Professional Documents

Culture Documents

En Datasheet Tricor

En Datasheet Tricor

Uploaded by

Jorge Lazaro LinarezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

En Datasheet Tricor

En Datasheet Tricor

Uploaded by

Jorge Lazaro LinarezCopyright:

Available Formats

www.kem-kueppers.

com

info@kem-kueppers.com

Certifed according to DIN EN ISO 9001

Technical Datasheet

TRICOR Series

Mass Flow Meters

2

Tricor - Mass Flow Meter

Rotation and deformation of two parallel looped pipes by the Coriolis force Fc.

Movement to the inside

no flow

Movement to the inside

with flow

Movement to the ouside

no flow

Cycle of excursion (simplified)

Movement to the outside

with flow

Principle

Description

The Tricor Mass Flow Meters measure simultaneously mass flow,

volume flow, temperature and density and consequently can replace

different measuring instruments.

Due to a construction free of dead spots the meters are well flushable

and can be easily sterilized.

The Tricor Mass Flow Meters do not contain any moving parts and

consequently are suited for polluted media as well.

According to the requirements the Tricor Mass Flow Meters are

available as compact version with on site display and remote version

with electronis in a wall mount or panel mount housing.

For the compact version an additional remote display (TRD 8001) is

available, designed for cable lengths up to 1 km.

Application

Flow measurement of PU components and

paints

Flow measurement of aggressive and

contaminated media

Measurement of mass flow, density,

temperature and volume flow

Besonderheiten

Pmax. 350 bar

Short response time

DKD calibration

Excellent puring and sterilization qualities

due to a construction free of dead spots

Up to +150C medium temperature

Individual 8-point-calibration including

report

Ex protected as per ATEX and EMC tested

Two parallel flow tubes inside the TCM Flow Meter are vibrating

at their resonant frequency in opposite direction. Any mass flow

passing through the tubes will delay the vibration at the incoming

side and accelerate the vibration at the outgoing side. This causes

a small time delay between both ends of the tube. This time delay

is measured and used to calculate the mass flow through the tubes.

By measuring the resonant frequency of the tubes the mass of the

medium and - given a constant volume inside the tubes - the density

of the medium can be calculated.

As both effects are temperature dependent, the temperature is

measured via a precise sensor for correcting the temperature effects

of flow and density measurement.

As a consequence a Tricor Mass Flow Meter directly measures mass

flow, density and temperature of the medium. Knowing the mass flow

and the specific cravity, also the volume flow can be calculated.

3

Tricor - Mass Flow Meter

Overview

Compact version

Remote Display TRD 8001

Exd housing for wall-mounting

(separated version, also with flange ends)

Remote panel-mounted housing

(separated version, also with flange ends)

4

Tricor - Mass Flow Meter

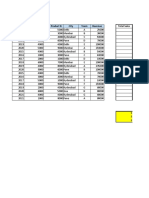

TCM7900 TCM28k TCM65k

Max. fow (kg/h) 7900 28 800 65 000

Min. fow (kg/h) 79 288 650

Max. fow (lb/min) 209 1060 2390

Min. fow (lb/min) 2.90 10,6 23.90

Basic Accuracy (% of fow reading) 0.1 0.1 0.1

Zero Stability (% of full scale) 0.01 0.01 0.01

Zero Drift (% f.s. per C) 0.001 0.001 0.001

Repeatability (% of fow) 0.1 0.1 0.1

Density measuring range 0 - 4500 kg/m

Density accuracy 0.002 kg/ltr

Temperature accuracy 1C 0.5% of reading

Process and Ambient

Process connections fanges EN1092, ANSI B16.5, DIN2512

Max. pressure 100 bar

Max. pressure (Option) on request

Pressure Drop at max. fow H

2

0 see diagramm

Operating Density range 100 - 2500 kg/m (lower densities on request)

Process temperature -20 ... +100C (options: -100 ... 150C)

Ambient temperture -40 ... +100C

Storage temperature -40 ... +80C

Electr. connections remote screw type terminals

Electr. connections compact. none (internally connected to the electronics)

Ingress Protection IP67

General

Tube arrangement 2 parallel 2 parallel 2 parallel

tube inner diameter 12mm 18mm 34mm

tube material ss 1.4404 / 1.4571

housing material stainless steel

Dimensions see drawings

Technical Data - TCM Transducer

5

Tricor - Mass Flow Meter

Technical Data - TCE 8000 Transmitter

General

Display: Graphic, 132 x 32 dot

Supply votage: 24 VDC, 20% and / or 100 - 240 VAC (version dependent)

