Professional Documents

Culture Documents

Catalogo Soplador Atlascopco

Catalogo Soplador Atlascopco

Uploaded by

JOSEANTONIOGOMEZMORECopyright:

Available Formats

You might also like

- PESTEL Analysis of GermanyDocument14 pagesPESTEL Analysis of GermanyBishal PaulNo ratings yet

- Terex RT 230 1 ChartDocument22 pagesTerex RT 230 1 ChartAlfred Hitchcock100% (1)

- Atlas Copco Roc F9Document1 pageAtlas Copco Roc F9Diego Lima100% (1)

- Movax Products 2012 ENGDocument20 pagesMovax Products 2012 ENGstephaneggNo ratings yet

- Baby Mait PDFDocument2 pagesBaby Mait PDFChris LuNo ratings yet

- About Axle Diff Case Rev1Document6 pagesAbout Axle Diff Case Rev1hwachooNo ratings yet

- Catálogo Gradall 534D6Document2 pagesCatálogo Gradall 534D6Adriano Alves Silva0% (1)

- Sheet 1 SolvedDocument2 pagesSheet 1 SolvedAyman Esa50% (2)

- Beware 03122019-1en PDFDocument14 pagesBeware 03122019-1en PDFJose Castro0% (1)

- DAL 2008 FullDocument164 pagesDAL 2008 FullYair Doram LightingNo ratings yet

- Y 19 ADocument20 pagesY 19 Ayolimar escorciaNo ratings yet

- Parts Replacement Manual For Dodge® Torque-Arm ™: Speed Reducers Straight Bore & Taper BushedDocument16 pagesParts Replacement Manual For Dodge® Torque-Arm ™: Speed Reducers Straight Bore & Taper BushedRomulo Davila GarciaNo ratings yet

- 9852 3027 01a Secoroc YT29A Pusher Leg Rock Drill - Operator's Instruction and Spare Parts List - tcm572-3511855Document20 pages9852 3027 01a Secoroc YT29A Pusher Leg Rock Drill - Operator's Instruction and Spare Parts List - tcm572-3511855marioxxyNo ratings yet

- New Microsoft Word DocumentDocument274 pagesNew Microsoft Word DocumentdraghiceanuNo ratings yet

- 6991 5105 01c PugDocument34 pages6991 5105 01c PugAndrew KochNo ratings yet

- KLR BrochureDocument23 pagesKLR BrochureblamarceloNo ratings yet

- The Rotary Drum Filter: DescriptionDocument6 pagesThe Rotary Drum Filter: Descriptionagrocel_bhv5591No ratings yet

- Windsor Saber SX24Document72 pagesWindsor Saber SX24Nestor Marquez-DiazNo ratings yet

- 3M Window Film Application, Care & Cleaning and Removal ManualDocument17 pages3M Window Film Application, Care & Cleaning and Removal ManualAntanas Zilys100% (1)

- VOLVO FMX 6x4rDocument4 pagesVOLVO FMX 6x4rDarylGonzalezNo ratings yet

- Mining in Action G: July 2011Document106 pagesMining in Action G: July 2011Ricardo MuñozNo ratings yet

- Robot Atlas MEYCO ME3Document8 pagesRobot Atlas MEYCO ME3Frank Prudencio ObregonNo ratings yet

- Air-Winch Manual PDFDocument56 pagesAir-Winch Manual PDFQuyet Nguyen0% (1)

- Kundendokumentation enDocument309 pagesKundendokumentation enHarri Mündel100% (1)

- PE28 and PE38 ManualDocument18 pagesPE28 and PE38 Manualkarijoseph100% (1)

- Waterwell Catalog WebDocument96 pagesWaterwell Catalog WebJuan Carlos Sequeira RoblesNo ratings yet

- Brochure Burg 1450Document2 pagesBrochure Burg 1450serge.pungweNo ratings yet

- XA400S Parts ManualDocument172 pagesXA400S Parts ManualBenjamin MurphyNo ratings yet

- Danbar - Eurodrill HeadDocument55 pagesDanbar - Eurodrill Headmark100% (1)

- Joy Bolting Brochure - MiningDocument11 pagesJoy Bolting Brochure - MiningkevinNo ratings yet

- HDP170 KatalogDocument2 pagesHDP170 KatalogAnonymous zq0b2Ea5No ratings yet

- Repuesto Transmision 962gIIDocument6 pagesRepuesto Transmision 962gIIWilliams ArayaNo ratings yet

- RMS3260 TBMDocument2 pagesRMS3260 TBMSiritape PromsopaNo ratings yet

- Warrior 2400 Illustrated Parts Catalog Rev 4Document237 pagesWarrior 2400 Illustrated Parts Catalog Rev 4sanzostefNo ratings yet

- Menzi Muck All Terain ExcavatorDocument5 pagesMenzi Muck All Terain ExcavatorPanagiotis AnagnostopoulosNo ratings yet

