor design has a clarifier but no gas cap.

PRATIBHA: INTERNATIONAL JOURNAL OF SCIENCE, SPIRITUALITY,

BUSINESS AND TECHNOLOGY (IJSSBT), Vol. 2, No.1, November 2013

ISSN (Print) 22777261

54

Schematic diagram of UASB reactor

Internal three-phase GSL device:

Installed at the top of the tank, the GSL

device constitutes an essential part of an UASB

reactor with following functions:

1) To collect, separate and discharge the

biogas formed.

2) To reduce liquid turbulences, resulting from

the gas production, in the settling

compartment.

3) To allow sludge particles to separate by

sedimentation, flocculation or entrapment in

the sludge blanket.

4) To limit expansion of the sludge bed in the

digester compartment.

5) To reduce or prevent the carry-over of

sludge particles from the system.

6. CASE STUDIES

Thorat Milk Production: Sangamner

Dairy has set up on UASB reactor by March 1998,

the reactor was the first UASB treatment for dairy

in the state of Maharashtra. The reactor was

designed by Netherlands technology. This reactor

made the table of waste water treatment much

easier effective and also was much economical

giving good end-result.

Dimensions: Ht 6.5 m.

PRATIBHA: INTERNATIONAL JOURNAL OF SCIENCE, SPIRITUALITY,

BUSINESS AND TECHNOLOGY (IJSSBT), Vol. 2, No.1, November 2013

ISSN (Print) 22777261

55

a) Equalization tank:

At first the waste water gets collected so

that the waste substrate can be equalized and the

pH is maintained strictly processing to the UASB

reactor.

b) Oil skimming tank:

The waste water after being neutralized is

passed through the oil skimming tank in order to

remove the oils fats, grease remained in the waste;

because if this goes without skimming then if

chock up the UASB and proper working will not

be done.

c) Buffer tank:

It is a storage tank where the waste water

from oil skimming tank comes and from the here is

supplied is the UASB reactor. Also the excess of

waste-waste that is present in UASB is again

brought to the buffer tank.

d) UASB Reactor: It is a reactor where sludge

from and waste is treated at the bottom of reactor.

The wastewater blows up through a sludge blanket

composed of biologically formed granules. Thus

treating under anaerobic condition gives out geese

which are collected to the dome shaped structure

and the waste water is collected in the side way

hoods. The up flow velocity is in the range of 0.6-

0.9 m/hr.

Figure 6.2: UASB Reactor (Plan)

Figure 6.3: UASB Blanket Process

There is a small pipe attached through which is

goes down in to the tank. The gas collected in

transferred to the foam trap

Figure 6.4: Bottom Distribution System

7. CONCLUSION

This anaerobic system of digestion can be

used in small scale for the treatment of

domestic waste water.

An arrangement can be made for the

continuous loading of digesters and a better

gas collection system.

PRATIBHA: INTERNATIONAL JOURNAL OF SCIENCE, SPIRITUALITY,

BUSINESS AND TECHNOLOGY (IJSSBT), Vol. 2, No.1, November 2013

ISSN (Print) 22777261

56

After the treatment Dairy waste water can

be used for agriculture purpose and the

formed methane (CH4) which can be used

as an energy source.

In this process the use of primary treatment

and the filter bed is completely eliminated.

The UASB process is seen as one of the

most cost effective & efficient anaerobic

treatment.

9. REFERENCES:-

[1]. Treatability studies of dairy wastewater by upflow

anaerobic sludge blanket reactor.

R.Thenmozhi*,R.N.Uma

[2]. Department of Civil Engineering, Sri Ramakrishna

Institute of Technology

thenmozhir2008@yahoo.in

Anaerobic wastewater treatment processB. Mrowiec*, J.

Suschka*

[3]. University of Bielsko-Biala, Willowa 2 Street, Bielsko-

Biala 43-309, Poland,(E-mail:bmrowiec@ath.bielsko.pl;

jsuschka@ath.bielsko.pl)

[4]. Dynamic Model for UASB Reactor and Reactor

Hydraulics", May. M. Wu and Robart F. Hickey-Journal

of Env. Engg./244/March 97.

[5]. Use of UASB Technology to treat wastewaters",

Gregory D. Board man and Peter J. Meveigh / Journal

of Env. Engg./776/Aug.97.

[6]. National Environment Engineering Research Institute:

Manual on water and Waste water analysis, Nagpur,

1986.

[7]. Rao M.N. and Datta A.K.