Programming: via front keyboard

Interface: RS 485, Option HART, option Foundation Fieldbus

EMC: according to EN 61000-6-4 und 61000-6-2

Power consumption: max. 4 W

Exd housing:

Dimensions: see drawing

Connections: internal clamp terminals

cable gland for 7 - 13 mm cables

Material: aluminium diecast

Protection class IP 67

Weight: approx. 2 kg

Temperature: operating: - 20 up to 70C (up to + 80C on request)

storage and transport: -40 up to 80C

Panel-mounted housing:

Dimensions: 96 x 96 x 83mm (h x w x d)

Connections: rear clamp terminals

Material: Noryl

Protection class: front: IP 40, rear: IP 30

Weight: approx. 500g

Temperature: operation: 0 to 60C

storage and transport: -20 up to 70C

Analog Outputs

Two current outputs: 4-20 mA passive, two-wire, isolated

Resolution: 14 bit

Linearity: 0.05% of full scale

Temperature drift: 0.05% per 10K

Load: < 800

Output value: programmable: fow, total, density, temperature

Pulse Output

Frequency range: 0.5-10,000 Hz

Output signal: active push pull output for fow rate

Status In-and Output

Status output push pull programmable

Control input programmable

6

-1,5

-1

-0,5

0

0,5

1

1,5

0 10 20 30 40 50 60 70 80 90 100

Accuracy Basic Accuracy + Zero Stability

max. Flow

Current Flow

Accuracy %

Flow %

Tricor - Mass Flow Meter

Display Graphic, 132 x 32 dot

Supply voltage: via interface

Programming: via front keyboard

Interface to TCM: RS 485

EMC: according to EN 61000-6-4 und 61000-6-2

Dimensions: 90 x 120 x 50 mm3 (h x w x d)

Connections: connector M12, B coded

Material: ABS-FR

Protection class: IP 64

Weight: approx. 500g

Temperature: operation: 0 to 60C

storage and transport: -20 up to 80C

Wall mount hidden screws

ATEX Zone 1: different versions Ex d or Ex i

Zone 2: available

IECEx in Preparation

Technical Data - TRD 8001 Remote Display

7

Tricor - Mass Flow Meter

Dimensional drawing (mm) TCM 28k to TCM 65k

H

L

S

P

B

C

N

M

D

Sensor Type A B C H L* Connection**

TCM 7900 197 61 204 260 460 a. N.

TCM 28k 218 80 253 315 625 a. N.

TCM 65k 360 151 387 480 830 a. N.

* further lengths on request

** flange types on request

Elektronic Type D M N P S -

Housing C 110 205 118 188 218 -

Housing E 130 240 111 217 243 -

8

Tricor - Mass Flow Meter

Dimensional drawing (mm) TCE 80xx - W

5

,2

5

R

68

54

19.3

9.3

4

2

.

8

3

2

.

8

3

7

.

5

2

8

8

2

1

3

1

1

0

145

220

203

9

Tricor - Mass Flow Meter

Dimensional drawing (mm) TCE 80xx - E with cable connection

189

147

45

4

5

4x 5,7

8

265

238

1

8

6

1

3

2

10

Tricor - Mass Flow Meter

Dimensional drawing (mm) TCE 80xx - E with Junction Box

189

147

4

5

45

4x 5,7

8

265

3

1

8

1

3

2

238

11

Tricor - Mass Flow Meter

Dimensional drawing (mm) Panel-Mounted Housing (drawing not to scale)

Dimensional drawing (mm) Remote Display TRD 8001

Type A B - - - - -

TCE 80** - S 96 96 - - - - -

TCE 80** - L 96 144 - - - - -

9

0

120

4

8

1

6

8

144

83

A

B

You might also like

- AT235-service ManualDocument86 pagesAT235-service Manualfadi100% (3)

- Product Data Sheet: Hybrid Ultrasonic Flow MeterDocument8 pagesProduct Data Sheet: Hybrid Ultrasonic Flow MeterABie ShallabyNo ratings yet

- Ultrasonic Flowmeter: Katflow 160Document4 pagesUltrasonic Flowmeter: Katflow 160ChevronelleNo ratings yet