- BOP CatalogDocument20 pagesBOP CatalogOpe Opie UdinNo ratings yet

- MC3 Sullair PartsListManual 750XHH 900XH 900XHH 1150XH TC - Sullair Reman HighlightsDocument228 pagesMC3 Sullair PartsListManual 750XHH 900XH 900XHH 1150XH TC - Sullair Reman HighlightsnNo ratings yet

- AP Asphaltline TankdrumDocument8 pagesAP Asphaltline TankdrumKelvin CeliNo ratings yet

- DuFlex Cable Data Sheet PDFDocument23 pagesDuFlex Cable Data Sheet PDFMareeswaran RamasamyNo ratings yet

- Blower Performance Data SheetDocument48 pagesBlower Performance Data SheetRavi KantNo ratings yet

- Bomba P13 y OtrosDocument75 pagesBomba P13 y OtrosRonald Garcia100% (1)

- DM901HDE: Diesel Driven & Electric DrillerDocument6 pagesDM901HDE: Diesel Driven & Electric DrillerEnzo VanderlindenNo ratings yet

- Dichta CatalogueDocument62 pagesDichta CataloguemaxatadesignNo ratings yet

- Diamec Brochure PDFDocument12 pagesDiamec Brochure PDFDangol RupeshNo ratings yet

- Arjes-Br-Impaktor en 2022 04Document8 pagesArjes-Br-Impaktor en 2022 04Giuro KralevNo ratings yet

- Saga Drillmec G 55 1.9MBDocument19 pagesSaga Drillmec G 55 1.9MBleoNo ratings yet

- Ahs Kilavuz Son - Akyapak 2016.03.25Document86 pagesAhs Kilavuz Son - Akyapak 2016.03.25EDUARDONo ratings yet

- PR14251 - Envasadora EVO V8Document63 pagesPR14251 - Envasadora EVO V8enrique polarNo ratings yet

- Lista Partes SH6 (08.2019)Document64 pagesLista Partes SH6 (08.2019)Alfredo Simon Alcazar EscuderoNo ratings yet

- J - Manual Series 4 EnglishDocument49 pagesJ - Manual Series 4 EnglishCésar David Pedroza DíazNo ratings yet

- Raptor 44 ReseminDocument6 pagesRaptor 44 ReseminlucasmaltaNo ratings yet

- Metal Detector With Conveyor Application: Operator Set-Up ManualDocument69 pagesMetal Detector With Conveyor Application: Operator Set-Up ManualRafa 7niteNo ratings yet

- Monarch TT 30Document4 pagesMonarch TT 30Migue ToasaNo ratings yet

- Catalytic Converter For Volvo XC60 XC60Document3 pagesCatalytic Converter For Volvo XC60 XC6047ASSONo ratings yet

- Checkllist Mecánico - Filtro Prensa Dorr OliverDocument12 pagesCheckllist Mecánico - Filtro Prensa Dorr OliverMarco Valverde MorenoNo ratings yet

- Manual de Martillo HidraulicoDocument146 pagesManual de Martillo HidraulicoJoshua RobinsonNo ratings yet

- Datasheet Kleemann MR110 EVO 2Document2 pagesDatasheet Kleemann MR110 EVO 2ila reehasNo ratings yet

- Esquema Eletrico - 177926-1Document481 pagesEsquema Eletrico - 177926-1Sam Päron100% (1)

- CD-35655bb Trocola GiratoriaDocument82 pagesCD-35655bb Trocola GiratoriaJESUSCALVILLONo ratings yet

- Feam Junction Box EnclosureDocument36 pagesFeam Junction Box EnclosureMiky MooseNo ratings yet

- ZM Low Pressure 12p Brochure 2013 0423 LR tcm795-3550460 PDFDocument12 pagesZM Low Pressure 12p Brochure 2013 0423 LR tcm795-3550460 PDFhardik033No ratings yet

- ZM Low Pressure Leaflet EN Antwerp 2935 0624 11Document12 pagesZM Low Pressure Leaflet EN Antwerp 2935 0624 11Andry HermawanNo ratings yet

- Centrifugal Aftermarket Solutions BrochureDocument8 pagesCentrifugal Aftermarket Solutions BrochureJose Renato MendesNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- National Earth Olympiad 2012Document5 pagesNational Earth Olympiad 2012Science Olympiad Blog40% (5)

- Alarm SystemsDocument12 pagesAlarm SystemsDavid AcloNo ratings yet

- 21 49 PlansDocument7 pages21 49 PlansShehab Abu AhmadNo ratings yet

- 9-2 Reading Answers1Document4 pages9-2 Reading Answers1adalinefallingstarNo ratings yet

- Speaker72599 Session16724 1Document17 pagesSpeaker72599 Session16724 1Kent RenemberNo ratings yet

- Briganti Andrea Self Hypnosis Scripts Flirting ConfidenceDocument5 pagesBriganti Andrea Self Hypnosis Scripts Flirting ConfidenceBrian MakeredzaNo ratings yet

- Viscosity Index When Selecting A LubricantDocument6 pagesViscosity Index When Selecting A LubricantANGEL MURILLONo ratings yet

- 020 Basis of Design ChecklistDocument2 pages020 Basis of Design Checklistali ahmadNo ratings yet