[8]. Mark J Hammer Water and Wastewater technology

John Wiley & sons, Inc, New York

You might also like

- Press MUd To Bio GasDocument5 pagesPress MUd To Bio GasAyush AgrawalNo ratings yet

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationFrom EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationNo ratings yet

- Refining HistoryDocument26 pagesRefining HistoryS M AseemNo ratings yet

- Internal Circulation Reactor Pushing The LimitsDocument9 pagesInternal Circulation Reactor Pushing The LimitsAbhishek TripathiNo ratings yet

- Minimization of Excess Sludge Production For Biological Wastewater TreatmentDocument15 pagesMinimization of Excess Sludge Production For Biological Wastewater Treatmentashoori79No ratings yet

- ReviewPaperonindustrialwastewatertreatmentprocesses PDFDocument19 pagesReviewPaperonindustrialwastewatertreatmentprocesses PDFPrathamesh KanganeNo ratings yet

- Anarebic PondsDocument5 pagesAnarebic Pondsunitechwater6517100% (2)

- Use of The Upflow Sludge Blanket (USB) ReactorDocument36 pagesUse of The Upflow Sludge Blanket (USB) ReactorinscNo ratings yet

- Anaerobic Treatments ProcessDocument6 pagesAnaerobic Treatments Processashe zinabNo ratings yet

- Application of Uasbr in Treatment of Dairy Waste Water: 1, PG Student, 2, Assistant ProfessorDocument9 pagesApplication of Uasbr in Treatment of Dairy Waste Water: 1, PG Student, 2, Assistant Professorvk100No ratings yet

- International Refereed Journal of Engineering and Science (IRJES)Document8 pagesInternational Refereed Journal of Engineering and Science (IRJES)www.irjes.comNo ratings yet

- Anaerobic Digestion in CanadaDocument44 pagesAnaerobic Digestion in Canadascience4uNo ratings yet

- Anaerobic MBR Potentials VisuDocument10 pagesAnaerobic MBR Potentials VisuAhmad HashimNo ratings yet

- Anaerobic Waste Stabilization Ponds A Low-Cost ConDocument6 pagesAnaerobic Waste Stabilization Ponds A Low-Cost ConrajeshNo ratings yet

- Chapter-1: 1.1 GeneralDocument33 pagesChapter-1: 1.1 GeneralAbhinay SinghNo ratings yet

- The Treatment of Baker - S Yeast Wastewater by An Up Flow Anaerobic Sludge Blanket (UASB) Reactor (#409483) - 448477Document6 pagesThe Treatment of Baker - S Yeast Wastewater by An Up Flow Anaerobic Sludge Blanket (UASB) Reactor (#409483) - 448477AlexandraGuajánNo ratings yet

- Powar (2013) Review On Applications of UASB Technology For Wastewater TreatmentDocument9 pagesPowar (2013) Review On Applications of UASB Technology For Wastewater TreatmentchemNo ratings yet

- Hossain 2019 Energy Efficient COD by Passively Aerated GAODocument11 pagesHossain 2019 Energy Efficient COD by Passively Aerated GAOFelipe galarceNo ratings yet

- IJE_Volume 36_Issue 3_Pages 490-496Document7 pagesIJE_Volume 36_Issue 3_Pages 490-496Muhammad TurmuziNo ratings yet

- PASSEGGI - 2012 - Modified UASB Reactor For Dairy Industry Wastewater Performance Indicators and Comparison With The Traditional AppDocument5 pagesPASSEGGI - 2012 - Modified UASB Reactor For Dairy Industry Wastewater Performance Indicators and Comparison With The Traditional AppThobiasNo ratings yet

- BIOLOGICAL TREATMENT AND COMPOSTING NewDocument9 pagesBIOLOGICAL TREATMENT AND COMPOSTING NewKiruthika KiruthiNo ratings yet

- Bioresource Technology: Byung-Gon Ryu, Jungmin Kim, Jong-In Han, Ji-Won YangDocument9 pagesBioresource Technology: Byung-Gon Ryu, Jungmin Kim, Jong-In Han, Ji-Won YangThirumalaivasanNo ratings yet

- Pilot Scale Study of Horizontal Anaerobic Digester For Biogas Production Using Food WasteDocument4 pagesPilot Scale Study of Horizontal Anaerobic Digester For Biogas Production Using Food WasteAl AkilNo ratings yet