- HYB-DS-00086-EN - Dynasonics DXN Portable Clamp-On Ultrasonic Flow Meter Product Data SheetDocument8 pagesHYB-DS-00086-EN - Dynasonics DXN Portable Clamp-On Ultrasonic Flow Meter Product Data Sheetamir.bptpkaNo ratings yet

- CBGN Product CatalogueDocument8 pagesCBGN Product Cataloguesivak78mduguhaNo ratings yet

- Memograph rsg40 Ti133ren - 0707Document20 pagesMemograph rsg40 Ti133ren - 0707cristianmihaiNo ratings yet

- TTM-DS-00085-EN-01 TFX Ultra 07 09 13Document8 pagesTTM-DS-00085-EN-01 TFX Ultra 07 09 13Ahmed AbdelwaneesNo ratings yet

- ABB CoriolisMaster FCM2000Document68 pagesABB CoriolisMaster FCM20001234567890No ratings yet

- TTM DS 02221 en - TFX - 5000Document16 pagesTTM DS 02221 en - TFX - 5000EyuNo ratings yet

- Micro-Processor Based Moisture Transmitter: Accupoint 2Document2 pagesMicro-Processor Based Moisture Transmitter: Accupoint 2Guillermo ZapataNo ratings yet

- Sitrans T Measuring Instrument For TemperatureDocument56 pagesSitrans T Measuring Instrument For TemperaturejadetorresNo ratings yet

- Multi Vision™: Multivariable TransmitterDocument10 pagesMulti Vision™: Multivariable TransmitterRaja RamNo ratings yet

- 135 FR en HydrusDocument7 pages135 FR en HydrusJabnon NonjabNo ratings yet

- Analizador de Humedad BARTECDocument11 pagesAnalizador de Humedad BARTECFabian GomezNo ratings yet

- BFU-100M: Low Cost DIN Rail Mount DesignDocument3 pagesBFU-100M: Low Cost DIN Rail Mount DesignMeindert gerssenNo ratings yet

- Endress HauserDocument24 pagesEndress Hauserfuty_889107No ratings yet

- FM and FMC Approved!: Model Ft2 Gas Mass Flowmeter & Temperature TransmitterDocument4 pagesFM and FMC Approved!: Model Ft2 Gas Mass Flowmeter & Temperature TransmitterMonica AguilarNo ratings yet

- Ultrasonic Portable TypeDocument3 pagesUltrasonic Portable TypesyamsundariitmNo ratings yet

- Tiger Btu MeterDocument18 pagesTiger Btu MeterMUBASHIRNo ratings yet

- CP 060 en ThermovacDocument14 pagesCP 060 en ThermovacMayur ChauhanNo ratings yet

- Current MeterDocument7 pagesCurrent MeterBudi HarliantoNo ratings yet

- Dynasonics TFXL DatasheetDocument8 pagesDynasonics TFXL DatasheetJuan Luis Loaiza CorreaNo ratings yet

- Boq of Lab EquipmentsDocument5 pagesBoq of Lab EquipmentsMuhammad TausifNo ratings yet

- Flomat EngDocument8 pagesFlomat Engalex.amaral9292No ratings yet

- MAG-DS-00493-EN M3000 Electromagnetic Flow Meter Product Data SheetDocument4 pagesMAG-DS-00493-EN M3000 Electromagnetic Flow Meter Product Data SheetSebastián Alexander Flores OroscoNo ratings yet

- Ds Uhp Wuc 1x en Us 20710Document10 pagesDs Uhp Wuc 1x en Us 20710behnamatgNo ratings yet

- Kalorimetar Data Sheet UH50 - UH106 101kDocument15 pagesKalorimetar Data Sheet UH50 - UH106 101kbobesponjakockaloneNo ratings yet

- Signet 8550Document2 pagesSignet 8550Ricardo AkermanNo ratings yet

- Sick-Traductoare de Nivel HidrostaticeDocument4 pagesSick-Traductoare de Nivel HidrostaticeChioibasNicolaeNo ratings yet

- Calorimetres SHARKY 775 Heat MeterDocument7 pagesCalorimetres SHARKY 775 Heat MeterJoan AymerichNo ratings yet

- Techincal Specifications With DetailsDocument11 pagesTechincal Specifications With Detailsruturaj v delekarNo ratings yet

- Vibration TransducerDocument13 pagesVibration TransducerLawren IgnatiusNo ratings yet