- Datasheet Growatt MAX 100 125KTL3 X LVDocument2 pagesDatasheet Growatt MAX 100 125KTL3 X LVJeroen SNo ratings yet

- 9783319395913Document214 pages9783319395913iki292100% (1)

- Understanding Defibrillation WaveformsDocument3 pagesUnderstanding Defibrillation WaveformsLatha Reddy100% (1)

- Cummins Part CatalogDocument11 pagesCummins Part CatalogChen Caroline100% (1)

- Pollution in Bangalore - CiSTUP PaperDocument12 pagesPollution in Bangalore - CiSTUP PaperSathya SankaranNo ratings yet

- 17-0049 - Abdallah Osama - GTP1 - Stage 02Document10 pages17-0049 - Abdallah Osama - GTP1 - Stage 02abdallah OsamaNo ratings yet

- Controlled Circulation PumpDocument5 pagesControlled Circulation PumpLakshminarayanNo ratings yet

- Tvl-Ict-Css: Quarter 2 - Module 3-4Document17 pagesTvl-Ict-Css: Quarter 2 - Module 3-4anderson villalunaNo ratings yet

- TSM Personnel FormDocument10 pagesTSM Personnel FormMano VijayNo ratings yet

- Oil Gas Industry in The MENA Region 2009 PDFDocument73 pagesOil Gas Industry in The MENA Region 2009 PDFRajan DhandayudhapaniNo ratings yet

- MODULE 2 Foundations of PhysicsDocument7 pagesMODULE 2 Foundations of PhysicschloeNo ratings yet

- Nanotechnology: Chee 401Document19 pagesNanotechnology: Chee 401michsantosNo ratings yet

- Renewable and Sustainable Energy Reviews: Wei-Bo ZhangDocument11 pagesRenewable and Sustainable Energy Reviews: Wei-Bo ZhangFredy Akenaton ArroyoNo ratings yet

- Questbank1 AnswersDocument8 pagesQuestbank1 Answersjay garciaNo ratings yet

- Water Hammering Effects in Pipe System and Dynamic Stress PredictionDocument8 pagesWater Hammering Effects in Pipe System and Dynamic Stress PredictionDuzzysNo ratings yet

- 03.GuardMagic - Fuel Level SensorsDocument4 pages03.GuardMagic - Fuel Level SensorsvkmsNo ratings yet

- BOE Review CommentDocument451 pagesBOE Review CommentGULF BUSINESS CONTRACTINGNo ratings yet

- Threshold VoltageDocument4 pagesThreshold VoltagejudineshNo ratings yet

Catalogo Soplador Atlascopco

Catalogo Soplador Atlascopco

Uploaded by

JOSEANTONIOGOMEZMOREOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catalogo Soplador Atlascopco

Catalogo Soplador Atlascopco

Uploaded by

JOSEANTONIOGOMEZMORECopyright:

Available Formats

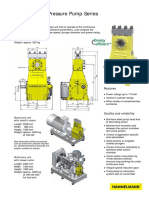

Atlas Copco

ZM Oil-free multistage centrifugal pressure and vacuum blowers

100 - 40,000 cfm / 2 - 24 psi / 5 - 3,600 hp

3 - 1160 m

3

/m / 100 - 1700 mbar / 4 - 2600 kW

POWER INDUSTRY

READY-TO-USE

These innovative centrifugal blowers are ideal for applications such as ue gas desulphurization,

oxidation air, and uidized beds. When your application absolutely requires continuous operation

the ZM is your preferred choice.

MINING

GLOBAL SERVICE

The ZM is a worldwide proven leader in mining applications such as reclaiming heavy metals from

slurry in oatation cells, a leaching process or methane extraction. Our centrifugal blowers

showcase their durability and reliability in the harshest of conditions with options to handle tough

environments such as temperature, dust, high altitude, or long life with limited maintenance.

PETROCHEMICAL INDUSTRY

TOTALLY DEPENDABLE

Sulfur recovery, sour gas, thermal oxidation or renery tail gas, the ZMs high reliability and low

maintenance make it the perfect centrifugal blower for vital processes. ZM blowers meet the most

exacting industry standards in the testing and documentation needs.

ENVIRONMENTAL

RELIABILITY ENSURED

From water and wastewater applications to landll gas recovery systems, Atlas Copcos years of

experience, backed up by a strong global service network, ensure that ZM blowers meet all your

environmental application requirements including basin aeration, digester gas, soil remediation,

lter backwash systems and other processes

A ZM for every application

Atlas Copcos ZM oil-free multistage centrifugal blowers are working successfully in thousands of installations around the world.

These reliable blowers are ideal for applications ranging from air to gas and pressure to vacuum. The ZM can be equipped with

all the necessary accessories such as motor, valves, lters and skid as well as local or networked control panels to ensure a

complete working system. Ask our group to nd a ZM blower system to meet your exact requirements.