- A Review On Palm Oil Mill Biogas Plant Wastewater Treatment Using Coagulation-OzonationDocument7 pagesA Review On Palm Oil Mill Biogas Plant Wastewater Treatment Using Coagulation-OzonationMaizan Sofia Binti Mohd MaarofNo ratings yet

- Ijisrt20may964 PDFDocument6 pagesIjisrt20may964 PDFUna Isma100% (23)

- Parametric Study of Brewery Wastewater Effluent Treatment Using Chlorella Vulgaris MicroalgaeDocument8 pagesParametric Study of Brewery Wastewater Effluent Treatment Using Chlorella Vulgaris MicroalgaeAA0809No ratings yet

- Performances of An Activated Sludge Proc20160202 15516 14586m1 With Cover Page 1.2Document9 pagesPerformances of An Activated Sludge Proc20160202 15516 14586m1 With Cover Page 1.2Abdul rahmanNo ratings yet

- Energies 16 00571 v2Document18 pagesEnergies 16 00571 v2loliNo ratings yet

- Aerobic and Anaerobic ProcessDocument20 pagesAerobic and Anaerobic ProcessNayan GanjiNo ratings yet

- Heat New Chemical with New Starch Research ProgressDocument13 pagesHeat New Chemical with New Starch Research ProgressEudkrenutNo ratings yet

- Starch Research ProgressDocument15 pagesStarch Research ProgressEudkrenutNo ratings yet

- Water: Influence of Pre-Hydrolysis On Sewage Treatment in An Up-Flow Anaerobic Sludge BLANKET (UASB) Reactor: A ReviewDocument27 pagesWater: Influence of Pre-Hydrolysis On Sewage Treatment in An Up-Flow Anaerobic Sludge BLANKET (UASB) Reactor: A ReviewrajeshNo ratings yet

- Aip Conference Proceedings Aip Publishing LLC International Conference of Chemical and Material Engineering Iccme 2015-g1.4938380Document9 pagesAip Conference Proceedings Aip Publishing LLC International Conference of Chemical and Material Engineering Iccme 2015-g1.4938380Marcin ChęcińskiNo ratings yet

- Master Thesis: Moving Biofiles in Sequential Discharge Reactor (SBR)Document88 pagesMaster Thesis: Moving Biofiles in Sequential Discharge Reactor (SBR)DianerNo ratings yet

- Anaerobic Digestion Use in Wastewater Treatment - Sustainable DevelopmentsDocument7 pagesAnaerobic Digestion Use in Wastewater Treatment - Sustainable DevelopmentsUmutNo ratings yet

- Biogas From Organic Waste - A Case Study: SciencedirectDocument8 pagesBiogas From Organic Waste - A Case Study: Sciencedirectd3 tekim2018No ratings yet

- Challenges in UASB Reactor System Design: A Review: September 2015Document9 pagesChallenges in UASB Reactor System Design: A Review: September 2015song1088No ratings yet

- 5 ReportDocument20 pages5 ReportPRATEEK KUMAR DASNo ratings yet

- Critical Stage in Starch WastewaterDocument10 pagesCritical Stage in Starch WastewaterEudkrenutNo ratings yet

- 26-11 ProjDocument57 pages26-11 ProjSharath ChandraNo ratings yet

- Starch WastewaterDocument6 pagesStarch WastewaterEudkrenutNo ratings yet

- Use of Biomethane As A Sustainable FuelDocument35 pagesUse of Biomethane As A Sustainable FuelVedant KarnatakNo ratings yet

- Biogas Production From Municipal Sewage Sludge Using Ultrasound Speeding Digestion ProcessDocument10 pagesBiogas Production From Municipal Sewage Sludge Using Ultrasound Speeding Digestion ProcessInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Zhang Et Al. (2021) - UASBDocument9 pagesZhang Et Al. (2021) - UASBĐào Ngọc Bảo TrânNo ratings yet

- Biogas Production From Sawdust Waste, Cow Dung and Water Hyacinth-Effect of Sawdust ConcentrationDocument3 pagesBiogas Production From Sawdust Waste, Cow Dung and Water Hyacinth-Effect of Sawdust ConcentrationInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Recent Applications of Coagulation, Flocculation and Ballast Flocculation in Treatment of Wastewater-A ReviewDocument5 pagesRecent Applications of Coagulation, Flocculation and Ballast Flocculation in Treatment of Wastewater-A ReviewIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- 1 Treatment Process: 1.1 ThickeningDocument10 pages1 Treatment Process: 1.1 ThickeningAnang ARNo ratings yet

- Activated Sludge ProcessDocument48 pagesActivated Sludge Processrozma khanNo ratings yet