- Amtron® - Sonic - D - 3 290 TD en 01Document8 pagesAmtron® - Sonic - D - 3 290 TD en 01wasim khanNo ratings yet

- Unitrans Universal Pressure Transmitters Type Ut-10, Ut-11: ApplicationsDocument4 pagesUnitrans Universal Pressure Transmitters Type Ut-10, Ut-11: ApplicationsbehnamatgNo ratings yet

- DE550016 BA 3 Select 01Document4 pagesDE550016 BA 3 Select 01seve1No ratings yet

- Ultrasonic Flow Meter 201 and 221Document14 pagesUltrasonic Flow Meter 201 and 221royNo ratings yet

- Portable Ultrasonic Flow Measurement of Gas in Hazardous AreasDocument30 pagesPortable Ultrasonic Flow Measurement of Gas in Hazardous AreasrudrakrNo ratings yet

- Sitranst th100 Fi01enDocument4 pagesSitranst th100 Fi01enGhassan Al HaririNo ratings yet

- Flow Switch With 4-20 Ma OutputDocument20 pagesFlow Switch With 4-20 Ma OutputHariprasad ManavalanNo ratings yet

- Traductor de PresiuneDocument22 pagesTraductor de PresiuneCamelia PăduraruNo ratings yet

- VersaFlow Coriolis 100 Mass Flow Sensor Specifications, 34-VF-03-09Document20 pagesVersaFlow Coriolis 100 Mass Flow Sensor Specifications, 34-VF-03-09Javier Alejandro QuingaNo ratings yet

- SS 23.400 ATEX en PDFDocument2 pagesSS 23.400 ATEX en PDFJharey Japon ReynosaNo ratings yet

- High-Precision Air / Gas Velocity Transmitter For Industrial ApplicationsDocument5 pagesHigh-Precision Air / Gas Velocity Transmitter For Industrial ApplicationsMasoudNo ratings yet

- Explosion-Proof Asic or Hart Pressure Transmitter: FeaturesDocument12 pagesExplosion-Proof Asic or Hart Pressure Transmitter: FeaturesMkgt HemaautomationNo ratings yet

- Hydrus: Ultrasonic MeterDocument8 pagesHydrus: Ultrasonic MeterARCC2030No ratings yet

- Tcy3 T0121RDocument4 pagesTcy3 T0121RMarcelo Magalhães QuaiottiNo ratings yet

- CIL Rotameters CBGN 2016Document8 pagesCIL Rotameters CBGN 2016Hisham ABD ALRASOULNo ratings yet

- 1020Document7 pages1020eeng_nnabilNo ratings yet

- Indicador de Nivel MagneticoDocument6 pagesIndicador de Nivel MagneticoEdivan Laurindo FerreiraNo ratings yet

- 34 Xy 03 51 PDFDocument10 pages34 Xy 03 51 PDFAnonymous 8edbEtNo ratings yet

- Suportes e RTD EuropaDocument26 pagesSuportes e RTD EuropaPaulo CostaNo ratings yet

- Eurosonic 2000Document75 pagesEurosonic 2000Sandra Carr100% (1)

- Electromagnetic Flowmeter Type MAGNETOFLOW™ M2000: DescriptionDocument4 pagesElectromagnetic Flowmeter Type MAGNETOFLOW™ M2000: DescriptionAlphatech1No ratings yet

- YokogawaDocument32 pagesYokogawadcperfectNo ratings yet

- Data Sheet KATflow 110 V10 E0803Document4 pagesData Sheet KATflow 110 V10 E0803Chevronelle100% (1)

- Switch de Flujo - TI014AENDocument8 pagesSwitch de Flujo - TI014AENSebastian BustosNo ratings yet

- Wika DS - Pe8160 - GB - 1631Document8 pagesWika DS - Pe8160 - GB - 1631Francisco Mozart B. MeirellesNo ratings yet

- 699 Pressure Sensor PDFDocument5 pages699 Pressure Sensor PDFEnriqueQNo ratings yet

- Amtron Sonic D BtuDocument5 pagesAmtron Sonic D Btuwasim khanNo ratings yet

- Deleting Old History Files On The As 400Document2 pagesDeleting Old History Files On The As 400rachmat99No ratings yet

- Design of Single and Double Balanced Gilbert Cell Mixer Using CMOS Processing TechnologyDocument6 pagesDesign of Single and Double Balanced Gilbert Cell Mixer Using CMOS Processing TechnologyIJSTENo ratings yet