INDUSTRIAL

EXCEEDS YOUR EXPECTATIONS

A wide variety manufacturing applications can be served by the ZM. Pulp and paper, carbon black,

printing, or blow off systems are a few of many strong examples of ZM being the preferred

technology that will outperformance your expectations

VACUUM APPLICATIONS

CLEAN AND DUST FREE

Pharmaceutical, breweries, and other food production facilities need

clean and oil free environments. Central vacuum systems serve a

variety of applications. ZM has the power to achieve their

requirements

GLOBAL SERVICE SUPPORT

At Atlas Copco we place high value on outstanding

customer service and are on call at all times to help with

urgent situations. We pride ourselves in responding

quickly to your requests for information and quotations.

Contact your local Atlas Copco representative and nd out

how we can make a difference in your next project.

EFFICIENT

ZM oil-free multistage centrifugal blowers were developed using the most

advanced technology available. Tools including 3D Modeling, Computational Fluid

Dynamics and Finite Element Analysis were used at the design stage to pinpoint

areas where we make improvements. The resulting modern and innovative design

allows for increased efciency, while the wide product range and conguration

options ensure we can offer the best solution possible to meet your needs.

LIMITED MAINTENANCE

You wont suffer from lengthy downtimes or process interruptions when your

ZM is maintained. Service intervals are reduced to a minimum and

maintenance is quick and simple. Maintenance points are easily accessible and

basic repairs can be conducted with a minimum of time and materials offering you a

low cost of ownership.

What makes the ZM special?

RELIABLE

The ZM blowers have earned the reputation of being the most reliable

blowers in the industry. Even so, we still work to continually enhance

the reliability of the ZM product line. In order to do this, we have made

signicant investments in the best people, facilities and equipment in

the industry. Our commitment to Research and Development, Quality

Control, and Product Testing, is driven by our desire to offer our

customers the reliability they require in a variety of air and gas as well

as pressure and vacuum applications.

ZM centrifugal blowers:

durability and performance

Atlas Copcos ZM centrifugal blowers are built to last. Solidly constructed out of premium components, they will run and run, with

minimum maintenance requirements and unbeatable cost-effectiveness.

Shaft

Carbon or stainless steel

Greater reliability is achieved with subcritical speed operations

5

8

Lubrication

Self lubricated oil, grease, or mist connections

Low preventative maintenance

6

Seals

Gas or Air Seals

To protect the environment

3

3

Bearings

10 year L10 minimum life

Less maintenance

4

4

Casing

Cast iron, ductile iron available

For low vibration

1

1

Guide Vanes

Stainless steel guide vanes

Improve efciency

2

2

5

6

Turning Vanes

Cast intermediate sections

Improved performance

7

Impellers

Aluminum or stainless

Suitable for your application

8

7

Balance drum

Improves bearing life

9

External coating

Standard 2 coat epoxy

Custom available

Long life

10

9

10

11

Case Drains

Optional

For harsh environments

11

12

Tie rods

High strength steel

12

Engineered control solutions

for all your needs

Atlas Copco understands that every application is different, which is why we offer

controls that are easy to customize to your specic installation.

LOCAL CONTROL

The pre-engineered local controls for ZM blowers offer many options from standard analog controls

to panels with full touch-screen interfaces. These panels protect the blower and motor from

unexpected upsets in the system and can alarm or shut down the unit to prevent damage. They can

also be programmed to communicate with almost any type of plant master control system.

ZM-IB 1100

PLC control

Basic surge protection

Bearing temperature

and vibration

monitoring

R

R

R

R

R

R

LOCAL CONTROL PANEL

ZM-IB 2100

PLC control with touch screen HMI

Advanced surge protection

Bearing temperature and vibration monitoring

Flow regulation by:

- inlet throttle valve

- blow off valve

- vacuum bleed valve

Variable process input

- ow/pressure

- dissolved oxygen

- user dened

ZM-IB 3100

PLC control with touch screen HMI

Advanced dynamic surge protection

Bearing temperature and vibration monitoring

Flow regulation by variable speed drive control

Variable process input

- ow/pressure

- dissolved oxygen

- user dened

SCADA interface

PROCESS CONTROL

Atlas Copco has developed complete control systems to manage entire processes. Adding a smart

sequencer to automate multiple units in operation will both save time in operating, but also

improve the efciency of your entire system. These smart systems are sufciently advanced to

monitor and control your entire process such as wastewater aeration, or virtually any application

that requires ow to be matched to the process requirements.

ES 5100 PROCESS CONTROL AND

BLOWER SEQUENTIAL PANEL

All ES 4100 functions

Flow matched to process requirements

Auxiliary equipment control

Single point responsibility

Direct process control

- automated valves

- pressure sensors

- ow meters

R

R

R

R

R

R

PROCESS

CONTROL

PANEL

PLANT

SCADA

CONTROL VALVES

CONTROL SENSORS

ES 4100 BLOWER

SEQUENCER PANEL

Multiple blower control

PLC control with touch screen HMI

Optimizes effciencies

Variable process input

- ow/pressure

- dissolved oxygen

- user dened

Auto sequencing

System integration

SCADA interface

ZM Design and Standards

At Atlas Copco we have made a commitment to be the technical leader in our industry. We have achieved our strong position in

this area through continued investment in engineering personnel, the latest design tools, advanced inspection and testing

technology, and ongoing R&D projects.