- 1 PDFDocument7 pages1 PDFsong1088No ratings yet

- Removal of CO From Biogas Plant Using Chemical Absorption ColumnDocument7 pagesRemoval of CO From Biogas Plant Using Chemical Absorption ColumnanirudhNo ratings yet

- Chapter OneDocument46 pagesChapter OneibukunadedayoNo ratings yet

- Sharda University: Bio Gas PlantsDocument19 pagesSharda University: Bio Gas PlantsEdrisNo ratings yet

- Biogas Fro Chicken WasteDocument8 pagesBiogas Fro Chicken WasteSekarNTutyNo ratings yet

- Oxidation PondDocument10 pagesOxidation PondCoc LoverNo ratings yet

- Optimization of Anaerobic Mechanism Using Response Surface Methodology (RSM) To Treat Pulp and Paper Industry Wastewater: A ReviewDocument9 pagesOptimization of Anaerobic Mechanism Using Response Surface Methodology (RSM) To Treat Pulp and Paper Industry Wastewater: A ReviewEditor IJTSRDNo ratings yet

- Granulation Strategies Applied To Industrial Wastewater TreatmentDocument11 pagesGranulation Strategies Applied To Industrial Wastewater TreatmentLixin YangNo ratings yet

- D M W T U L S S B R (SBR) : Airy Ilking Astewater Reatment Sing A AB Cale Equencing Atch EactorDocument10 pagesD M W T U L S S B R (SBR) : Airy Ilking Astewater Reatment Sing A AB Cale Equencing Atch EactorMinh Hằng TrầnNo ratings yet

- Applying Internal Circulation Anaerobic Reactor FoDocument8 pagesApplying Internal Circulation Anaerobic Reactor FoAlvaro HueteNo ratings yet

- Use of CowDung As A Source of Bio Culturing For ETPDocument7 pagesUse of CowDung As A Source of Bio Culturing For ETPRG SegaranNo ratings yet

- Biological Sludge Minimization and Biomaterials/Bioenergy Recovery TechnologiesFrom EverandBiological Sludge Minimization and Biomaterials/Bioenergy Recovery TechnologiesEtienne PaulNo ratings yet

- Climate Change and Cotton Production in Modern Farming SystemsFrom EverandClimate Change and Cotton Production in Modern Farming SystemsNo ratings yet

- Follow The Schedule As Per Given Guideline Without Fail. Prof. V.R. Kasar Subject Teacher/GuideDocument2 pagesFollow The Schedule As Per Given Guideline Without Fail. Prof. V.R. Kasar Subject Teacher/Guidevk100No ratings yet

- CE ESE Objective Volume-1 (2017)Document12 pagesCE ESE Objective Volume-1 (2017)vk100No ratings yet

- Sr. No. Item/Particulars Material Required Qty Actual QtyDocument11 pagesSr. No. Item/Particulars Material Required Qty Actual Qtyvk100No ratings yet

- Civil Event Details-Shodh2018Document4 pagesCivil Event Details-Shodh2018vk100No ratings yet

- External Optical Level (2-Peg Test) SurveyDocument7 pagesExternal Optical Level (2-Peg Test) Surveyvk100No ratings yet

- Laboratory Manual For The Microbiological Analyses of Public Drinking Water 2001Document74 pagesLaboratory Manual For The Microbiological Analyses of Public Drinking Water 2001vk100No ratings yet

- Capr I En6273Document45 pagesCapr I En6273vk100No ratings yet

- Auto Cad ListDocument6 pagesAuto Cad Listvk100No ratings yet

- ATM Networks: © N. Ganesan, PH.DDocument19 pagesATM Networks: © N. Ganesan, PH.Dvk100No ratings yet

- Chinease Postman ProblemDocument9 pagesChinease Postman Problemvk100No ratings yet

- Basic Concepts and Definitions of Graph TheoryDocument39 pagesBasic Concepts and Definitions of Graph Theoryvk100No ratings yet

- Basic Graph Theory Definitions and NotationDocument2 pagesBasic Graph Theory Definitions and Notationvk100No ratings yet

- Origin of Graph TheoryDocument5 pagesOrigin of Graph Theoryvk100No ratings yet

- Capr I En6273Document45 pagesCapr I En6273vk100No ratings yet

- Basis of SafetyDocument2 pagesBasis of SafetyTen Dye MungwadziNo ratings yet

- Dam Design and Completion ReportDocument8 pagesDam Design and Completion ReportPasi C4SieleNo ratings yet