- India - EU Free Trade AgreementDocument3 pagesIndia - EU Free Trade AgreementJay KothariNo ratings yet

- Xang2020 - Phanloai Boc HoiDocument16 pagesXang2020 - Phanloai Boc HoiQuỳnh HoàngNo ratings yet

- Determination of Adsorption Isotherm of Acetic Acid On Activated CharcoalDocument5 pagesDetermination of Adsorption Isotherm of Acetic Acid On Activated CharcoalShashank ChandraNo ratings yet

- Hand Auger MethodDocument4 pagesHand Auger Methodnrsyhira salihinNo ratings yet

- History of CalendarDocument2 pagesHistory of CalendarMuhammad Muhammad AliNo ratings yet

- Internet Control Message ProtocolDocument86 pagesInternet Control Message Protocolkshitij avhadNo ratings yet

- MSM Tech List 125mm TapnaDocument2 pagesMSM Tech List 125mm TapnaThanosaekk P.No ratings yet

- Michel Houellebecq, The Art of Fiction No. 206Document34 pagesMichel Houellebecq, The Art of Fiction No. 206Sergio Fortuño100% (2)

- Excel - Assignment - 1 (1Document16 pagesExcel - Assignment - 1 (1Ashish ChangediyaNo ratings yet

- Ultralearning NotesDocument14 pagesUltralearning Noteste100% (2)

- Department of Education: Republic of The PhilippinesDocument3 pagesDepartment of Education: Republic of The PhilippinesGraceRasdasNo ratings yet

- An Integrated Multifunctional Battery Charger With Three-Phase Charging For Plug-In Electric VehiclesDocument6 pagesAn Integrated Multifunctional Battery Charger With Three-Phase Charging For Plug-In Electric VehiclesmsmegovindNo ratings yet

- Elective Chapter 1 and 2Document5 pagesElective Chapter 1 and 2Edward James TablazonNo ratings yet

- Voyager™: 12.5 To 25 Tons Packaged Rooftop Units Cooling and Gas/ElectricDocument2 pagesVoyager™: 12.5 To 25 Tons Packaged Rooftop Units Cooling and Gas/ElectricRenan GonzalezNo ratings yet

- Chapter 17 Absorption Refrigeration ExercisesDocument2 pagesChapter 17 Absorption Refrigeration ExercisesAndrew PantaleonNo ratings yet

- In Vitro Dissolution Testing Models: DR Rajesh MujariyaDocument35 pagesIn Vitro Dissolution Testing Models: DR Rajesh MujariyaRajesh MujariyaNo ratings yet

- Journal of Adolescence: Sarbhan Singh, Rafdzah Ahmad Zaki, Nik Daliana Nik Farid TDocument19 pagesJournal of Adolescence: Sarbhan Singh, Rafdzah Ahmad Zaki, Nik Daliana Nik Farid TNova SafitriNo ratings yet

- CALL CENTER Interview Questions N AnsDocument9 pagesCALL CENTER Interview Questions N AnsMohammed UmrazuddinNo ratings yet

- 315020-DOC-3483 - (V-4083 Condensate Accumulator) - RevADocument7 pages315020-DOC-3483 - (V-4083 Condensate Accumulator) - RevAAnwar SadatNo ratings yet

- Introduction To Research An - (Z-Library)Document284 pagesIntroduction To Research An - (Z-Library)espoirsdentisteNo ratings yet

- Soalan Assignment emDocument9 pagesSoalan Assignment emafieqafariha1904No ratings yet

- Intro Revit 9Document27 pagesIntro Revit 9Danny Anton AsanzaNo ratings yet

- Tez PortalDocument1 pageTez Portalkiran BawadkarNo ratings yet

- Introduction To Representation TheoryDocument108 pagesIntroduction To Representation TheoryAbhijeet BhalkikarNo ratings yet

- Mini-Space Series Installation, Operation & Maintenance ManualDocument52 pagesMini-Space Series Installation, Operation & Maintenance ManualsantiagoNo ratings yet

- Have Space To Grow: With Password Protection Data SheetDocument2 pagesHave Space To Grow: With Password Protection Data SheetMuhammad Usama SheikhNo ratings yet

- IMI Herion Valve CatalogDocument12 pagesIMI Herion Valve CatalogjbkimNo ratings yet