ENGINEERED SOLUTIONS

EXPERIENCE COUNTS

With a global competency center focused on

research and development of centrifugal

blower technology we are able to provide

custom engineered solutions for the ZM

product for the most demanding applications.

This often includes special materials and

testing to accomplish the toughest tasks

TESTING

PROVING GROUNDS

With a world class test facility, we are able to

offer comprehensive testing according to

industry and customer standards. Every ZM is

tested to ensure quality and to make way for a

successful start up. We are able to simulate

site conditions to ensure that the complete

system is tested and ready to go.

PROJECT MANAGEMENT

TEAMWORK

People make the difference. A project

management staff is assigned to larger capital

projects that require detailed documentation

and testing to ensure the entire project goes

smoothly and on time.

MODEL NUMBER

OF STAGES

INLET

FLANGE

DISCHARGE

FLANGE

FLOW

RANGE

MAXIMUM

PRESSURE

MAXIMUM

VACUUM

MOTOR

POWER

ZM 31 1 to 11 DN80 / 3" DN80 / 3" 0 300 cfm (0 510 m

3

/hr) 7 psi (480 mbar) 10 hg (339 mbar) 1 20 (1 15kW)

ZM 51 1 to 10 DN150 / 5" DN150 / 5" 200-1,100 cfm (340 1,869 m

3

/hr) 12 psi (830 mbar) 11 hg (372 mbar) 5-100 (4 75 kW)

ZM 52 1 to 10 DN175 / 6" DN175 / 5" 300-1,300 cfm (510 2209 m

3

/hr) 12 psi (830 mbar) 11 hg (372 mbar) 5-100 (4 75 kW)

ZM 61 1 to 9 DN175 / 6" DN175 / 6" 400-2,200 cfm (680 3378 m

3

/hr) 11 psi (760 mbar) 10 hg (339 mbar) 5-200 (4 149 kW)

ZM 81 1 to 9 DN200 / 8" DN200 / 8" 600-3,000 cfm (1,019 5,097 m

3

/hr) 14 psi (970 mbar) 12 hg (407 mbar) 5-250 (4 186 kW)

ZM 82 1 to 9 DN200/ 8" DN200/ 8" 750-3,500 cfm (1274 5,946 m

3

/hr) 15 psi (1030 mbar) 19 hg (644 mbar) 5-250 (4 186 kW)

ZM 86 1 to 10 DN200 / 8" DN200 / 8" 500-4,400 cfm (849 7,476 m

3

/hr) 16 psi (1100 mbar) 15 hg (508 mbar) 10-350 (7 261 kW)

ZM 88 1 to 12 DN250 / 10" DN250 / 8" 500-4,500 cfm (849 7,645 m

3

/hr) 21psi (1450 mbar) 18 hg (609 mbar) 10-400 (7 298 kW)

ZM 126 1 to 9 DN300 / 12" DN300 / 12" 1,000 - 8,250 cfm (1,699 14,017 m

3

/hr) 14 psi (970 mbar) 14 hg (475 mbar) 25-500 (19 373 kW)

ZM 141 1 to 9 DN450 / 18" DN450 / 14" 3,500-12,000 cfm (5,946 20,388 m

3

/hr) 13 psi (900 mbar) 12 hg (407 mbar) 40 700 (30 522 kW)

ZM 143 1 to 8 DN450 / 18" DN450 / 14" 3,500- 13,500 cfm (5,946 22,936 m

3

/hr) 20 psi (1380 mbar) 17 hg (576 mbar) 40 700 (30 522 kW)

ZM 186 1 to 6 DN600 / 24" DN600 / 18" 2,500-30,000 cfm (4,247 50,970 m

3

/hr) 21psi (1450 mbar) 17 hg (576 mbar) 200 - 2,500 (149 1,864 kW)

ZM 187 1 to 8 DN500 / 20" DN500 / 18" 2,000-22,000 cfm (3,398 37,378 m

3

/hr) 18 psi (1240 mbar) 17 hg (576 mbar) 150-1,750 (112 -1305 kW)

ZM 246 1 to 6 DN800 / 30" DN800 / 24" 3,000-40,000 cfm (5,097 67,960 m

3

/hr) 24 psi (1650 mbar) 19 hg (644 mbar) 250-3,000 (186 2,237 kW)

ZM complete line of

centrifugal blowers and exhausters

31

51

52

61

81 82 86 88

126

141

143

186

187

246

P

R

E

S

S

U

R

E

(

P

S

I

G

)

V

A

C

U

U

M

(

i

n

H

g

)

20

20

15

15

10

10

5

5

0

VOLUME (SCFM)

0 100 200 300 750 1250 2000 3000 4000 6000 8000 10000 12000 15000 20000 25000 30000 35000 40000

VOLUME (m

3

/hr)

0 200 250 500 1000 2000 2500 5000 7500 10000 12500 17000 20000 25000 35000 42000 45000 60000 70000

25

25

P

R

E

S

S

U

R

E

(

m

b

a

r

)