- Experiment 2: Water Analysis Colour Measurement On Suspended Solid DeterminationDocument4 pagesExperiment 2: Water Analysis Colour Measurement On Suspended Solid DeterminationSyafiq Shaffiai0% (1)

- Unit 4Document37 pagesUnit 4achuilmajokaNo ratings yet

- EDTA MsdsDocument5 pagesEDTA MsdsĐại Việt Quốc XãNo ratings yet

- Calculator Programmable ThermostatDocument5 pagesCalculator Programmable Thermostataravoof84No ratings yet

- School Dampalit ES Grade Level Five Teacher Joanne S. Velarde Learning Areas Science Teaching Dates and Time Day Quarter FirstDocument7 pagesSchool Dampalit ES Grade Level Five Teacher Joanne S. Velarde Learning Areas Science Teaching Dates and Time Day Quarter FirstAnatasuki100% (1)

- ALPHA MOTORS LTD Integrating Life Cycle EnviroDocument9 pagesALPHA MOTORS LTD Integrating Life Cycle EnviroSharif ShaikNo ratings yet

- Solid Waste Technology PDFDocument37 pagesSolid Waste Technology PDFJohn Feil JimenezNo ratings yet

- Aspect Impact Register - DAICECDocument59 pagesAspect Impact Register - DAICECmaxscribdNo ratings yet

- aBHISHEK SEMINAR ON CIGRATTE BUTTS BRICKSDocument16 pagesaBHISHEK SEMINAR ON CIGRATTE BUTTS BRICKSAvinash Noubade100% (1)

- Elec & I&C Cable Construction Progress (As of 21 June, 2018)Document7 pagesElec & I&C Cable Construction Progress (As of 21 June, 2018)Kharisma Pangeran LanangNo ratings yet

- MSDS Vanadium PentoxideDocument5 pagesMSDS Vanadium PentoxideRezer AxelNo ratings yet

- Air Pollution in NepalDocument2 pagesAir Pollution in NepalEducational HubNo ratings yet

- Lecture No. 4 Fate and Transport of ContaminantsDocument12 pagesLecture No. 4 Fate and Transport of ContaminantsJorn DoeNo ratings yet

- 2 Summary Report of Planning and Management - Rspo NPP PT - Agro Muara RupitDocument16 pages2 Summary Report of Planning and Management - Rspo NPP PT - Agro Muara RupitDede AhdiyatNo ratings yet

- Design and Analysis of Muffler To Reduce The Back PressureDocument5 pagesDesign and Analysis of Muffler To Reduce The Back PressureijsretNo ratings yet

- Human Influences On EcosystemsDocument10 pagesHuman Influences On Ecosystemsnurul sakeenaNo ratings yet

- Experimental Study On Concrete With Partial Replacement of Cement With Fly Ash & Coarse Aggregate by Ceramic TilesDocument7 pagesExperimental Study On Concrete With Partial Replacement of Cement With Fly Ash & Coarse Aggregate by Ceramic TilesIJSTENo ratings yet

- Final Project ReportDocument24 pagesFinal Project Reportapi-436879593No ratings yet

- 9th Grade Lesson Plan-1-1Document121 pages9th Grade Lesson Plan-1-1Aigerim MurzamdamovaNo ratings yet

- Iaea Tecdoc 1472 PDFDocument584 pagesIaea Tecdoc 1472 PDFRussell ClarkNo ratings yet

- BrandixDocument15 pagesBrandixshreay12345100% (1)

- API SN 5w 30 MsdsDocument5 pagesAPI SN 5w 30 MsdsahmetNo ratings yet

- Dolomite and Kaliwa Dam DefenseDocument8 pagesDolomite and Kaliwa Dam DefenseEa YangNo ratings yet

- Slide Presentation by Lesley Allen Kabigting For The Role of Economics in Environmental ManagementDocument35 pagesSlide Presentation by Lesley Allen Kabigting For The Role of Economics in Environmental ManagementLee K.No ratings yet

- River MorphologyDocument20 pagesRiver Morphologyale hopeju2009100% (1)

- Case Study On Environmental PollutionDocument34 pagesCase Study On Environmental PollutionDr Dheeraj Mehrotra63% (8)

- Responsibility For Preserving The Environment Ultimately Belongs To Each Individual & Not To GovernmentDocument1 pageResponsibility For Preserving The Environment Ultimately Belongs To Each Individual & Not To GovernmentHammad HassanNo ratings yet