V

A

C

U

U

M

(

m

b

a

r

)

1400

1400

1050

1050

700

700

350

350

0

1750

1750

3

1

2

4

5

6

7

8

9

10

12

11

Standard

1

Inlet Filter

2

Isolation Valve

3

Check Valve

4

Blow Off Silencer

5

Blow Off Valve

6

Coupling and Guard

7

Actuated Inlet Valve

8

Expansion Joints

9

Spool Pieces

10

Motor

11

Structural Base

12

Disconnect and/or Motor Starter

9

ZM Optional Packaging

and Accessories

Let Atlas Copco engineer a complete packaged option to suit your application. Below is a common air blower

installation but the accessories and congurations can vary greatly depending on the type of system needed.

Certifcate Number

887-10506-1111-1028

www.climatepartner.com

2

9

3

5

0

6

2

4

1

0

P

r

i

n

t

e

d

i

n

t

h

U

.

S

.

A

.

-

S

u

b

j

e

c

t

t

o

a

l

t

e

r

a

t

i

o

n

w

i

t

h

o

u

t

p

r

i

o

r

n

o

t

i

c

e

.

N

e

v

e

r

u

s

e

c

o

m

p

r

e

s

s

e

d

a

i

r

a

s

b

r

e

a

t

h

i

n

g

a

i

r

w

i

t

h

o

u

t

p

r

i

o

r

p

u

r

i

f

c

a

t

i

o

n

i

n

a

c

c

o

r

d

a

n

c

e

w

i

t

h

l

o

c

a

l

l

e

g

i

s

l

a

t

i

o

n

s

a

n

d

s

t

a

n

d

a

r

d

s

.

Driven by innovation

With more than 135 years of innovation and experience, Atlas Copco will deliver the products and services

to help maximize your companys efciency and productivity. As an industry leader, we are dedicated to

offering high air quality at the lowest possible cost of ownership. Through continuous innovation, we

strive to safeguard your bottom line and bring you peace of mind.

Building on interaction

As part of our long-term relationship with our customers, we have accumulated extensive knowledge of

a wide diversity of processes, needs and objectives. This gives us the exibility to adapt and efciently

produce customized compressed air solutions that meet and exceed your expectations.

A committed business partner

With a presence in over 170 countries, we will deliver high-quality customer service anywhere, anytime.

Our highly skilled technicians are available 24/7 and are supported by an effcient logistics organization,

ensuring fast delivery of genuine spare parts when you need them. We are committed to providing the

best possible know-how and technology to help your company produce, grow, and succeed. With Atlas

Copco you can rest assured that your superior productivity is our rst concern!

www.atlascopco.com

E-ZM-001, REV00 01/15/2013

8

You might also like

- PESTEL Analysis of GermanyDocument14 pagesPESTEL Analysis of GermanyBishal PaulNo ratings yet

- Terex RT 230 1 ChartDocument22 pagesTerex RT 230 1 ChartAlfred Hitchcock100% (1)

- Atlas Copco Roc F9Document1 pageAtlas Copco Roc F9Diego Lima100% (1)

- Movax Products 2012 ENGDocument20 pagesMovax Products 2012 ENGstephaneggNo ratings yet

- Baby Mait PDFDocument2 pagesBaby Mait PDFChris LuNo ratings yet

- About Axle Diff Case Rev1Document6 pagesAbout Axle Diff Case Rev1hwachooNo ratings yet

- Catálogo Gradall 534D6Document2 pagesCatálogo Gradall 534D6Adriano Alves Silva0% (1)

- Sheet 1 SolvedDocument2 pagesSheet 1 SolvedAyman Esa50% (2)

- Beware 03122019-1en PDFDocument14 pagesBeware 03122019-1en PDFJose Castro0% (1)

- DAL 2008 FullDocument164 pagesDAL 2008 FullYair Doram LightingNo ratings yet

- Y 19 ADocument20 pagesY 19 Ayolimar escorciaNo ratings yet

- Parts Replacement Manual For Dodge® Torque-Arm ™: Speed Reducers Straight Bore & Taper BushedDocument16 pagesParts Replacement Manual For Dodge® Torque-Arm ™: Speed Reducers Straight Bore & Taper BushedRomulo Davila GarciaNo ratings yet

- 9852 3027 01a Secoroc YT29A Pusher Leg Rock Drill - Operator's Instruction and Spare Parts List - tcm572-3511855Document20 pages9852 3027 01a Secoroc YT29A Pusher Leg Rock Drill - Operator's Instruction and Spare Parts List - tcm572-3511855marioxxyNo ratings yet

- New Microsoft Word DocumentDocument274 pagesNew Microsoft Word DocumentdraghiceanuNo ratings yet

- 6991 5105 01c PugDocument34 pages6991 5105 01c PugAndrew KochNo ratings yet

- KLR BrochureDocument23 pagesKLR BrochureblamarceloNo ratings yet

- The Rotary Drum Filter: DescriptionDocument6 pagesThe Rotary Drum Filter: Descriptionagrocel_bhv5591No ratings yet

- Windsor Saber SX24Document72 pagesWindsor Saber SX24Nestor Marquez-DiazNo ratings yet

- 3M Window Film Application, Care & Cleaning and Removal ManualDocument17 pages3M Window Film Application, Care & Cleaning and Removal ManualAntanas Zilys100% (1)

- VOLVO FMX 6x4rDocument4 pagesVOLVO FMX 6x4rDarylGonzalezNo ratings yet

- Mining in Action G: July 2011Document106 pagesMining in Action G: July 2011Ricardo MuñozNo ratings yet

- Robot Atlas MEYCO ME3Document8 pagesRobot Atlas MEYCO ME3Frank Prudencio ObregonNo ratings yet

- Air-Winch Manual PDFDocument56 pagesAir-Winch Manual PDFQuyet Nguyen0% (1)

- Kundendokumentation enDocument309 pagesKundendokumentation enHarri Mündel100% (1)

- PE28 and PE38 ManualDocument18 pagesPE28 and PE38 Manualkarijoseph100% (1)

- Waterwell Catalog WebDocument96 pagesWaterwell Catalog WebJuan Carlos Sequeira RoblesNo ratings yet

- Brochure Burg 1450Document2 pagesBrochure Burg 1450serge.pungweNo ratings yet

- XA400S Parts ManualDocument172 pagesXA400S Parts ManualBenjamin MurphyNo ratings yet

- Danbar - Eurodrill HeadDocument55 pagesDanbar - Eurodrill Headmark100% (1)

- Joy Bolting Brochure - MiningDocument11 pagesJoy Bolting Brochure - MiningkevinNo ratings yet

- HDP170 KatalogDocument2 pagesHDP170 KatalogAnonymous zq0b2Ea5No ratings yet

- Repuesto Transmision 962gIIDocument6 pagesRepuesto Transmision 962gIIWilliams ArayaNo ratings yet

- RMS3260 TBMDocument2 pagesRMS3260 TBMSiritape PromsopaNo ratings yet

- Warrior 2400 Illustrated Parts Catalog Rev 4Document237 pagesWarrior 2400 Illustrated Parts Catalog Rev 4sanzostefNo ratings yet

- Menzi Muck All Terain ExcavatorDocument5 pagesMenzi Muck All Terain ExcavatorPanagiotis AnagnostopoulosNo ratings yet

- BOP CatalogDocument20 pagesBOP CatalogOpe Opie UdinNo ratings yet

- MC3 Sullair PartsListManual 750XHH 900XH 900XHH 1150XH TC - Sullair Reman HighlightsDocument228 pagesMC3 Sullair PartsListManual 750XHH 900XH 900XHH 1150XH TC - Sullair Reman HighlightsnNo ratings yet

- AP Asphaltline TankdrumDocument8 pagesAP Asphaltline TankdrumKelvin CeliNo ratings yet

- DuFlex Cable Data Sheet PDFDocument23 pagesDuFlex Cable Data Sheet PDFMareeswaran RamasamyNo ratings yet

- Blower Performance Data SheetDocument48 pagesBlower Performance Data SheetRavi KantNo ratings yet

- Bomba P13 y OtrosDocument75 pagesBomba P13 y OtrosRonald Garcia100% (1)

- DM901HDE: Diesel Driven & Electric DrillerDocument6 pagesDM901HDE: Diesel Driven & Electric DrillerEnzo VanderlindenNo ratings yet

- Dichta CatalogueDocument62 pagesDichta CataloguemaxatadesignNo ratings yet

- Diamec Brochure PDFDocument12 pagesDiamec Brochure PDFDangol RupeshNo ratings yet

- Arjes-Br-Impaktor en 2022 04Document8 pagesArjes-Br-Impaktor en 2022 04Giuro KralevNo ratings yet

- Saga Drillmec G 55 1.9MBDocument19 pagesSaga Drillmec G 55 1.9MBleoNo ratings yet

- Ahs Kilavuz Son - Akyapak 2016.03.25Document86 pagesAhs Kilavuz Son - Akyapak 2016.03.25EDUARDONo ratings yet

- PR14251 - Envasadora EVO V8Document63 pagesPR14251 - Envasadora EVO V8enrique polarNo ratings yet

- Lista Partes SH6 (08.2019)Document64 pagesLista Partes SH6 (08.2019)Alfredo Simon Alcazar EscuderoNo ratings yet

- J - Manual Series 4 EnglishDocument49 pagesJ - Manual Series 4 EnglishCésar David Pedroza DíazNo ratings yet

- Raptor 44 ReseminDocument6 pagesRaptor 44 ReseminlucasmaltaNo ratings yet

- Metal Detector With Conveyor Application: Operator Set-Up ManualDocument69 pagesMetal Detector With Conveyor Application: Operator Set-Up ManualRafa 7niteNo ratings yet

- Monarch TT 30Document4 pagesMonarch TT 30Migue ToasaNo ratings yet

- Catalytic Converter For Volvo XC60 XC60Document3 pagesCatalytic Converter For Volvo XC60 XC6047ASSONo ratings yet

- Checkllist Mecánico - Filtro Prensa Dorr OliverDocument12 pagesCheckllist Mecánico - Filtro Prensa Dorr OliverMarco Valverde MorenoNo ratings yet

- Manual de Martillo HidraulicoDocument146 pagesManual de Martillo HidraulicoJoshua RobinsonNo ratings yet

- Datasheet Kleemann MR110 EVO 2Document2 pagesDatasheet Kleemann MR110 EVO 2ila reehasNo ratings yet

- Esquema Eletrico - 177926-1Document481 pagesEsquema Eletrico - 177926-1Sam Päron100% (1)

- CD-35655bb Trocola GiratoriaDocument82 pagesCD-35655bb Trocola GiratoriaJESUSCALVILLONo ratings yet

- Feam Junction Box EnclosureDocument36 pagesFeam Junction Box EnclosureMiky MooseNo ratings yet

- ZM Low Pressure 12p Brochure 2013 0423 LR tcm795-3550460 PDFDocument12 pagesZM Low Pressure 12p Brochure 2013 0423 LR tcm795-3550460 PDFhardik033No ratings yet

- ZM Low Pressure Leaflet EN Antwerp 2935 0624 11Document12 pagesZM Low Pressure Leaflet EN Antwerp 2935 0624 11Andry HermawanNo ratings yet

- Centrifugal Aftermarket Solutions BrochureDocument8 pagesCentrifugal Aftermarket Solutions BrochureJose Renato MendesNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- National Earth Olympiad 2012Document5 pagesNational Earth Olympiad 2012Science Olympiad Blog40% (5)

- Alarm SystemsDocument12 pagesAlarm SystemsDavid AcloNo ratings yet

- 21 49 PlansDocument7 pages21 49 PlansShehab Abu AhmadNo ratings yet

- 9-2 Reading Answers1Document4 pages9-2 Reading Answers1adalinefallingstarNo ratings yet

- Speaker72599 Session16724 1Document17 pagesSpeaker72599 Session16724 1Kent RenemberNo ratings yet

- Briganti Andrea Self Hypnosis Scripts Flirting ConfidenceDocument5 pagesBriganti Andrea Self Hypnosis Scripts Flirting ConfidenceBrian MakeredzaNo ratings yet

- Viscosity Index When Selecting A LubricantDocument6 pagesViscosity Index When Selecting A LubricantANGEL MURILLONo ratings yet

- 020 Basis of Design ChecklistDocument2 pages020 Basis of Design Checklistali ahmadNo ratings yet

- Datasheet Growatt MAX 100 125KTL3 X LVDocument2 pagesDatasheet Growatt MAX 100 125KTL3 X LVJeroen SNo ratings yet

- 9783319395913Document214 pages9783319395913iki292100% (1)

- Understanding Defibrillation WaveformsDocument3 pagesUnderstanding Defibrillation WaveformsLatha Reddy100% (1)

- Cummins Part CatalogDocument11 pagesCummins Part CatalogChen Caroline100% (1)

- Pollution in Bangalore - CiSTUP PaperDocument12 pagesPollution in Bangalore - CiSTUP PaperSathya SankaranNo ratings yet

- 17-0049 - Abdallah Osama - GTP1 - Stage 02Document10 pages17-0049 - Abdallah Osama - GTP1 - Stage 02abdallah OsamaNo ratings yet

- Controlled Circulation PumpDocument5 pagesControlled Circulation PumpLakshminarayanNo ratings yet

- Tvl-Ict-Css: Quarter 2 - Module 3-4Document17 pagesTvl-Ict-Css: Quarter 2 - Module 3-4anderson villalunaNo ratings yet

- TSM Personnel FormDocument10 pagesTSM Personnel FormMano VijayNo ratings yet

- Oil Gas Industry in The MENA Region 2009 PDFDocument73 pagesOil Gas Industry in The MENA Region 2009 PDFRajan DhandayudhapaniNo ratings yet

- MODULE 2 Foundations of PhysicsDocument7 pagesMODULE 2 Foundations of PhysicschloeNo ratings yet

- Nanotechnology: Chee 401Document19 pagesNanotechnology: Chee 401michsantosNo ratings yet

- Renewable and Sustainable Energy Reviews: Wei-Bo ZhangDocument11 pagesRenewable and Sustainable Energy Reviews: Wei-Bo ZhangFredy Akenaton ArroyoNo ratings yet

- Questbank1 AnswersDocument8 pagesQuestbank1 Answersjay garciaNo ratings yet

- Water Hammering Effects in Pipe System and Dynamic Stress PredictionDocument8 pagesWater Hammering Effects in Pipe System and Dynamic Stress PredictionDuzzysNo ratings yet

- 03.GuardMagic - Fuel Level SensorsDocument4 pages03.GuardMagic - Fuel Level SensorsvkmsNo ratings yet

- BOE Review CommentDocument451 pagesBOE Review CommentGULF BUSINESS CONTRACTINGNo ratings yet

- Threshold VoltageDocument4 pagesThreshold VoltagejudineshNo ratings yet